Industry 4.0: A Technological-Oriented Definition Based on Bibliometric Analysis and Literature Review

Abstract

:1. Introduction

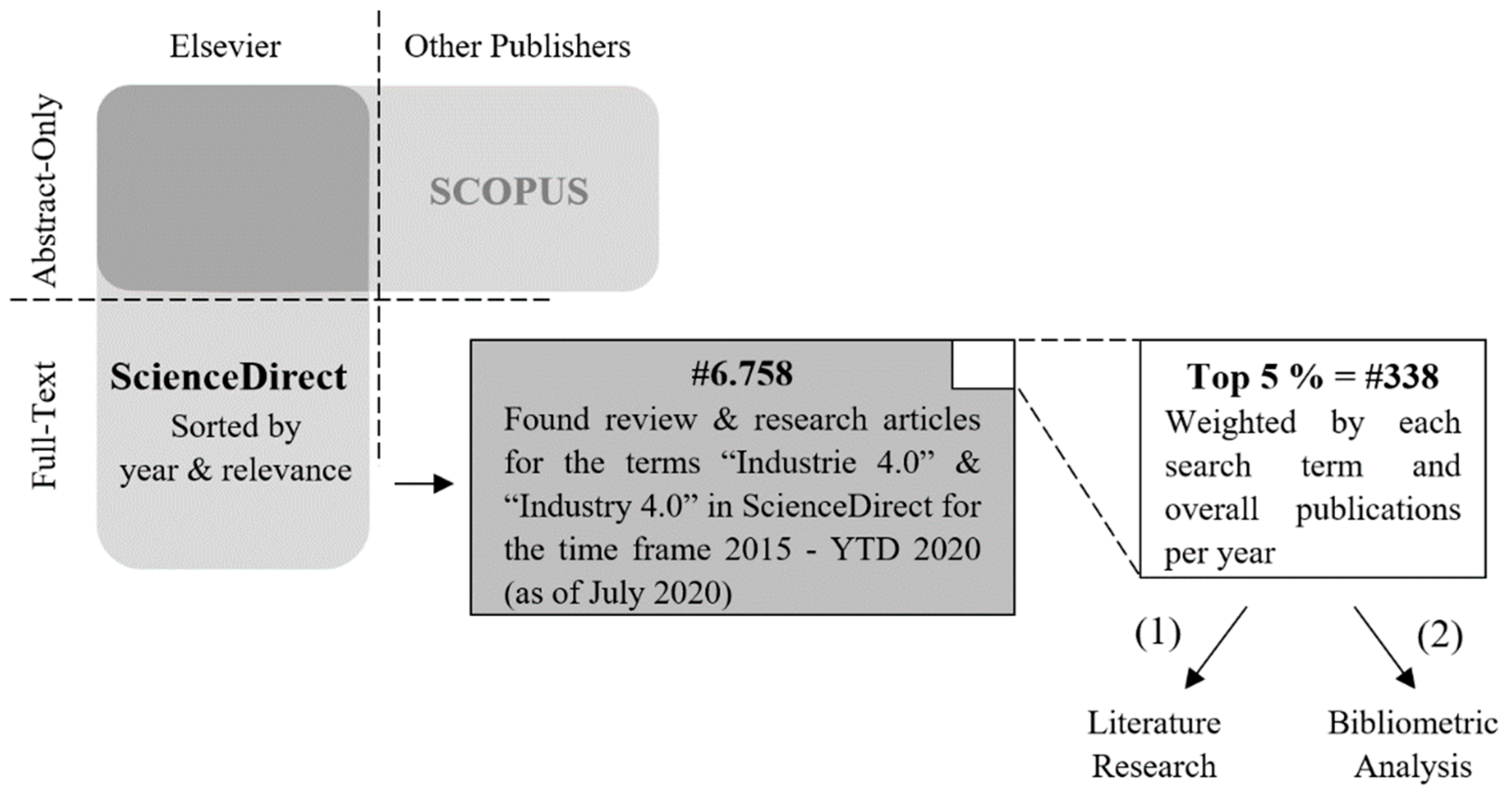

2. Material and Methods

2.1. Planning and Preparation

2.2. Data Collection

3. Structuring Industry 4.0

3.1. Organization

3.1.1. Vision, Strategy, Integration

3.1.2. Challenges

3.1.3. SMEs

3.1.4. Lean 4.0

3.2. People

3.2.1. The Human Role

3.2.2. Human-Machine Interaction

3.2.3. Learning Factories

3.3. Technology

3.3.1. Enabler of Industry 4.0

3.3.2. Key Technologies

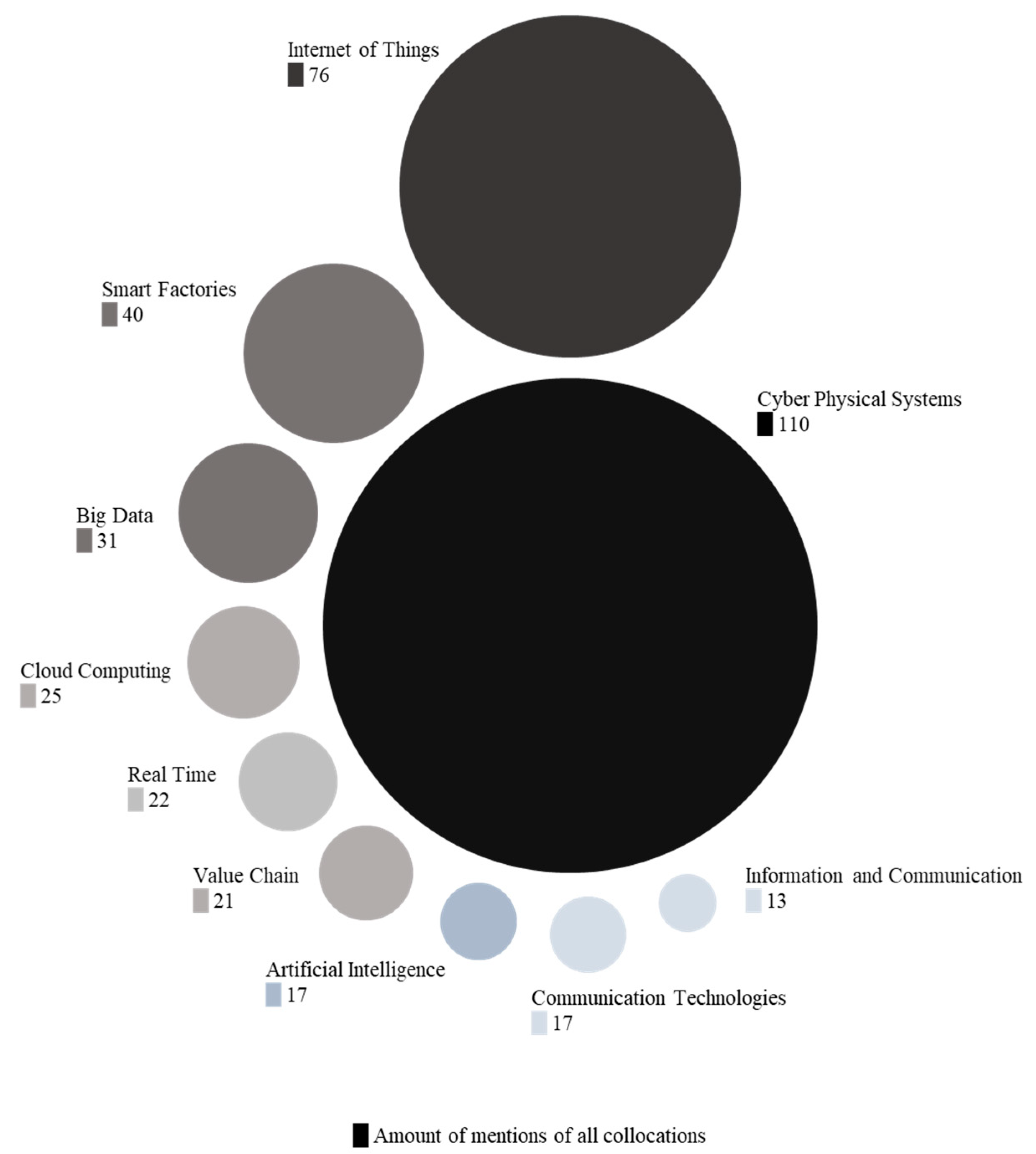

4. Results of the Bibliometric Analysis

5. Forming a New Definition

“Industry 4.0 is the implementation of Cyber Physical Systems for creating Smart Factories by using the Internet of Things, Big Data, Cloud Computing, Artificial Intelligence and Communication Technologies for Information and Communication in Real Time over the Value Chain.”

6. Discussion

7. Examples and Validation

8. Summary and Conclusions

- Many authors do not focus on a definition or description of Industry 4.0 in their publications. On the one hand, the term might be seen as implicitly understood; on the other hand, there is no clear and holistic definition available. Moreover, they describe Industry 4.0 as an umbrella term, concept or vision.

- The literature review shows the focus on key technologies and the lack of research in a worker environment. This trend was increased by the selection of the technological-oriented database. However, a trend towards compensating for these deficits is recognizable in the appearance of the journals in which the articles were published.

- The top three collocations are on Cyber Physical Systems, the Internet of Things and smart factories. This shows a very technological direction, which was to be expected due to the selected database.

- Within the methodology, the definition of Industry 4.0 is as follows: ‘Industry 4.0 could be defined as the implementation of Cyber Physical Systems for creating Smart Factories by using the Internet of Things, Big Data, Cloud Computing, Artificial Intelligence and Communication Technologies for Information and Communication in Real Time over the Value Chain.’

- The definition successfully was tested and validated on four examples from different professional areas such as construction, food, health system and supply chain management.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deppe, K. Geschichte der Arbeit-Arbeit 4.0. Arbeitsgemeinschaft der Öffentlich-Rechtlichen Rundfunkanstalten der Bundesrepublik Deutschland. 2019. Available online: https://www.planet-wissen.de/gesellschaft/arbeit/die_geschichte_der_arbeit_und_was_sie_heute_bedeutet/arbeit-vier-punkt-null-100.html (accessed on 23 October 2020).

- Kagermann, H.; Wahlster, W.; Helbig, J. Umsetzungsempfehlungen für das Zukunftsprojekt Industrie 4.0. Available online: https://www.bmbf.de/files/Umsetzungsempfehlungen_Industrie4_0.pdf (accessed on 10 November 2020).

- Scharlack, U. Industrie 4.0. BMBF. 2019. Available online: https://www.bmbf.de/de/zukunftsprojekt-industrie-4-0-848.html (accessed on 20 November 2020).

- Schwab, K. The Fourth Industrial Revolution. World Economic Forum. 2016. Available online: https://www.weforum.org/agenda/2016/01/the-fourth-industrial-revolution-what-it-means-and-how-to-respond/ (accessed on 27 October 2020).

- Andrews, D.; Criscuolo, C.; Gal, P. The Best versus the Rest: The Global Productivity Slowdown, Divergence across Firms and the Role of Public Policy. OECD Productivity Working Papers. 2019. Available online: https://www.oecd.org/going-digital/productivity-growth-in-the-digital-age.pdf (accessed on 1 December 2020).

- Mubarak, M.F.; Petraite, M. Industry 4.0 technologies, digital trust and technological orientation: What matters in open innovation? Technol. Forecast. Soc. Chang. 2020, 161, 120332. [Google Scholar] [CrossRef]

- Travaglioni, M.; Ferazzoli, A.; Petrillo, A.; Cioffi, R.; De Felice, F.; Piscitelli, G. Digital manufacturing challenges through open innovation perspective. Procedia Manuf. 2020, 42, 165–172. [Google Scholar] [CrossRef]

- Sag, S.; Sezen, B.; Alpkan, L. Determinants of Open Innovation and their Interrelations. Int. J. Innov. Technol. Manag. 2018, 16, 1940001. [Google Scholar] [CrossRef] [Green Version]

- Hizam-Hanafiah, M.; Soomro, M.A. The Situation of Technology Companies in Industry 4.0 and the Open Innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 34. [Google Scholar] [CrossRef]

- Urbinati, A.; Davide, C.; Vittorio, C.; Federico, F. The role of digital technologies in open innovation processes: An explanatory multiple case study analysis. R D Manag. 2018, 50, 136–160. [Google Scholar] [CrossRef]

- Lee, M.; Yun, J.J.; Pyka, A.; Won, D.; Kodama, F.; Schiuma, G.; Park, H.; Jeo, J.; Park, K.; Jung, K.; et al. How to Respond to the Fourth Industrial Revolution or the Second Information Technology Revolution? Dynamic New Combinations between Technology, Market, and Society through Open Innovation. J. Open Innov. Technol. Mark. Complex. 2021, 4, 21. [Google Scholar] [CrossRef] [Green Version]

- Zezulka, F.; Marcon, P.; Bradac, Z.; Arm, J.; Benesl, T.; Vesely, I. Communication Systems for Industry 4.0 and the IIoT. IFAC-Pap. 2018, 51, 150–155. [Google Scholar] [CrossRef]

- Ayatollahi, I.; Brier, J.; Mörzinger, B.; Heger, M.; Bleicher, F. SOA on Smart Manufacturing Utilities for Identification, Data Access and Control. Procedia CIRP 2018, 67, 162–166. [Google Scholar] [CrossRef]

- Arnold, C.; Kiel, D.; Voigt, K.-I. Innovative Business Models for the Industrial Internet of Things. Bhm Berg- Und Hüttenmännische Mon. 2017, 162, 371–381. [Google Scholar] [CrossRef]

- Jeske, T.; Lennings, F.; Stowasser, S. Industrie 4.0–Umsetzung in der deutschen Metall- und Elektroindustrie. Z. Arb. Wiss. 2016, 70, 115–125. [Google Scholar] [CrossRef]

- Hurley, P. A Concise Introduction to Logic 2008, 10th ed.; Thomson Wadsworth: California, CA, USA, 2007; ISBN 978-0495503835. [Google Scholar]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Luque, A.; Peralta, M.E.; las Heras, A.D.; Córdoba, A. State of the Industry 4.0 in the Andalusian food sector. Procedia Manufa. 2017, 13, 1199–1205. [Google Scholar] [CrossRef]

- Thuemmler, C.; Bai, C. Health 4.0: Application of Industry 4.0 Design Principles in Future Asthma Management. In Health 4.0: How Virtualization and Big Data Are Revolutionizing Healthcare; Springer: Cham, Switzerland, 2017; Volume 372, pp. 23–37. [Google Scholar]

- Javaid, M.; Haleem, A. Industry 4.0 applications in medical field: A brief review. Curr. Med. Res. Pract. 2019, 9, 102–109. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Werner, F.; Ivanova, M. A dynamic model and an algorithm for short-term supply chain scheduling in the smart factory industry 4.0. Int. J. Prod. Res. 2016, 54, 386–402. [Google Scholar] [CrossRef] [Green Version]

- Tjahjono, B.; Esplugues, C.; Ares, E.; Pelaez, G. What does Industry 4.0 mean to Supply Chain? Procedia Manuf. 2017, 13, 1175–1182. [Google Scholar] [CrossRef]

- Braun, A.-T.; Colangelo, E.; Steckel, T. Farming in the Era of Industrie 4.0. Procedia CIRP 2018, 72, 979–984. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Jun, S.-P.; Yoo, H.S.; Choi, S. Ten years of research change using Google Trends: From the perspective of big data utilizations and applications. Technol. Forecast. Soc. Chang. 2018, 130, 69–87. [Google Scholar] [CrossRef]

- Chumnumpan, P.; Shi, X. Understanding new products’market performance using Google Trends. Australas. Mark. J. 2019, 27, 91–103. [Google Scholar] [CrossRef]

- Preis, T.; Moat, S. Adaptive nowcasting of influenza outbreaks using Google search. R. Soc. Open Sci. 2014, 1, 140095. [Google Scholar] [CrossRef] [Green Version]

- ScienceDirect.com Science, Health and Medical Journals, Full Text Articles and Books. ScienceDirect. 2019. Available online: https://www.sciencedirect.com/ (accessed on 27 August 2020).

- Elsevier What Is the Difference between ScienceDirect and Scopus Data. 2020. Available online: https://service.elsevier.com/app/answers/detail/a_id/28240/supporthub/agrm/p/15838/ (accessed on 8 October 2020).

- Elsevier What Does “Relevance” Mean in Science Direct. ScienceDirect Support Center. 2019. Available online: https://service.elsevier.com/app/answers/detail/a_id/28453/supporthub/sciencedirect/kw/sort+by/track/APNNygrMDv8a~ZB5Guka~yCgiP8qTy75Mv_F~zj~PP9M/ (accessed on 8 October 2020).

- Israel, G. Determining Sample Size. University of Florida Cooperative Extension Service. Institute of Food and Agriculture Sciences. 1992. Available online: https://www.psycholosphere.com/DeterminingsamplesizebyGlenIsrael.pdf (accessed on 12 January 2021).

- Williams, R.; Bornmann, L. Sampling issues in bibliometric analysis. J. Informetr. 2016, 10, 1225–123223. [Google Scholar] [CrossRef] [Green Version]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Toro, C.; Barandiaran, I.; Posada, J. A Perspective on Knowledge Based and Intelligent Systems Implementation in Industrie 4.0. Procedia Computsci. 2015, 60, 362–370. [Google Scholar] [CrossRef] [Green Version]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Shyu, J.Z.; Ding, K. Industrial revitalization via industry 4.0–A comparative policy analysis among China, Germany and the USA. Glob. Transit. 2019, 1, 3–14. [Google Scholar] [CrossRef]

- Tupa, J.; Simota, J.; Steiner, F. Aspects of Risk Management Implementation for Industry 4.0. Procedia Manuf. 2017, 11, 1223–1230. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R. A Categorical Framework of Manufacturing for Industry 4.0 and Beyond. Procedia CIRP 2016, 52, 173–178. [Google Scholar] [CrossRef] [Green Version]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of Industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Bigliardi, B.; Bottani, E.; Casella, G. Enabling technologies, application areas and impact of industry 4.0: A bibliographic analysis. Procedia Manuf. 2020, 42, 322–326. [Google Scholar] [CrossRef]

- Beier, G.; Ullrich, A.; Niehoff, S.; Reißig, M.; Habich, M. Industry 4.0: How it is defined from a sociotechnical perspective and how much sustainability it includes—A literature review. J. Clean. Prod. 2020, 259, 120856. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in Management Studies: A Systematic Literature Review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef] [Green Version]

- Kiangala, K.S.; Wang, Z. An Industry 4.0 approach to develop auto parameter configuration of a bottling process in a small to medium scale industry using PLC and SCADA. Procedia Manuf. 2019, 35, 725–730. [Google Scholar] [CrossRef]

- Buer, S.-V.; Fragapane, G.I.; Strandhagen, J.O. The Data-Driven Process Improvement Cycle: Using Digitalization for Continuous Improvement. IFAC-Pap. 2018, 51, 1035–1040. [Google Scholar] [CrossRef]

- Paravizo, E.; Chaim, O.C.; Braatz, D.; Muschard, B.; Rozenfeld, H. Exploring gamification to support manufacturing education on industry 4.0 as an enabler for innovation and sustainability. Procedia Manuf. 2018, 21, 438–445. [Google Scholar] [CrossRef]

- Shafiq, S.I.; Sanin, C.; Szczerbicki, E.; Toro, C. Virtual Engineering Object / Virtual Engineering Process: A specialized form of Cyber Physical System for Industrie 4.0. Procedia Comput. Sci. 2015, 60, 1146–1155. [Google Scholar] [CrossRef] [Green Version]

- Faller, C.; Feldmüller, D. Industry 4.0 Learning Factory for regional SMEs. Procedia CIRP 2015, 32, 88–91. [Google Scholar] [CrossRef] [Green Version]

- Weyer, S.; Schmitt, M.; Ohmer, M.; Gorecky, D. Towards Industry 4.0–Standardization as the crucial challenge for highly modular, multi-vendor production systems. IFAC-Pap. 2015, 48, 579–584. [Google Scholar] [CrossRef]

- Long, F.; Zeiler, P.; Bertsche, B. Modelling the production systems in industry 4.0 and their availability with high-level Petri nets. IFAC-Pap. 2016, 49, 145–150. [Google Scholar] [CrossRef]

- Motyl, B.; Baronio, G.; Uberti, S.; Speranza, D.; Filippi, S. How will Change the Future Engineers’ Skills in the Industry 4.0 Framework? A Questionnaire Survey. Procedia Manuf. 2017, 11, 1501–1509. [Google Scholar] [CrossRef]

- Zezulka, F.; Marcon, P.; Vesely, I.; Sajdl, O. Industry 4.0–An Introduction in the phenomenon. IFAC-Pap. 2016, 49, 8–12. [Google Scholar] [CrossRef]

- Davies, R.; Coole, T.; Smith, A. Review of Socio-technical Considerations to Ensure Successful Implementation of Industry 4.0. Procedia Manuf. 2017, 11, 1288–1295. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A Maturity Model for Assessing Industry 4.0 Readiness and Maturity of Manufacturing Enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A Scenario-Based Approach to Learning for the Future of Production. Procedia CIRP 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Arm, J.; Zezulka, F.; Bradac, Z.; Marcon, P.; Kaczmarczyk, V.; Benesl, T.; Schroeder, T. Implementing Industry 4.0 in Discrete Manufacturing. Options and Drawbacks. IFAC-Pap. 2018, 51, 473–478. [Google Scholar] [CrossRef]

- Badri, A.; Boudreau-Trudel, B.; Souissi, A. Occupational health and safety in the industry 4.0 era. A cause for major concern? Saf. Sci. 2018, 109, 403–411. [Google Scholar] [CrossRef]

- Bauer, H.; Brandl, F.; Lock, C.; Reinhart, G. Integration of Industrie 4.0 in Lean Manufacturing Learning Factories. Procedia Manuf. 2018, 23, 147–152. [Google Scholar] [CrossRef]

- Ribeiro da Silva, E.; Shinohara, A.; Lima, E.; Angelis, J.; Machado, C. Reviewing Digital Manufacturing concept in the Industry 4.0 paradigm. Procedia CIRP 2019, 81, 240–245. [Google Scholar] [CrossRef]

- Meissner, H.; Ilsen, R.; Aurich, J. Analysis of Control Architectures in the Context of Industry 4.0. Procedia CIRP 2017, 62, 165–169. [Google Scholar] [CrossRef]

- Müller, F.; Jaeger, D.; Hanewinkel, M. Digitization in wood supply–A review on how Industry 4.0 will change the forest value chain. Comput. Electron. Agr. 2019, 162, 206–218. [Google Scholar]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Angelopoulou, A.; Mykoniatis, K.; Boyapati, N. Industry 4.0: The use of simulation for human reliability assessment. Procedia Manuf. 2020, 42, 296–301. [Google Scholar] [CrossRef]

- Zeng, P.; Wang, Z.; Jia, Z.; Kong, L.; Li, D.; Jin, X. Time-slotted software-defined Industrial Ethernet for real-time Quality of Service in Industry 4.0. Future Gener. Comp. Syst. 2019, 99, 1–10. [Google Scholar] [CrossRef]

- Benitez, G.; Ayala, N.; Frank, A. Industry 4.0 innovation ecosystems: An evolutionary perspective on value cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Müller, J. Assessing the barriers to Industry 4.0 implementation from a workers’ perspective. IFAC-Pap. 2019, 52, 2189–2194. [Google Scholar]

- Long, F.; Zeiler, P.; Bertsche, B. Modelling the flexibility of production systems in Industry 4.0 for analysing their productivity and availability with high-level Petri nets. IFAC-Pap. 2017, 50, 5680–5687. [Google Scholar] [CrossRef]

- Pereira, M.; Silva, A.; Ferreira, L.P.; Sá, J.; Silva, F. A DMS to Support Industrial Process Decision-Making: A contribution under Industry 4.0. Procedia Manuf. 2019, 38, 613–620. [Google Scholar] [CrossRef]

- Brettel, M.; Fischer, F.; Bendig, D.; Weber, A.; Wolff, B. Enablers for Self-optimizing Production Systems in the Context of Industrie 4.0. Procedia CIRP 2016, 41, 93–98. [Google Scholar] [CrossRef] [Green Version]

- Man, J.; Strandhagen, J. An Industry 4.0 Research Agenda for Sustainable Business Models. Procedia CIRP 2017, 63, 721–726. [Google Scholar] [CrossRef]

- Tiwari, K.; Khan, M. Sustainability accounting and reporting in the industry 4.0. J. Clean. Prod. 2020, 258, 120783. [Google Scholar] [CrossRef]

- Yadav, G.; Kumar, A.; Luthra, S.; Garza-Reyes, J.; Kumar, V.; Batista, L. A framework to achieve sustainability in manufacturing organisations of developing economies using industry 4.0 technologies’ enablers. Comput. Ind. 2020, 122, 103280. [Google Scholar] [CrossRef]

- Henao-Hernández, I.; Solano-Charris, E.; Muñoz-Villamizar, A.; Santos, J.; Henríquez-Machado, R. Control and monitoring for sustainable manufacturing in the Industry 4.0: A literature review. IFAC-Pap. 2019, 52, 195–200. [Google Scholar]

- Villalobos, K.; Ramírez-Durán, V.; Diez, B.; Blanco, J.; Goñi, A.; Illarramendi, A. A three level hierarchical architecture for an efficient storage of industry 4.0 data. Comput. Ind. 2020, 12, 103257. [Google Scholar] [CrossRef]

- Schleipen, M.; Gilani, S.; Bischoff, T.; Pfrommer, J. OPC UA & Industrie 4.0—Enabling Technology with High Diversity and Variability. Procedia CIRP 2016, 57, 315–320. [Google Scholar]

- Raj, A.; Dwivedi, G.; Sharma, A.; Lopes de Sousa Jabbour, A.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar]

- Lucato, W.; Pacchini, A.; Facchini, F.; Mummolo, G. Model to evaluate the Industry 4.0 readiness degree in Industrial Companies. IFAC-Pap. 2019, 52, 1808–1813. [Google Scholar]

- Leineweber, S. Concept for an evolutionary maturity based Industrie 4.0 migration model. Procedia CIRP 2018, 72, 404–409. [Google Scholar]

- Issa, A.; Hatiboglu, B.; Bildstein, A.; Bauernhansl, T. Industrie 4.0 roadmap: Framework for digital transformation based on the concepts of capability maturity and alignment. Procedia CIRP 2018, 72, 973–978. [Google Scholar]

- Taurino, T.; Villa, A. A method for applying Industry 4.0 in Small Enterprises. IFAC-Pap. 2019, 52, 439–444. [Google Scholar]

- Villa, A.; Taurino, T. SME Innovation and Development in the Context of Industry 4.0. Procedia Manuf. 2019, 39, 1415–1420. [Google Scholar] [CrossRef]

- Wienbruch, T.; Leineweber, S.; Kreimeier, D.; Kuhlenkötter, B. Evolution of SMEs towards Industrie 4.0 through a scenario based learning factory training. Procedia Manuf. 2018, 23, 141–146. [Google Scholar] [CrossRef]

- Kolla, S.; Minufekr, M.; Plapper, P. Deriving essential components of lean and industry 4.0 assessment model for manufacturing SMEs. Procedia CIRP 2019, 81, 753–758. [Google Scholar] [CrossRef]

- Lentes, J.; Zimmermann, N.; Hertwig, M. Industrie 4.0-Scouts Programme. IFAC-Pap. 2019, 52, 445–450. [Google Scholar] [CrossRef]

- Horváth, D.; Szabó, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Niemeyer, C.L.; Gehrke, I.; Müller, K.; Küsters, D.; Gries, T. Getting Small Medium Enterprises started on Industry 4.0 using retrofitting solutions. Procedia Manuf. 2020, 45, 208–214. [Google Scholar] [CrossRef]

- Magadán, L.; Suárez, F.J.; Granda, J.C.; García, D.F. Low-cost real-time monitoring of electric motors for the Industry 4.0. Procedia Manuf. 2020, 42, 393–398. [Google Scholar] [CrossRef]

- Mrugalska, B.; Wyrwicka, M.K. Towards Lean Production in Industry 4.0. Procedia Eng. 2017, 182, 466–473. [Google Scholar] [CrossRef]

- Wagner, T.; Herrmann, C.; Thiede, S. Industry 4.0 Impacts on Lean Production Systems. Procedia CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Prinz, C.; Kreggenfeld, N.; Kuhlenkötter, B. Lean meets Industrie 4.0–a practical approach to interlink the method world and cyber-physical world. Procedia Manuf. 2018, 23, 21–26. [Google Scholar] [CrossRef]

- Rossini, M.; Costa, F.; Staudacher, A.P.; Tortorella, G. Industry 4.0 and Lean Production: An empirical study. IFAC-Pap. 2019, 52, 42–47. [Google Scholar] [CrossRef]

- Kadir, B.A.; Broberg, O.; Conceição, C.S. Current research and future perspectives on human factors and ergonomics in Industry 4.0. Comput. Ind. Eng. 2019, 137, 106004. [Google Scholar] [CrossRef]

- Prinz, C.; Morlock, F.; Freith, S.; Kreggenfeld, N.; Kreimeier, D.; Kuhlenkötter, B. Learning Factory Modules for Smart Factories in Industrie 4.0. Procedia CIRP 2016, 54, 113–118. [Google Scholar] [CrossRef] [Green Version]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Louw, L.; Deacon, Q. Teaching Industrie 4.0 technologies in a learning factory through problem-based learning: Case study of a semi-automated robotic cell design. Procedia Manuf. 2020, 45, 265–270. [Google Scholar] [CrossRef]

- Chaim, O.; Muschard, B.; Cazarini, E.; Rozenfeld, H. Insertion of sustainability performance indicators in an industry 4.0 virtual learning environment. Procedia Manuf. 2018, 21, 446–453. [Google Scholar] [CrossRef]

- Wittenberg, C. Human-CPS Interaction—Requirements and human-machine interaction methods for the Industry 4.0. IFAC-Pap. 2016, 49, 420–425. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Industry 4.0 integration with socio-technical systems theory: A systematic review and proposed theoretical model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Baena, F.; Guarin, A.; Mora, J.; Sauza, J.; Retat, S. Learning Factory: The Path to Industry 4.0. Procedia Manuf. 2017, 9, 73–80. [Google Scholar] [CrossRef]

- Karre, H.; Hammer, M.; Kleindienst, M.; Ramsauer, C. Transition towards an Industry 4.0 State of the LeanLab at Graz University of Technology. Procedia Manuf. 2017, 9, 206–213. [Google Scholar] [CrossRef]

- Büth, L.; Blume, S.; Posselt, G.; Herrmann, C. Training concept for and with digitalization in learning factories: An energy efficiency training case. Procedia Manuf. 2018, 23, 171–176. [Google Scholar] [CrossRef]

- Tosello, E.; Castaman, N.; Menegatti, E. Using robotics to train students for Industry 4.0. IFAC-Pap. 2019, 52, 153–158. [Google Scholar] [CrossRef]

- Sallati, C.; de Andrade Bertazzia, J.; Schützer, K. Professional skills in the Product Development Process: The contribution of learning environments to professional skills in the Industry 4.0 scenario. Procedia CIRP 2019, 84, 203–208. [Google Scholar] [CrossRef]

- Liagkou, V.; Salmas, D.; Stylios, C. Realizing Virtual Reality Learning Environment for Industry 4.0. Procedia CIRP 2019, 79, 712–717. [Google Scholar] [CrossRef]

- Hennig, M.; Reisinger, G.; Trautner, T.; Hold, P.; Gerhard, D.; Mazak, A. TU Wien Pilot Factory Industry 4.0. Procedia Manuf. 2019, 31, 200–205. [Google Scholar] [CrossRef]

- Dombrowski, U.; Wullbrandt, J.; Fochler, S. Center of Excellence for Lean Enterprise 4.0. Procedia Manuf. 2019, 31, 66–71. [Google Scholar] [CrossRef]

- Oestreich, H.; Töniges, T.; Wojtynek, M.; Wrede, S. Interactive Learning of Assembly Processes using Digital Assistance. Procedia Manuf. 2019, 31, 14–19. [Google Scholar] [CrossRef]

- Scholz, J.-A.; Sieckmann, F.; Kohl, H. Implementation with agile project management approaches: Case Study of an Industrie 4.0 Learning Factory in China. Procedia Manuf. 2020, 45, 234–239. [Google Scholar] [CrossRef]

- Wermann, J.; Colombo, A.W.; Pechmann, A.; Zarte, M. Using an interdisciplinary demonstration platform for teaching Industry 4.0. Procedia Manuf. 2019, 31, 302–308. [Google Scholar] [CrossRef]

- Landherr, M.; Schneider, U.; Bauernhansl, T. The Application Center Industrie 4.0—Industry-driven Manufacturing, Research and Development. Procedia CIRP 2016, 57, 26–31. [Google Scholar] [CrossRef]

- Santos, K.; Loures, E.; Piechnicki, F.; Canciglieri, O. Opportunities Assessment of Product Development Process in Industry 4.0. Procedia Manuf. 2017, 11, 1358–1365. [Google Scholar] [CrossRef]

- Zaimovic, T. Setting speed-limit on Industry 4.0–an outlook of power-mix and grid capacity challenge. Procedia Comput. Sci. 2019, 158, 107–115. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Inkermann, D.; Schneider, D.; Martin, N.L.; Lembeck, H.; Zhang, J.; Thiede, S. A framework to classify Industry 4.0 technologies across production and product development. Procedia CIRP 2019, 84, 973–978. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Pacchini, A.P.T.; Lucato, W.C.; Facchini, F.; Mummolo, G. The degree of readiness for the implementation of Industry 4.0. Comput. Ind. 2019, 113, 103125. [Google Scholar] [CrossRef]

- García, S.G.; García, M.G. Industry 4.0 implications in production and maintenance management: An overview. Procedia Manuf. 2019, 41, 415–422. [Google Scholar]

- Sahal, R.; Breslin, J.G.; Ali, M.I. Big data and stream processing platforms for Industry 4.0 requirements mapping for a predictive maintenance use case. J. Manuf. Syst. 2020, 54, 138–151. [Google Scholar] [CrossRef]

- Oberc, H.; Prinz, C.; Glogowski, P.; Lemmerz, K.; Kuhlenkötter, B. Human Robot Interaction–learning how to integrate collaborative robots into manual assembly lines. Procedia Manuf. 2019, 31, 26–31. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Merayo, D.; Rodríguez-Prieto, A.; Camacho, A.M. Comparative analysis of artificial intelligence techniques for material selection applied to manufacturing in Industry 4.0. Procedia Manuf. 2019, 41, 42–49. [Google Scholar] [CrossRef]

- Muñoz-Saavedra, L.; Miró-Amarante, L.; Domínguez-Morales, M. Augmented and Virtual Reality Evolution and Future Tendency. Appl. Sci. 2020, 10, 332. [Google Scholar] [CrossRef] [Green Version]

- Masoni, R.; Ferrise, F.; Bordegoni, M.; Gattullo, M.; Uva, A.E.; Fiorentino, M.; Carrabba, E.; Di Donato, M. Supporting Remote Maintenance in Industry 4.0 through Augmented Reality. Procedia Manuf. 2017, 11, 1296–1302. [Google Scholar] [CrossRef]

- Gattullo, M.; Scurati, G.W.; Fiorentino, M.; Uva, A.E.; Ferrise, F.; Bordegoni, M. Towards augmented reality manuals for industry 4.0: A methodology. Robot. Comput. Integr. Manuf. 2019, 56, 276–286. [Google Scholar] [CrossRef]

- Ceruti, A.; Marzocca, P.; Liverani, A.; Bil, C. Maintenance in aeronautics in an Industry 4.0 context: The role of Augmented Reality and Additive Manufacturing. J. Comput. Des. Eng. 2019, 6, 516–526. [Google Scholar] [CrossRef]

- Boyack, K.W.; Klavans, R.; Börner, K. Mapping the backbone of science. Scientometrics 2005, 64, 351–374. [Google Scholar] [CrossRef]

- Jacomy, M.; Venturini, T.; Heymann, S.; Bastian, M. ForceAtlas2, a Continuous Graph Layout Algorithm for Handy Network Visualization Designed for the Gephi Software. PLoS ONE 2014, 9, e98679. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Landström, A.; Fast-Berglund, Å.; Almström, P. Human-Centred Dissemination of Data, Information and Knowledge in Industry 4.0. Procedia CIRP 2019, 84, 380–386. [Google Scholar] [CrossRef]

- Yildiz, T. Examining the Concept of Industry 4.0 Studies Using Text Mining and Scientific Mapping Method. Procedia Comput. Sci. 2019, 158, 498–507. [Google Scholar] [CrossRef]

- Mariani, M.; Borghi, M. Industry 4.0: A bibliometric review of its managerial intellectual structure and potential evolution in the service industries. Technol. Forecast. Soc. Chang. 2019, 149, 119752. [Google Scholar] [CrossRef]

- Muhuri, P.K.; Shukla, A.K.; Abraham, A. Industry 4.0: A bibliometric analysis and detailed overview. Eng. Appl. Artif. Intell. 2019, 78, 218–235. [Google Scholar] [CrossRef]

- Pellegrini, T.; Blumauer, A. Semantic Web: Wege zur Vernetzten Wissensgesellschaft; Springer: Berlin/Heidelberg, Germany, 2006; Available online: https://www.springer.com/de/book/9783540293248 (accessed on 30 November 2020).

- Tantik, E.; Anderl, R. Industrie 4.0: Using Cyber-physical Systems for Value-stream Based Production Evaluation. Procedia CIRP 2016, 57, 207–212. [Google Scholar] [CrossRef]

- Ezugwu, A.E.; Shukla, A.K.; Agbaje, M.B.; Oyelade, O.N.; José-Garcia, A.; Agushaka, J.O. Automatic clustering algorithms: A systematic review and bibliometric analysis of relevant literature. Neural Comput. Appl. 2020. [Google Scholar] [CrossRef]

- Borges, A.F.S.; Laurindo, F.J.B.; Spínola, M.M.; Goncalves, R.F.; Mattos, C.A. The strategic use of artificial intelligence in the digital era: Systematic literature review and future research directions. Int. J. Inf. Manag. 2021, 57, 102225. [Google Scholar] [CrossRef]

| Li [130] | Yildiz [131] | Mariani [132] | Muhuri [133] | |

|---|---|---|---|---|

| Time period | 2012–2019 | 2012–2018 | 2012–2018 * | 2012–2017 * |

| Number of papers | 3.548 | 4.029 | 757 | 1.619 |

| Database | Scopus | Scopus | Scopus, WoS **, Google Scholar | Scopus, WoS ** |

| Analyze | Keywords | Complete Text | Authors, Ranking, Citations | Authors, Journals, Keywords |

| Evaluation software | N/A | Scimat, VoSviewer | Proprietary software based on Python | VoSviewer |

| Search queue | Industry 4.0, Industrie 4.0 | Industry 4.0 | Industry 4.0, Industrie 4.0, Industrial Revolution | Industry 4.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rupp, M.; Schneckenburger, M.; Merkel, M.; Börret, R.; Harrison, D.K. Industry 4.0: A Technological-Oriented Definition Based on Bibliometric Analysis and Literature Review. J. Open Innov. Technol. Mark. Complex. 2021, 7, 68. https://doi.org/10.3390/joitmc7010068

Rupp M, Schneckenburger M, Merkel M, Börret R, Harrison DK. Industry 4.0: A Technological-Oriented Definition Based on Bibliometric Analysis and Literature Review. Journal of Open Innovation: Technology, Market, and Complexity. 2021; 7(1):68. https://doi.org/10.3390/joitmc7010068

Chicago/Turabian StyleRupp, Mario, Max Schneckenburger, Markus Merkel, Rainer Börret, and David K. Harrison. 2021. "Industry 4.0: A Technological-Oriented Definition Based on Bibliometric Analysis and Literature Review" Journal of Open Innovation: Technology, Market, and Complexity 7, no. 1: 68. https://doi.org/10.3390/joitmc7010068

APA StyleRupp, M., Schneckenburger, M., Merkel, M., Börret, R., & Harrison, D. K. (2021). Industry 4.0: A Technological-Oriented Definition Based on Bibliometric Analysis and Literature Review. Journal of Open Innovation: Technology, Market, and Complexity, 7(1), 68. https://doi.org/10.3390/joitmc7010068