How to Identify Potentials and Barriers of Raw Materials Recovery from Tailings? Part II: A Practical UNFC-Compliant Approach to Assess Project Sustainability with On-Site Exploration Data

Abstract

:1. Introduction

2. Terms and Methods

2.1. Key Words and Definitions

2.2. Considerations for the Development of the Case Study TSF Bollrich

2.3. UNFC-Compliant Anthropogenic Raw Materials Assessment and Classification Approach

- Definition of project and generation of information.

- Assessment of project’s development status.

- UNFC-compliant categorisation of criteria and project classification.

2.4. Case Study Assessment Methods

2.4.1. Environmental Assessment

2.4.2. Social Assessment

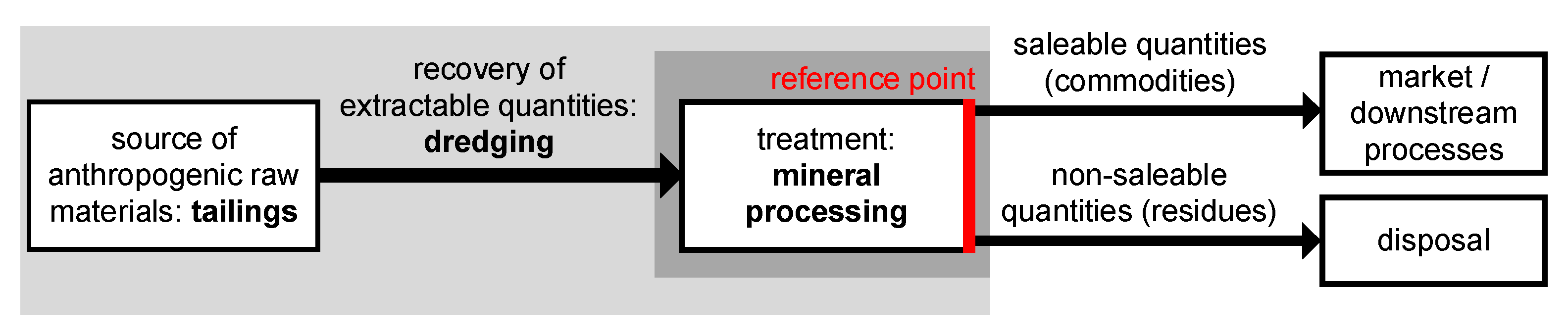

2.4.3. Material Characterisation and Material Flow Analysis

- Scenario definition and selection of relevant processes and mass flows.

- Mass flow quantification with published and estimated data, and model assumptions for unavailable data.

- Mass flow visualisation with Sankey diagrams.

2.4.4. Economic Assessment

2.4.5. Sensitivity and Uncertainty Analysis

2.4.6. Legal Assessment

2.5. Development of a Categorisation Matrix for a UNFC-Compliant Project Rating

3. Results

3.1. Definition of the Project and Generation of Information

3.1.1. Knowledge Base on the Case Study Deposit

3.1.2. Setting Objectives of the Project

3.1.3. Scenario Modelling

3.2. Case Study Assessment

3.2.1. Environmental Assessment: Status Quo Risks

3.2.2. Social Assessment: Stakeholder Considerations

3.2.3. Techno-Economic Assessment: Material Flow Analysis

3.2.4. Techno-Economic Assessment: Discounted Cash Flow Analysis

3.2.5. Techno-Economic Assessment: Sensitivity and Uncertainty Analysis

3.2.6. Legal Assessment: Basic Considerations

4. Discussion

4.1. Interpretation of the Case Study Results

4.2. Reconciliation of Stakeholder Perspectives with an Application of the UNFC Principles

4.3. Path Forward for the Case Study Bollrich

4.4. Integrating Sustainability Aspects into Raw Materials Classification

4.5. Development Potential of the Assessment and Classification Approach

5. Conclusions and Recommendations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation/Unit | Description |

| Ag | lat. argentum (silver) |

| Al | aluminium |

| Au | lat. aurum (gold) |

| BaSO4 | barium sulphate (barite) |

| Cd | lat. cadmia (cadmium) |

| Co | cobalt |

| Cu | lat. cuprum (copper) |

| CuFeS2 | copper iron disulphide (chalcopyrite) |

| Fe | lat. ferrum (iron) |

| FeS2 | iron disulphide (pyrite) |

| Ga | lat. gallia (gallium) |

| In | indium |

| Mn | manganese |

| Mo | molybdenum |

| Ni | nickel |

| Pb | lat. plumbum (lead) |

| PbS | lead sulphide (galena) |

| Tl | lat. tellus (tellurium) |

| Zn | zinc |

| ZnS | zinc sulphide (sphalerite) |

| ADRIANA | Airborne spectral Detection of Reusable Industry mAterials in tailiNgs fAcilities |

| BMBF | German Ministry of Research and Education |

| CAPEX | capital expenditure |

| CL:AIRE | Contaminated Land: Applications in Real Environments |

| CRM | Critical Raw Material |

| DCF | discounted cash flow |

| E | East |

| EC | European Commission |

| EU | European Union |

| LOM | Life of Mine |

| N | North |

| NPV | net present value |

| OPEX | operating expenditure |

| Qty. | quantity |

| RM | raw material |

| TSF | tailings storage facility |

| UNECE | United Nations Economic Commission for Europe |

| UNFC | United Nations Framework Classification for Resources |

| UNFC E category | represents environmental-socio-economic viability |

| UNFC F category | represents technical feasibility |

| UNFC G category | represents degree of confidence in the geological estimate |

| USGS | U.S. Geological Survey |

| W | West |

| °C | degree Celsius (unit of temperature on the Celsius scale) |

| µm | micrometre (unit of length, equivalent to 10-6 metres) |

| a | year |

| km | kilometre (unit of length, equivalent to 103 metres) |

| kW | kilowatt (SI-derived unit of power) |

| kWh | kilowatt-hour (SI-derived unit of energy) |

| l | litre (SI-derived unit of volume, equivalent to 10-3 m³) |

| m | metre (SI unit of length) |

| m2 | square metre (SI-derived unit of surface) |

| m3 | cubic metre (SI-derived unit of volume) |

| mm | millimetre (unit of length, equivalent to 10-3 metres) |

| t | metric tonne (unit of weight, equivalent to 1000 kilograms) |

Appendix A

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| Geological conditions (relevant for project development) | ||||

| (1) quantity | amount of target RMs | ore quality, former processing efficiency, deposit volume | [45] | degree of geological certainty: |

| high (G1) | ||||

| medium (G2) | ||||

| low (G3) | ||||

| (2) quality | physico-chemical properties of target RMs | former processing, storage conditions | [45] | degree of geological certainty: |

| high (G1) | ||||

| medium (G2) | ||||

| low (G3) | ||||

| (3) homogeneity | distribution of target RMs inside the deposit | manner of former deposition | [24] | degree of geological certainty: |

| high (G1) | ||||

| medium (G2) | ||||

| low (G3) | ||||

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| TSF condition & risks (relevant for project development) | ||||

| (4) ordnance | unexploded ordnance from armed conflicts | regional history, former searching activities | - | degree of knowledge: |

| non-existence proven (F1) | ||||

| existence proven (F2) | ||||

| unclarified (F3) | ||||

| Mine planning considerations (relevant for project execution) | ||||

| (5) mine/operational design | optimising RMs recovery under consideration of strategic goals & restrictions | geological knowledge on deposit, project planning phase, quality of model assumptions, legal restrictions | [45] | level of detail of planning: |

| extended (incl. detailed operational factors) (F1) | ||||

| advanced (incl. pit configuration & processing scheme) (F2) | ||||

| basic (conceptual) (F3) | ||||

| (6) metallurgical testwork | investigation of possible methods for mineral processing | sampling techniques, representativeness of test feed, testing techniques | [45] | degree of research on mineral processability: |

| industrial scale (F1) | ||||

| pilot scale (F2) | ||||

| laboratory scale (F3) | ||||

| (7) water consumption | demand of fresh water supply for mining & processing | available water resources, water efficiency of mining system | [13,97,98] | percentage of recycled water: |

| high (>80%) (F1) | ||||

| medium (50–80%) (F2) | ||||

| low (<50%) (F3) | ||||

| Infrastructure (relevant for project development) | ||||

| (8) real estate | availability of land & reusability of buildings | former mine closure, current land use, time lapsed after abandonment | [45] | condition of infrastructure: |

| highly developed (fully reusable) (F1) | ||||

| acceptable (usable after upgrade) (F2) | ||||

| bleak (requires (re-)construction) (F3) | ||||

| (9) mining & processing | reusability of equipment related to general services, mining & processing | former mine closure, current land use, time lapsed after abandonment | [45] | condition of equipment: |

| highly developed (fully reusable) (F1) | ||||

| acceptable (usable after upgrade) (F2) | ||||

| bleak (requires new acquisition) (F3) | ||||

| (10) utilities | access to utilities supply lines (e.g., electricity) | mine closure & time lapsed after abandonment, current land use, proximity to human settlements | [45] | condition of infrastructure: |

| highly developed (full access) (F1) | ||||

| acceptable (access after upgrade) (F2) | ||||

| bleak (requires (re-)construction) (F3) | ||||

| (11) transportation & access | access to mine & markets via air, road, railway, or waterway | topography, former mine closure, current land use, time lapsed after mine abandonment, proximity to human settlements | [45] | condition of infrastructure: |

| highly developed (fully reusable) (F1) | ||||

| acceptable (usable after upgrade) (F2) | ||||

| bleak (requires (re-)construction) (F3) | ||||

| Post-mining state (relevant for future impacts) | ||||

| (12) residue storage safety | ability of new storage facility to safely store new residues for an indefinite time period | amount of new residues, topography, type of construction, climate, regional seismic activity | [13,98,99,100] | suitability of new disposal site for safe storage: |

| high degree of safety proven (F1) | ||||

| preliminary assertion of safety (F2) | ||||

| unsafe or unclarified (G3) | ||||

| (13) rehabilitation | process of recontouring, revegetating, & restoring the water & land values | residue characteristics, local ecosystem, landscape, environmental laws, local climate | [101] | level of detail of planning: |

| concrete (F1) | ||||

| conceptual (F2) | ||||

| none (F3) | ||||

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| Microeconomic aspects (relevant for project development) | ||||

| (14) economic viability | economic returns from project | mine planning, RMs prices, costs of input factors (labour, energy, materials), payments to public sector (e.g., taxes) | [45,97] | discounted cash flow over projected LOM: |

| positive (NPV >> 0€) (E3.1a) | ||||

| neutral (NPV~0€) (E3.2a) | ||||

| negative (NPV << 0€) (E3.3a) | ||||

| (15) economic uncertainty | overall uncertainty of economic estimates | degree of detail in planning, data quality of economic estimate | [45] | uncertainty of cash flow in pessimistic scenario: |

| low (NPV >> 0€) (E3.1a) | ||||

| medium (NPV~0€) (E3.2a) | ||||

| high (NPV << 0€) (E3.3a) | ||||

| Financial aspects (relevant for project development) | ||||

| (16) investment conditions | conditions concerning taxes, royalties, & other financial regulations, which are a precondition for decision makers with respect to location & investment | country-specific regulations, condition of financial market, social considerations, environmental considerations | [45,68] | country rank on the ease-of-doing-business index: |

| country rank < 75 (E3.1a) | ||||

| country rank 75–125 (E3.2a) | ||||

| country rank > 125 (E3.3a) | ||||

| (17) financial support | financial support from political institutions for innovative projects such as loans, equity financing, or guarantees can incentivise RMs from mineral waste | active socio-political support | [102] | probability of approval: |

| high (E3.1a) | ||||

| medium (E3.2a) | ||||

| low (E3.3a) | ||||

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| Environmental impacts during project execution | ||||

| (18) air emission | risk of tailings being eroded by wind | particle size, TSF cover, local climate, wind conditions, pit configuration | [13,98] | risk of dust emission: |

| low (<80%) (E1b) | ||||

| medium (50–80%) (E2b) | ||||

| high (>50%) (E3b) | ||||

| (19) liquid effluent emission | effluents from tailings can contaminate soil & surface water | soil liner, drainage system, wet tailings storage, local environment, tailings’ chemical properties | [13,98] | risk of groundwater contamination: |

| low (E1b) | ||||

| medium (E2b) | ||||

| high (E3b) | ||||

| (20) noise emission | noise & vibrations during mining; transport & processing can cause disturbances of local communities determined by individual & collective perception | mine planning, protective measures, topography, proximity to human settlements | [97] | expected degree of impact: |

| low (E1b) | ||||

| medium (E2b) | ||||

| high (E3b) | ||||

| Environmental impacts after project execution | ||||

| (21) biodiversity | influence on habitats & species | local ecosystem, mining system, landscape, rehabilitation measures | [97] | total number of protected species that are affected by mining activities & that will be resettled on post-mining land: |

| all (100%) (E1b) | ||||

| some (1–99%) (E2b) | ||||

| none (0%) (E3b) | ||||

| (22) land use | land requirement after mine closure | amount of new residues, type of disposal, rehabilitation, land development opportunities | [97] | freely available post-mining land: |

| most (>80%) (E1b) | ||||

| some (50–80%) (E2b) | ||||

| little (<50%) (E3b) | ||||

| (23) material reactivity | capability of contained minerals to produce AMD | target minerals, concentration of sulphidic minerals | [13,103] | reduction of reactive material’s mass: |

| high (>80%) (E1b) | ||||

| medium (50–80%) (E2b) | ||||

| low (<50%) (E3b) | ||||

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| Social impacts during project execution | ||||

| (24) local community | commitment beyond formal regulatory requirements, the recognition of diverse values, & the right to be informed about issues & conditions that influence lives | communication with stakeholders, proximity to human urban, protected, or culturally relevant areas, participation of local communities in decision-making | [68,97,104] | probability of approval through active commitment: |

| high (>80%) (E3.1c) | ||||

| medium (50–80%) (E3.2c) | ||||

| low (>50%) (E3.3c) | ||||

| (25) health & safety | protection of workers & local communities from injuries & diseases, & environmentalpollution | mining system, local health & safety standards, corporate values for the establishment of a safe work environment & lively safety culture | [97] | total number of complaints or prosecutions for non-compliance in planning phase: |

| none (plans have been communicated publicly) (E3.1.c) | ||||

| more than 1 (plans have been communicated publicly) (E3.2c) | ||||

| none (plans have not been communicated publicly) (E3.3c) | ||||

| (26) human rights & business ethics | degree to which a mining company values ethically correct behaviour | wages, right to organise trade unions, bribery & corruption, violation of human rights, forcefully gained control over land, a country’s governance | [97] | total number of complaints or prosecutions for non-compliance in planning phase: |

| none (plans have been communicated publicly) (E3.1.c) | ||||

| more than 1 (plans have been communicated publicly) (E3.2c) | ||||

| none (plans have not been communicated publicly) (E3.3c) | ||||

| Social impacts due to project execution | ||||

| (27) wealth distribution | distribution of earning between mining company, local communities, & government | a country’s governance, choice of suppliers, & contractors; percentage of locally hired workers; wages | [97] | total number of complaints or prosecutions for non-compliance in planning phase: |

| none (plans have been communicated publicly) (E3.1.c) | ||||

| more than 1 (plans have been communicated publicly) (E3.2c) | ||||

| none (plans have not been communicated publicly) (E3.3c) | ||||

| (28) investment in local human capital | fostering personal skill development & capacity-building of employees by education & skill development | percentage of locally hired workers, offering higher education & training & transferable skill development; degree to which work is contracted out | [97] | percentage of employees sourced from local communities: |

| high (>80%) (E3.1c) | ||||

| medium (50–80%) (E3.2c) | ||||

| low (<50%) or unclarified (E3.3c) | ||||

| (29) degree of RM recovery | RMs can become inaccessible for recovery for future generations | disposal of new residues, mineral processing, residue stabilisation, residue characteristics | - | residue disposal: |

| complete residue valorisation (E1c) | ||||

| separate disposal (E3.1c) | ||||

| mixed disposal (E3.2c) | ||||

| sterilisation (E3.3c) | ||||

| (30) RM valorisation | utilising a RM in a sustainable manner to limit the impact of its recovery on the environment | target minerals, maturity of valorisation technologies, potential markets, RMs prices | [97] | total mass reduction as percentage of original tailings mass: |

| high (>80%) (E1c) | ||||

| medium (50–80% (E2c) | ||||

| low (<50%) (E3c) | ||||

| Social impacts after project execution | ||||

| (31) aftercare | level of commitment & necessary measures on post-mining land | land management, national regulations, rehabilitation measures | - | duration of aftercare measures: |

| short-term (<5 years) (E1c) | ||||

| mid-term (5–30 years) (E2c) | ||||

| long-term (>30 years) (E3c) | ||||

| (32) landscape | mining activities can cause a visual impact by transforming landscapes | topography, local ecosystem, mine planning, local climate | [97] | impact on the environment: |

| positive (E1c) | ||||

| neutral (E2c) | ||||

| negative (E3c) | ||||

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| Legal situation (relevant for project development) | ||||

| (33) right of mining | regulations affecting project planning & realisation | supranational, national, & regional laws & rules | [45] | state of development: |

| application in development (E3.1d) | ||||

| authorities engaged (E3.2d) | ||||

| application not begun or unclarified (E3.3d) | ||||

| (34) environmental protection | regulations affecting project planning & realisation | supranational, national, & regional laws & rules | [45,53,97] | state of development: |

| application in development (E3.1d) | ||||

| authorities engaged (E3.2d) | ||||

| application not begun or unclarified (E3.3d) | ||||

| (35) water protection | regulations affecting project planning & realisation | supranational, national & regional laws & rules | [45] | state of development: |

| application in development (E3.1d) | ||||

| authorities engaged (E3.2d) | ||||

| application not begun or unclarified (E3.3d) | ||||

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| Geological situation (relevant for project development) | ||||

| (36) quantity | amount of target RMs | ore quality, former processing efficiency, deposit volume | [45] | degree of geological certainty: |

| high (G1) | ||||

| medium (G2) | ||||

| low (G3) | ||||

| (37) quality | physico-chemical properties of target RMs | former processing, potential revenues | [45] | degree of geological certainty: |

| high (G1) | ||||

| medium (G2) | ||||

| low (G3) | ||||

| (38) homogeneity | distribution of target RMs inside the deposit | mine planning, mineral feed grade, timing of revenues | [45] | degree of geological certainty: |

| high (G1) | ||||

| medium (G2) | ||||

| low (G3) | ||||

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| Mine planning considerations (relevant for project execution) | ||||

| (39) recoverability | ability to extract a wanted RM from the tailings | technological development, state of metallurgical testing, equipment availability, state of target RM | - | percentage of RM which is extracted from the tailings: |

| high (>80%) (F1) | ||||

| medium (50–80%) (F2) | ||||

| low (<50%) (F3) | ||||

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| Microeconomic aspects (relevant for project development) | ||||

| (40) demand | existence of a current practical use for the RM & absence of geological, technological, economic, environmental, social, &/or legal objections against its recovery | market, price, available technology, public acceptance, regulations | - | favourable conditions for RM extraction: |

| yes (E3.1a) | ||||

| conditionally (E3.2a) | ||||

| no (E3.3a) | ||||

| (41) RM criticality | importance of a RM in an industry or economy | economic importance, supply risk, substitutability | [59] | allocation to EC’s criticality assessment: |

| CRM (E1a) | ||||

| high economic importance or supply risk (E2a) | ||||

| no criticality (E3a) | ||||

| (42) price development | forecasted RM price behaviour | demand, supply risk, quality, & quantity of historical data | - | forecasted mean price development over the project’s duration: |

| positive trend (E3.1a) | ||||

| stagnant trend (E3.2a) | ||||

| negative trend (E3.3a) | ||||

| Factor | Explanation | Dependence on | Modification after | Indicator & UNFC Rating |

|---|---|---|---|---|

| Impacts after project execution | ||||

| (43) solid matter | a RM’s potential to harm human health, flora, &/or fauna | concentration, toxicity, valorisation path | [13,105,106] | concentration of RM solid matter in new residues to qualify for class DK 0 (inert waste) according to German Landfill Regulation DepV [61]: |

| non-hazardous material (E1a) | ||||

| threshold value not exceeded (E3.1a) | ||||

| threshold value exceeded (E3.2a) | ||||

| unclarified (E3.3a) | ||||

| (44) eluate | a RM’s potential to harm human health, flora, &/or fauna | concentration, toxicity, valorisation path, solubility | [13,105,106] | concentration of RM in eluate from new residues to qualify for class DK 0 (inert waste) according to German Landfill Regulation DepV [61]: |

| non-hazardous material (E1a) | ||||

| threshold value not exceeded (E3.1a) | ||||

| threshold value exceeded (E3.2a) | ||||

| unclarified (E3.3a) | ||||

| Category & Factor | Data | Sources | UNFC Axis 1 |

|---|---|---|---|

| (A) type of study | very preliminary study | - | |

| (B) basic information | |||

| (a) geography | |||

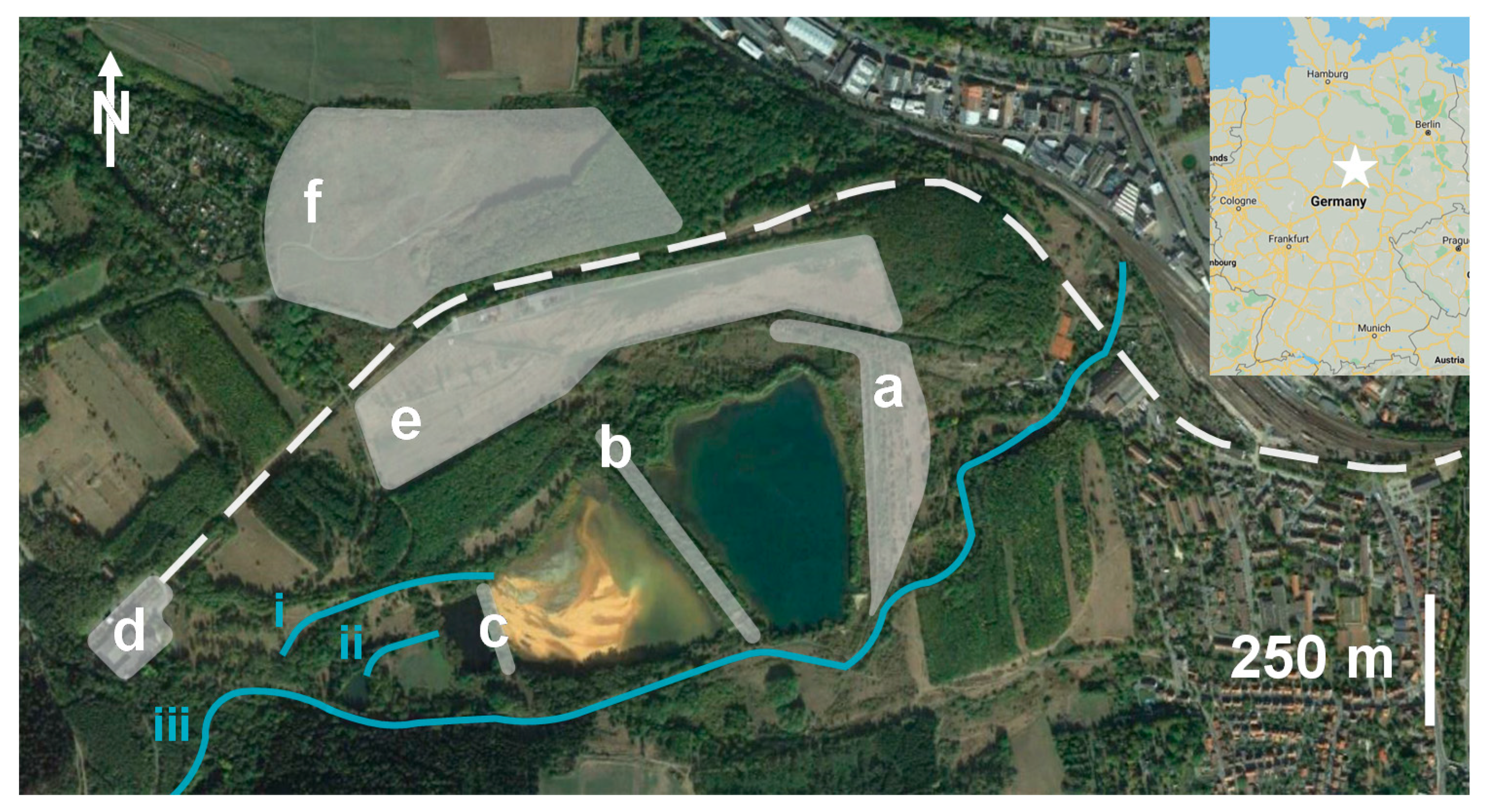

| (i) location | Goslar district, Lower Saxony (Germany) (51°54′8.97″ N, 10°27′47.31″ E), 270 m above mean sea level nearest human settlement ~400 m E air-line distance downstream of main dam | [50] | |

| (ii) topography | at the foot of Harz mountain range, up to 1141 m altitude with deep valleys | [107] | |

| (iii) local geology | folded & faulted Paleozoic rocks of the Harz Mountains are uplifted & thrust over younger Mesozoic rocks of the Harz foreland along the Northern Harz Boundary fault leading to steeply tilting & partly inverted Mesozoic strata; Mesozoic rocks are largely composed of Triassic to Cretaceous sedimentary rocks of varying composition (i.e., mostly impure limestones, clastic sandstones (greywackes) & shales); younger Quaternary sediments are rare & locally limited | [108] | |

| (iv) land use | in near vicinity: agricultural, forest, industrial & commercial, & recreation & residential areas | observed on Google Earth [50] | |

| (v) surface waters | Four small rivers observed downstream of TSF within a 1.5 km radius (Abzucht, Ammentalbach, Gelmke & Oker) | observed on Google Earth [50] | |

| (vi) climate | moderately warm, temperature −0.7 to 16.3 °C (average 7.2 °C), average rain precipitation 911 mm/a, average climatic water balance 366 mm/a | [109,110] | |

| (b) geogenic deposit | |||

| (i) mineralisation | two strongly deformed lens-shaped main ore bodies (high & low grade), sedimentary exhalative deposit (SedEx), fine grained (10–30 μm) principle sulphide minerals sphalerite ((Zn,Fe)S) & pyrite (FeS2), less amounts of galena (PbS) & chalcopyrite (CuFeS2), Ag, Au, (average estimated grades 14 wt% Zn, 6 wt% Pb, 2 wt% Cu, 140 g/t Ag & 1 g/t Au), barite (BaSO4) (average grade 20 wt%)—additionally ca. 30 trace elements such as Co, Ga, & In, hosted by Middle Devonian Wissenbach shales | [50,107,111] | |

| (ii) former mining | underground mine, closed for economic reasons in 1988 after >1000 years of operation, now UNESCO World Heritage site located ~3 km W air-line distance from second processing plant Bollrich & TSF | [50,107,111] | |

| (c) tailings deposit | |||

| (i) data collection methods | scientific publications or publicly accessible data, assumptions based on scientific publications, &/or own reasoning | - | |

| (ii) history | was in operation for ~49 years, decommissioned in 1987; supplied by processing plants Rammelsberg (into upper pond, 1938–1987) & Bollrich (into lower pond, 1956–1987); course of river Gelmke was changed several times | [53,57,107] | |

| (iii) recoverability | |||

| previously & non-previously mined minerals | - | G |

| Vtailings = 2,030,000 m3, mdry = 7,100,000 t, ρ = 3.5 t/m3 (weighted mean value), ρneutralisation sludge = 2.3 t/m3 | [53,54] | |

| exploration of deposit: (i) 10 drill cores (17–28 m) taken in upper pond along main dam & parallel to main dam in the middle of the pond, analysis of 16 elements; (ii) 90 water depth metering points | [53] | G | |

| 26 drill cores taken in upper & lower ponds, analysis of 4 elements & 3 minerals | [54] | ||

| low degree of alteration associated with oxidation | [53] | ||

| valley impoundment, estimated surface area 315,000 m3 consists of 3 ponds: (i) lower pond (west, 74 vol% of TSF, ρ = 3.0 t/m3, max. water depth 4 m, average water depth 2 m), (ii) upper pond (middle, 26 vol% of TSF, ρ = 3.7 t/m3, max. water depth 0.5 m, average water depth 0.4 m), (iii) water retention pond (East) consists of 3 dams: (i) main dam (max. 33 m height, max. 18° slope, raised 6 times, up-stream), (ii) middle dam (max. 19 m height), (iii) water retention dam (max. 8 m height) | [53,66], Ruler Tool [50], average water depth estimated with data from Reference [53] | F |

| drill core data of upper pond shows relatively homogeneous deposit with slightly increasing Ba grades with depth; deposit modelled based on historical & current terrain models, water depth measurements, historical & current core data; validation by comparison to production records | [53] | G, F |

| dam stability: occurrence of sinkhole at northern part of TSF documented in 1986 & several sinkholes near TSF reported in the past, which are associated with karstified geological structures nearby; expertise from 1986 concludes that TSF is not imminently threatened; confirmed by current calculations; unexploded ordnance: existence of WWII 2 ordnance cannot be excluded based on historical data so it needs to be investigated prior to mining | [53] | F |

| (iv) rehabilitation | not rehabilitated, left to ecological succession, no signs of AMD 3 or erosion observable | [53], observed on Google Earth [50] | |

| (v) assessment status | |||

| research work | - | |

| complete for lower pond | [53] | |

| partial for upper pond; not all elements/minerals analysed; amount, composition, & shape of deposition of mine water neutralisation sludge in upper & lower pond roughly estimated | |||

| partial | - | |

| prospective project (E3F3G4) | [43] | |

| (vi) economics | |||

| BaSO4, Co, Ga, & In are CRMs in EU with very high economic importance; Cu, Pb, & Zn have high economic importance in EU | [112] | E a |

| industrial & metalliferous minerals of interest, use of residues in construction materials conceivable | - | E a |

| (vii) social impacts | |||

| no apparent imminent hazards known; negative impacts through dermal contact, ingestion or inhalation not given; risk assessment not performed | [53] | E c |

| first scientific exploration shortly in 1983 before TSF abandonment in 1988; one recent research project (REWITA) with focus on mineral RMs recovery (2015–2018); proposal for follow-up project (REMINTA) on material extraction submitted | [53,54], www.cutec.de/fileadmin/Cutec/documents/cutec-news/2020/new58_dezember2020.pdf (accessed on 24 February 2021) | E c |

| positive perception of project idea by administrative bodies, environmental NGOs, & scientists | [52] | E c |

| local population’s perception of project idea unknown | - | ||

| (viii) environmental impacts | |||

| possible negative impacts unknown; disused landfill “Paradiesgrund” located 250 m N air-line distance from TSF; possible influence on landfill when mining the TSF needs to be investigated | [53] | E b |

| TSF’s base not sealed & in direct contact with tailings | |||

| integrated into landscape (visible only from up close or from hills); environment has been adapting through natural succession; active gilder airfield ~100 m N air-line distance from TSF; hiking trails next to TSF & biking Euroroute R1 near TSF | cf., Figure 2 | E b |

| on-site inspection of the TSF showed that rare flora, & aerial & soil fauna colonise the site | [53] | E b |

| conservation areas & protected landscapes nearby, protected species of flora & fauna sighted in area around TSF | [53] | E b |

| since 1966, neutralised mine water from the Rammelsberg mine has been discharged into the TSF (mainly upper pond, currently ~450,000 to 900,000 m3/a); overlay of tailings and neutralisation sludge | [54] | E b |

| (d) technology | |||

| (i) mine planning | mine planning considerations on conceptual basis (dredging) | - | F |

| (ii) processing | extraction of BaSO4, Co, Cu, Ga, In, Pb, Zn, & inert residues evaluated in discontinuous laboratory experiments on tailings from lower pond, processing sequences: (i) sulphide separation together with contaminants (rougher+cleaner+leaching), (ii) BaSO4 separation (rougher+cleaner+scavenger+conditioning); recovery rates (tested on material from lower pond; ammonia leaching route for sulphides): BaSO4 (74%), Co (12%), Cu (74%), Ga (2%), In (26%), Pb (65%), Zn (72%) & inert material (93%) processing tests on tailings from upper pond not performed; precipitation of SO4 ions in multiple stages necessary to recover metals | [60] | F |

| (e) infrastructure | |||

| (i) real estate | buildings & land from former processing available | [53] | F |

| (ii) mining & processing | former processing plant available ~550 m E air-line distance from TSF | [53] | |

| (iii) utilities | access to public electricity, gas, & water grid assumed | based on observation on Google Earth [50] | F |

| (iv) transportation & access | dirt roads, federal highway B6 ~1.6 km N air-line distance from TSF & public railway ~500 m E air-line distance from TSF; disused railway tracks from processing plant Bollrich to public network (estimated abandonment in 1988) | [53], observed on Google Earth [50] | F |

| (f) politics | |||

| (i) political willingness | - | - | E c |

| (g) legislation/licensing | |||

| (i) ownership | Bergbau Goslar GmbH (address: Bergtal 18, 38640 Goslar, Germany) | [53] | E d |

| (ii) legal exploration framework | currently supervised under German Federal Mining Act (BBergG) | [53] | E d |

| (iii) legal mining framework | - | - | E d |

| (iv) operating license | - | - | E d |

| (v) contracts | - | - | E d |

| (C) mineral- & material-centric information | |||

| (a) chemical & mineralogical composition | |||

| (i) elements | Ba (14.4), Cu (0.15), Fe (12.5), Pb (1.2), Zn (1.3) [mean, wt%]; Ag (-), As (700), Cd (30), Co (185), Ga (23), In (5.9), Tl (70) [mean, μg/g] | [53] | G |

| (ii) minerals | G | ||

| silica-based: Al, Si, K, Ni, Ga carbonate: Ca, Mn, Fe, (Mg), (Co) sulphidic: Fe, Co, Cu, Zn, Pb, As, Cd, In, Tl sulphate: Ba, Ca | [53,54] | |

| estimated cumulated minerals content (total dry mass/share of tailings’ mass) | [53] | |

| 1,739,000 t/24.5 wt% (monomineralic) | ||

| 31,000 t/0.44 wt% | ||

| 1,086,000 t/15.3 wt% (7.1 wt% Fe in tailings) | ||

| 85,000 t/1.2 wt% | ||

| 149,000 t/2.1 wt% | ||

| 2,350,000 t/33.1 wt% | ||

| 1,611,000 t/22.7 wt% | ||

| masses unknown; high & low concentrations of Zn & BaSO4, respectively | [54] | |

| CaCO3 | ||

| Al2O3 | ||

| Zn(OH)2 | ||

| SiO2 | ||

| CaSO4·2 H2O | ||

| (b) physico-chemical properties | |||

| tailings: very fine, 90% of particles < 60 μm, predominantly 2–60 μm & partially >20% below 3 μm, analysed with 4 samples from 2 drill coresneutralisation sludge: very fine, ~80% of particles < 20 μm | [53,54] | G |

| classified into geomechanical category GK III according to DIN 1054: highly difficult regarding the interaction of structure & subsoil | [113] | G |

| expected to be abrasive (30 wt% abrasive material in tailings) | [53] | G |

| 29 wt%, estimated mean water content | [53] | G |

| no valorisation as soil possible due to heavy metal concentration (As, Cd, Cr, Cu, Hg, Ni, Pb, Tl, & Zn) according to guideline “LAGA TR Boden” (note: tailings are not soil per definition); classified as DK IV hazardous waste according to Landfill Regulation DepV; As, Cd, & Tl mainly associated with sulphides (As mainly with FeS2 & Cd mainly with ZnS) | [53,114] | G |

| Parameter | Unit | Value | Source | Remarks |

|---|---|---|---|---|

| surface area | m2 | 315,000 | estimated with Google Earth [50] | - |

| duration of closure & leachate phase | a | 5 | following scenario B in Reference [51] (p. 104) | leachate emission constant; influx assumed only to occur in closure phase until in-situ stabilisation is completed & influx of rainwater or groundwater is phase neglected |

| duration of aftercare phase | a | 30 | Landfill Ordinance DepV [61] | minimum duration according to Landfill Ordinance DepV [61] |

| average emission of leachate | m3/a | 39,000 | average water depth for lower & upper ponds calculated based on 82 out of 90 measurements taken from Reference [53]; visible water surface measured with Google Earth [50] | based on the assumption of a constant leachate flow & that only the standing water is drained |

| leachate treatment | - | - | assumption | active on-site treatment unit |

| Parameter | Unit | Value | Source | Remarks |

|---|---|---|---|---|

| In-situ Stabilisation & Surface Sealing | ||||

| final surface cover including infrastructure | €/m2 | 100 | [51] | closure & leachate phase |

| concrete injection | €/m3 | 68 | [69] (p. 77) | closure & leachate phase |

| Leachate treatment | ||||

| active on-site treatment | €/m3 | 50 | [51] | closure & leachate phase |

| Other Costs | ||||

| maintenance & repair of leachate collection system | €/(a m2) | 0.6 | [51] | closure & leachate phase |

| monitoring of leachates | €/(a m2) | 0.4 | [51] | closure & leachate phase |

| monitoring of groundwater | €/(a m2) | 0.3 | [51] | closure & leachate phase |

| insurances | €/(a m2) | 0.4 | [51] | closure & leachate phase |

| maintenance of surface sealing | €/(a m2) | 1.0 | [51] | aftercare phase |

| maintenance of infrastructure | €/(a m2) | 0.6 | [51] | aftercare phase |

| monitoring of settlement | €/(a m2) | 0.1 | [51] | aftercare phase |

| monitoring of environment including weather | €/(a m2) | 0.2 | [51] | aftercare phase |

| aftercare management, reports, & documentation | €/(a m2) | 0.6 | [51] | aftercare phase |

| Parameter | Unit | Value | Source | Remarks | Qty. |

|---|---|---|---|---|---|

| CAPEX | |||||

| Mining | |||||

| dredger (including cutterhead) | € | 1,579,000 | [117] (p. SU 12), www.cat.com/en_US/products/new/power-systems/marine-power-systems/commercial-propulsion-engines/18493267.html (accessed on 14 March 2021) | 230 kW ship engine (d) 1, 272 kW cutterhead (d–e) 2, Caterpillar C18 ACERT engine used as reference | 1 |

| excavator | € | 160,000 | www.cat.com/en_US/products/new/equipment/excavators/medium-excavators/1000032601.html (accessed on 14 March 2021) | CAT 320 GC, 1 m3 bucket capacity, (d) | 1 |

| wheel loader | € | 269,000 | [117] (p. SU 22) | 157 kW (d), 3.8 m3 bucket capacity | 1 |

| bulldozer (with ripper) | € | 145,000 | [117] (p. SU 28) | - | 1 |

| dump truck | € | 384,000 | [117] (p. SU 34) | 6x6 traction, 15 m3 loading capacity, (d) | 1 |

| rubber boat (incl. engine) | € | 4800 | www.marine-sales.de (accessed on 14 March 2021) | transport of crew & light material to dredger, (d) | 2 |

| twin silo (2 × 810 m3) | € | 343,000 | [117] (p. Misc 92) | ensuring continuous processing plant feed & contingency for feed stream disruptions; integrated stirring function assumed to keep tailings suspended | 1 |

| slurry pump | € | 24,000 | [117] (p. misc 56) | 41 kW (e) 3, 40 m head @ 90 m3/h, redundant system foreseen | 6 |

| pipeline | €/m | 1350 | [118] (p. 42) | 300 mm nominal diameter, assumed to be suitable for offshore & onshore application; 800 m one-way, redundant system foreseen; water recirculation included | 267 |

| floating bodies for pipeline | € | 8750 | [118] (p. 46) | longest distance to cover from landing site at northern part of middle dam to bottom right corner of lower dam (480 m) | 40 |

| Processing | |||||

| processing plant reactivation | € | 6,000,000 | [119] (p. 13) | low value is chosen since assets & machinery were assumed to be in place & reusable | - |

| Infrastructure | |||||

| mine site development (paving roads, reactivating railway, etc.) | € | 1,300,000 | [119] (p. 13) | low value chosen due to simple mine plan, good mine site accessibility & available buildings | - |

| reclamation | - | ||||

| removal of assets, surface rehabilitation, & environmental monitoring | €/ttailings | 2 | [101] (p. 117) | mean value assumed due to relatively small reclamation area & off-site residue disposal | - |

| Other Fixed Economic Parameters | |||||

| discount rate | % | 15 | [8] (p. 297) | low value chosen to reflect very high risk | - |

| contingency factor | % | 30 | [45] (p. 58) | accounts for required non-specified assets | - |

| liquidating value | % | 10 | [120] (p. 16) | applied to assets & machinery under mining to estimate residual value | - |

| mine life | a | 11 | estimated with Taylor’s Rule [62] (p. 80) | reclamation & asset liquidation only in year 11 | - |

| run-of-mine (ROM) | t/h | 170 | assumption | - | - |

| working days administration | d/a | 260 | assumption | - | - |

| working days mining | d/a | 260 | assumption | - | - |

| working days processing | d/a | 365 | assumption | - | - |

| shift system mining | shifts/d | 2 | assumption | 8 h per shift | - |

| shift system processing | shifts/d | 3 | assumption | 8 h per shift | - |

| working hours administration | h/d | 8 | assumption | - | - |

| working hours mining | h/d | 16 | assumption | - | - |

| working hours processing | h/d | 24 | assumption | - | - |

| %-NSRCu (Europe) | % | 65 | [62] (p. 75) | percentage of net smelter return for Cu | - |

| %-NSRPb | % | 65 | [62] (p. 75) | percentage of net smelter return for Pb | - |

| %-NSRZn | % | 50 | [62] (p. 75) | percentage of net smelter return for Zn | - |

| Technological Parameters | |||||

| tailings mass | t | 7,100,000 | [53] (p. AP1/75) | low value chosen for conservative approach | - |

| pump head | m | 55 | [53] (p. AP5/19) | - | - |

| rBa 4 | % | 74 | [60] (p. 254) | - | - |

| rCo | % | 12 | [60] (p. 254) | for ammonia leaching path of sulphides | - |

| rCu | % | 74 | [60] (p. 176) | - | - |

| rFeS2 | % | 87 | [60] (p. 176) | - | - |

| rGa | % | 2 | [60] (p. 254) | for ammonia leaching path of sulphides | - |

| rIn | % | 26 | [60] (p. 254) | for ammonia leaching path of sulphides | - |

| rinert material | % | 93 | [60] (p. 254) | - | - |

| rPb | % | 68 | [60] (p. 176) | - | - |

| rZn | % | 70 | [60] (p. 176) | - | - |

| Machine/Item | Energy Consumption [ldiesel/h] | Energy Consumption [kWelectricity] | Maintenance & Overhaul [€/h] | Remarks |

|---|---|---|---|---|

| dredger | 125 | - | 112 | fuel consumption @ 502 kW approximated based on specification sheet & CAT engine assumed to constantly deliver 502 kW, http://s7d2.scene7.com/is/content/Caterpillar/LEHM0004-00 (accessed on 15 March 2021) |

| excavator | 13 | - | 13 | - |

| wheel loader | 24 | - | 20 | - |

| bulldozer (with ripper) | 21 | - | 16 | - |

| dump truck | 15 | - | 13 | - |

| rubber boat (including engine) | 2 | - | - | no data could be retrieved for maintenance & overhaul, negligible due to expected low value |

| twin silo (2 × 810 m3) | - | - | 5.8 | - |

| slurry pump | - | 41 | 3.2 | - |

| Parameter | Unit | Value | Source | Remarks | Qty. |

|---|---|---|---|---|---|

| OPEX | |||||

| mining | |||||

| machine operating costs | €/h | 200 | derived from Reference [117] | overhaul, maintenance, lubricants, & wear | - |

| diesel consumption | l/h | 202 | derived from Reference [117] | - | - |

| electric energy consumption | kW | 246 | derived from Reference [117] | - | - |

| shift supervisor | €/(a person) | 78.4 | based on Reference [120] | including assumed employers’ share of 40% | 2 |

| machine driver | €/(a person) | 58.8 | based on Reference [120] | including assumed employers’ share of 40% | 10 |

| metal worker | €/(a person) | 70.0 | based on Reference [120] | including assumed employers’ share of 40% | 2 |

| processing | |||||

| processing costs | €/tmetal recovered | 7.2 | [119] | - | - |

| machine operating costs | €/tmetal recovered | 10.7 | [119] | electric energy only | - |

| shift supervisor | €/(a person) | 78.4 | [120] | including assumed employers’ share of 40% | 3 |

| control panel operator | €/(a person) | 58.8 | [120] | including assumed employers’ share of 40% | 3 |

| machine operator | €/(a person) | 58.8 | [120] | including assumed employers’ share of 40% | 3 |

| metal worker | €/(a person) | 70.0 | [120] | including assumed employers’ share of 40% | 3 |

| services & administration | |||||

| general services | €/d | 5210 | [119] | - | - |

| administrative services | €/d | 1310 | [119] | - | - |

| RM prices | |||||

| electricity | €/kWh | cf., Figure S1 | raw data from Reference [85] | forecast based on yearly average prices in Germany for commercial customers from 2014–2019 | - |

| diesel | €/l | cf., Figure S2 | raw data from Reference [86] | forecast based on yearly average prices in Germany from 1950–2020 | - |

| BaSO4 | €/ttailings | cf., Figure S3 | raw data from References [87,88,89,90] | forecast based on yearly BaSO4 prices from 2011–2020 1 | - |

| Co | €/ttailings | cf., Figure S4 | raw data from References [87,89,90,91,92,93] | forecast based on yearly Co prices from 1996–2020 1 | - |

| Cu | €/ttailings | cf., Figure S5 | raw data from Reference [94] | forecast based on monthly Cu prices from November 1999–March 2021 1 & price per tonne tailings estimated after Wellmer et al. [62] (p. 47 ff.) | - |

| Ga | €/ttailings | cf., Figure S6 | raw data from References [87,89,90,91,92,93] | forecast based on yearly Ga prices from 1999–2020 1 | - |

| In | €/ttailings | cf., Figure S7 | raw data from References [87,89,90,91,92,93] | forecast based on yearly In prices from 1999–2020 1 | - |

| Pb | €/ttailings | cf., Figure S8 | raw data from Reference [95] | forecast based on monthly Pb prices from November 1999–March 2021 1 & price per tonne tailings estimated after Wellmer et al. [62] (p. 74 ff.) | - |

| Zn | €/ttailings | cf., Figure S9 | raw data from Reference [96] | forecast based on monthly Zn prices from November 1999–March 2021 1 & price per tonne tailings estimated after Wellmer et al. [62] (p. 74 ff.) | - |

| residue sales | €/t | 5.0 | assumption | intended valorisation as filler in construction materials; reference value for high-quality sand in Goslar is EUR 19.5 (www.recyclingpark.de/startseite.html, accessed on 2 June 2021); lower price assumed to estimate conservatively due to lack of information on effort to condition residues | - |

| residue disposal | €/t | 40.0 | [53] (p. AP7-9/58) | high value chosen to estimate conservatively | - |

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| Geological conditions (relevant for project development) | ||||

| (1) quantity | degree of geological certainty: | |||

| medium | G2 | NRR0, CRR1, & ERR2: deposit modelled based on direct data on 10 drill cores from lower pond, and pre-processed historical data on 14 & 12 drill cores from lower & upper pond, respectively. Model was validated with historical production data. Extension & volume of TSF known with medium confidence. Overall knowledge on mineral quantity with medium confidence in both ponds. Knowledge gap on quantity of neutralisation sludge & other dumped material. | [53] | |

| (2) quality | degree of geological certainty: | |||

| medium | G2 | NRR0, CRR1, & ERR2: physico-chemical properties known with medium confidence. | [53] | |

| (3) homogeneity | degree of geological certainty: | |||

| medium | G2 | NRR0, CRR1, & ERR2: mineral distribution in lower pond known with medium confidence. Knowledge gap on distribution of tailings & neutralisation sludge in both ponds. | [53,54] | |

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| TSF condition & risks (relevant for project development) | ||||

| (4) ordnance | degree of knowledge: | |||

| unclarified | F3 | NRR0, CRR1, & ERR2: existence cannot be excluded based on historical data. Requires clarification. | [53] | |

| Mine planning considerations (relevant for project execution) | ||||

| (5) mine/operational design | level of detail of planning: | |||

| basic | F3 | NRR0, CRR1, & ERR2: conceptual planning. | - | |

| (6) metallurgical testwork | degree of research on mineral processing: | |||

| - | - | NRR0: factor not applicable. | - | |

| laboratory scale | F3 | CRR1 & ERR2: extraction of BaSO4, Co, Cu, Ga, In, Pb, Zn, & inert material (Wissenbach shales, ankerit) evaluated in discontinuous laboratory experiments on tailings from lower pond. | [60] | |

| (7) water consumption | percentage of recycled water: | |||

| high (>80%) | F1 | CRR1 & ERR2: water recirculated in dredging operation. Processing water can be recirculated, too. | [53] | |

| unclarified | F3 | NRR0: unclear if TSF water can be used for making concrete. | - | |

| Infrastructure (relevant for project development) | ||||

| (8) real estate | condition of infrastructure: | |||

| highly developed | F1 | NRR0, CRR1, & ERR2: buildings & land from former processing available. | [53] | |

| (9) mining & processing | condition of equipment: | |||

| - | - | NRR0: not applicable since specialised non-mining equipment is required. | - | |

| bleak | F3 | CRR1 & ERR2: unclarified. | - | |

| (10) utilities | condition of infrastructure: | |||

| acceptable | F2 | NRR0, CRR1, & ERR2: access to public electricity, gas, & water grid assumed. | based on observation on Google Earth [50] | |

| (11) transportation & access | condition of infrastructure: | |||

| acceptable | F2 | NRR0, CRR1, & ERR2: dirt roads, federal highway B6 ~1.6 km N air-line distance from TSF & public railway ~500 m E air-line distance from TSF, disused railway tracks from processing plant Bollrich to public network (estimated abandonment in 1988). | [53], observed on Google Earth [50] | |

| Post-mining state (relevant for future impacts) | ||||

| (12) residue storage safety | suitability of new disposal site for safe storage: | |||

| unclarified | F3 | NRR0: predicting long-term stability might be difficult. CRR1 & ERR2: new disposal site unknown. | [69] | |

| (13) rehabilitation | level of detail of planning: | |||

| conceptual | F2 | NRR0, CRR1, & ERR2: conceptual planning. | - | |

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| Microeconomic aspects (relevant for project development) | ||||

| (14) economic viability | discounted cash flow over projected LOM: | |||

| positive (NPV >> 0€) | E3.1a | CRR1m & ERR2m: NPVs of EUR 73 mio. & EUR 172 mio., respectively, with mean price forecast. | - | |

| negative (NPV << 0€) | E3.3a | NRR0: costs of EUR 125 mio. incurred. | - | |

| (15) economic uncertainty | uncertainty of cash flow in pessimistic scenario: | |||

| - | - | NRR0: no forecast performed. | - | |

| low (NPV in pessimistic scenario >> 0€) | E3.1a | ERR2p: NPV = EUR 73 mio. | - | |

| high (NPV in pessimistic scenario << 0€) | E3.3a | CRR1p: NPV = EUR −17 mio. | - | |

| Financial aspects (relevant for project development) | ||||

| (16) investment conditions | country rank in the ease-of-doing-business Index. | |||

| - | - | NRR0: not applicable since company works on assignment basis. | - | |

| high (<75) | E3.1a | CRR1 & ERR2: country rank 22 (Germany). Good investment conditions assumed. | [121] | |

| (17) financial support | probability of approval: | |||

| high | E3.1a | CRR1 & ERR2: research on TSF was funded publicly & positive results give rise to the assumption that follow-up project proposal REWIMET might be accepted. | - | |

| no financial support scheme available | E3.3a | NRR0: no financial support scheme known at the moment. | - | |

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| Environmental impacts during project execution | ||||

| (18) air emission | risk of dust emission: | |||

| unclarified | E3.3b | NRR0: unclarified if TSF needs to be drained prior to concrete injection, which could lead to wind erosion of the tailings. | - | |

| high (>80%) | E3.1b | CRR1 & ERR2: complete submersion of tailings in dredging operation. | - | |

| (19) liquid effluent emission | risk of groundwater contamination: | |||

| low | E3.1b | NRR0, CRR1, & ERR2: status quo is expected to be retained. | - | |

| (20) noise emission | expected degree of impact: | |||

| medium | E3.2b | NRR0, CRR1, & ERR2: constant noise emission from TSF in 2 working shifts from Mondays to Fridays. Noise is expected to be audible, especially in the surrounding mountain area & areas on the same plane. It is possible that the noise would not be audible in residential areas to topography. CRR1 & ERR2: the processing plant is to be soundproofed. | based on observation on Google Earth [50] | |

| Environmental impacts after projection execution | ||||

| (21) biodiversity | total number of protected species that are affected by mining activities & that will be resettled on post-mining land: | |||

| none (0%) | E3b | NRR0, CRR1, & ERR2: protected flora & fauna species were sighted during an on-site inspection. Capturing the exact types & number of species is required for planning a resettlement or other compensation measures. | [53] | |

| (22) land use | freely available post-mining land: | |||

| some (50–80%) | E3.2b | NRR0: surface area of current wet cover is made available for reuse. CRR1 & ERR2: original topography is restored. NRR0, CRR1, & ERR2: it is expected that a solution for the collection & further treatment of the neutralisation sludge requires a permanent land use. | - | |

| (23) material reactivity | reduction in reactive material’s mass: | |||

| high (>80%) | E3.1b | CRR1: 84 wt% of sulphides leave the system boundaries as commodities. ERR2: all tailings are valorised. | - | |

| low (<50%) | E3.3b | NRR0: factually, reactive materials remain in place. Long-term stability difficult to predict. | [69] | |

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| Social impacts during project execution | ||||

| (24) local community | probability of approval through active commitment: | |||

| medium (50–80%) | E3.2c | CRR1 & ERR2: first indication of positive prospects by stakeholder assessment (local government, industry, university, & environmental NGOs). Local population’s opinion unknown. | [52] | |

| unclarified | E3.3c | NRR0: no data available. | - | |

| (25) health & safety | total number of complaints or prosecutions for non-compliance in planning phase: | |||

| none | E3.3c | NRR0, CRR1, & ERR2: plans have not been communicated publicly. | - | |

| (26) human rights & business ethics | total number of complaints or prosecutions for non-compliance in planning phase: | |||

| none | E3.3c | NRR0, CRR1, & ERR2: plans have not been communicated publicly. | - | |

| Social impacts due to project execution | ||||

| (27) wealth distribution | total number of complaints or prosecutions for non-compliance in planning phase: | |||

| none | E3.3c | NRR0, CRR1, & ERR2: plans have not been communicated publicly. | - | |

| (28) investment in local human capital | percentage of employees sourced from local communities: | |||

| unclarified | E3.3c | NRR0: it can be expected that an external contractor must be hired due to the special character of the required services. Aftercare measures could be carried out by local workers. CRR1 & ERR2: unclarified how many local workers could be employed. | - | |

| (29) degree of RM recovery | residue disposal: | |||

| complete residue valorisation | E1c | ERR2: no loss since all tailings are valorised. | - | |

| mixed disposal | E3.2c | CRR1: it is assumed that the site for the disposal of new residues has no option to store different residues separately. | - | |

| sterilisation | E3.3c | NRR0: access to RM potential for future generations with reasonable effort prevented. | - | |

| (30) RM valorisation | total mass reduction as percentage of original tailings mass: | |||

| high (>80%) | E3.1c | ERR2: all tailings are valorised. | - | |

| low (<50%) | E3.3c | NRR0: no valorisation takes place. CRR1: 38 wt% of tailings are valorised. | - | |

| Social impacts after project execution | ||||

| (31) aftercare | duration of aftercare measures: | |||

| short-term (up to 5 years) | E1c | CRR1 & ERR2: aftercare assumed to be complete after 1 year | - | |

| long-term (more than 30 years) | E3c | NRR0: long-term behaviour difficult to predict & long-term monitoring might be necessary. | [69] | |

| (32) landscape | impact on the environment: non-perceptible partially perceptible | |||

| E1c | CRR1 & ERR2: former topography is restored. | - | ||

| E2c | NRR0: is expected to be well integrated into landscape with an according surface design. Main dam remains perceptible. | - | ||

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| Legal situation (relevant for project development) | ||||

| (33) right of mining | state of development: | |||

| application not begun or unclarified | E3.3d | NRR0, CRR1, & ERR2: no concrete activities initiated. | - | |

| (34) environmental protection | state of development: | |||

| application not begun or unclarified | E3.3d | NRR0, CRR1, & ERR2: no concrete activities initiated. | - | |

| (35) water protection | state of development: | |||

| application not begun or unclarified | E3.3d | NRR0, CRR1, & ERR2: no concrete activities initiated. | - | |

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| Geological conditions (relevant for project development) | ||||

| (36) quantity | degree of geological certainty: | |||

| medium | G2 | CRR1 & ERR2: knowledge on BaSO4, Cu, FeS2, Pb, Zn, & inert material (Wissenbach shales, ankerit) with medium confidence in both ponds. | [53,54] | |

| low | G3 | CRR1 & ERR2: knowledge on Co, Ga, & In with medium confidence in lower pond. Co, Ga, & In quantity in upper pond inferred. | [53] | |

| (37) quality | degree of geological certainty: | |||

| medium | G2 | CRR1 & ERR2: knowledge on BaSO4, Cu, FeS2, Pb, Zn, & inert material (Wissenbach shales, ankerit) with medium confidence in both ponds. | [53,54] | |

| low | G3 | CRR1 & ERR2: knowledge on Co, Ga, & In with medium confidence in lower pond. Co, Ga, & In quantity in upper pond inferred. | [53] | |

| (38) homogeneity | degree of geological certainty: | |||

| medium | G2 | CRR1 & ERR2: knowledge on the distribution of BaSO4, Cu, FeS2, Pb, Zn, & inert material (Wissenbach shales, ankerit) with medium confidence. | [53,54] | |

| low | G3 | CRR1 & ERR2: knowledge on the distribution of Co, Ga, & In with medium confidence in lower pond. Knowledge on Co, Ga, & In in upper pond inferred. | [53] | |

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| Mine planning considerations (relevant for project execution) | ||||

| (39) recoverability | percentage of RM which is extracted from the tailings: | |||

| high (>80%) | F1 | CRR1 & ERR2: FeS2 (87 wt% recovered in mixed sulphide concentrate), inert material (Wissenbach shales, ankerit) (93 wt% are recovered with the new residues). | [60] | |

| medium (50–80%) | F2 | CRR1 & ERR2: BaSO4 (74 wt%), Cu (74 wt%), Pb (68 wt%), Zn (70 wt%). | [60] | |

| low (>50%) | F3 | CRR1, ERR2: Co (12 wt%), Ga (2 wt%), In (26 wt%). | [60] | |

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| Microeconomic aspects (relevant for project development) | ||||

| (40) demand | favourable conditions for RM extraction: | |||

| yes | E3.1a | CRR1 & ERR2: there is a demand for BaSO4, Cu, Pb, Zn, Co, Ga, & In | [122] | |

| conditionally | E3.2a | CRR1 & ERR2: Fe & H2SO4 could theoretically be produced from CuFeS2 & FeS2. | [123] | |

| no | E3.3a | CRR1 & ERR2: residues theoretically usable in construction materials, but experiments are necessary. Currently, there is per se not a demand for residues so that a potential application of the inert fraction (Wissenbach shales, ankerit) of the new residues needs to be clarified. | - | |

| (41) RM criticality | allocation to EC’s criticality assessment: | |||

| CRM | E1a | CRR1 & ERR2: BaSO4, Co, Ga, & In. | [112] | |

| high economic importance or supply risk | E2a | CRR1 & ERR2: Cu, Pb, S (from CuFeS2 & FeS2), & Zn. | [112] | |

| no criticality | E3a | CRR1 & ERR2: inert material (Wissenbach shales, ankerit). | ||

| (42) price development | forecasted mean price development over the project’s duration: | |||

| - | - | CRR1 & ERR2: FeS2 is recovered as a non-paid co-product, & no price forecast was performed for the inert material (Wissenbach shales, ankerit). | - | |

| positive trend | E3.1a | CRR1 & ERR2: BaSO4, Co, In. | Figures S3, S4 and S7 | |

| stagnant trend | E3.2a | CRR1 & ERR2: Pb, Zn. | Figures S8 and S9 | |

| negative trend | E3.3a | CRR1 & ERR2: Cu, Ga. | Figures S5 and S6 | |

| Factor | Indicator | UNFC Rating | Justification | Source |

|---|---|---|---|---|

| Impacts after project execution | ||||

| (43) solid matter | concentration of RM solid matter in new residues to qualify for class DK 0 (inert waste) according to German Landfill Regulation DepV [61]: | |||

| - | - | NRR0: not applicable since no new residues are produced. ERR2: not applicable since no new residues are disposed of. | - | |

| non-hazardous material | E1b | CRR1 & ERR2: inert material (Wissenbach shales, ankerit). | - | |

| threshold value not exceeded | E3.1b | CRR1: Cu, Zn. | [60] | |

| threshold value exceeded | E3.2b | CRR1: Pb. | [60] | |

| (44) eluate | concentration of RM in eluate from new residues to qualify for class DK 0 (inert waste) according to German Landfill Regulation DepV [61]: | |||

| - | - | NRR0: not applicable since no new residues are produced. ERR2: not applicable since no new residues are disposed of. | - | |

| non-hazardous material | E1b | CRR1 & ERR2: inert material (Wissenbach shales, ankerit). | - | |

| threshold value not exceeded | E3.1b | CRR1: Ba, Cu, Zn. | [60] | |

| threshold value exceeded | E3.2b | CRR1: Pb. | [60] | |

References

- Henckens, M.L.C.M.; Driessen, P.P.J.; Worrell, E. Molybdenum resources: Their depletion and safeguarding for future generations. Resour. Conserv. Recycl. 2018, 134, 61–69. [Google Scholar] [CrossRef]

- Kleijn, R.; van der Voet, E.; Kramer, G.J.; van Oers, L.; van der Giesen, C. Metal requirements of low-carbon power generation. Energy 2011, 36, 5640–5648. [Google Scholar] [CrossRef]

- Maung, K.N.; Hashimoto, S.; Mizukami, M.; Morozumi, M.; Lwin, C.M. Assessment of the Secondary Copper Reserves of Nations. Environ. Sci. Technol. 2017, 51, 3824–3832. [Google Scholar] [CrossRef]

- Watari, T.; McLellan, B.C.; Giurco, D.; Dominish, E.; Yamasue, E.; Nansai, K. Total material requirement for the global energy transition to 2050: A focus on transport and electricity. Resour. Conserv. Recycl. 2019, 148, 91–103. [Google Scholar] [CrossRef]

- Elshkaki, A.; Graedel, T.E.; Ciacci, L.; Reck, B.K. Resource Demand Scenarios for the Major Metals. Environ. Sci. Technol. 2018, 52, 2491–2497. [Google Scholar] [CrossRef]

- Valenta, R.K.; Kemp, D.; Owen, J.R.; Corder, G.D.; Lèbre, É. Re-thinking complex orebodies: Consequences for the future world supply of copper. J. Clean. Prod. 2019, 220, 816–826. [Google Scholar] [CrossRef]

- Fellner, J.; Lederer, J.; Scharff, C.; Laner, D. Present Potentials and Limitations of a Circular Economy with Respect to Primary Raw Material Demand. J. Ind. Ecol. 2017, 21, 494–496. [Google Scholar] [CrossRef]

- Revuelta, M.B. Mineral Resources; Springer International Publishing: Cham, Germany, 2018; 653p. [Google Scholar]

- Schoenberger, E. Environmentally sustainable mining: The case of tailings storage facilities. Resour. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- Wei, Z.; Yin, G.; Wang, J.G.; Wan, L.; Li, G. Design, construction and management of tailings storage facilities for surface disposal in China: Case studies of failures. Waste Manag. Res. 2013, 31, 106–112. [Google Scholar] [CrossRef]

- Giurco, D.; Cooper, C. Mining and sustainability: Asking the right questions. Miner. Eng. 2012, 29, 3–12. [Google Scholar] [CrossRef] [Green Version]

- Franks, D.M.; Boger, D.V.; Côte, C.M.; Mulligan, D.R. Sustainable development principles for the disposal of mining and mineral processing wastes. Resour. Policy 2011, 36, 114–122. [Google Scholar] [CrossRef]

- Lottermoser, B. Mine Wastes, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2010; 400p. [Google Scholar]

- Worrall, R.; Neil, D.; Brereton, D.; Mulligan, D. Towards a sustainability criteria and indicators framework for legacy mine land. J. Clean. Prod. 2009, 17, 1426–1434. [Google Scholar] [CrossRef]

- Laurence, D. Establishing a sustainable mining operation: An overview. J. Clean. Prod. 2011, 19, 278–284. [Google Scholar] [CrossRef]

- Roche, C.; Thygesen, K.; Baker, E. Mine Tailings Storage: Safety Is No Accident: A UNEP Rapid Response Assessment. United Nations Environment Programme and GRID-Arendal, Nairobi and Arendal; 2017; ISBN 978-827-701-170-7. Available online: https://www.grida.no/publications/383 (accessed on 10 January 2020).

- Anawar, H.M. Sustainable rehabilitation of mining waste and acid mine drainage using geochemistry, mine type, mineralogy, texture, ore extraction and climate knowledge. J. Environ. Manag. 2015, 158, 111–121. [Google Scholar] [CrossRef]

- Luptakova, A.; Ubaldini, S.; Macingova, E.; Fornari, P.; Giuliano, V. Application of physical–chemical and biological–chemical methods for heavy metals removal from acid mine drainage. Process Biochem. 2012, 47, 1633–1639. [Google Scholar] [CrossRef]

- Silva Rotta, L.H.; Alcântara, E.; Park, E.; Negri, R.G.; Lin, Y.N.; Bernardo, N.; Mendes, T.S.G.; Souza Filho, C.R. The 2019 Brumadinho tailings dam collapse: Possible cause and impacts of the worst human and environmental disaster in Brazil. Int. J. Appl. Earth. Obs. Geoinf. 2020, 90, 102119. [Google Scholar] [CrossRef]

- Lyu, Z.; Chai, J.; Xu, Z.; Qin, Y.; Cao, J. A Comprehensive Review on Reasons for Tailings Dam Failures Based on Case History. Adv. Civ. Eng. 2019, 2019, 1–18. [Google Scholar] [CrossRef]

- World Information System on Energy Uranium Project (WISE). Chronology of Major Tailings Dam Failures. 2021. Available online: http://www.wise-uranium.org/mdaf.html (accessed on 2 February 2021).

- Lèbre, É.; Stringer, M.; Svobodova, K.; Owen, J.R.; Kemp, D.; Côte, C.; Arratia-Solar, A.; Valenta, R.K. The social and environmental complexities of extracting energy transition metals. Nat. Commun. 2020, 11, 4823. [Google Scholar] [CrossRef] [PubMed]

- Owen, J.R.; Kemp, D.; Lèbre, É.; Svobodova, K.; Pérez Murillo, G. Catastrophic tailings dam failures and disaster risk disclosure. Int. J. Disaster Risk Reduct. 2020, 42, 101361. [Google Scholar] [CrossRef]

- Žibret, G.; Lemiere, B.; Mendez, A.-M.; Cormio, C.; Sinnett, D.; Cleall, P.; Szabó, K.; Carvalho, M.T. National Mineral Waste Databases as an Information Source for Assessing Material Recovery Potential from Mine Waste, Tailings and Metallurgical Waste. Minerals 2020, 10, 446. [Google Scholar] [CrossRef]

- European Commission (EC). Towards a Circular Economy: A Zero Waste Programme for Europe: COM(2014) 398 Final. 2014. Available online: https://ec.europa.eu/environment/circular-economy/pdf/circular-economy-communication.pdf (accessed on 4 August 2019).

- European Commission (EC). A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. COM(2020) 98 Final. 2020. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:9903b325-6388-11ea-b735-01aa75ed71a1.0017.02/DOC_1&format=PDF (accessed on 14 January 2021).

- Nuss, P.; Blengini, G.A. Towards better monitoring of technology critical elements in Europe: Coupling of natural and anthropogenic cycles. Sci. Total Environ. 2018, 613, 569–578. [Google Scholar] [CrossRef] [PubMed]

- Falagán, C.; Grail, B.M.; Johnson, D.B. New approaches for extracting and recovering metals from mine tailings. Miner. Eng. 2017, 106, 71–78. [Google Scholar] [CrossRef]

- Kuhn, K.; Meima, J.A. Characterization and Economic Potential of Historic Tailings from Gravity Separation: Implications from a Mine Waste Dump (Pb-Ag) in the Harz Mountains Mining District, Germany. Minerals 2019, 9, 303. [Google Scholar] [CrossRef] [Green Version]

- López, F.; García-Díaz, I.; Rodríguez Largo, O.; Polonio, F.; Llorens, T. Recovery and Purification of Tin from Tailings from the Penouta Sn–Ta–Nb Deposit. Minerals 2018, 8, 20. [Google Scholar] [CrossRef] [Green Version]

- Niu, H.; Abdulkareem, M.; Sreenivasan, H.; Kantola, A.M.; Havukainen, J.; Horttanainen, M.; Telkki, V.-V.; Kinnunen, P.; Illikainen, M. Recycling mica and carbonate-rich mine tailings in alkali-activated composites: A synergy with metakaolin. Miner. Eng. 2020, 157. [Google Scholar] [CrossRef]

- Pashkevich, M.A.; Alekseenko, A.V. Reutilization Prospects of Diamond Clay Tailings at the Lomonosov Mine, Northwestern Russia. Minerals 2020, 10, 517. [Google Scholar] [CrossRef]

- Tang, C.; Li, K.; Ni, W.; Fan, D. Recovering Iron from Iron Ore Tailings and Preparing Concrete Composite Admixtures. Minerals 2019, 9, 232. [Google Scholar] [CrossRef] [Green Version]

- Alfonso, P.; Tomasa, O.; Garcia-Valles, M.; Tarragó, M.; Martínez, S.; Esteves, H. Potential of tungsten tailings as glass raw materials. Mater. Lett. 2020, 228, 456–458. [Google Scholar] [CrossRef]

- Okereafor, U.; Makhatha, M.; Mekuto, L.; Mavumengwana, V. Gold Mine Tailings: A Potential Source of Silica Sand for Glass Making. Minerals 2020, 10, 448. [Google Scholar] [CrossRef]

- Zheng, W.; Cao, H.; Zhong, J.; Qian, S.; Peng, Z.; Shen, C. CaO–MgO–Al2O3–SiO2 glass-ceramics from lithium porcelain clay tailings for new building materials. J. Non-Cryst. Solids 2015, 409, 27–33. [Google Scholar] [CrossRef]

- Attila Resources. Attila to Acquire the Century zinc Mine. 2017. Available online: https://www.newcenturyresources.com/wp-content/uploads/2018/01/170301-AYA-Acquisition-of-Century-ASX-Ann.pdf (accessed on 22 May 2021).

- Campbell, M.D.; Absolon, V.; King, J.; David, C.M. Precious Metal Resources of the Hellyer Mine Tailings; 2015; Available online: http://www.i2massociates.com/downloads/I2MHellyerTailingsResourcesMar9-2015Rev.pdf (accessed on 22 May 2021).

- Cronwright, M.; Gasela, I.; Derbyshire, J. Kamativi Lithium Tailings Project; 2018; Available online: http://sectornewswire.com/NI43-101TechnicalReport-Kamativi-Li-Nov-2018.pdf (accessed on 22 May 2021).

- Johansson, N.; Krook, J.; Eklund, M.; Berglund, B. An integrated review of concepts and initiatives for mining the technosphere: Towards a new taxonomy. J. Clean. Prod. 2013, 55, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Corder, G. Mining and sustainable development. In Mining in the Asia-Pacific; O’Callaghan, T., Graetz, G., Eds.; Springer International Publishing: Cham, Germany, 2017; pp. 253–269. [Google Scholar]

- United Nations General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development (A/RES/70/1). 2015. Available online: https://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E (accessed on 16 May 2021).

- Suppes, R.; Heuss-Aßbichler, S. How to Identify Potentials and Barriers of Raw Materials Recovery from Tailings? Part I: A UNFC-Compliant Screening Approach for Site Selection. Resources 2021, 10, 26. [Google Scholar] [CrossRef]

- United Nations Economic Commission for Europe (UNECE). United Nations Framework Classification for Resources—Update 2019. 2020, p. 20. Available online: https://www.unece.org/fileadmin/DAM/energy/se/pdfs/UNFC/publ/UNFC_ES61_Update_2019.pdf (accessed on 13 November 2020).

- Committee for Mineral Reserves International Reporting Standards (CRIRSCO). International Reporting Template for the Public Reporting of Exploration Results, Mineral Resources and Mineral Reserves. 2019. Available online: http://www.crirsco.com/templates/CRIRSCO_International_Reporting_Template_November_2019.pdf (accessed on 9 June 2020).

- Winterstetter, A.; Heuss-Assbichler, S.; Stegemann, J.; Kral, U.; Wäger, P.; Osmani, M.; Rechberger, H. The role of anthropogenic resource classification in supporting the transition to a circular economy. J. Clean. Prod. 2021, 297, 126753. [Google Scholar] [CrossRef]

- Heuss-Aßbichler, S.; Kral, U.; Løvik, A.; Mueller, S.; Simoni, M.; Stegemann, J.; Wäger, P.; Horváth, Z.; Winterstetter, A. Strategic Roadmap on Sustainable Management of Anthropogenic Resources. 2020. Available online: https://zenodo.org/record/3739269#.X6WBG1Bo3b1 (accessed on 6 November 2020).

- Lederer, J.; Kleemann, F.; Ossberger, M.; Rechberger, H.; Fellner, J. Prospecting and Exploring Anthropogenic Resource Deposits: The Case Study of Vienna’s Subway Network. J. Ind. Ecol. 2016, 20, 1320–1333. [Google Scholar] [CrossRef]

- Suppes, R.; Heuss-Aßbichler, S. Resource potential of mine wastes: A conventional and sustainable perspective on a case study tailings mining project. J. Clean. Prod. 2021, 126446. [Google Scholar] [CrossRef]

- Google Earth. Available online: https://www.google.com/earth/ (accessed on 6 July 2021).

- Stegmann, R.; Heyer, K.-U.; Hupe, K. Landfill Aftercare—Options for Action, Duration, Costs and Quantitative Criteria for the Discharge from Aftercare; Hamburg (Germany). 2006. Available online: http://www.ifas-hamburg.de/PDF/UFOPLAN_IFAS.pdf (accessed on 29 July 2020). (In German).

- Bleicher, A.; David, M.; Rutjes, H. When environmental legacy becomes a resource: On the making of secondary resources. Geoforum 2019, 101, 18–27. [Google Scholar] [CrossRef]

- Goldmann, D.; Zeller, T.; Niewisch, T.; Klesse, L.; Kammer, U.; Poggendorf, C.; Stöbich, J. Recycling of Mine Processing Wastes for the Extraction of Economically Strategic Metals Using the Example of Tailings at the Bollrich in Goslar (REWITA): Final Report; TU Clausthal: Clausthal-Zellerfeld, Germany, 2019; Available online: https://www.tib.eu/de/suchen/id/TIBKAT:1688127496/ (accessed on 22 July 2020). (In German)

- Woltemate, I. Assessment of the Geochemical and Sedimentpetrographic Significance of Drilling Samples from Flotation Tailings in Two Tailing Ponds of the Rammelsberg Ore Mine. Ph.D. Thesis, University of Hanover, Hanover, Germany, 5 November 1987. (In German). [Google Scholar]

- Brunner, P.H.; Rechberger, H. Practical Handbook of Material Flow Analysis; Lewis Publishers: Boca Raton, FL, USA, 2004; 318p. [Google Scholar]

- Zhou, X.; Lin, H. Sensitivity analysis. In Encyclopedia of GIS; Shekhar, S., Xiong, H., Zhou, X., Eds.; Springer International Publishing: Cham, Germany, 2017; pp. 1884–1887. [Google Scholar]

- Eichhorn, P. Ore Processing Rammelsberg—Origin, Operation, Comparison; Goslar (Germany); 2012; Available online: https://docplayer.org/16359673-Erzaufbereitung-rammelsberg.html (accessed on 30 August 2020). (In German)

- European Commission. Communication on the 2017 list of Critical Raw Materials for the EU. COM (2017) 490 final. 2017. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52017DC0490&from=EN (accessed on 14 August 2019).

- European Commission (EC). Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability. COM (2020) 474 final. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52020DC0474&from=EN (accessed on 21 December 2020).

- Roemer, F. Investigations into the Processing of Deposited Flotation Residues at the Bollrich Tailings Pond with Special Regard to the Extraction of Raw Materials of Strategic Economic Importance. Ph.D. Thesis, Technical University of Clausthal, Clausthal-Zellerfeld, Germany, 4 February 2020. (In German). [Google Scholar]

- German Federal Ministry of Justice and Consumer Protection. Ordinance on Landfills and Long-Term Storage Facilities (Landfill Ordinance—DepV)—Landfill ordinance of 27 April 2009 (BGBl. I p. 900), last amended by Article 2 of the ordinance of 30 June 2020 (BGBl. I p. 1533). 2009. Available online: https://www.gesetze-im-internet.de/depv_2009/DepV.pdf (accessed on 11 April 2021). (In German).

- Wellmer, F.-W.; Dalheimer, M.; Wagner, M. Economic Evaluations in Exploration, 2nd ed.; Springer: Berlin, Germany, 2008. [Google Scholar]

- Federal Office of Justice. Federal Soil Protection and Contaminated Sites Ordinance (BBodSchV). 1999. Available online: https://www.gesetze-im-internet.de/bbodschv/anhang_2.html (accessed on 4 April 2021). (In German).

- District of Goslar|Environmental Service. Map of contaminated Ground. 2020. Available online: https://www.landkreis-goslar.de/index.phtml?mNavID=1749.35&sNavID=1749.35&La=1 (accessed on 30 September 2020). (In German).

- Ackers, W.; Pechmann, S. Integrated Urban Development Concept Goslar 2025. Goslar (Germany). 2011. Available online: https://www.goslar.de/stadt-buerger/stadtentwicklung/isek-2025 (accessed on 28 July 2020). (In German).

- Gesellschaft für Grundbau und Umwelttechnik mbH (GGU). Gelmke Dam Safety Report; Braunschweig, Germany, Unpublished material; 2003. (In German) [Google Scholar]

- Poggendorf, C.; Rüpke, A.; Gock, E.; Saheli, H.; Kuhn, K.; Martin, T. Utilisation of the Raw Material Potential of Mining and Metallurgical Dumps Using the Example of the Western Harz Region. 2015, p. 22. Available online: https://www.researchgate.net/profile/Tina_Martin5/publication/303941732_Nutzung_des_Rohstoffpotentials_von_Bergbau-_und_Huttenhalden_am_Beispiel_des_Westharzes/links/575fbf8d08aed884621bbfa3/Nutzung-des-Rohstoffpotentials-von-Bergbau-und-Huettenhalden-am-Beispiel-des-Westharzes.pdf (accessed on 13 November 2020). (In German).

- Expert Group on Resource Management (EGRM). United Nations Framework Classification for Resources—Draft Update Version 2019 EGRM-10/2019/INF.2. 2019. Available online: https://www.unece.org/fileadmin/DAM/energy/se/pdfs/egrm/egrm10_apr2019/UNFC_Update_2019_2.1_clean_rev.pdf (accessed on 1 June 2020).

- CL:AIRE Technology and Research Group. Contaminated Land Remediation; 2010; Available online: https://www.claire.co.uk/ (accessed on 14 August 2020).

- European Commission (EC). Critical Raw Materials for Strategic Technologies and Sectors in the EU—A Foresight Study; European Union: Luxembourg, 2020; 100p. [Google Scholar]

- Krzemień, A.; Riesgo Fernández, P.; Suárez Sánchez, A.; Diego Álvarez, I. Beyond the pan-european standard for reporting of exploration results, mineral resources and reserves. Resour. Policy 2016, 49, 81–91. [Google Scholar] [CrossRef]

- Norgate, T.; Haque, N. Energy and greenhouse gas impacts of mining and mineral processing operations. J. Clean. Prod. 2010, 18, 266–274. [Google Scholar] [CrossRef]

- Bouchard, J.; Sbarbaro, D.; Desbiens, A. Plant automation for energy-efficient mineral processing. In Energy Efficiency in the Minerals Industry; Awuah-Offei, K., Ed.; Springer International Publishing: Cham, Germany, 2018; pp. 233–250. [Google Scholar]

- Soofastaei, A.; Karimpour, E.; Knights, P.; Kizil, M. Energy-efficient loading and hauling operations. In Energy Efficiency in the Minerals Industry; Awuah-Offei, K., Ed.; Springer International Publishing: Cham, Germany, 2018; pp. 121–146. [Google Scholar]