On the Highly Ordered Graphene Structure of Non-Graphitic Carbons (NGCs)—A Wide-Angle Neutron Scattering (WANS) Study

Abstract

:1. Introduction

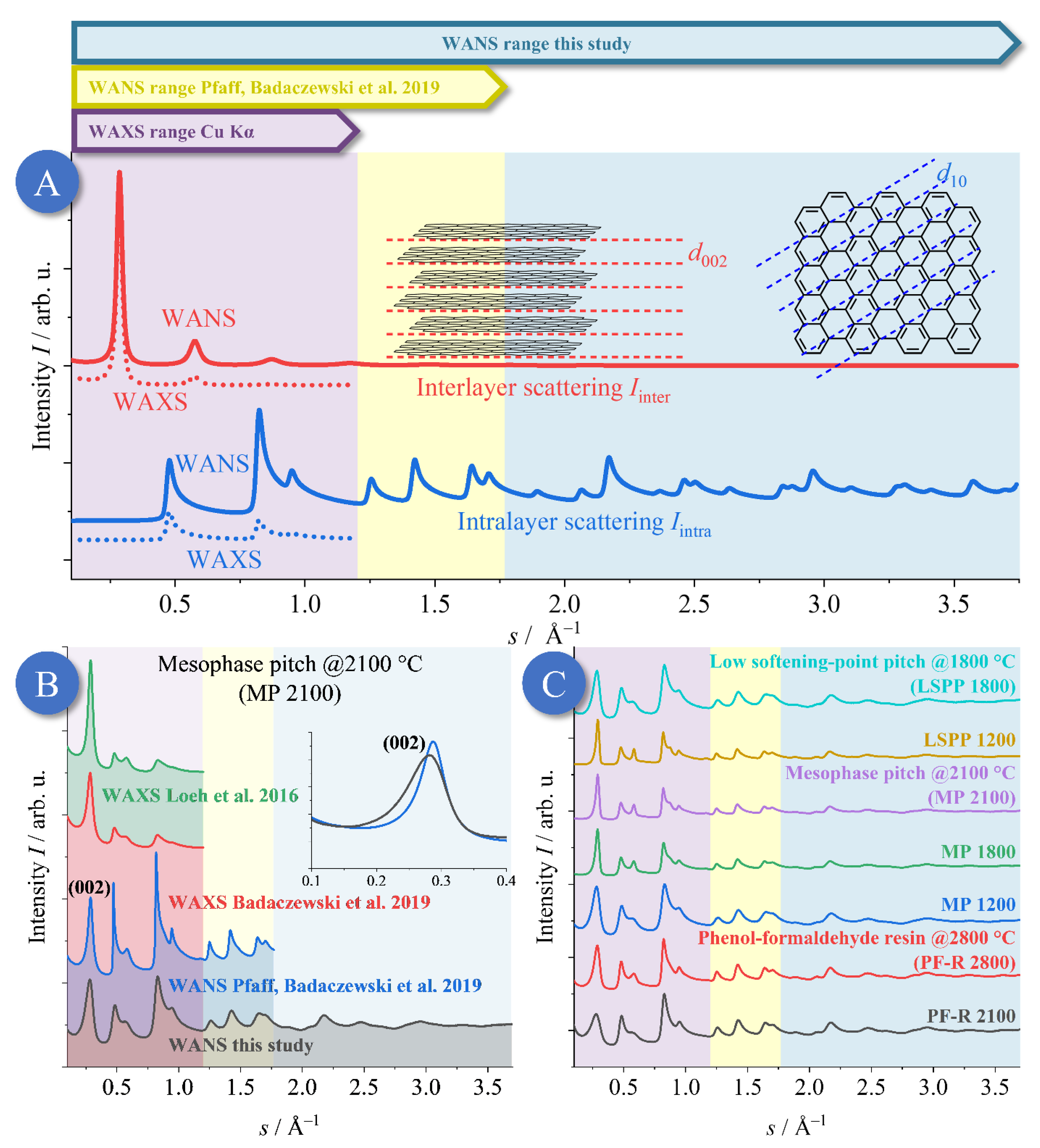

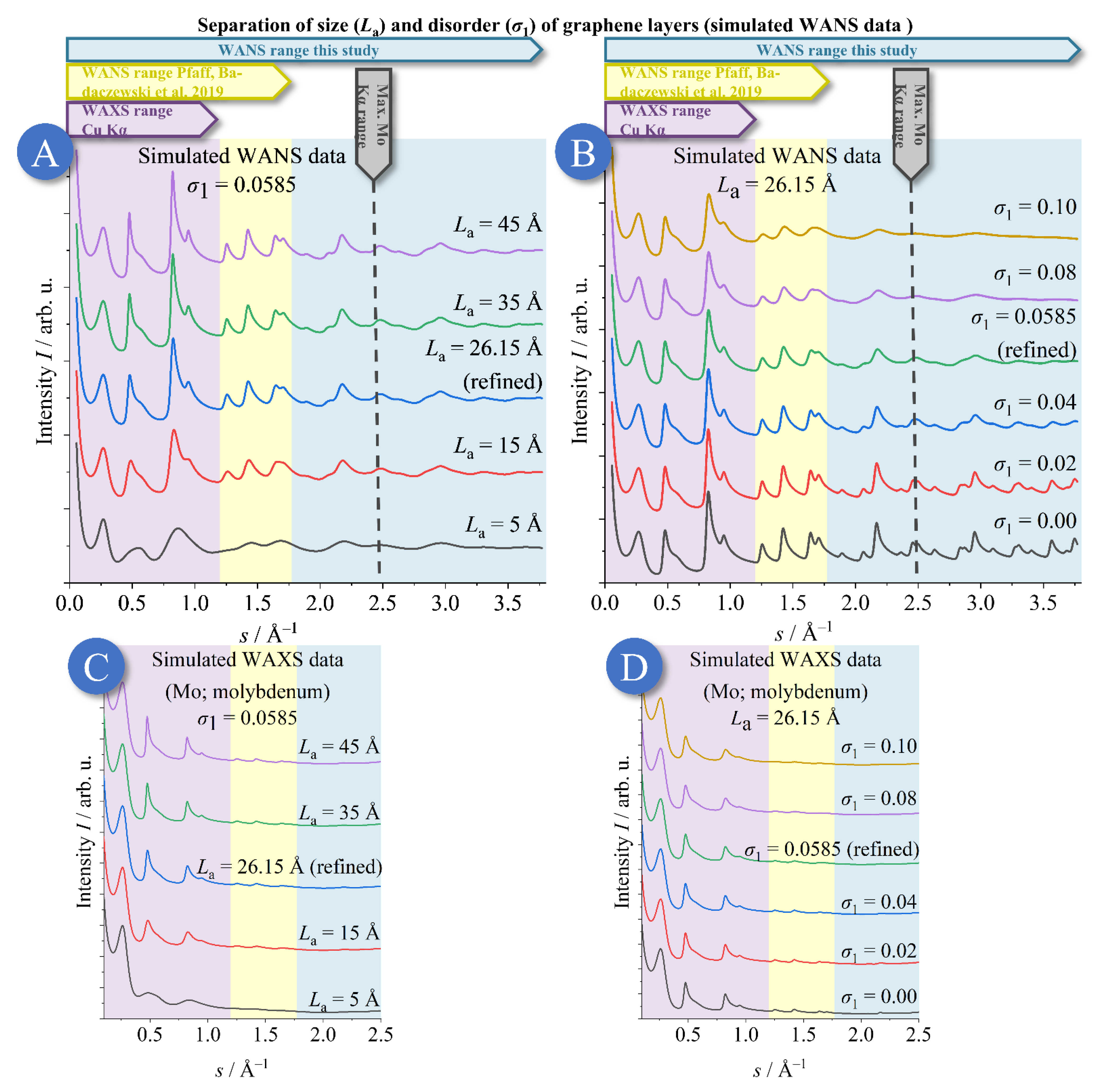

- Atomic form factors result in the damping of WAXS data at larger s values. This effect is significant for typical XRD setups using a CuKα wavelength.

- The Compton scattering has to be exactly taken into account, but has a complex dependence on s.

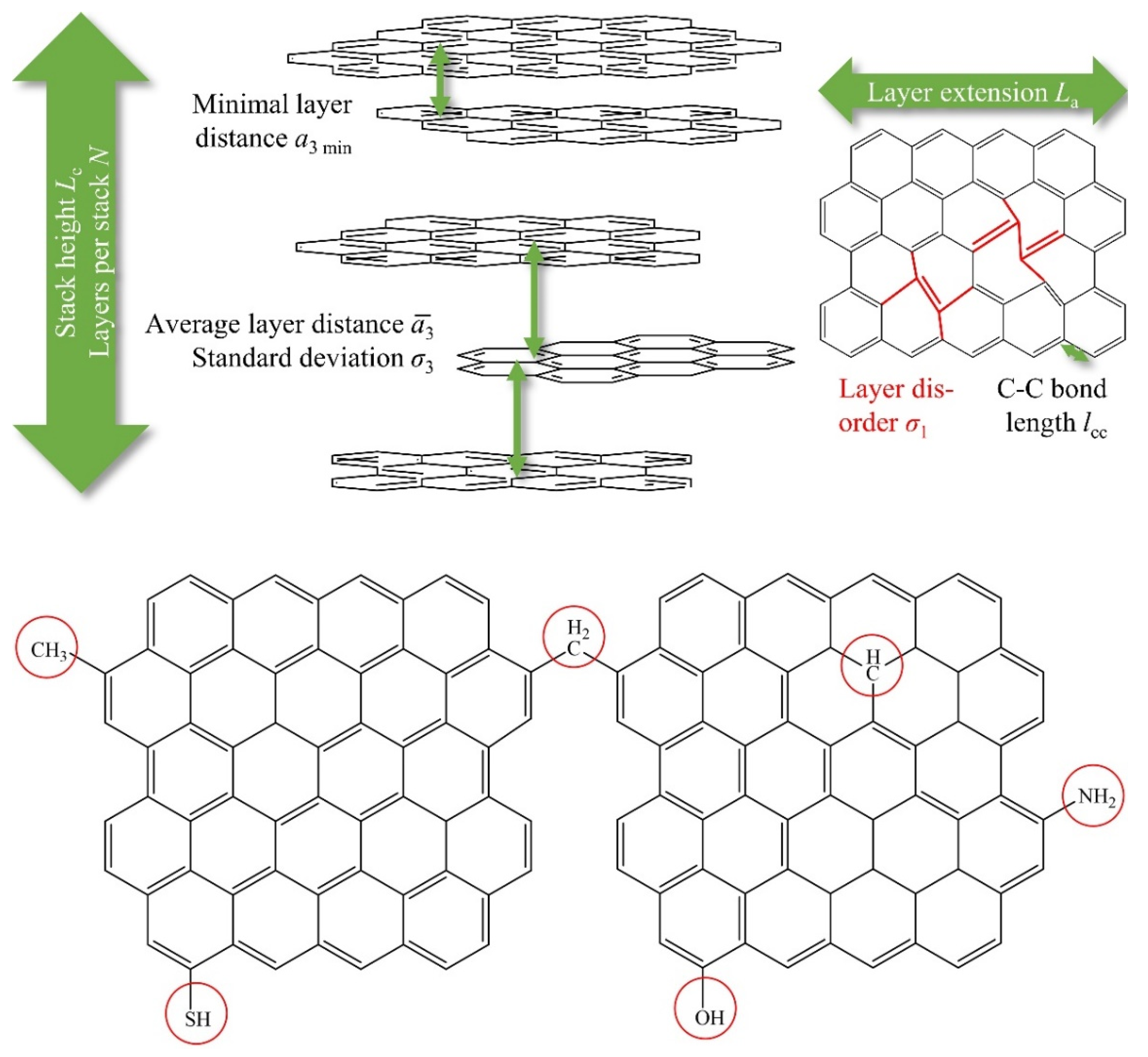

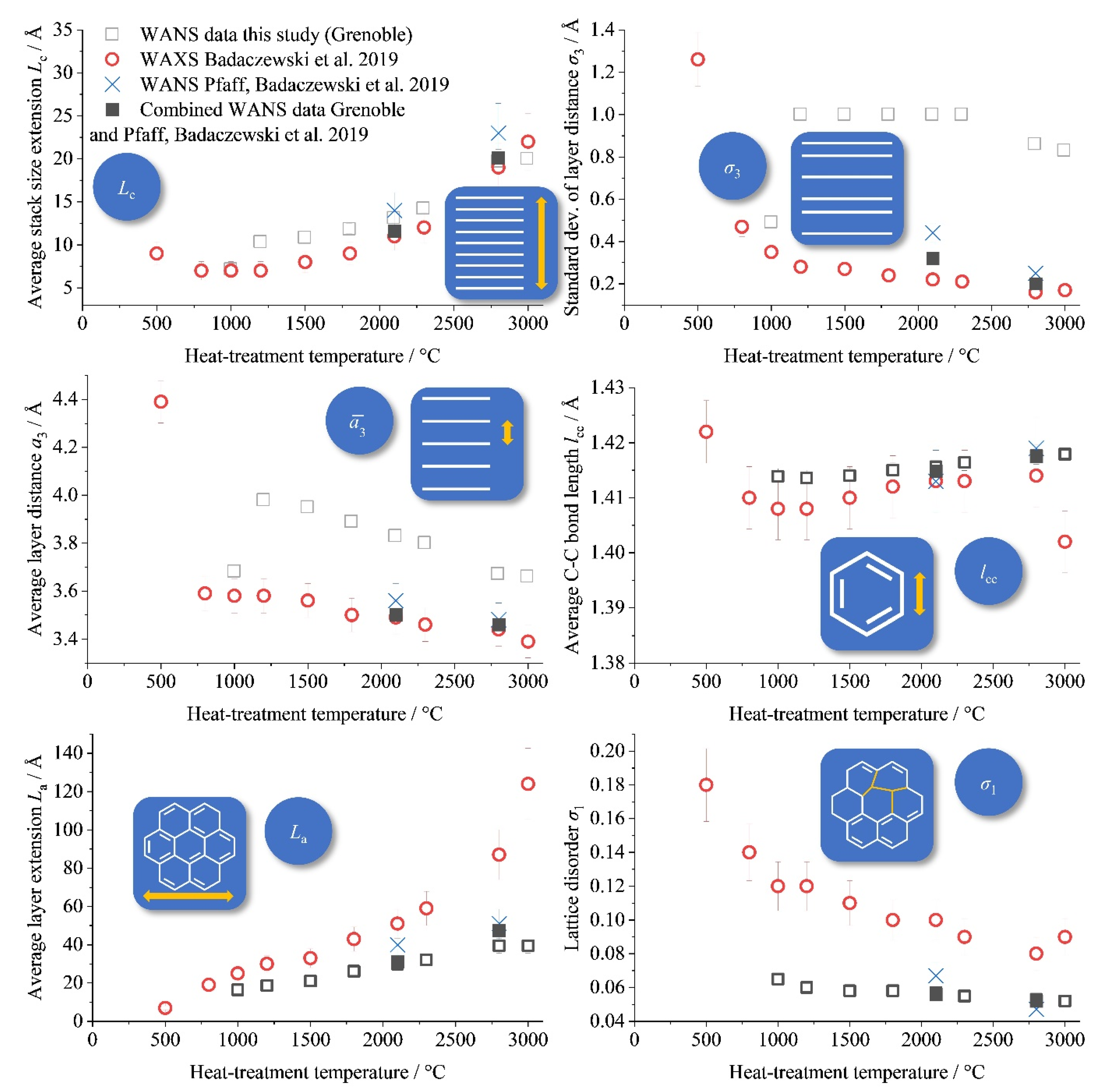

- The limited range of s (s = 2/λ sin (θ)) commonly available in standard lab XRD setups reduces the number of accessible WAXS reflections. A large number of reflections is, however, crucial to quantitatively disentangle size (𝐿a and 𝐿c) and disorder effects (𝜎1 and 𝜎3 in our approach), which both influence the significant width of the NGC reflections.

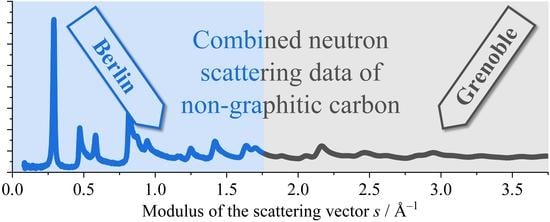

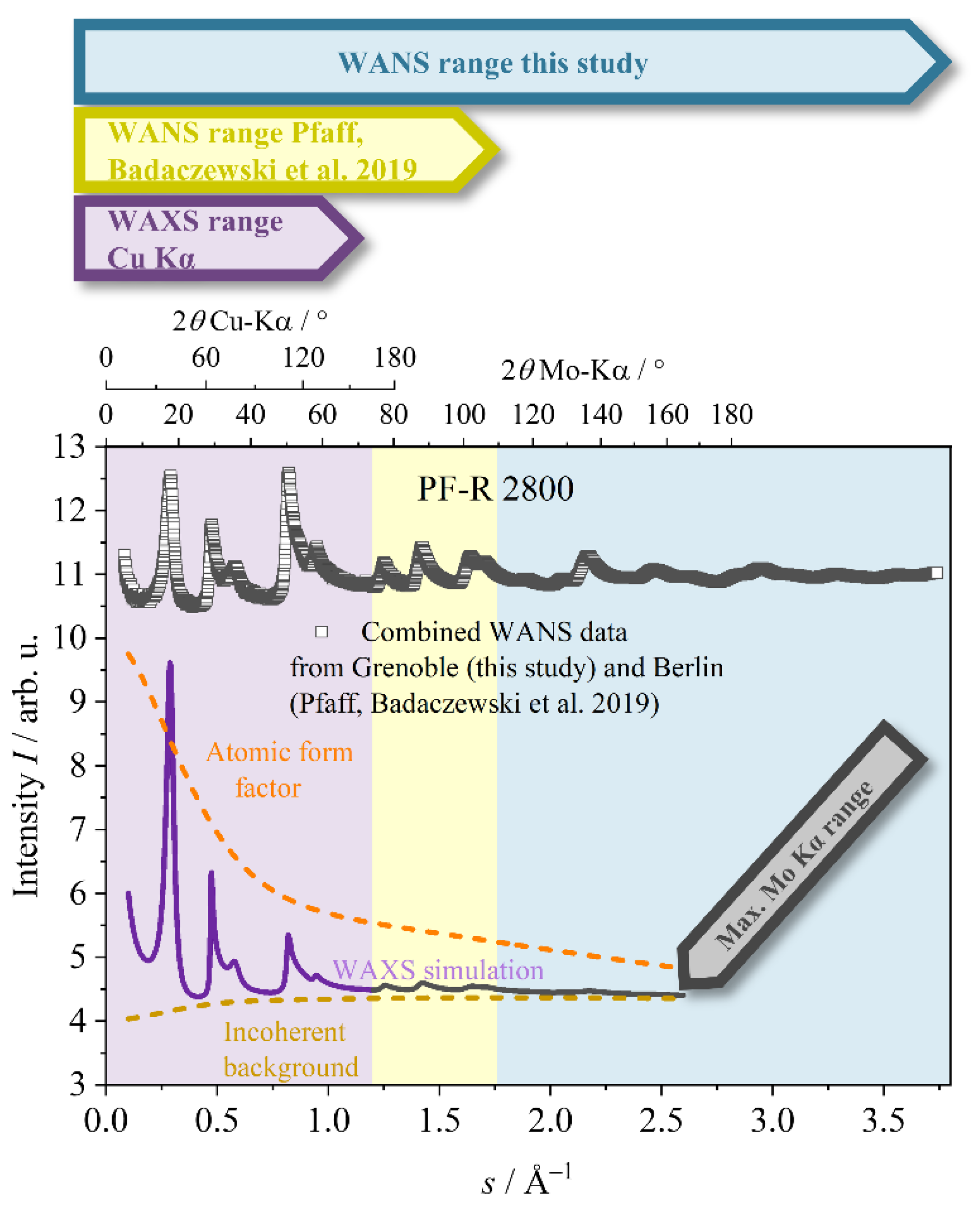

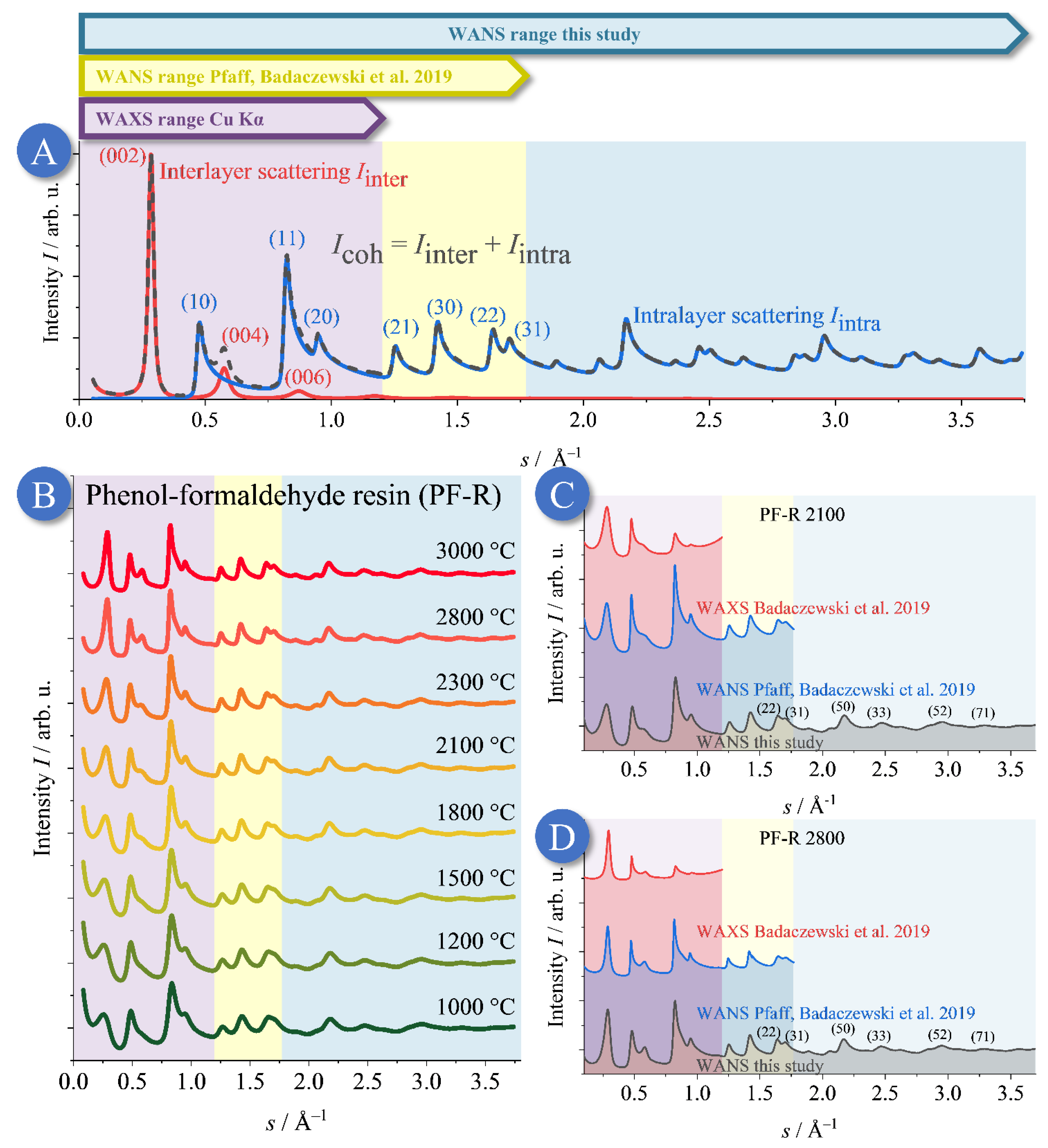

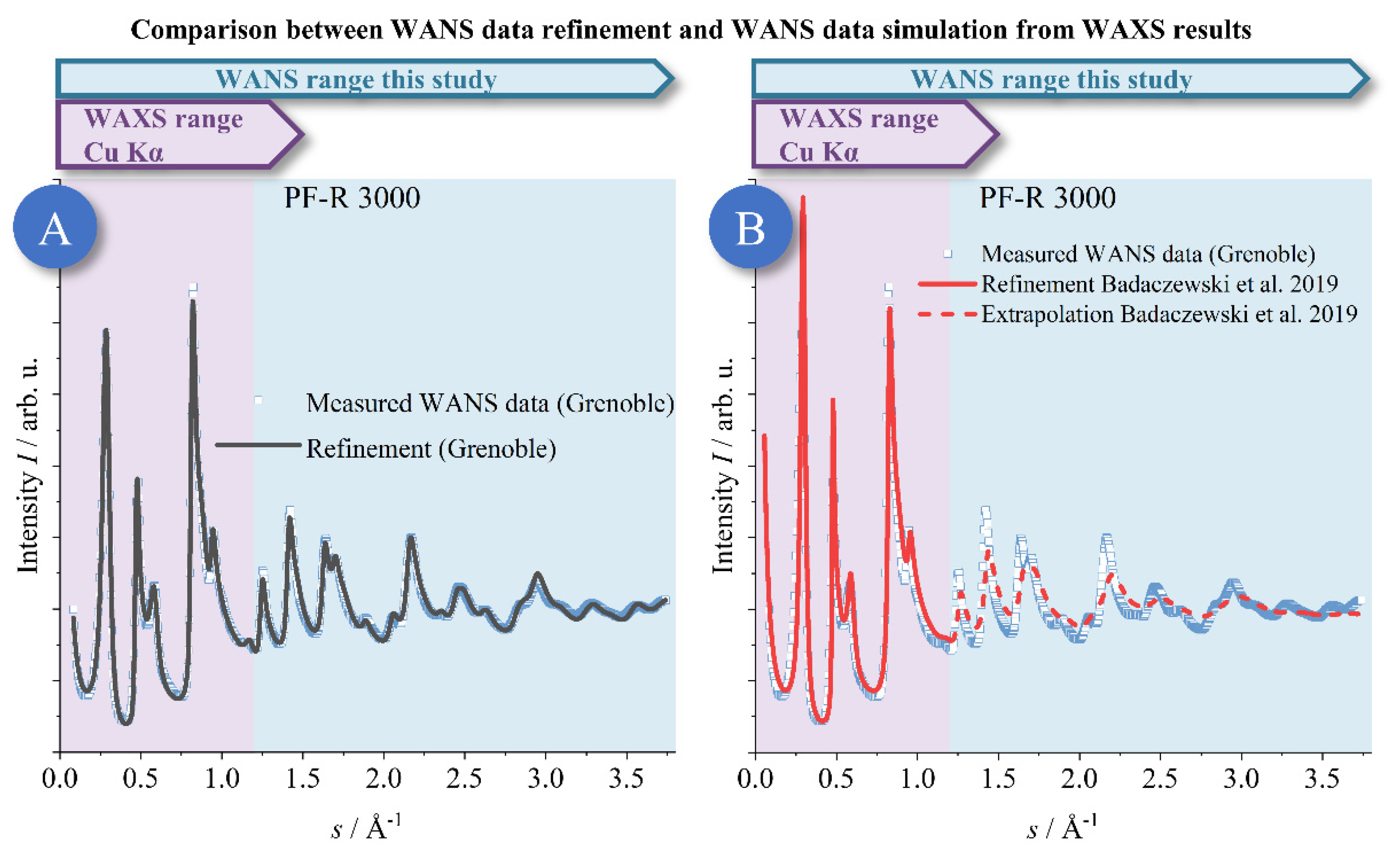

- While the WANS data acquired in our previous study featured high precision particularly at low s (Berlin; Pfaff et al., 2019 [43]), the facility at Grenoble featured advantageous resolution at high s (0.052 Å−1 < s < 3.76 Å−1). However, the Berlin HZB WANS data (0.400 Å−1 < s < 1.44 Å−1) possessed better resolution in the region of the (002) reflection compared to the WANS data acquired in Grenoble. Thus, combining both data sets for the very same sample was intended to test if a valid deconvolution of the effects of finite size and disorder in both the interlayer and intralayer structure was possible.

- The noise of the Grenoble WANS beam line was very low; therefore, the refinement quality and the resulting microstructure parameters were superior. In particular, the analysis of the higher-order reflections, possessing decreasing intensity, benefited from a low background and noise.

- The high neutron flux available at the D4 in Grenoble allowed for the acquisition of high-quality data for a substantial number of materials. In particular, in this study, extensive temperature series were possible for materials exposed to a lot of temperature steps. Together with the high data quality, fine changes in the evolution of the microstructure upon temperature treatment were thus accessible.

2. Materials and Methods

2.1. Sample Preparation

2.2. Wide-Angle Scattering

2.3. Elemental Analysis

2.4. Raman Spectroscopy

2.5. Data Treatment

2.5.1. Background Correction

2.5.2. WANS Data Combination

2.5.3. WANS Data Refinement

3. Results

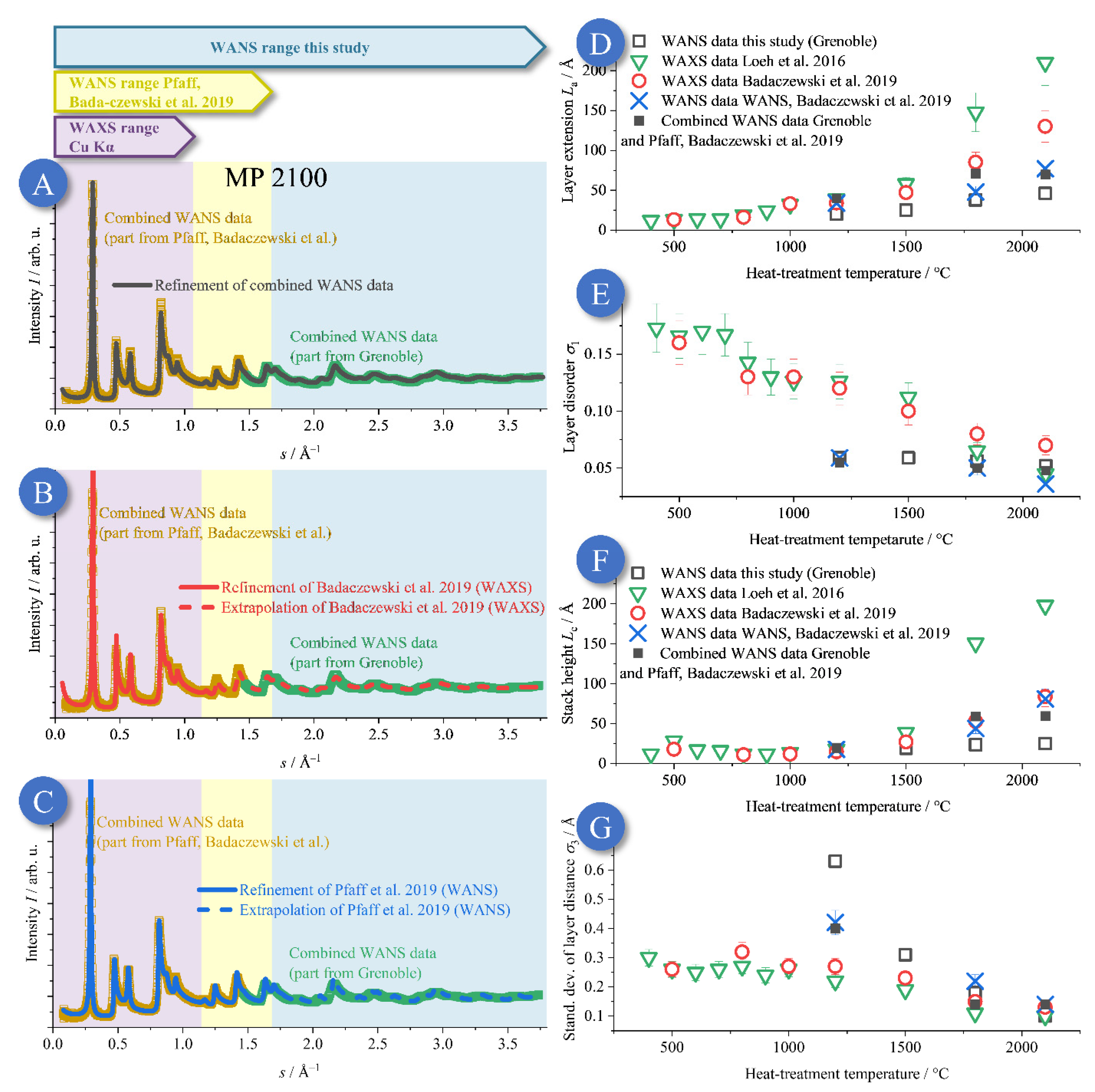

3.1. Qualitative Discussion of the WANS Data

3.2. Non-Graphitic Carbons from Phenol-Formaldehyde Resin (PF-R)

3.2.1. Graphene Stacks of the PF-R Carbons Temperature Series

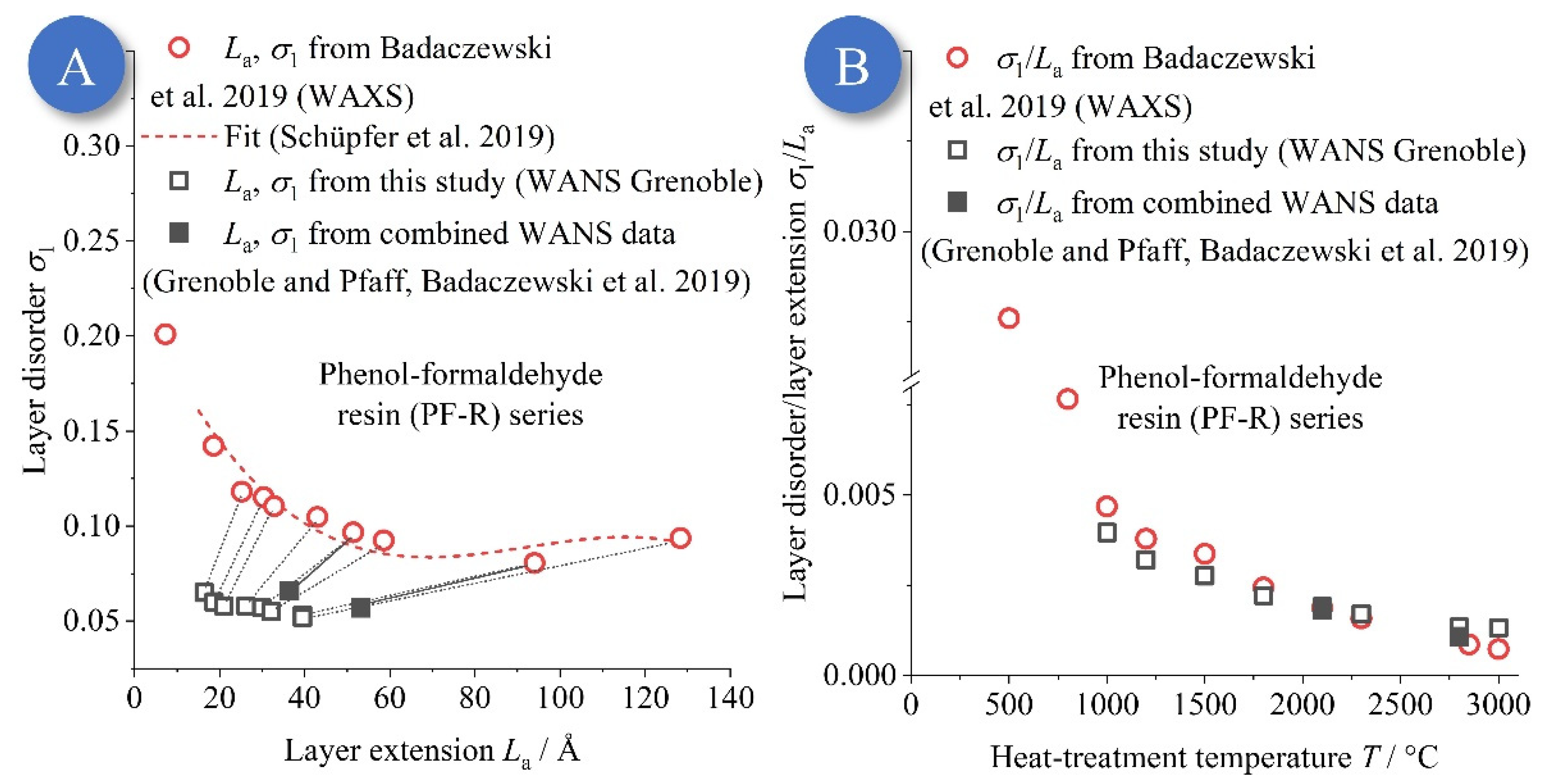

3.2.2. Layer Structure of the Phenol-Formaldehyde Resin (PF-R) Temperature Series

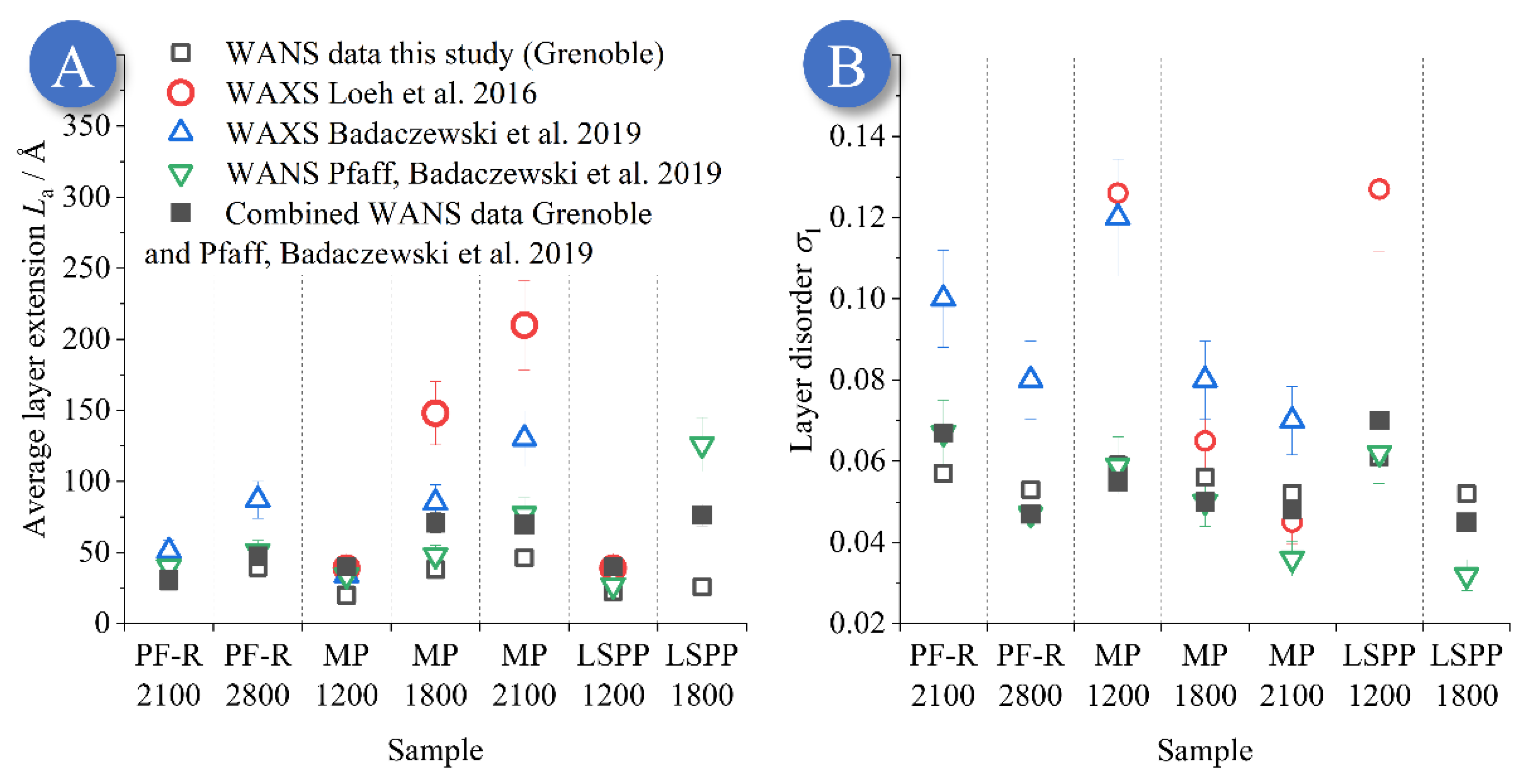

3.3. NGCs from Mesophase (MP) and Low Softening-Point Pitch (LSPP)

Comparison to Previous WANS and WAXS Studies

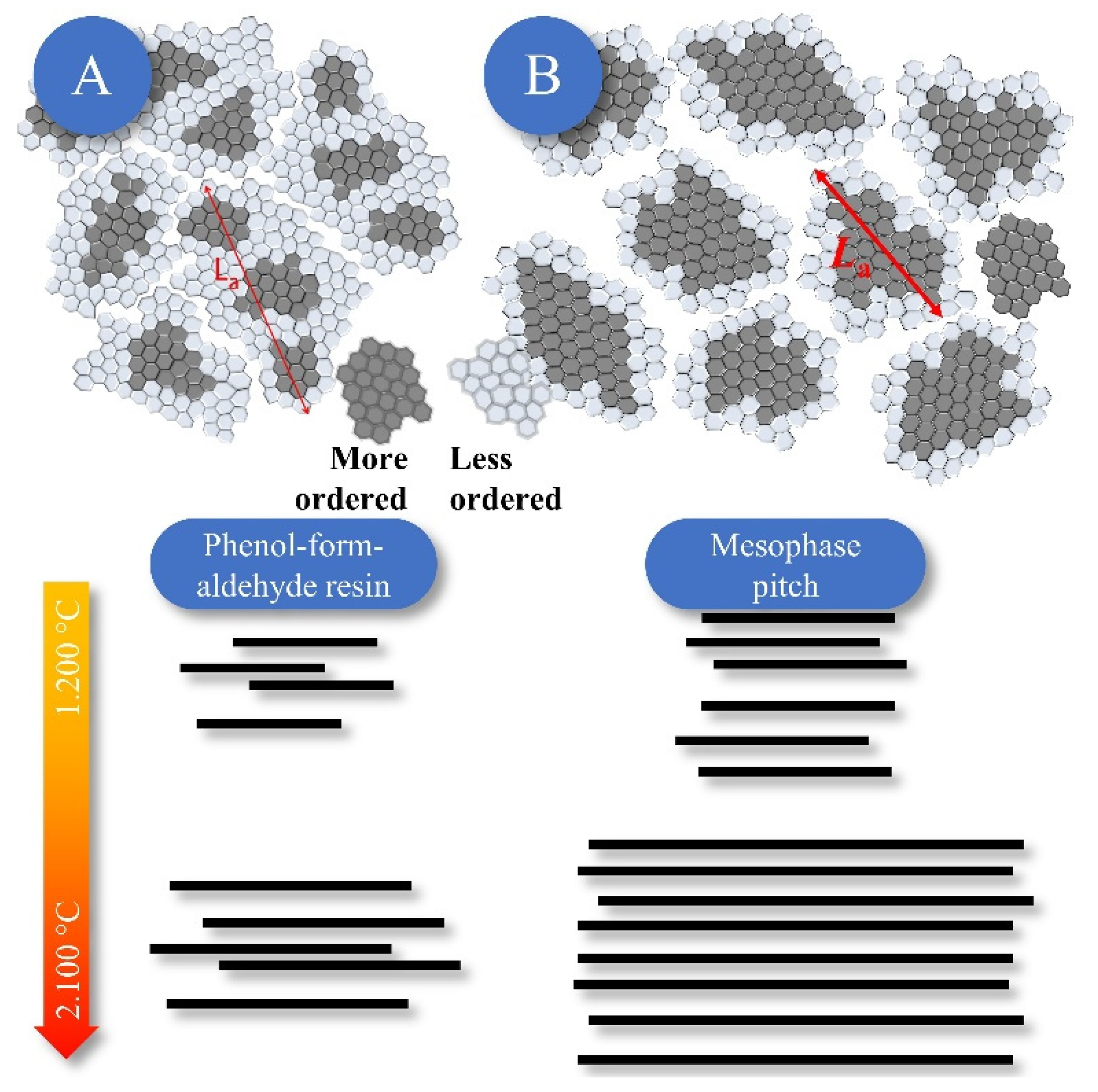

3.4. Structural Differences between the Resin and the Pitches

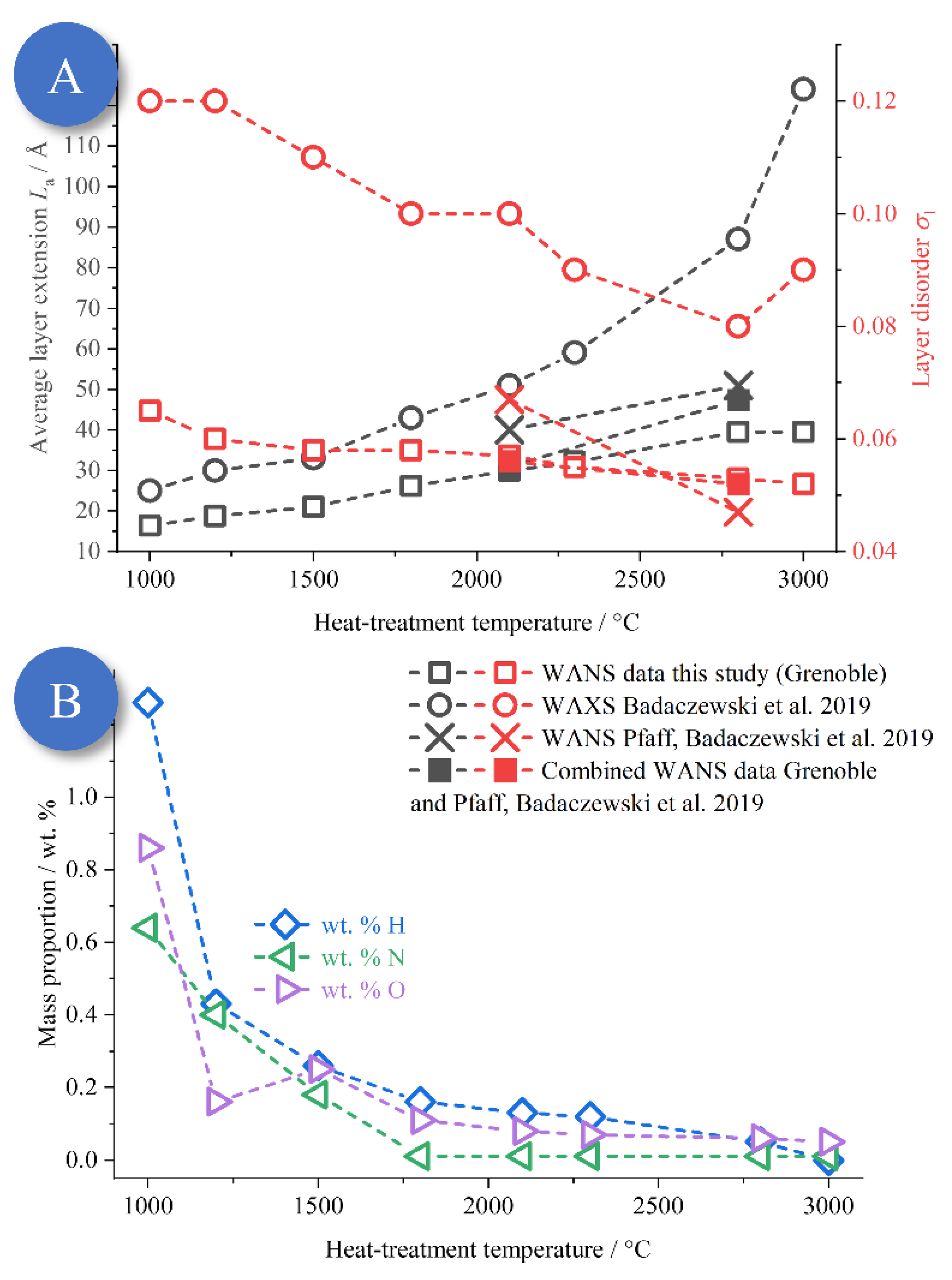

3.5. Comparison of Structural and Chemical Analysis

- The stack height, stack disorder and the layer extension/disorder are strongly linked to the amount of foreign atoms, especially oxygen. Due to the very low amount of foreign atoms at this temperature, sp3-hybridized domains probably cause this disorder.

- A detailed comparison of composition and disorder, as described by the parameter σ1, is only meaningful using valid microstructural data, which could not be obtained in previous studies, except for by using the high-quality WANS data in this study.

- Oxygen or oxygen-containing functional groups are located on the edges as well as on the lower/upper side of the graphene layers; otherwise, either the layers or the stacks would have to grow faster at high temperatures, especially for the PF-R carbon.

- Oxygen is believed to often be removed as water or other functional groups that contain hydrogen. While hydrogen is still required at the edges of the graphene layers to saturate the free electrons, the hydrogen content nonetheless decreases significantly. Therefore, oxygen and hydrogen are believed to be removed together. Similar trends for lower heat treatment temperatures have been shown and proven in previous studies [37,40].

- Nitrogen has no direct correlation with the stack/layer size and order. Therefore, nitrogen must be mainly built in into the graphene structure. This is possible and plausible, since nitrogen can also make sp2-hybridized structures.

- For the formation of three-dimensional ordered graphite, the amount of foreign atoms must be small, close to zero. It seems that the absence of hydrogen (or a not-detectable amount) is a good indicator.

- At very high temperatures (2500 °C and above for LSPP), it is not the foreign atoms, but the heat treatment temperature, i.e., the thermal energy, that causes the higher order of the graphite stacks.

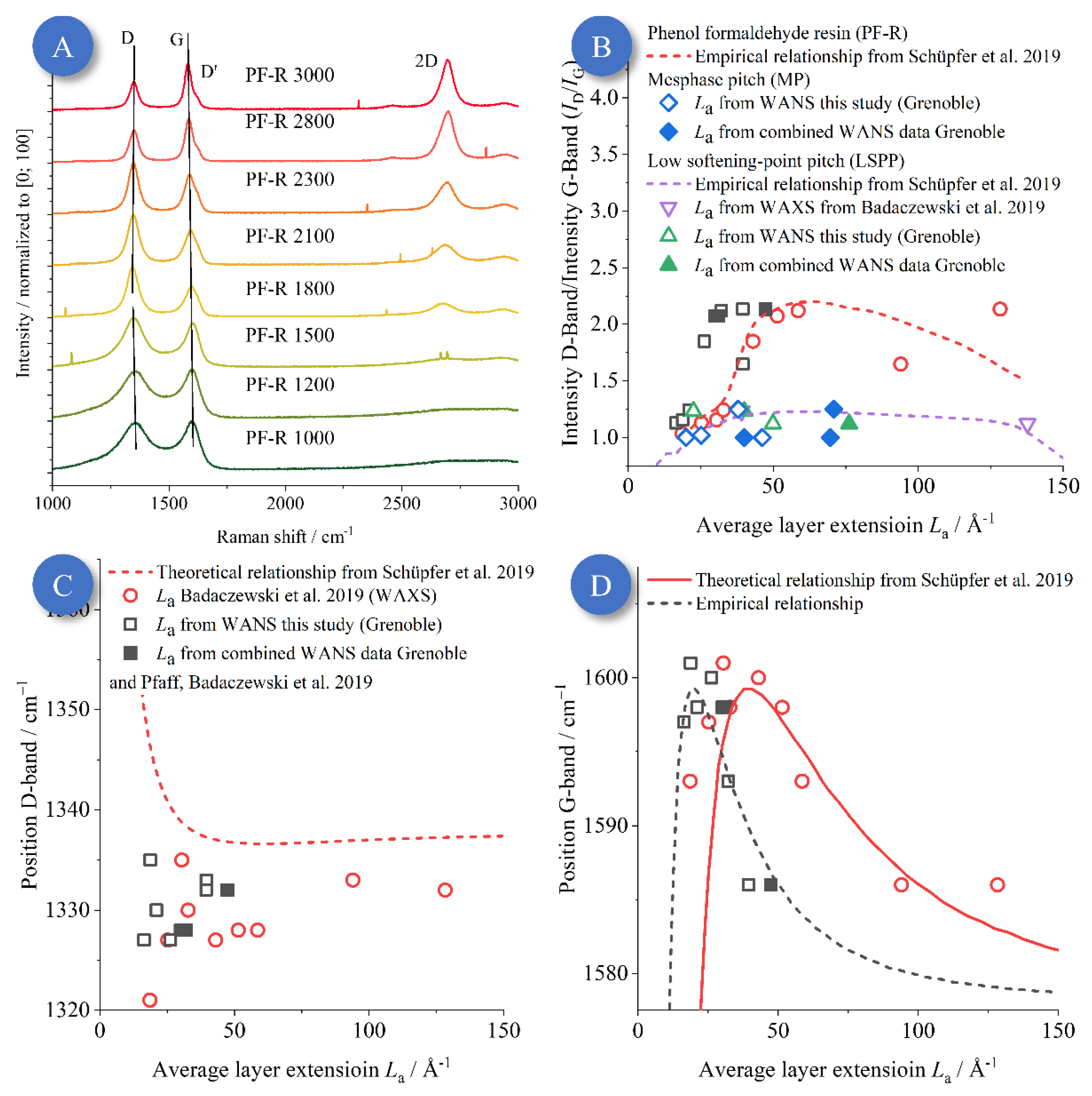

3.6. Raman Spectroscopy

4. Discussion/Outlook: Usage of Small-Wavelength-Radiation for X-ray Scattering vs. WANS

5. Conclusions

- Only WANS data with a high s-range lead to a reliable and reproducible determination of the dimension and disorder of the graphene layers. Using WAXS data or WANS data with a small s-range, e.g., using typical XRD instruments using Cu-Kα radiation, leads e.g. to unreliable intralayer parameters La and σ1.

- The refinement approach of Ruland and Smarsly [34] allows for excellent fitting of WANS data, even up to quite large s values, which enables a precise determination of the microstructural parameters describing the graphene structure.

- Raman spectroscopy studies by Schüpfer et al. [24,25] established and advanced methods for the correlation between signal width/height of the different bands and the microstructure, especially La, based on a validation with WANS/WAXS. While the present study showed that the previously determined values for La were too large, we demonstrated that the method by Schüpfer et al. is still usable to quantify the graphene structure and, in particular, to describe qualitative changes e.g., upon temperature treatment. Further theoretical work needs to be advanced in order to establish a quantitative relationship between band positions and the graphene dimension.

- As a most relevant finding, apparently “disordered” carbons (especially prepared from phenol-formaldehyde resin; PF-R) are much less disordered as previously assumed, based on the σ1 values. Concomitantly, the graphene layers in such PF-R carbon samples are smaller (on the order of a few nm at most) but are internally more highly ordered than predicted in prior studies (Figure 15) in which the layer extension and disorder were overestimated systematically. We think this insight represents a paradigmatic, fundamental advance in the view on the structure of these materials. They are by no means “amorphous”, but, on the contrary, the graphenes in NGCs possess an order close to an ideal “graphene”. This result might contribute to the understanding of graphitization in the formation of graphite in the future.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Doherty, C.M.; Caruso, R.A.; Smarsly, B.M.; Adelhelm, P.; Drummond, C.J. Hierarchically Porous Monolithic LiFePO4/Carbon Composite Electrode Materials for High Power Lithium Ion Batteries. Chem. Mater. 2009, 21, 5300–5306. [Google Scholar] [CrossRef]

- Kumar, R.; Dhakate, S.R.; Mathur, R.B. The role of ferrocene on the enhancement of the mechanical and electrochemical properties of coal tar pitch-based carbon foams. J. Mater. Sci. 2013, 48, 7071–7080. [Google Scholar] [CrossRef]

- Oberlin, A. Carbonization and graphitization. Carbon 1984, 22, 521–541. [Google Scholar] [CrossRef]

- Goel, C.; Bhunia, H.; Bajpai, P.K. Synthesis of nitrogen doped mesoporous carbons for carbon dioxide capture. RSC Adv. 2015, 5, 46568–46582. [Google Scholar] [CrossRef]

- Oschatz, M.; Borchardt, L.; Thommes, M.; Cychosz, K.A.; Senkovska, I.; Klein, N.; Frind, R.; Leistner, M.; Presser, V.; Gogotsi, Y.; et al. Carbide-derived carbon monoliths with hierarchical pore architectures. Angew. Chem. Int. Ed. Engl. 2012, 51, 7577–7580. [Google Scholar] [CrossRef]

- Oschatz, M.; Kockrick, E.; Rose, M.; Borchardt, L.; Klein, N.; Senkovska, I.; Freudenberg, T.; Korenblit, Y.; Yushin, G.; Kaskel, S. A cubic ordered, mesoporous carbide-derived carbon for gas and energy storage applications. Carbon 2010, 48, 3987–3992. [Google Scholar] [CrossRef]

- Silvestre-Albero, A.; Rico-Francés, S.; Rodríguez-Reinoso, F.; Kern, A.M.; Klumpp, M.; Etzold, B.J.; Silvestre-Albero, J. High selectivity of TiC-CDC for CO2/N2 separation. Carbon 2013, 59, 221–228. [Google Scholar] [CrossRef]

- Li, J.; Lu, R.; Dou, B.; Ma, C.; Hu, Q.; Liang, Y.; Wu, F.; Qiao, S.; Hao, Z. Porous graphitized carbon for adsorptive removal of benzene and the electrothermal regeneration. Environ. Sci. Technol. 2012, 46, 12648–12654. [Google Scholar] [CrossRef]

- Manthiram, A.; Fu, Y.; Chung, S.-H.; Zu, C.; Su, Y.-S. Rechargeable lithium-sulfur batteries. Chem. Rev. 2014, 114, 11751–11787. [Google Scholar] [CrossRef]

- Dash, R.; Chmiola, J.; Yushin, G.; Gogotsi, Y.; Laudisio, G.; Singer, J.; Fischer, J.; Kucheyev, S. Titanium carbide derived nanoporous carbon for energy-related applications. Carbon 2006, 44, 2489–2497. [Google Scholar] [CrossRef]

- Inagaki, M.; Konno, H.; Tanaike, O. Carbon materials for electrochemical capacitors. J. Power Sources 2010, 195, 7880–7903. [Google Scholar] [CrossRef]

- Oschatz, M.; Borchardt, L.; Pinkert, K.; Thieme, S.; Lohe, M.R.; Hoffmann, C.; Benusch, M.; Wisser, F.M.; Ziegler, C.; Giebeler, L.; et al. Hierarchical Carbide-Derived Carbon Foams with Advanced Mesostructure as a Versatile Electrochemical Energy-Storage Material. Adv. Energy Mater. 2014, 4, 1300645. [Google Scholar] [CrossRef]

- Wang, J.; Sugita, S.; Nagayama, K.; Matsumoto, T. OS18-3 Spatiotemporal Dynamics of Actin during Adhesion Process of MC3T3-E1 Cells to Substrate (Cell and Tissue mechanics 1,OS18 Cell and tissue mechanics, BIOMECHANICS). ATEM 2015, 2015, 237. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Guo, X.-F.; Kim, G.-J. Synthesis of carbon monolith with bimodal meso/macroscopic pore structure and its application in asymmetric catalysis. Catal. Today 2010, 150, 91–99. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, L.; Zhou, S.; Zhao, D.; Wu, L. Facile Synthesis of Hierarchically Ordered Porous Carbon via in Situ Self-Assembly of Colloidal Polymer and Silica Spheres and Its Use as a Catalyst Support. Chem. Mater. 2010, 22, 3433–3440. [Google Scholar] [CrossRef]

- Perret, R.; Ruland, W. X-ray small-angle scattering of glassy carbon. J. Appl. Crystallogr. 1972, 5, 183–187. [Google Scholar] [CrossRef]

- Tzeng, S.-S.; Chr, Y.-G. Evolution of microstructure and properties of phenolic resin-based carbon/carbon composites during pyrolysis. Mater. Chem. Phys. 2002, 73, 162–169. [Google Scholar] [CrossRef]

- Warren, B.E. X-ray Diffraction in Random Layer Lattices. Phys. Rev. 1941, 59, 693–698. [Google Scholar] [CrossRef]

- Fitzer, E.; Kochling, K.-H.; Boehm, H.P.; Marsh, H. Recommended terminology for the description of carbon as a solid (IUPAC Recommendations 1995). Pure Appl. Chem. 1995, 67, 473–506. [Google Scholar] [CrossRef]

- Faber, K.; Badaczewski, F.; Oschatz, M.; Mondin, G.; Nickel, W.; Kaskel, S.; Smarsly, B.M. In-Depth Investigation of the Carbon Microstructure of Silicon Carbide-Derived Carbons by Wide-Angle X-ray Scattering. J. Phys. Chem. C 2014, 118, 15705–15715. [Google Scholar] [CrossRef]

- Osswald, O.; Smarsly, B.M. OctCarb—A GNU Octave Script for the Analysis and Evaluation of Wide-Angle Scattering Data of Non-Graphitic Carbons. C 2022, 8, 78. [Google Scholar] [CrossRef]

- Sharma, A.; Kyotani, T.; Tomita, A. Comparison of structural parameters of PF carbon from XRD and HRTEM techniques. Carbon 2000, 38, 1977–1984. [Google Scholar] [CrossRef]

- Kovalevski, V.; Buseck, P.R.; Cowley, J. Comparison of carbon in shungite rocks to other natural carbons: An X-ray and TEM study. Carbon 2001, 39, 243–256. [Google Scholar] [CrossRef]

- Schüpfer, D.B.; Badaczewski, F.; Peilstöcker, J.; Guerra-Castro, J.M.; Shim, H.; Firoozabadi, S.; Beyer, A.; Volz, K.; Presser, V.; Heiliger, C.; et al. Monitoring the thermally induced transition from sp3-hybridized into sp2-hybridized carbons. Carbon 2021, 172, 214–227. [Google Scholar] [CrossRef]

- Schüpfer, D.B.; Badaczewski, F.; Guerra-Castro, J.M.; Hofmann, D.M.; Heiliger, C.; Smarsly, B.M.; Klar, P.J. Assessing the structural properties of graphitic and non-graphitic carbons by Raman spectroscopy. Carbon 2020, 161, 359–372. [Google Scholar] [CrossRef]

- Zickler, G.A.; Smarsly, B.M.; Gierlinger, N.; Peterlik, H.; Paris, O. A reconsideration of the relationship between the crystallite size La of carbons determined by X-ray diffraction and Raman spectroscopy. Carbon 2006, 44, 3239–3246. [Google Scholar] [CrossRef]

- Biscoe, J.; Warren, B.E. An X-ray Study of Carbon Black. J. Appl. Phys. 1942, 13, 364–371. [Google Scholar] [CrossRef]

- Diamond, R. X-ray studies of some carbonized coals. Phil. Trans. R. Soc. Lond. A 1960, 252, 193–223. [Google Scholar] [CrossRef]

- Houska, C.R.; Warren, B.E. X-ray Study of the Graphitization of Carbon Black. J. Appl. Phys. 1954, 25, 1503–1509. [Google Scholar] [CrossRef]

- Warren, B.E.; Bodenstein, P. The diffraction pattern of fine particle carbon blacks. Acta Cryst. 1965, 18, 282–286. [Google Scholar] [CrossRef]

- Shi, H.; Reimers, J.N.; Dahn, J.R. Structure-refinement program for disordered carbons. J. Appl. Crystallogr. 1993, 26, 827–836. [Google Scholar] [CrossRef]

- Azuma, H. A New Structural Model for Nongraphitic Carbons. J. Appl. Crystallogr. 1998, 31, 910–916. [Google Scholar] [CrossRef]

- Fujimoto, H.; Shiraishi, M. Characterization of unordered carbon using Warren–Bodenstein’s equation. Carbon 2001, 39, 1753–1761. [Google Scholar] [CrossRef]

- Ruland, W.; Smarsly, B.M. X-ray scattering of non-graphitic carbon: An improved method of evaluation. J. Appl. Crystallogr. 2002, 35, 624–633. [Google Scholar] [CrossRef]

- Krüner, B.; Schreiber, A.; Tolosa, A.; Quade, A.; Badaczewski, F.; Pfaff, T.; Smarsly, B.M.; Presser, V. Nitrogen-containing novolac-derived carbon beads as electrode material for supercapacitors. Carbon 2018, 132, 220–231. [Google Scholar] [CrossRef]

- Wang, H.; Delacroix, S.; Osswald, O.; Anderson, M.; Heil, T.; Lepre, E.; Lopez-Salas, N.; Kaner, R.B.; Smarsly, B.M.; Strauss, V. Laser-carbonization: Peering into the formation of micro-thermally produced (N-doped) carbons. Carbon 2021, 176, 500–510. [Google Scholar] [CrossRef]

- Badaczewski, F.; Loeh, M.O.; Pfaff, T.; Dobrotka, S.; Wallacher, D.; Clemens, D.; Metz, J.; Smarsly, B.M. Peering into the structural evolution of glass-like carbons derived from phenolic resin by combining small-angle neutron scattering with an advanced evaluation method for wide-angle X-ray scattering. Carbon 2019, 141, 169–181. [Google Scholar] [CrossRef]

- Badaczewski, F.M.; Loeh, M.O.; Pfaff, T.; Wallacher, D.; Clemens, D.; Smarsly, B.M. An advanced structural characterization of templated meso-macroporous carbon monoliths by small- and wide-angle scattering techniques. Beilstein J. Nanotechnol. 2020, 11, 310–322. [Google Scholar] [CrossRef]

- Faber, K.; Badaczewski, F.; Ruland, W.; Smarsly, B.M. Investigation of the Microstructure of Disordered, Non-graphitic Carbons by an Advanced Analysis Method for Wide-Angle X-ray Scattering. Z. Anorg. Allg. Chem. 2014, 640, 3107–3117. [Google Scholar] [CrossRef]

- Loeh, M.O.; Badaczewski, F.; Faber, K.; Hintner, S.; Bertino, M.F.; Mueller, P.; Metz, J.; Smarsly, B.M. Analysis of thermally induced changes in the structure of coal tar pitches by an advanced evaluation method of X-ray scattering data. Carbon 2016, 109, 823–835. [Google Scholar] [CrossRef]

- Loeh, M.O.; Badaczewski, F.; von der Lehr, M.; Ellinghaus, R.; Dobrotka, S.; Metz, J.; Smarsly, B.M. Hard-templating of carbon using porous SiO2 monoliths revisited—Quantitative impact of spatial confinement on the microstructure evolution. Carbon 2018, 129, 552–563. [Google Scholar] [CrossRef]

- Pfaff, T.; Simmermacher, M.; Smarsly, B.M. CarbX: A program for the evaluation of wide-angle X-ray scattering data of non-graphitic carbons. J. Appl. Crystallogr. 2018, 51, 219–229. [Google Scholar] [CrossRef]

- Pfaff, T.; Badaczewski, F.M.; Loeh, M.O.; Franz, A.; Hoffmann, J.-U.; Reehuis, M.; Zeier, W.G.; Smarsly, B.M. Comparative Microstructural Analysis of Nongraphitic Carbons by Wide-Angle X-ray and Neutron Scattering. J. Phys. Chem. C 2019, 123, 20532–20546. [Google Scholar] [CrossRef]

- Hoffmann, J.-U.; Reehuis, M. E2: The Flat-Cone Diffractometer at BER II. JLSRF 2018, 4, A129. [Google Scholar] [CrossRef]

- Smarsly, B.M.; Badaczewski, F.; Fischer, H.E.; Loeh, M.; Osswald, O.; Pfaff, T. Analysis of the Wide-Angle Neutron Scattering of Non-Graphitic Carbon—Testing of an Advanced Evaluation Approach; Institut Laue-Langevin (ILL): Grenoble, France, 2019. [Google Scholar] [CrossRef]

- Fischer, H.E.; Cuello, G.J.; Palleau, P.; Feltin, D.; Barnes, A.C.; Badyal, Y.S.; Simonson, J.M. D4c: A very high precision diffractometer for disordered materials. Appl. Phys. A Mater. Sci. Process. 2002, 74, s160–s162. [Google Scholar] [CrossRef]

- Fischer, H.E.; Barnes, A.C.; Salmon, P.S. Neutron and x-ray diffraction studies of liquids and glasses. Rep. Prog. Phys. 2006, 69, 233–299. [Google Scholar] [CrossRef]

- Placzek, G. The Scattering of Neutrons by Systems of Heavy Nuclei. Phys. Rev. 1952, 86, 377–388. [Google Scholar] [CrossRef]

- Masson, O.; Thomas, P. Exact and explicit expression of the atomic pair distribution function as obtained from X-ray total scattering experiments. J. Appl. Crystallogr. 2013, 46, 461–465. [Google Scholar] [CrossRef]

- Olds, D.P.; Duxbury, P.M. Efficient algorithms for calculating small-angle scattering from large model structures. J. Appl. Crystallogr. 2014, 47, 1077–1086. [Google Scholar] [CrossRef]

- Peterson, P.F.; Božin, E.S.; Proffen, T.; Billinge, S.J.L. Improved measures of quality for the atomic pair distribution function. J. Appl. Crystallogr. 2003, 36, 53–64. [Google Scholar] [CrossRef]

- Weisbecker, P.; Leyssale, J.-M.; Fischer, H.E.; Honkimäki, V.; Lalanne, M.; Vignoles, G.L. Microstructure of pyrocarbons from pair distribution function analysis using neutron diffraction. Carbon 2012, 50, 1563–1573. [Google Scholar] [CrossRef]

- Willinger, E. Analysis of Local Structure by Atomic Pair Distribution Function; Department of Inorganic Chemistry, Fritz Haber Institute: Berlin, Germany, 2017. [Google Scholar]

- Scherrer, P. Bestimmung der inneren Struktur und der Größe von Kolloidteilchen mittels Röntgenstrahlen. In Kolloidchemie Ein Lehrbuch; Zsigmondy, R., Ed.; Springer: Berlin/Heidelberg, Germany, 1912; pp. 387–409. ISBN 978-3-662-33517-8. [Google Scholar]

- Stephens, P.W. International Tables for Crystallography 8v Set 4e (Updated Sept 2014); John Wiley & Sons Inc.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Putman, K.J.; Rowles, M.R.; Marks, N.A.; Suarez-Martinez, I. The role of the 2D-to-3D transition in X-ray diffraction analysis of crystallite size. J. Phys. Condens. Matter 2021, 33, 294002. [Google Scholar] [CrossRef] [PubMed]

- Bragg, W.H.; Bragg, W.L. The reflection of X-rays by crystals. Proc. R. Soc. Lond. A 1913, 88, 428–438. [Google Scholar] [CrossRef]

- Strunz, H.; Nickel, E.H. Strunz Mineralogical Tables: Chemical-Structural Mineral Classification System, 9th ed.; E. Schweizerbart’sche Verlagsbuchhandlung: Stuttgart, Germany, 2001; ISBN 351065188X. [Google Scholar]

- Holleman, A.F.; Wiberg, N. Anorganische Chemie, Aufl. 103; De Gruyter: Berlin, Germany, 2016; ISBN 9783110269321. [Google Scholar]

- Ferrari, A.C.; Basko, D.M. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat. Nanotechnol. 2013, 8, 235–246. [Google Scholar] [CrossRef] [PubMed]

- Jorio, A.; Dresselhaus, M.S.; Saito, R.; Dresselhaus, G. Raman Spectroscopy in Graphene Related Systems; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 9783527643905. [Google Scholar]

- Tuinstra, F.; Koenig, J.L. Raman Spectrum of Graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Vinado, R.; Fischbach, D.B. New Lines in the Raman Spectra of Carbons and Graphite. J. Am. Ceram. Soc. 1978, 61, 13–17. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cançado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1291. [Google Scholar] [CrossRef]

- Campbell, I.H.; Fauchet, P.M. The effects of microcrystal size and shape on the one phonon Raman spectra of crystalline semiconductors. Solid State Commun. 1986, 58, 739–741. [Google Scholar] [CrossRef]

- Fauchet, P.M.; Campbell, I.H. Raman spectroscopy of low-dimensional semiconductors. Crit. Rev. Solid State Mater. Sci. 1988, 14, s79–s101. [Google Scholar] [CrossRef]

| Heat Treatment Temperature | Long Name | Short Name | WANS This Study | WAXS Ref. [40] | WAXS Ref. [37] | WANS Ref. [43] |

|---|---|---|---|---|---|---|

| Phenol-formaldehyde resin (PF-R) | ||||||

| 1000 °C | PF-R 1000 | H 1000 | X | - | X | - |

| 1200 °C | PF-R 1200 | H 1200 | X | - | X | - |

| 1500 °C | PF-R 1500 | H 1500 | X | - | X | - |

| 1800 °C | PF-R 1800 | H 1800 | X | - | X | - |

| 2100 °C | PF-R 2100 | H 2100 | X | - | X | X |

| 2300 °C | PF-R 2300 | H 1300 | X | - | X | - |

| 2800 °C | PF-R 2800 | H 2800 | X | - | X | X |

| 3000 °C | PF-R 3000 | H 3000 | X | - | X | - |

| Mesophase pitch (MP) | ||||||

| 1200 °C | MP 1200 | MP 1200 | X | X | X | X |

| 1500 °C | MP 1500 | MP 1500 | X | X | X | - |

| 1800 °C | MP 1800 | MP 1800 | X | X | X | X |

| 2100 °C | MP 2100 | MP 2100 | X | X | X | X |

| Low softening-point pitch (LSPP) | ||||||

| 1200 °C | LSPP 1200 | WP 1200 | X | X | - | X |

| 1800 °C | LSPP 1800 | WP 1800 | X | - | - | X |

| 2500 °C | LSPP 2500 | WP 2500 | X | - | - | X |

| 2800 °C | LSPP 2800 | WP 2800 | X | - | - | X |

| 3000 °C | LSPP 3000 | WP 3000 | X | - | X | X |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osswald, O.; Loeh, M.O.; Badaczewski, F.M.; Pfaff, T.; Fischer, H.E.; Franz, A.; Hoffmann, J.-U.; Reehuis, M.; Klar, P.J.; Smarsly, B.M. On the Highly Ordered Graphene Structure of Non-Graphitic Carbons (NGCs)—A Wide-Angle Neutron Scattering (WANS) Study. C 2023, 9, 27. https://doi.org/10.3390/c9010027

Osswald O, Loeh MO, Badaczewski FM, Pfaff T, Fischer HE, Franz A, Hoffmann J-U, Reehuis M, Klar PJ, Smarsly BM. On the Highly Ordered Graphene Structure of Non-Graphitic Carbons (NGCs)—A Wide-Angle Neutron Scattering (WANS) Study. C. 2023; 9(1):27. https://doi.org/10.3390/c9010027

Chicago/Turabian StyleOsswald, Oliver, Marc O. Loeh, Felix M. Badaczewski, Torben Pfaff, Henry E. Fischer, Alexandra Franz, Jens-Uwe Hoffmann, Manfred Reehuis, Peter J. Klar, and Bernd M. Smarsly. 2023. "On the Highly Ordered Graphene Structure of Non-Graphitic Carbons (NGCs)—A Wide-Angle Neutron Scattering (WANS) Study" C 9, no. 1: 27. https://doi.org/10.3390/c9010027

APA StyleOsswald, O., Loeh, M. O., Badaczewski, F. M., Pfaff, T., Fischer, H. E., Franz, A., Hoffmann, J.-U., Reehuis, M., Klar, P. J., & Smarsly, B. M. (2023). On the Highly Ordered Graphene Structure of Non-Graphitic Carbons (NGCs)—A Wide-Angle Neutron Scattering (WANS) Study. C, 9(1), 27. https://doi.org/10.3390/c9010027