1. Introduction

Innovation is a business activity carried out by a company in its development efforts by creating added value in its business processes [

1]. A company has a differentiating competence to face global competition with other competitors with added value. Several studies have witnessed a positive correlation between innovation and increased company business performance [

2,

3,

4]. The Ministry of State-Owned Enterprises (SOEs) of Indonesia encourages the growth of a culture of innovation in state-owned companies. This is an effort to increase the role of SOEs in the Indonesian economy, which is considered relatively low compared other countries. Pranoto [

5] presented data that the contribution of Indonesian SOEs to Indonesia’s overall GDP was only 6%; compared to other developing countries in Latin America, Mexico, Brazil, Argentina for example have reached 8%, 15% for countries in Africa, and up to 50% contribution of SOEs for overall GDP in the Middle East region countries. Since 2013, the Ministry of SOEs has held an innovation competition among state-owned companies. While various kinds of innovation arose from the event, only a small number of SOEs participated. This shows that not all SOEs can foster a culture of innovation in their corporate environment. Innovation culture can grow positively when subjected to reliable innovation management. A good innovation management system is significant in influencing the number of innovations in a company, although it does not directly determine the success of innovation in that company.

Based on the open innovation concept, innovation management is one of the types of knowledge that can be copied or transferred from one company to another [

6]. Some companies meet difficulties in their innovation; therefore, they have to adopt open innovation [

7]. While process innovation tends to be tacit [

8], its conditions differ in state-owned companies. SOEs are under the auspices of the same institution (Ministry of SOEs), and they are required to synergize with one another [

9]. Thus, the process of transferring knowledge between SOEs is relatively frictionless. Mathrani and Edwards [

10] stated that organization structure and management style have a significant role in knowledge transfer. With the same management characteristics evident among state-owned companies, the copying process will be easier, albeit with minor adjustments/modifications. Companies proven to be sustainable in successful innovation can be an example for other SOEs when it comes to managing their own innovations. Tajudeen et al. [

11] also found positive correlation between external technology exploitation (ETE) and the effort of increasing a company’s innovation performance.

SOEs also continuously strive to improve their business performance. Even some SOEs are starting to expand abroad. In order to survive in global competition, SOEs must improve themselves in doing innovation. Postpaid electricity products by PT PLN (power production company), the production of liquid fertilizer by PT Pupuk Indonesia (Indonesian fertilizer holding company), the conversion of household fuel consumption from kerosene to LPG by PT Pertamina (oil and gas company)—even the promotion of electric induction cookers by PT PLN—are all examples of successes of product innovation by SOEs. Some additional examples of the success of process innovation include the development of automatic train stops (ATS) and e-ticketing by PT Kereta Api Indonesia 9train operator company), dust return technology by PT Semen Indonesia (Persero) Tbk. (portland cement holding company), the application of digital technology at several airports by PT Angkasa Pura (airport operating company), the emergence of several android-based customer service applications, such as m-banking, owned by state-owned banks, and PLN Mobile, developed by PT PLN. The best example of successful marketing innovation is King Market, created by PT Bulog (logistics company), which can utilize Bulog’s warehouses for online food distribution (Panganan.com). The Ministry of SOEs encourages several SOEs from the same industry cluster to form a holding company in organizational innovation. PT Semen Indonesia (Persero) Tbk. and PT Pupuk Indonesia are two real examples of successful organizational transformation. This description of success in innovating can be one of the knowledge transfer materials between SOE companies; therefore, other SOEs can do the same. This is an area of study in the research that we accomplished.

The present study focuses on examining process innovation, as it dramatically affects financial performance [

12], although [

13] suggests that investment in new technology (process innovation) in Southeast Asian countries, especially Indonesia, has a negative correlation to sales growth. More than half of state-owned companies spent budgets on operational costs. If all state-owned companies can innovate in this area, the resulting efficiency will be sufficient to increase their performance. While the measurement of innovation readiness level has not been applied to all SOEs, several lists showing SOEs participating in innovation competitions demonstrate that only leading SOEs can create innovation. Therefore, a study to describe the success of innovation—especially process innovation—is needed so that such innovation can become the primary orientation of other state-owned companies that are eager to improve their innovation performance. While this research aimed to examine the main factors that significantly influence the success of process innovation, a comprehensive study was carried out on the overall implementation of process innovation in each company. The development of the innovation performance measurement model framework proposed by Detecon Consulting was applied in the study [

14]. Modifications were made by adding several indicators considered highly important in the implementation of innovation, i.e., diffusion of innovation and push-pull factors that influence motivational actors.

The Delphi method approach was used to obtain consensus from the sources. This approach usually involves a small number of people (between eight and fifteen panel members). Delphi methods that do not require large data are very suitable for the data collection process during the COVID pandemic. Generally, the pandemic period requires reducing interaction with others, especially in groups. With these difficulties, the data obtained will be very limited so that they cannot be analyzed with other statistical methods such as confirmatory factor analysis. The resources involved in this study consisted of experts from SOE industry practitioners, officials handling innovation issues at the Ministry of Research and Technology/BRIN, and academics in innovation. The panelists’ discussions and data collection were carried out online due to the current COVID-19 pandemic.

5. Discussion

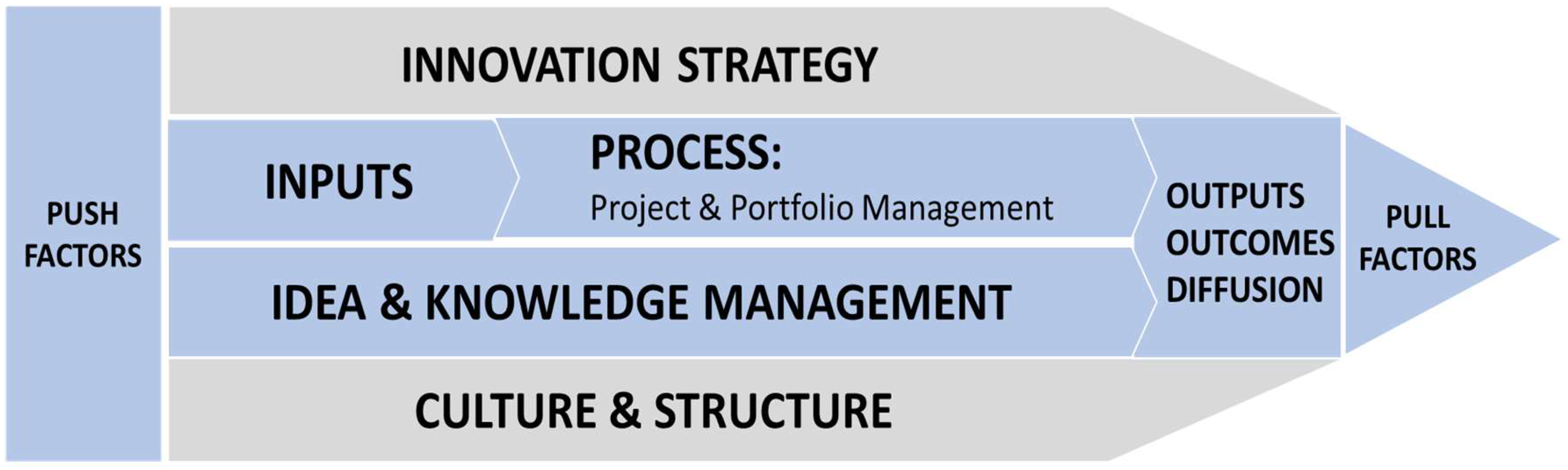

In summary, the conclusions regarding the speakers’ overview related to the success factors in the implementation of process innovation are shown in

Figure 2 below. There were 28 success factors collected from the ten indicators used by the researchers. The researchers restructured the conclusions after conducting another discussion with the speakers related to the analysis results in

Table 3,

Table 4,

Table 5,

Table 6,

Table 7,

Table 8,

Table 9,

Table 10,

Table 11 and

Table 12. From the discussion, we agreed that there were four leading indicators in the success of process innovation in SOEs: indicators of input, process, outputs and outcomes, and diffusion indicators. Other critical supporting indicators at a more strategic level included strategy, culture, and push and pull factors. The idea and knowledge management indicator eventually became one of the success factors in the input indicator. We agreed that the existence of a knowledge management system was considered an obligation. In other words, companies that are successful in innovation must invest in creating a knowledge management system. Several researchers in the literature we obtained stated that an ICT budget is one of the most critical innovation inputs [

73,

86,

88].

The success of process innovation in SOE input indicators—according to the results of the analysis in

Table 3—include organizational culture, organizational support and commitment, and employee understanding of company problems. This is different from the findings gathered by previous researchers, who stated that the R&D budget was the most critical factor. Our experts also compared the operational unit with the higher innovation culture, such as more innovation proposals than other units. The ratio is approximately two to six each year.

This statement shows that organizational culture contributes significantly to a climate of innovation. This is indicated by the higher level of employee involvement in innovation activities in companies with a good innovation culture than in those with a poor innovation culture. This is in line with a statement by [

116], which argues that innovation culture can increase innovation capability. Menzel et al. [

117] also stated that an excellent organizational culture could encourage increased employee innovation in implementing new ideas. Specifically in the manufacturing industry, Ali et al. [

118] stated that companies with good organizational culture must also implement Total Quality Management (TQM) and Supply Chain Management (SCM) to obtain process innovation. TQM is used to build and maintain commitment from leaders and employees to realize innovation [

119].

At the beginning of employee recruitment, HR introduces a culture of innovation and innovation achievements created by the company and provides information on how innovation dramatically affects employees’ career development. Na [

120] suggests that the early recruitment period is the most appropriate time to instill an innovation mindset. This is performed to maintain and improve a company’s innovation culture and instill an innovation mindset in employees. In line with this,

Table 9 lists additional success factors: creative and innovative mindset on cultural indicators. A creative and innovative mindset should also be encouraged at an early stage. When employees are introduced and adapt to standard operating procedures (SOPs), a company can give advice/suggestions to its employees to make operational improvements. Ultimately, the improvements made will make it easier for employees to complete the work themselves.

In selecting the innovation strategy, the experts obtained consensus on two strategies: market-driven and continuous improvement. A comprehensive understanding of market needs is the primary source of inspiration for innovation. Gonzhales-Sanches et al. [

121] stated that the market is the primary source of external knowledge in obtaining an innovation. Medne and Lapina [

122] found that companies that develop with a focus on sustainability and continuous improvement can create a good innovation environment. Employees will be familiar with the continuous improvement process, so they will be more confident in producing innovation.

The support and commitment of a company’s management are the main factors that mobilize employees in innovation activities, and they create a suitable climate for culturing innovation. Zaman et al. [

123] found that transformational leadership determines the success of innovation. Support and commitment are not always in the form of providing an R&D budget but can also be characterized by, for example, company leaders’ willingness to seek innovation implementations [

124]. Support for developing specific skills of subordinates also results in innovative behavior [

125]. Management at all levels can involve actively in the innovation management structure. The leader in the work unit with the highest number of employees could become the driver of innovation. This leader could encourage all employees to innovate actively so that innovation output will be high. Usually, the company’s most prominent expenditure also comes from these work units; if they could innovate and achieve better cost efficiency, then it will have a significant impact on the company’s expenditure.

Management support and commitment also apply to other indicators, such as during the innovation implementation process and the diffusion stage of the resulting innovations (

Table 6 and

Table 8). In the opinion of the experts, each level of management has a responsibility and is actively involved in the entire innovation process. All levels of management form a coordination chain in innovation management to ensure the implementation of innovative programs in their respective work units. As leaders, managers must explore solutions and ideas from subordinates to then realize how these ideas produce innovations. As stated by [

126], innovation is the result of successful leadership. In a horizontal coordination chain, leaders can often diffuse innovation results through other leaders. This is achieved through the functional synchronization of work to facilitate the process of changes in operating activities. Companies can create an integrated innovation management system from the early stage to the diffusion stage of innovation management as a form of commitment to innovation. All employees can contribute their innovation ideas by registering them through the system in the initial stage. The idea can be verified by the leader in each work unit and then realized with a pilot project. Through this innovation management system, work unit leaders can also directly evaluate the innovation performance of subordinates. In doing so, the leadership also actively participates in maintaining the company’s innovation culture.

Employees’ understanding of company problems is one of the most influential factors in the innovation process. Ettlie and Reza [

127] stated that process innovation requires more company-specific knowledge, which is the primary source of knowledge for employees. This is then compared with the implementation of product innovation; Guo et al. [

128] found that higher and more thorough knowledge is needed for process innovation than for product innovation.

In the idea generation stage, three main factors influence innovation success: strategy, employee personal KPIs (Key Performance Indicators), and benchmarking. An innovation strategy must be clearly stated so that all employees are aware of their company’s development and improvement needs. Skordoulis et al. [

129] confirmed the importance of an integrated innovation strategy with contemporary corporate strategies. In addition, mentoring and coaching programs have a high average expert rating but slightly below the standard deviation. This finding supports the statement of Rosa and Lace [

130] that coaching supports the creation of an innovative environment in a company.

With the imposition of innovation KPIs on employees (transparent measurement) comes an awareness of the need for new ideas in company efficiency and new product development [

131]. Personal or individual KPIs are part of annual employee appraisals. Companies usually use these indicators to determine the acceleration of promotions, salary increases, benefits, and other incentive bonuses. Several companies use the notion of an innovation KPI as a condition for promotion and an increase in the annual benefits and bonuses that employees receive.

Benchmarking is one of seven strategies for generating ideas in innovation [

132]. A company conducts benchmarking to compare how work practices in innovation management might be compared to examples of innovation implementation in other companies. Several informants provided information that their company is often the benchmark destination for other SOEs.

Dziallas and Blind [

133] stated that an innovative idea needs to be evaluated to observe its potential for future success. In the idea selection stage, the success factors for process innovation and an assessment of the impact of the process innovation to be carried out are obtained. While Arpaci [

90] suggests that all good ideas must be realized, a limited budget and resources may force a company to determine which ideas are more feasible to implement. In addition, companies must also prepare for changes in management because of systematic innovation.

At the stage of implementing ideas to produce innovations, success factors include the need for pilot projects, good supervision from facilitators (managers) and previous innovation implementers, and commitment and support from company management. Before companies spend large amounts of money implementing innovations, a pilot project should be tested. A pilot would also require a smaller budget [

134]. Companies should also receive sufficient time to anticipate potential resistance and prepare for systemic changes in management.

Many studies have shown that innovation winners can positively impact the sustainability of project innovation [

135,

136,

137,

138,

139]. The implementation of this mentoring program is a form of support and commitment from management to create sustainable innovation. As stated by our resource expert, the presence of innovation facilitators can provide inspiration and guidance to other employees in carrying out innovation projects. Therefore, several innovation projects can run in parallel and may even synergize. In addition, investment in a computerized innovation management system can make it easier for innovators to develop their concepts.

Our findings regarding the outputs and outcomes indicators are generally similar to previous studies [

8,

91,

92,

93,

95,

140], showing that the primary goal of process innovation is to achieve lower costs and process effectiveness while increasing productivity. Furthermore, our informants made a similar conclusion about the innovation results, namely that they can develop a company’s business processes and increase its competitiveness. This is the main push and pulls factor for implementing process innovation in each company.

This study has some critical theoretical implications related to the factors that determine the successful implementation of process innovation. First, the primary inputs of process innovation in SOEs are human resource and organizational factors such as leadership, strategy, and culture. These findings are different from the previous research that stated the R&D budget as the main input in the innovation process, although Oudgou [

87] stated that every company must pay attention to investment in R&D to produce product innovation or process innovation. Second, another essential factor in the innovation process of SOEs is the computerization of the innovation management system. This finding supports the new research of ICT’s role in innovation. This study contributes to the practical implementation of the innovation process in SOEs, especially in managing the innovation. This study shows that the most essential factor in all stages of innovation management is the support and commitment from the company leader. A company should regularly measure the output of innovation and communicate it to all employees. The leader can implement innovations as a key performance indicator of individuals to trigger their innovation mindset. The commitment of leaders to evaluate and give feedback regularly on the implementation of innovation can increase the output of innovation. Employee annual rewards and promotions could be based on the achievement of key performance indicators related to the implementation of innovation. They could show the leader’s support to employees that have good performance on innovation.