Addressing Stakeholder Concerns Regarding the Effective Use of Bio-Based and Biodegradable Plastics

Abstract

:1. Introduction

2. Context

2.1. Concerns from the Academic Community

2.2. Concerns from the Non-Academic Community

2.3. Relevant Mechanisms across the Policy Landscape

3. Methodology

4. Results

4.1. Regulation and Legislative Instruments

4.2. Material Quality and Performance

4.3. Market Penetration and Availability

4.4. Waste Management Infrastructure

4.5. Sourcing and Supply Chain

4.6. Communication and Information Provision

4.7. Material Health and Safety

5. Discussion

- Continued confusion regarding the meaning of terms, such as biodegradability/compostability, and the communication of these qualities and characteristics throughout the value chain.

- Difficulties for inexperienced companies in navigating, comprehending and interpreting the plethora of documents related to the safety of BB-P/BD-P with respect to their company/product.

- Applicability and appropriateness of existing safety documents for new BB-P/BD-P products.

- Overall appropriateness of using BB-P/BD-P as a sustainable alternative to traditional petroleum-based plastics.

5.1. Recommendations for Research

5.2. Recommendations for Policy

5.3. Recommendations for Practice

5.4. Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EC. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and The Committee of the Regions A Sustainable Bioeconomy For Europe: Strengthening the Connection Between Economy, Society and the Environment; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- EC. Bioeconomy Strategy. Available online: https://ec.europa.eu/info/research-and-innovation/research-area/environment/bioeconomy/bioeconomy-strategy_en#relatedlinks (accessed on 9 June 2021).

- EC. Bioeconomy: The European Way to Use Our Natural Resources: Action Plan 2018; Directorate-General for Research and Innovation (European Commission): Brussels, Belgium, 2019. [Google Scholar] [CrossRef]

- Philp, J.C.; Bartsev, A.; Ritchie, R.J.; Baucher, M.-A.; Guy, K. Bioplastics science from a policy vantage point. New Biotechnol. 2013, 30, 635–646. [Google Scholar] [CrossRef] [PubMed]

- De Besi, M.; McCormick, K. Towards a bioeconomy in Europe: National, regional and industrial strategies. Sustainability 2015, 7, 10461–10478. [Google Scholar] [CrossRef] [Green Version]

- Acquavia, M.A.; Pascale, R.; Martelli, G.; Bondoni, M.; Bianco, G. Natural polymeric materials: A solution to plastic pollution from the agro-food sector. Polymers 2021, 13, 158. [Google Scholar] [CrossRef] [PubMed]

- Andrady, A.L.; Neal, M.A. Applications and Societal Benefits of Plastics. Philos. Trans. Biol. Sci. 2009, 364, 1977–1984. [Google Scholar] [CrossRef]

- UN. Goal 12: Ensure Sustainable Consumption and Production Patterns. Available online: https://www.un.org/sustainabledevelopment/sustainable-consumption-production/ (accessed on 9 June 2021).

- EMF. New Plastics Economy. A Ciruclar Economy for Plastic in Which It Never Becomes Waste. Available online: https://www.ellenmacarthurfoundation.org/our-work/activities/new-plastics-economy (accessed on 9 June 2021).

- Ahmed, T.; Shahid, M.; Azeem, F.; Rasul, I.; Shah, A.A.; Noman, M.; Hameed, A.; Manzoor, N.; Manzoor, I.; Muhammad, S. Biodegradation of plastics: Current scenario and future prospects for environmental safety. Environ. Sci. Pollut. Res. 2018, 25, 7287–7298. [Google Scholar] [CrossRef]

- Bhagwat, G.; Gray, K.; Wilson, S.P.; Muniyasamy, S.; Vincent, S.G.T.; Bush, R.; Palanisami, T. Benchmarking Bioplastics: A Natural Step Towards a Sustainable Future. J. Polym. Environ. 2020, 28, 3055–3075. [Google Scholar] [CrossRef]

- Dilkes-Hoffman, L.; Ashworth, P.; Laycock, B.; Pratt, S.; Lant, P. Public attitudes towards bioplastics—Knowledge, perception and end-of-life management. Resour. Conserv. Recycl. 2019, 151, 104479. [Google Scholar] [CrossRef]

- Mederake, L.; Knoblauch, D. Shaping EU Plastic Policies: The Role of Public Health vs. Environmental Arguments. Int. J. Environ. Res. Public Health 2019, 16, 3928. [Google Scholar] [CrossRef] [Green Version]

- Taghikhah, F.; Voinov, A.; Shukla, N. Extending the supply chain to address sustainability. J. Clean. Prod. 2019, 229, 652–666. [Google Scholar] [CrossRef]

- Meeusen, M.; Peuckert, J.; Quitzow, R. Acceptance Factors for Bio-Based Products and Related Information Systems; 2015; Available online: https://www.biobasedeconomy.eu/app/uploads/sites/2/2017/07/Acceptance-factors-for-bio-based-products-and-related-information-systems.pdf (accessed on 3 July 2021).

- Beltrán, F.R.; Barrio, I.; Lorenzo, V.; del Río, B.; Martínez Urreaga, J.; de la Orden, M.U. Valorization of poly(lactic acid) wastes via mechanical recycling: Improvement of the properties of the recycled polymer. Waste Manag. Res. 2019, 37, 135–141. [Google Scholar] [CrossRef]

- Gawel, E.; Pannicke, N.; Hagemann, N. A path transition towards a bioeconomy—The crucial role of sustainability. Sustainability 2019, 11, 3005. [Google Scholar] [CrossRef] [Green Version]

- Falcone, P.M.; Imbert, E. Social life cycle approach as a tool for promoting the market uptake of bio-based products from a consumer perspective. Sustainability 2018, 10, 1031. [Google Scholar] [CrossRef] [Green Version]

- Lindström, T.; Österberg, F. Evolution of biobased and nanotechnology packaging—A review. Nord. Pulp Pap. Res. J. 2020, 35, 491–515. [Google Scholar] [CrossRef]

- Abou-Yousef, H.; Saber, E.; Abdel-Aziz, M.S.; Kamel, S. Efficient alternative of antimicrobial nanocomposites based on cellulose acetate/Cu-NPs. Soft Mater. 2018, 16, 141–150. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Jafari, S.M. Impact of metal nanoparticles on the mechanical, barrier, optical and thermal properties of biodegradable food packaging materials. Crit. Rev. Food Sci. Nutr. 2020, 61, 2640–2658. [Google Scholar] [CrossRef]

- Almeida, C.M.R.; Magalhães, J.M.C.S.; Souza, H.K.S.; Gonçalves, M.P. The role of choline chloride-based deep eutectic solvent and curcumin on chitosan films properties. Food Hydrocoll. 2018, 81, 456–466. [Google Scholar] [CrossRef]

- Al-Tayyar, N.A.; Youssef, A.M.; Al-hindi, R. Antimicrobial food packaging based on sustainable Bio-based materials for reducing foodborne Pathogens: A review. Food Chem. 2020, 310, 125915. [Google Scholar] [CrossRef] [PubMed]

- Ferreira-Filipe, D.A.; Paço, A.; Duarte, A.C.; Rocha-Santos, T.; Patrício Silva, A.L. Are Biobased Plastics Green Alternatives?—A Critical Review. Int. J. Environ. Res. Public Health 2021, 18, 7729. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef]

- Corvellec, H.; Campos, M.J.Z.; Zapata, P. Infrastructures, lock-in, and sustainable urban development: The case of waste incineration in the Göteborg Metropolitan Area. J. Clean. Prod. 2013, 50, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Brizga, J.; Hubacek, K.; Feng, K. The Unintended Side Effects of Bioplastics: Carbon, Land, and Water Footprints. One Earth 2020, 3, 45–53. [Google Scholar] [CrossRef]

- De Paoli, M.A.; Waldman, W.R. Bio-based additives for thermoplastics. Polimeros 2019, 29. [Google Scholar] [CrossRef] [Green Version]

- Park, M.; Choi, I.; Lee, S.; Hong, S.-J.; Kim, A.; Shin, J.; Kang, H.-C.; Kim, Y.-W. Renewable malic acid-based plasticizers for both PVC and PLA polymers. J. Ind. Eng. Chem. 2020, 88, 148–158. [Google Scholar] [CrossRef]

- Bracco, S.; Calicioglu, O.; Juan, M.G.S.; Flammini, A. Assessing the contribution of bioeconomy to the total economy: A review of national frameworks. Sustainability 2018, 10, 1698. [Google Scholar] [CrossRef] [Green Version]

- Krzan, A.; Hemjinda, S.; Miertus, S.; Corti, A.; Chiellini, E. Standardization and certification in the area of environmentally degradable plastics. Polym. Degrad. Stab. 2006, 91, 2819–2833. [Google Scholar] [CrossRef]

- Downes, J.; Borg, K.; Florin, N. A Type of ‘Biodegradable’ Plastic will Soon be Phased Out in Australia. That’s a Big Win for the Environment. Available online: https://theconversation.com/a-type-of-biodegradable-plastic-will-soon-be-phased-out-in-australia-thats-a-big-win-for-the-environment-156566 (accessed on 29 April 2021).

- Goldsberry, C. Consumers Confused by Distinction Between Biobased and Biodegradable Plastics. Available online: https://www.plasticstoday.com/sustainability/consumers-confused-distinction-between-biobased-and-biodegradable-plastics (accessed on 29 April 2021).

- Gunter, J. China Biodegradable Plastics ‘Failing to Solve Pollution Crisis’. Available online: https://www.bbc.co.uk/news/world-asia-55301203 (accessed on 29 April 2021).

- Krieger, A. Are Bioplastics Better for the Environment Than Conventional Plastics? Available online: https://ensia.com/features/bioplastics-bio-based-biodegradable-environment/ (accessed on 29 April 2021).

- Hennig, C. What Are Bioplastics Anyway? Confusion Over Term Hinders Fight Against Waste, Expert Says. Available online: https://www.cbc.ca/news/canada/british-columbia/bioplastics-expert-clear-confusion-on-terminology-1.4837685 (accessed on 29 April 2021).

- Fairs, M. Bioplastics Could Be “Just As Bad If Not Worse” for the Planet Than Fossil-Fuel Plastics. Available online: https://www.dezeen.com/2019/04/15/bioplastics-bad-environment-damage-arthur-huang/ (accessed on 29 April 2021).

- Cho, R. The Truth about Bioplastics. Available online: https://news.climate.columbia.edu/2017/12/13/the-truth-about-bioplastics/ (accessed on 29 April 2021).

- Miles, L. Biodegradable Plastic: Is It Really Eco-Friendly? Available online: https://treadingmyownpath.com/2018/03/22/biodegradable-plastic-is-it-really-eco-friendly/ (accessed on 29 April 2021).

- Gaule, B. Clearing Up the Bioplastic Confusion. Available online: https://cleanroomtechnology.com/news/article_page/Clearing_up_the_bioplastic_confusion/175767 (accessed on 29 April 2021).

- Morrison, O. Bioplastics Just As Toxic As Other Plastics, Study Finds. Available online: https://www.foodnavigator.com/Article/2020/10/28/Bioplastics-just-as-toxic-as-other-plastics-study-finds (accessed on 29 April 2021).

- Fera-Science. Bio-Based Packaging Needs Rigorous Testing to Avoid a New Food Safety Threat. Available online: https://www.thegrocer.co.uk/food-safety/bio-based-packaging-needs-rigorous-testing-to-avoid-a-new-food-safety-threat/647690.article (accessed on 29 April 2021).

- Addy, R. FSA: Study Green Food Contact Materials. Available online: https://www.foodmanufacture.co.uk/Article/2019/09/20/Call-to-study-green-food-contact-materials (accessed on 29 April 2021).

- Larson, D.B.; Jordan, S.R. Playing it safe: Toy safety and conformity assessment in Europe and the United States. Int. Rev. Adm. Sci. 2018, 85, 763–779. [Google Scholar] [CrossRef]

- Young, A.R. Europe as a global regulator? The limits of EU influence in international food safety standards. J. Eur. Public Policy 2014, 21, 904–922. [Google Scholar] [CrossRef]

- CEN-CENELEC. What Is a Standard. Available online: https://www.standardsbuildtrust.eu/what-is-a-standard (accessed on 26 May 2021).

- Berti, K.; Falvey, R. Does trade weaken product standards? Rev. Int. Econ. 2018, 26, 852–868. [Google Scholar] [CrossRef]

- EC. Directive 2001/95/EC of the European Parliament and of the Council of 3 December 2001 on General Product Safety; The European Parliament and the Council of The European Union: Brussels, Belguim, 2001. [Google Scholar]

- Rausand, M.; Utne, I.B. Product safety—Principles and practices in a life cycle perspective. Saf. Sci. 2009, 47, 939–947. [Google Scholar] [CrossRef]

- EC. Commission Regulation (EC) No 2023/2006 of 22 December 2006 on Good Manufacturing Practice for Materials and Articles Intended to Come into Contact With Food; European Commission: Brussels, Belgium, 2006. [Google Scholar]

- EC. Regulation (EC) No 1935/2004 of The European Parliament and of The CounciL of 27 October 2004 on Materials and Articles Intended to Come into Contact with Food and Repealing Directives 80/590/EEC and 89/109/EEC; European Commission: Brussels, Belgium, 2004. [Google Scholar]

- EC. Commission Regulation (EU) No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- EC. M/429 Mandate Addressed to CEN, CENELEC and ETSI for the Elaboration of a Standardisation Programme for Bio-Based Products; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- EC. M/430 Mandate Addressed to CEN for the Development of European Standards and CEN Workshop Agreements for Bio-Polymers and Bio-Lubricants in Relation to Bio-Based Product Aspects; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- CEN. Final Report of CEN/BT/WG 209 “Bio-Based Products”; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- CEN. Business Plan: CEN/TC 411 Bio-Based Products; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- Ørngreen, R.; Levinsen, K. Workshops As a Research Methodology. Electron. J. E-Learn. 2017, 15, 70–81. [Google Scholar]

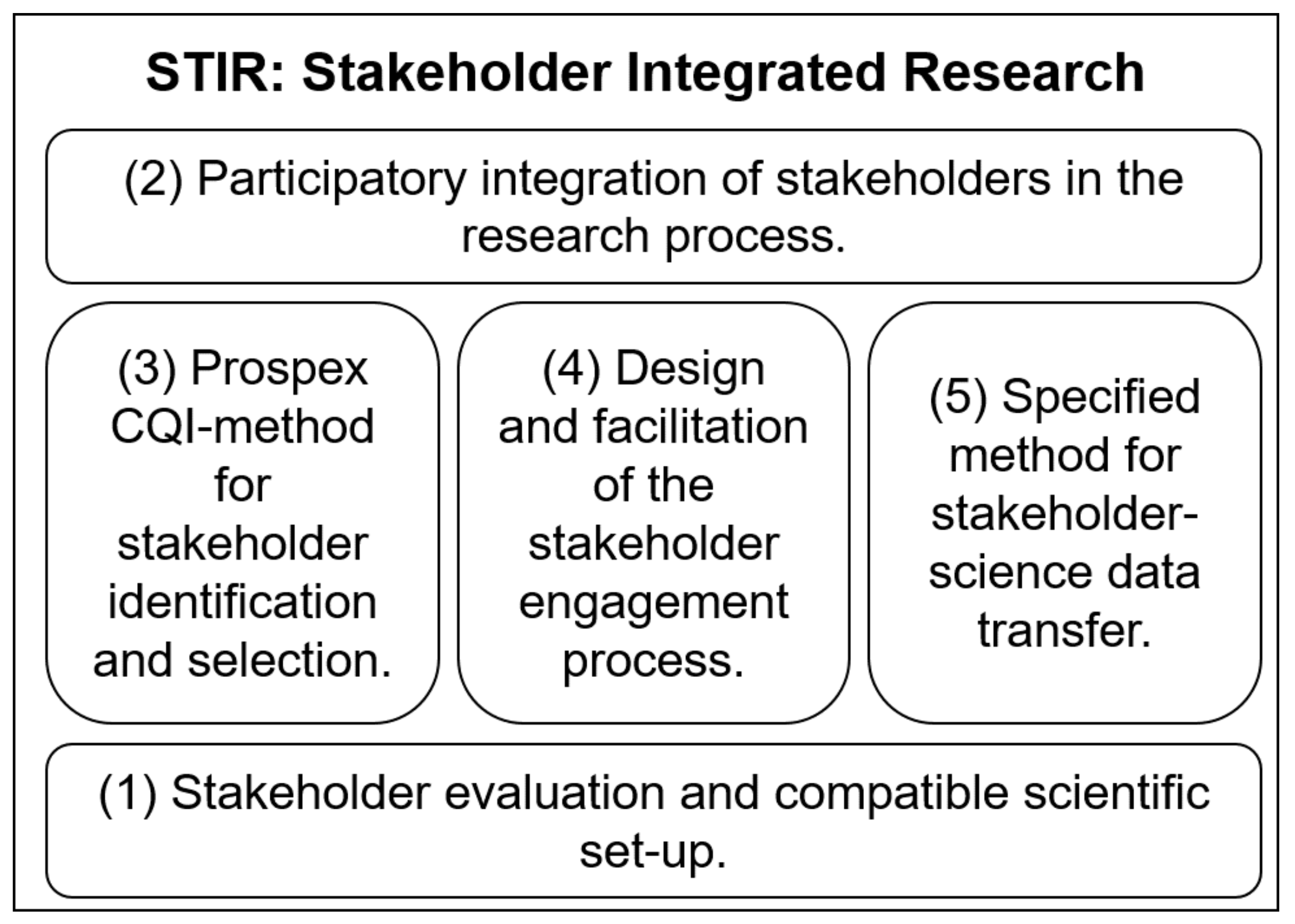

- Gramberger, M.; Zellmer, K.; Kok, K.; Metzger, M.J. Stakeholder integrated research (STIR): A new approach tested in climate change adaptation research. Clim. Chang. 2015, 128, 201–214. [Google Scholar] [CrossRef]

- Van de Poel, I.; Robaey, Z. Safe-by-Design: From Safety to Responsibility. Nanoethics 2017, 11, 297–306. [Google Scholar] [CrossRef] [Green Version]

- CS3. Science to Enable Sustainable Plastics—A White Paper from the 8th Chemical Sciences and Society Summit (CS3); Royal Society of Chemistry: London, UK, 2020. [Google Scholar]

- Platt, R.; Bauen, A.; Reumerman, P.; Geier, C.; Van Ree, R.; Gursel, I.V.; Garcia, L.; Behrens, M.; von Bothmer, P.; Howes, J.; et al. EU Biorefinery Outlook to 2030: Studies on Support to Research and Innovation in the Area of Bio-Based Products and Services; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Haddaway, N.R.; Kohl, C.; da Silva, N.R.; Schiemann, J.; Spök, A.; Stewart, R.; Sweet, J.B.; Wilhelm, R. A framework for stakeholder engagement during systematic reviews and maps in environmental management. Environ. Evid. 2017, 6, 11. [Google Scholar] [CrossRef]

- Raby, C.L.; Madden, J.R. Moving academic conferences online: Understanding patterns of delegate engagement. Ecol. Evol. 2021, 11, 3607–3615. [Google Scholar] [CrossRef]

- Wiederhold, B.K. Connecting through Technology during the Coronavirus Disease 2019 Pandemic: Avoiding “Zoom Fatigue”; Mary Ann Liebert, Inc.: New Rochelle, NY, USA, 2020. [Google Scholar]

- Bailenson, J.N. Nonverbal overload: A theoretical argument for the causes of Zoom fatigue. Technol. Mind Behav. 2021, 2. [Google Scholar] [CrossRef]

| Stakeholder Engagement Event | Total Number of Participants | Manufacturers/Producers | * Industry Association | Retail | End-user/Consumer | End of Life | Gender Balance Male: Female |

|---|---|---|---|---|---|---|---|

| Event 1 (Consultation) | 11 (6) | 2 (1) | 7 (3) | n/a | 1 (1) | 1 (1) | 65:35 (65:35) |

| Event 2 (Workshop) | 18 (10) | 11 (4) | 7 (6) | n/a | n/a | n/a | 50:50 (40:60) |

| Event 3 (Workshop) | 9 (5) | n/a | 3 (2) | 1 (0) | 1 (1) | 4 (2) | 20:80 (40:60) |

| Event 4 (Workshop) | 18 (5) | 7 (2) | 8 (2) | 2 (1) | n/a | 1 (0) | 45:55 (40:60) |

| Stakeholder Engagement Event | Event 1 (Consultation) | Event 2 (Workshop) | Event 3 (Workshop) | Event 4 (Workshop) |

|---|---|---|---|---|

| Focus | Status of the existing policy landscape. | Identify concerns, challenges, and opportunities regarding BB-P/BD-P efficacy from industry point of view | Identify concerns, challenges, and opportunities regarding BB-P/BD-P efficacy from consumer point of view | Reflect on previous discussions. Collect opinions across the full value chain. |

| Regulation and Legislative Instruments | √ | √ | ||

| Material Quality and Performance | √ | √ | ||

| Market Penetration and Availability | √ | √ | ||

| Waste Management Infrastructure | √ | √ | √ | |

| Sourcing and Supply Chain | √ | √ | √ | |

| Communication and Information Provision | √ | √ | √ | |

| Material Health and Safety | √ | |||

| Stakeholder engagement event | Event 1 (Consultation) | |||

| Regulation and Legislative Instruments | The range of existing standards, regulations, and directives applicable to BB-P/BD-P were highlighted “Bio-based and biodegradable plastics already need to adhere to a range of standards, regulations, and directives” Potential difficulties for companies to navigate and understand all documents was also noted. “There is no point in reinventing the wheel. There is a plethora of documents out there that concern the production, use and disposal of biobased and biodegradable plastics. The issue concerns how companies’ access and understand them.” | |||

| Stakeholder engagement event | Event 2 (Workshop) | |||

| Regulation and Legislative Instruments | It was suggested that companies new to the industry are often unfamiliar with the applicable documents, unsure which are relevant for them, and struggle with unfamiliar/complex language. “The language used in the existing standards is often difficult to understand for new users” It was also noted that paywalls (to access documents) can create additional (and sometime unnecessary) financial burdens. “Standards are copyrighted and you have to pay for full access of them. A bit more information about what’s included in the standards document should be made available, before you then actually go ahead and buy the standard yourself.” Increased support and positive policies from intra-national and national governments were suggested. “What we need to bring biobased materials on a high level is the positive support from Brussels as well as the national authorities. We can sell our products by our own, but support is required.” | |||

| Material Quality and Performance | The exploration of “safety by design” prinicples was suggested. (The safety by design principle aims to address, overcome, or eliminate any risks to safety in the design phase [59]) “I am very interested in the safety by design principle. The safety by design principle is the start of everything. It is a nice principle, but we have to work on it and bring meat to this principle.” | |||

| Market Penetration and Availability | The concept of appropriate alternatives was introduced. “The value of biodegradability and bio-based materials is always connected to the application into the material that you are producing. So, it should always be seen in the context of where those materials make most sense with the sustainability values.” It was suggested that producers work with retailers to ensure competitive price points. “I think that one of the main hurdles for consumers might be price. It is not in all applications that you see the actual cost of the material, but this is definitely an issue.” | |||

| Waste Management Infrastructure | It was argued that current waste management infrastructure is inconsistent arcoss different countries. “Then another very important point is that we get access to end-of-life options, such as mechanical recycling and composting infrastructure. In some countries we do have this, but there are still many countries where we don’t. That is very important, because if you bring products to the market, it is of key importance that you have an end-of-life solution for that. You cannot just throw it away or incinerate it, so access to end-of-life options is key.” “The role of these materials with biodegradable and biobased materials has to be inextricably linked to the end of life through biowaste treatment. And the reason why Italy is biggest market, I think in Europe but possibly in the world at the moment outside of China, is because it collects more food waste than anybody else. Two thirds of all food waste in the EU is collected in Italy. If you’re going to treat food waste, you need materials which mimics food waste, safe food waste treatment, and this is the role of biodegradable and biobased materials. The reason why we don’t have big markets elsewhere in Europe is because we simply don’t have ubiquitous collections of food waste. That’s coming in 2024 across the whole EU, and I think that will be the main driver for our industry.” “I agree that we need more acceptability for compostable packaging by the waste industry.” | |||

| Sourcing and Supply Chain | It was suggested that a clearer understanding about the benefits and limitations of BB-P/BD-P in the context of sustainability is needed. “We do need a better understanding of the benefits and limitations of bioplastics for downstream users, in particular consumers.” Arguments were made for the importance of considering environmental impacts across the whole lifecycle. “It is very important that life cycle environmental impacts are being taken into account in decision-making, when it comes to promoting and advancing these kinds of new materials. Also, the industry should be encouraged to go towards that direction. Our lifecycle approach means that the viewpoint should be from the product design for the use and for the recycling onto the next life stages.” | |||

| Communication and Information Provision | Arguments were made for more (and clearer) communication to break down and simplify the facts about BB-P/BD-P products, both in terms of provenance and use/disposal. “We need many of the waste processing technologies to improve before we can communicate this to end users and consumers (e.g., whilst a PLA yoghurt pot can technically be chemically recycled back into monomers, the collection, sorting and processing infrastructure is not yet available).” | |||

| Stakeholder engagement event | Event 3 (Workshop) | |||

| Material Quality and Performance | The performance levels of innovative materials were discussed as a key concern. “We need a good performance of these innovations. The first developments were quite weak. For instance, the supermarket plastic bags were initially not so resistant” It was argued that some of these issues are inherent to the material itself and that the use of additives, such as inks and dyes (commonly used in traditional plastic products), may require further consideration. “Different additives are needed, for instance inks or dyes, on the packaging or labelling. I think we should consider the safety aspects. Because as we need to use different chemicals, we need to be sure that they are they are not creating any problems. Because these additives are developed and tested with conventional plastics, not bio-based plastics, we don’t know the behaviour or the degradation itself.” “To ensure that it actually biodegrades and just doesn’t break down in small pieces or small microplastics in the environment. Most of the risk of these microplastics is not only the physical particles of microplastics. Most of the chemical problems begin because parts of the microplastics contain these additives. So, all the ingredients of the bioplastics. The bioplastics itself can be safe and it can degrade in a safe way, but we need to test the degradation in real conditions: not just with plastics, but with the additives, glues and components that are needed to create it, and which can be different from conventional additives.” | |||

| Market Penetration and Availability | It was felt that the current low levels of product availability and information resticted informed decision making. It was argued that retailers and manufacturers need to provide more offers and/or alternatives, focusing on competitive price points. “We need to have enough offers and different alternatives to choose from. For instance in supermarkets, I need to have enough things to choose from, otherwise I cannot make an informed choice.” The growth and visbility of organic products as a potential framework was highlighted. “I think it is very important that these bio-based products are properly displayed in shops. For example, if you are in shop right now it is easier to find organic products and it would be really good if that would be the same case for bio-based products.” The concept of appropriate alternatives in conjunction with third party certification was highlighted. “There are also issues with biodegradability itself, because we need to make sure that the composting processes do have processes for bio-based and bio-degradable plastics, and that the composting time is long enough to ensure that we don’t end up with microplastics. In terms of safety, it is important that the end-of-life processes are ensured. I also support the argument that we should have third-party certification. Especially when talking about bio-based content, this is important to ensure that we actually have 100 per cent recyclable products and that it is not a false claim.” “A trustworthy chain of custody and 3rd party certification is important, because we have claims that products are bio-based but you have some very loose accounting methods that allow the counting of biobased characteristic that is not fully in the physical product, in the physical polymer. So, we have this mass balance method chain of custody, but more generally for plastics, and the same lines could be applicable for bio-based products.” | |||

| Waste Management Infrastructure | The need to consider existing and future waste management system was highlighted as a key concern. “a proper sorting or recycling system. If I make the effort to buy recyclable plastic bags, for example, I need to be sure that I can put them in the organic container. If we are talking about bio-based products, they are disturbing the recycling processes nowadays, because the facilities are not ready to sort them. If the end of life is the same for conventional and bioplastics, we are not doing anything good.” Suggested direct, simple, and practical information regarding the optimal waste management option, such as explicit instructions on which bin (or waste stream) should be used. “Just to echo comments from before, is it home composting, can it go in my organic waste bin or composting or anaerobic digestion? I want the communications that go with those problems to be really clear.” “I want it to be really clearly labelled, I want to make sure that it is more sustainable than its fossil fuel-based alternatives in terms of life cycle and impact on the environment.” “Very clear information that enables me to make that kind of decisions, and then again having the option for what to do with it when I no longer need it.” | |||

| Sourcing and Supply Chain | Potential conflicts regarding feedstock sourcing (specifically with reference to developing nations) were highlighted, as well as potential issues of genetically modified (GMO) crops. “We need to ensure that these materials stem from sustainable sources, we are not competing with primary, so we are not using potatoes for a packaging when people don’t have enough for eating, for instance.” “When we are creating new products on the market, for developing countries it can be a problem if we are using as bio-based products some of the raw materials or primary materials like potatoes, maize, or something like that. In the long term it is a problem if we are using these materials for creating bio-based products, because we are decreasing the amount of food that stays in developing countries. So, we should only allow for secondary materials, or residual or waste streams to be used.” “Can we also raise the issue of using genetically modified crops for producing bioplastics? GMO is a possible option, but I don’t think it is good for the humans and the environment to use GMO modified crops.” | |||

| Communication and Information Provision | In-depth discussion regarding communication, specifically related to how information is conveyed to the end-user. Covering claims of sustainability, notification of content, and correct methods of use/disposal. Reliability and clarity of information provided was discussed as a key concern. “I would need reliable information. For instance, everything is biodegradable nowadays, so I think we would need a certificate or some sort of external assessment. For me personally, it is only biodegradable if it is compostable, because we need it to adapt to the recycling process.” “I agree with the previous comment that informing consumers is important, but today there is confusion regarding what is bio-based and what is bio-degradable. It is very important to make these claims clear to the consumers, so that bio-based products do not end up in the organic waste bin if they are not biodegradable.” “To have very clear labelling and be able to first of all find those products and then be able to select them and actually know what I am purchasing when I am actually in the supermarket or in cafes or restaurants. More labelling and clear communication for the consumers” Discussed the potential issue around mixed-messages regarding the avoidance of plastic use and zero-waste ambitions. “We should also ensure that any products made out of these bioplastics are more beneficial than products made of traditional plastics. Obviously, conventional plastics have very developed recycling systems. By replacing something that has a very established recycling scheme, are we actually making it worse by doing that?” “what will be important will be the prevention, and we see that for example the use of single use plastics should still be banned, even if it is bio-based. So, changes in the perception may be interesting, but just because something is biodegradable it does not mean we should promote single-used items. For instance, if you go to a shop or you buy your meal, it is maybe bio-based, but it is not actually biodegradable, and the change of perception may in this sense undermine the objective of limiting the use of single use plastics.” Argued that any information presented for BB-P/BD-P products should not give the impression that “biodegradability” gives the consumer the license to dispose of these products outside of the recommended environment (e.g., littering in the open environment). “Bioplastics should never give the impression that because they are biodegradable, they can be thrown away. It should be very clearly indicated in the labelling and in the communication strategy, that these should not be thrown away into the environment.” It was suggested that sustainability criteria should be applied to the entire value chain and life cycle of the product. “One important point is the sustainability of the whole value chain of the biobased plastics, meaning the sustainability of the production, making sure that there’s no competition for food or making sure that if we produce them from waste, what about the competition for example with the paper waste industry? I think we can sum it up as the whole sustainability criteria behind the biobased plastics and in the life cycle assessment in general.” | |||

| Stakeholder engagement event | Event 4 (Workshop) | |||

| Regulation and Legislative Instruments | It was suggested that simplicity is key when developing and implementing norms and/or certifictaion schemes. “Any norm or EU certification has to explain to the people what the real advantage of using certain materials is, and how they should be handled. In my opinion, everything has to be created to simplify the life of the of the people.” It was also argued that better leadership from European governments is required, specifically in terms of labelling and explanations. “Because on the market today, there is a very big confusion; people write on any packaging, compostable, sustainable, and so on, and nobody really understands what is going on. And this confusion has come about, because there is not very clear input from the European government in terms of labelling and explanations… Because very few know what industrially compostable, compostable, biodegradable mean. It is not just about the expert community, but we have to create something that makes it clear to everybody.” | |||

| Material Quality and Performance | It was argued that producers should take responsibility to ensure the sustainability of their product. “Maybe I’m generalising here, but I suspect from most consumers point of view, let’s say they unwrap their food, and they have a pack in their hand. And actually, they just want to know what to do with it. I suspect most people don’t want to read about how much biobased content there is or how sustainable the package is. Probably a lot of those a lot people would just like to leave that that sort of decision to the people putting the packaging on the market, and you would like to think that they’ve made the right choices further back in the chain, and that actually they wouldn’t be putting things on the market that are clearly unsustainable. There will be a small percentage of consumers who are interested in all the details, but I think generally the messaging needs to be simple. And again, it applies to conventional packaging, you just need a message on the pack, whatever it is, that tells you what to do with it. And I think from the consumers point of view, it should just be simple.” | |||

| Waste Management Infrastructure | Raised the issue of microplastics. Highlighted the similarities in the generation of microplastics when BB-P/BD-P and traditional plastics were compared, especially when products are wrongly discarded within the environment. “Often, the questions we receive are about microplastics. I think that is one of the hottest topics at the moment.” | |||

| Sourcing and Supply Chain | Raised the issue concerning unknown variables that may impact the supply of materials (either feedstock or compounded materials), especially in relation to the limited capacity within the EU (outside research and development) to produce and process such materials itself compared with the amount required to fulfil the EU’s ambitions for use. “The supply of the new material. Because as I as far as I understood, Europe has just limited that capacity to introduce new polymers, and we are just buying all the material from Asia, which is every day coming up with a new offer, as well as from the United States and Canada. Europe is at the moment just doing research, but we don’t have the pipeline and supply chain needed in order to deliver us enough material to make the project a reality. So it’s just research, which is not fulfilling the industrial demand.” | |||

| Communication and Information Provision | Discussed the impact of approriate and reliable information provided to consumers. “Not just those scientific facts, but also this appropriate or inappropriate information about biobased and biodegradable products in the market that that can lead to not enough knowledge for the consumer, which can also lead to lack of safety of the product.” It was suggested that simplicity is key when concerning consumer information. “All this activity has to be simplified for the end user or the market. Because today there is quite a lot of confusion about the packaging; what is compostable, recyclable and so on.” “This is creating a lot of confusion, and it is not clear for people how bioplastics and all the new materials coming to the market can be used and recollected and how they can be managed” | |||

| Material Health and Safety | A key issue concerned the role of standardization. Here, the discussion centered around the EU standard for composting (EN 13432) and the apparent lack of emphasis on the importance of safety regarding the application of the subsequent compost to soil. “Conforming to the European EN 13432 standard about the producing of compost, and the safety for the end of life of this compostable plastic when it becomes compost, and then returns to the nature to fertilise the soil. The importance for the soil and the circular thinking when it comes to producing bio-based and compostable plastics; to offer to consumers a new product that are in circular economy that can compost.” Noted that appropriate information is required to ensure safety in the market, where novel and newly developed materials should be checked to meet all relevant requirements. Did not consider it appropriate to treat BB-P/BD-P with more caution than traditional plastics and that raising such concerns publicly around the former (and out of proportion when considering the latter) could imply to consumers that BB-P/BD-Ps are more hazardous. “I understand that bio plastics are new and people want to know about them. And I guess it’s a little bit like building a house; when you build the latest house, it has to be built to the latest specifications and probably has more safety features built in et cetera. But sometimes we perhaps just need to go back and look at the existing houses and just check that they are still up to scratch and still meet all the requirements. There are aspects within conventional materials that could potentially be the same as the bioplastic materials, but they are not highlighted, in a way. […] I think the bar is very, very high for bioplastics, whereas maybe conventional materials… I accept that they’re well known and they’ve been used for many years, but maybe there are things that might not be as good as everyone believes.” | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fletcher, C.A.; Niemenoja, K.; Hunt, R.; Adams, J.; Dempsey, A.; Banks, C.E. Addressing Stakeholder Concerns Regarding the Effective Use of Bio-Based and Biodegradable Plastics. Resources 2021, 10, 95. https://doi.org/10.3390/resources10100095

Fletcher CA, Niemenoja K, Hunt R, Adams J, Dempsey A, Banks CE. Addressing Stakeholder Concerns Regarding the Effective Use of Bio-Based and Biodegradable Plastics. Resources. 2021; 10(10):95. https://doi.org/10.3390/resources10100095

Chicago/Turabian StyleFletcher, Carly A., Karolina Niemenoja, Rhiannon Hunt, Jill Adams, Alan Dempsey, and Craig E. Banks. 2021. "Addressing Stakeholder Concerns Regarding the Effective Use of Bio-Based and Biodegradable Plastics" Resources 10, no. 10: 95. https://doi.org/10.3390/resources10100095

APA StyleFletcher, C. A., Niemenoja, K., Hunt, R., Adams, J., Dempsey, A., & Banks, C. E. (2021). Addressing Stakeholder Concerns Regarding the Effective Use of Bio-Based and Biodegradable Plastics. Resources, 10(10), 95. https://doi.org/10.3390/resources10100095