Twisted Silica Microstructured Optical Fiber with Equiangular Spiral Six-Ray Geometry

Abstract

1. Introduction

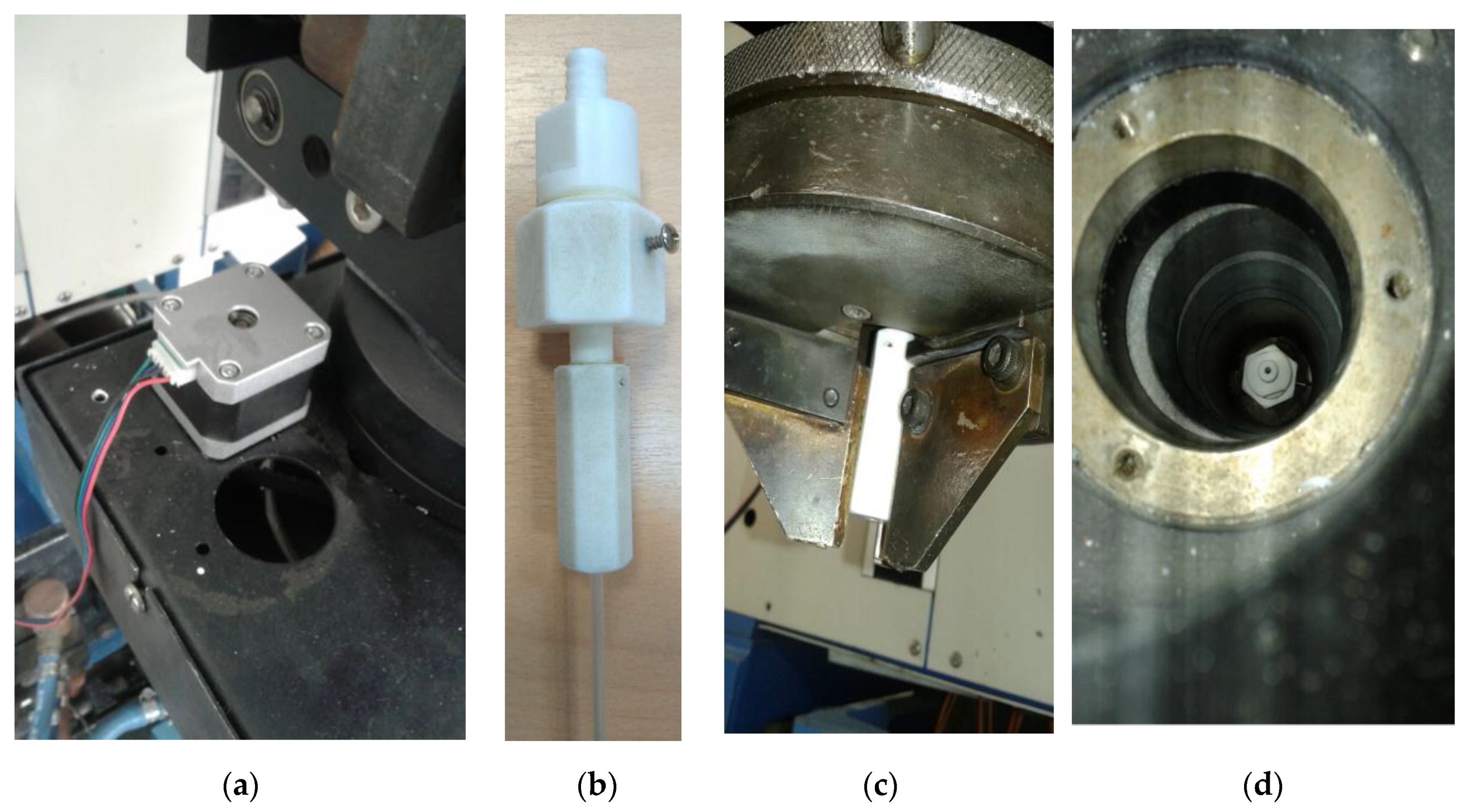

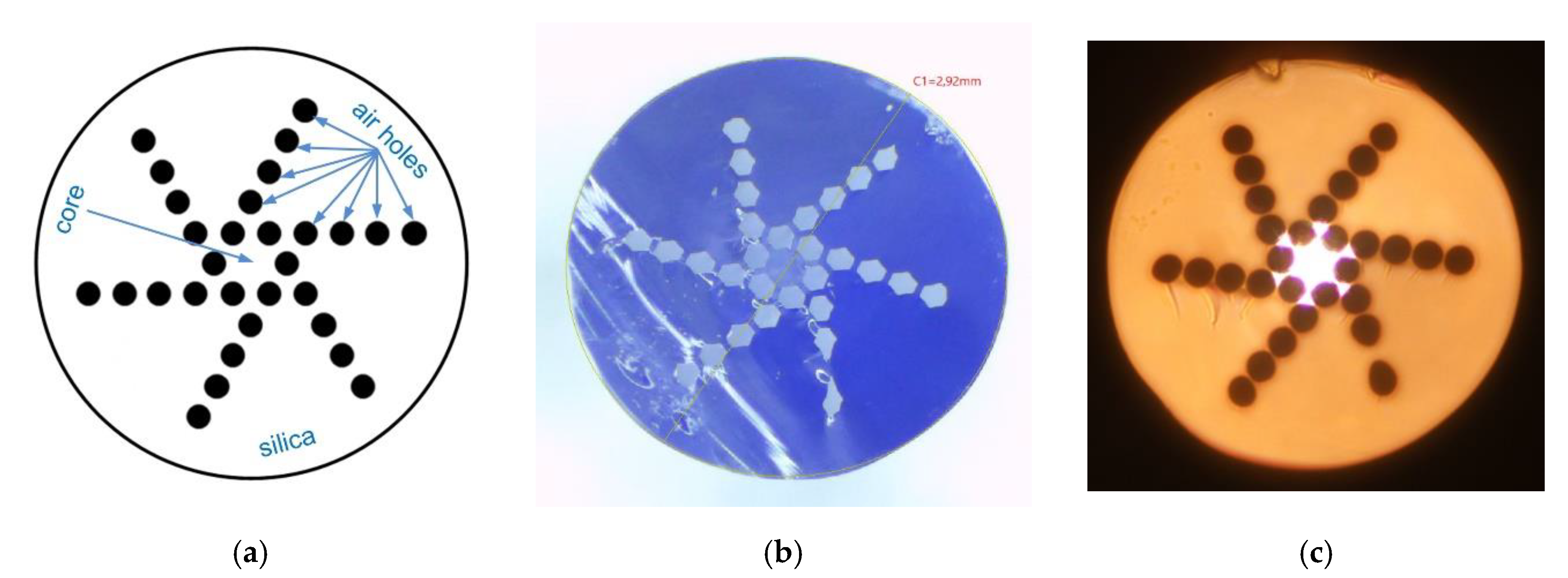

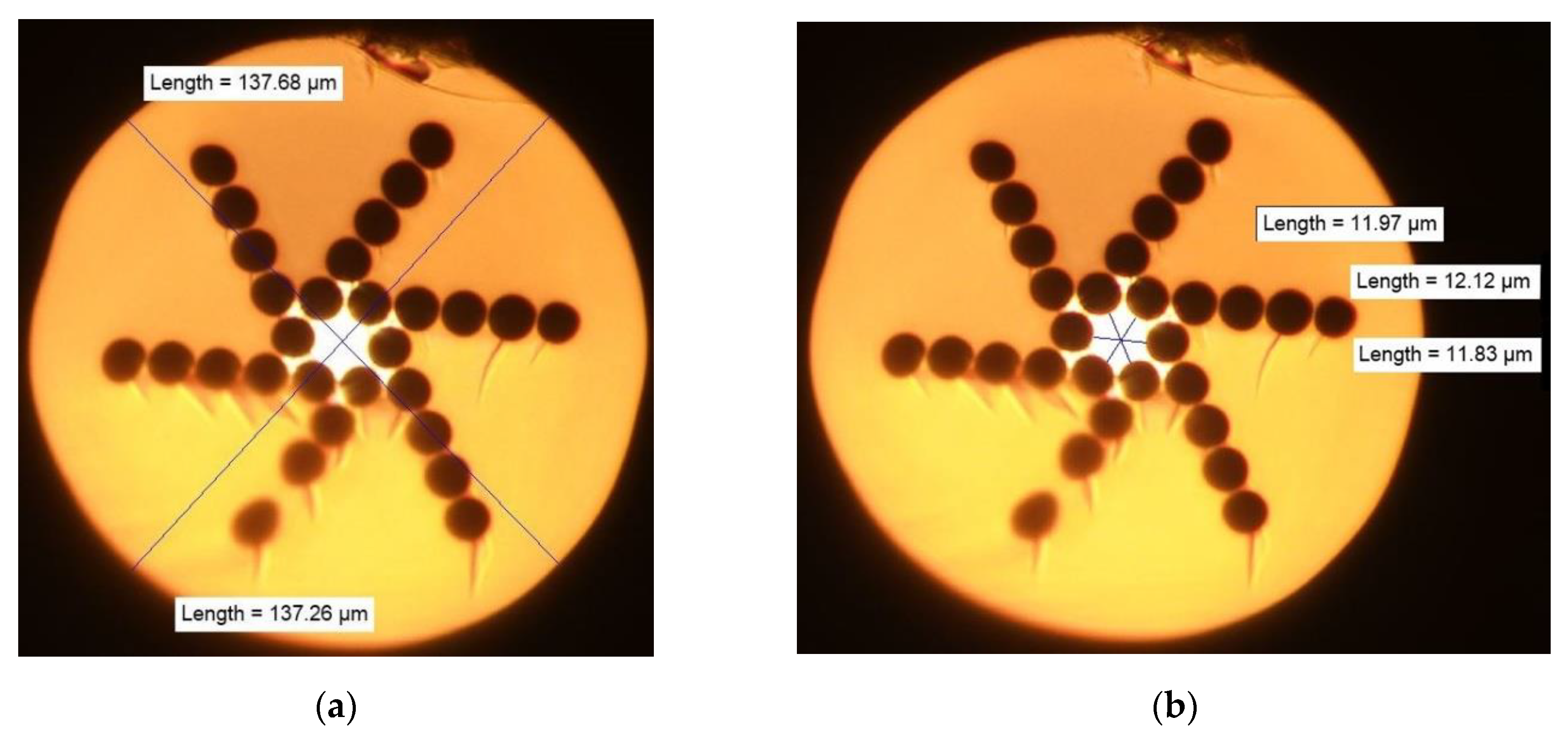

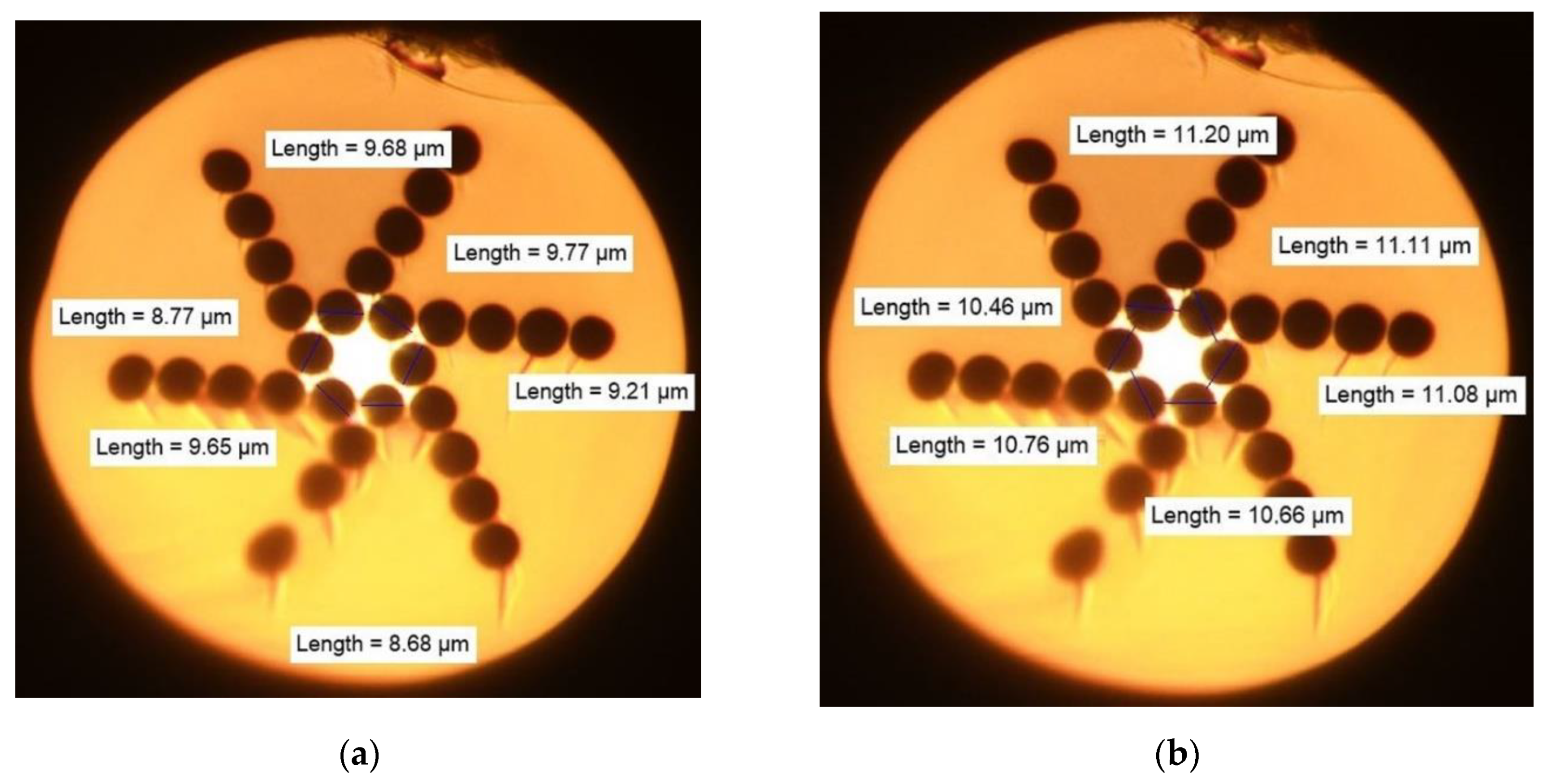

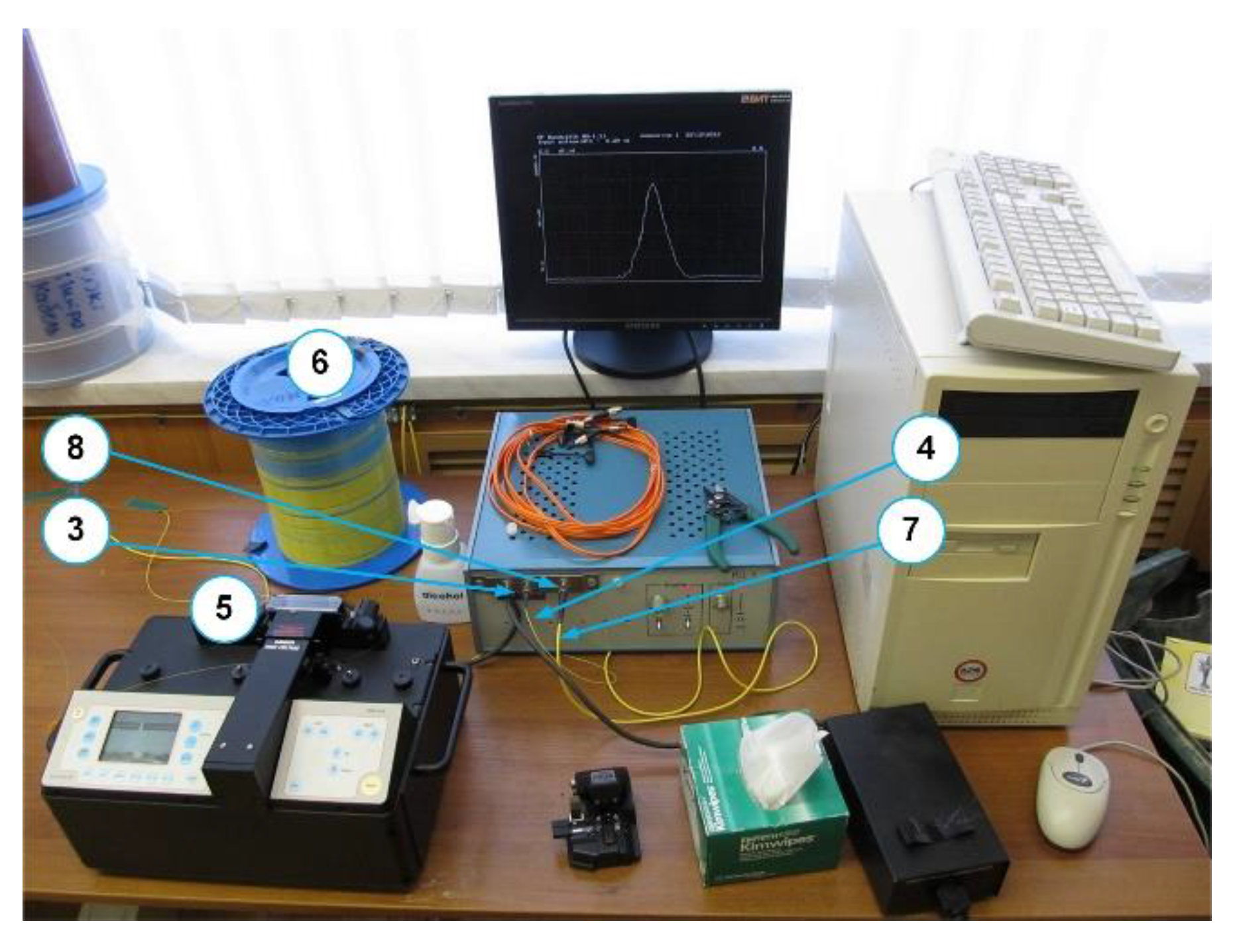

2. Fabrication of Twisted Silica Microstructured Optical Fibers

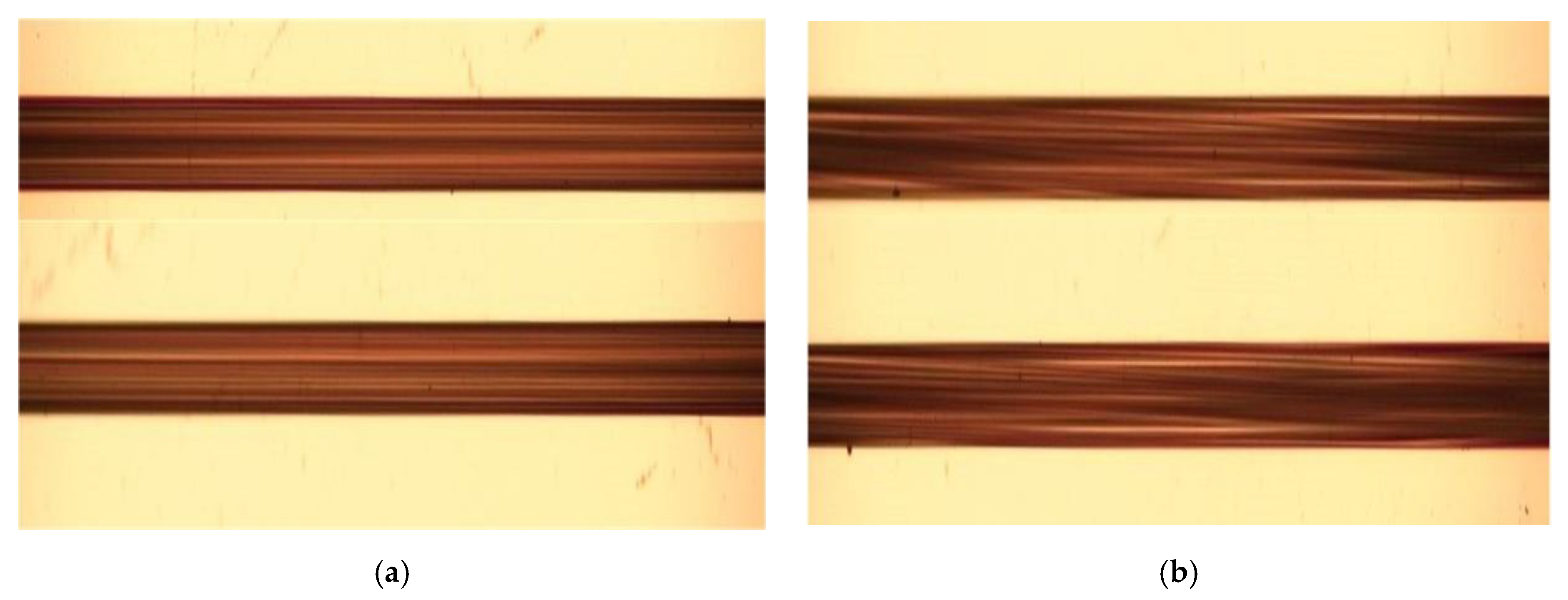

3. Twisted Silica Microstructured Optical Fibers with Equiangular Spiral Six-Ray Geometry

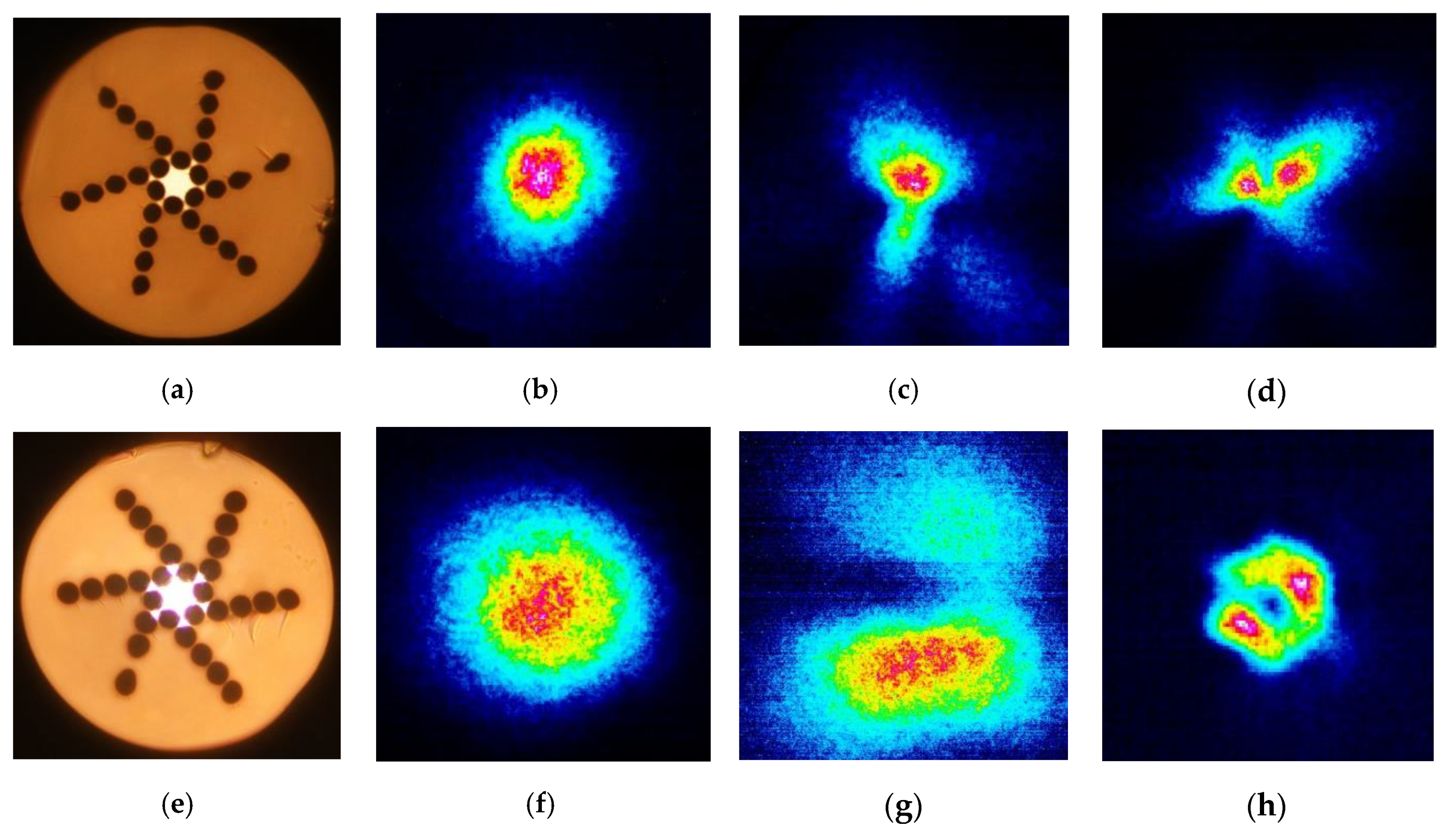

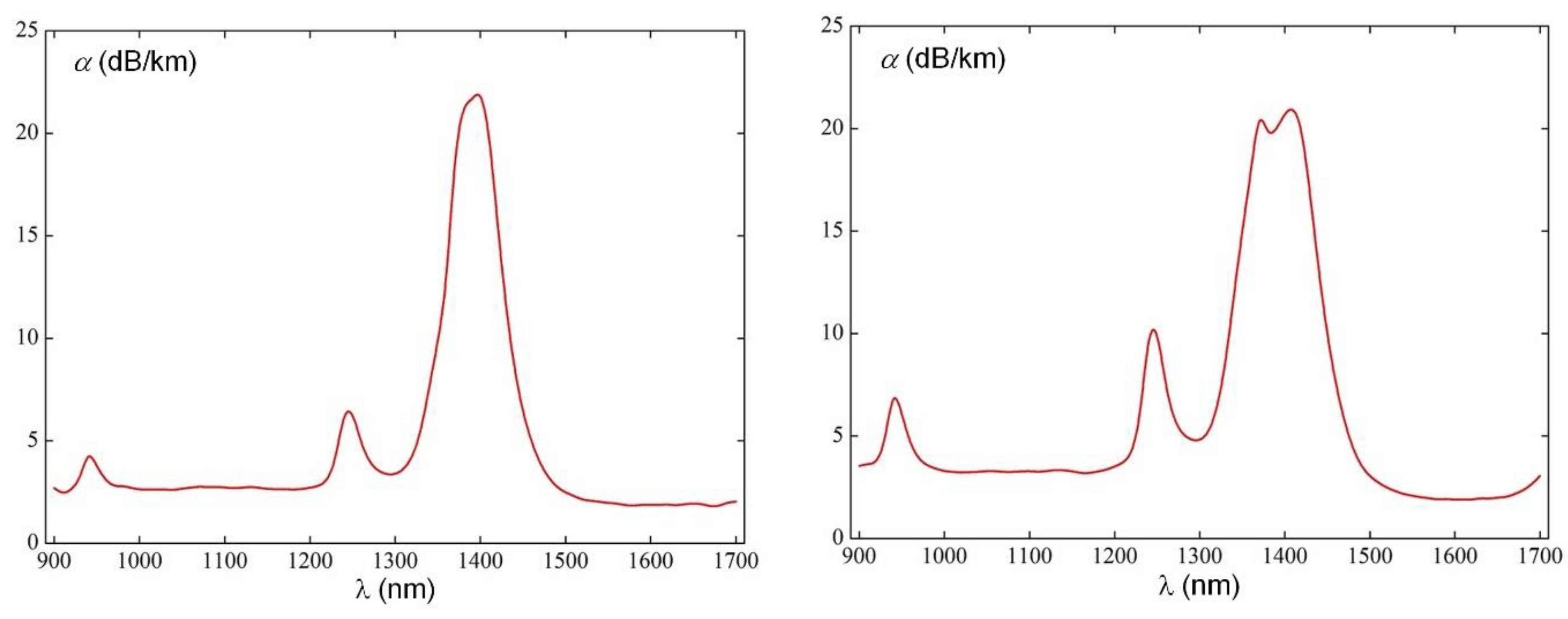

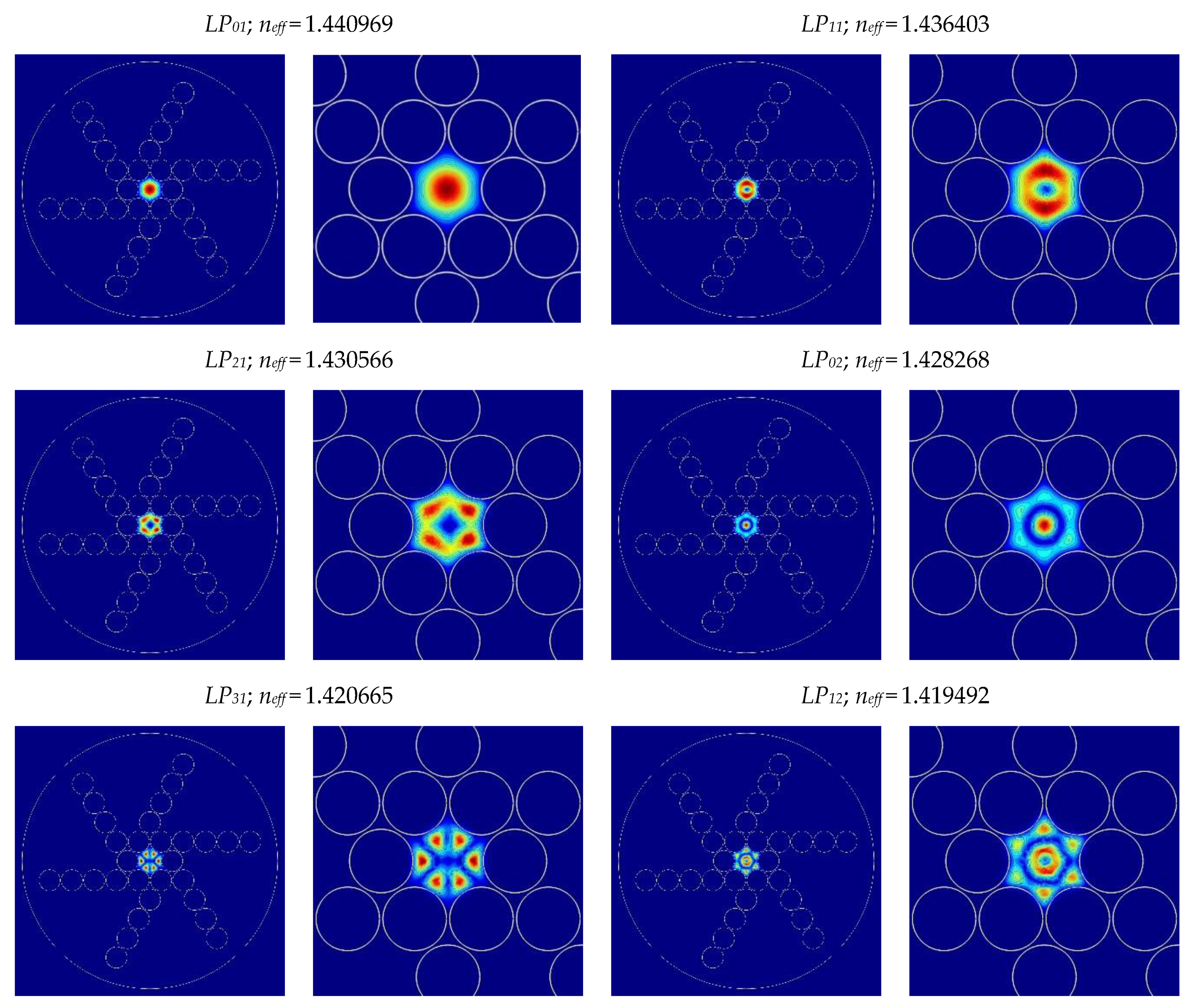

4. Attenuation

5. Analysis of Silica Microstructured Optical Fibers with Equiangular Spiral Six-Ray Geometry

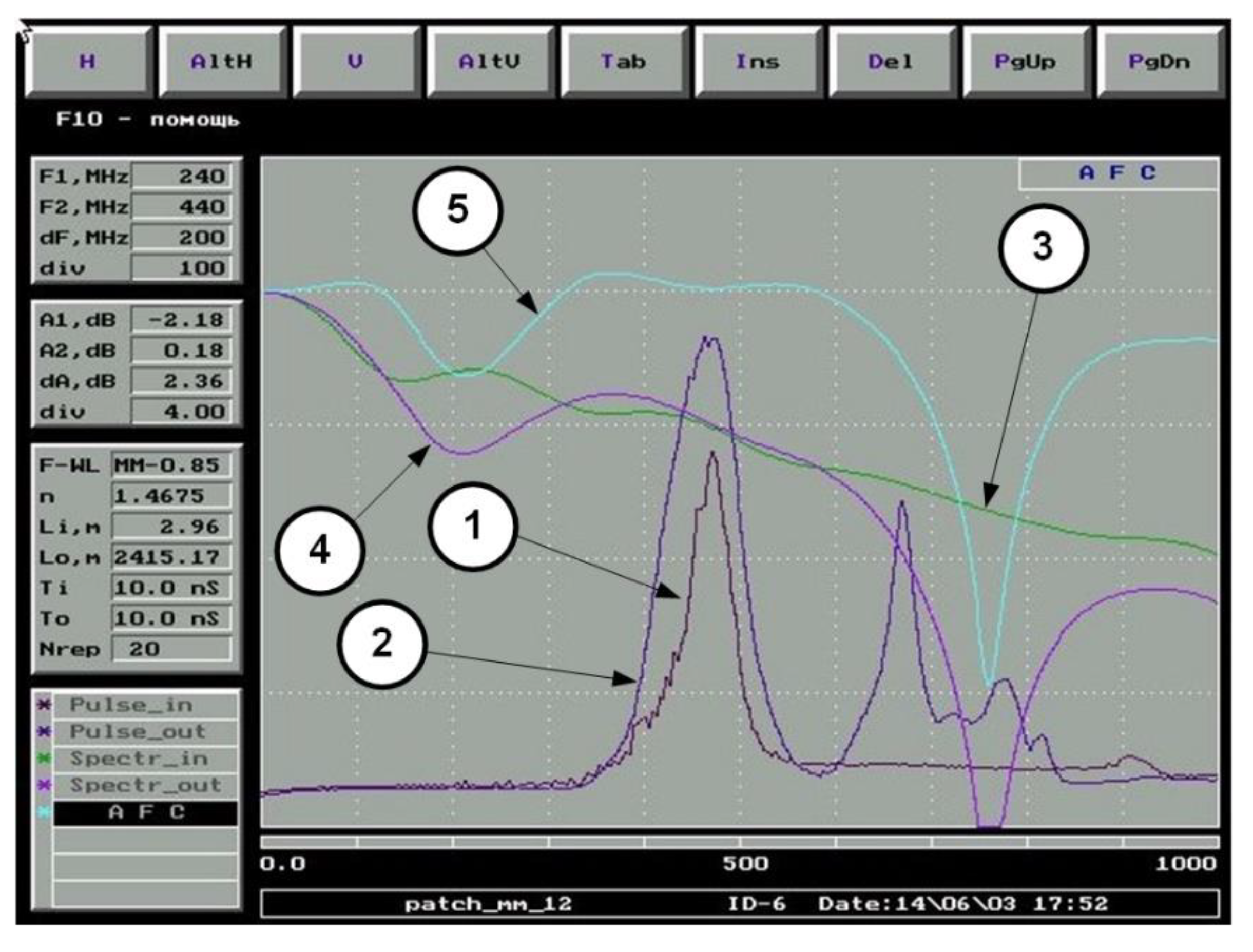

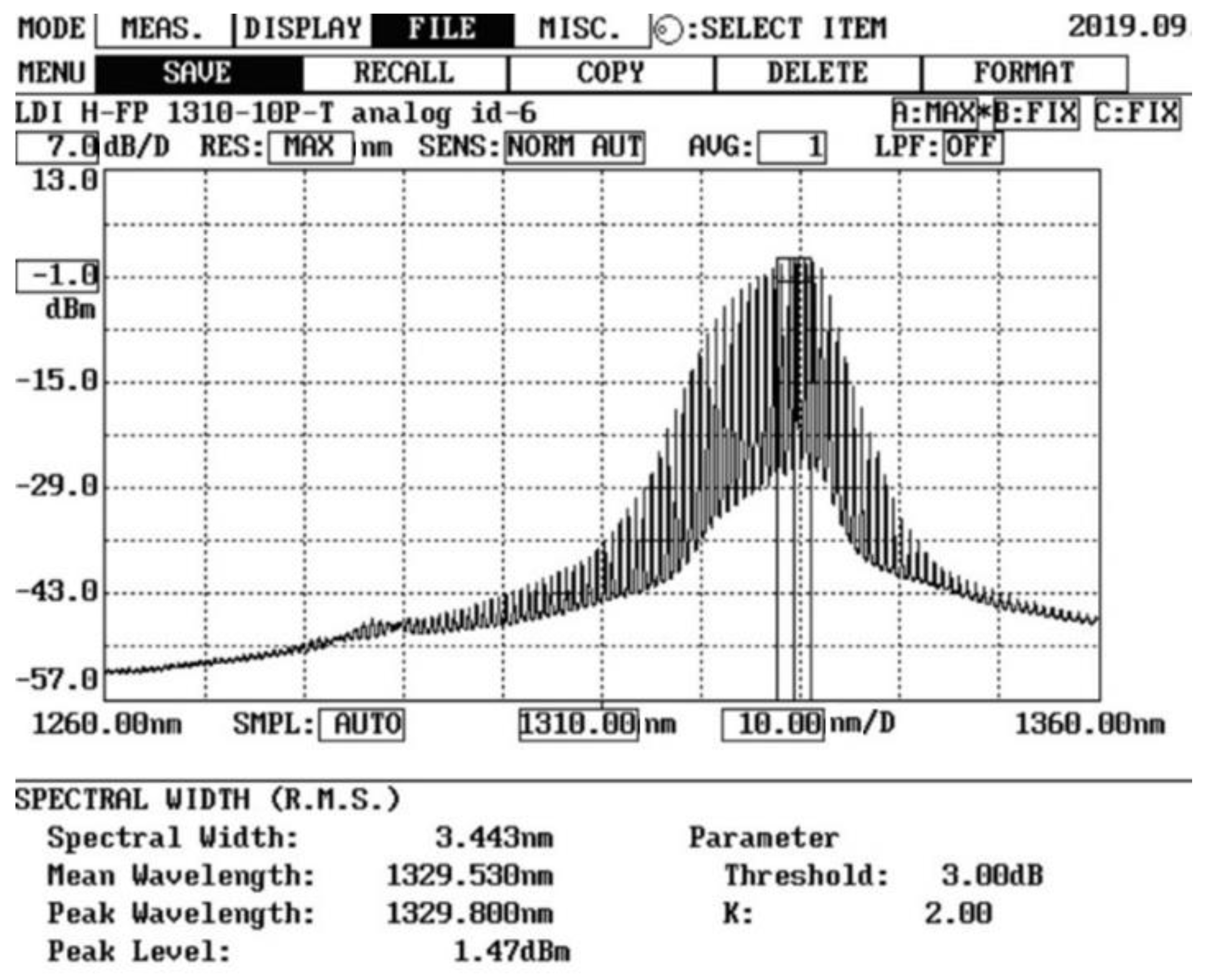

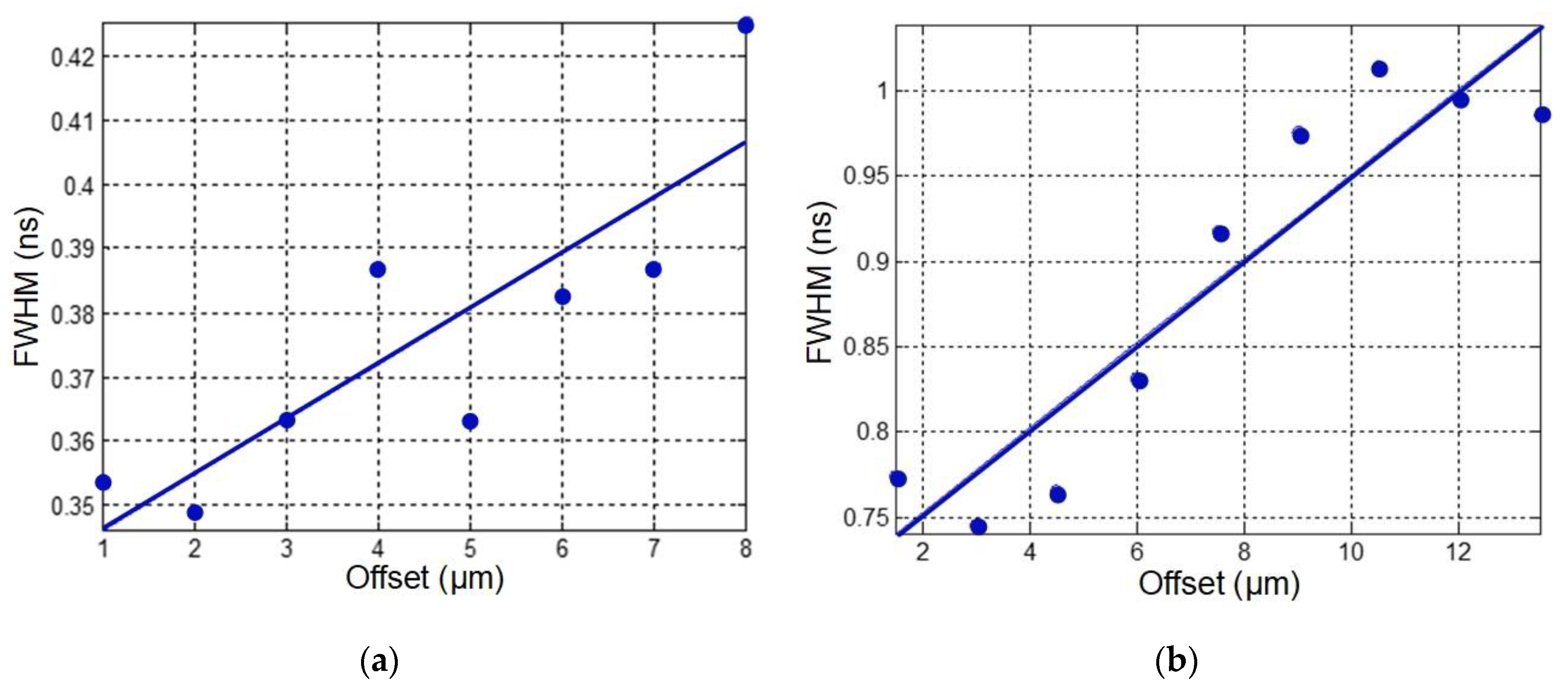

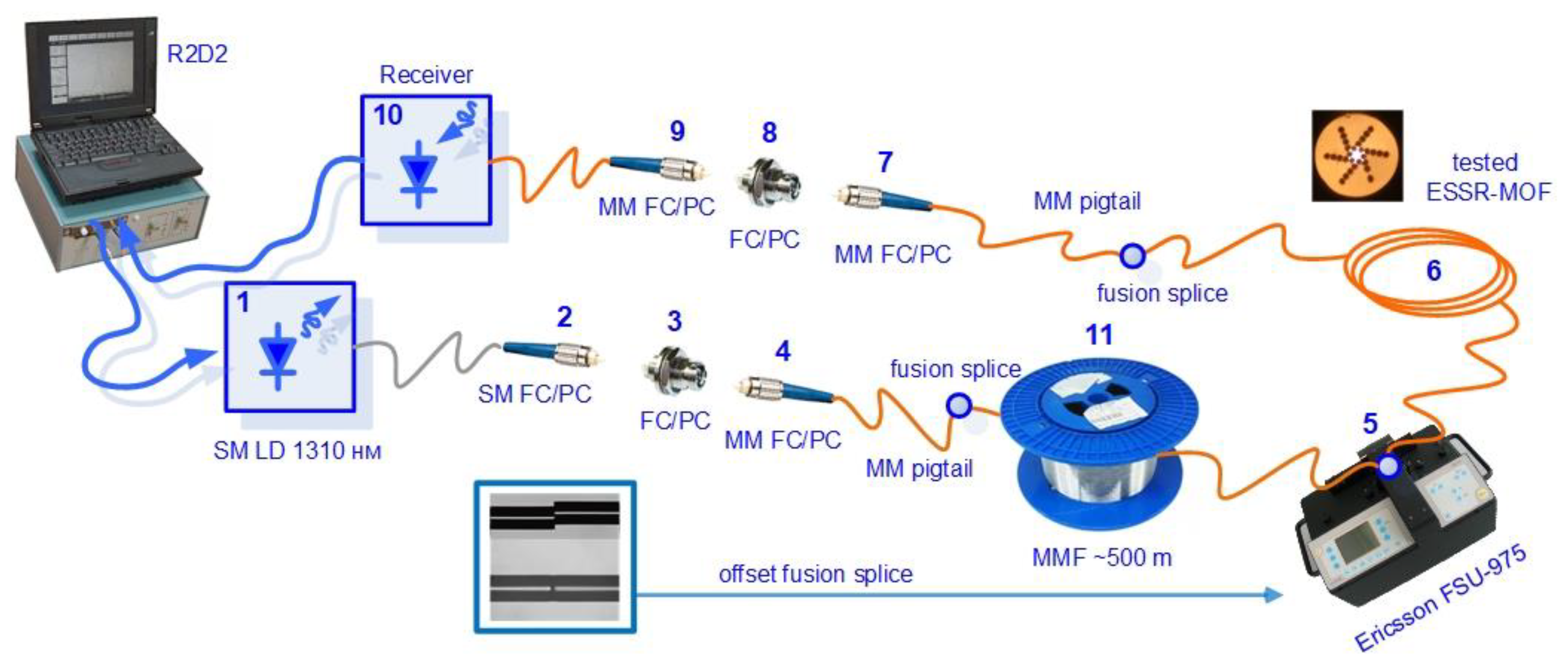

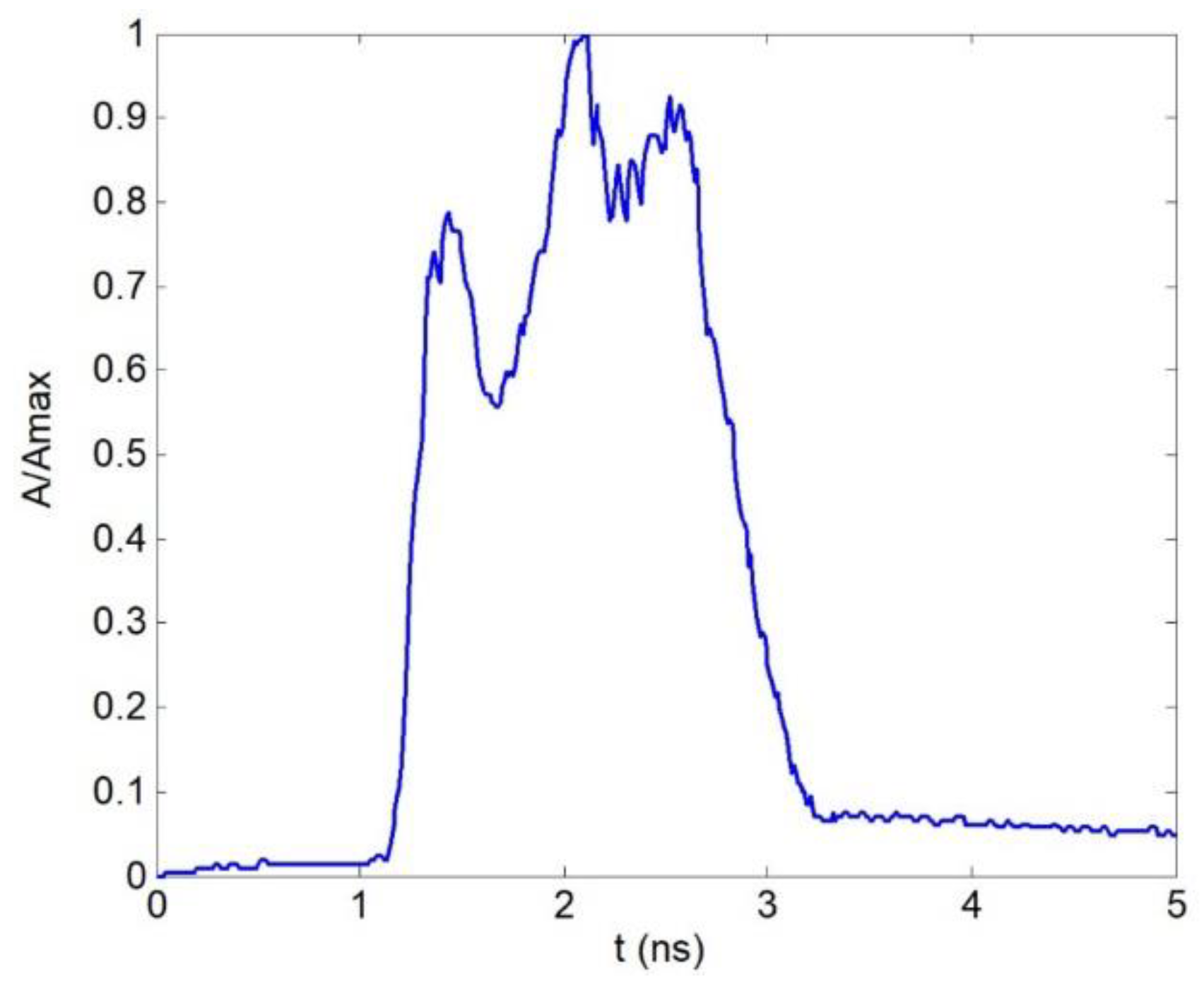

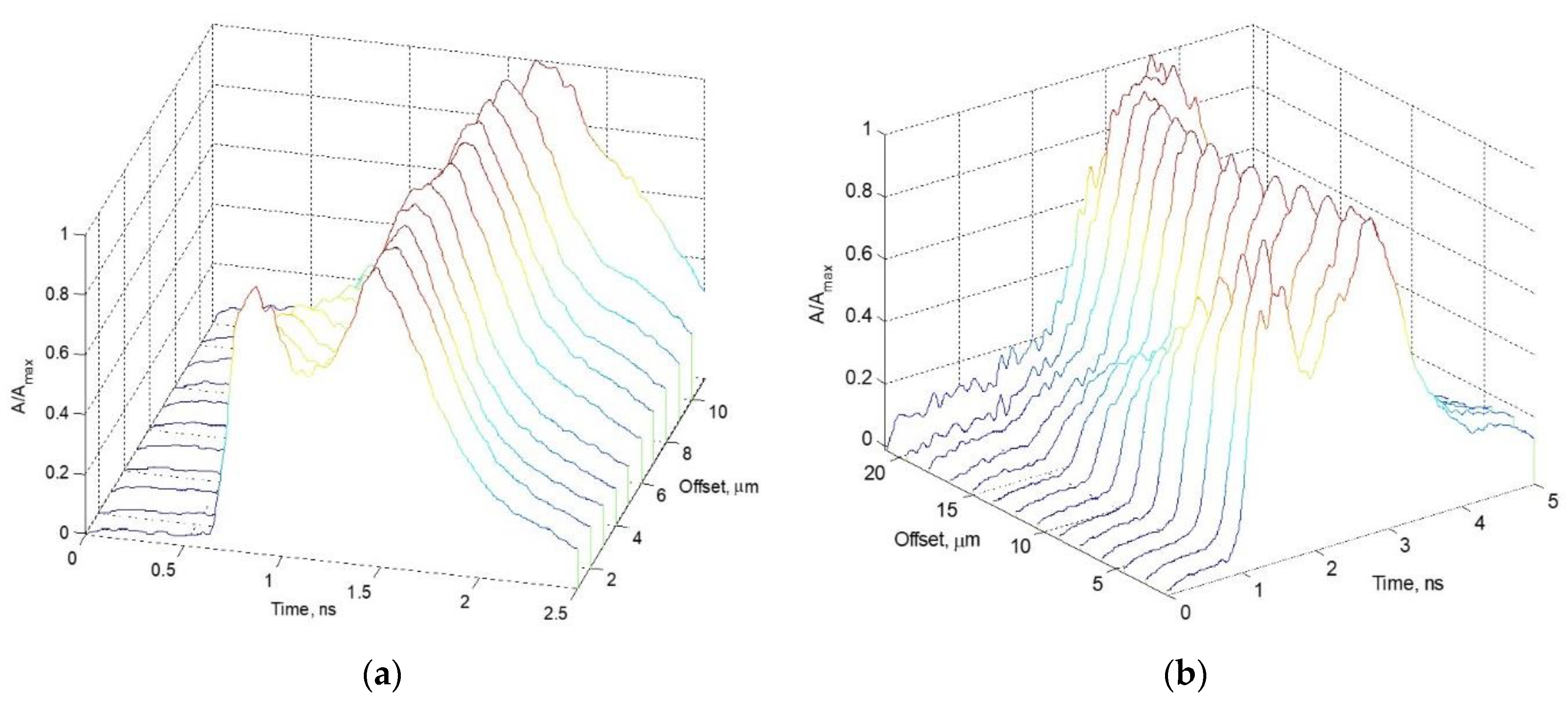

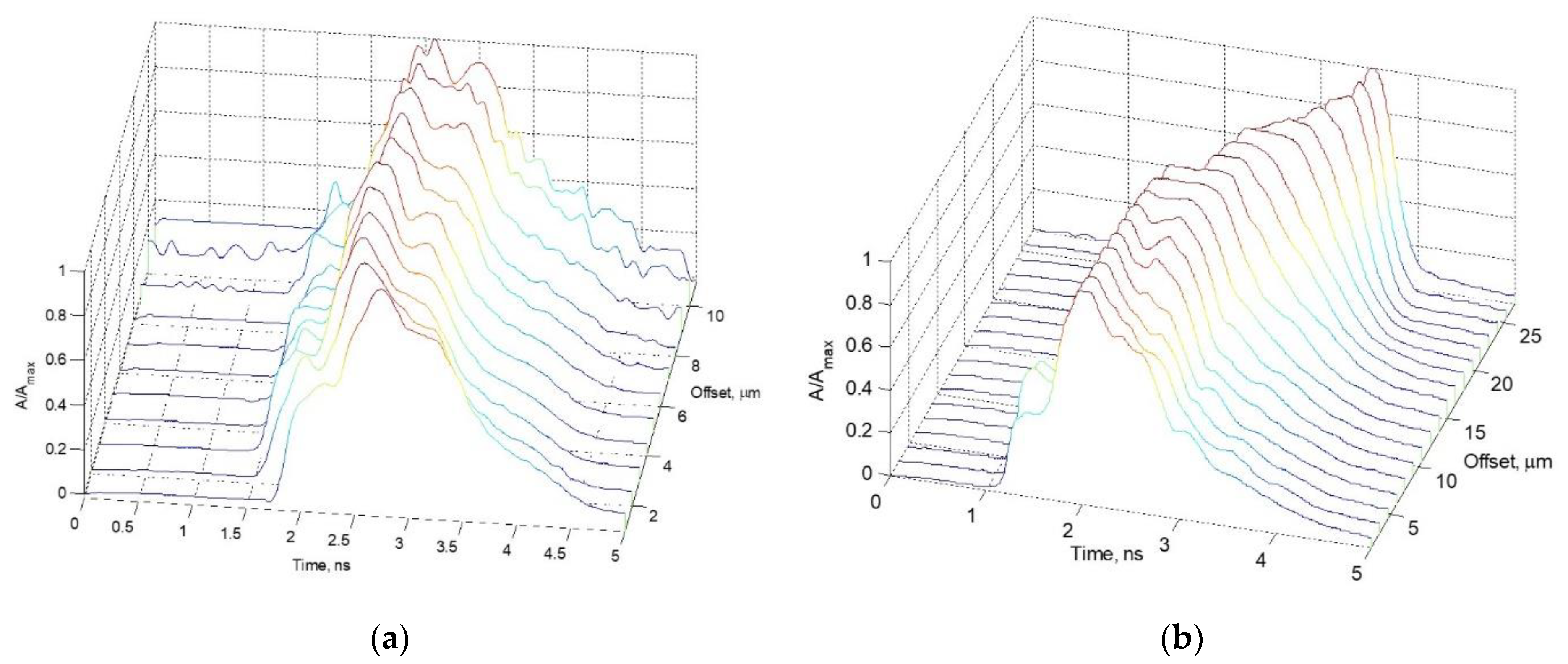

6. Pulse Response/Differential Mode Delay Measurement

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barlow, A.J.; Ramskov-Hansen, J.J.; Payne, D.N. Birefringence and polarization mode dispersion in spun single-mode fibers. Appl. Opt. 1981, 20, 2962–2968. [Google Scholar] [CrossRef] [PubMed]

- Hart, A.C., Jr.; Huff, R.G.; Walker, K.L. Method of Making a Fiber Having Low Polarization Mode Dispersion Due to a Permanent Spin. U.S. Patent 5298047, 29 March 1994. [Google Scholar]

- Blaszyk, P.E.; Christoff, W.R.; Gallagher, D.E.; Hawk, R.M.; Kiefer, W.J. Method and Apparatus for Introducing Controlled Spin in Optical Fibers. U.S. Patent 6324872 B1, 4 December 2001. [Google Scholar]

- Li, M.-J.; Chen, X.; Nolan, D.A. Fiber spinning for reducing polarization mode dispersion in single-mode fibers: Theory and applications. Proc. SPIE 2003, 5247, 97–110. [Google Scholar]

- DiGiovanni, D.J.; Golowich, S.E.; Jones, S.L.; Reed, W.A. Method of Making an Improved Multimode Optical Fiber and Fiber Made by Method. U.S. Patent 2001/0019652, 16 May 2001. [Google Scholar]

- DiGiovanny, D.J.; DiMarcello, F.V.; Jiang, X.L.; Oulundsen, G.E.; Pandit, S.P. Multimode optical Fiber with Increased Bandwidth. U.S. Patent 2004/0228590 A1, 18 November 2004. [Google Scholar]

- Koponen, J.; Sosnowki, T.; Ye, C. Spun Non-Circular and Non-Elliptical Core Optical Fibers and Apparatuses Utilizing the Same. U.S. Patent US2014268310A1, 18 September 2014. [Google Scholar]

- Koska, P.; Peterka, P.; Doya, V. Numerical modeling of pump absorption in coiled and twisted double-clad fibers. IEEE J. Sel. Top. Quantum Electron. 2016, 22, 4401508. [Google Scholar] [CrossRef]

- Wong, G.K.L.; Beravat, R.; Russell, P.S.J. Helically twisted photonic crystal fibres. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2017, 375, 20150440. [Google Scholar]

- Fuochi, M.; Hayes, J.R.; Furusawa, K.; Belardi, W.; Baggett, J.C.; Monro, T.M.; Richardson, D.J. Polarization mode dispersion reduction in spun large mode area silica holey fibres. Opt. Express 2004, 12, 1972–1977. [Google Scholar] [CrossRef][Green Version]

- Weiss, T.; Wong, G.K.L.; Biancalana, F.; Barnett, S.M.; Xi, X.M.; Russell, P.S.J. Topological Zeeman effect and circular birefringence in twisted photonic crystal fibers. J. Opt. Soc. Am. B 2013, 30, 2921–2927. [Google Scholar] [CrossRef]

- Xi, X.M.; Weiss, T.; Wong, G.K.L.; Biancalana, F.; Barnett, S.M.; Padgett, M.J.; Russell, P.S.J. Optical activity in twisted solid-core photonic crystal fibers. Phys. Rev. Lett. 2013, 110, 143903. [Google Scholar] [CrossRef] [PubMed]

- Wong, G.K.L.; Xi, X.M.; Frosz, M.H.; Russell, P.S.J. Enhanced optical activity and circular dichroism in twisted photonic crystal fiber. Opt. Lett. 2015, 40, 4639–4642. [Google Scholar] [CrossRef] [PubMed]

- Alexeyev, C.N.; Lapin, B.P.; Milione, G.; Yavorsky, M.A. Optical activity in multihelicoidal optical fibers. Phys. Rev. A 2015, 92, 033809. [Google Scholar] [CrossRef]

- Alexeyev, C.N.; Lapin, B.P.; Milione, G.; Yavorsky, M.A. Resonance optical activity in multihelicoidal optical fibers. Opt. Lett. 2016, 41, 962–965. [Google Scholar] [CrossRef] [PubMed]

- Xi, X.M.; Wong, G.K.L.; Weiss, T.; Russell, P.S.J. Measuring mechanical strain and twist using helical photonic crystal fiber. Opt. Lett. 2013, 38, 5401–5404. [Google Scholar] [CrossRef]

- Bohnert, K.; Gabus, P.; Kostovic, J.; Brandle, H. Optical fiber sensors for the electric power industry. Opt. Lasers Eng. 2005, 43, 511–526. [Google Scholar] [CrossRef]

- Ma, X.; Zhu, C.; Hu, I.-N.; Kaplan, A.; Galvanauskas, A. Single-mode chirally-coupled-core fibers with larger than 50 μm diameter cores. Opt. Express 2014, 22, 9206–9219. [Google Scholar] [CrossRef] [PubMed]

- Wong, G.K.L.; Kang, M.S.; Lee, H.W.; Biancalana, F.; Conti, C.; Weiss, T.; Russell, P.S.J. Excitation of orbital angular momentum resonances in helically twisted photonic crystal fiber. Science 2012, 337, 446–449. [Google Scholar] [CrossRef]

- Willner, A.E.; Huang, H.; Yan, Y.; Ren, Y.; Ahmed, N.; Xie, G.; Bao, C.; Li, L.; Cao, Y.; Zhao, Z.; et al. Optical communications using orbital angular momentum beams. Adv. Opt. Photonics 2015, 7, 66–106. [Google Scholar] [CrossRef]

- Barshak, E.V.; Alexeyev, C.N.; Lapin, B.P.; Yavorsky, M.A. Twisted anisotropic fibers for robust orbital-angular-momentum-based information transmission. Phys. Rev. A 2015, 91, 033833. [Google Scholar] [CrossRef]

- Stefani, A.; Kuhlmey, B.T.; Fleming, S. Orbital angular momentum modes by twisting of a hollow core antiresonant fiber. In Proceedings of the 2017 European Conference on Lasers and Electro-Optics and European Quantum Electronics Conference, Munich, Germany, 25–29 June 2017. [Google Scholar]

- Stefani, A.; Fleming, S.C.; Kuhlmey, B.T. Terahertz orbital angular momentum modes with flexible twisted hollow core antiresonant fiber. APL Photonics 2018, 3, 051708. [Google Scholar] [CrossRef]

- Napiórkowski, M.; Urbanczyk, W. The effect of coupling between core and cladding modes in twisted microstructured optical fibers. Proc. SPIE 2018, 10681, 106810H. [Google Scholar] [CrossRef]

- Fu, C.; Liu, S.; Wang, Y.; Bai, Z.; He, J.; Liao, C.; Zhang, C.; Zhang, F.; Yu, B.; Gao, S.; et al. High-order orbital angular momentum mode generator based on twisted photonic crystal fiber. Opt. Lett. 2018, 43, 1786–1789. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Ye, J.; Li, Y.; Dai, P.; Qu, S. Vortex chirality-dependent filtering in helically twisted single-ring photonic crystal fibers. Opt. Express 2019, 27, 20816–20823. [Google Scholar] [CrossRef]

- Zhou, G.; Liu, J.; Xia, C.; Hou, Z. Orbital-angular-momentum-amplifying helical vector modes in Yb3+-doped three-core twisted microstructure fiber. Opt. Express 2020, 28, 21110–21120. [Google Scholar]

- Bourdine, A.V. Differential mode delay of different generations of silica multimode optical fibers. Photon Express 2008, 5–6, 20–22. [Google Scholar]

- Bourdine, A.V. On multimode optical fiber DMD diagnostics. Inforcomm. Tech. 2008, 6, 33–38. [Google Scholar]

- Gowar, J. Optical Communication Systems; Prentice Hall/International/Radio i Svyaz (Radio and Communications): Moscow, Russia, 1989. [Google Scholar]

- Bottacchi, S. Multi-Gigabit Transmission over Multimode Optical Fibre: Theory and Design Methods for 10GbE Systems; JohnWiley & Sons Ltd.: New York, NY, USA, 2008. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bourdine, A.V.; Barashkin, A.Y.; Burdin, V.A.; Dashkov, M.V.; Demidov, V.V.; Dukelskii, K.V.; Evtushenko, A.S.; Ismail, Y.; Khokhlov, A.V.; Kuznetsov, A.A.; et al. Twisted Silica Microstructured Optical Fiber with Equiangular Spiral Six-Ray Geometry. Fibers 2021, 9, 27. https://doi.org/10.3390/fib9050027

Bourdine AV, Barashkin AY, Burdin VA, Dashkov MV, Demidov VV, Dukelskii KV, Evtushenko AS, Ismail Y, Khokhlov AV, Kuznetsov AA, et al. Twisted Silica Microstructured Optical Fiber with Equiangular Spiral Six-Ray Geometry. Fibers. 2021; 9(5):27. https://doi.org/10.3390/fib9050027

Chicago/Turabian StyleBourdine, Anton V., Alexey Yu. Barashkin, Vladimir A. Burdin, Michael V. Dashkov, Vladimir V. Demidov, Konstantin V. Dukelskii, Alexander S. Evtushenko, Yaseera Ismail, Alexander V. Khokhlov, Artem A. Kuznetsov, and et al. 2021. "Twisted Silica Microstructured Optical Fiber with Equiangular Spiral Six-Ray Geometry" Fibers 9, no. 5: 27. https://doi.org/10.3390/fib9050027

APA StyleBourdine, A. V., Barashkin, A. Y., Burdin, V. A., Dashkov, M. V., Demidov, V. V., Dukelskii, K. V., Evtushenko, A. S., Ismail, Y., Khokhlov, A. V., Kuznetsov, A. A., Matrosova, A. S., Morozov, O. G., Pchelkin, G. A., Petruccione, F., Sakhabutdinov, A. Z., Singh, G., Ter-Nersesyants, E. V., Tiwari, M., Zaitseva, E. S., ... Yin, J. (2021). Twisted Silica Microstructured Optical Fiber with Equiangular Spiral Six-Ray Geometry. Fibers, 9(5), 27. https://doi.org/10.3390/fib9050027