Ecological Footprint at the Micro-Scale—How It Can Save Costs: The Case of ENPRO

Abstract

:1. Introduction

2. Conceptual Framework and Methods

2.1. Ecological Footprint vs. Carbon Footprint

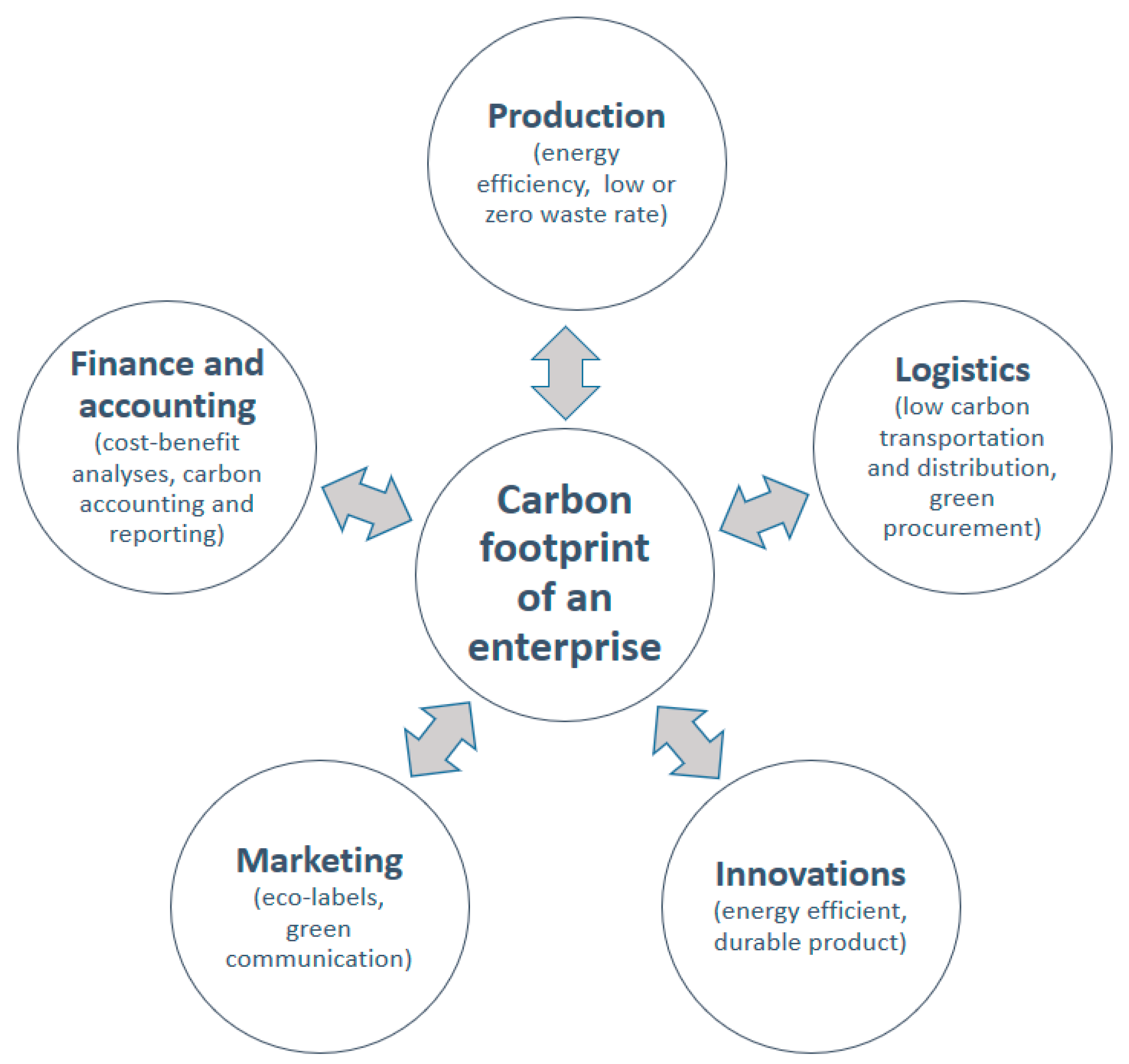

2.2. Corporate Carbon Footprints

- ■

- Scope 1: Direct emissions, sources possessed or controlled by the organization (e.g., emissions from own boilers, vehicles etc.)

- ■

- Scope 2: Indirect emissions related to electricity from the generation of purchased electricity consumed by the organization. (Furthermore, other types of purchased energy—such as steam or heat—can also be covered here.)

- ■

- Scope 3: Other indirect emissions in connection with activities such as external transportation or downstream phase of products (use, end-of-life etc.). Scope 3 is a voluntary accounting category that enables us to cover all other indirect emissions related to the carbon impacts embedded in the value chain. In addition to upstream emissions (indirect emissions along the supply chain from raw material extraction to the activity of the specific company), Lenzen and Murray [31] highlight the inclusion of downstream impacts (from the company to the end-of-life of the product including the product use phase, as well) in organizational carbon footprint accounts, too. Taking into account all these indirect emissions is usually a much bigger challenge when compared to Scopes 1 and 2.

- ■

- providing data for external and internal carbon reporting (delivering information for both final consumers and other stakeholders along the supply chain),

- ■

- as part of a carbon accounting system, pointing out inefficiencies can serve as a basis for interventions for cost savings,

- ■

- achieving synergies with other functional areas of the enterprise (for example, research and development (R&D) for promoting greener and cleaner innovations, design for the environment),

- ■

- motivating employees as a climate-conscious enterprise,

- ■

- improving corporate image, etc.

- Environmental management accounting first emerged when interest towards organizational-level environmental costs (such as resource or waste management costs) arose in the 1990s.

- Carbon accounting (direct emissions) appeared at the same time as regulatory and public attention to climate change and accounting, auditing, and reporting of company-level CO2 emissions arose.

- Carbon accounting (with indirect emissions) supplemented the previous points as attention was focused on the transboundary impacts (covering a larger set of organizations) of entire supply chains.

- Climate change accounting is developing right now, as the horizon is being widened from carbon accounting to climate accounting and the focus shifts from emission-related costs to climate adaptation cost at the company level as well (for instance in the form of higher insurance costs, higher resource prices etc.).

2.3. Methodology of EF and CCF Calculation in Practice—The Case of ENPRO

- ■

- the fuel consumption of the company’s vehicles (machinery, passenger cars, maintenance vehicles),

- ■

- the energy consumption (power, heat and natural gas) and the physical area of properties,

- ■

- the energy consumption of ENPRO’s own power transmission network, based on the data of substations.

3. Results and Discussion

- ■

- During the years examined, neither the size nor the structure of EF resulting from fuel consumption changed significantly.

- ■

- EF resulting from vehicles was about 900 gha, of which the share of passenger cars was about 10% (90 gha). Cab riding added only 2 gha to this, which was a negligibly small part of EF.

- ■

- The maintenance 4 × 4 vehicle group’s fuel consumption accounts for 50% of the EF.

- ■

- Related to the EF of fuel consumption per km, as a future opportunity, electric vehicles can offer a 30–50% reduction. In this respect, there is another significance of applying EF calculation in corporate analysis, since we were able to create a common denominator for units (liters and kWh) that could not be compared directly before.

- ■

- Another possibility to reduce fuel consumption EF may also be to reconsider the chances of using vehicles more sparingly.

- ■

- The size of EF coming from the properties’ energy consumption was 3500–2500 gha, which was the most significant part of the corporate footprint.

- ■

- During the years examined the structure ENPRO properties’ energy consumption EF has changed only slightly because, in spite of decreases in electricity and gas use, the consumption of district heating has not changed.

- ■

- The most important component of the properties’ EF was the consumption of electricity (39–44%).

- ■

- There were 12 priority properties that accounted for 64–74% of all properties’ EF. In the future, it would be worth concentrating on measures intending to reduce EF in these properties.

- ■

- The built-up land footprint of ENPRO only accounts for a minimal share (a little more than 1%) of the total property EF.

- ■

- To compensate for the per square meter EF of ENPRO property, an average of 200 square meters forest area was needed.

- ■

- The overall EF of substations varied between 1290 and 1900 gha.

- ■

- The weight of substations in the structure of the company’s EF has increased (this can also be a sign of increasing network losses due to the declining overall condition of the power grid and may need improvements in the future).

- ■

- The ecological footprint is 46–58 times larger than the substations’ physical area.

- ■

- There was a lack of data at a given operating substation.

- ■

- There was at least an order of magnitude fluctuation in the consumption between years, which could not be justified by any technical or professional reasons.

- (1)

- Washed fruits on a plate—with no investment, only reorganizational or behavior-change measures, in other words, zero payback period;

- (2)

- Low-hanging fruits—Measures involving investments with a payback period of fewer than three years; and

- (3)

- High-hanging fruits—Measures involving investments with a payback period of over 3 years.

4. Conclusions

- ■

- environmental analytics,

- ■

- measuring environmental improvements,

- ■

- economic calculations,

- ■

- economic improvements (cost savings), and

- ■

- public reporting.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wackernagel, M.; Rees, W. Our Ecological Footprint—Reducing Human Impact on the Earth; New Society Publisher: Gabriola Island, BC, Canada, 1996. [Google Scholar]

- Rees, W.E. Ecological footprints and appropriated carrying capacity: What urban economics leave out. Environ. Urban. 1992, 4, 120–130. [Google Scholar] [CrossRef]

- Wackernagel, M.; Onisto, L.; Bello, P.; Linares, A.C.; Falfán, I.S.L.; Garcıa, J.M.; Guerrero, M.G.S. National natural capital accounting with the ecological footprint concept. Ecol. Econ. 1999, 29, 375–390. [Google Scholar] [CrossRef]

- Stiglitz, J.E.; Sen, A.; Fitoussi, J.-P. Report by the Commission on the Measurement of Economic Performance and Social Progress. 2009. Available online: http://ec.europa.eu/eurostat/documents/118025/118123/Fitoussi+Commission+report (accessed on 31 July 2018).

- Global Footprint Network. Footprint Basics—Overview. Global Footprint Network, 2012. Available online: www.footprintnetwork.org (accessed on 19 April 2018).

- World Wildlife Fund (WWF). Living Planet Report; WWF: Gland, Switzerland, 2016. [Google Scholar]

- Tóth, G.; Szigeti, C. The historical ecological footprint: From over-population to over-consumption. Ecol. Indic. 2016, 60, 283–291. [Google Scholar] [CrossRef]

- Vackár, D. Ecological Footprint, environmental performance and biodiversity: A cross-national comparison. Ecol. Indic. 2012, 16, 40–46. [Google Scholar] [CrossRef]

- York, R.; Rosa, E.A.; Dietz, T. The ecological footprint intensity of national economies. J. Ind. Ecol. 2004, 4, 139–154. [Google Scholar] [CrossRef]

- Szigeti, C.; Tóth, G.; Borzán, A.; Farkas, S. GDP Alternatives and their Correlations. J. Environ. Sustain. 2013, 3, 35–46. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; UN Sustainable Development Summit: New York, NY, USA, 2015. [Google Scholar]

- Organisation for Economic Co-operation and Development (OECD). Towards Green Growth; OECD: Paris, France, 2011. [Google Scholar]

- Urhammer, E.; Røpke, I. Macroeconomic narratives in a world of crises: An analysis of stories about solving the system crisis. Ecol. Econ. 2013, 96, 62–70. [Google Scholar] [CrossRef] [Green Version]

- Wiedmann, T.; Minx, J. A definition of ‘carbon footprint’. Ecol. Econ. Res. Trends 2008, 1, 1–11. [Google Scholar]

- Galli, A.; Wiedmann, T.; Ercin, E.; Knoblauch, D.; Ewing, B.; Giljum, S. Integrating ecological, carbon and water footprint into a “footprint family” of indicators: Definition and role in tracking human pressure on the planet. Ecol. Indic. 2012, 16, 100–112. [Google Scholar] [CrossRef]

- Csutora, M. Az ökológiai lábnyom számításának módszertani alapjai. In Az Ökológiai Lábnyom Ökonómiája: Tematikus Kötet; Mária, C., Ed.; Aula Kiadó: Budapest, Hungary, 2011; pp. 6–15. [Google Scholar]

- Mancini, M.S.; Galli, A.; Niccolucci, V.; Lin, D.; Bastianoni, S.; Wackernagel, M.; Marchettini, N. Ecological footprint: Refining the carbon footprint calculation. Ecol. Indic. 2016, 61, 390–403. [Google Scholar] [CrossRef]

- Wiedmann, T.O.; Lenzen, M.; Barrett, J.R. Companies on the scale comparing and benchmarking the sustainability performance of businesses. J. Ind. Ecol. 2009, 13, 361–383. [Google Scholar] [CrossRef]

- Song, G.; Che, L.; Zhang, S. Carbon footprint of a scientific publication: A case study at Dalian University of Technology, China. Ecol. Ind. 2016, 60, 275–282. [Google Scholar] [CrossRef]

- Johnson, E. Carbon footprints of heating oil and LPG heating systems. Environ. Impact Assess. Rev. 2012, 35, 11–22. [Google Scholar] [CrossRef]

- Johnson, E.; Tschudi, D. Baseline effects on carbon footprints of biofuels: The case of wood. Environ. Impact Assess. Rev. 2012, 37, 12–17. [Google Scholar] [CrossRef]

- Fang, K.; Heijungs, R.; Snoo, G.R. Theoretical exploration for the combination of the ecological, energy, carbon, and water footprints: Overview of a footprint family Ecol. Indic. 2014, 36, 508–518. [Google Scholar] [CrossRef]

- Kim, B.; Neff, R. Measurement and communication of greenhouse gas emissions from US food consumption via carbon calculators. Ecol. Econ. 2009, 69, 186–196. [Google Scholar] [CrossRef]

- Downie, J.; Stubbs, W. Evaluation of Australian companies’ Scope 3 greenhouse gas emissions assessments. J. Clean. Prod. 2013, 56, 156–163. [Google Scholar] [CrossRef]

- Herva, M.; Franco, A.; Carrasco, E.; Roca, E. Review of corporate environmental indicators. J. Clean. Prod. 2011, 19, 1687–1699. [Google Scholar] [CrossRef] [Green Version]

- Bagliani, M.; Martini, F. A joint implementation of ecological footprint methodology and cost accounting techniques for measuring environmental pressures at the company level. Ecol. Indic. 2012, 16, 148–156. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Villanueva-Rey, P.; Mallo, J.; De la Cerda, J.; Moreira, T.; Feijoo, G. Carbon footprint of a multi-ingredient seafood product from a business-to-business perspective. J. Clean. Prod. 2013, 44, 200–210. [Google Scholar] [CrossRef]

- Penela, A.C.; García-Negro, M.C.; Quesada, J.L.D. A methodological proposal for corporate carbon footprint and its application to a wine-producing company in Galicia, Spain. Sustainability 2009, 1, 302–318. [Google Scholar] [CrossRef]

- WBCSD, WRI. The Greenhouse Gas Protocol—A Corporate Accounting and Reporting Standard; World Business Council for Sustainable Development and World Resources Institute: Geneva, Switzerland, 2004; p. 116. [Google Scholar]

- WBCSD, WRI. The Greenhouse Gas Protocol—Corporate Value Chain (Scope 3) Accounting and Reporting Standard. Supplement to the GHG Protocol Corporate Accounting and Reporting Standard; World Business Council for Sustainable Development and World Resources Institute: Geneva, Switzerland, 2011; p. 152. [Google Scholar]

- Lenzen, M.; Murray, J. Conceptualising Environmental Responsibility. Ecol. Econ. 2010, 70, 261–270. [Google Scholar] [CrossRef]

- Csutora, M.; Harangozó, G. Twenty years of carbon accounting and auditing. Soc. Econ. 2017, 39, 459–480. [Google Scholar]

- Schaltegger, S.; Csutora, M. Carbon accounting for sustainability and Management. Status quo and challenges. J. Clean. Prod. 2012, 36, 1–16. [Google Scholar] [CrossRef]

- Harangozó, G.; Szigeti, C. Corporate carbon footprint analysis in practice—With a special focus on validity and reliability issues. J. Clean. Prod. 2017, 167, 1177–1183. [Google Scholar] [CrossRef]

- Heineken. Heineken Holding N.V. 2015 Sustainability Report. Available online: http://www.theheinekencompany.com/sustainability/focus-areas/reducing-co2-emissions (accessed on 2 March 2017).

- Stein, M.; Khare, A. Calculating the carbon footprint of a chemical plant: A case study of Akzonobel. J. Environ. Assess. Policy Manag. 2009, 11, 291–310. [Google Scholar] [CrossRef]

- Matthews, H.S.; Hendrickson, C.T.; Weber, C.L. The importance of carbon footprint estimation boundaries. Environ. Sci. Technol. 2008, 42, 5839–5842. [Google Scholar] [CrossRef] [PubMed]

- BFF (Best Foot Forward). A Carbon Footprint Analysis of Three GUINNESS Partnership Employees; The Guinness Partnership: London, UK, 2007. [Google Scholar]

- DEFRA—Department of Environment Food & Rural Affairs. UK Government Conversion Factors for Company Reporting. 2013. Available online: http://www.ukconversionfactorscarbonsmart.co.uk (accessed on 5 February 2017).

- Global Footprint Network. National Footprint Accounts, 2015 ed.; Global Footprint Network: Budapest, Hungary, 2017. [Google Scholar]

- Herner, K.; Szám, D.; Tóth, G. Money Back through the Window XII—Ten Case Studies on Measures Bringing both Environmental and Economic Benefits. KÖVET: Budapest, 2017; p. 28. Available online: http://ec.europa.eu/environment/archives/sme/cases/article_9099_en.htm a full-text database (accessed on 20 July 2018).

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; Capstone: Oxford, UK, 1997. [Google Scholar]

- Daly, H.E. On Nicholas Georgescu-Roegen’s contribution to economics: An obituary essay. Ecol. Econ. 1995, 13, 149–154. [Google Scholar] [CrossRef]

- Schumacher, E.F. Small is Beautiful—A Study of Economics as if People Mattered; Blond & Briggs: London, UK, 1973. [Google Scholar]

| Years | EF Property (gha) | EF Vehicle (gha) | EF Substation (gha) | EF Total (gha) | Property % | Vehicle % | Substation % |

|---|---|---|---|---|---|---|---|

| 2011 | 3548.2 | 905.26 | 1286.29 | 5694.49 | 62 | 16 | 23 |

| 2012 | 3163.53 | 923.28 | 1780.54 | 5823.29 | 54 | 16 | 31 |

| 2013 | 2910.73 | 902.83 | 1901.22 | 5669.52 | 51 | 16 | 34 |

| 2014 | 2442.76 | 902.78 | 1900.09 | 5200.38 | 46 | 17 | 37 |

| 2015 | 2609.57 | 923.02 | 1850.21 | 5337.54 | 48 | 17 | 35 |

| Years | EF Machinery (gha) | EF Cars (gha) | EF Mainte-Nance Vehicles (gha) | EF 4 × 4 Maintenance Vehicles (gha) | EF Total Vehicle (gha) | Machin Ery % | Cars % | Maintenance Vehicles % | 4 × 4 Maintenance Vehicles % |

|---|---|---|---|---|---|---|---|---|---|

| 2011 | 146.54 | 95.60 | 216.18 | 446.94 | 905.26 | 16 | 11 | 24 | 49 |

| 2012 | 137.87 | 95.37 | 222.75 | 467.29 | 923.28 | 15 | 10 | 24 | 51 |

| 2013 | 118.79 | 93.50 | 216.70 | 473.84 | 902.83 | 13 | 10 | 24 | 52 |

| 2014 | 125.76 | 86.08 | 218.66 | 472.29 | 902.78 | 14 | 10 | 24 | 52 |

| 2015 | 121.58 | 88.87 | 218.07 | 494.50 | 923.02 | 13 | 10 | 24 | 54 |

| Years | EF Electricity (gha) | EF Gas (gha) | EF District Heat (gha) | EF Infra-Structure (gha) | Property Total EF (gha) | Electricity % | Gas % | District Heat % | Infra-Structure % |

|---|---|---|---|---|---|---|---|---|---|

| 2011 | 1553.95 | 1150.22 | 798.77 | 45.25 | 3548.2 | 44 | 32 | 23 | 1 |

| 2012 | 1326.22 | 1026.4 | 766.86 | 45.25 | 3163.53 | 42 | 32 | 24 | 1 |

| 2013 | 1196.30 | 935.45 | 733.72 | 45.25 | 2910.73 | 41 | 32 | 25 | 2 |

| 2014 | 958.98 | 807.63 | 630.90 | 45.25 | 2442.76 | 39 | 33 | 26 | 2 |

| 2015 | 1001.01 | 776.2 | 787.10 | 45.25 | 2609.57 | 38 | 30 | 30 | 2 |

| Branches | Categories | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|---|

| ENPRO 1 | corrected data (kWh) | 5,266,855 | 7,977,983 | 8,596,979 | 8,667,828 | 8,785,837 |

| initial data sets (kWh) | 5,196,662 | 7,267,332 | 8,184,723 | 8,289,621 | 10,208,644 | |

| Difference | 1% | 9% | 5% | 4% | −16% | |

| ENPRO 2 | corrected data (kWh) | 3,823,505 | 4,605,318 | 4,839,196 | 4,760,376 | 4,289,838 |

| initial data sets (kWh) | 3,359,458 | 4,254,932 | 4,379,829 | 5,076,581 | 4,317,579 | |

| Difference | 12% | 8% | 9% | −7% | −1% |

| Measure, Project | Since | Quantified Environmental Benefit Per Annum |  Investment Investment Yearly Operational Cost Yearly Operational Cost Yearly Savings Yearly Savings Payback Period Payback Period |

|---|---|---|---|

| (i) Smart building management system, rationalization of building-use, awareness raising of employees | 2011 | Yearly mean resource saving: 957 MWh of electricity 110,600 m3 of natural gas 1438 GJ of district heating 4300 m3 of water used 1700 tons of CO2 equivalent |  0€ 0€ 0€ 0€ 192 thousand € 192 thousand € Immediate Immediate |

| (ii) Modernization of the lighting system, change of indoor and outdoor lamps for LED lights | 2015 | 163 MWh of electricity 92 tons of CO2 equivalent |  110 thousand € 110 thousand € 0€ 0€ 20 thousand € 20 thousand € 5 years and 6 months 5 years and 6 months |

| (iii) Central air conditioning of two central buildings, installing a photovoltaic system | 2013 | 137 MWh of electricity 78 tons of CO2 equivalent |  423 thousand € 423 thousand € 0€ 0€ 17 thousand € 17 thousand € Over 10 years Over 10 years |

| (iv) Modernization of boilers and smart control of office temperature | 2014 | 35,410 m3 of natural gas 107 tons of CO2 equivalent |  123 thousand € 123 thousand € 0€ 0€ 12 thousand € 12 thousand € 10 years 10 years |

| (v) Purchase and operation of electric vehicles | 2011–2012 | 1700 L of fuel 3.3 tons of CO2 equivalent |  87 thousand € 87 thousand € 0€ 0€ 2 thousand € 2 thousand € Over 10 years Over 10 years |

| Saving from Electricity | Savings from Natural Gas | Savings from District Heating | Total Savings | |

|---|---|---|---|---|

| Saving compared to 2011 (in natural units) | 6112 MWh | 510,732 m3 | 5752 GJ | - |

| Saving compared to 2011 (thousand €) | 670 | 190 | 87 | 947 |

| Saving in CO2 equivalent (tons) | 3460 | 3075 | 1365 | 7900 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tóth, G.; Szigeti, C.; Harangozó, G.; Szabó, D.R. Ecological Footprint at the Micro-Scale—How It Can Save Costs: The Case of ENPRO. Resources 2018, 7, 45. https://doi.org/10.3390/resources7030045

Tóth G, Szigeti C, Harangozó G, Szabó DR. Ecological Footprint at the Micro-Scale—How It Can Save Costs: The Case of ENPRO. Resources. 2018; 7(3):45. https://doi.org/10.3390/resources7030045

Chicago/Turabian StyleTóth, Gergely, Cecília Szigeti, Gábor Harangozó, and Dániel Róbert Szabó. 2018. "Ecological Footprint at the Micro-Scale—How It Can Save Costs: The Case of ENPRO" Resources 7, no. 3: 45. https://doi.org/10.3390/resources7030045

APA StyleTóth, G., Szigeti, C., Harangozó, G., & Szabó, D. R. (2018). Ecological Footprint at the Micro-Scale—How It Can Save Costs: The Case of ENPRO. Resources, 7(3), 45. https://doi.org/10.3390/resources7030045