Improved Active and Reactive Control of a Small Wind Turbine System Connected to the Grid

Abstract

:1. Introduction

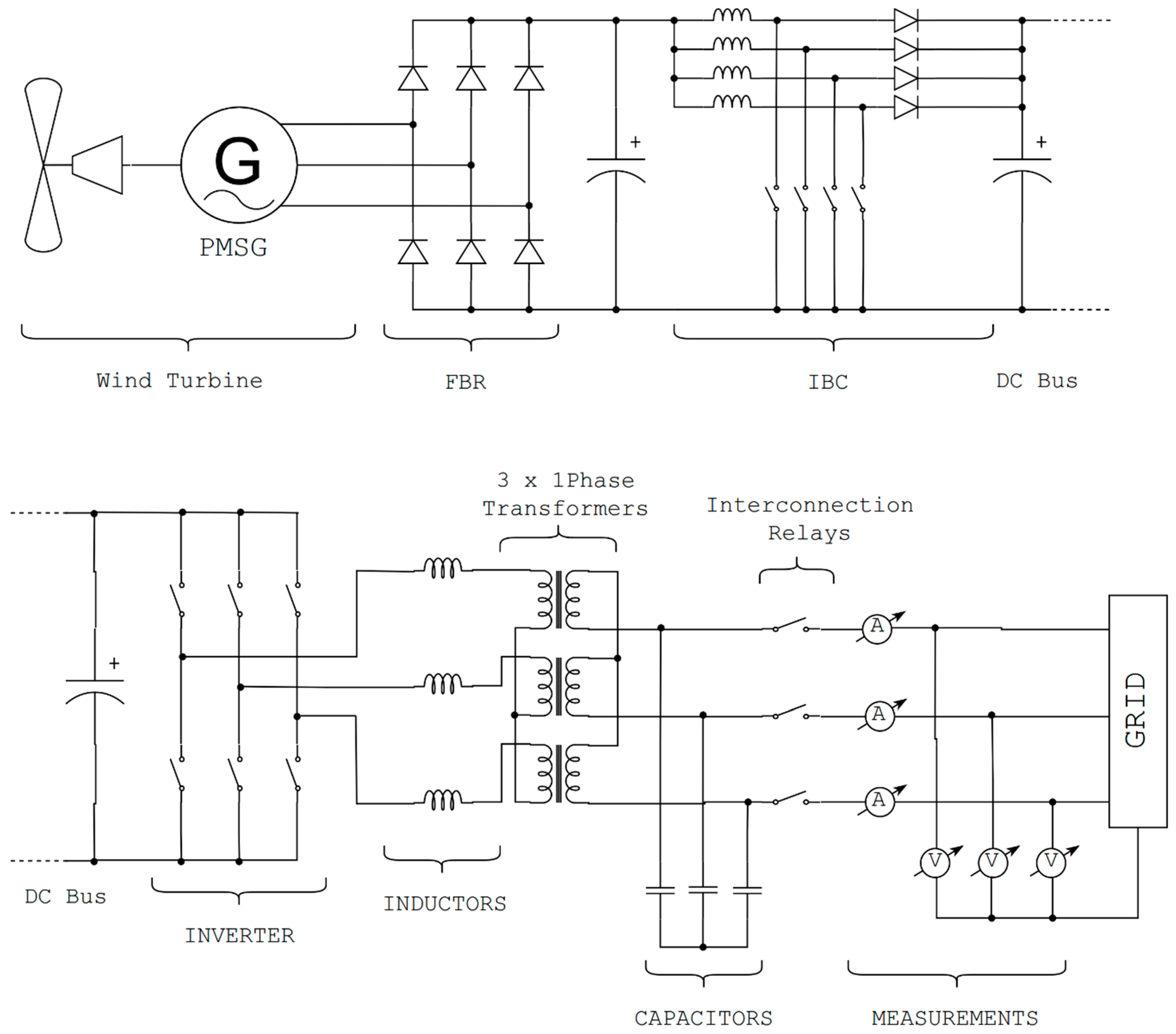

2. System Description

- PMSG: Power generation, with voltage and frequency proportional to the rotation speed of the shaft, that is, the wind speed. Minimum and maximum output voltage 40 and 120 V respectively. Nominal speed 1000 rpm, for wind speed 11.6 m/s.

- FBR: Uncontrolled three-phase 6-pulse bridge. It aims at rectifying and smoothing the output voltage of the wind turbine to provide a DC voltage, regardless of the wind speed.

- IBC: Finding the optimum point of operation of the wind turbine using MPPT methods. The use of an interleaved type converter enables more power at lower cost and a reduction in ripple.

- DC Bus: Separation of the two subsystems and intermediate energy storage to control active power supply to the grid. The total capacity is 10 mF.

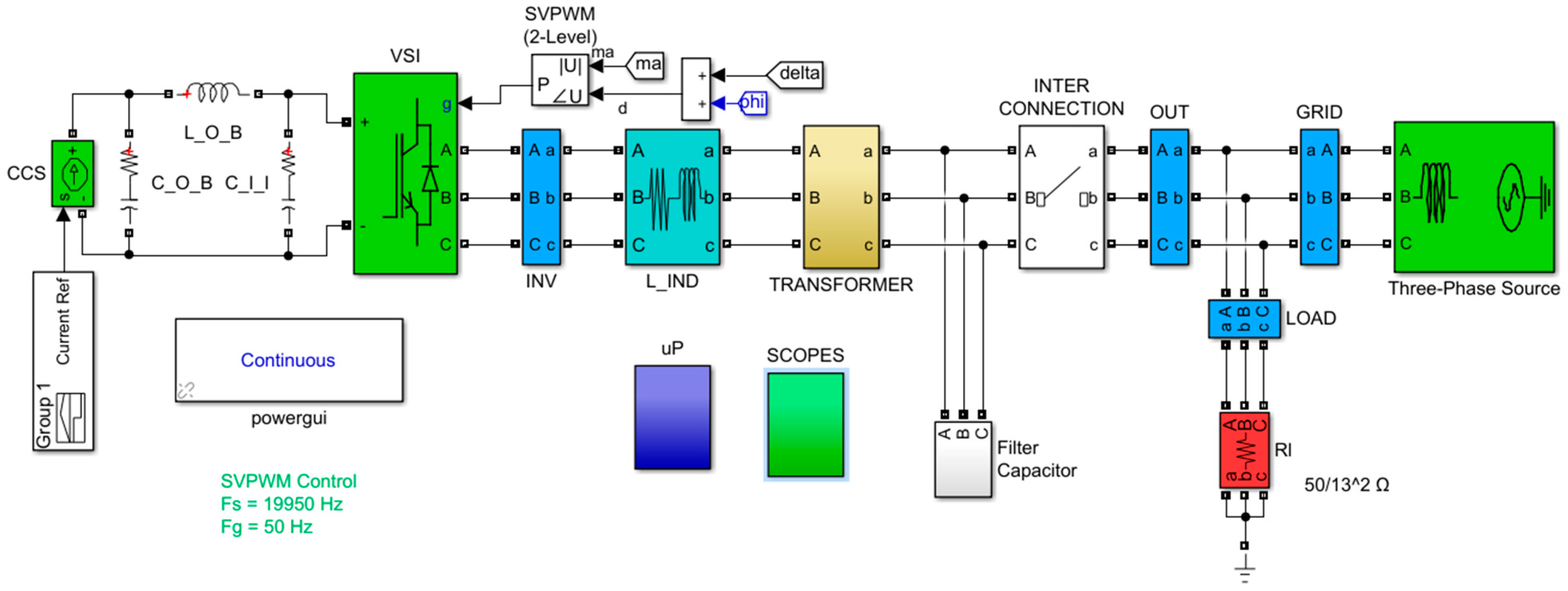

- INV: Three-phase inverter with IGBT semiconductor switches (single module) and SVPWM pulsing method. It aims to convert the DC voltage at its input, to AC at the output and to control the active and reactive power injected to the grid, through the parameters m (modulation width) and δ (phase difference between the mains voltage and the basic harmonic voltage of the inverter).

- LI: Three single phase inductors with 2 mH induction. A sufficiently large induction was chosen so that there are correspondingly large margins for adjusting the angle δ.

- TF: Three single phase transformers, with a 1:13 lifting ratio. In addition to lifting, they offer a galvanic isolation between the inverter and the grid, essential for the safe operation of the system in a laboratory environment.

- CG: Three capacitors, which are aiming to suppress the higher harmonics of the current and are permanently connected to the side of the network, compensate part of the reactive power.

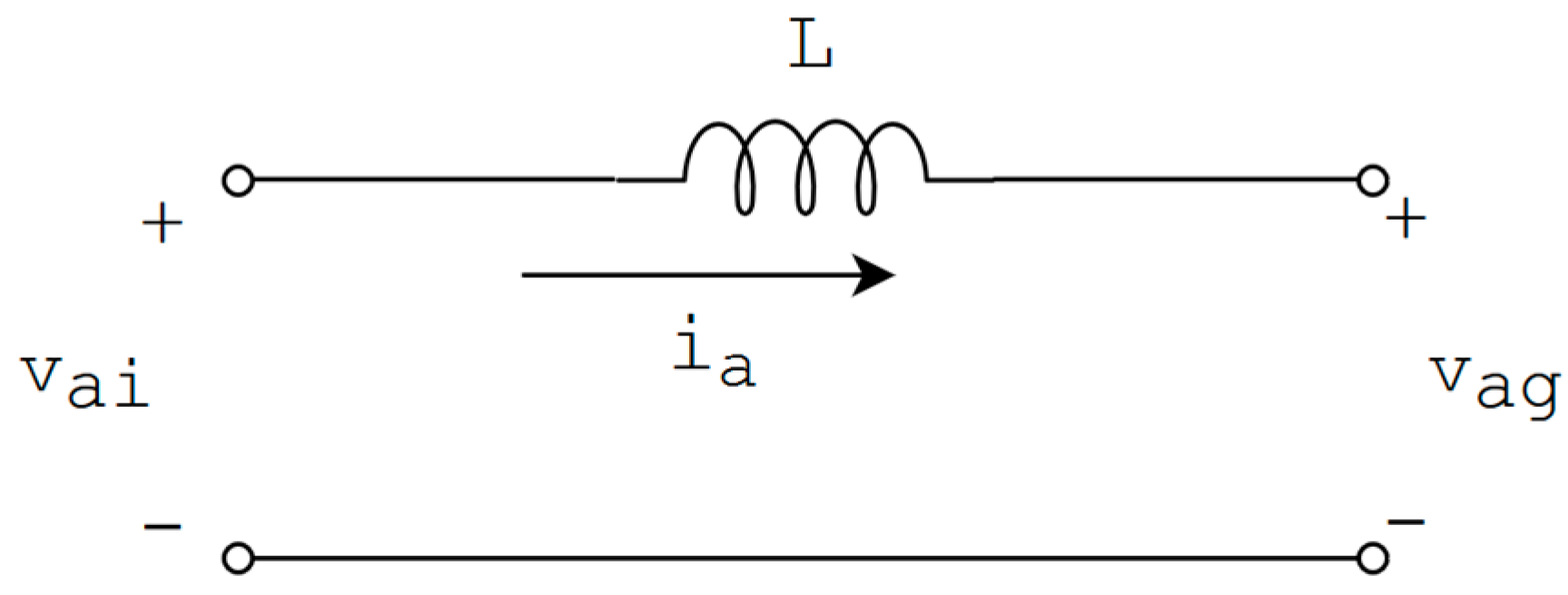

3. Control Architecture

- vai: basic voltage harmonic of inverter’s output

- vag: grid voltage

- L: interconnection inductor

4. Investigation of PI Parameters

- Starting from an arbitrary value of KP and for KI = 0. Based on the above analysis, KP is positive and it affects the speed at which PI output reaches the reference signal, something that is well known from control theory.

- A random series of extreme transitions is assigned to the system. If the system is unstable or the variables are congruent with the constraints, at any time, KP is reduced. Otherwise, KP is increased. Extreme transitions are those between extreme states or points of operations, which in this case are {p, q} = {0, 0}, {1000, 0}, {0, 800}, {1000, 800} {[W], [VAR]}.

- Step 2 is repeated until the system is close to the marginal stability or limitations. Let be the critical gain Ku = KP for this situation. In addition, for this KP the Tu of the oscillation of the variables are calculated.

- From the equations of Table 1 (Ziegler-Nichols Method), the values of KP and KI are calculated, according to the control method. In this case PI controller is used, since PID was vulnerable to instability.

- Based on the values of Step 4, small changes are made to optimize the response. Typically, ±15% of the original calculated value.

5. DC Bus Auto-Charging and Reactive Power Injection

- When the voltage of DC Bus is less than ~15V, antiparallel diodes are forward biased and start conducting, charging the bus.

- After that, inverter can modulate its voltage output, so that power flows from grid to the bus, by utilizing a negative δ value, hence a negative P value.

- Increased stability and better transient behavior

- Reduced transmission losses

- Reduced emissions of greenhouse gases

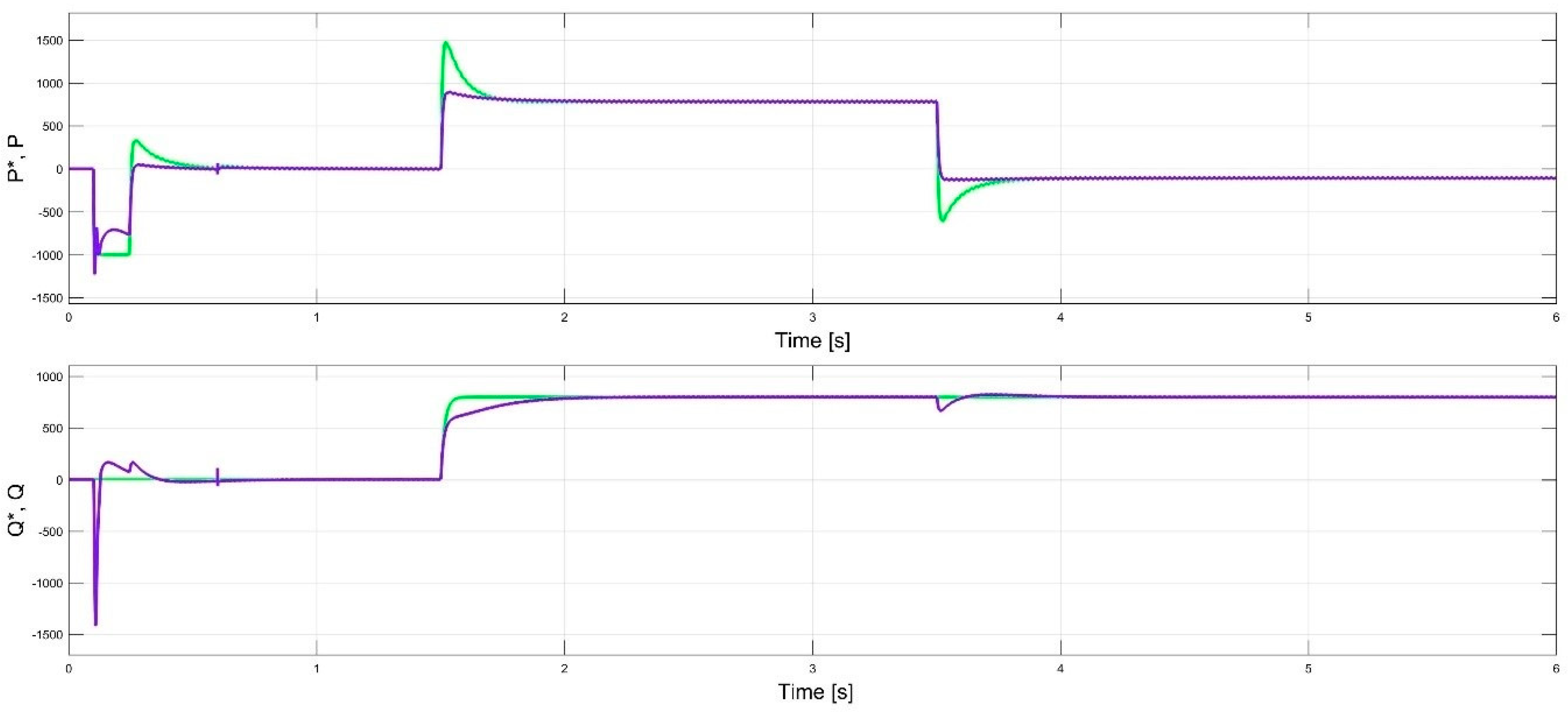

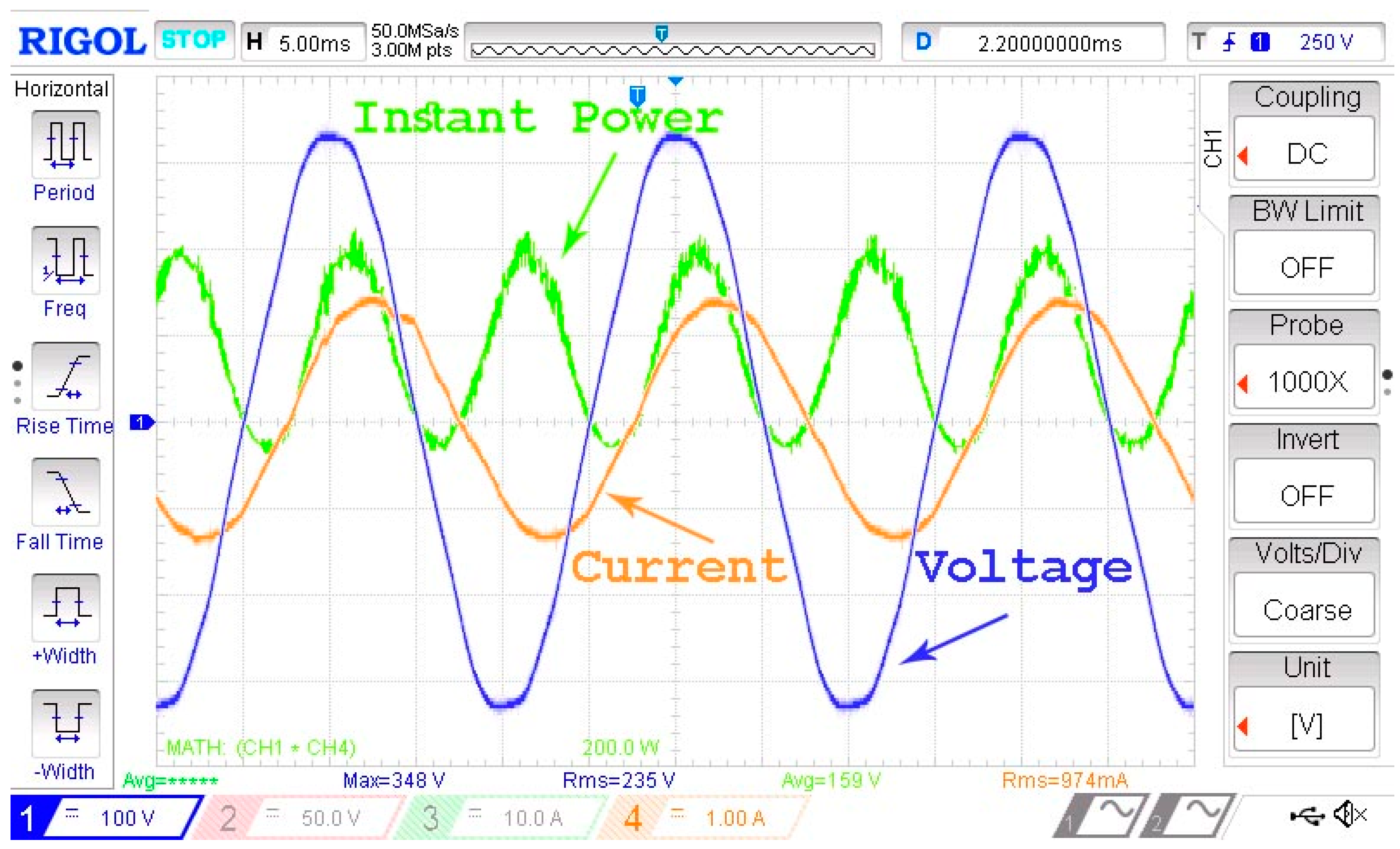

6. System Simulation and Experimental Results

- t = [0, 0.1] sec. control is offline and the PLL is synchronized with the grid’s frequency and phase.

- t = [0.1, 0.6] sec. the DC Bus is charging from 0 to 120 V. The overshoot is less that 135 V, which is acceptable since the capacitors of the DC Bus were designed for 200 V.

- t = [0.6, 1.5] sec. both active and reactive power are set to zero. Since voltage of the DC Bus is considered constant at 120 V, input active power is defined only by the current of CCS (independent current source).

- t = [1.5, 3.5] sec. active power is set to 1000 W (or CCS reference current is set to 8.3 A) and reactive power is set to 800 VAR.

- t > 3.5 sec. active power is set to 0 W and reactive to 800 VAR.

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pasini, S.; Ghezzi, U.; Ferri, L.D.A. Combustion and emissions. In Proceedings of the Thirty-Second Intersociety Energy Conversion Engineering Conference (IECEC’97), Honolulu, HI, USA, 27 July–1 August 1997; pp. 922–926. [Google Scholar]

- Alexopoulos, T.; Thomakos, D.; Tzavara, D. CO2 emissions, fuel mix, final energy consumption and regulation of renewable energy sources in the EU-15. In Proceedings of the 2012 9th International Conference on the European Energy Market, Florence, Italy, 10–12 May 2012. [Google Scholar]

- Williams, A. Role of fossil fuels in electricity generation and their environmental impact. IEEE Proc. A 1993, 140, 8–12. [Google Scholar] [CrossRef]

- Üney, M.Ş.; Çetinkaya, N. Comparison of CO2 Emissions Fossil Fuel Based Energy Generation Plants and Plants with Renewable Energy Source. In Proceedings of the 2014 6th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Bucharest, Romania, 23–25 October 2014. [Google Scholar]

- Zobaa, F. An overview of the different situations of renewable energy in the European Union. In Proceedings of the 2005 IEEE Russia Power Tech, St. Petersburg, Russia, 27–30 June 2005. [Google Scholar]

- EPA. Greenhouse Gas Inventory Data Explorer. Available online: https://www3.epa.gov/climatechange/ghgemissions/inventoryexplorer/ (accessed on 28 February 2019).

- Pazouki, S.; Haghifam, M.-R.; Pazouki, S.i. Transition from Fossil Fuels Power Plants toward Virtual Power Plants of Distribution Networks. In Proceedings of the 21st Electrical Power Distribution Conference, Karaj, Iran, 5–6 May 2016. [Google Scholar]

- Gill, S.K.; Vu, K.; Aimone, C. Quantifying Fossil Fuel Savings from Investment in Renewables and Energy Storage. In Proceedings of the 2017 Saudi Arabia Smart Grid (SASG), Jeddah, Saudi Arabia, 12–14 December 2017. [Google Scholar]

- Hatziargyriou, N.; Asano, H.; Iravani, R.; Marnay, C. Microgrids: An Overview of Ongoing Research, Development, and Demonstration Projects. IEEE Power Energy Mag. 2007, 5, 78–94. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Koukoulis, E. Analysis, Construction and Control of Wind System for Interconnection with the Low-Voltage Grid. Diploma Thesis, University of Patras, Patras, Greece, July 2018. [Google Scholar]

- Pyrris, G. Study of the Connection of a Wind Turbine to the Grid—Construction of the Inverter. Diploma Thesis, University of Patras, Patras, Greece, December 2012. [Google Scholar]

- Koutsogiorgos, D. Study of Microgrid System—Analysis and Construction of Three-Phase Inverter. Diploma Thesis, University of Patras, Patras, Greece, July 2017. [Google Scholar]

- Zogogianni, C. Connection of Wind Turbine with the Low-Voltage Grid—Construction of Three-Phase Inverter Controlled by MicroController. Diploma Thesis, University of Patras, Patras, Greece, February 2013. [Google Scholar]

- Mohan, N.; Undeland, T.M.; Robbins, W.R. Power Electronics; Wiley & Sons: Hoboken, NJ, USA, 1995; p. 201. [Google Scholar]

- Zhang, W.; Chen, W. Research on Voltage-Source PWM Inverter Based on State Analysis Method. In Proceedings of the 2009 IEEE International Conference onMechatronics and Automation, Changchun, China, 9–12 August 2009. [Google Scholar]

- Pham, C. Modeling and Simulation of Two Level Three-Phase Voltage Source Inverter with Voltage Drop. In Proceedings of the 7th International Conference on Information Science and Technology, Da Nang, Vietnam, 16–19 April 2017. [Google Scholar]

- Jayanth, K.G.; Boddapati, V.; Geetha, R.S. Comparative Study Between Three-leg and Four-leg Current-Source Inverter for Solar PV Application. In Proceedings of the 2018 International Conference on Power, Instrumentation, Control and Computing (PICC), Thrissur, India, 18–20 January 2018. [Google Scholar]

- Hojabri, M.; Ahmad, A.Z.; Toudeshki, A.; Soheilirad, M. An Overview on Current Control Techniques for Grid Connected Renewable Energy Systems. In Proceedings of the International Computer Science and Information Technology, Kuala Lumpur, Malaysia, 26–28 November 2012. [Google Scholar]

- Lindgren, M.; Svensson, J. Control of a voltage-source converter connected to the grid through an LCL-filter-application to active filtering. In Proceedings of the PESC 98 Record, 29th Annual IEEE Power Electronics Specialists Conference, Fukuoka, Japan, 17–22 May 1998; Volume 1, pp. 229–235. [Google Scholar]

- Kazmierkowski, M.P.; Malesani, L. Current control techniques for three-phase voltage-source PWM converters: A survey. IEEE Trans. Ind. Electron. 1998, 45, 691–703. [Google Scholar] [CrossRef]

- Voglitsis, D.; Adamidis, G.; Papanikolaou, N. Investigation of the control scheme of a single phase Cascade H-Bridge multilevel converter capable for grid interconnection of a PV park along with reactive power regulation and maximum power point tracking. In Proceedings of the 2014 IEEE 5th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Galway, Ireland, 24–27 June 2014. [Google Scholar]

- Niu, H.; Jiang, M.; Zhang, D.; Fletcher, J. Autonomous Micro-grid Operation by Employing Weak Droop Control and PQ Control. In Proceedings of the Australasian Universities Power Engineering Conference, AUPEC 2014, Perth, Australia, 28 September–1 October 2014. [Google Scholar]

- Zogogianni, C.G.; Tatakis, E.C. A simple direct power control of a three-phase inverter for a grid-connected wind energy system. In Proceedings of the 16th European Conference on Power Electronics and Applications (EPE’2014-ECCE Europe), Lappeenranta, Finland, 26–28 August 2014. [Google Scholar]

- Loukas, C.; Zogogianni, C.; Tatakis, E. Control of a single-phase full bridge inverter for the interconnection of a wind generator to the low voltage grid. In Proceedings of the 17th Power and Energy Student Summit (PESS’2016), Aachen, Germany, 19–20 January 2016. [Google Scholar]

- Chen, Y.; Zhao, J.; Wang, J.; Qu, K.; Ushiki, S.; Ohshima, M. A Decupled PQ Control strategy of Voltage-Controlled Inverters. In Proceedings of the 9th International Conference on Power Electronics, Seoul, Korea, 1–5 June 2015. [Google Scholar]

- Zhang, D.; Ambikairajah, E. De-coupled PQ Control for Operation of Islanded Microgrid. In Proceedings of the 2015 Australasian Universities Power Engineering Conference (AUPEC), Wollongong, Australia, 27–30 September 2015. [Google Scholar]

- Chauhan, J.; Chauhan, P.; Maniar, T.; Joshi, A. Comparison of MPPT algorithms for DC-DC converters based photovoltaic systems. In Proceedings of the 2013 International Conference on Energy Efficient Technologies for Sustainability, Kanyakumari, India, 10–12 April 2013. [Google Scholar]

- Lahfaoui, B.; Zouggar, S.; Elhafyani, M.L.; Seddik, M. Experimental study of P&O MPPT control for wind PMSG turbine. In Proceedings of the 2015 3rd International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 10–13 December 2015. [Google Scholar]

- Xu, H.; Hui, J.; Wu, D.; Yan, W. Implementation of MPPT for PMSG-based small-scale wind turbine. In Proceedings of the 2009 4th IEEE Conference on Industrial Electronics and Applications, Xi’an, China, 25–27 May 2009. [Google Scholar]

- Ögren, J. PLL Design for Inverter Grid Connection—Simulations for Ideal and Non-Ideal Grid Conditions; Uppsala Universitet: Uppsala, Sweden, July 2011. [Google Scholar]

- ManishBhardwaj. Software Phase Locked Loop Design Using C2000™ Microcontrollers for Single Phase Grid Connected Inverter; Texas Instruments: Dallas, TX, USA, July 2017. [Google Scholar]

- Binh, T.C.; Dat, M.T.; Dung, N.M.; An, P.Q.; Truc, P.D.; Phuc, N.H. Active and Reactive Power Controller for Single-Phase Grid-Connected Photovoltaic Systems. In Proceedings of the AUN-SEEDNet Conference on Renewable Energy, Bandung, Indonesia, 12–13 March 2009. [Google Scholar]

- Ogata, K. Modern Control Engineering; Pearson Education, Prentice Hall: Upper Saddle River, NJ, USA, 2010; pp. 568–577. [Google Scholar]

- Ziegler, J.; Nichols, N.B. Optimum Settings for Automatic Controllers. Trans. ASME 1942, 64, 759–765. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papadopoulos, T.; Tatakis, E.; Koukoulis, E. Improved Active and Reactive Control of a Small Wind Turbine System Connected to the Grid. Resources 2019, 8, 54. https://doi.org/10.3390/resources8010054

Papadopoulos T, Tatakis E, Koukoulis E. Improved Active and Reactive Control of a Small Wind Turbine System Connected to the Grid. Resources. 2019; 8(1):54. https://doi.org/10.3390/resources8010054

Chicago/Turabian StylePapadopoulos, Theofilos, Emmanuel Tatakis, and Efthymios Koukoulis. 2019. "Improved Active and Reactive Control of a Small Wind Turbine System Connected to the Grid" Resources 8, no. 1: 54. https://doi.org/10.3390/resources8010054

APA StylePapadopoulos, T., Tatakis, E., & Koukoulis, E. (2019). Improved Active and Reactive Control of a Small Wind Turbine System Connected to the Grid. Resources, 8(1), 54. https://doi.org/10.3390/resources8010054