Digitalization of Small and Medium-Sized Enterprises and Economic Growth: Evidence for the EU-27 Countries

Abstract

:1. Introduction

- (1)

- What is the level of digital maturity of SMEs among the EU-27 countries?

- (2)

- What are similarities between the EU-27 countries in terms of digital technologies implemented in SMEs?

- (3)

- Do the economic parameters of the EU-27 economies affect the state of digitalization (which is measured by the value of the digitalization index) in these countries?

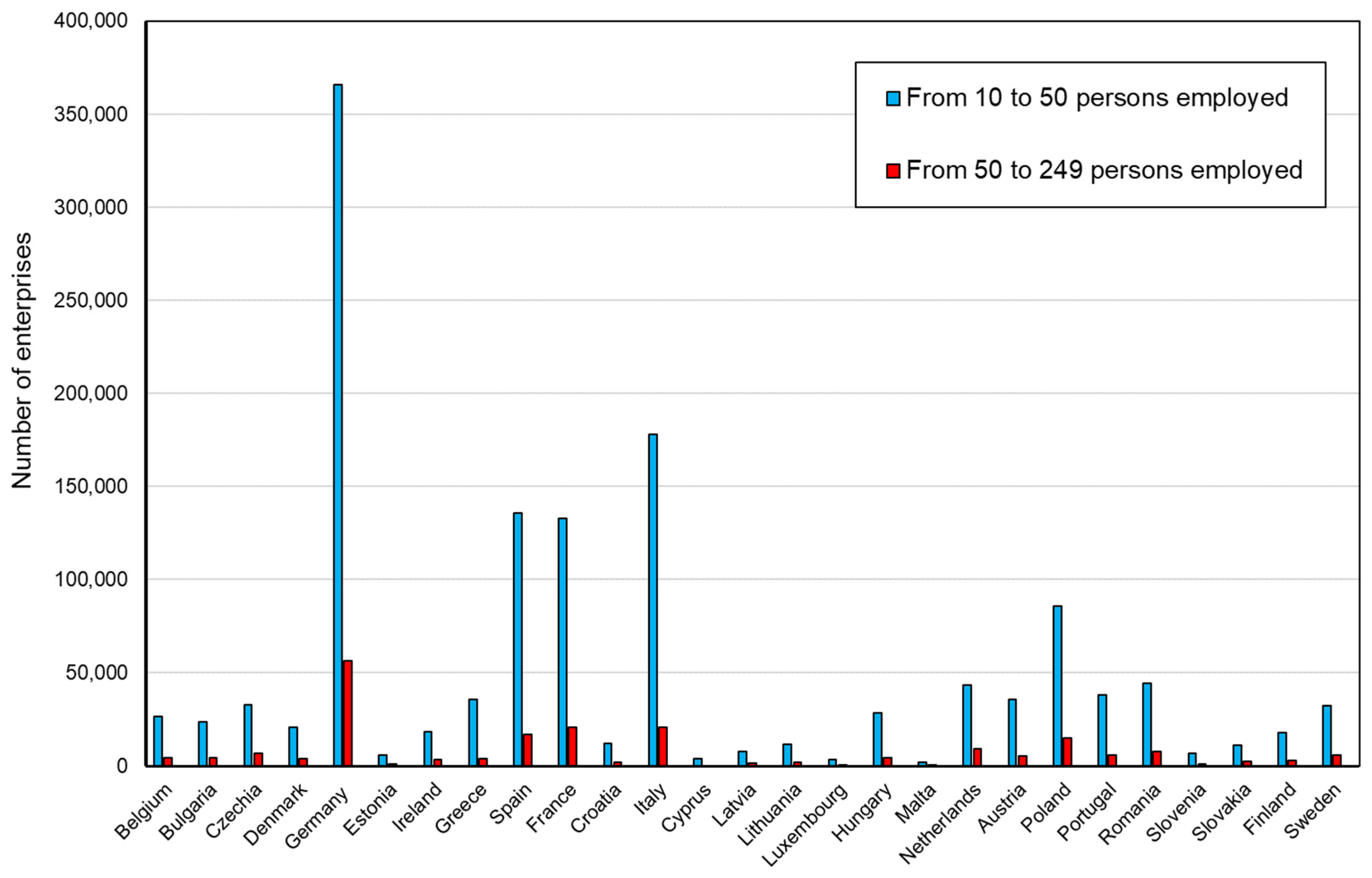

2. The Role and Significance of SMEs in the EU

- –

- A medium-sized enterprise has up to 250 employees (and not more than 10), a turnover of up to EUR 50 million, or a balance sheet total of up to EUR 43 million.

- –

- A small enterprise has between 10 and 50 employees and a turnover or balance sheet total up to EUR 10 million.

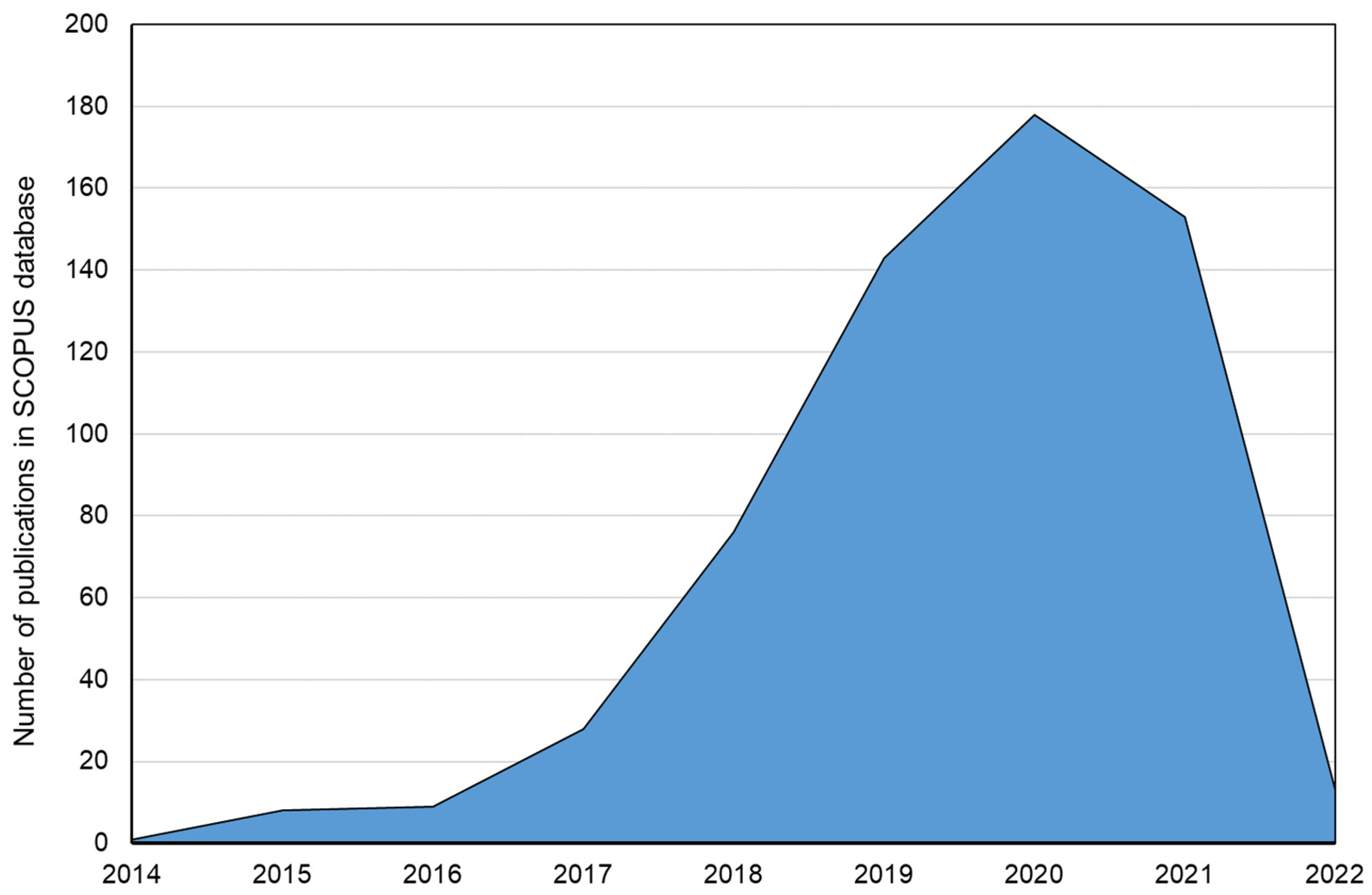

3. Literature Review

3.1. Industry 4.0 in SMEs

3.2. Models Used to Assess the Digital Maturity and Readiness of Enterprises

3.3. Open Innovation Dynamics in the Context of Industry 4.0 and SME’s

4. Materials and Methods

4.1. Data

4.2. Methods

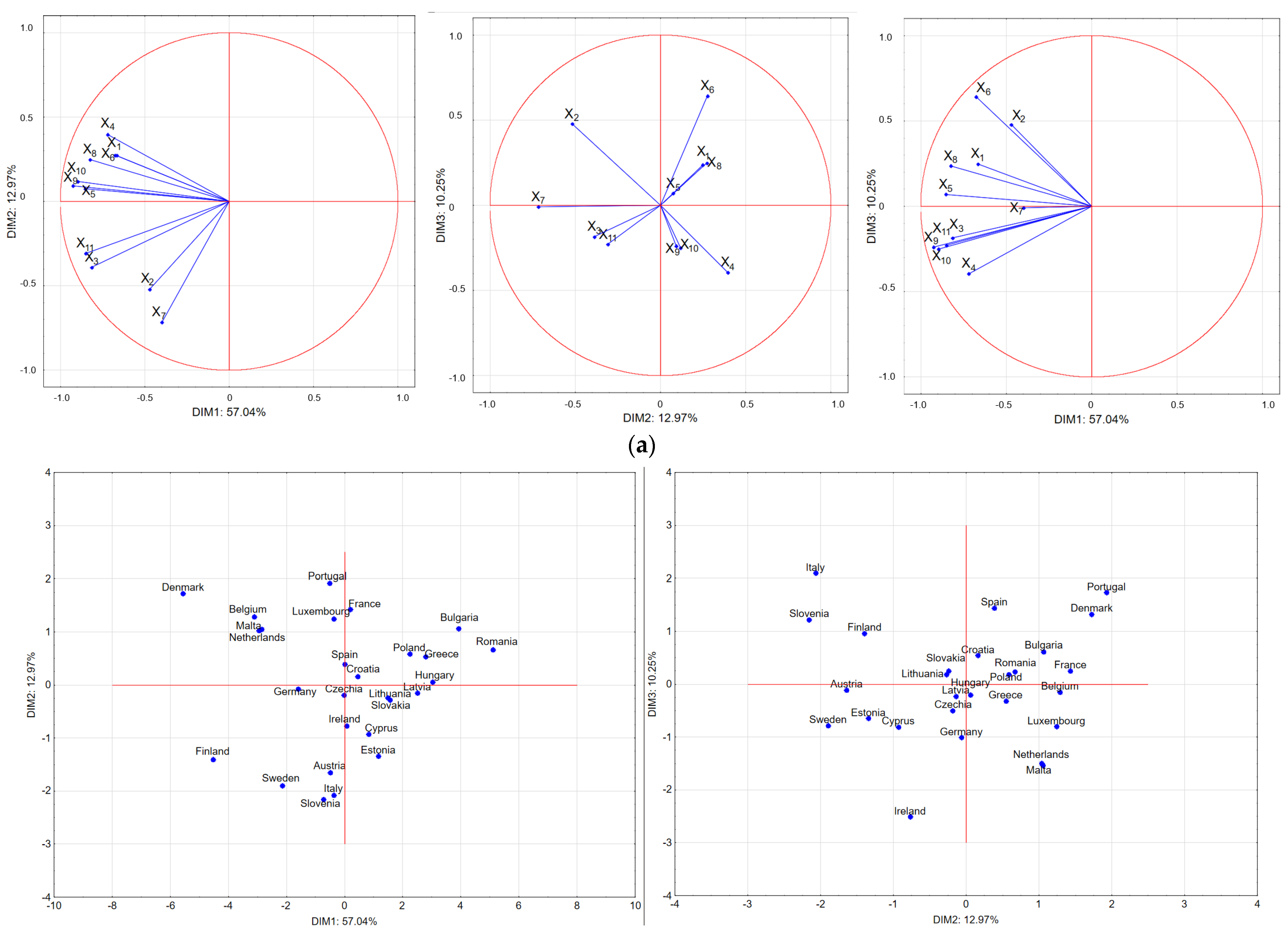

4.2.1. The PCA Method

4.2.2. The EDAS Method

- To construct a decision matrix with m number of alternatives and n number of criteria:

- To determine an average solution for all criteria:

- To calculate, for each alternative, the PDA matrix (positive distance from the mean solution) and the NDA matrix (negative distance):where for stimulants:and for destimulants:

- To determine the weighted sums of PDA and NDA for each alternative (from Equations (12) and (13)):where wj is the weight of the j-th criterion determined according to Equation (14):wherewhere nij is the proportion of samples in time t in the i indicator.

- To normalize the SP and SN values, according to Equations (17) and (18):

- To determine the appraisal score (ASi) index for each alternative:

- To rank the ASi values in descending order.

- (1)

- Expert level:

- (2)

- Advanced level:

- (3)

- Intermediate level:

- (4)

- Beginner level:where is the mean value of the ASi, and is the standard deviation of ASi.

4.2.3. Nonparametric Tests

5. Results

5.1. The Preliminary Analysis

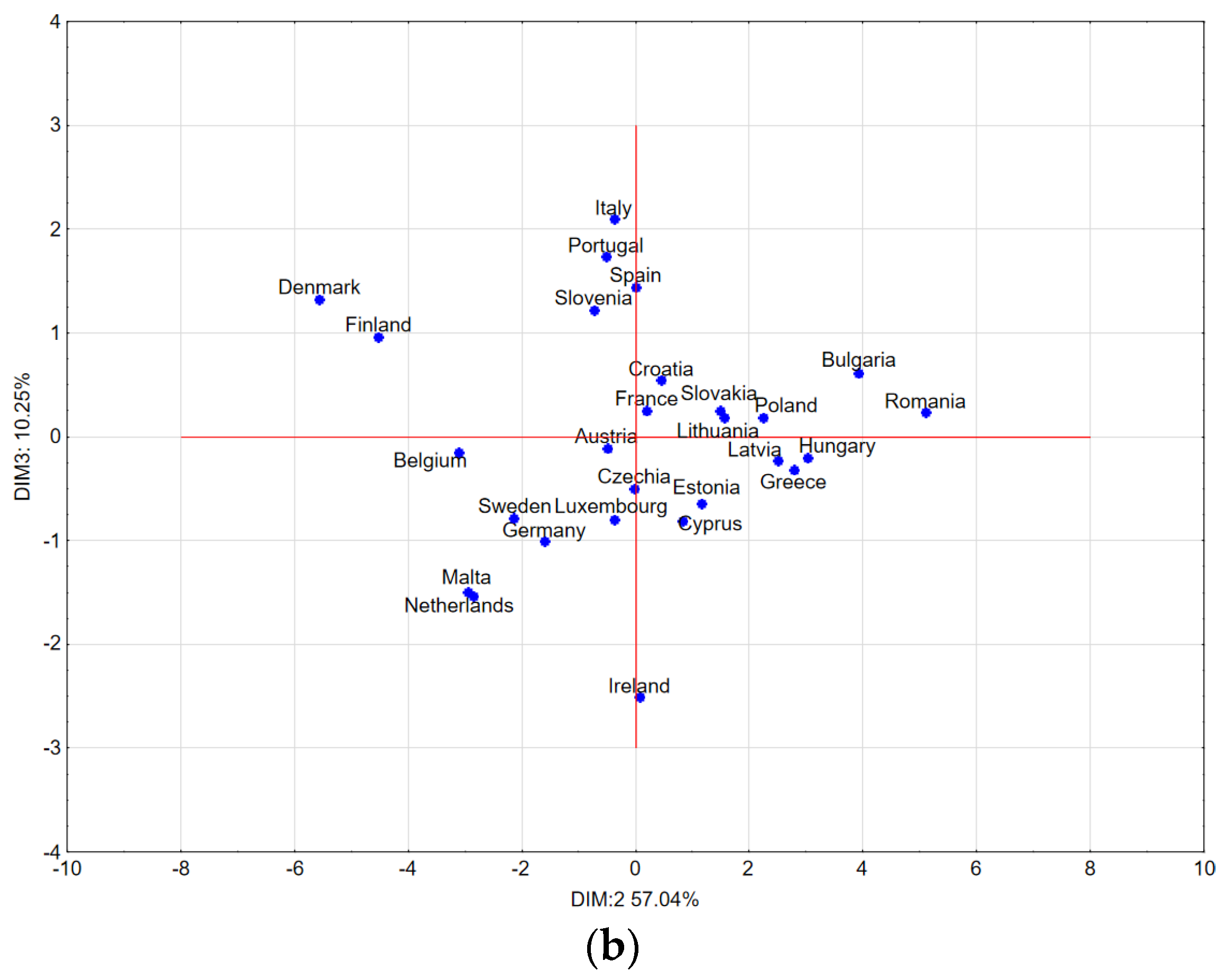

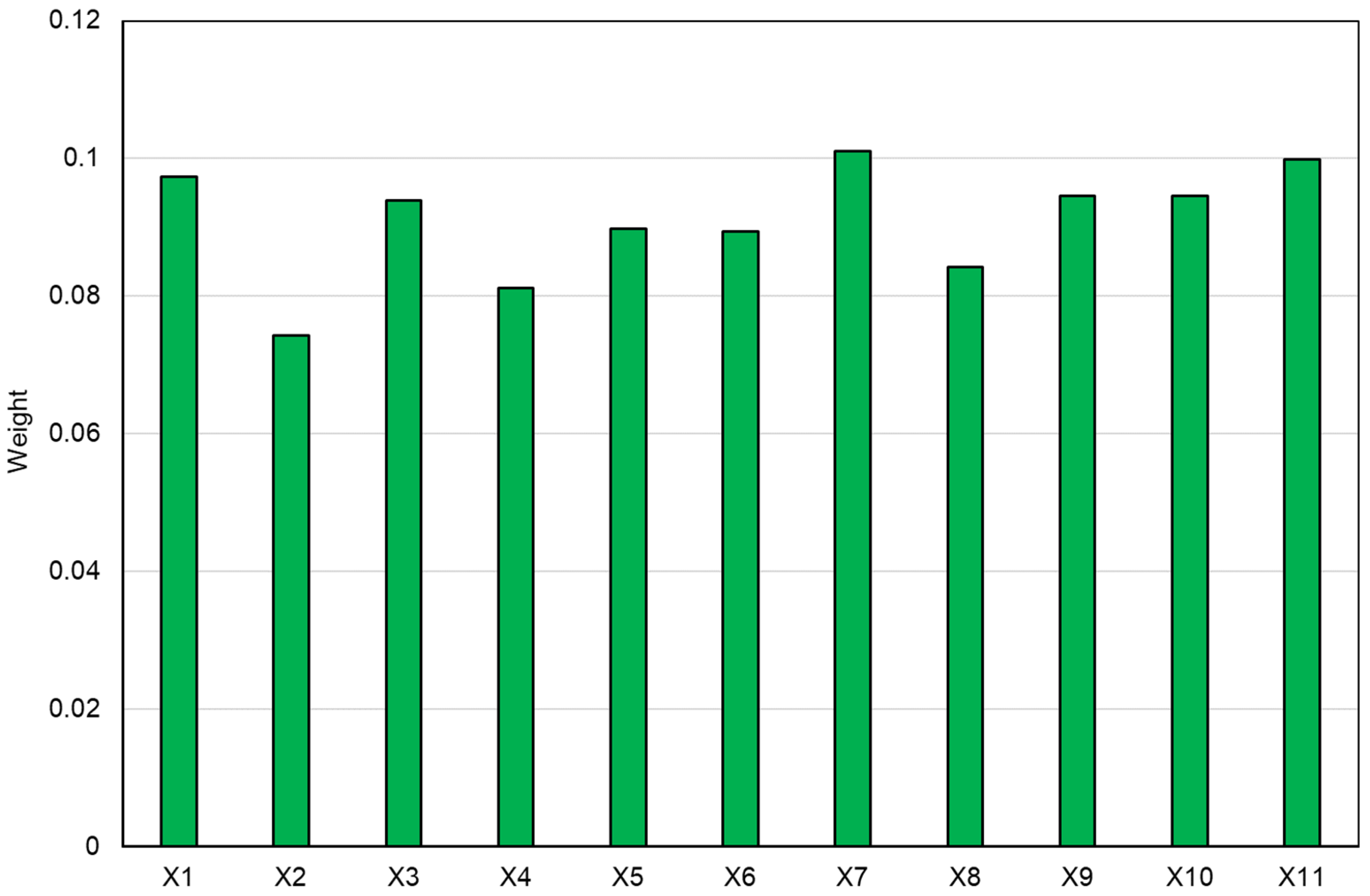

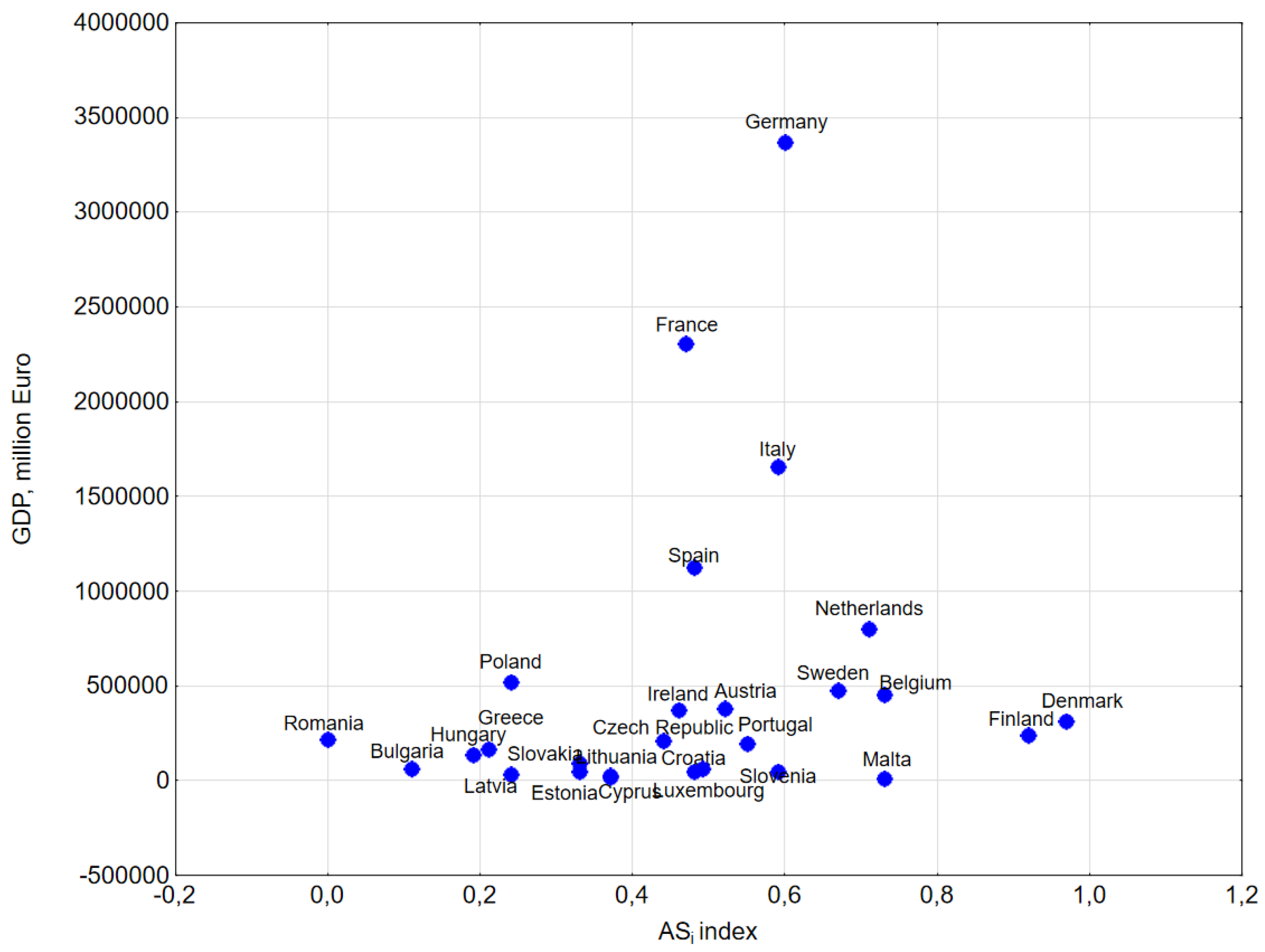

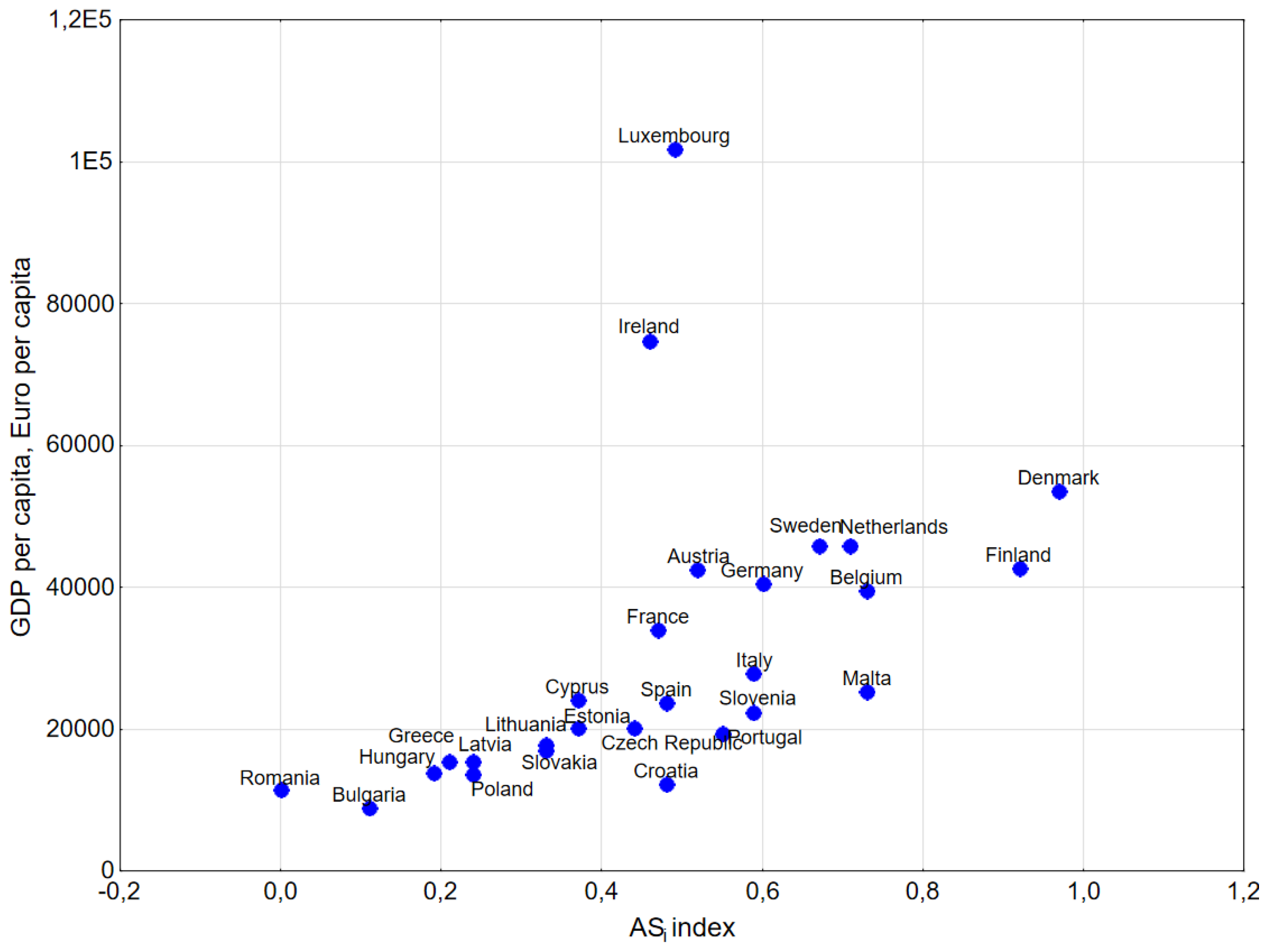

5.2. The Fundamental Research

6. Discussion

6.1. Digitalization of SMEs

6.2. Digitalization of SMEs and Open Innovation

7. Conclusions

- Digital technologies identified with Industry 4.0 most frequently used by SMEs in the EU-27 are the use of websites, cloud services, and having a VPN as a cybersecurity measure. At the same time, the least used technologies are 3D printing and industrial or service robots.

- The EU-27 countries are very heterogeneous in terms of the sophistication of digital technologies implemented in SMEs. Within the EU-27 as a whole, two groups of countries can be distinguished, with few exceptions, in terms of the digitalization of this group of enterprises. Definitely more advanced in this regard are the countries of the old union (except Greece), and much less—the countries of the new union (except Malta and Slovenia).

- The expert level of digital maturity of SMEs was achieved by Denmark, Finland, Malta, the Netherlands, and Belgium, and the advanced level by Sweden, Portugal, Germany, Slovenia, Austria, Luxembourg, Italy, Croatia, France, Spain, and Ireland. The intermediate-level countries included the Czech Republic, Estonia, Cyprus, Latvia, Lithuania, Poland, and Slovakia. The group of countries with the lowest, beginner level of digital maturity in SMEs included Bulgaria, Hungary, Romania, and Greece.

- A positive, statistically significant relationship was confirmed between economic parameters such as GDP per capita, business enterprise expenditure on R&D (for SMEs), business enterprise expenditure on R&D, and gross domestic expenditure on R&D, and the digital index (ASi) of SMEs for the EU-27 countries. Thus, these parameters were found to be relevant for the digitalization process of SMEs. At the same time, it was confirmed that the GDP value of each country is not more significant for the digital development of SMEs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Adedoyin, F.F.; Bekun, F.V.; Driha, O.M.; Balsalobre-Lorente, D. The effects of air transportation, energy, ICT and FDI on economic growth in the industry 4.0 era: Evidence from the United States. Technol. Forecast. Soc. Chang. 2020, 160, 12029. [Google Scholar] [CrossRef] [PubMed]

- Karaman Aksentijević, N.; Ježić, Z.; Zaninović, P.A. The Effects of Information and Communication Technology (ICT) Use on Human Development—A Macroeconomic Approach. Economies 2021, 9, 128. [Google Scholar] [CrossRef]

- Lee, J. Industry 4.0 in big data environment. Ger. Harting Mag. 2013, 1, 8–10. [Google Scholar]

- Ober, J.; Kochmańska, A. Adaptation of Innovations in the IT Industry in Poland: The Impact of Selected Internal Communication Factors. Sustainability 2022, 14, 140. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. Int. J. Ind. Manuf. Syst. Eng. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Sima, V.; Gheorghe, I.G.; Subić, J.; Nancu, D. Influences of the Industry 4.0 Revolution on the Human Capital Development and Consumer Behavior: A Systematic Review. Sustainability 2020, 12, 4035. [Google Scholar] [CrossRef]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, E.; Eburdy, R. Identification of critical success factors, risks and opportunities of Industry 4.0 in SMEs. Int. J. Prod. Res. 2020, 58, 1384–1400. [Google Scholar] [CrossRef]

- Linder, C. Customer orientation and operations: The role of manufacturing capabilities in small- and medium-sized enterprises. Int. J. Prod. Econ. 2019, 216, 105–117. [Google Scholar] [CrossRef]

- Amaral, A.; Peças, P. A Framework for Assessing Manufacturing SMEs Industry 4.0 Maturity. Appl. Sci. 2021, 11, 6127. [Google Scholar] [CrossRef]

- Gherghina, Ș.C.; Botezatu, M.A.; Hosszu, A.; Simionescu, L.N. Small and Medium-Sized Enterprises (SMEs): The Engine of Economic Growth through Investments and Innovation. Sustainability 2020, 12, 347. [Google Scholar] [CrossRef] [Green Version]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef] [Green Version]

- Bag, S.; Gupta, S.; Kumar, S. Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. Int. J. Prod. Econ. 2021, 231, 107844. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.K.; Dwivedi, Y.K. Application of industry 4.0 technologies in SMEs for ethical and sustainable operations: Analysis of challenges. J. Clean. Prod. 2020, 275, 124063. [Google Scholar] [CrossRef] [PubMed]

- Poor, P.; Basl, J. Czech republic and processes of industry 4.0 implementation. Ann. DAAAM Proc. Int. DAAAM Symp. 2018, 29, 454–459. [Google Scholar]

- EUR-Lex. A Digital Agenda for Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52010DC0245&from=en (accessed on 20 February 2022).

- EUR-Lex. European Broadband: Investing in Digitally Driven Growth. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=LEGISSUM:si0017&from=EN (accessed on 20 February 2022).

- EUR-Lex. Towards a Thriving Data-Driven Economy. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2014%3A0442%3AFIN (accessed on 20 February 2022).

- EUR-Lex. The EU’s New Digital Single Market. Strategy. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=legissum:3102_3 (accessed on 20 February 2022).

- EUR-Lex. Building a European Data Economy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1521790097276&uri=CELEX:52017DC0009 (accessed on 20 February 2022).

- EUR-Lex. Information Society. Available online: http://eur-lex.europa.eu/summary/chapter/information_society.html?root_default=SUM_1_CODED%3D31&locale=en#s_1244 (accessed on 20 February 2022).

- European Commission. The Age of Artificial Intelligence: Towards a European Strategy for Human-Centric Machines. Available online: https://ec.europa.eu/jrc/communities/en/node/1286/document/age-artificial-intelligence-towards-european-strategy-human-centric-machines (accessed on 20 February 2022).

- The Digital Europe Programme. Available online: https://digital-strategy.ec.europa.eu/en/activities/digital-programme (accessed on 20 February 2022).

- Bouwman, H.; Nikou, S. Digitalization, business models, and SMEs: How do business model innovation practices improve performance of digitalizing SMEs? Telecommun. Policy 2019, 43, 101828. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Ching, N.T. Adoption of digital technologies of smart manufacturing in smes. J. Ind. Inf. Integr. 2019, 16, 100107. [Google Scholar] [CrossRef]

- Gillani, F.; Chatha, K.A.; Sadiq Jajja, M.S.; Farooq, S. Implementation of digital manufacturing technologies: Antecedents and consequences. Int. J. Prod. Econ. 2020, 229, 107748. [Google Scholar] [CrossRef]

- Türkeș, M.C.; Oncioiu, I.; Aslam, H.D.; Marin-Pantelescu, A.; Topor, D.I.; Căpușneanu, S. Drivers and Barriers in Using Industry 4.0: A Perspective of SMEs in Romania. Processes 2019, 7, 153. [Google Scholar] [CrossRef] [Green Version]

- Basl, J. Pilot study of readiness of Czech companies to implement the principles of industry 4.0. Manag. Prod. Eng. Rev. 2017, 8, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Nikolova-Alexieva, V.; Bogdanova Mihova, T. Measuring the level of digital maturity of Bulgarian industrial enterprises. Int. Sci. J. Ind. 4.0 2019, 4, 258–264. [Google Scholar]

- Castelo-Branco, I.; Cruz-Jesus, F.; Oliveira, T. Assessing industry 4.0 readiness in manufacturing: Evidence for the European union. Comput. Ind. 2019, 107, 22–32. [Google Scholar] [CrossRef]

- Commission Recommendation of 6 May 2003 Concerning the Definition of Micro, Small and Medium-Sized Enterprises (Notified under Document Number C(2003) 1422) (OJ L 124, 20.5.2003). 2003. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32003H0361 (accessed on 3 March 2022).

- Glossary of Summaries—Small and Medium-Sized Enterprises. Available online: https://eur-lex.europa.eu/summary/glossary/sme.html (accessed on 20 February 2022).

- Annual Report on European SMEs 2020/2021. Available online: https://www.ggb.gr/sites/default/files/basic-page-files/SME%20Annual%20Report%20-%202021.pdf (accessed on 20 February 2022).

- An SME Strategy for a Sustainable and Digital Europe. Available online: https://ec.europa.eu/info/sites/default/files/communication-sme-strategy-march-2020_en.pdf (accessed on 20 February 2022).

- Booth, A.; Papaioannou, D.; Sutton, A. Systematic Approaches to a Successful Literature Review; Sage Publications: London, UK, 2012. [Google Scholar]

- Herkommer, O.; Kauffmann, M.; Hieble, K. Erfolg der Produktion von morgen: Transparenz, Durchgängigkeit und die Integration aller Ebenen. Succes of the production of tomorrow. ZWF Z. Fuer Wirtsch. Fabr. 2014, 109, 153–158. [Google Scholar]

- Cotrino, A.; Sebastián, M.A.; González-Gaya, C. Industry 4.0 Roadmap: Implementation for Small and Medium-Sized Enterprises. Appl. Sci. 2020, 10, 8566. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Liebrecht, C.; Kandler, M.; Lang, M.; Schaumann, S.; Stricker, N.; Wuest, T.; Lanza, G. Decision support for the implementation of Industry 4.0 methods: Toolbox, Assessment and Implementation Sequences for Industry 4.0. J. Manuf. Syst. 2021, 58, 412–430. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.I. Sustainable Industrial Value Creation in SMEs: A Comparison between Industry 4.0 and Made in China 2025. Int. J. Precis. Eng. Manuf.-Green Tech. 2018, 5, 659–670. [Google Scholar] [CrossRef] [Green Version]

- Hamidi, S.R.; Aziz, A.A.; Shuhidan, S.M.; Aziz, A.A.; Mokhsin, M. SMEs Maturity Model Assessment of IR4.0 Digital Transformation. In Proceedings of the 7th International Conference on Kansei Engineering and Emotion Research 2018. KEER 2018; Lokman, A., Yamanaka, T., Lévy, P., Chen, K., Koyama, S., Eds.; Advances in Intelligent Systems and Computing; Springer: Singapore, 2018; Volume 739. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Mittal, S.; Romero, D.; Wuest, T. Towards a Smart Manufacturing Maturity Model for SMEs (SM3E). Advances in Production. Manag. Syst. Smart Manuf. Ind. 2018, 4, 155–163. [Google Scholar]

- Orzes, G.; Rauch, E.; Bednar, S.; Poklemba, R. Industry 4.0 implementation barriers in small and medium sized enterprises: A focus group study. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 1348–1352. [Google Scholar]

- Rauch, E.; Matt, D.T.; Brown, C.A.; Towner, W.; Vickery, A.; Santiteerakul, S. Transfer of industry 4.0 to small and medium sized enterprises. Adv. Transdisc. Eng. 2018, 7, 63–71. [Google Scholar]

- Sevinç, A.; Gür, Ş.; Eren, T. Analysis of the Difficulties of SMEs in Industry 4.0 Applications by Analytical Hierarchy Process and Analytical Network Process. Processes 2018, 6, 264. [Google Scholar] [CrossRef] [Green Version]

- Brozzi, R.; Riedl, M.; Matta, D. Key Readiness Indicators To Assess The Digital Level of Manufacturing SMEs. Procedia CIRP 2021, 96, 201–206. [Google Scholar] [CrossRef]

- Genest, M.C.; Gamache, S. Prerequisites for the implementation of Industry 4.0 in manufacturing SMEs. Procedia Manuf. 2020, 51, 1215–1220. [Google Scholar] [CrossRef]

- Lassnig, M.; Müller, J.M.; Klieber, K.; Zeislerand, A.; Schirl, M. A digital readiness check for the evaluation of supply chain aspects and company size for Industry 4.0. J. Manuf. Technol. Manag. 2021, 33, 1–18. [Google Scholar] [CrossRef]

- Pirola, F.; Cimini, C.; Pinto, R. Digital readiness assessment of Italian SMEs: A case-study research. J. Manuf. Technol. Manag. 2020, 31, 1045–1083. [Google Scholar] [CrossRef]

- Azevedo, A.; Almeida, A.H. Grasp the Challenge of Digital Transition in SMEs—A Training Course Geared towards. Decis.-Mak. Educ. Sci. 2021, 11, 151. [Google Scholar]

- Christensen, C.; Schmitt, M.K.; Larsen, M.S.S.; Heidemann Lassen, A. The Effect of Digital Maturity on Strategic Approaches to Digital Transformation. In Towards Sustainable Customization: Bridging Smart Products and Manufacturing Systems. CARV 2021, MCPC 2021; Andersen, A.L., Andersen, R., Brunoe, T.D., Larsen, M.S.S., Nielsen, K., Napoleone, A., Kjeldgaard, S., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Cognet, B.; Pernot, J.P.; Rivest, L.; Danjou, C.; Wuest, T.; Kärkkäinen, H.; Lafleur, M. Towards a Novel Comparison Framework of Digital Maturity Assessment Models. In Product Lifecycle Management in the Digital Twin Era. PLM 2019; Fortin, C., Rivest, L., Bernard, A., Bouras, A., Eds.; IFIP Advances in Information and Communication Technology; Springer: Berlin, Germany, 2019; Volume 565. [Google Scholar]

- Garzoni, A.; De TuriSecundo, G.I.; Del Vecchio, P. Fostering digital transformation of SMEs: A four levels approach. Manag. Decis. 2020, 58, 1543–1562. [Google Scholar] [CrossRef]

- Sassanelli, C.; Panetto, H.; Guédria, W.; Terzi, S.; Doumeingts, G. Towards a reference model for configuring services portfolio of digital innovation hubs: The ETBSD model. In Proceedings of the 21st IFIP/SOCOLNET Working Conference on Virtual Enterprises, PRO-VE 2020, Valencia, Spain, 23–25 November 2020; pp. 597–607. [Google Scholar]

- Verhovnik, J.; Duh, E.S. The importance of industry 4.0 and digital transformation for SMEs. Elektroteh. Vestn. 2021, 88, 147–149. [Google Scholar]

- Cunha, L.; Sousa, C. A Model for Designing SMES’ Digital Transformation Roadmap. In Trends and Applications in Information Systems and Technologies. WorldCIST 2021; Rocha, Á., Adeli, H., Dzemyda, G., Moreira, F., Ramalho Correia, A.M., Eds.; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity approach for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp. 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Pacchini, A.P.T.; Lucatoa, W.C.; Facchini, F.; Mummolo, G. The degree of readiness for the implementation of Industry 4.0. Comput. Ind. 2019, 113, 103125. [Google Scholar] [CrossRef]

- Kljajić Borštnar, M.; Pucihar, A. Multi-Attribute Assessment of Digital Maturity of SMEs. Electronics 2021, 10, 885. [Google Scholar] [CrossRef]

- Jung, K.; Kulvatunyou, B.; Choi, S.; Brundage, M.P. An Overview of a Smart Manufacturing System Readiness Assessment. IFIP-Adv. Inf. Commun. Technol. 2016, 488, 705–712. [Google Scholar]

- Rockwellautomation: The Connected Enterprise Maturity Model. 2014. Available online: https://literature.rockwellautomation.com/idc/groups/literature/documents/wp/cie-wp002_-en-p.pdf (accessed on 20 February 2022).

- Lichtblau, K.; Stich, V.; Bertenrath, R.; Blum, M.; Bleider, M.; Millack, A.; Schmitt, K.; Schmitz, E.; Schröter, M. IMPULS-Industrie 4.0-Readiness; Impuls-Stiftung des VDMA: Stuttgart, Germany, 2015. [Google Scholar]

- PwC. Price Water House Coopers: The Industry 4.0/Digital Operations Self Assessment. 2016. Available online: https://i40-self-assessment.pwc.de/i40/landing/ (accessed on 20 February 2022).

- Leyh, C.; Schäffer, T.; Bley, K.; Forstenhäusler, S. SIMMI 4.0—A Maturity Model for Classifying the Enterprise-wide IT and Software. Landscape Focusing on Industry 4.0. Proc. Fed. Conf. Comput. Sci. Inf. Syst. 2016, 8, 1297–1302. [Google Scholar]

- Oleśków-Szłapka, J.; Stachowiak, A. The Framework of Logistics 4.0 Maturity Model. In Intelligent Systems in Production Engineering and Maintenance. ISPEM 2018; Burduk, A., Chlebus, E., Nowakowski, T., Tubis, A., Eds.; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2019; Volume 835. [Google Scholar]

- Lee, J.; Jun, S.; Chang, T.-W.; Park, J. A Smartness Assessment Framework for Smart Factories Using Analytic Network Process. Sustainability 2017, 9, 794. [Google Scholar] [CrossRef] [Green Version]

- Veza, I.; Crnjac, M.; Mladineo, M. The Croatian model of Innovative smart Enterprise for Different Sizes of Enterprise. 18th International Conference on Applied Mechanics and Mechanical Engineering. Available online: https://amme.journals.ekb.eg/article_34996_11ed4bd537135288df5f25089c1147e2.pdf (accessed on 20 February 2022).

- Akdil, K.Y.; Ustundag, A.; Cevikcan, E. Maturity and Readiness Model for Industry 4.0 Strategy. In Industry 4.0: Managing The Digital Transformation; Springer Series in Advanced Manufacturing; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Scremin, L.; Armellini, F.; Brun, A.; Solar-Pelletier, L.; Beaudry, C. Towards a framework for assessing the maturity of manufacturing companies in industry 4.0 adoption. In Analyzing the Impacts of Industry 4.0 in Modern Business Environments; IGI Global: Hershey, PA, USA, 2018; pp. 224–254. [Google Scholar]

- Ganzarain, J.; Errasti, N. Three Stage Maturity Model in SME’s towards Industry 4.0. J. Ind. Eng. Manag. 2016, 9, 1119–1128. [Google Scholar] [CrossRef]

- Schneider, P. Managerial challenges of Industry 4.0: An empirically backed research agenda for a nascent field. Rev. Manag. Sci. 2018, 12, 3, 803–848. [Google Scholar] [CrossRef]

- West, J.; Lakhani, K.R. Getting clear about communities in open innovation. Ind. Innov. 2008, 15, 223–231. [Google Scholar] [CrossRef]

- Dahlander, L.; Gann, D.M. How open is innovation? Res. Policy 2010, 39, 699–709. [Google Scholar] [CrossRef]

- Narula, R. R&D collaboration by SMEs: New opportunities and limitations in the face of globalisation. Technovation 2004, 25, 153–161. [Google Scholar]

- Ingaldi, M.; Ulewicz, R. Problems with the Implementation of Industry 4.0 in Enterprises from the SME Sector. Sustainability 2020, 12, 217. [Google Scholar] [CrossRef] [Green Version]

- Horváth, D.; Szabó, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2017, 56, 8, 2975–2987. [Google Scholar] [CrossRef]

- Leiponen, A.; Helfat, C.E. Innovation objectives, knowledge sources, and the bene-fits of breadth. Strateg. Manag. J. 2010, 31, 224–236. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.H.; Newby, M.; Macaulay, M.J. Information technology adoption in small business: Confirmation of a proposed framework. J. Small Bus. Manag. 2015, 53, 207–227. [Google Scholar] [CrossRef]

- Agostini, L.; Filippini, R. Organizational and managerial challenges in the path toward Industry 4.0. Eur. J. Innov. Manag. 2019, 22, 406–421. [Google Scholar] [CrossRef]

- Eurostat Database. Available online: https://ec.europa.eu/eurostat/web/main/data/database (accessed on 10 January 2022).

- Daszykowski, M.; Walczak, B. Analiza czynników głównych i inne metody eksploracji danych. In Chemometria w Analityce; Zuba, D., Parczewski, A., Eds.; IES: Kraków, Poland, 2008. [Google Scholar]

- Keshavarz Ghorabaee, M.; Amiri, M.; Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J. Stochastic EDAS method for multi-criteria decision-making with normally distributed data. J. Intell. Fuzzy Syst. 2017, 33, 1627–1638. [Google Scholar] [CrossRef]

- Abdi, H. Kendall rank correlation. In Encyclopedia of Measurement and Statistics; Salkind, W.N.J., Ed.; Sage: Thousand Oaks, CA, USA, 2007. [Google Scholar]

- Kaiser, H.F. The application of electronic computers to factor analysis. Educ. Psychol. Meas. 1960, 20, 141–151. [Google Scholar] [CrossRef]

- Gower, J.C.; Le Roux, N.C.; Gardner-Lubbe, S. Understanding Biplots; John Wiley&Sons, Ltd.: Hoboken, NJ, USA, 2011. [Google Scholar]

- DESI. The Digital Economy and Society Index. 2021. Available online: https://digital-strategy.ec.europa.eu/en/policies/desi (accessed on 20 February 2022).

- Ozekicioglu, S.; Yetiz, F. Financial Supports Provided to SMEs Within the Context of the European Union’s Budget. In Handbook of Research on Social and Economic Development in the European Union; 2020; Available online: https://www.igi-global.com/chapter/financial-supports-provided-to-smes-within-the-context-of-the-european-unions-budget/242879 (accessed on 20 February 2022).

- Laitsou, E.; Kargas, A.; Varoutas, D. Digital Competitiveness in the European Union Era: The Greek Case. Economies 2020, 8, 85. [Google Scholar] [CrossRef]

- Trașcă, D.L.; Ștefan, G.M.; Sahlian, D.N.; Hoinaru, R.; Șerban-Oprescu, G.-L. Digitalization and Business Activity. The Struggle to Catch Up in CEE Countries. Sustainability 2019, 11, 2204. [Google Scholar] [CrossRef] [Green Version]

- Endrődi-Kovács, V.; Stukovszky, T. The adoption of industry 4.0 and digitalisation of Hungarian SMEs. Soc. Econ. 2021, 44, 138–158. [Google Scholar] [CrossRef]

- Mićić, L. Digital transformation and its influence on GDP. Economics 2017, 5, 135–147. [Google Scholar] [CrossRef] [Green Version]

- Demirkan, I.; Srinivasan, R.; Nand, A.A. Innovation in SMEs: The role of employee training in German SMEs. J. Small Bus. Enterp. Dev. 2021. [Google Scholar] [CrossRef]

- Yu, F.; Shi, Y.; Wang, T. R&D investment and Chinese manufacturing SMEs’ corporate social responsibility: The moderating role of regional innovative milieu. J. Clean. Prod. 2020, 258, 120840. [Google Scholar]

- Petruzzelli, A.M.; Murgia, G.; Parmentola, A. How can open innovation support SMEs in the adoption of I4.0 technologies? An empirical analysis. R&D Manag. 2021. [Google Scholar] [CrossRef]

- Santoro, G.; Vrontis, D.; Thrassou, A.; Dezi, L. The Internet of Things: Building a knowledge management system for open innovation and knowledge management capacity. Technol. Forecast. Soc. Chang. 2018, 136, 347–354. [Google Scholar] [CrossRef]

- Draghici, A.; Baban, C.-F.; Gogan, M.-L.; Ivascu, L.-V. A Knowledge Management Approach for The University-industry Collaboration in Open Innovation. Procedia Econ. Financ. 2015, 23, 23–32. [Google Scholar] [CrossRef] [Green Version]

- Urbinati, A.; Chiaroni, D.; Chiesa, V.; Frattini, F. The role of digital technologies in open innovation processes: An exploratory multiple case study analysis. R&D Manag. 2020, 50, 136–160. [Google Scholar] [CrossRef]

- Peltier, J.W.; Zhao, Y.; Schibrowsky, J.A. Technology adoption by small businesses: An exploratory study of the interrelationships of owner and environmental factors. Int. Small Bus. J. 2012, 30, 406–431. [Google Scholar] [CrossRef]

- Albats, E.; Podmetina, D.; Vanhaverbeke, W. Open innovation in SMEs: A process view towards business model innovation. J. Small Bus. Manag. 2021. [Google Scholar] [CrossRef]

- Valdez-Juárez, L.E.; Castillo-Vergara, M. Technological Capabilities, Open Innovation, and Eco-Innovation: Dynamic Capabilities to Increase Corporate Performance of SMEs. J. Open Innov. Technol. Mark. Complex. 2021, 7, 8. [Google Scholar] [CrossRef]

- Ryu, D.; Baek, K.H.; Yoon, J. Open Innovation with Relational Capital, Technological Innovation Capital, and International Performance in SMEs. Sustainability 2021, 13, 3418. [Google Scholar] [CrossRef]

- Yoon, B.; Shin, J.; Lee, S. Open Innovation Projects in SMEs as an Engine for Sustainable Growth. Sustainability 2016, 8, 146. [Google Scholar] [CrossRef] [Green Version]

- Colombo, M.G.; Piva, E.; Rossi-Lamastra, C. Open innovation and within-industry diversification in small and medium enterprises: The case of open source software firms. Res. Policy 2014, 43, 891–902. [Google Scholar] [CrossRef]

- Stanisławski, R. Open Innovation as a Value Chain for Small and Medium-Sized Enterprises: Determinants of the Use of Open Innovation. Sustainability 2020, 12, 3290. [Google Scholar] [CrossRef] [Green Version]

| Maturity/Readiness Models | Source |

|---|---|

| A maturity model for Industry 4.0 Readiness | [57] |

| The Degree of readiness for the implementation of Industry 4.0 | [58] |

| The multi-attribute mode | [59] |

| An Overview of a Smart Manufacturing System Readiness Assessment | [60] |

| The Connected Enterprise Maturity Model | [61] |

| IMPULS—Industry 4.0 readiness | [62] |

| Digital readiness for Industry 4.0 | [63] |

| SIMMI 4.0 | [64] |

| Towards a Smart Manufacturing Maturity Model for SMEs | [41] |

| The Logistics 4.0 Maturity Model | [65] |

| A Smartness Assessment Framework for Smart Factories Using Analytic Network Process | [66] |

| Croatian Model of Innovative Smart Enterprise (HR-ISE model) | [67] |

| Maturity and Readiness Model for Industry 4.0 | [68] |

| AMM (Adoption Maturity Model) | [69] |

| Three Stage Maturity Model in SME’s | [70] |

| Area | Indicator | Marking |

|---|---|---|

| Integration of internal processes | Enterprises that have ERP software package to share information between different functional areas | X1 |

| Integration with customers/suppliers | Enterprises sending eInvoices, suitable for automated processing | X2 |

| Cloud computing | Purchase of cloud computing services used over the internet | X3 |

| Big data analysis | Analysis of big data from smart devices or sensors | X4 |

| 3D printing | Use of 3D printing | X5 |

| Robotics | Use of robots (industrial/service) | X6 |

| Internet of Things | Use of interconnected devices or systems that can be monitored or remotely controlled via the internet | X7 |

| Artificial intelligence (AI) | Enterprises using the AI technologies | X8 |

| Cybersecurity | ICT security measure used: Virtual Private Network (VPN) | X9 |

| Digital skills (ICT training) | Enterprises that provide training to develop/upgrade ICT skills of their personnel | X10 |

| Website | Enterprises with a website | X11 |

| Indicator | Average | Median | Min | Max | Variance | Standard Deviation | Coefficient of Variation | Skewness | Kurtosis |

|---|---|---|---|---|---|---|---|---|---|

| X1 | 35.41 | 35.00 | 16.00 | 56.00 | 110.10 | 10.49 | 29.63 | −0.05 | −0.66 |

| X2 | 29.41 | 21.00 | 9.00 | 95.00 | 527.40 | 22.97 | 78.09 | 1.60 | 1.87 |

| X3 | 42.00 | 39.00 | 12.00 | 75.00 | 300.54 | 17.34 | 41.28 | 0.29 | −0.71 |

| X4 | 11.56 | 8.00 | 2.00 | 29.00 | 56.64 | 7.53 | 65.13 | 0.84 | −0.47 |

| X5 | 4.37 | 4.00 | 1.00 | 9.00 | 4.09 | 2.02 | 46.27 | 0.47 | −0.38 |

| X6 | 5.78 | 6.00 | 2.00 | 12.00 | 5.64 | 2.38 | 41.11 | 0.60 | 0.28 |

| X7 | 27.26 | 27.00 | 10.00 | 50.00 | 92.35 | 9.61 | 35.25 | 0.77 | 0.55 |

| X8 | 7.52 | 7.00 | 1.00 | 23.00 | 26.87 | 5.18 | 68.95 | 1.20 | 1.72 |

| X9 | 39.04 | 38.00 | 14.00 | 61.00 | 158.58 | 12.59 | 32.26 | −0.05 | −0.85 |

| X10 | 9.33 | 9.00 | 3.00 | 16.00 | 12.00 | 3.46 | 37.12 | 0.41 | −0.35 |

| X11 | 76.26 | 77.00 | 50.00 | 96.00 | 154.35 | 12.42 | 16.29 | −0.41 | −0.42 |

| Indicator | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | X10 | X11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | 1.00 | 0.10 | 0.29 | 0.40 | 0.53 | 0.63 | 0.28 | 0.61 | 0.56 | 0.56 | 0.51 |

| X2 | 1.00 | 0.63 | 0.10 | 0.35 | 0.47 | 0.30 | 0.35 | 0.25 | 0.26 | 0.40 | |

| X3 | 1.00 | 0.54 | 0.65 | 0.33 | 0.43 | 0.51 | 0.76 | 0.74 | 0.79 | ||

| X4 | 1.00 | 0.57 | 0.35 | −0.06 | 0.60 | 0.76 | 0.76 | 0.55 | |||

| X5 | 1.00 | 0.66 | 0.29 | 0.66 | 0.79 | 0.75 | 0.63 | ||||

| X6 | 1.00 | 0.06 | 0.74 | 0.52 | 0.47 | 0.36 | |||||

| X7 | 1.00 | 0.20 | 0.30 | 0.26 | 0.58 | ||||||

| X8 | 1.00 | 0.73 | 0.71 | 0.56 | |||||||

| X9 | 1.00 | 0.86 | 0.83 | ||||||||

| X10 | 1.00 | 0.75 | |||||||||

| X11 | 1.00 |

| Indicator | Eigenvalue | % of Total Variance | Cumulative Eigenvalue | Cumulative % |

|---|---|---|---|---|

| X1 | 6.27 | 57.04 | 6.27 | 57.04 |

| X2 | 1.43 | 12.97 | 7.70 | 70.01 |

| X3 | 1.13 | 10.25 | 8.83 | 80.26 |

| X4 | 0.92 | 8.36 | 9.75 | 88.62 |

| X5 | 0.37 | 3.33 | 10.11 | 91.95 |

| X6 | 0.30 | 2.70 | 10.41 | 94.65 |

| X7 | 0.18 | 1.66 | 10.59 | 96.31 |

| X8 | 0.17 | 1.59 | 10.77 | 97.90 |

| X9 | 0.10 | 0.95 | 10.87 | 98.86 |

| X10 | 0.08 | 0.74 | 10.96 | 99.60 |

| X11 | 0.04 | 0.40 | 11.00 | 100.00 |

| Indicator | Component 1 | Component 2 | Component 3 |

|---|---|---|---|

| X1 | 0.668 | −0.265 | 0.231 |

| X2 | 0.471 | 0.513 | 0.495 |

| X3 | 0.814 | 0.386 | −0.174 |

| X4 | 0.719 | −0.397 | −0.389 |

| X5 | 0.855 | −0.075 | 0.070 |

| X6 | 0.642 | −0.276 | 0.677 |

| X7 | 0.398 | 0.724 | −0.025 |

| X8 | 0.827 | −0.249 | 0.235 |

| X9 | 0.928 | −0.091 | −0.241 |

| X10 | 0.899 | −0.117 | −0.250 |

| X11 | 0.851 | 0.310 | −0.232 |

| Countries | SPi | SNi | NSPi | NSNi | ASi | Rank | Old (EU-14)/New (EU-13) Union |

|---|---|---|---|---|---|---|---|

| Belgium | 0.36 | 0.01 | 0.48 | 0.98 | 0.73 | 3 | UE-14 |

| Bulgaria | 0.00 | 0.47 | 0.00 | 0.23 | 0.11 | 26 | UE-13 |

| Czech Republic | 0.06 | 0.12 | 0.07 | 0.81 | 0.44 | 17 | UE-13 |

| Denmark | 0.74 | 0.03 | 1.00 | 0.95 | 0.97 | 1 | UE-14 |

| Germany | 0.21 | 0.05 | 0.28 | 0.93 | 0.60 | 7 | UE-14 |

| Estonia | 0.12 | 0.26 | 0.16 | 0.57 | 0.37 | 18 | UE-13 |

| Ireland | 0.16 | 0.18 | 0.22 | 0.71 | 0.46 | 16 | UE-14 |

| Greece | 0.00 | 0.35 | 0.00 | 0.42 | 0.21 | 24 | UE-14 |

| Spain | 0.09 | 0.09 | 0.12 | 0.85 | 0.48 | 13 | UE-14 |

| France | 0.11 | 0.13 | 0.14 | 0.79 | 0.47 | 15 | UE-14 |

| Croatia | 0.07 | 0.08 | 0.10 | 0.87 | 0.48 | 14 | UE-13 |

| Italy | 0.27 | 0.11 | 0.36 | 0.82 | 0.59 | 8 | UE-14 |

| Cyprus | 0.09 | 0.24 | 0.12 | 0.61 | 0.37 | 19 | UE-13 |

| Latvia | 0.01 | 0.32 | 0.01 | 0.47 | 0.24 | 23 | UE-13 |

| Lithuania | 0.02 | 0.22 | 0.03 | 0.64 | 0.33 | 20 | UE-13 |

| Luxembourg | 0.14 | 0.13 | 0.18 | 0.79 | 0.49 | 12 | UE-14 |

| Hungary | 0.00 | 0.38 | 0.00 | 0.38 | 0.19 | 25 | UE-13 |

| Malta | 0.37 | 0.02 | 0.49 | 0.97 | 0.73 | 4 | UE-13 |

| Netherlands | 0.36 | 0.04 | 0.48 | 0.93 | 0.71 | 5 | UE-14 |

| Austria | 0.13 | 0.09 | 0.18 | 0.85 | 0.52 | 11 | UE-14 |

| Poland | 0.00 | 0.31 | 0.00 | 0.48 | 0.24 | 22 | UE-13 |

| Portugal | 0.20 | 0.11 | 0.27 | 0.82 | 0.55 | 10 | UE-14 |

| Romania | 0.00 | 0.61 | 0.00 | 0.00 | 0.00 | 27 | UE-13 |

| Slovenia | 0.23 | 0.07 | 0.30 | 0.88 | 0.59 | 9 | UE-13 |

| Slovakia | 0.00 | 0.21 | 0.00 | 0.65 | 0.33 | 21 | UE-13 |

| Finland | 0.63 | 0.00 | 0.84 | 1.00 | 0.92 | 2 | UE-14 |

| Sweden | 0.28 | 0.02 | 0.37 | 0.97 | 0.67 | 6 | UE-14 |

| Tested Parameters | TAU KEN | p | Spearman Rank | p |

|---|---|---|---|---|

| GDP, million EUR | 0.193 | 0.159 | 0.319 | 0.105 |

| GDP per capita, EUR per capita | 0.601 | 0.001 | 0.760 | 0.001 |

| Business enterprise expenditure on R&D (SMEs), million EUR | 0.319 | 0.020 | 0.477 | 0.012 |

| Business enterprise expenditure on R&D (SMEs), EUR per inhabitant | 0.624 | 0.001 | 0.791 | 0.001 |

| Gross domestic expenditure on R&D, million EUR | 0.313 | 0.022 | 0.458 | 0.016 |

| Gross domestic expenditure on R&D, EUR per inhabitant | 0.595 | 0.001 | 0.743 | 0.001 |

| Gross domestic expenditure on R&D, % of GDP | 0.457 | 0.001 | 0.603 | 0.001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brodny, J.; Tutak, M. Digitalization of Small and Medium-Sized Enterprises and Economic Growth: Evidence for the EU-27 Countries. J. Open Innov. Technol. Mark. Complex. 2022, 8, 67. https://doi.org/10.3390/joitmc8020067

Brodny J, Tutak M. Digitalization of Small and Medium-Sized Enterprises and Economic Growth: Evidence for the EU-27 Countries. Journal of Open Innovation: Technology, Market, and Complexity. 2022; 8(2):67. https://doi.org/10.3390/joitmc8020067

Chicago/Turabian StyleBrodny, Jarosław, and Magdalena Tutak. 2022. "Digitalization of Small and Medium-Sized Enterprises and Economic Growth: Evidence for the EU-27 Countries" Journal of Open Innovation: Technology, Market, and Complexity 8, no. 2: 67. https://doi.org/10.3390/joitmc8020067