Development of Business Models in the Fourth Industrial Revolution: Conditions in the Context of Empirical Research on Worldwide Scope Companies Located in Poland

Abstract

1. Introduction

2. Theoretical Framework

- Artificial intelligence that automates the recognition of events and decision making.

- Connectivity that creates connections between separate network nodes and increases the level of availability of market participants.

- Flexible automation, which includes automation and remote monitoring.

3. Materials and Methods

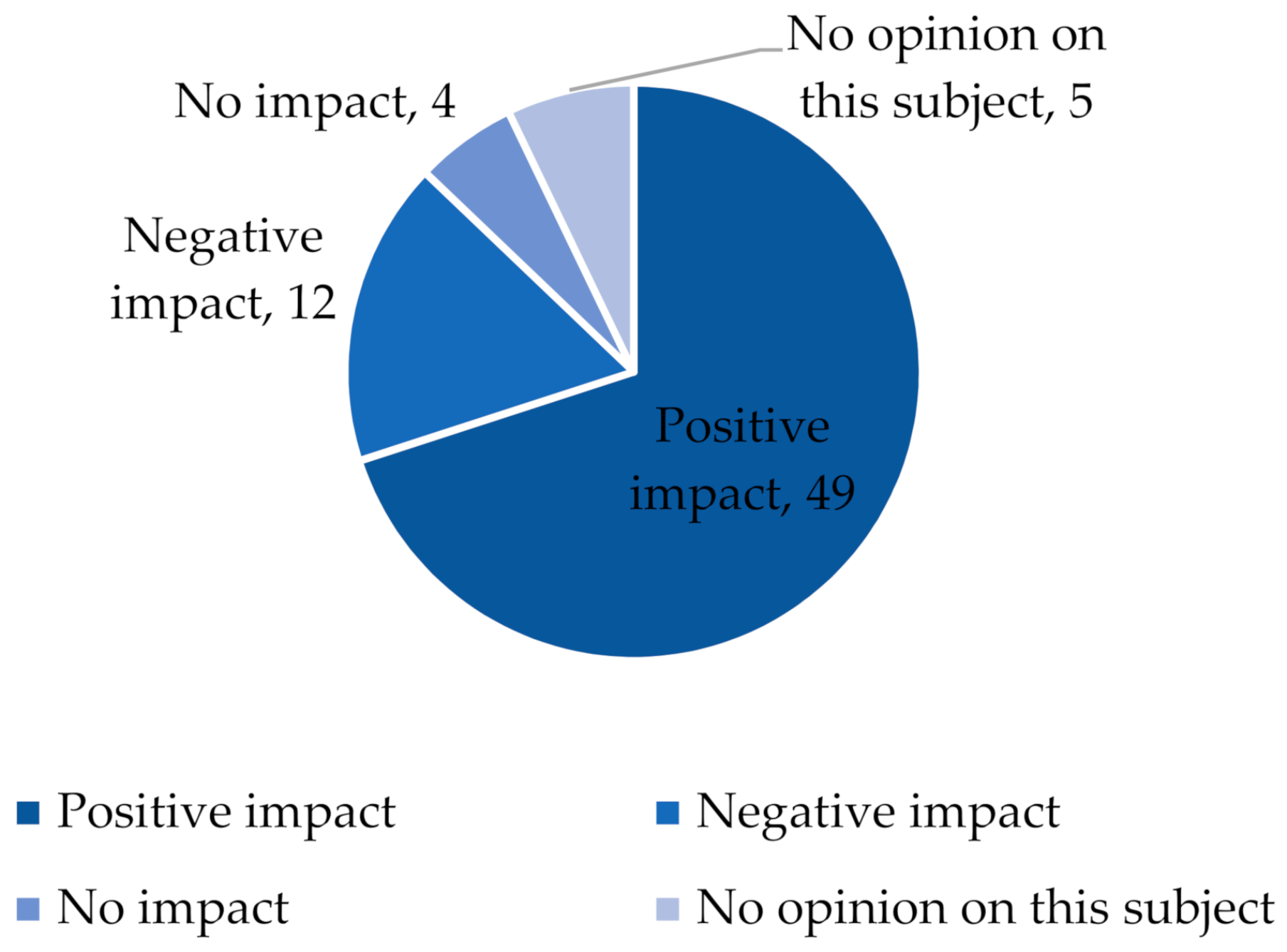

- How do companies view the Fourth Industrial Revolution and its impact on the company’s business model?

- At what stage of digitalization are the surveyed companies?

- In what areas have the business models of the surveyed companies changed under the influence of implemented Industry 4.0 technologies?

- What are the barriers to implementing Industry 4.0 technologies?

4. Results

4.1. The Results of the Surveys

4.2. Verification of Hypotheses

5. Discussion

5.1. Business Model in the 4th Industrial Revolution

5.2. Business Model with Open Innovtion Dynamics in the 4th Industrial Revolution

- There is a dynamic pushing of the boundaries of existing business models;

- The bottom-up framework of the modern business model is expanded through the pillars of Industry 4.0;

- The frontal neighborhood of the modern business model is cultivated and cyber-physical networks of cooperating enterprises are formed within it;

- The key actors in this concept are engineers, technology, customers, and social entrepreneurs.

- The new role of customers as partners and participants in the product design process;

- Partners working in a cyber-physical network, forming agile teams to deliver a specific project;

- Automated production in line with personalized customer expectations;

- Manufacturing as a service;

- Eliminating unused production capacity by making spare capacity available to cyber-physical network partners;

- Offering personalized products, maximally adapted to customer preferences, at the price of a mass-produced product;

- Partnering with the customer throughout the entire product lifecycle, having a positive impact on sustainable consumption;

- Servitization.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards Future Industrial Opportunities and Challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Reischauer, G. Industry 4.0 as policy-driven discourse to institutionalize innovation systems in manufacturing. Technol. Forecast. Soc. Chang. 2018, 132, 26–33. [Google Scholar] [CrossRef]

- Kliment, M.; Pekarcikova, M.; Trebuna, P.; Trebuna, M. Application of TestBed 4.0 Technology within the Implementation of Industry 4.0 in Teaching Methods of Industrial Engineering as Well as Industrial Practice. Sustainability 2021, 13, 8963. [Google Scholar] [CrossRef]

- Digitalizacja po Polski—Jak Wypadamy na tle Europy? Available online: https://brief.pl/digitalizacja-po-polsku-jak-wypadamy-na-tle-europy/ (accessed on 23 April 2022).

- Digitalizacja w Polsce Nadal Postępuje. Available online: https://biznes.newseria.pl/biuro-prasowe/it_i_technologie/digitalizacja-w-polsce,b455172763 (accessed on 23 April 2022).

- Olsen, T.L.; Tomlin, B. Industry 4.0: Opportunities and challenges for operations management. Manuf. Serv. Oper. Manag. 2020, 22, 113–122. [Google Scholar] [CrossRef]

- Arnold, C.; Kiel, D.; Voigt, K.I. How Industry 4.0 Changes Business Models in Different Manufacturing Industries. In Proceedings of the International Society for Professional Innovation Management (ISPIM), Boston, MA, USA, 13–16 March 2016; p. 1. [Google Scholar]

- Weking, J.; Stocker, M.; Kowalkiewicz, M.; Bohm, M.; Krcmar, H. Archetypes for Industry 4.0 Business Model Innovations. In Proceedings of the 24th Americas Conference on Information Systems (AMCIS), New Orleans, LA, USA, 16 August 2018; Bush, A., Grover, V., Schiller, S., Eds.; Association for Information Systems (AIS): Atlanta, GA, USA, 2018; pp. 1–10. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios, a Literature Review; Technische Universität: Dortmund, Germany, 2015. [Google Scholar]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Rekommendations for implementing the strategic initiative INUDSTIRE 4.0. Final Report of the Industrie 4.0 Working Group; Acatech-National Academy of Science and Engineering: München, Germany, 2013; Available online: https://en.acatech.de/publication/recommendations-for-implementing-the-strategic-initiative-industrie-4-0-final-report-of-the-industrie-4-0-working-group/ (accessed on 1 May 2022).

- Kagermann, H. Change through Digitization—Value Creation in the Age of Industry 4.0. In Management of Permanent Change; Springer: Wiesbaden, Germany, 2015. [Google Scholar]

- Khumalo, M.; Van Der Lingen, E. The open business model in a dynamic business environment: A literature review. S. Afr. J. Ind. Eng. 2017, 28, 147–160. [Google Scholar] [CrossRef]

- Schmidt, R.; Möhring, M.; Härting, R.-C.; Reichstein, C.; Neumaier, P.; Jozinović, P. Industry 4.0—Potentials for Creating Smart Products: Empirical Research Results. In Proceedings of the International Conference on Business Information Systems, Poznan, Poland, 24–26 June 2015; pp. 16–27. [Google Scholar]

- Sandulli, F.; Chesbrough, H. The Two Faces of Open Business Models. Research Paper Series (RPS). Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=1325682 (accessed on 30 March 2022).

- Chesbrough, H. Managing open innovation. Res.-Technol. Manag. 2004, 47, 23–26. [Google Scholar] [CrossRef]

- Chesbrough, H. Open Business Models: How to Thrive in the New Innovation Landscape; Harvard Business Press: Boston, MA, USA, 2006. [Google Scholar]

- Grabowska, S.; Saniuk, S. Assessment of the Competitiveness and Effectiveness of an Open Business Model in the Industry 4.0 Environment. J. Open Innov. Technol. Mark. Complex. 2022, 8, 57. [Google Scholar] [CrossRef]

- Chiaroni, D.; Chiesa, V.; Frattini, F. The Open Innovation Journey: How firms dynamically implement the emerging innovation management paradigm. Technovation 2011, 31, 34–43. [Google Scholar] [CrossRef]

- Matějíček, M.; Marešová, P. Open Business Model and Open Innovation: Bibliographic Analysis; Hradec Economic Days. Available online: https://doi.org/10.36689/uhk/hed/2020-01-059 (accessed on 30 March 2022).

- Bogers, M.; Chesbrough, H.; Heaton, S.; Teece, D.J. Strategic Management of Open Innovation: A Dynamic Capabilities Perspective. Calif. Manag. Rev. 2019, 62, 77–95. [Google Scholar] [CrossRef]

- Brasseur, T.; Mladenow, A.; Strauss, C. Open business model innovation: Literature review and agenda for future research. Bus. Inform. 2017, 4, 7–16. [Google Scholar] [CrossRef]

- Berre, A.; de Man, H.; Lew, Y.; Elvesæter, B.; Ursin-Holm, B. Open Business Model, Process and Service Innovation with VDML and ServiceML. Available online: https://digilib.uhk.cz/bitstream/handle/20.500.12603/259/Matejicek_Maresova.pdf?sequence=1&isAllowed=y (accessed on 1 May 2022).

- Santos, K.; Loures, E.; Piechnicki, F.; Canciglieri, O. Opportunities Assessment of Product Development Process in Industry 4.0. Procedia Manuf. 2017, 11, 1358–1365. [Google Scholar] [CrossRef]

- Berger, R. Industry 4.0—The New Industrial Revolution—How Europe Will Succeed; Roland Berger Strategy Consultants: Munich, Germany, 2014. [Google Scholar]

- Deloitte-Industry 4.0. The Industry 4.0 Paradox. Overcoming Disconnects on the Path to Digital Transformation, Deloitte Insights, 2018 Deloitte Development LLC. Available online: https://www2.deloitte.com/content/dam/Deloitte/cn/Documents/energy-resources/deloitte-cn-er-industry-4.0-paradox-overcoming-disconnects-en-full-report-190225.pdf (accessed on 25 March 2022).

- PwC-Global Industry 4.0 Survey. What We Mean by INDUSTRY 4.0/Survey Key Findings/Blueprint for Digital Success, PwC 2016. Available online: https://www.pwc.com/gx/en/industries/industries-4.0/landing-page/industry-4.0-building-your-digital-enterprise-april-2016.pdf (accessed on 25 March 2022).

- Moradi, E.; Jafari, S.M.; Doorbash, Z.M.; Mirzaei, A. Impact of organizational inertia on business model innovation, open innovation and corporate performance. Asia Pac. Manag. Rev. 2021, 26, 171–179. [Google Scholar] [CrossRef]

- Xie, X.; Wang, H. How to bridge the gap between innovation niches and exploratory and exploitative innovations in open innovation ecosystems. J. Bus. Res. 2021, 124, 299–311. [Google Scholar] [CrossRef]

- Pile, T. Developing a Framework for Open Innovation; Pepperdine Graziadio Business School: Los Angeles, CA, USA, 2018. [Google Scholar]

- Elmquist, M.; Fredberg, T.; Ollila, S. Exploring the field of open innovation. Eur. J. Innov. Manag. 2009, 12, 326–345. [Google Scholar] [CrossRef]

- Bican, P.M.; Guderian, C.C.; Ringbeck, A.; Bican, P.M. Managing knowledge in open innovation processes: An intellectual property perspective. J. Knowl. Manag. 2017, 21, 1384–1405. [Google Scholar] [CrossRef]

- Ozkan, N.N. An Example of Open Innovation: P&G. Procedia-Soc. Behav. Sci. 2015, 195, 1496–1502. [Google Scholar]

- Wantabe, C.; Shin, J.; Heikkinen, J.; Tarasyev, A. Optimal Dynamics of Functionality Development in Open Innovation. IFAC Proc. Vol. 2009, 42, 173–178. [Google Scholar]

- Berger, R. The Industrie 4.0 Transition Quantified. How the Fourth Industrial Revolution is Reshuffling the Economic, Social and Industrial Model; Roland Berger: Munich, Germany, 2016. [Google Scholar]

- Chesbrough, H.; Kim, S.; Agogino, A. Chez Panisse: Building an Open Innovation Ecosystem. Calif. Manag. Rev. 2014, 56, 144–171. [Google Scholar] [CrossRef]

- Berglund, H.; Sandström, C. Business model innovation from an open systems perspective: Structural challenges and managerial solutions. Int. J. Prod. Dev. 2013, 18, 274–285. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution; World Economic Forum; Deloitte: Cologny, Switzerland, 2016. [Google Scholar]

- Holtgrewe, U. New technologies: The future and the present of work in information and communication technology. New Technol. Work. Employ. 2014, 29, 9–24. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Critical factors for the successful implementation of Industry 4.0: A review and future research direction. Prod. Plan. Control. 2020, 31, 799–815. [Google Scholar] [CrossRef]

- McKinsey- Industry 4.0: How to Navigate Digitization of the Manufacturing Sector. Report, McKinsey Company. 2015. Available online: https://www.mckinsey.com/~/media/McKinsey/Business%20Functions/Operations/Our%20Insights/Industry%2040%20How%20to%20navigate%20digitization%20of%20the%20manufacturing%20sector/Industry-40-How-to-navigate-digitization-of-the-manufacturing-sector.pdf (accessed on 5 March 2022).

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries 09 April 2015, Overview. Available online: https://www.inovasyon.gen.tr/images/Haberler/bcgperspectives_Industry40_2015.pdf (accessed on 10 March 2022).

- Kale, V. Guide to Cloud Computing for Business and Technology Managers: From Distributed Computing to Cloudware Applications; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Chui, M.; Löffler, M.; Roberts, R. The Internet of Things. McKinsey Q. 2016, 2, 1–9. [Google Scholar]

- Burmeister, C.; Luettgens, D.; Piller, F.T. Business Model Innovation for Industrie 4.0: Why the Industrial Internet Mandates a New Perspective on Innovation; RWTH-TIM: Aachen, Germany, 2015. [Google Scholar]

- Ghezzi, A.; Cavallo, A.; Sanasi, S.; Rangone, A. Opening up to startup collaborations: Open business models and value co-creation in SMEs. Compet. Rev. Int. Bus. J. 2022, 32, 40–61. [Google Scholar] [CrossRef]

- Cohen, B.; Almirall, E.; Chesbrough, H. The City as a Lab: Open Innovation Meets the Collaborative Economy. Calif. Manag. Rev. 2016, 59, 5–13. [Google Scholar] [CrossRef]

- Hansen, E.; Gomm, M.; Reichwald, R. Providing Sustainable Mobility for All through Open Innovation: The Case of Gopping.De. In Proceedings of the 39th World Congress of the International Institute of Sociology, Yerevan, Armenia, 11–14 June 2009; Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=1440746 (accessed on 26 April 2022).

- Sarasini, S.; Langeland, O. Business model innovation as a process for transforming user mobility practices. Environ. Innov. Soc. Transit. 2021, 39, 229–248. [Google Scholar] [CrossRef]

- Wiprächtiger, D.; Narayanamurthy, G.; Moser, R.; Sengupta, T. Access-based business model innovation in frontier markets: Case study of shared mobility in Timor-Leste. Technol. Forecast. Soc. Chang. 2019, 143, 224–238. [Google Scholar] [CrossRef]

- Weiblen, T. The Open Business Model: Understanding an Emerging Concept. J. Multi Bus. Model Innov. Technol. 2016, 2, 35–66. [Google Scholar] [CrossRef]

- Peñarroya-Farell, M.; Miralles, F. Business Model Dynamics from Interaction with Open Innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 81. [Google Scholar] [CrossRef]

- Enkel, E.; Gassmann, O.; Chesbrough, H. Open R&D and open innovation: Exploring the phenomenon. R&D Manag. 2009, 39, 311–316. [Google Scholar]

- Grabowska, S.; Saniuk, S. Business Models in the Industry 4.0 Environment—Results of Web of Science Bibliometric Analysis. J. Open Innov. Technol. Mark. Complex. 2022, 8, 19. [Google Scholar] [CrossRef]

- West, J.; Bogers, M. Leveraging External Sources of Innovation: A Review of Research on Open Innovation. J. Prod. Innov. Manag. 2014, 31, 814–831. [Google Scholar] [CrossRef]

- Visnjic, I.; Neely, A.; Jovanovic, M. The path to outcome delivery: Interplay of service market strategy and open business models. Technovation 2019, 72–73, 46–59. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. The Use of the Open Innovation Concept to Develop a Method to Improve Safety during the Mining Production Process: A Case Study of the Integration of University and Industry. J. Open Innov. Technol. Mark. Complex. 2022, 8, 75. [Google Scholar] [CrossRef]

- Najar, T. Antecedents to open business model in the ICT-based sectors. J. High Technol. Manag. Res. 2020, 31, 100388. [Google Scholar] [CrossRef]

- Rebekić, A.; Lončarić, Z.; Petrović, S.; Marić, S. Pearson’s or Spearman’s correlation coefficient-which one to use? Poljoprivreda 2015, 21, 47–54. [Google Scholar] [CrossRef]

- Luczak, J.; Tran, M.-C. University–Real Estate Industry Cooperation in Open Innovation in the Topic of Walkability (breakout presentation). J. Transp. Health 2017, 7, S54. [Google Scholar] [CrossRef]

- Xie, X.; Wang, H. How can open innovation ecosystem modes push product innovation forward? An fsQCA analysis. J. Bus. Res. 2020, 108, 29–41. [Google Scholar] [CrossRef]

- Chesbrough, H.W. Open Innovation: The New Imperative for Creating and Profiting from Technology; Harvard Business School Press: Boston, MA, USA, 2003; ISBN 978-1578518371. [Google Scholar]

- West, J.; Lakhani, K.R. Getting Clear About Communities in Open Innovation. Ind. Innov. 2008, 15, 223–231. [Google Scholar] [CrossRef]

- Chesbrough, H.; Bogers, M. Explicating Open Innovation: Clarifying an Emerging Paradigm for Understanding Innovation. In New Frontiers in Open Innovation; Chesbrough, H., Vanhaverbeke, W., West, J., Eds.; Oxford University Press: Oxford, UK, 2014; pp. 3–28. [Google Scholar]

- Kirschbaum, R. Open Innovation in Practice. Res.-Technol. Manag. 2005, 48, 24–28. [Google Scholar] [CrossRef]

- Vaisnore, A.; Petraite, M. Customer Involvement into Open Innovation Processes: A Conceptual Model. Soc. Sci. 2011, 73, 62–73. [Google Scholar] [CrossRef][Green Version]

- Nguyen, T.; Huang, F.; Tian, X. A Meta-Analysis of the Impact of Open Innovation on Performance. Available online: https://www.cambridge.org/core/journals/journal-of-management-and-organization/article/abs/metaanalysis-of-the-impact-of-open-innovation-on-performance/FF995E5012F4C5D757AFE3678E0A5142 (accessed on 26 April 2022).

- Bašić, M. How Does Open Business Model Transform Elements of Innovation Culture into Open Innovation Practices of High and Low Internationalisation Firms? J. Knowl. Econ. 2022, 11, 1–27. [Google Scholar] [CrossRef]

- Malm, H.; Pikkarainen, M.; Hyrkäs, E. Impact of coupled open innovation on company business models: A case study of demand-driven co-creation. J. Innov. Manag. 2020, 8, 75–108. [Google Scholar] [CrossRef]

- Tsutsui, Y.; Yamada, N.; Mitake, Y.; Sholihah, M.; Shimomura, Y. A Strategic Design Guideline for Open Business Models. Int. J. Autom. Technol. 2020, 14, 678–689. [Google Scholar] [CrossRef]

- Trzaska, R.; Mazgajczyk, E. Industry 4.0: Overview of Business Models in Additive Manufacturing. Available online: https://wir.ue.wroc.pl/docstore/download/UEWR638c09a26f4640d79627a840c4d6fa6c/Trzaska_Mazgajczyk_Industry_4.0_Overview_of_Business.pdf (accessed on 16 April 2022).

- Bongomin, O.; Nganyi, E.O.; Abswaidi, M.R.; Hitiyise, E.; Tumusiime, G. Sustainable and dynamic competitiveness towards technological leadership of industry 4.0: Implications for East african community. J. Eng. 2020, 2020, 8545281. [Google Scholar] [CrossRef]

- Martínez-Olvera, C.; Mora-Vargas, J. A Comprehensive Framework for the Analysis of Industry 4.0 Value Domains. Sustainability 2019, 11, 2960. [Google Scholar] [CrossRef]

- Polyanska, A.; Savchuk, S.; Zapukhliak, I.; Zaiachuk, Y.; Stankovska, I. Digital Maturity of the Enterprise as an Assessment of its Ability to Function in Industry 4.0. In Advances in Manufacturing III, Manufacturing 2022, Lecture Notes in Mechanical Engineering; Trojanowska, J., Kujawińska, A., Machado, J., Pavlenko, I., Eds.; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Lorenz, M.; Rüfimann, M.; Strack, R.; Luetk, K.L.; Bolle, M. Man and Machine in Industry 4.0. How Will Technology Transform the Industrial Workforce through 2025; BCG Perspectives: Berlin, Germany, 2015. [Google Scholar]

- Piller, F.T.; Tseng, M.M. Handbook of Research in Mass Customization and Personalization; World Scientific: Singapore, 2010. [Google Scholar]

- Zhou, F.; Ji, Y.; Jiao, R. Affective and cognitive design for mass personalization: Status and prospect. J. Intell. Manuf. 2013, 24, 1047–1069. [Google Scholar] [CrossRef]

- Korena, Y.; Shpitalnib, M.; Guc, P.; Hu, S.J. Product Design for Mass-Individualization. Procedia CIRP 2015, 36, 64–71. [Google Scholar] [CrossRef]

- Rogers, M.P.; Kasanoff, D.B. Making It Personal: How to Profit from Personalization without Invading Privacy; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Lüftenegger, E. Achieving Business Model Innovation with the Personalized Product Business Model Radar Template. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Novi Sad, Serbia, 30 August–3 September 2020; pp. 130–137. [Google Scholar]

- Frank, A.; Mendes, G.; Ayala, N.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Grabowska, S. Business model metallurgical company built on the competitive advantage. In Proceedings of the 25th International Conference on Metallurgy and Materials METAL 2016, Brno, Czech Republic, 25–27 May 2016; pp. 1800–1807. [Google Scholar]

- Baden-Filler, C.; Haefliger, S. Business models and technological innovation. Long Range Plan 2017, 46, 419–426. [Google Scholar] [CrossRef]

- Safar, L.; Sopko, J.; Bednar, S.; Poklemba, R. Concept of SME business model for industry 4.0 environment. TEM J. 2018, 7, 626. [Google Scholar]

- JinHyo, J. Business Model Design Compass. Open Innovation Funnel to Schumpeterian New Combination Business Model Developing Circle; Springer: Singapore, 2017. [Google Scholar]

- Chesbrough, H. Business model innovation: It’s not just about technology anymore. Strategy Leadersh. 2007, 35, 12–17. [Google Scholar] [CrossRef]

- Safdari Ranjbar, M.; Manteghi, M.; Tavakoli, G. Open innovation, a comprehensive overview of concepts, approaches, trends and key success factors. Technol. Growth 2014, 10, 10–17. [Google Scholar]

- Gurca, A.; Bagherzadeh, M.; Markovic, S.; Koporcic, N. Managing the challenges of business-to-business open innovation in complex projects: A multi-stage process model. Ind. Mark. Manag. 2021, 94, 202–215. [Google Scholar] [CrossRef]

- McGahan, A.M.; Bogers, M.; Chesbrough, H.; Holgersson, M. Tackling Societal Challenges with Open Innovation. Calif. Manag. Rev. 2021, 63, 49–61. [Google Scholar] [CrossRef]

- Chesbrough, H. The logic of open innovation: Managing intellectual property. Calif. Manag. Rev. 2003, 45, 33–58. [Google Scholar] [CrossRef]

- Christensen, J.F.; Olesen, M.H.; Kjær, J.S. The industrial dynamics of Open Innovation—Evidence from the transformation of consumer electronics. Res. Policy 2005, 34, 1533–1549. [Google Scholar] [CrossRef]

| Industry 4.0 Technologies | Implemented | Implementation Is in Progress | We Do Not Plan to Implement |

|---|---|---|---|

| Autonomous Robots | 4 | 2 | 64 |

| Big Data | 15 | 3 | 52 |

| Cloud Computing | 18 | 4 | 48 |

| Systems Integration | 24 | 16 | 30 |

| Additive Manufacturing | 5 | 3 | 62 |

| Industrial Internet of Things | 12 | 6 | 52 |

| Augmented Reality | 21 | 7 | 42 |

| Simulations | 29 | 7 | 34 |

| Technologies Supporting Cyber Security | 65 | 5 | 0 |

| Industry 4.0 Technologies | Rating on a Scale of 1–5 (Where 1 Indicates No Importance and 5 Indicates Very High Importance) | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Autonomous Robots | 0 | 0 | 0 | 6 | 64 |

| Big Data | 2 | 23 | 34 | 9 | 2 |

| Cloud Computing | 4 | 22 | 29 | 12 | 3 |

| Systems Integration | 2 | 12 | 38 | 15 | 3 |

| Additive Manufacturing | 2 | 15 | 28 | 19 | 6 |

| Industrial Internet of Things | 0 | 10 | 13 | 23 | 24 |

| Augmented Reality | 0 | 7 | 19 | 16 | 28 |

| Simulations | 0 | 5 | 17 | 12 | 10 |

| Technologies Supporting Cyber Security | 7 | 23 | 12 | 19 | 9 |

| Aspects of the Company’s Business Model | Rating on a Scale of 1–5 (Where 1 Indicates No Importance and 5 Indicates Very High Importance) | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Increase in productivity and efficiency of external processes | 2 | 18 | 45 | 3 | 2 |

| Increase in efficiency and effectiveness of internal processes | 0 | 4 | 3 | 5 | 57 |

| More efficient company management | 0 | 2 | 6 | 58 | 4 |

| Decrease in costs | 0 | 9 | 15 | 43 | 3 |

| Increase in sales | 12 | 19 | 37 | 2 | 0 |

| Increase in profitability | 0 | 15 | 17 | 36 | 2 |

| Creating a new business model for the company | 25 | 28 | 12 | 2 | 3 |

| Increasing the quality of customer service | 0 | 12 | 18 | 34 | 6 |

| Possibility to offer personalized products at a price similar to those of mass production | 4 | 48 | 12 | 3 | 4 |

| Ability to offer personalized services at a price similar to those of a standard offering | 5 | 50 | 12 | 2 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grabowska, S.; Saniuk, S. Development of Business Models in the Fourth Industrial Revolution: Conditions in the Context of Empirical Research on Worldwide Scope Companies Located in Poland. J. Open Innov. Technol. Mark. Complex. 2022, 8, 86. https://doi.org/10.3390/joitmc8020086

Grabowska S, Saniuk S. Development of Business Models in the Fourth Industrial Revolution: Conditions in the Context of Empirical Research on Worldwide Scope Companies Located in Poland. Journal of Open Innovation: Technology, Market, and Complexity. 2022; 8(2):86. https://doi.org/10.3390/joitmc8020086

Chicago/Turabian StyleGrabowska, Sandra, and Sebastian Saniuk. 2022. "Development of Business Models in the Fourth Industrial Revolution: Conditions in the Context of Empirical Research on Worldwide Scope Companies Located in Poland" Journal of Open Innovation: Technology, Market, and Complexity 8, no. 2: 86. https://doi.org/10.3390/joitmc8020086

APA StyleGrabowska, S., & Saniuk, S. (2022). Development of Business Models in the Fourth Industrial Revolution: Conditions in the Context of Empirical Research on Worldwide Scope Companies Located in Poland. Journal of Open Innovation: Technology, Market, and Complexity, 8(2), 86. https://doi.org/10.3390/joitmc8020086