Mechanical Properties of Concrete with Steel and Polypropylene Fibres at Elevated Temperatures

Abstract

:1. Introduction and State of Art

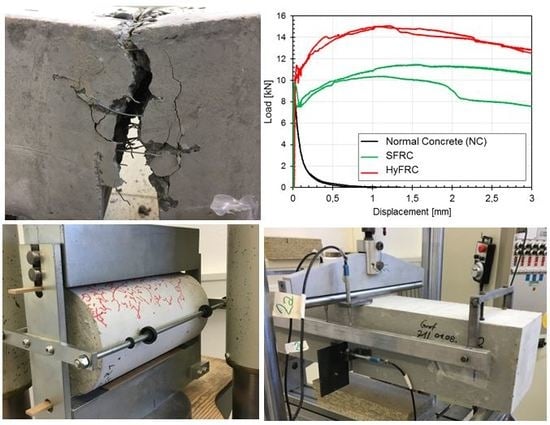

- NC—Normal concrete without fibres;

- SFRC—Steel fibre reinforced concrete having 50 kg/m3 of hooked end steel fibres and

- HyFRC—Hybrid fibre reinforced concrete having 50 kg/m3 of hooked end steel fibres +1 kg/m3 of micro PP fibres.

2. Background

- the pre-peak response where the strain over a certain gauge length is used to define the behaviour and

- the post-peak response where the crack opening displacement is used to describe the behaviour.

3. Materials and Methods

3.1. Concrete Mixture

3.2. Test Specimen

3.3. Heat Treatment

4. Test Results and Discussion

4.1. General

4.2. Compressive Strength

4.3. Split Tensile Strength

4.4. Flexural Tensile Strength (Modulus of Rupture) and Fracture Energy

4.5. Static Modulus of Elasticity

5. Conclusions

- The compressive strength of SFRC and HyFRC was found to be comparable to that of NC for entire temperature range, which is related to the relatively low volumetric content of fibres in concrete.

- The split tensile strength as well as the modulus of rupture (flexural tensile strength) for concrete with fibres (both SFRC and HyFRC) was significantly higher than that of NC for all the temperatures. An increase in strength of the order of 40% to 150% was observed due to the presence of the fibres. The increase is primarily owed to the relatively high content of hooked-end steel fibres, which can take up the load upon concrete cracking. However, the bond between steel fibres and concrete is damaged due to thermal exposure, resulting in a decay of tensile strength with increasing temperature.

- The highest influence of the presence of fibres was observed in the fracture energy of concrete. For both SFRC and HyFRC, the fracture energy was at least two orders of magnitude higher than that of NC over the entire temperature range investigated in this work.

- The static modulus of elasticity of all types of concrete investigated is of similar magnitude and the variation with the temperature is also similar. The addition of fibres cannot affect elasticity modulus due to their small volumetric content.

- No negative influence of the presence of 1 kg/m3 of micro PP fibres was observed on the strength, fracture energy or modulus of elasticity of concrete with steel fibres.

- Such hybrid FRC has a huge potential in real-life applications to provide high mechanical as well as fire resistance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Khan, M.I.; Abbas, Y.M.; Fares, G. Review of high and ultrahigh performance cementitious composites incorporating various combinations of fibres and ultrafines. J. King Saud Univ. Eng. Sci. 2017, 29, 339–347. [Google Scholar]

- Bosnjak, J. Explosive Spalling and Permeability of High Performance Concrete under Fire—Numerical and Experimental Investigations. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2014. [Google Scholar]

- Jang, S.J.; Yun, H.D. Combined effects of steel fibre and coarse aggregate size on the compressive and flexural toughness of high-strength concrete. Compos. Struct. 2018, 185, 203–211. [Google Scholar] [CrossRef]

- Behnood, A.; Verian, K.P.; Gharehveran, M.M. Evaluation of the splitting tensile strength in plain and steel fibre-reinforced concrete based on the compressive strength. Constr. Build. Mater. 2015, 98, 519–529. [Google Scholar] [CrossRef]

- Kooiman, A.G. Modelling Steel Fibre Reinforced Concrete for Structural Design. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 2000. [Google Scholar]

- Hanna, A.N. Steel Fiber Reinforced Concrete Properties and Resurfacing Applications; Report RD049.01P; Portland Cement Association: Skokie, IL, USA, 1977. [Google Scholar]

- Abbas, A.A.; Mohsin, S.M.S.; Cotsovos, D.M. Seismic response of steel fibre reinforced concrete beam-column joints. Eng. Struct. 2014, 59, 261–283. [Google Scholar] [CrossRef]

- Filiatrault, A.; Pineau, S.; Houde, J. Seismic behaviour of steel fibre-reinforced concrete interior beam–column joints. ACI Struct. J. 1995, 92, 543–552. [Google Scholar]

- Liu, C. Seismic Behavior of Beam-Column Joint Subassemblies Reinforced with Steel Fibers. Master’s Thesis, Department of Civil Engineering, University of Canterbury Christchurch, Christchurch, New Zealand, 2006. [Google Scholar]

- Chidambaram, R.S.; Agarwal, P. Seismic behaviour of hybrid fibre reinforced cementitious composite beam-column joints. Mater. Design 2015, 86, 771–781. [Google Scholar] [CrossRef]

- Sharma, A.; Reddy, G.R.; Varshney, L.; Kumar, H.B.; Vaze, K.K.; Ghosh, A.K.; Kushwaha, H.S.; Krishnamoorthy, T.S. Experimental investigations on mechanical and radiation shielding properties of hybrid lead-steel fibre reinforced concrete. Nuclear Eng. Design 2009, 239, 1180–1185. [Google Scholar] [CrossRef]

- Horiguchi, T.; Sugawara, T.; Saeki, N. Fire resistance of hybrid fibre reinforced high strength concrete. In Proceedings of the 6th RILEM symposium on Fiber Reinforced Concretes (FRC)—BEFIB 2004, Varenna, Italy, 20–22 September 2004. [Google Scholar]

- Caggiano, A.; Gambarelli, S.; Martinelli, E.; Nistico, N.; Pepe, M. Experimental characterization of the postcracking response in Hybrid Steel/Polypropylene Fiber-Reinforced Concrete. Constr. Build. Mater. 2016, 125, 1035–1043. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Compressive behaviour of fibre reinforced high-performance concrete subjected to elevated temperatures. Cement Concr. Res. 2004, 34, 2215–2222. [Google Scholar] [CrossRef]

- Pliya, P.; Beaucour, A.L.; Noumowé, A. Contribution of cocktail of polypropylene and steel fibres in improving the behaviour of high strength concrete subjected to high temperature. Constr. Build. Mater. 2011, 25, 1926–1934. [Google Scholar] [CrossRef]

- Reinhardt, H.-W. Werkstoffe des Bauwesens (Building materials). In Der Ingenieurbau; Mehlhorn, G., Ed.; Ernst & Sohn: Berlin, Germany, 1997; pp. 1–163. (In Germany) [Google Scholar]

- Balaguru, P.N.; Shah, S.P. Fiber-Reinforced Cement Composites; McGraw-Hill: New York, NY, USA, 1992; ISBN 0070564000 9780070564008. [Google Scholar]

- American Concrete Institute Committee 544. State-of-the-Art Report on Fiber Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2009. [Google Scholar]

- British Standard Institution. BS EN 14889-1, Fibres for Concrete, Part 1. Steel Fibres—Definition; British Standard Institution: London, UK, 2006. [Google Scholar]

- International Federation for Structural Concrete (fib). fib Model Code for Concrete Structures 2010; International Federation for Structural Concrete: Lausanne, Switzerland, 2013. [Google Scholar]

- Khoury, G.; Anderberg, Y. Concrete Spalling Review; Swedish National Road Administration: Borlänge, Sweden, 2000.

- National Road Administration. Technical Data Sheet: Hooked-End Steel Fibers HE 75/35, ArcelorMittal. 2000. Available online: http://ds.arcelormittal.com/wiresolutions/steelfibres/products/hooked_end_fibres_he/language/EN (accessed on 7 April 2017).

- EN 12390:3 Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; European Committee for Standardization: Brussels, Belgium, 2009.

- EN 12390:6 Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens; European Committee for Standardization: Brussels, Belgium, 2009.

- RILEM TC-50 FMC (Draft Recommendation). Determination of the fracture energy of mortar and concrete by means of three-point bend tests on notched beams. Mater. Struct. 1985, 18, 285–290. [Google Scholar]

- Zhang, B.; Bicanic, N. Residual Fracture Toughness of Normal- and High Strength Gravel Concrete after Heating to 600 °C. ACI Mater. J. 2002, 99, 217–226. [Google Scholar]

- EN 14651 Test Method for Metallic Fibre Concrete—Measuring the Flexural Tensile Strength (Limit or Proportionality (LOP), Residual); European Committee for Standardization: Brussels, Belgium, 2005.

- EN 12390:13 Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression; European Committee for Standardization: Brussels, Belgium, 2013.

| Mixture ID | Cement (kg/m3) | Sand (kg/m3) | Aggregate 1 (2–4 mm) (kg/m3) | Aggregate 2 (4–8 mm) (kg/m3) | Aggregate 3 (8–16 mm) (kg/m3) | Water/Cement Ratio (-) | Superplasticizer (% of cement) | Steel fibres (kg/m3) | Micro PP fibres (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| NC | 370 | 562 | 259 | 392 | 571 | 0.48 | 0.2 | 0 | 0 |

| SFRC | 370 | 556 | 256 | 389 | 565 | 0.48 | 0.3 | 50 | 0 |

| HyFRC | 370 | 556 | 256 | 389 | 565 | 0.48 | 0.4 | 50 | 1 |

| Material property | Specimen type | Specimen dimensions | Shape |

|---|---|---|---|

| Compressive strength | Cube | 150 mm × 150 mm × 150 mm |  |

| Split tensile strength | Cylinder | 150 mm (D) × 300 mm (H) |  |

| Flexural tensile strength | Notched beam | 150 mm × 150 mm × 600 mm Central notch: 5 mm wide and 50 mm high |  |

| Fracture energy | Notched beam | ||

| Static modulus of elasticity | Square prism | 100 mm × 100 mm × 200 mm |  |

| Dynamic modulus of elasticity | Square prism |

| Tmax (°C) | Compressive strength (MPa) | Tmax (°C) | Splitting strength (MPa) | Tmax (°C) | Bending strength (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| - | NC | SFRC | HyFRC | - | NC | SFRC | HyFRC | - | NC | SFRC | HyFRC |

| 20 | 60.5 | 65.8 | 71.1 | 20 | 3.83 | 4.89 | 5.59 | 20 | 4.71 | 6.99 | 9.05 |

| 61.2 | 68.0 | 70.9 | 4.10 | 5.32 | 5.84 | 20 | 4.82 | 6.22 | 9.03 | ||

| 100 | 63.9 | 58.9 | 69.7 | 300 | 2.62 | 4.98 | 5.17 | 20 | 4.36 | 6.88 | - |

| 65.5 | 57.6 | 69.9 | 3.03 | 4.86 | 5.48 | 20 | 5.17 | 5.99 | - | ||

| 300 | 58.3 | 60.0 | 70.4 | 500 | 1.39 | 4.14 | 2.7 | 100/150 1) | 5.77 | 5.17 | - |

| 62.1 | 61.6 | 68.2 | 1.46 | 3.44 | 3.21 | 200 | - | 4.79 | - | ||

| 500 | 45.6 | 45.8 | 58.9 | 600 | 1.39 | - | - | 200 | - | 5.12 | - |

| 41.2 | 45.6 | 56.8 | 1.46 | - | - | 300 | 3.56 | 5.06 | 5.32 | ||

| 600 | 46.9 | 51.4 | 52.6 | 700 | 0.82 | 2.37 | 2.05 | 300 | 3.16 | 4.01 | 5.51 |

| 46.7 | 46.3 | 47.7 | - | 0.77 | 2.18 | 1.75 | 400 | 2.18 | 3.30 | 4.13 | |

| 800 | 29.5 | 21.1 | 19.1 | - | - | - | - | 400 | 2.54 | 3.23 | 5.21 |

| 27.1 | 26.5 | 20.7 | - | - | - | - | 500 | 1.81 | 3.82 | 3.32 | |

| - | 600 | 1.07 | 4.13 | 2.77 | |||||||

| 600 | - | 2.59 | 3.95 | ||||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bošnjak, J.; Sharma, A.; Grauf, K. Mechanical Properties of Concrete with Steel and Polypropylene Fibres at Elevated Temperatures. Fibers 2019, 7, 9. https://doi.org/10.3390/fib7020009

Bošnjak J, Sharma A, Grauf K. Mechanical Properties of Concrete with Steel and Polypropylene Fibres at Elevated Temperatures. Fibers. 2019; 7(2):9. https://doi.org/10.3390/fib7020009

Chicago/Turabian StyleBošnjak, Josipa, Akanshu Sharma, and Kevin Grauf. 2019. "Mechanical Properties of Concrete with Steel and Polypropylene Fibres at Elevated Temperatures" Fibers 7, no. 2: 9. https://doi.org/10.3390/fib7020009

APA StyleBošnjak, J., Sharma, A., & Grauf, K. (2019). Mechanical Properties of Concrete with Steel and Polypropylene Fibres at Elevated Temperatures. Fibers, 7(2), 9. https://doi.org/10.3390/fib7020009