Systematic Assessment of Product Quality

Abstract

:1. Introduction

- (1)

- Quality of the entry materials;

- (2)

- Composition of materials (recipe);

- (3)

- Proper definition of efficiency norms.

2. Materials and Methods

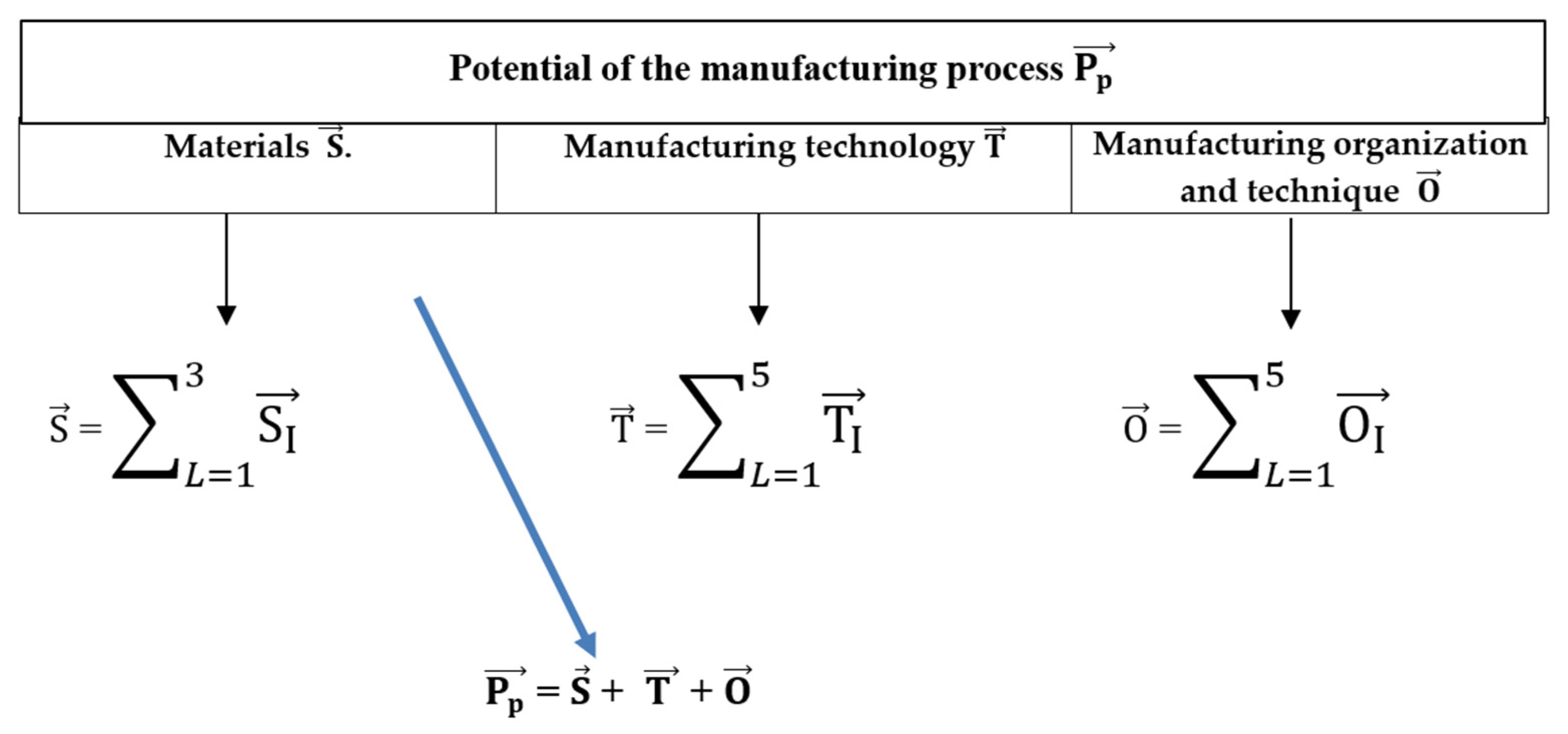

Systemic Structure of a Manufacturing Process in the Baking Industry

3. Results

3.1. Components of the Manufacturing Potential

- (1)

- Quality of the production raw materials

- (2)

- Material composition (recipe)

- (3)

- Proper setting of efficiency norms

- (1)

- Selection of optimal process parameters

- (2)

- Stability of the assumed manufacturing processes

- (3)

- Process efficiency control, including:

- -

- that of individual process phases

- -

- that of interoperational semi-finished product quality

- -

- that of the proper setting of efficiency norms

- (1)

- Staff qualification and involvement

- (2)

- Functionality and reliability of manufacturing machinery

- (3)

- Technological progress

- (4)

- Hygienic and sanitary conditions

- (5)

- Conditions for storage and shipment

3.2. Normalized Form of the Manufacturing Process Potential Vector

4. Discussion

- (1)

- The application of data science and statistics—allowing for the construction of product quality models and the use of the full potential of methods such as the current paper’s vector analysis of quality.

- (2)

- Supporting technologies—sensors, measurement equipment, Internet of Things, Industrial Internet of Things, and cloud computing.

- (3)

- Big data—collection and analysis of large pools of data in real time,

- (4)

- Artificial intelligence—the application of AI to make complex decisions based on the collected metrizable data,

- (5)

- Machine learning—allowing for the discovery of information patterns and heuristics to be used in decision-making.

- (a)

- Nutritional value—determined by the general chemical composition,

- (b)

- Palatability—determined mainly by the composition and quality of the raw materials used,

- (c)

- Healthiness—defined as the lack of risks to the consumer’s health,

- (d)

- Attractiveness—determined by shape, color, and packaging,

- (e)

- Durability—ensuring storage without quality changes,

- (f)

- Freshness—equated with flexibility, smell, and taste of the bread.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Worth, M.J. Nonprofit Management, 6th ed.; SAGE: Los Angeles, CA, USA, 2020; pp. 233–291. Available online: https://www.ebooks.com/en-ax/book/210040209/nonprofit-management/michael-j-worth/ (accessed on 17 July 2021).

- Robbins, S.; Coulter, M.; De Cenzo, D. Fundamentals of Management, 10th ed.; Pearson: London, UK, 2016; pp. 115–128. [Google Scholar]

- Rothaermel, F. Strategic Management: Concepts; McGraw-Hill: New York, NY, USA, 2021; pp. 2–18. [Google Scholar]

- Ładoński, W.; Szołtysek, K. Quality Management. Part 3. Methods of Shaping Quality in an Organization; Publishing House of the University of Economics in Wroclaw: Wroclaw, Poland, 2008; pp. 45–58. [Google Scholar]

- Liker, J.K. The Toyota Way—14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2004; pp. 103–109. [Google Scholar]

- Lock, D. Quality Management Manual; Scientific Publisher PWN: Warsaw, Poland, 2012; pp. 55–61. [Google Scholar]

- Oakland, J.S.; Oakland, R.J.; Turner, M.A. Total Quality Management and Operational Excellence: Text with Cases, 5th ed.; Routledge: London, UK, 2020; pp. 345–376. [Google Scholar]

- Drozd, R.; Wolniak, R. Metrisable Assessment of the Course of Stream-Systemic Processes in Vector Form in Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–16. [Google Scholar]

- Michlowicz, E. Logistics systems and systems theory. In Proceedings of the 13th Applied Logistics Conference “Total Logistics Management”, Zakopane, Poland, 1–5 June 2009. [Google Scholar]

- Newton, R. The Management Book; FT Publishing International: Upper Saddle River, NJ, USA, 2012; pp. 223–267. [Google Scholar]

- Cempel, C. Systems Theory and Engineering—Principles of Applying Systems Thinking; Institute of Sustainable Technologies: Radom, Poland, 2006; pp. 34–51. [Google Scholar]

- Pogorzelski, W. Systems Theory and Optimization Methods; Warsaw University of Technology Publishing House: Warsaw, Poland, 2009; pp. 34–37. [Google Scholar]

- Powierża, L. Elements of Systems Engineering; Publishing House of the Warsaw University of Technology: Warsaw, Poland, 2007; pp. 18–49, 89–93, 105–113. [Google Scholar]

- Sałaciński, T. Quality Engineering in Manufacturing Technology; Technical University of Warsaw: Warsaw, Poland, 2019; pp. 190–210. [Google Scholar]

- Schonberger, R.J. World Class Manufacturing; Free Press: New York, NY, USA, 2008; pp. 112–145. [Google Scholar]

- Jung, M.; Glardon, R. Manufacturing Operations Management; World Scientific: Singapore, 2018; pp. 160–190. [Google Scholar]

- Kalpakjian, S. Manufacturing Engineering and Technology; Pearson Education Centre: London, UK, 2013; pp. 670–724. [Google Scholar]

- Wang, C.-H.; Dang, T.-H.; Nguyen, N.-A. A Computational Model for Determining Levels of Factors in Inventory Management Using Response Surface Methodology. Mathematics 2020, 8, 1210. [Google Scholar] [CrossRef]

- Wang, C.-H.; Nguyen, N.-A.; Dang, T.-H. Solving Order Planning Problem Using a Heuristic Approach: The Case in a Building Material Distributor. Appl. Sci. 2020, 10, 8959. [Google Scholar] [CrossRef]

- Wang, C.-H.; Chen, D.; Huang, H.; Zhan, W.; Lai, X. MIMO LS-SVR-Based Multi-Point Vibration Response Prediction in the Frequency Domain. Appl. Sci. 2020, 10, 8784. [Google Scholar] [CrossRef]

- Martinez-Comesaña, M.; Febrero-Garrido, L.; Granada-Alvarez, E.; Martinez-Torrez, J.; Martinez-Mariño, S. Heat Loss Coefficient Estimation Applied to Existing Buildings through Machine Learning Models. Appl. Sci. 2020, 10, 8968. [Google Scholar] [CrossRef]

- Wolniak, R.; Skotnicka-Zasadzień, B. Developing a Model of Factors Influencing the Quality of Service for Disabled Customers in the Condition s of Sustainable Development, Illustrated by an Example of the Silesian Voivodeship Public Administration. Sustainability 2018, 10, 2171. [Google Scholar] [CrossRef] [Green Version]

- Bartosiewicz, A.; Burzyńska, J.; Januszewicz, P. Polish Nurses’ Attitude to e-Health Solutions and Self-Assessment of Their IT Competence. J. Clin. Med. 2021, 10, 4799. [Google Scholar] [CrossRef]

- Tsuen-Ho, H.; Sen-Tien, H.; Jia-Jeng, H. Developing Universally Applicable Service Quality Assessment Model Based on the Theory of Consumption Values, and Using Fuzzy Linguistic Preference Relations to Empirically Test Three Industries. Mathematics 2021, 9, 2608. [Google Scholar] [CrossRef]

- Dennis, P. Lean Production Simplified, 3rd ed.; Taylor & Francis Inc.: London, UK, 2015; pp. 88–112. [Google Scholar]

- Althaus, B.; Blanke, M. Development of a Freshness Index for Fruit Quality Assessment—Using Bell Pepper as a Case Study. Horticulturae 2021, 7, 405. [Google Scholar] [CrossRef]

- Sannakustim, S.; Laitinen, M.; Sontag-Strohm, T. Baking Quality Assessment of Twenty Whole Grain Oat Cultivar Samples. Foods 2021, 10, 2461. [Google Scholar] [CrossRef]

- Neshitov, A.; Tyapochkin, K.; Smorodnikova, E.; Pradvin, P. Wavelet Analysis and Self-Similarity of Photoplethysmography Signals for HRV Estimation and Quality Assessment. Sensors 2021, 21, 6798. [Google Scholar] [CrossRef] [PubMed]

- Selmy, S.A.H.; Al-Aziz, S.H.A.A.; Jimenez-Ballesta, R.; Garcia-Navarro, F.J.; Fadl, M.E. Soil Quality Assessment Using Multivariate Approaches: A Case Study of the Dakhla Oasis Arid Lands. Land 2021, 10, 1074. [Google Scholar] [CrossRef]

- Chryssolouris, G. Manufacturing Systems; Springer: Berlin/Heidelberg, Germany, 2015; pp. 251–294. [Google Scholar]

- Bhowmik, S.; Jagadish Gupta, K. Modeling and Optimization of Advanced Manufacturing Processes; Springer: Berlin/Heidelberg, Germany, 2018; pp. 380–420. [Google Scholar]

- Bijan, Y.; Yu, J.; Stracener, J.; Woods, Y. Systems Requirements Engineering—State of the methodology. Syst. Eng. 2012, 16, 267–276. [Google Scholar] [CrossRef]

- Drozd, R.; Piwnik, J. Metrisability of Managing of Stream-Systemic Processes; Series No. 151; Scientific Papers of Silesian University of Technology, Organization and Management: Warsaw, Poland, 2021; pp. 145–156. [Google Scholar]

- Drozd, R.; Piwnik, J. The influence of robotization on the reliability of the production process in the bakery industry. Sci. Didact. Equip. 2019, 3, 221–228. [Google Scholar]

- Drozd, R. Functional model of the impact of factors on product quality in the baking industry. Sci. Didact. Equip. 2020, 3, 173–180. [Google Scholar]

- Drozd, R. The role of robotisation in improving bakery product quality industry. Sci. Didact. Equip. 2020, 261–267. Available online: http://abid.cobrabid.pl/download.php?ma_id=4265&o=1 (accessed on 15 July 2021).

- Fast, L.E. The 12 Principles of Manufacturing Excellence: A Lean Leader’s Guide to Achieving and Sustaining Excellence, 2nd ed.; CRC Press: Boca Raton, FL, USA; Taylor@Francis Group: London, UK; Productivity Press: London, UK, 2015; pp. 211–267. [Google Scholar]

- Groover, M.P. Fundamentals of Modern Manufacturing: Materials, Processes and Systems, 7th ed.; Wiley: Hoboken, NJ, USA, 2020; pp. 51–98. [Google Scholar]

- Jawad, A. Production Planning and Control with SAP ERP; Rheinwerk Verlag: Bonn, Germany, 2016; pp. 830–890. [Google Scholar]

- Lefteri, C.H. Making It: Manufacturing Techniques for Product Design, 3rd ed.; Laurence King: London, UK, 2019; pp. 120–145. [Google Scholar]

- Miller, W.B.; Schenk, V.L. All I Need to Know about Manufacturing I Learned in Joe’s Garage: World Class Manufacturing Made Simple; Bayrock Press: Fort Collins, CO, USA, 2004; pp. 56–89. [Google Scholar]

- Deming, E.W.; Latzko, W.J.; Saunders, D.M. Four Days with Dr. Deming—Modern Management Theory; WNT: Warsaw, Poland, 1998; pp. 274–288. [Google Scholar]

- Garvin, D.A. What Does Product Quality Really Mean; Sloan Management Review: Cambridge, UK, 1994; pp. 123–145. [Google Scholar]

- Kinicki, A.; Williams, B. Management. Practical Introduction; McGraw-Hill Education: New York, NY, USA, 2019; pp. 45–57. [Google Scholar]

- Pyzdek, T.; Keller, P. The Handbook for Quality Management, Second Edition: A Complete Guide to Operational Excellence, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2013; pp. 119–152. [Google Scholar]

- Sikora, T.; Strada, A. Safety and Quality Assurance and Management Systems in Food Industry: An Overview; The Food Industry in Europe, Agricultural University of Athens: Athens, Greece, 2005; pp. 89–95. [Google Scholar]

- Ambroziak, Z. The quality of bread. In Baking—Recipes, Standards, Advice and Legal Regulations; Publisher Organization and Management: Warsaw, Poland, 2002; pp. 109–113. [Google Scholar]

- Dziugan, P. Jakość I warunki produkcji pieczywa w Polsce. Przegląd Piek. 2006, 12, 14–15. [Google Scholar]

- Ellis, C.J. The Quality Bread Baking Methods and Recipes for Beginners: Detailed Guide to Baking Yeast, No-Yeast and Favorite Bread Recipes for Beginners; Independen Publishing: New York, NY, USA, 2020. [Google Scholar]

- Crandall, W.R.; Parnell, J.A.; Spillan, J.E. Crisis Management: Leading in the New Strategy Landscape; SAGE Publishing: New York, NY, USA, 2019. [Google Scholar]

- Drucker, P.F. Management: Tasks, Responsibilities, Practices; Elsevier Science & Technology: Amsterdam, The Netherlands, 1999; pp. 101–135. [Google Scholar]

- Khan, M. Principles of Management & Marketing; Independently Published: New York, NY, USA, 2021. [Google Scholar]

- Drozd, R.; Piwnik, J. The concept of stream and system reliability on the example of the bakery industry. Apar. Badaw. I Dydakt. 2019, 24, 257–264. [Google Scholar]

- Drozd, R. Concept of Managing Quality in Baking Industry, in Vector Representation; Series No. 151; Scientific Papers of Silesian University of Technology, Organization and Management: Warsaw, Poland, 2021; pp. 157–172. [Google Scholar]

- Foidl, H.; Felderer, M. Challenges of Industry 4.0 for Quality Management. In Innovations in Enterprise Information Systems Management and Engineering; Felderer, M., Piazolo, F., Ortner, W., Brehm, L., Hof, H.J., Eds.; ERP Future 2015; Lecture Notes in Business Information Processing; Springer: Berlin/Heidelberg, Germany, 2016; Volume 245. [Google Scholar] [CrossRef]

- Saraiva, M.; Novas, J.C.; Gomes, P.G. How Communication and Control Processes Improve Quality. In Achieving Competitive Advantage through Quality Management; Peris-Ortiz, M., Álvarez-García, J., Rueda-Armengot, C., Eds.; Springer: Cham, Switzerland, 2015; pp. 219–231. [Google Scholar]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2015, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- ASQ. Industry and Quality 4.0: Bringing Them Together. Qual. Mag. 2018. Available online: https://www.qualitymag.com/articles/95011-industry-and-quality-40-bringing-them-together (accessed on 15 July 2021).

- Jacob, D. Top 4 Reasons to Update to Quality 4.0. 2021. Available online: https://blog.lnsresearch.com/top-4-reasons-to-update-to-quality-4.0 (accessed on 15 July 2021).

- Radziwill, N. Designing a Quality 4.0 Strategy and Selecting High-Impact Initiatives. In ASQ Quality 4.0 Summit, Disruption, Innovation and Change; ASQ: Dallas, TX, USA, 2018. [Google Scholar]

- Sisodia, R.; Villegas-Forero, D. Quality 4.0—How to Handle Quality in the Industry 4.0 Revolution; Chalmers University of Technology: Gotheburg, Sweden, 2020. [Google Scholar]

- Söderqvist, L. Quality 4.0 Hetast Internationellt. Kvalitets Magasinet. 2021. Available online: https://kvalitetsmagasinet.se/quality-4-0-hetast-i-kvalitetsbranschen (accessed on 15 July 2021).

- Watson, G.H. The ascent of Quality 4.0: How the new age of quality might look like in 20 years. Qual. Prog. 2019, 52, 24–30. [Google Scholar]

- Carvalho, A.V.; Enrique, D.V.; Chouchene, A.; Charrua-Santos, F. Quality 4.0: An overview. Procedia Comput. Sci. 2021, 181, 341–346. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R. Digitalisation and Innovation in the Steel Industry in Poland-Selected Tools of ICT in an Analysis of Statistical Data and a Case Study. Energies 2021, 14, 3034. [Google Scholar] [CrossRef]

- Miśkiewicz, R.; Wolniak, R. Practical application of the Industry 4.0 concept in a steel company. Sustainability 2020, 12, 5776. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R. Transitioning of steel producers to the steelworks 4.0—Literature review with case studies. Energies 2021, 14, 4109. [Google Scholar] [CrossRef]

- Stawiarska, E.; Szwajca, D.; Matusek, M.; Wolniak, R. Diagnosis of the maturity level of implementing industry 4.0 solutions in selected functional areas of management of automotive companies in Poland. Sustainability 2021, 13, 4867. [Google Scholar] [CrossRef]

| Quality of the production raw materials | Selection of optimal process parameters | Staff qualification and involvement |

| Material composition | Stability of the assumed manufacturing processes | Functionality and reliability of machinery |

| Proper setting of efficiency norms | Process efficiency control, including: | Technological progres |

| - that of individual process phases | Hygiene and sanitary conditions | |

| - that of interoperational semi-finished product quality | Storage and shipment conditions | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drozd, R.; Wolniak, R. Systematic Assessment of Product Quality. J. Open Innov. Technol. Mark. Complex. 2021, 7, 235. https://doi.org/10.3390/joitmc7040235

Drozd R, Wolniak R. Systematic Assessment of Product Quality. Journal of Open Innovation: Technology, Market, and Complexity. 2021; 7(4):235. https://doi.org/10.3390/joitmc7040235

Chicago/Turabian StyleDrozd, Radoslaw, and Radoslaw Wolniak. 2021. "Systematic Assessment of Product Quality" Journal of Open Innovation: Technology, Market, and Complexity 7, no. 4: 235. https://doi.org/10.3390/joitmc7040235

APA StyleDrozd, R., & Wolniak, R. (2021). Systematic Assessment of Product Quality. Journal of Open Innovation: Technology, Market, and Complexity, 7(4), 235. https://doi.org/10.3390/joitmc7040235