Adapting the ESSENZ Method to Assess the Criticality of Construction Materials: Case Study of Herne, Germany

Abstract

1. Introduction

2. Method

- In the first step, the categories were examined regarding their ability to assess resource criticality in the local context. Categories that quantify aspects, which do not occur in the local context are omitted. For example, trade barriers describe restricted trade across borders. Since trade barriers exist mostly in border regions and do not play a considerable role in accessing locally traded building materials, the category is excluded from the analysis. The categories relevant to local trade are further evaluated in the next steps.

- In the second step, the not-omitted categories were analysed regarding the used indicators and their suitability to assess the local context. For example, one category that was not omitted was the feasibility of exploration projects, as the category assesses the situation regarding the overall investment settings in the mining sector within a country. The conditions for exploration projects are highly influenced by the political framework [31], which is assumed to be similar to the local markets of a country, as it is strongly influenced by a national government. Thus, the indicator is used in its original form and not modified.

- For the remaining categories not omitted but requiring adaptation, the associated indicators were adjusted to reflect local markets in the third step. For example: in the original ESSENZ method, there are three categories quantified by the Herfindahl–Hirschmann Index (HHI) [32] regarding market concentration at a global level (company and country concentration of global reserves and global production). The calculation of the HHI was adapted to consider the concentration of domestic and local production, e.g., regionally active quarries.

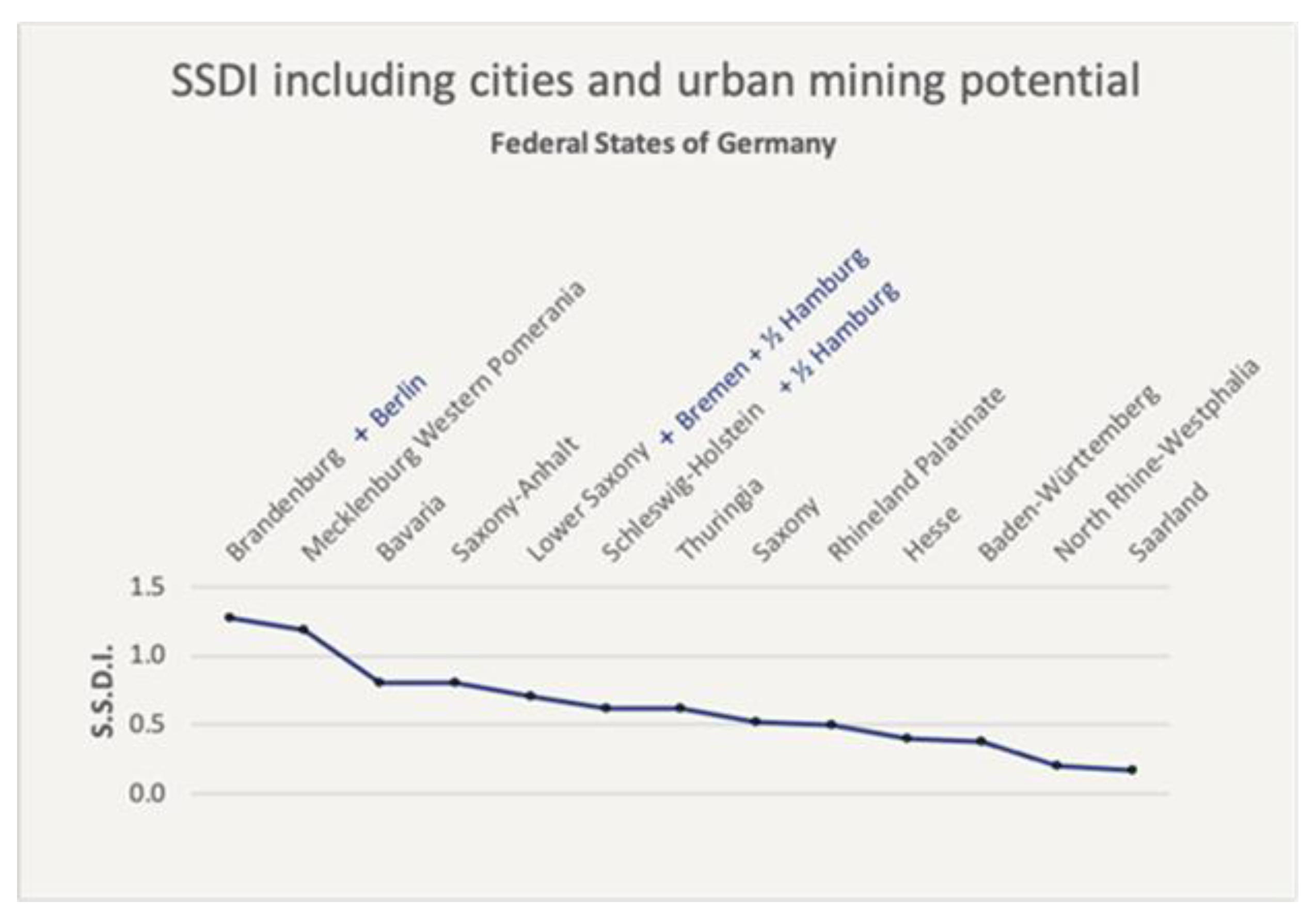

- In the fourth step, the data availability of the reconceptualized indicators was evaluated with a focus on the case study of Germany. For example, to calculate indicator values for the category concentration, global production data were replaced by data from the individual German federal states.

3. Case Study—City of Herne

Calculation Procedure

4. Results

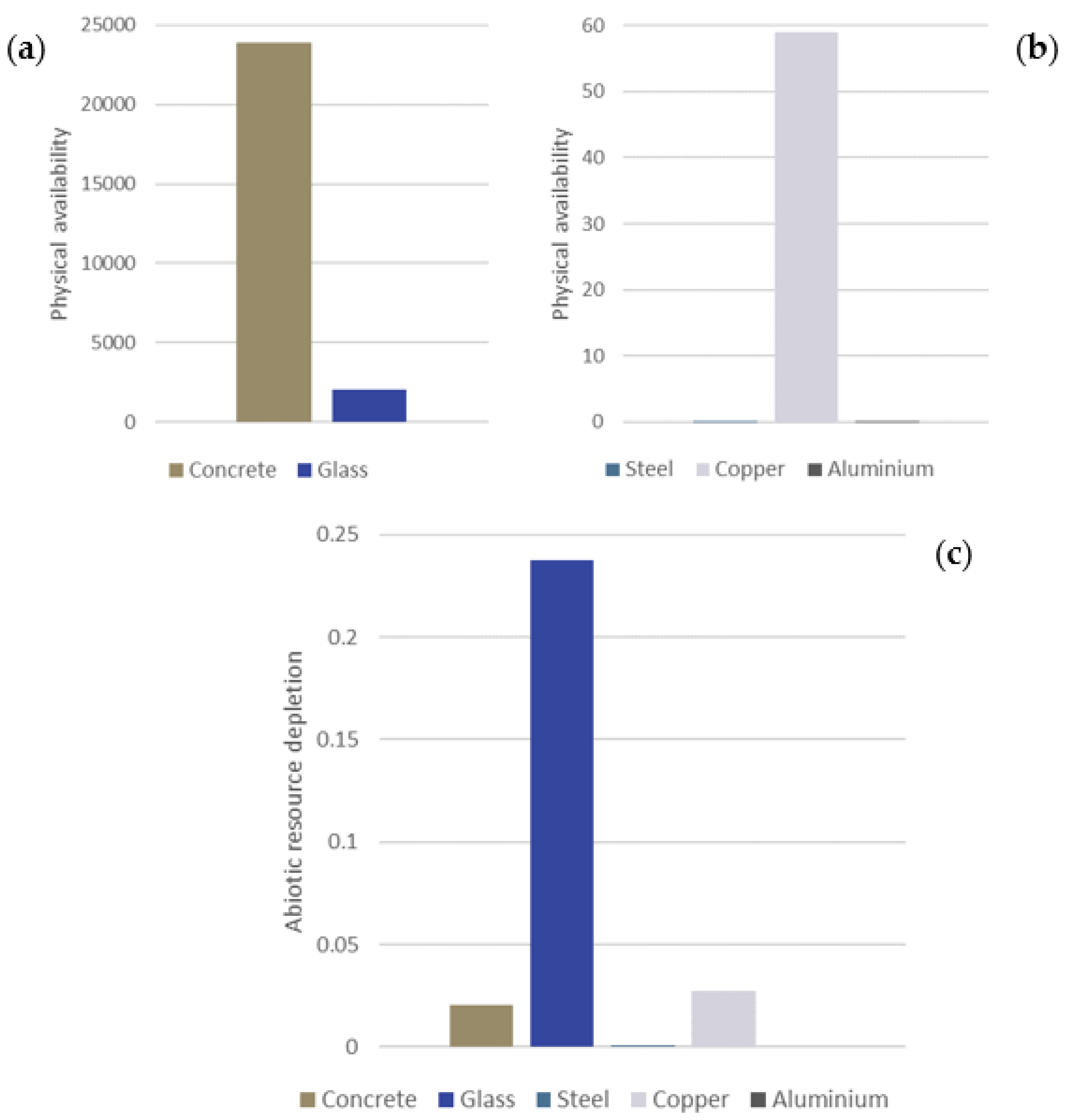

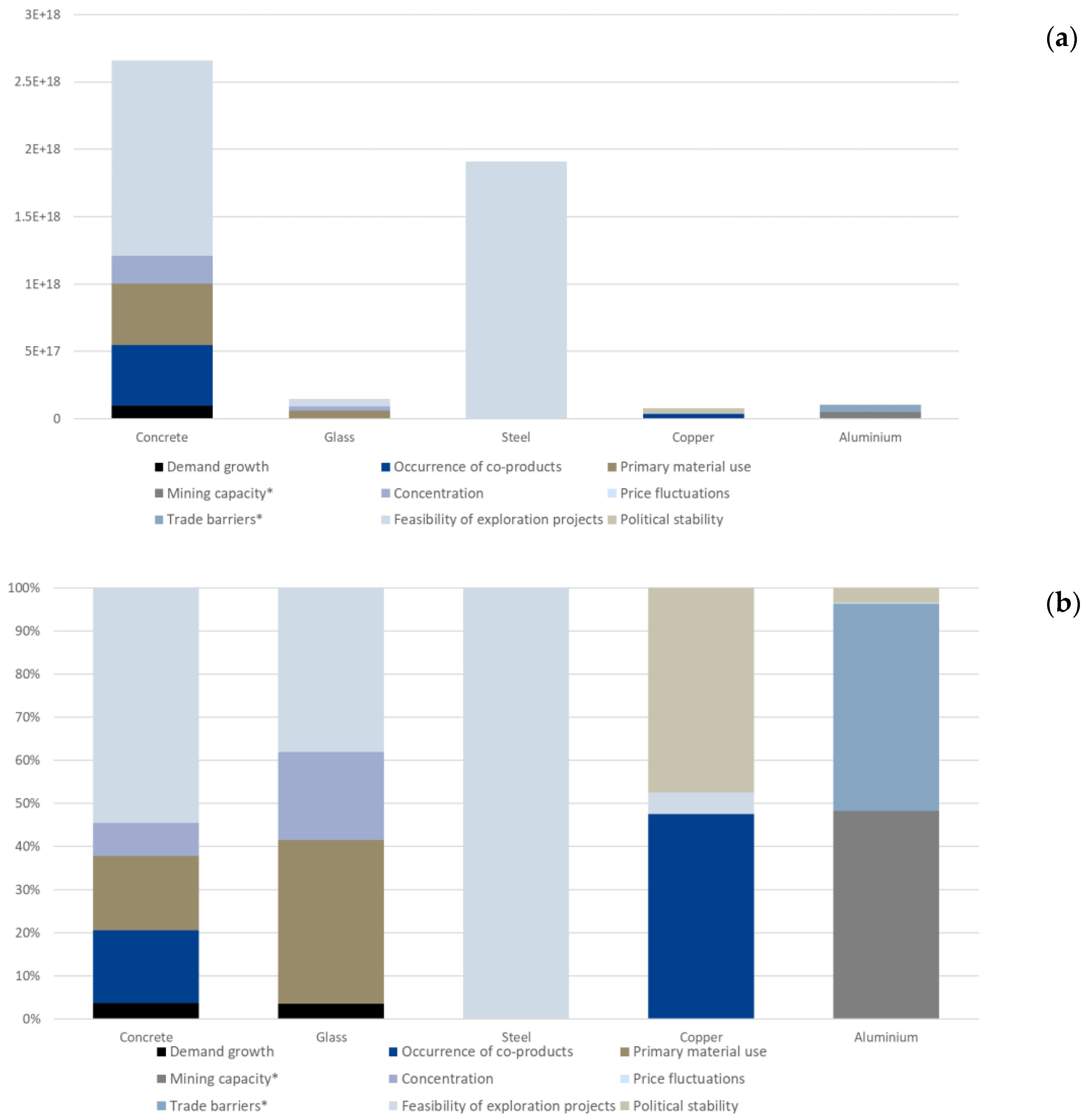

4.1. Adapted ESSENZ Method

4.2. Results of the Case Study

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bringezu, S.; Ramaswami, A.; Schandl, H.; O’Brien, M.; Pelton, R.; Acquatella, J.; Ayuk, E.T.; Chiu, A.S.F.; Flanegin, R.; Fry, J.; et al. Assessing Global Resource Use: A Systems Approach to Resource Efficiency and Pollution Reduction; International Resource Panel; UN Environment: Nairobi, Kenya, 2019. [Google Scholar]

- United Nations Environment Programme 2020 Global Status Report for Buildings and Construction; Programme, Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector; UN Environment: Nairobi, Kenya, 2020.

- Herczeg, M.; McKinnon, D.; Milios, L.; Bakas, I.; Klaassens, E.; Widerberg, S.; Oscar, K. Resource Efficiency in the Building Sector; European Commission, D.G. Environment: Rotterdam, The Netherlands, 2014. [Google Scholar]

- Elsner, H.; Kuhn, K.; Schmitz, M. Heimische Mineralische Rohstoffe—Unverzichtbar für Deutschland! Deutsche Rohstoffagentur: Hannover, Germany, 2017.

- Elsner, H.; Homberg-Heumann, D.; Huy, D.; Lutz, R.; Moldenhauer, K.; Pein, M.; Schauer, M.; Schmidt, S.; Schmitz, M.; Sievers, H.; et al. Rohstoffsituationsbericht 2018; Bundesanstalt für Geowissenschaften und Rohstoffe (BGR): Hannover, Germany, 2019. [Google Scholar]

- Weber, F.; Kühne, O.; Jenal, C.; Aschenbrand, E.; Artuković, A. Sand im Getriebe; Springer: Wiesbaden, Germany, 2018; ISBN 978-3-658-21525-5. [Google Scholar]

- Grünewald, A.; Biscoping, M. Transportbeton—Festlegung, Bestellung, Lieferung, Abnahme; Verein Deutscher Zementwerke: Düsseldorf, Germany, 2021. [Google Scholar]

- Dybas, C. Sand: A Resource That’s Washing Away. Oceanography 2020, 33, 8–10. [Google Scholar] [CrossRef]

- Federal Government of Germany. National Sustainable Development Strategy 2012; Progress Report; Federal Government of Germany: Berlin, Germany, 2012.

- Habib, K.; Wenzel, H. Reviewing resource criticality assessment from a dynamic and technology specific perspective—Using the case of direct-drive wind turbines. J. Clean. Prod. 2016, 112, 3852–3863. [Google Scholar] [CrossRef]

- Sonderegger, T.; Pfister, S.; Hellweg, S. Criticality of Water: Aligning Water and Mineral Resources Assessment. Environ. Sci. Technol. 2015, 49, 12315–12323. [Google Scholar] [CrossRef] [PubMed]

- Bach, V.; Berger, M.; Henßler, M.; Kirchner, M.; Leiser, S.; Mohr, L.; Rother, E.; Ruhland, K.; Schneider, L.; Tikana, L.; et al. Integrated method to assess resource efficiency—ESSENZ. J. Clean. Prod. 2016, 137, 118–130. [Google Scholar] [CrossRef]

- European Commission Report on Critical Raw Materials for the EU; EU Comission: Brussels, Belgium, 2014; pp. 1–41.

- Arendt, R.; Muhl, M.; Bach, V.; Finkbeiner, M. Criticality assessment of abiotic resource use for Europe—Application of the SCARCE method. Resour. Policy 2020, 67, 101650. [Google Scholar] [CrossRef]

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Nuss, P.; Reck, B.K. Criticality of metals and metalloids. Proc. Natl. Acad. Sci. USA 2015, 112, 4257–4262. [Google Scholar] [CrossRef]

- Ioannidou, D.; Pommier, R.; Habert, G.; Sonnemann, G. Evaluating the risks in the construction wood product system through a criticality assessment framework. Resour. Conserv. Recycl. 2019, 146, 68–76. [Google Scholar] [CrossRef]

- Kumar, V.; Hewage, K.; Sadiq, R. Life Cycle Assessment of Residential Buildings. A Case Study in Canada. Eng. Technol. Int. J. Energy Environ. Eng. 2015, 9, 1017–1025. [Google Scholar]

- Petrovic, B.; Myhren, J.A.; Zhang, X.; Wallhagen, M.; Eriksson, O. Life Cycle Assessment of Building Materials for a Single-family House in Sweden. Energy Procedia 2019, 158, 3547–3552. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H.; Bunster, V.; Warren-Myers, G.; Moosavi, S. Towards a multiscale framework for modeling and improving the life cycle environmental performance of built stocks. J. Ind. Ecol. 2022, 26, 1195–1217. [Google Scholar] [CrossRef]

- Lausselet, C.; Urrego, J.P.F.; Resch, E.; Brattebø, H. Temporal analysis of the material flows and embodied greenhouse gas emissions of a neighborhood building stock. J. Ind. Ecol. 2020, 25, 419–434. [Google Scholar] [CrossRef]

- Francis, A.; Thomas, A. A framework for dynamic life cycle sustainability assessment and policy analysis of built environment through a system dynamics approach. Sustain. Cities Soc. 2021, 76, 103521. [Google Scholar] [CrossRef]

- Umweltbundesamt. Die Nutzung natürlicher Ressourcen. In Bericht für Deutschland 2018; Umweltbundesamt: Dessau-Roßlau, Germany, 2018. [Google Scholar]

- Mineralische Rohstoffe. Bundesverband Mineralische Rohstoffe. 2018. Available online: https://www.bv-miro.org/ (accessed on 14 April 2023).

- Ioannidou, D.; Nikias, V.; Brière, R.; Zerbi, S.; Habert, G. Land-cover-based indicator to assess the accessibility of resources used in the construction sector. Resour. Conserv. Recycl. 2015, 94, 80–91. [Google Scholar] [CrossRef]

- Graedel, T.E.; Barr, R.; Chandler, C.; Chase, T.; Choi, J.; Christoffersen, L.; Friedlander, E.; Henly, C.; Jun, C.; Nassar, N.T.; et al. Methodology of Metal Criticality Determination. Environ. Sci. Technol. 2012, 46, 1063–1070. [Google Scholar] [CrossRef] [PubMed]

- Sonderegger, T.; Berger, M.; Alvarenga, R.; Bach, V.; Cimprich, A.; Dewulf, J.; Drielsma, J.; Frischknecht, R.; Guinée, J.; Helbig, C.; et al. Mineral resources in Life Cycle Impact Assessment part I: A review. Int. J. Life Cycle Assess. 2019, 25, 784–797. [Google Scholar] [CrossRef]

- Berger, M.; Sonderegger, T.; Alvarenga, R.; Bach, V.; Cimprich, A.; Dewulf, J.; Frischknecht, R.; Guinée, J.; Helbig, C.; Huppertz, T.; et al. Mineral resources in Life Cycle Impact assessment—Part II: Recommendations on application-dependent use of existing methods and on future method development needs. Int. J. Life Cycle Assess. 2019, 25, 798–813. [Google Scholar] [CrossRef]

- Sun, X.; Bach, V.; Finkbeiner, M.; Yang, J. Criticality Assessment of the Life Cycle of Passenger Vehicles Produced in China. Circ. Econ. Sustain. 2021, 1, 435–455. [Google Scholar] [CrossRef]

- Dolganova, I.; Bach, V.; Rödl, A.; Kaltschmitt, M.; Finkbeiner, M. Assessment of Critical Resource Use in Aircraft Manufacturing. Circ. Econ. Sustain. 2022, 2, 1193–1212. [Google Scholar] [CrossRef]

- Pelzeter, J.; Bach, V.; Henßler, M.; Ruhland, K.; Finkbeiner, M. Enhancement of the ESSENZ Method and Application in a Case Study on Batteries. Resources 2022, 11, 52. [Google Scholar] [CrossRef]

- Jackson, T.; Green, K.P. Fraser Institute Annual Survey of Mining Companies; Fraser Institute: Vancouver, BC, Canada, 2016. [Google Scholar]

- Rhoades, S.A. The Herfindahl-Hirschman Index. Fed. Reserve Bull. 1993, 188–189. [Google Scholar]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Statistikstelle der Stadt Herne. Stadtteilprofile Herne; Stadt Herne: Herne, Germany, 2020.

- Marinova, S.; Deetman, S.; van der Voet, E.; Daioglou, V. Global construction materials database and stock analysis of residential buildings between 1970–2050. J. Clean. Prod. 2020, 247, 119146. [Google Scholar] [CrossRef]

- Deetman, S.; Marinova, S.; van der Voet, E.; van Vuuren, D.P.; Edelenbosch, O.; Heijungs, R. Modelling global material stocks and flows for residential and service sector buildings towards 2050. J. Clean. Prod. 2020, 245, 118658. [Google Scholar] [CrossRef]

- Ministerium des Innern des Landes Nordrhein-Westfalen Geoportal NRW. Available online: https://www.geoportal.nrw/ (accessed on 14 April 2023).

- Vujicic, D. Verhältnis Der Nutzungsfläche (NUF) Zur Brutto-Grundfläche (BGF). Ph.D. Thesis, Technische Universität Wien, Wien, Austria, 2020. [Google Scholar]

- Wiedenhofer, D.; Steinberger, J.K.; Eisenmenger, N.; Haas, W. Maintenance and Expansion: Modeling Material Stocks and Flows for Residential Buildings and Transportation Networks in the EU25. J. Ind. Ecol. 2015, 19, 538–551. [Google Scholar] [CrossRef]

- Krausmann, F.; Lauk, C.; Haas, W.; Wiedenhofer, D. From resource extraction to outflows of wastes and emissions: The socio-economic metabolism of the global economy, 1900–2015. Glob. Environ. Chang. 2018, 52, 131–140. [Google Scholar] [CrossRef]

- Forum Sozial-Ökologische Marktwirtschaft. Kostenrisiken für die Gesell Schaft Durch den Deutschen Braunkohletagebau; Forum Ökologisch-Soziale Marktwirtschaft: Berlin, Germany, 2014. [Google Scholar]

- Statistisches Bundesamt. Bodenfläche nach Art der tatsächlichen Nutzung—Fachserie 3 Reihe 5.1; Statistisches Bundesamt: Wiesbaden, Germany, 2019.

- Kresilaufwirtschaft Bau. Mineralische Bauabfälle Monitoring 2018; Bundesverband Baustoffe–Steine und Erden e.V.; Kresilaufwirtschaft Bau: Berlin, Germany, 2021. [Google Scholar]

- Ioannidou, D.; Meylan, G.; Sonnemann, G.; Habert, G. Is gravel becoming scarce? Evaluating the local criticality of construction aggregates. Resour. Conserv. Recycl. 2017, 126, 25–33. [Google Scholar] [CrossRef]

- Schiller, G.; Ortlepp, R.; Krauß, N.; Steger, S.; Schütz, H.; Fernández, J.A.; Reichenbach, J.; Wagner, J.; Baumann, J. Kartierung des anthropogenen Lagers in Deutschland zur Optimierung der Sekundärrohstoffwirtschaft; Umwelt Bundesamt: Vienna, Austria, 2015.

- Sphera GaBi. Product Sustainability Software, Spher: Echterdingen, Germany, 2021.

- Bundesverband Baustoffe—Steine und Erden. Zahlenspiegel; Bundesverband Baustoffe: Berlin, Germany, 2020. [Google Scholar]

- Heeren, N.; Mutel, C.L.; Steubing, B.; Ostermeyer, Y.; Wallbaum, H.; Hellweg, S. Environmental Impact of Buildings—What Matters? Environ. Sci. Technol. 2015, 49, 9832–9841. [Google Scholar] [CrossRef] [PubMed]

- Hörnschemeyer, B.; Söfker-Rieniets, A.; Niesten, J.; Arendt, R.; Kleckers, J.; Klemm, C.; Stretz, C.J.; Reicher, C.; Grimsehl-Schmitz, W.; Wirbals, D.; et al. The ResourcePlan—An Instrument for Resource-Efficient Development of Urban Neighborhoods. Sustainability 2022, 14, 1522. [Google Scholar] [CrossRef]

- Börner, A. (Ed.) Geologisches Jahrbuch Sonderhefte Reihe D, Mineralogie, Petrographie, Geochemie, Lagerstättenkunde. In Steine- und Erden-Rohstoffe in der Bundesrepublik Deutschland; Schweizerbart: Stuttgart, Germany, 2012. [Google Scholar]

- British Geological Survey. European Mineral Statistics 2008–2012; Keyworth: Nottingham, UK, 2014. [Google Scholar]

- Börner, A. (Ed.) Steine- und Erden-Rohstoffe in der Bundesrepublik Deutschland; Schweizerbart: Stuttgart, Germany, 2012; Volume 10, ISBN 9783510959952. [Google Scholar]

- Elsner, H. Sand-Auch in Deutschland Bald Knapp? Deutsche Rohstoffagentur: Hannover, Germany, 2018.

- Elsner, H.; Tallig, A. Feldspatrohstoffe in Deutschland; Stand: Aug.; Bundesanstalt für Geowissenschaften und Rohstoffe (BGR): Hannover, Germany, 2017; ISBN 9783943566970. [Google Scholar]

- Elsner, H.; Szurlies, M. Kies-der Wichtigste Heimische Baustoff; Deutsche Rohstoffagentur: Hannover, Germany, 2020.

- Hilgers, C.; Becker, I. Geologische Aspekte und Umfeldanalyse zur überregionalen Rohstoffverfügbarkeit von Beton—Sand, Kalkstein, Gips. In Ressourceneffizienter Beton—Zukunftsstrategien für Baustoffe und Baupraxis: 15. Symposium Baustoffe und Bauwerkserhaltung; Nolting, U., Dehn, F., Link, J., Mercedes Kind, V., Eds.; KIT Scientific Publishing: Karlsruhe, Deutschand, 2020; pp. 21–30. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodity Summaries 2016; National Minerals Information Center: Reston, VA, USA, 2016.

- Erdmann, L.; Graedel, T.E. Criticality of non-fuel minerals: A review of major approaches and analyses. Environ. Sci. Technol. 2011, 45, 7620–7630. [Google Scholar] [CrossRef] [PubMed]

- Reyer, S.; Fohlert, K. Untersuchung zur Rohstoffsicherung der Rohstoffart Gips/Anhydrit in Nordthüringen; Sachverständigenbüro Reyer: Erfurt, Germany, 2017. [Google Scholar]

- Hillebrand, E. Branchenanalyse Rohstoffindustrie; Hans-Böckler-Stiftung: Düsseldorf, Germany, 2017; Volume 315, ISBN 978-3-86593-222-8. [Google Scholar]

- SNL Metals & Mining. Available online: http://www.snl.com (accessed on 14 April 2023).

- IBISWorld GmbH Herstellung von Flachglas in Deutschland. Available online: https://www.schott.com/de-de/flachglas?gclid=CjwKCAjw_aemBhBLEiwAT98FMoV6G94NcboAo1lqyLeQQvSBUCDjKq26asmA7i1kYP2QUVopb5xwJhoCNfIQAvD_BwE (accessed on 24 April 2023).

- Verein Deutscher Zementwerke, e.V. (VDZ) Zementindustrie im Überblick 2020/2021; Verein Deutscher Zementwerke: Berlin, Germany, 2020. [Google Scholar]

- Bundeskartellamt. Sektoruntersuchung Zement und Transportbeton; Bundeskartellamt: Bonn, Gemrany, 2017.

- Bundesverband der deutschen Kalkindustrie. Geschäftsbericht 2020/2021; Bundesverband der deutschen Kalkindustrie: Köln, Germany, 2021. [Google Scholar]

- Bundesministerium für Wirtschaft und Energie Stahlindustrie. Available online: https://www.bmwi.de/Redaktion/DE/Artikel/Branchenfokus/branchenfokus-stahl-und-metall-01.html (accessed on 14 April 2023).

- Bundesverand der Gipsindustrie. GIPS-Datenbuch; Bundesverand der Gipsindustrie: Berlin, Germany, 2013. [Google Scholar]

- Elsner, H. Quarzrohstoffe in Deutschland; Bundesanstalt für Geowissenschaften und Rohstoffe (BGR): Hannover, Germany, 2016. [Google Scholar]

- Federal Institute for Geosciences and Natural Resources. Volatilitätsmonitor Juli 2020; Federal Institute for Geosciences and Natural Resources: Berlin, Germany, 2020.

- Schaeffer, H.A.; Langfeld, R. Werkstoff Glas; 2. Auflage.; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 9783662602591. [Google Scholar]

| Dimension | Category | Status in Adapted Assessment Title 4 | ||

|---|---|---|---|---|

| Economic Dimension | Physical Availability | Abiotic Depletion Potential (ADP) | ≈ | Omitted in step 4 due to limited data availability; only qualitatively assessed |

| Anthropogenic Stock Extended Abiotic Depletion Potential (AADP) | ᵡ | Omitted in step 4 due to missing data | ||

| Socio-economic Availability | Concentration of Reserves, Production, and Companies (HHI) | ≈ | Omitted in step 4 due to limited data availability; only qualitatively assessed | |

| Mining Capacity | ° | Omitted in step 4 due to limited data availability; category is assessed with SSDI | ||

| Feasibility of Exploration Projects | √ | Kept category with original indicator and data source applied | ||

| Trade Barriers | ᵡ | Omitted category in step 1, as trade barriers are not occurring in the local market | ||

| Occurrence of Co-Products | √ | Kept category with original indicator and data source applied | ||

| Political Stability | √ | Kept category with original indicator and data source applied | ||

| Price Fluctuations | √ | Kept category with original indicator and data source applied | ||

| Demand Growth | √ | Kept category with original indicator and data source applied | ||

| Primary Material Use | √ | Kept category with original indicator and data source applied | ||

| Environmental Dimension | Environmental Impacts | The Global Warming Potential (GWP) | √ | Kept category with original indicator and data source applied |

| Acidification Potential (AP) | √ | Kept category with original indicator and data source applied | ||

| Eutrophication Potential (EP) | √ | Kept category with original indicator and data source applied | ||

| Photochemical Ozone Creation Potential (POCP) | √ | Kept category with original indicator and data source applied | ||

| Material | Share | Raw Materials | Physical Availability | Weighted Average | ||

|---|---|---|---|---|---|---|

| Concrete | Aggregates | 33.8% | Gravel and sand | Long term | 0.0204 | |

| 29.8% | Natural stones | |||||

| 9.6% | Recycled building materials | |||||

| 4.3% | Industrial by-products | Long term | ||||

| Cement | Clinker | 9.6% | Limestone, marl and chalk | |||

| 0.27% | Silica sand | Decades | ||||

| 0.15% | Clay | Long term | ||||

| 0.06% | Fly ash | |||||

| 0.04% | Foundry sand | |||||

| 0.04% | Input materials from the metal, iron and steel industries | |||||

| 0.04% | Other input materials | |||||

| 1.7% | Blast furnace slag | Short term | ||||

| 0.1% | Gypsum from flue gas desulphurisation (REA-Gips) | |||||

| 0.4% | Natural gypsum and anhydrite | Medium | ||||

| 0.1% | Others (kaolinite, bentonite, oil shale, iron, etc.) | |||||

| Additives | 7.5% | Water | ||||

| 2.6% | Additives | |||||

| Glass | Soda | 7.0% | Salt | 0.2376 | ||

| 7.0% | Limestone | |||||

| 72.0% | Silica sand | |||||

| 9.0% | Limestone | |||||

| 4.5% | Dolomite | |||||

| 0.5% | Alumina/feldspar | |||||

| Federal State | Rank | SSDI | Demand Growth | Result ESSENZ |

|---|---|---|---|---|

| Brandenburg + Berlin | 1 | 1.27 | 92.31 | 0% |

| Mecklenburg Western Pomerania | 2 | 1.19 | 84.62 | 6% |

| Bavaria | 3 | 0.81 | 76.92 | 36% |

| Saxony-Anhalt | 4 | 0.80 | 69.23 | 37% |

| Lower Saxony + Bremen + ½ Hamburg | 5 | 0.71 | 61.54 | 44% |

| Schleswig-Holstein + ½ Hamburg | 6 | 0.62 | 53.85 | 51% |

| Thuringia | 7 | 0.62 | 46.15 | 51% |

| Saxony | 8 | 0.52 | 38.46 | 59% |

| Rhineland Palatinate | 9 | 0.50 | 30.77 | 61% |

| Hesse | 10 | 0.40 | 23.08 | 69% |

| Baden-Württemberg | 11 | 0.38 | 15.38 | 70% |

| North Rhine-Westphalia | 12 | 0.20 | 7.69 | 84% |

| Saarland | 13 | 0.17 | 0.00 | 87% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Randebrock, I.; Marinova, S.; Bach, V.; Arendt, R.; Finkbeiner, M. Adapting the ESSENZ Method to Assess the Criticality of Construction Materials: Case Study of Herne, Germany. Resources 2023, 12, 92. https://doi.org/10.3390/resources12080092

Randebrock I, Marinova S, Bach V, Arendt R, Finkbeiner M. Adapting the ESSENZ Method to Assess the Criticality of Construction Materials: Case Study of Herne, Germany. Resources. 2023; 12(8):92. https://doi.org/10.3390/resources12080092

Chicago/Turabian StyleRandebrock, Inka, Sylvia Marinova, Vanessa Bach, Rosalie Arendt, and Matthias Finkbeiner. 2023. "Adapting the ESSENZ Method to Assess the Criticality of Construction Materials: Case Study of Herne, Germany" Resources 12, no. 8: 92. https://doi.org/10.3390/resources12080092

APA StyleRandebrock, I., Marinova, S., Bach, V., Arendt, R., & Finkbeiner, M. (2023). Adapting the ESSENZ Method to Assess the Criticality of Construction Materials: Case Study of Herne, Germany. Resources, 12(8), 92. https://doi.org/10.3390/resources12080092