Implementing Open Innovation Using Quality Management Systems: The Role of Organizational Commitment and Customer Loyalty

Abstract

1. Introduction

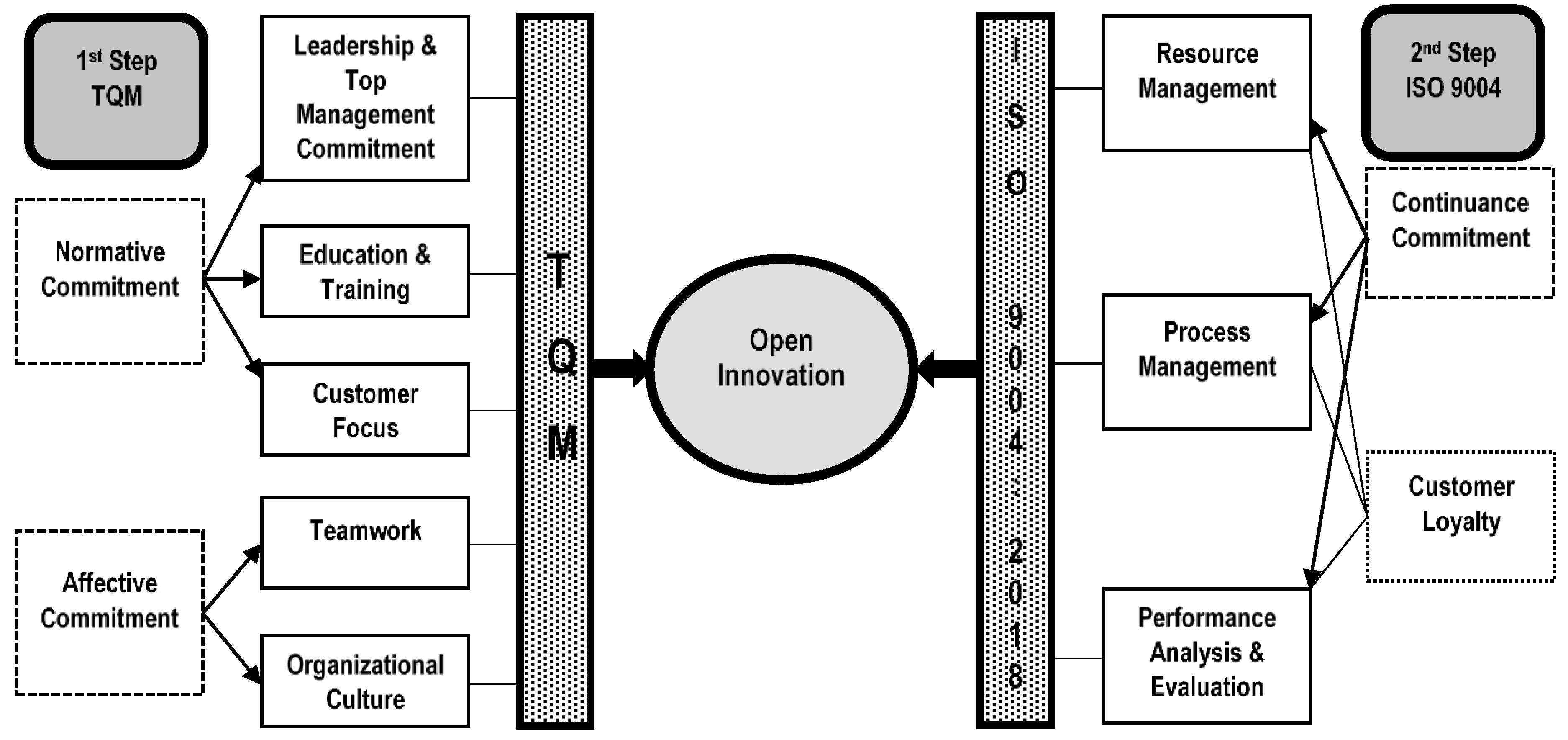

2. Supporting Open Innovation through Quality Management Systems

2.1. Total Quality Management for Open Innovation

2.2. ISO 9004:2018 for Open Innovation

3. Leaders’ and Employees’ Commitment in the TQM

4. Employee Commitment and Customer Loyalty in the ISO 9004:2018

5. Case Study

- quality management could significantly improve the organizational performance;

- corporate R&D activity has declined over the last three years and IT support services have begun to replace it, and this has not been in line with the strategic ideas.

- they achieved a higher level of job atmosphere and satisfaction among the employees and a significant reduction in absenteeism;

- employees’ own efforts to train and develop themselves became a real value in the organization, which was also supported by organizational tools.

- in terms of Resource Management, customers were considered as important a resource as were the employees, as required by the standard;

- according to the Process Management requirements, the organizational process management already not only coordinated and streamlined the internal organizational processes, but also was able to organize these with relevant external processes on the customer and supplier side;

- in line with the requirements of Performance Analysis and Evaluation, they developed an incentive system that aimed to increase customer loyalty, which is an essential element for open innovation, and rewarded employees with both premiums and opportunities to advance.

6. Discussion

- Applying quality management systems helps to create open innovation by enabling organizations to make the customers (and other external stakeholders) be real collaborators through cultural change and quality management.

- An effective—but not exclusive—solution to open innovation is to implement TQM first, and then, once its values have been consolidated, to implement the ISO 9004:2018.

- Most quality management systems rely heavily on employees’ commitment. TQM can support open innovation by targeted enhancement of affective and normative commitment, and the ISO 9004:2018 can also support open innovation by targeted enhancement of continuance commitment and customer loyalty.

- There are interdependences between customer loyalty and process management; resource management; and the performance analysis and evolution, meaning that these elements of the ISO 9004:2018 individually strengthen the customer focus, and stronger customer focus helps to develop these functional areas.

Funding

Conflicts of Interest

References

- Chesbrough, H. Open Innovation: Where We’ve Been and We’re Going. Res. Technol. Manag. 2012, 55, 20–27. [Google Scholar] [CrossRef]

- Salge, T.O.; Bohné, T.M.; Farchi, T.; Piening, E.P. Harnessing the value of open innovation: The moderating role of innovation management. Int. J. Innov. Manag. 2012, 16, 1–26. [Google Scholar] [CrossRef]

- Dahlander, L.; Gann, D.M. How open is innovation? Res. Policy 2010, 39, 699–709. [Google Scholar] [CrossRef]

- Gassmann, O.; Enkel, E.; Chesbrough, H. The future of open innovation. R D Manag. 2010, 40, 213–221. [Google Scholar] [CrossRef]

- Yusr, M.M. Innovation capability and its role in enhancing the relationship between TQM practices and innovation performance. J. Open Innov. Technol. Mark. Complex. 2016, 2, 1–15. [Google Scholar] [CrossRef]

- Hernandez-Vivanco, A.; Bernardo, M.; Cruz-Cázares, C. Relating open innovation, innovation and management systems integration. Ind. Manag. Data Syst. 2016, 116, 1540–1556. [Google Scholar] [CrossRef][Green Version]

- Shi, Y.; Lin, W.; Chen, P.-K.; Su, C.-H. How can the ISO 9000 QMS improve the organizational innovation of supply chains? Int. J. Innov. Sci. 2019, 11, 278–298. [Google Scholar] [CrossRef]

- Seetharaman, A.; Sreenivasan, J.; Boon, L.P. Critical Success Factors of Total Quality Management. Qual. Quant. 2006, 40, 675–695. [Google Scholar] [CrossRef]

- van de Vrande, V.; de Jong, J.P.J.; Vanhaverbeke, W.; de Rochemont, M. Open innovation in SMEs: Trends, motives and management challenges. Technovation 2009, 29, 423–437. [Google Scholar] [CrossRef]

- West, J.; Gallagher, S. Challenges of open innovation: The paradox of firm investment in open-source software. R D Manag. 2006, 36, 319–331. [Google Scholar] [CrossRef]

- Chesbrough, H. Bringing Open Innovation to Services. MIT Sloan Manag. Rev. 2011, 52, 84–91. [Google Scholar]

- Hellsten, U.; Klefsjö, B. TQM as a management system consisting of values, techniques and tools. TQM Mag. 2000, 12, 238–244. [Google Scholar] [CrossRef]

- Maistry, K.; Hurreeram, D.K.; Ramessur, V. Total quality management and innovation: Relationships and effects on performance of agricultural R&D organisations. Int. J. Qual. Reliab. Manag. 2017, 34, 418–437. [Google Scholar]

- Dahlgaard, J.J.; Dahlgaard-Park, S.M. Lean production, six sigma quality, TQM and company culture. TQM Mag. 2006, 18, 263–281. [Google Scholar] [CrossRef]

- Lorente, A.M.R.; Dewhurst, F.; Dale, B.G. TQM and business innovation. Eur. J. Innov. Manag. 1999, 2, 12–19. [Google Scholar] [CrossRef]

- Singh, P.J.; Smith, A.J.R. Relationship between TQM and innovation: An empirical study. J. Manuf. Technol. M. 2004, 15, 394–401. [Google Scholar] [CrossRef]

- ISO—International Organization for Standardization. ISO 9004: 2018. Guidance to Achieve Sustained Success. 2018. Available online: https://www.iso.org/standard/70397.html (accessed on 19 August 2019).

- Boys, K.A.; Wilcock, A.E. Improving integration of human resources into quality management system standards. Int. J. Qual. Reliab. Manag. 2014, 31, 738–750. [Google Scholar] [CrossRef]

- Arunachalam, T.; Palachinamy, Y. Does the soft aspects of TQM influence job satisfaction and commitment? An empirical analysis. TQM J. 2017, 29, 385–402. [Google Scholar] [CrossRef]

- Boys, K.; Karapetrovic, S.; Wilcock, A. Is ISO 9004 a path to business excellence? Opinion of Canadian standards experts. Int. J. Qual. Reliab. Manag. 2004, 21, 841–860. [Google Scholar] [CrossRef]

- ISO—International Organization for Standardization. ISO 9000: 2005. Fundamentals and Vocabulary. 2005. Available online: https://www.iso.org/standard/42180.html (accessed on 19 August 2019).

- ISO—International Organization for Standardization. ISO 9000: 2015. Fundamentals and Vocabulary. 2015. Available online: https://www.iso.org/standard/45481.html (accessed on 19 August 2019).

- ISO—International Organization for Standardization. ISO 9004: 2009. Managing for the Sustained Success of an Organization–A Quality Management Approach. 2009. Available online: https://www.iso.org/standard/41014.html (accessed on 19 August 2019).

- Amin, M.; Aldakhil, A.M.; Wu, C.; Rezaei, S.; Cobanoglu, C. The structural relationship between TQM, employee satisfaction and hotel performance. Int. J. Contemp. Hosp. Manag. 2017, 29, 1256–1278. [Google Scholar] [CrossRef]

- Prajogo, D.I.; Cooper, B. The individual and organizational level effects of TQM practices on job satisfaction. Int. J. Manpower 2017, 38, 215–225. [Google Scholar] [CrossRef]

- Harari, O. Three very difficult steps to total quality. Manag. Rev. 1993, 82, 39–42. [Google Scholar]

- Longenecker, C.O.; Scazzero, J.A. The ongoing challenge of total quality management. TQM Mag. 1996, 8, 55–60. [Google Scholar] [CrossRef]

- Allen, N.J.; Meyer, J.P. The measurement and antecedents of affective, continuance, and normative commitment to the organization. J. Occup. Psychol. 1990, 63, 1–18. [Google Scholar] [CrossRef]

- Mercurio, Z.A. Affective Commitment as a Core Essence of Organizational Commitment: An Integrative Literature Review. Hum. Resour. Dev. Rev. 2015, 14, 389–414. [Google Scholar] [CrossRef]

- Hackett, R.D.; Bycio, P.; Hausdorf, P.A. Further Assessments of Meyer and Allen’s (1991) Three-Component Model of Organizational Commitment. J. Appl. Psychol. 1994, 79, 15–23. [Google Scholar] [CrossRef]

- Solinger, O.N.; van Olffen, W.; Roe, R.A. Beyond the Three-Component Model of Organizational Commitment. J. Appl. Psychol. 2008, 93, 70–83. [Google Scholar] [CrossRef]

- Wasti, S.A. Commitment profiles: Combinations of organizational commitment forms and job outcomes. J. Vocat. Behav. 2005, 67, 290–308. [Google Scholar] [CrossRef]

- Vandenberghe, C.; Bentein, K.; Stinglhamber, F. Affective commitment to the organization, supervisor, and work group: Antecedents and outcomes. J. Vocat. Behav. 2004, 64, 47–71. [Google Scholar] [CrossRef]

- Carmeli, A. Perceived External Prestige, Affective Commitment, and Citizenship Behaviors. Organ. Stud. 2005, 26, 443–464. [Google Scholar] [CrossRef]

- Meyer, J.P.; Paunonen, S.V.; Gellatly, I.R.; Goffin, R.D.; Jackson, D.N. Organizational Commitment and Job Performance: It’s the Nature of the Commitment That Counts. J. Appl. Psychol. 1989, 74, 152–156. [Google Scholar] [CrossRef]

- Suliman, A.; Iles, P. Is continuance commitment beneficial to organizations? Commitment-performance relationship: A new look. J. Man. Psychol. 2000, 15, 407–422. [Google Scholar] [CrossRef]

- Ooi, K.-B.; Arumugam, V.; Teh, P.-L.; Chong, A.Y.-L. TQM practices and its association with production workers. Ind. Manag. Data Syst. 2008, 108, 909–927. [Google Scholar] [CrossRef]

- González, T.F.; Guillén, M. Leadership ethical dimension: A requirement in TQM implementation. TQM Mag. 2002, 14, 150–164. [Google Scholar] [CrossRef]

- Telleria, K.M.; Little, D.; MacBryde, J. Managing processes through teamwork. Bus. Proc. Man. J. 2002, 8, 338–350. [Google Scholar] [CrossRef]

- Awasthi, V.N.; Chow, C.W.; Wu, A. Cross-cultural differences in the behavioral consequences of imposing performance evaluation and reward systems: An experimental investigation. Int. J. Account. 2001, 36, 291–309. [Google Scholar] [CrossRef]

| Management Principles in ISO 9000:2005 | Management Principles in ISO 9000:2015 | A Brief Evaluation of the Change |

|---|---|---|

| Customer-focus | Customer-focus | - |

| Leadership | Leadership | - |

| Involvement of people | Engagement of people | Management involvement is transformed into voluntary participation |

| Mutually-beneficial supplier relationships | Relationship management | The customers become as strategic partners as the others |

| Process approach | Process approach | - |

| System approach to management | - | The bureaucratic form of the management is reduced and the hierarchy is destroyed |

| Continual improvement | Improvement | Development and innovation can be leaps and bounds. |

| Factual approach to decision making | Evidence-based decision making | - |

| Essential Elements of ISO 9004:2009 | Essential Elements of ISO 9004:2018 | A Brief Evaluation of the Change |

|---|---|---|

| Managing for the sustained success of an organization | Identity of an organization (mission, vision, values, culture) | There are no lasting successes without consciously shaping the organizational culture |

| Strategy and policy | Leadership (strategy, policy, objectives) | Leadership principles and practices become goal-oriented |

| Resource management | Resource management | - |

| Process management | Process management | - |

| Monitoring, measurement analysis, and review | Performance analysis and evaluation | The role of the benchmarking in planning, and the analysis of the weaknesses and risks in the management system become more valuable |

| Improvement, innovation, and learning | Improvement, learning, and innovation | - |

| TQM Practices | Essential Elements of ISO 9004:2018 | The Necessary Dimension(s) of Commitment |

|---|---|---|

| Organizational Culture | Identity of an Organization (Mission, Vision, Values, Culture) | Affective Commitment (TQM) |

| Leadership and Top Management Commitment | Leadership (Strategy, Policy, Objectives) | Normative Commitment (TQM) |

| Teamwork + Customer Focus | Resource Management | Affective Commitment (TQM) +Normative Commitment (TQM) +Continuance Commitment (ISO 9004:2018) +Customer Loyalty (ISO 9004:2018) |

| Process Management | ||

| Performance Analysis and Evaluation | ||

| Education and Training | Improvement, Learning, and Innovation | Normative Commitment (TQM) |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krajcsák, Z. Implementing Open Innovation Using Quality Management Systems: The Role of Organizational Commitment and Customer Loyalty. J. Open Innov. Technol. Mark. Complex. 2019, 5, 90. https://doi.org/10.3390/joitmc5040090

Krajcsák Z. Implementing Open Innovation Using Quality Management Systems: The Role of Organizational Commitment and Customer Loyalty. Journal of Open Innovation: Technology, Market, and Complexity. 2019; 5(4):90. https://doi.org/10.3390/joitmc5040090

Chicago/Turabian StyleKrajcsák, Zoltán. 2019. "Implementing Open Innovation Using Quality Management Systems: The Role of Organizational Commitment and Customer Loyalty" Journal of Open Innovation: Technology, Market, and Complexity 5, no. 4: 90. https://doi.org/10.3390/joitmc5040090

APA StyleKrajcsák, Z. (2019). Implementing Open Innovation Using Quality Management Systems: The Role of Organizational Commitment and Customer Loyalty. Journal of Open Innovation: Technology, Market, and Complexity, 5(4), 90. https://doi.org/10.3390/joitmc5040090