Product Quality Planning in Laser Metal Processing Based on Open Innovation Using Quality Function Deployment

Abstract

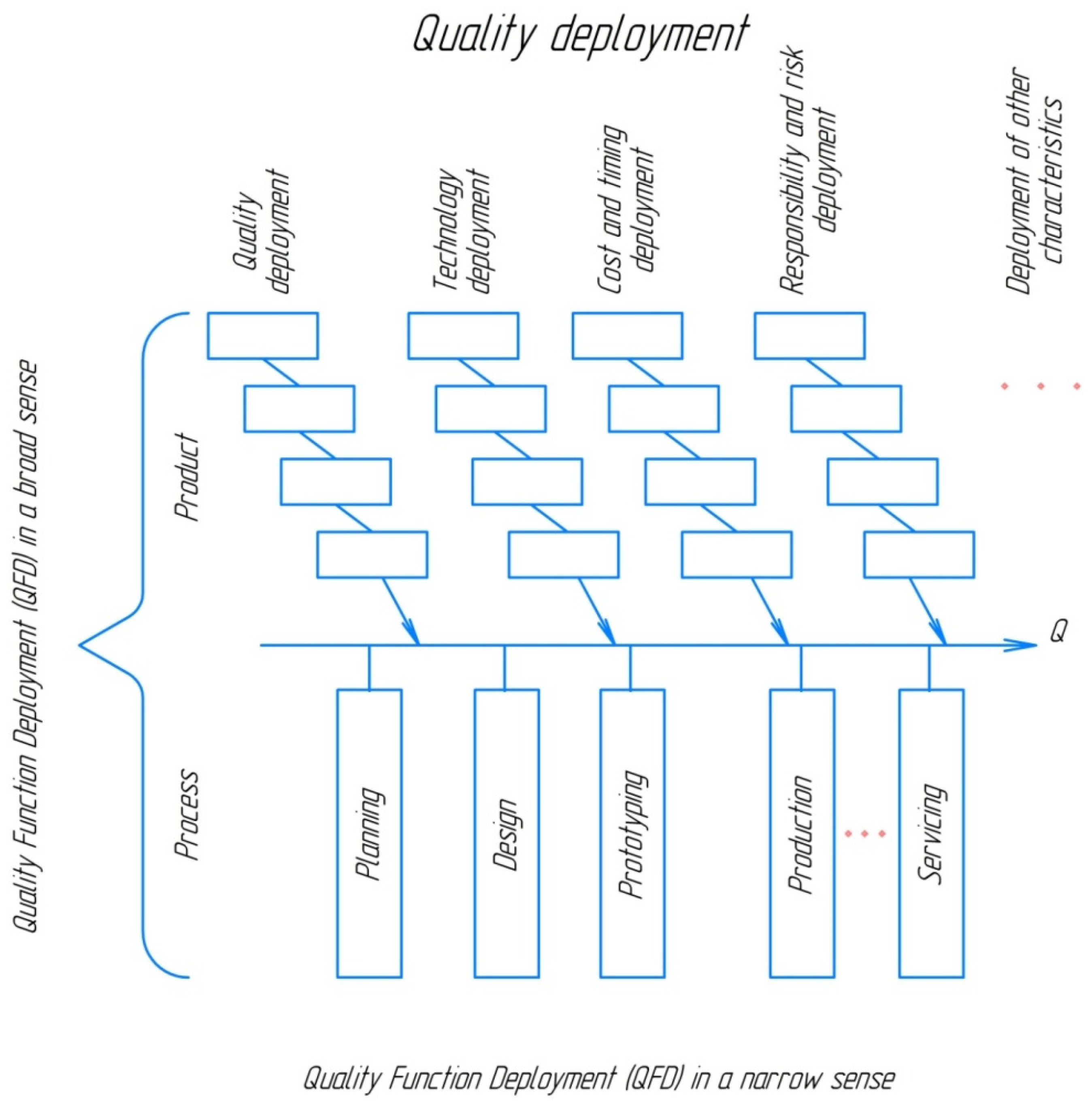

:1. Introduction

“… it is not products, but the processes of creating them which bring companies long-term success.”M. Hammer, J. Champy

2. Materials and Methods

- Production part approval process (PPAP) (the process of approving the manufacture of automobile parts);

- Advanced product Quality Planning (APQP) (quality planning in the development and manufacture of automobile parts);

- Failure mode and effects analysis (FMEA) (analysis of the forms and effects of failures);

- Measurement system analysis (MSA);

- Statistical process control (SPC);

- Quality system assessment (QSA).

3. Results and Discussion

- The importance of each consumer requirement R (1—not at all important, 2—slightly important, 3—important, 4—fairly important, 5—important);

- The link between the consumer requirements and the technical characteristics of the product P (●—strong (9), ○—average (6), ∆—weak (3)).

4. Summary

- Makes it possible to provide a systematic approach to determine the needs or requirements of consumers for product quality and outline ways to satisfy them (to allow placing a large amount of information in a compressed form convenient for efficient and clear analysis; allows a reduction in the development time by 30–50%);

- Allows you to identify the expectations of consumers in the most effective way, highlight key requirements among them, and translate them into products, optimizing the technical characteristics of the project according to the degree of customer satisfaction;

- Makes it possible to provide assurances that consumers will accept and use new products even before they are produced and placed on the market;

- Makes it possible to ensure a large market share due to the earlier appearance on the market of products with a higher level of quality;

- Makes it possible to provide a clearer definition of the processes of the organization itself;

- Provides an opportunity for optima distribution, and therefore an opportunity to use the organization’s limited resources most effectively to ensure both tactical and strategic goals are reached.

- The principle of “customer orientation” with an increase in customer satisfaction and loyalty, with an expansion of the consumer base, accompanied by an increase in income;

- The principle of “employee interaction” with the creation of teams and increasing the involvement of employees in improvement activities;

- The principle of “process approach” in the implementation of process controllability, reduction in cross-functional barriers, and efficient use of resources.

- The principle of “improvement” with strengthening the incentive to innovate, improving the results of processes;

- The principle of “evidence-based decision making” with improved decision making, increased efficiency and effectiveness of work and the use of statistical thinking.

5. Conclusions

- Competitive advantages are provided for both existing and newly developed types of products;

- Provides a systematic approach to determine the needs and requirements of consumers for product quality and creates ways to satisfy them; customer expectations are most effectively identified and translated into optimized product specifications;

- A large market share is ensured due to the earlier appearance of products with a high level of quality;

- The processes of the enterprise’s QMS are more clearly defined;

- Production resources are optimally allocated and used to ensure the tactical and strategic goals of the enterprise.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Issues Formulated by the Company’s Management | Approaches and Methods Applied by the Company’s Management to Resolve Issues | True Source of Issues |

|---|---|---|

| 1 Reduced quality of materials arriving from suppliers. | Assigning a warehouse attendant full responsibility for visual quality control. | No purchasing department. No partnership with the suppliers on creating an effective QC system. |

| 2 Insufficient managers. Poor training of managers. High personnel turnover. | Constant selection and replacement of managers. | No clear requirements for the work completed by managers. Insufficient control of management activity, which occurs on occasion. |

| 3 Confusion from the constant reworking of the organizational structure | The frequent firing of individuals in management positions. Responsibilities are passed on to staff for activities which are either above or outside of their job duties. | No reworking of management principles. Use of the most ineffective form of organizational structure (functional) in many Russian businesses. |

| 4 Disregarding the services of certain (small) segments of the consumer market. | Strengthening of the promotional department. | Incorrect promotional information. Ignorance of the issues and desires of customers. Lack of customer feedback. |

| Certification for quality systems per ISO 9001. | ||

| Lack of marketing research: the list of consumers, sectors, and market niches that are occupied by products that are not defined. | ||

| Focus on priority consumer (large). | ||

| 5 Dilapidated equipment | Expensive repairs of old equipment and acquisition of new equipment | The productivity of the production area and equipment has not been determined. The expected efficiency of equipment has not been determined. |

| 6 Lack of a friendly team atmosphere among staff | (No actions taken) | Inconsistencies and differences in the goals held by employees. Ignorance of the company’s strategy. |

| 7 Lack of information among staff about the work of the company. No transparency about the activity of management. | (No actions taken) | No feedback from staff. No consideration for the opinion of the staff. |

| The following issues, at first glance, are unrelated, or they may seem like the result of all of the aforementioned issues. However, executive management names them as factors which get in the way of developing the management system: “frequent rejection of factory goods involves searching for the guilty party, which leads to a system of fines against company personnel. As a result of these methods, personnel cannot participate in improving product quality; they sabotage the process of creating a system for quality control at the business”. | ||

| 8 Expenses from the rejection of goods (low quality of services offered). Lack of stimulus to improve efficiency among personnel (low wage, fines). | Searching for parties guilty for rejection of goods and harsh systems of punishment for personnel (wage deductions). Searching for new clients. Repair of old equipment, acquisition of new equipment. More strict process control in the manufacture of goods. | The inversely proportional relationship between the compensation received and level of responsibility among personnel and management, which makes it impossible to improve the quality of produced goods or build an effective system of management. |

| Total lack of both quality planning and control. | ||

| Inconsistencies in the quality costs system: many expenses on poor quality are not included in calculations. | ||

References

- Shim, S.-O.; Park, K.; Choi, S. Sustainable Production Scheduling in Open Innovation Perspective under the Fourth Industrial Revolution. J. Open Innov. Technol. Mark. Complex. 2018, 4, 42. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.-J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Spena, P.R. CO2 Laser Cutting of Hot Stamping Boron Steel Sheets. Metals 2017, 7, 456. [Google Scholar] [CrossRef] [Green Version]

- Syreyshchikova, N.V.; Pimenov, D.Y.; Mikolajczyk, T.; Moldovan, L. Automation of production activities of an industrial enterprise based on the ERP system. Procedia Manuf. 2020, 46, 525–532. [Google Scholar] [CrossRef]

- Huin, S.F.; Luong, L.H.S.; Abhary, K. Internal supply chain planning determinants in small and medium-sized manufacturers. Int. J. Phys. Distrib. Logist. Manag. 2002, 32, 771–782. [Google Scholar] [CrossRef]

- Saura, J.R.; Ribeiro-Soriano, D.; Palacios-Marqués, D. Setting B2B digital marketing in artificial intelligence-based CRMs: A review and directions for future research. Ind. Mark. Manag. 2021, 98, 161–178. [Google Scholar] [CrossRef]

- Saura, J.R.; Palacios-Marqués, D.; Ribeiro-Soriano, D. Digital marketing in SMEs via data-driven strategies: Reviewing the current state of research. J. Small Bus. Manag. 2021. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Pimenov, D.Y.; Kulygina, I.A.; Moldovan, L. Hybrid Model for Calculating Quality Costs. Russ. Eng. Res. 2021, 41, 382–386. [Google Scholar] [CrossRef]

- Mathrani, S.; Edwards, B. Knowledge-Sharing Strategies in Distributed Collaborative Product Development. J. Open Innov. Technol. Mark. Complex. 2020, 6, 194. [Google Scholar] [CrossRef]

- Oakland, J. Leadership and policy deployment: The backbone of TQM. Total Qual. Manag. Bus. Excell. 2011, 22, 517–534. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Pimenov, D.Y.; Yaroslavova, E.N.; Gupta, M.K.; Aamir, M.; Giasin, K. Managing Risks in the Improved Model of Rolling Mill Loading: A Case Study. J. Risk Financ. Manag. 2021, 14, 359. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Pimenov, D.Y.; Markopoulos, A.P.; Moldovan, L. Value Stream Maps in Clock Production. Russ. Eng. Res. 2021, 41, 378–381. [Google Scholar] [CrossRef]

- Tayal, A.; Kalsi, N.S.; Gupta, M.K.; Pimenov, D.Y.; Sarikaya, M.; Pruncu, C.I. Effectiveness Improvement in Manufacturing Industry; Trilogy Study and Open Innovation Dynamics. J. Open Innov. Technol. Mark. Complex. 2021, 7, 7. [Google Scholar] [CrossRef]

- Rianmora, S.; Werawatganon, S. Applying Quality Function Deployment in Open Innovation Engineering. J. Open Innov. Technol. Mark. Complex. 2021, 7, 26. [Google Scholar] [CrossRef]

- Schmeleva, A.N. Evaluation and improvement of the operating efficiency of enterprise quality management system (QMS): Conceptual bases. Qual.-Access Success 2017, 18, 100–107. [Google Scholar]

- Cordero, R.; Kirchhoff, B.A.; Walsh, S.T. Organization technologies, AMT and competent workers: Exploring relationships with manufacturing performance. J. Manuf. Technol. Manag. 2009, 20, 298–313. [Google Scholar] [CrossRef]

- Dufour, C.; Ivascu, L.; Mateescu, A.; Draghici, A. A proposed inventory of sustainable development indicators for the manufacturing process assessment. Qual.-Access Success 2019, 20, 253–258. [Google Scholar]

- Harding, J.A.; Shahbaz, M.; Srinivas; Kusiak, A. Data mining in manufacturing: A review. J. Manuf. Sci. Eng. Trans. ASME 2006, 128, 969–976. [Google Scholar] [CrossRef]

- Tripathi, V.; Chattopadhyaya, S.; Bhadauria, A.; Sharma, S.; Li, C.; Pimenov, D.Y.; Giasin, K.; Singh, S.; Gautam, G.D. An Agile System to Enhance Productivity through a Modified Value Stream Mapping Approach in Industry 4.0: A Novel Approach. Sustainability 2021, 13, 11997. [Google Scholar] [CrossRef]

- Wang, C.-H.; Chen, J.-N. Using quality function deployment for collaborative product design and optimal selection of module mix. Comput. Ind. Eng. 2012, 63, 1030–1037. [Google Scholar] [CrossRef]

- Carnevalli, J.A.; Miguel, P.C. Review, analysis and classification of the literature on QFD-Types of research, difficulties and benefits. Int. J. Prod. Econ. 2008, 114, 737–754. [Google Scholar] [CrossRef]

- Vinayak, K.; Kodali, R. Benchmarking the quality function deployment models. Benchmarking 2013, 20, 825–854. [Google Scholar] [CrossRef]

- Sivasamy, K.; Arumugam, C.; Devadasan, S.R.; Murugesh, R.; Thilak, V.M.M. Advanced models of quality function deployment: A literature review. Qual. Quant. 2015, 50, 1399–1414. [Google Scholar] [CrossRef]

- Fargnoli, M.; Sakao, T. Uncovering differences and similarities among quality function deployment-based methods in Design for X: Benchmarking in different domains. Qual. Eng. 2017, 29, 690–712. [Google Scholar] [CrossRef]

- Khan, S.A.; Dweiri, F.; Jain, V. Integrating analytical hierarchy process and quality function deployment in automotive supplier selection. Int. J. Bus. Excell. 2016, 9, 156. [Google Scholar] [CrossRef]

- Singh, M.; Sarfaraz, A.; Sarfaraz, M.; Jenab, K. Analytical QFD model for strategic justification of advanced manufacturing technology. Int. J. Bus. Excell. 2015, 8, 20. [Google Scholar] [CrossRef]

- Zheng, L.Y.; Chin, K.S. QFD based optimal process quality planning. Int. J. Adv. Manuf. Technol. 2005, 26, 831–841. [Google Scholar] [CrossRef]

- Khademi-Zare, H.; Zarei, M.; Sadeghieh, A.; Owlia, M.S. Ranking the strategic actions of Iran mobile cellular telecommunication using two models of fuzzy QFD. Telecommun. Policy 2010, 34, 747–759. [Google Scholar] [CrossRef]

- Cho, I.J.; Kim, Y.J.; Kwak, C. Application of SERVQUAL and fuzzy quality function deployment to service improvement in service centres of electronics companies. Total Qual. Manag. Bus. Excell. 2015, 27, 368–381. [Google Scholar] [CrossRef]

- Holmbom, M.; Bergquist, B.; Vanhatalo, E. Performance-based logistics—An illusive panacea or a concept for the future? J. Manuf. Technol. Manag. 2014, 25, 958–979. [Google Scholar] [CrossRef]

- Gumerov, A.V.; Biktemirova, M.K.; Babushkin, V.M.; Nuryyakhmetova, S.M.; Moiseev, R.E.; Nikolaeva, A.B.; Kharisova, R.R.; Rukomoinikova, V.P. Quality functions modeling of industrial enterprises products. Int. Rev. Manag. Market. 2016, 6, 165–169. [Google Scholar]

- Semenova, E.G.; Antokhina, Y.A.; Balashov, V.M.; Smirnova, M.S. Features of the QFD method in the development of software and hardware complexes for controlling groupings of unmanned aerial vehicles. J. Phys. Conf. Ser. 2020, 1515, 032050. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Guzeev, V.I. Planning the properties of a coated abrasive by quality function deployment. MATEC Web Conf. 2018, 224, 01026. [Google Scholar] [CrossRef]

- Pinto, A.L.D.; Paiva, C.L. Developing a functional ready to bake dough for pies using the Quality Function Deployment (QFD) method [Desenvolvimento de uma massa funcional pronta para tortas utilizando o método de Desdobramento da Função Qualidade (QFD)]. Cienc. E Tecnol. Aliment. 2010, 30 (Suppl. S1), 36–43. [Google Scholar] [CrossRef] [Green Version]

- Berkhout, A.J.; Hartmann, D.; Van Der Duin, P.; Ortt, R. Innovating the innovation process. Int. J. Technol. Manag. 2006, 34, 390–404. [Google Scholar] [CrossRef]

- Niaki, M.K.; Nonino, F. Additive manufacturing management: A review and future research agenda. Int. J. Prod. Res. 2017, 55, 1419–1439. [Google Scholar] [CrossRef]

- Obradović, T.; Vlačić, B.; Dabić, M. Open innovation in the manufacturing industry: A review and research agenda. Technovation 2021, 102, 102221. [Google Scholar] [CrossRef]

- Iqbal, M.; Suzianti, A. New Product Development Process Design for Small and Medium Enterprises: A Systematic Literature Review from the Perspective of Open Innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 153. [Google Scholar] [CrossRef]

- Hossain, M.; Kauranen, I. Open innovation in SMEs: A systematic literature review. J. Strategy Manag. 2016, 9, 58–73. [Google Scholar] [CrossRef]

- Cano, J.A.; Londoño-Pineda, A. Scientific Literature Analysis on Sustainability with the Implication of Open Innovation. J. Open Innov. Technol. Mark. Complex. 2020, 6, 162. [Google Scholar] [CrossRef]

- Enkel, E.; Gassmann, O.; Chesbrough, H. Open R&D and open innovation: Exploring the phenomenon. R D Manag. 2009, 39, 311–316. [Google Scholar] [CrossRef]

- Pogačnik, M.; Kopač, J. Technology and reducing the product development times [Tehnologija in skrajševanje časov razvoja novih izdelkov]. Stroj. Vestn.-J. Mech. Eng. 2000, 46, 103–109. [Google Scholar]

- Qattawi, A.; Mayyas, A.; Abdelhamid, M.; Omar, M.A. Incorporating quality function deployment and analytical hierarchy process in a knowledge-based system for automotive production line design. Int. J. Comput. Integr. Manuf. 2013, 26, 839–856. [Google Scholar] [CrossRef]

- Mottaeva, A.; Borisova, A. Improvement of quality of housing-and-communal services management. E3S Web Conf. 2019, 138, 02015. [Google Scholar] [CrossRef]

- Zhong-Kai, L.; Gui, L.; Yao-Dong, L. Management method and management system of non-model informationin in product design process. Chin. J. Eng. Des. 2020, 27, 13–18. [Google Scholar] [CrossRef]

- Babkin, A.V.; Kuzmina, S.N.; Oplesnina, A.V.; Kozlov, A.V. Selection of Tools of Automation of Business Processes of a Manufacturing Enterprise. In Proceedings of the 2019 International Conference “Quality Management, Transport and Information Security, Information Technologies” (IT&QM&IS), Sochy, Russia, 23–27 September 2019. [Google Scholar] [CrossRef]

- Troshkova, E.V.; Levshina, V.L. Quality management system of complex economic entity as organizational innovation. Int. J. Qual. Res. 2018, 12, 193–208. [Google Scholar] [CrossRef]

- Sharashkina, T.P. Methodical aspects of organization and carrying out of functional-cost analysis on the basis of process approach for the purpose of expenses and quality optimization. Eur. Res. Stud. J. 2016, 19, 77–96. [Google Scholar] [CrossRef] [Green Version]

- Ishak, A.; Ginting, R.; Malik, A.F. Integration of quality function deployment (QFD) and value engineering in improving the quality of product: A literature review. AIP Conf. Proc. 2020, 2217, 030158. [Google Scholar] [CrossRef]

- Savelyeva, O.S.; Syreishchikova, N.V. Product quality planning using the latest technologies. In Scientific. Works of International. Youth Scientific. Conference “XXXVI Gagarin Readings”; MATI: Moscow, Russia, 2010; Volume 6, pp. 157–159. [Google Scholar]

| Responsibility | ResponsibleParty |

|---|---|---|

| 1 Determining consumer demands | Head of marketing | |

| 2 Ranking consumer demands | Quality assurance manager | |

| 3 Developing technical characteristics | Engineers | |

| 4 Determining the relationship between consumer demands and technical characteristics | Engineers | |

| 5 Determining the correlations between technical characteristics | Quality assurance manager | |

| 6 Determining the weight of technical characteristic indicators | Quality assurance manager | |

| 7 Evaluating the importance of each indicator | Head engineer | |

| 8 Evaluation of the influence of competitors | Quality assurance manager | |

| 9 Adopting solutions | Head engineer | |

| 10 Formation of a part quality report | Quality assurance manager | |

| 11 House of quality analysis | CEO of Laser Technologies JV OOO | |

| 12 Final evaluation and determination of the importance of improving characteristics of the produced flange | CEO of Laser Technologies JV OOO | |

| 13 Determining if the house of quality is up to date and applicable | Head engineer | |

| 14 Making changes, adjustments | Quality assurance manager |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syreyshchikova, N.V.; Pimenov, D.Y.; Yaroslavova, E.N.; Gupta, M.K.; Sharma, S.; Giasin, K. Product Quality Planning in Laser Metal Processing Based on Open Innovation Using Quality Function Deployment. J. Open Innov. Technol. Mark. Complex. 2021, 7, 240. https://doi.org/10.3390/joitmc7040240

Syreyshchikova NV, Pimenov DY, Yaroslavova EN, Gupta MK, Sharma S, Giasin K. Product Quality Planning in Laser Metal Processing Based on Open Innovation Using Quality Function Deployment. Journal of Open Innovation: Technology, Market, and Complexity. 2021; 7(4):240. https://doi.org/10.3390/joitmc7040240

Chicago/Turabian StyleSyreyshchikova, Nelli Vladimirovna, Danil Yurievich Pimenov, Elena Nikolaevna Yaroslavova, Munish Kumar Gupta, Shubham Sharma, and Khaled Giasin. 2021. "Product Quality Planning in Laser Metal Processing Based on Open Innovation Using Quality Function Deployment" Journal of Open Innovation: Technology, Market, and Complexity 7, no. 4: 240. https://doi.org/10.3390/joitmc7040240

APA StyleSyreyshchikova, N. V., Pimenov, D. Y., Yaroslavova, E. N., Gupta, M. K., Sharma, S., & Giasin, K. (2021). Product Quality Planning in Laser Metal Processing Based on Open Innovation Using Quality Function Deployment. Journal of Open Innovation: Technology, Market, and Complexity, 7(4), 240. https://doi.org/10.3390/joitmc7040240