Understanding Learning Intention Complexities in Lean Manufacturing Training for Innovation on the Production Floor

Abstract

:1. Introduction

1.1. Workers’ Impact on Lean Manufacturing Innovations

1.2. Lean Manufacturing Training Complexities

1.3. The Aims of This Study

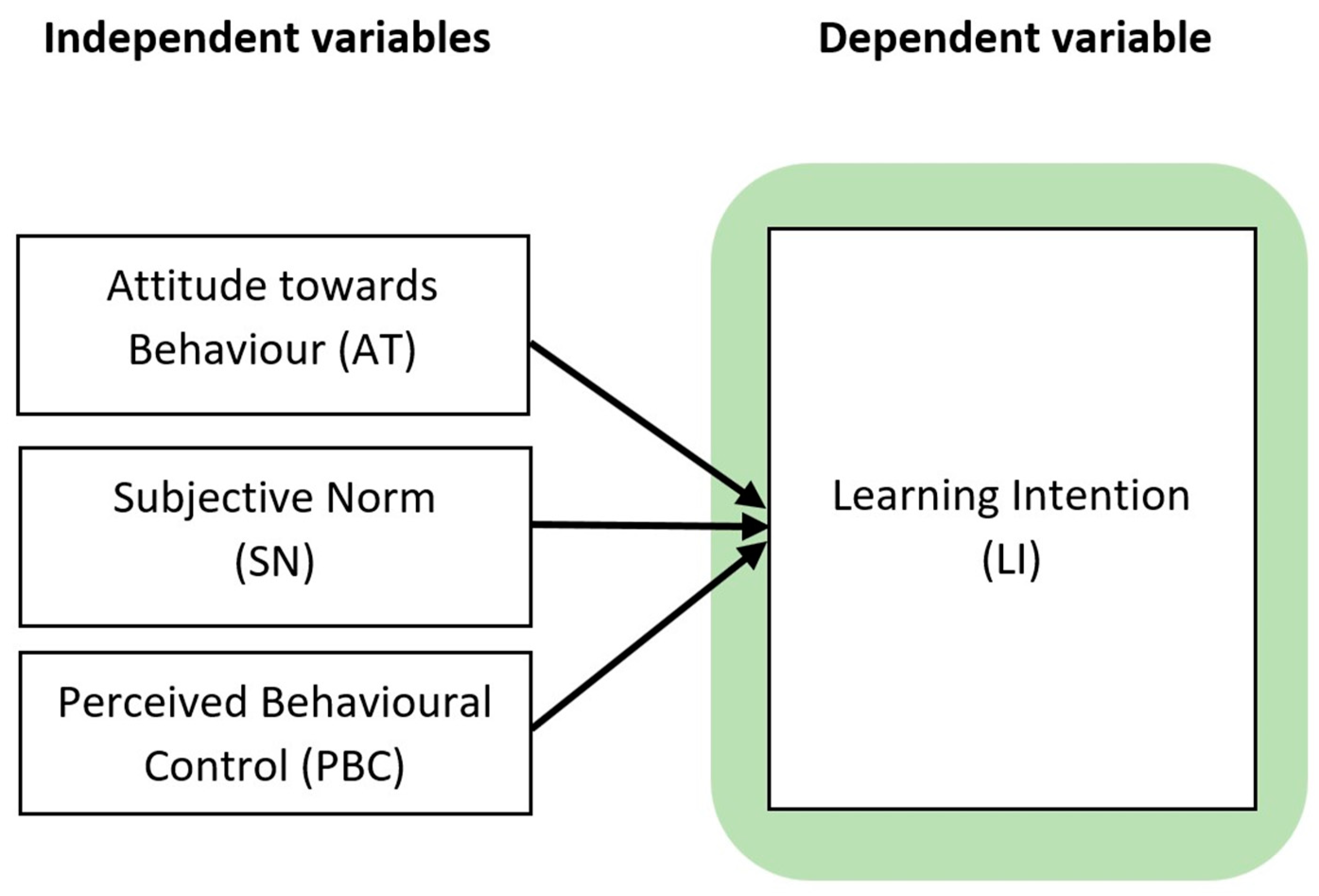

2. Theoretical Framework: Theory of Planned Behavior (TPB) and Hypothesis

3. Methodology

3.1. Background of the Industry and Participants of This Study

3.2. Data Collection and Survey

3.3. Measurements of Model Variables

3.4. Data Analysis

4. Results

4.1. Descriptive Statistics

4.2. Reliability and Discriminant Validity

4.3. Hypotheses Testing

5. Discussion

6. Conclusions

6.1. Theoretical and Managerial Implications

6.2. Limitation and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arnheiter, E.D.; Maleyeff, J. The integration of lean management and Six Sigma. TQM Mag. 2005, 17, 5–18. [Google Scholar] [CrossRef] [Green Version]

- Lai, N.Y.G.; Wong, K.H.; Halim, D.; Lu, J.; Kang, H.S. Industry 4.0 Enhanced Lean Manufacturing. In Proceedings of the 2019 8th International Conference on Industrial Technology and Management (ICITM), Cambridge, UK, 2–4 March 2019; pp. 206–211. [Google Scholar]

- Womack, J.; Jones, D.T.; Roos, D. The Machine That Changed the World; Rawson Associates: New York, NY, USA, 1990. [Google Scholar]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J. Industry 4.0 implies lean manufacturing: Research activities in industry 4.0 function as enablers for lean manufacturing. J. Ind. Eng. Manag. 2016, 9, 811–833. [Google Scholar] [CrossRef] [Green Version]

- Gaspar, F.; Leal, F. A methodology for applying the shop floor management method for sustaining lean manufacturing tools and philosophies: A study of an automotive company in Brazil. Int. J. Lean Six Sigma 2020, 11, 1233–1252. [Google Scholar] [CrossRef]

- Saini, S.; Singh, D. Impact of implementing lean practices on firm performance: A study of Northern India SMEs. Int. J. Lean Six Sigma 2020, 11, 1005–1034. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Lean manufacturing: Context, practice bundles, and performance. J. Oper. Manag. 2003, 21, 129–149. [Google Scholar] [CrossRef]

- Schonberger, R.J. Japanese production management: An evolution—With mixed success. J. Oper. Manag. 2007, 25, 403–419. [Google Scholar] [CrossRef]

- Needy, K.L.; Norman, B.A.; Bidanda, B.; Ariyawongrat, P.; Tharmmaphornphilas, W.; Warner, R.C. Assessing human capital: A lean manufacturing example. Eng. Manag. J. 2002, 14, 35–39. [Google Scholar] [CrossRef]

- Parker, S.K. Longitudinal effects of lean production on employee outcomes and the mediating role of work characteristics. J. Appl. Psychol. 2003, 88, 620. [Google Scholar] [CrossRef] [Green Version]

- Vidal, M. Lean production, worker empowerment, and job satisfaction: A qualitative analysis and critique. Crit. Sociol. 2007, 33, 247–278. [Google Scholar] [CrossRef] [Green Version]

- Hernandez-Matias, J.C.; Ocampo, J.R.; Hidalgo, A.; Vizan, A. Lean manufacturing and operational performance: Interrelationships between human-related lean practices. J. Manuf. Technol. Manag. 2019, 31, 217–235. [Google Scholar] [CrossRef]

- Durand, J.; Hatzfeld, N. Living Labour: Life on the Line at Peugeot France; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Lai, N.Y.G.; Jayasekara, D.; Wong, K.H.; Yu, L.J.; Kang, H.S.; Pawar, K.; Zhu, Y. Advanced automation and robotics for high volume labour-intensive manufacturing. In Proceedings of the 2020 International Congress on Human-Computer Interaction, Optimization and Robotic Applications (HORA), Ankara, Turkey, 26–28 June 2020; pp. 1–9. [Google Scholar]

- Castillo, C. The workers’ perspective: Emotional consequences during a lean manufacturing change based on VSM analysis. J. Manuf. Technol. Manag. 2022, 33, 19–39. [Google Scholar] [CrossRef]

- Zhang, L.; Narkhede, B.E.; Chaple, A.P. Evaluating lean manufacturing barriers: An interpretive process. J. Manuf. Technol. Manag. 2017, 28, 1086–1114. [Google Scholar] [CrossRef]

- Conti, R.; Angelis, J.; Cooper, C.; Faragher, B.; Gill, C. The effects of lean production on worker job stress. Int. J. Oper. Prod. Manag. 2006, 26, 1013–1038. [Google Scholar] [CrossRef]

- Möldner, A.K.; Garza-Reyes, J.A.; Kumar, V. Exploring lean manufacturing practices’ influence on process innovation performance. J. Bus. Res. 2020, 106, 233–249. [Google Scholar] [CrossRef]

- Koenigsaecker, G. Multiple sites multiply change and management challenges. Lean Manuf. Advis. 2000, 3–7. [Google Scholar]

- Leyer, M.; Reus, M.; Moormann, J. How satisfied are employees with lean environments? Prod. Plan. Control. 2021, 32, 52–62. [Google Scholar] [CrossRef]

- Imran, M.Y.; Elahi, N.S.; Abid, G.; Ashfaq, F.; Ilyas, S. Impact of perceived organizational support on work engagement: Mediating mechanism of thriving and flourishing. J. Open Innov. Technol. Mark. Complex. 2020, 6, 82. [Google Scholar] [CrossRef]

- Lewin, A.Y.; Välikangas, L.; Chen, J. Enabling open innovation: Lessons from Haier. Int. J. Innov. Stud. 2017, 1, 5–19. [Google Scholar] [CrossRef]

- Di Guardo, M.C.; Marku, E.; Bonivento, W.M.; Castriotta, M.; Ferroni, F.; Galbiati, C.; Gorini, G.; Loi, M. When nothing is certain, anything is possible: Open innovation and lean approach at MVM. RD Manag. 2022, 52, 165–177. [Google Scholar] [CrossRef]

- Chesbrough, H.; Tucci, C.L. The interplay between open innovation and lean startup, or, why large companies are not large versions of startups. Strat. Manag. Rev. 2020, 1, 277–303. [Google Scholar] [CrossRef]

- Lai, N.Y.G.; Kuah, A.T.H.; Kim, C.H.; Wong, K.H. Toward sustainable express deliveries for online shopping: Reusing packaging materials through reverse logistics. Thunderbird Int. Bus. Rev. 2022, 64, 351–362. [Google Scholar] [CrossRef]

- Näslund, D. Lean and six sigma-critical success factors revisited. Int. J. Qual. Serv. Sci. 2013, 5, 86–100. [Google Scholar]

- Demissie, A.; Zhu, W.; Kitaw, D.; Matebu, A. Quality assessment and improvement for Ethiopian garment enterprises. J. Ind. Prod. Eng. 2017, 34, 450–460. [Google Scholar] [CrossRef]

- Belhadi, A.; Sha’ri, Y.B.M.; Touriki, F.E.; El Fezazi, S. Lean production in SMEs: Literature review and reflection on future challenges. J. Ind. Prod. Eng. 2018, 35, 368–382. [Google Scholar] [CrossRef]

- Swarnakar, V.; Tiwari, A.K.; Singh, A. Evaluating critical failure factors for implementing sustainable lean six sigma framework in manufacturing organization. Int. J. Lean Six Sigma 2020, 11, 1069–1104. [Google Scholar] [CrossRef]

- Hoque, I. Buyer-assisted lean intervention in supplier firms: A supplier development approach. J. Manuf. Technol. Manag. 2021, 33, 146–168. [Google Scholar] [CrossRef]

- Zirar, A.; Trusson, C.; Choudhary, A. Towards a high-performance HR bundle process for lean service operations. Int. J. Qual. Reliab. Manag. 2021, 38, 25–45. [Google Scholar] [CrossRef] [Green Version]

- Hutton, E.A.; Skues, J.L.; Wise, L.Z. Using control-value theory to predict completion intentions in vocational education students. Int. J. Train. Res. 2019, 17, 157–175. [Google Scholar] [CrossRef]

- Sanders, A.; Wulfsberg, J. Industrie 4.0: Shopfloor Management im Wandel: Konzeptionelle Handlungsempfehlungen. ZWF Z. Wirtsch. Fabr. 2015, 110, 653–656. [Google Scholar] [CrossRef]

- Ninan, N.; Roy, J.C.; Thomas, M.R. Training the workforce for industry 4.0. Int. J. Res. Soc. Sci. 2019, 9, 782–790. [Google Scholar]

- Noronha, C.; Endow, T. Informal training for skilled workers: Issues arising from a qualitative study in four sites in Rajasthan and Madhya Pradesh. Int. J. Train. Res. 2011, 9, 110–122. [Google Scholar] [CrossRef]

- Na, K. The effect of on-the-job training and education level of employees on innovation in emerging markets. J. Open Innov. Technol. Mark. Complex. 2021, 7, 47. [Google Scholar] [CrossRef]

- Soti, A.; Shankar, R.; Kaushal, O. Modeling the enablers of Six Sigma using interpreting structural modeling. J. Model. Manag. 2010, 5, 124–141. [Google Scholar] [CrossRef]

- Maurer, T.J.; Weiss, E.M.; Barbeite, F.G. A model of involvement in work-related learning and development activity: The effects of individual, situational, motivational, and age variables. J. Appl. Psychol. 2003, 88, 707. [Google Scholar] [CrossRef]

- Klein, H.J.; Noe, R.A.; Wang, C. Motivation to learn and course outcomes: The impact of delivery mode, learning goal orientation, and perceived barriers and enablers. Pers. Psychol. 2006, 59, 665–702. [Google Scholar] [CrossRef]

- Sanders, J.; Oomens, S.; Blonk, R.W.; Hazelzet, A. Explaining lower educated workers’ training intentions. J. Workplace Learn. 2011, 23, 402–416. [Google Scholar] [CrossRef]

- Kyndt, E.; Govaerts, N.; Dochy, F.; Baert, H. The learning intention of low-qualified employees: A key for participation in lifelong learning and continuous training. Vocat. Learn. 2011, 4, 211–229. [Google Scholar] [CrossRef]

- Ho, Y.-Y.; Tsai, H.-T.; Day, J.-d. Using the theory of planned behaviour to predict public sector training participation. Serv. Ind. J. 2011, 31, 771–790. [Google Scholar] [CrossRef]

- Bates, R.A. Public sector training participation: An empirical investigation. Int. J. Train. Dev. 2001, 5, 136–152. [Google Scholar] [CrossRef]

- Tharenou, P. The relationship of training motivation to participation in training and development. J. Occup. Organ. Psychol. 2001, 74, 599–621. [Google Scholar] [CrossRef]

- Al Karim, R.; Islam, M.W.; Rashid, H. How Organizational Training Affects Employee Performance: A Case on Bangladesh Private Banking Sector. Int. J. Entrep. Res. 2019, 2, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Ajzen, I. The theory of planned behavior. Organ. Behav. Hum. Decis. Process. 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Wiethoff, C. Motivation to learn and diversity training: Application of the theory of planned behavior. Hum. Resour. Dev. Q. 2004, 15, 263–278. [Google Scholar] [CrossRef]

- Renkema, A.; van der Kamp, M. The impact of a learning incentive measure on older workers. In Promoting Lifelong Learning for Older Workers. An International Overview; Tikkanen, T., Nyham, B., Eds.; Cedefop Reference Series, 65; Office for Official Publications of the European Communities: Luxembourg, 2006. [Google Scholar]

- Alok, S.; Kabra, A.; Mudam, A. Predicting the behavioural intention to adopt lean practices: An empirical study in the manufacturing industry. Int. J. Serv. Oper. Manag. 2018, 29, 557. [Google Scholar] [CrossRef]

- Liu, Q.; Ye, G.; Feng, Y. Workers’ safety behaviors in the off-site manufacturing plant. Eng. Constr. Archit. Manag. 2020, 27, 765–784. [Google Scholar] [CrossRef]

- Sanders, J.M.; Damen, M.A.; Van Dam, K. Are positive learning experiences levers for lifelong learning among low educated workers? In Evidence-Based HRM: A Global Forum for Empirical Scholarship; Emerald Group Publishing: Bingley, UK, 2015. [Google Scholar]

- Dunstan, D.A.; Covic, T.; Tyson, G.A. What leads to the expectation to return to work? Insights from a Theory of Planned Behavior (TPB) model of future work outcomes. Work 2013, 46, 25–37. [Google Scholar] [CrossRef] [Green Version]

- Fielding, K.S.; McDonald, R.; Louis, W.R. Theory of planned behaviour, identity and intentions to engage in environmental activism. J. Environ. Psychol. 2008, 28, 318–326. [Google Scholar] [CrossRef]

- Smith, J.R.; Terry, D.J.; Manstead, A.S.; Louis, W.R.; Kotterman, D.; Wolfs, J. The attitude–behavior relationship in consumer conduct: The role of norms, past behavior, and self-identity. J. Soc. Psychol. 2008, 148, 311–334. [Google Scholar] [CrossRef]

- Fishbein, M.; Ajzen, I. Belief, attitude, intention, and behavior: An introduction to theory and research. Philos. Rhetor. 1977, 6, 244–245. [Google Scholar]

- Baert, H.; De Rick, K.; Van Valckenborgh, K. Towards the conceptualisation of learning climate. In Adult Education: New Routes in a New Landscape; Minho University: Braga, Portugal, 2006; pp. 87–111. [Google Scholar]

- Malik, M.; Abdallah, S. The relationship between organizational attitude and lean practices: An organizational sense-making perspective. Ind. Manag. Data Syst. 2020, 120, 1715–1731. [Google Scholar] [CrossRef]

- Cheng, E.W.; Sanders, K.; Hampson, I. An intention-based model of transfer of training. Manag. Res. Rev. 2015, 38, 908–928. [Google Scholar] [CrossRef]

- Steinmetz, H.; Knappstein, M.; Ajzen, I.; Schmidt, P.; Kabst, R. How effective are behavior change interventions based on the theory of planned behavior? Z. Für Psychol. 2016, 224, 216–233. [Google Scholar] [CrossRef]

- Ries, F.; Hein, V.; Pihu, M.; Armenta, J.M.S. Self-identity as a component of the theory of planned behaviour in predicting physical activity. Eur. Phys. Educ. Rev. 2012, 18, 322–334. [Google Scholar] [CrossRef]

- Chen, P.-K.; Lujan-Blanco, I.; Fortuny-Santos, J.; Ruiz-de-Arbulo-López, P. Lean Manufacturing and Environmental Sustainability: The Effects of Employee Involvement, Stakeholder Pressure and ISO 14001. Sustainability 2020, 12, 7258. [Google Scholar] [CrossRef]

- Ramadas, T.; Satish, K.P. Identification and modeling of process barriers. Int. J. Lean Six Sigma 2021, 12, 61–77. [Google Scholar] [CrossRef]

- Martin, H.J.; Hrivnak, M.W. Creating disciples: The transformation of employees into trainers. Bus. Horiz. 2009, 52, 605–616. [Google Scholar] [CrossRef]

- Prasad, S.; Baltov, M.; Rao, N.A.; Lanka, K. Interdependency analysis of lean manufacturing practices in case of Bulgarian SMEs: Interpretive structural modelling and interpretive ranking modelling approach. Int. J. Lean Six Sigma 2021, 12, 503–535. [Google Scholar] [CrossRef]

- Chenoy, D.; Ghosh, S.M.; Shukla, S.K. Skill development for accelerating the manufacturing sector: The role of ‘new-age’ skills for ‘Make in India’. Int. J. Train. Res. 2019, 17, 112–130. [Google Scholar] [CrossRef] [Green Version]

- Garrison, D.R. Self-directed learning: Toward a comprehensive model. Adult Educ. Q. 1997, 48, 18–33. [Google Scholar] [CrossRef]

- Teo, T.; Koh, N.K.; Lee, C.B. Teachers’ intention to teach financial literacy in Singapore: A path analysis of an extended Theory of Planned Behaviour (TPB). Asia-Pac. Educ. Res. 2011, 20, 410–419. [Google Scholar]

- Eisenberger, R.; Stinglhamber, F.; Vandenberghe, C.; Sucharski, I.L.; Rhoades, L. Perceived supervisor support: Contributions to perceived organizational support and employee retention. J. Appl. Psychol. 2002, 87, 565. [Google Scholar] [CrossRef]

- Tsai, W. Social structure of “coopetition” within a multiunit organization: Coordination, competition, and intraorganizational knowledge sharing. Organ. Sci. 2002, 13, 179–190. [Google Scholar] [CrossRef] [Green Version]

- Maurer, T.J.; Tarulli, B.A. Investigation of perceived environment, perceived outcome, and person variables in relationship to voluntary development activity by employees. J. Appl. Psychol. 1994, 79, 3. [Google Scholar] [CrossRef]

- Huo, M.-L.; Boxall, P.; Cheung, G.W. Lean production, work intensification and employee wellbeing: Can line-manager support make a difference? Econ. Ind. Democr. 2022, 43, 198–220. [Google Scholar] [CrossRef]

- Benkarim, A.; Imbeau, D. Exploring Lean HRM Practices in the Aerospace Industry. Sustainability 2022, 14, 5208. [Google Scholar] [CrossRef]

- Ajzen, I. Perceived behavioral control, self-efficacy, locus of control, and the theory of planned behavior 1. J. Appl. Soc. Psychol. 2002, 32, 665–683. [Google Scholar] [CrossRef]

- Al-Eisa, A.S.; Furayyan, M.A.; Alhemoud, A.M. An empirical examination of the effects of self-efficacy, supervisor support and motivation to learn on transfer intention. Manag. Decis. 2009, 47, 1221–1244. [Google Scholar] [CrossRef]

- Zimmerman, B.J. Self-efficacy: An essential motive to learn. Contemp. Educ. Psychol. 2000, 25, 82–91. [Google Scholar] [CrossRef]

- Kyndt, E.; Govaerts, N.; Claes, T.; De La Marche, J.; Dochy, F. What motivates low-qualified employees to participate in training and development? A mixed-method study on their learning intentions. Stud. Contin. Educ. 2013, 35, 315–336. [Google Scholar] [CrossRef]

- Alam, S.S.; Sayuti, N.M. Applying the Theory of Planned Behavior (TPB) in halal food purchasing. Int. J. Commer. Manag. 2011, 21, 8–20. [Google Scholar] [CrossRef]

- Lai, N.Y.G.; Wong, K.H.; Halim, D.; Mareta, S.; Ran, L.; Cheung, H. Learning through Formula Student Electric: Students and Staff Perspectives. In Proceedings of the 2021 IEEE International Conference on Engineering, Technology & Education (TALE), Wuhan, China, 5–8 December 2021; pp. 1–7. [Google Scholar]

- Robert, M.; Giuliani, P.; Guilloton, A.; Khallouk, M. Management innovation: A dynamic analysis of the implementation phase over time. Prod. Plan. Control. 2019, 30, 1219–1238. [Google Scholar] [CrossRef]

- Berg, B.L.; Lune, H.; Lune, H. Qualitative Research Methods for the Social Sciences; Pearson: Boston, MA, USA, 2004; Volume 5. [Google Scholar]

- Zikmund, W.G.; Carr, J.C.; Griffin, M. Business Research Methods; Cengage Learning: Boston, MA, USA, 2013. [Google Scholar]

- Etikan, I.; Musa, S.A.; Alkassim, R.S. Comparison of convenience sampling and purposive sampling. Am. J. Theor. Appl. Stat. 2016, 5, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Ajzen, I. The theory of planned behaviour is alive and well, and not ready to retire: A commentary on Sniehotta, Presseau, and Araújo-Soares. Health Psychol. Rev. 2015, 9, 131–137. [Google Scholar] [CrossRef]

- Alok, S.; Raveendran, J.; Jha Anil, K. Process conflict management among Indian software employees: Prediction of conflict handling intention in fast changing global IT market using the theory of planned behaviour. J. Indian Bus. Res. 2015, 7, 140–160. [Google Scholar] [CrossRef]

- Hickerson, S.C.; Fleming, M.L.; Sawant, R.V.; Ordonez, N.D.; Sansgiry, S.S. Predicting pharmacy students’ intention to apply for a residency: A systematic theory of planned behavior approach. Curr. Pharm. Teach. Learn. 2017, 9, 12–19. [Google Scholar] [CrossRef]

- Lee, C.G.; Middlestadt, S.E.; Park, S.; Kwon, J.; Noh, K.; Seo, D.-I.; Song, W.; Park, J.-J.; Lee, H.-J.; Kang, H.J. Predicting Voluntary Exercise Training among Korean Firefighters: Using Elicitation Study and the Theory of Planned Behavior. Int. J. Environ. Res. Public Health 2020, 17, 467. [Google Scholar] [CrossRef] [Green Version]

- Van Teijlingen, E.; Hundley, V. The importance of pilot studies. Nurs. Stand. 2002, 16, 33. [Google Scholar] [CrossRef] [Green Version]

- Johanson, G.A.; Brooks, G.P. Initial scale development: Sample size for pilot studies. Educ. Psychol. Meas. 2010, 70, 394–400. [Google Scholar] [CrossRef] [Green Version]

- Ajzen, I.; Joyce, N.; Sheikh, S.; Cote, N.G. Knowledge and the prediction of behavior: The role of information accuracy in the theory of planned behavior. Basic Appl. Soc. Psychol. 2011, 33, 101–117. [Google Scholar] [CrossRef]

- Kaye, S.-A.; Lewis, I.; Forward, S.; Delhomme, P. A priori acceptance of highly automated cars in Australia, France, and Sweden: A theoretically-informed investigation guided by the TPB and UTAUT. Accid. Anal. Prev. 2020, 137, 105441. [Google Scholar] [CrossRef]

- Nunnally, J.C. Psychometric Theory 3E; Tata McGraw-Hill Education: New York, NY, USA, 1994. [Google Scholar]

- Bagozzi, R.P.; Yi, Y. On the evaluation of structural equation models. J. Acad. Mark. Sci. 1988, 16, 74–94. [Google Scholar] [CrossRef]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53. [Google Scholar] [CrossRef]

- Ajzen, I. Constructing a TPB Questionnaire: Conceptual and Methodological Considerations. 2002. Available online: https://openaccess.city.ac.uk/id/eprint/1735/1/ (accessed on 20 June 2022).

- Francis, J.; Eccles, M.P.; Johnston, M.; Walker, A.; Grimshaw, J.M.; Foy, R.; Kaner, E.F.; Smith, L.; Bonetti, D. Constructing Questionnaires Based on the Theory of Planned Behaviour: A Manual for Health Services Researchers; University of Newcastle: Newcastle upon Tyne, UK, 2004. [Google Scholar]

- Aaker, D.A.; Kumar, V.; Leone, R.P.; Day, G.S. Marketing Research: International Student Version; John Wiley & Sons: New York, NY, USA, 2013. [Google Scholar]

- Wang, Y.-Y.; Lin, T.-C.; Tsay, C.H.-H. Encouraging IS developers to learn business skills: An examination of the MARS model. Inf. Technol. People 2016, 29, 381–418. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Tang, C. How does training improve customer service quality? The roles of transfer of training and job satisfaction. Eur. Manag. J. 2018, 36, 708–716. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Multivariate Data Analysis; Prentice Hall: Upper Saddle River, NJ, USA, 1998; Volume 5. [Google Scholar]

- Brace, N.; Snelgar, R.; Kemp, R. SPSS for Psychologists; Macmillan International Higher Education: London, UK, 2012. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Kline, R.B. Software review: Software programs for structural equation modeling: Amos, EQS, and LISREL. J. Psychoeduc. Assess. 1998, 16, 343–364. [Google Scholar] [CrossRef]

- Tabachnick, B.G.; Fidell, L.S.; Ullman, J.B. Using Multivariate Statistics; Pearson: Boston, MA, USA, 2007; Volume 5. [Google Scholar]

- Baron, R.M.; Kenny, D.A. The moderator–mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Personal. Soc. Psychol. 1986, 51, 1173. [Google Scholar] [CrossRef]

- Sekaran, U.; Bougie, R. Research Methods for Business: A Skill Building Approach; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Abdullah, L.; Rahim, A.F. A step-wise multiple linear regression analysis for identifying predictors of employees’ intention to undertake further study. J. Curr. Res. Sci. 2016, 4, 21. [Google Scholar]

- Gijbels, D.; Raemdonck, I.; Vervecken, D.; Van Herck, J. Understanding work-related learning: The case of ICT workers. J. Workplace Learn. 2012, 24, 416–429. [Google Scholar] [CrossRef]

- Raemdonck, I.; Gijbels, D.; Van Groen, W. The influence of job characteristics and self-directed learning orientation on workplace learning. Int. J. Train. Dev. 2014, 18, 188–203. [Google Scholar] [CrossRef]

- Parmar, P.S.; Desai, T.N. Ranking the solutions of Sustainable Lean Six Sigma implementation in Indian manufacturing organization to overcome its barriers. Int. J. Sustain. Eng. 2020, 14, 304–317. [Google Scholar] [CrossRef]

- Knol, W.H.; Slomp, J.; Schouteten, R.L.; Lauche, K. Implementing lean practices in manufacturing SMEs: Testing ‘critical success factors’ using Necessary Condition Analysis. Int. J. Prod. Res. 2018, 56, 3955–3973. [Google Scholar] [CrossRef] [Green Version]

- Noe, R.A.; Wilk, S.L. Investigation of the factors that influence employees’ participation in development activities. J. Appl. Psychol. 1993, 78, 291. [Google Scholar] [CrossRef]

- Tews, M.J.; Noe, R.A. Does training have to be fun? A review and conceptual model of the role of fun in workplace training. Hum. Resour. Manag. Rev. 2019, 29, 226–238. [Google Scholar] [CrossRef]

- Park, S.; Kang, H.-S.; Kim, E.-J. The role of supervisor support on employees’ training and job performance: An empirical study. Eur. J. Train. Dev. 2018, 42, 57–74. [Google Scholar] [CrossRef]

- Afzal, S.; Arshad, M.; Saleem, S.; Farooq, O. The impact of perceived supervisor support on employees’ turnover intention and task performance. J. Manag. Dev. 2019, 38, 369–382. [Google Scholar] [CrossRef]

- Cheng, J.-C.; O-Yang, Y. Hotel employee job crafting, burnout, and satisfaction: The moderating role of perceived organizational support. Int. J. Hosp. Manag. 2018, 72, 78–85. [Google Scholar] [CrossRef]

- Geue, P.E. Positive practices in the workplace: Impact on team climate, work engagement, and task performance. J. Appl. Behav. Sci. 2018, 54, 272–301. [Google Scholar] [CrossRef]

| Hypothesis | |

|---|---|

| H1 | There is a significant positive relationship between attitude (AT) and learning intention (LI) in the context of lean manufacturing training programs. |

| H2 | There is a significant positive relationship between subjective norm (SN) and learning intention (LI) in the context of lean manufacturing training programs. |

| H3 | There is a significant positive relationship between perceived behavior control (PBC) and learning intention (LI) in the context of lean manufacturing training programs. |

| Quantity | Percentage (%) | ||

|---|---|---|---|

| Gender | Male | 52 | 25.5 |

| Female | 152 | 74.5 | |

| Age Group | 19–23 | 89 | 44 |

| 24–28 | 51 | 25 | |

| 29–33 | 19 | 9 | |

| 34–38 | 25 | 12 | |

| 39–43 | 13 | 6 | |

| 44–48 | 7 | 3 | |

| Education level | Graduates and above | 19 | 9.3 |

| Secondary school | 158 | 77.5 | |

| Primary School | 27 | 13.2 | |

| Nationality | Malaysian | 64 | 31 |

| Indonesian | 100 | 49 | |

| Myanmar | 20 | 10 | |

| Nepal | 12 | 6 | |

| Vietnam | 8 | 4 | |

| Language preference | Malay | 178 | 87.3 |

| Other | 26 | 12.7 |

| Components | No. of Items | No. of Items Retained | Item | 1 | 2 | 3 | 4 |

|---|---|---|---|---|---|---|---|

| Attitude (AT) | 5 | 5 | at8 | 0.979 | - | - | - |

| at9 | 0.911 | - | - | - | |||

| at10 | 0.872 | - | - | - | |||

| at12 | 0.818 | - | - | - | |||

| at11 | 0.763 | - | - | - | |||

| Subjective Norm (SN) | 6 | 5 | sn8 | - | 0.919 | - | - |

| sn9 | - | 0.916 | - | - | |||

| sn6 | - | 0.900 | - | - | |||

| sn7 | - | 0.803 | - | - | |||

| sn10 | - | 0.735 | - | - | |||

| Learning Intention (LI) | 5 | 5 | li4 | - | - | 0.922 | - |

| li5 | - | - | 0.840 | - | |||

| li2 | - | - | 0.717 | - | |||

| li3 | - | - | 0.709 | - | |||

| li1 | - | - | 0.658 | - | |||

| Perceived Behavioral Control (PBC) | 5 | 3 | pbc6 | - | - | - | 0.917 |

| pbc7 | - | - | - | 0.816 | |||

| pbc5 | - | - | - | 0.795 |

| Cronbach’s Alpha | LI | AT | SN | PBC | |

|---|---|---|---|---|---|

| Learning Intention (LI) | 0.873 | 1.0 | 0.498 ** | 0.509 ** | 0.534 ** |

| Attitude (AT) | 0.930 | 0.498 ** | 1.0 | 0.457 ** | 0.431 ** |

| Subjective Norm (SN) | 0.913 | 0.509 ** | 0.457 ** | 1.0 | 0.484 ** |

| Perceived Behavioral Control (PBC) | 0.910 | 0.534 ** | 0.431 ** | 0.484 ** | 1.0 |

| VIF | Tolerance | CR | AVE | |

|---|---|---|---|---|

| Attitude (AT) | 1.78 | 0.56 | 0.94 | 0.76 |

| Subjective Norm (SN) | 1.72 | 0.58 | 0.93 | 0.73 |

| Perceived Behavioral Control (PBC) | 1.61 | 0.62 | 0.88 | 0.71 |

| Learning Intention (LI) | - | - | 0.88 | 0.60 |

| Model | Unstandardized Coefficients | Standardized Coefficients | t-Value | p-Value | ||

|---|---|---|---|---|---|---|

| β | Std. Error | Β | ||||

| 1 | (Constant) | 5.984 × 10−17 | 0.052 | 5.984 × 10−17 | 0.000 | 1.000 |

| Attitude (AT) | 0.247 | 0.069 | 0.247 | 3.557 | 0.000 | |

| Subjective Norm (SN) | 0.075 | 0.068 | 0.075 | 1.097 | 0.274 | |

| Perceived Behavioral Control (PBC) | 0.454 | 0.066 | 0.454 | 6.861 | 0.000 | |

| Model | R | R2 | Adjusted R2 | Std. Error of the Estimate |

|---|---|---|---|---|

| 1 | 0.633 a | 0.401 | 0.398 | 0.77599614 |

| 2 | 0.674 b | 0.454 | 0.449 | 0.74247293 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, N.Y.G.; Foo, W.C.; Tan, C.S.; Kang, M.S.; Kang, H.S.; Wong, K.H.; Yu, L.J.; Sun, X.; Tan, N.M.L. Understanding Learning Intention Complexities in Lean Manufacturing Training for Innovation on the Production Floor. J. Open Innov. Technol. Mark. Complex. 2022, 8, 110. https://doi.org/10.3390/joitmc8030110

Lai NYG, Foo WC, Tan CS, Kang MS, Kang HS, Wong KH, Yu LJ, Sun X, Tan NML. Understanding Learning Intention Complexities in Lean Manufacturing Training for Innovation on the Production Floor. Journal of Open Innovation: Technology, Market, and Complexity. 2022; 8(3):110. https://doi.org/10.3390/joitmc8030110

Chicago/Turabian StyleLai, Nai Yeen Gavin, Wai Choong Foo, Chon Siong Tan, Myoung Sook Kang, Hooi Siang Kang, Kok Hoong Wong, Lih Jiun Yu, Xu Sun, and Nadia Mei Lin Tan. 2022. "Understanding Learning Intention Complexities in Lean Manufacturing Training for Innovation on the Production Floor" Journal of Open Innovation: Technology, Market, and Complexity 8, no. 3: 110. https://doi.org/10.3390/joitmc8030110

APA StyleLai, N. Y. G., Foo, W. C., Tan, C. S., Kang, M. S., Kang, H. S., Wong, K. H., Yu, L. J., Sun, X., & Tan, N. M. L. (2022). Understanding Learning Intention Complexities in Lean Manufacturing Training for Innovation on the Production Floor. Journal of Open Innovation: Technology, Market, and Complexity, 8(3), 110. https://doi.org/10.3390/joitmc8030110