High-Transparency Linear Actuator Using an Electromagnetic Brake for Damping Modulation in Physical Human–Robot Interaction

Abstract

:1. Introduction

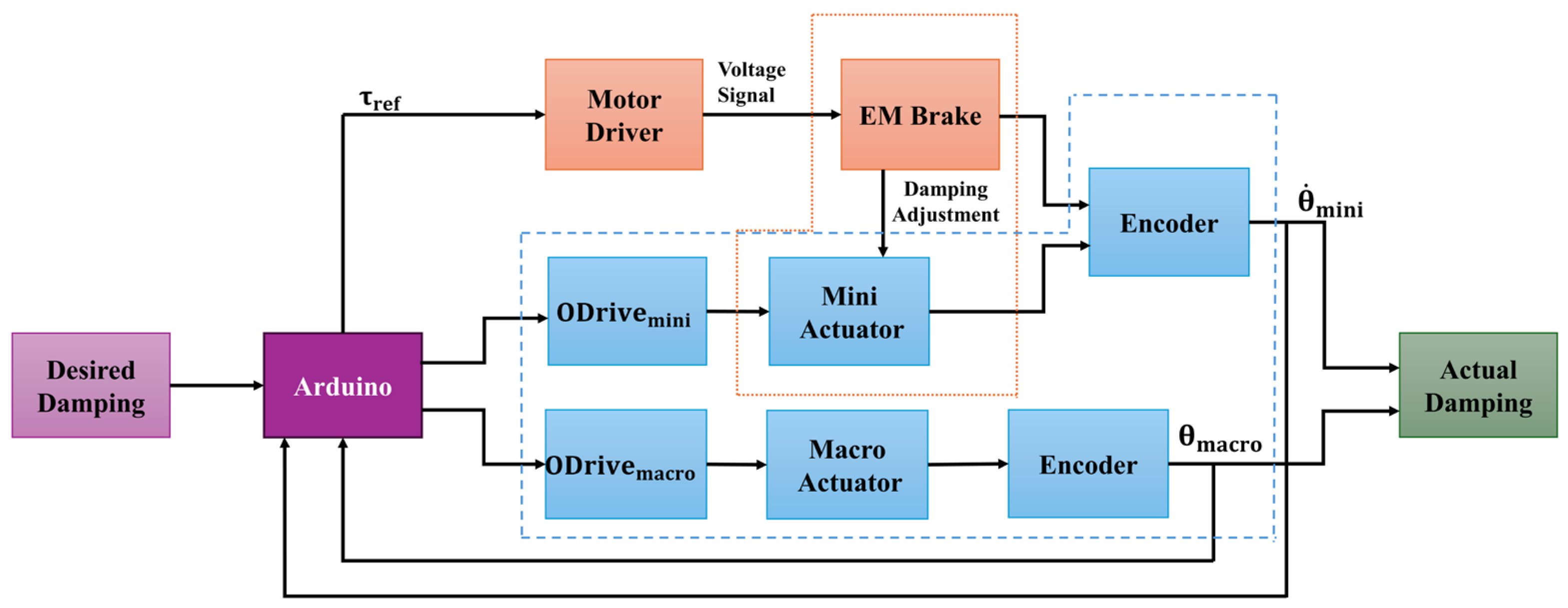

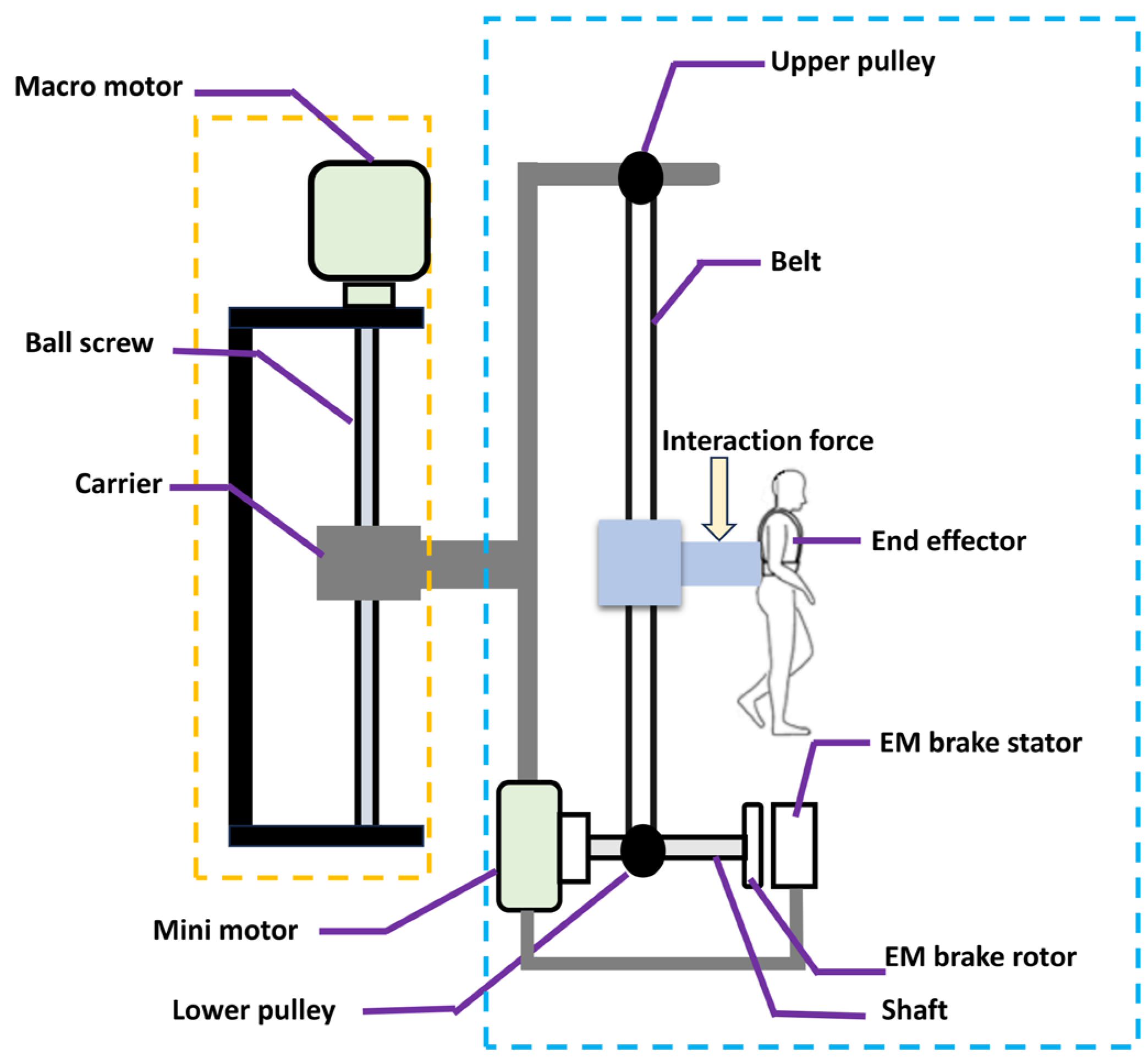

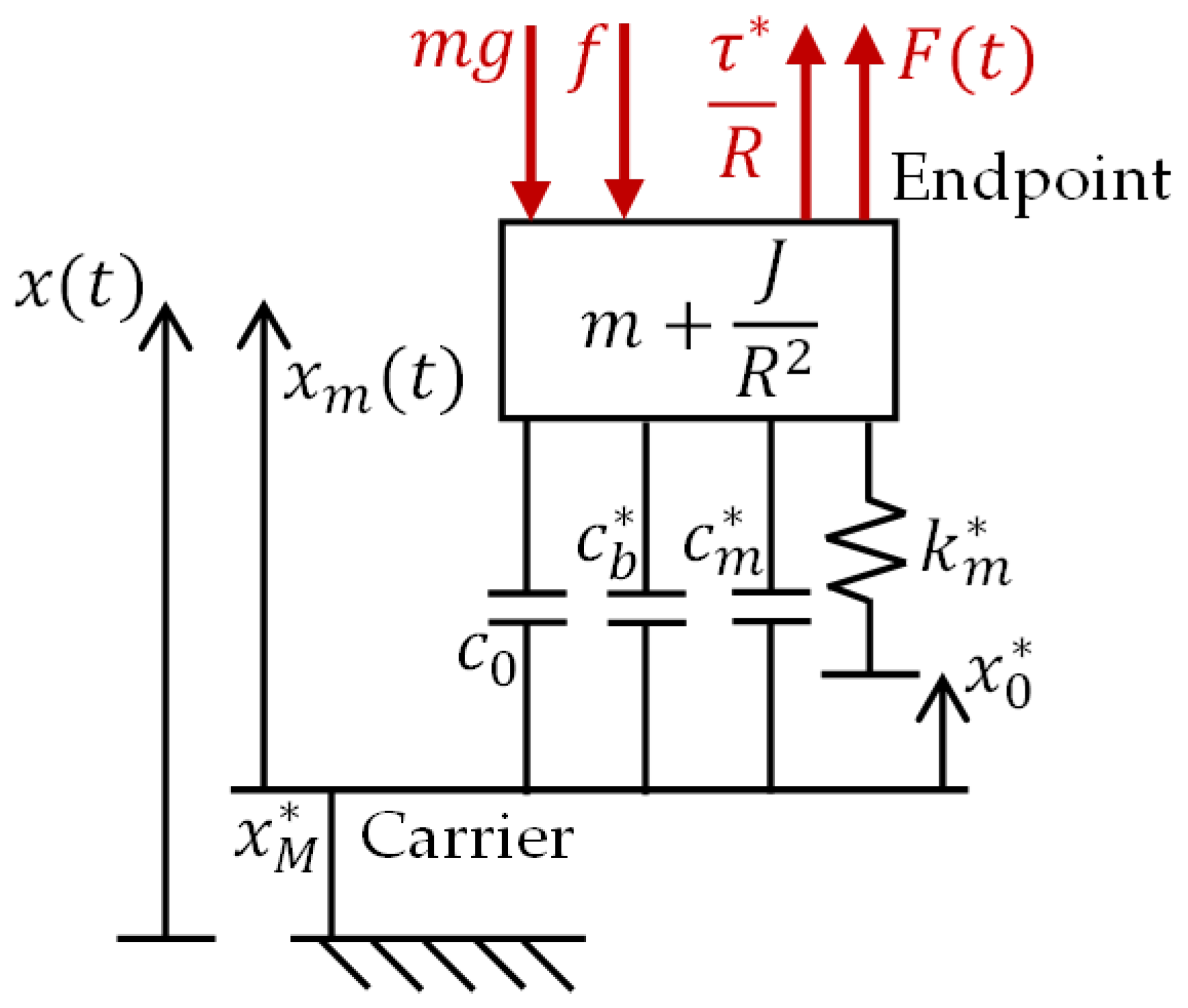

2. Macro–Mini Linear Actuation Concept

2.1. Operating Principle

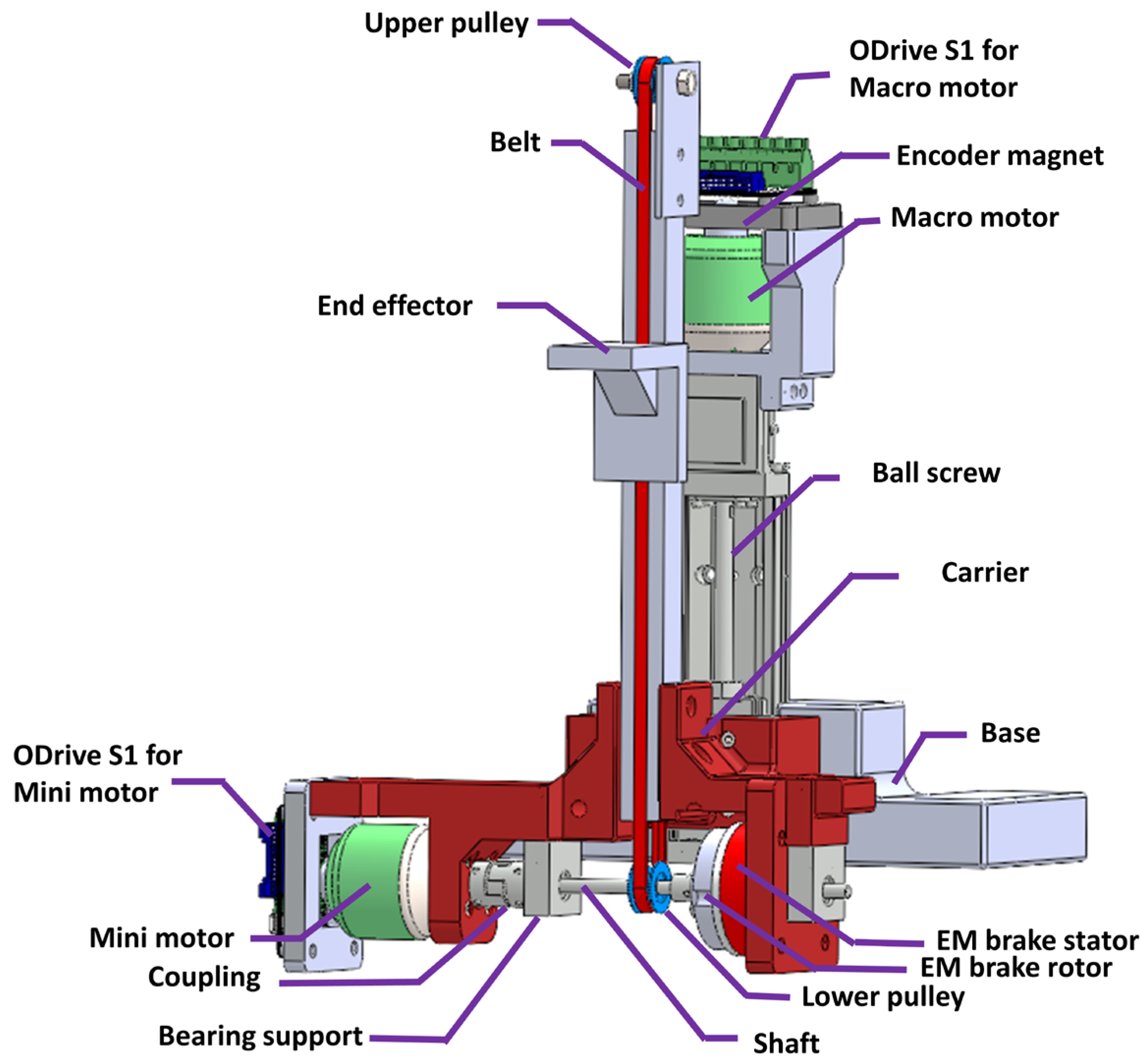

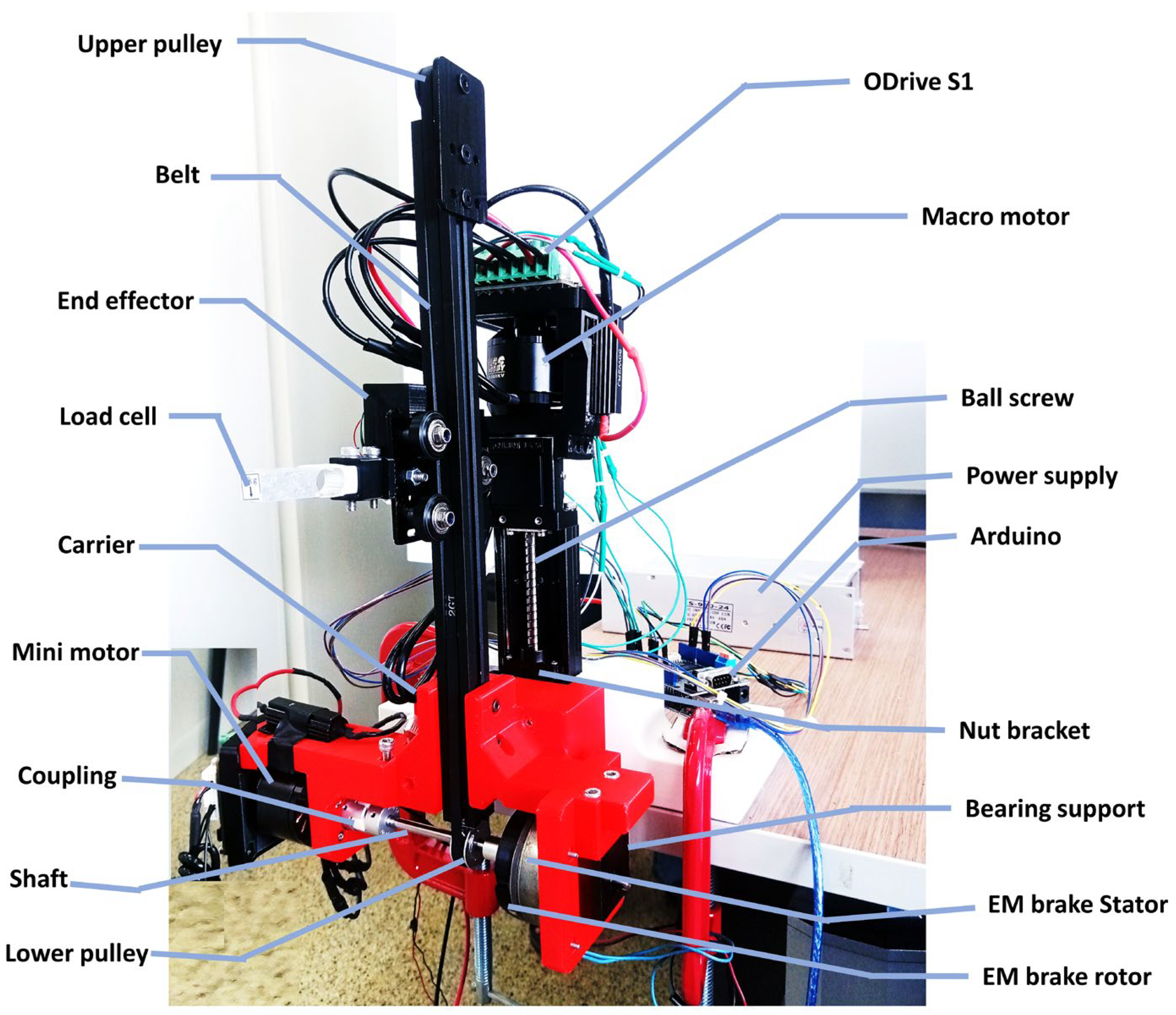

2.2. Hardware Prototype

3. Hardware Characterization of Mini Unit

3.1. Vibration Test

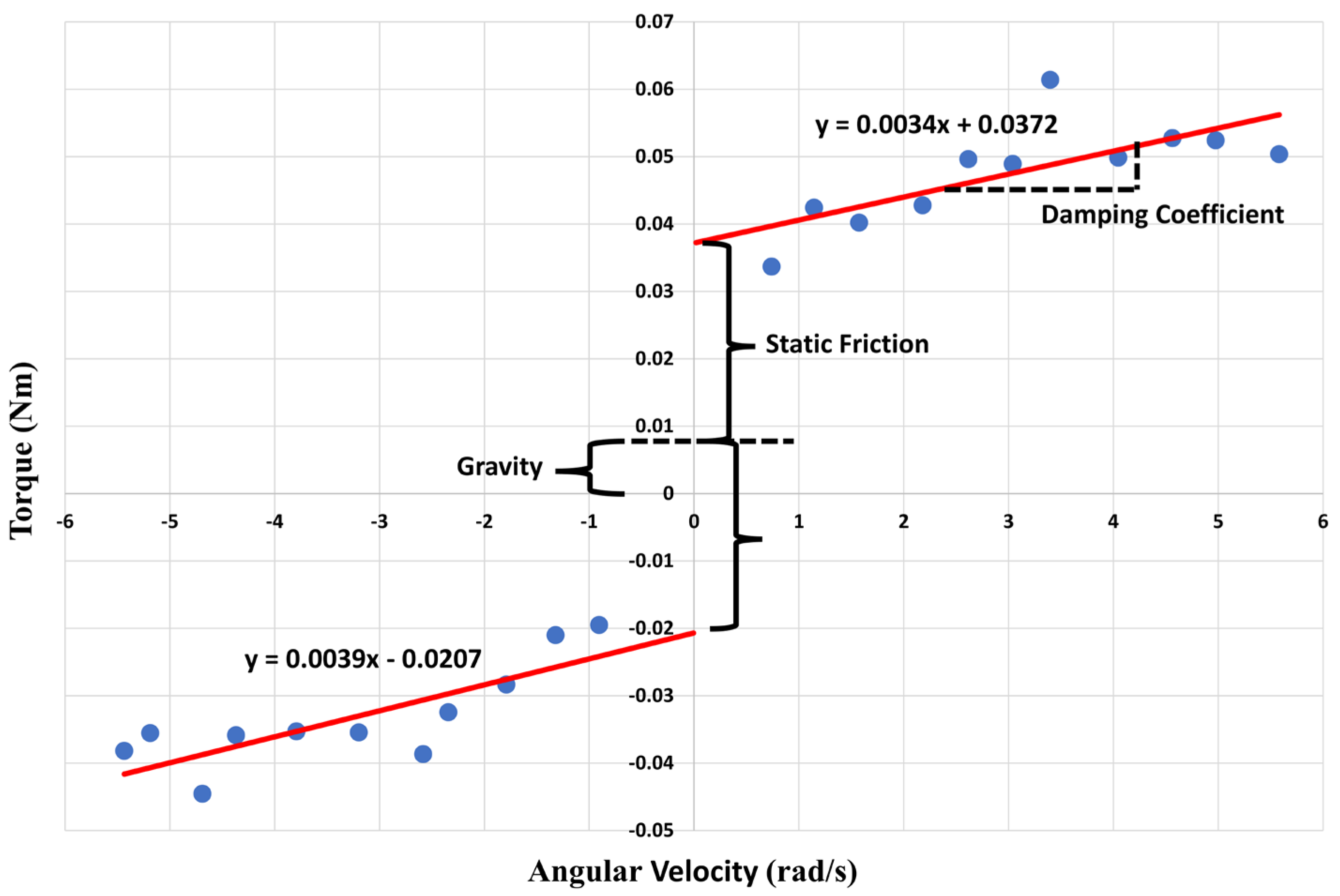

3.2. Constant Speed Test

4. Damping Modulation Using an EM Brake

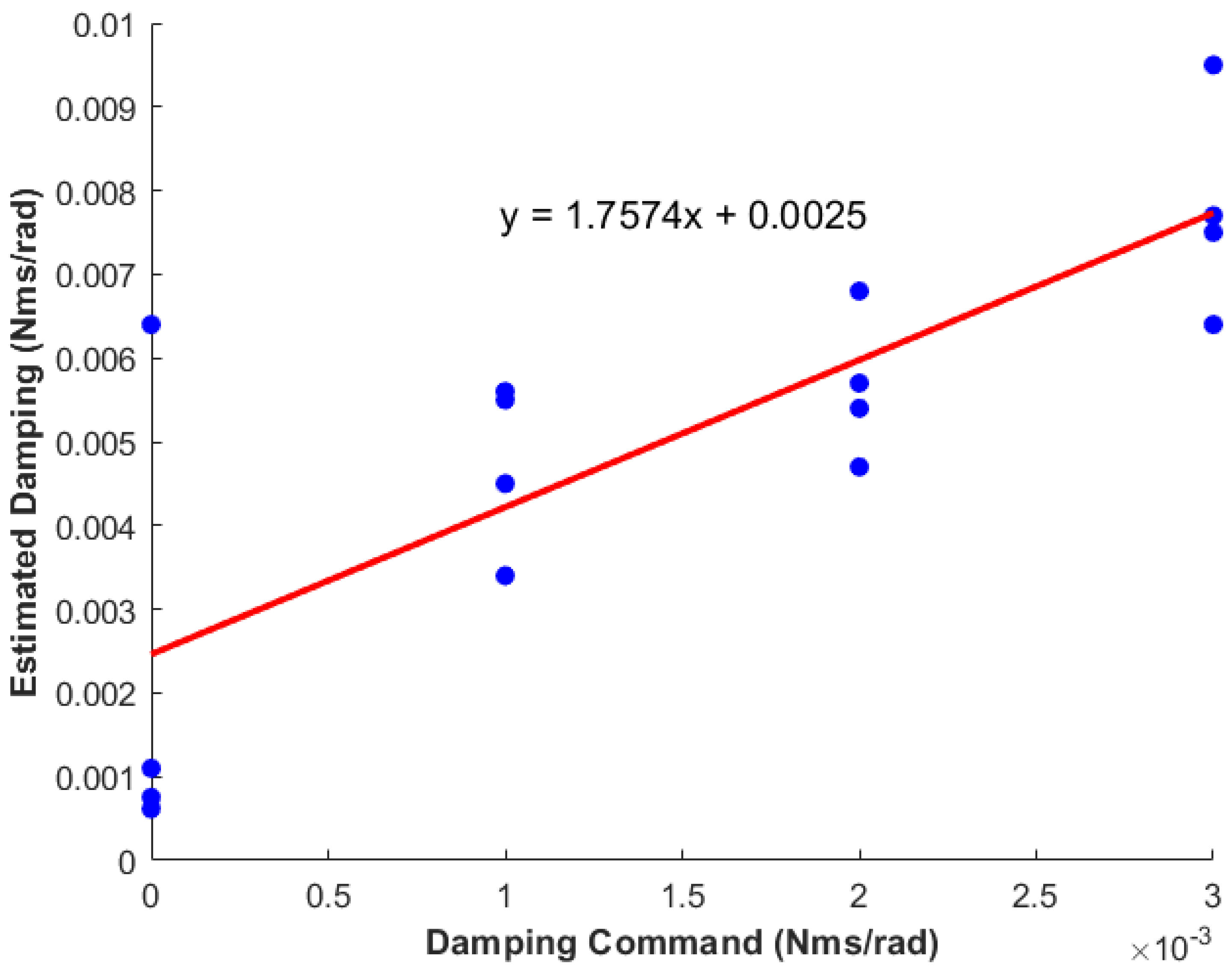

4.1. Experimental Setup

4.2. Constant Velocity Reference

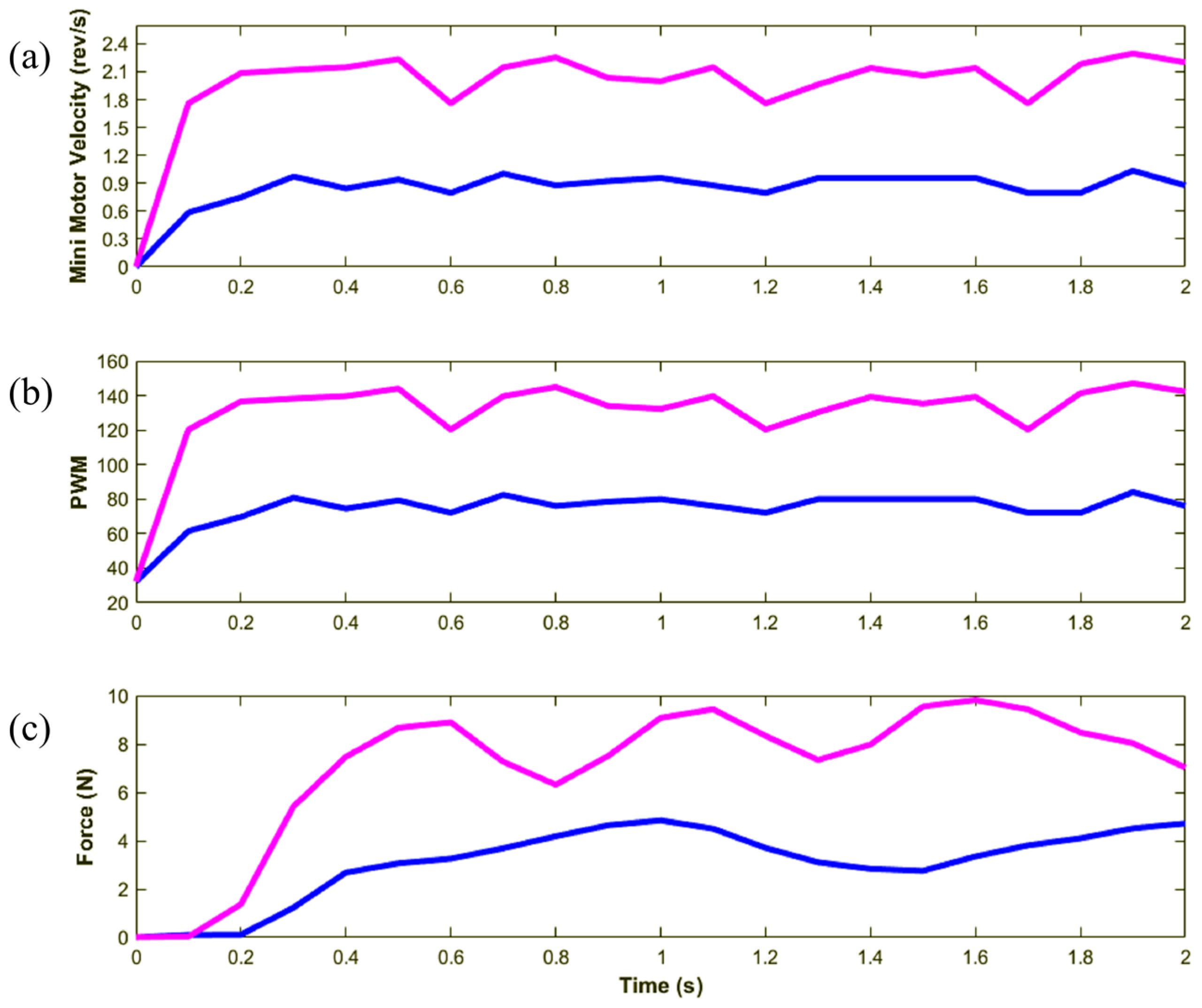

4.3. Sinusoidal Velocity Reference

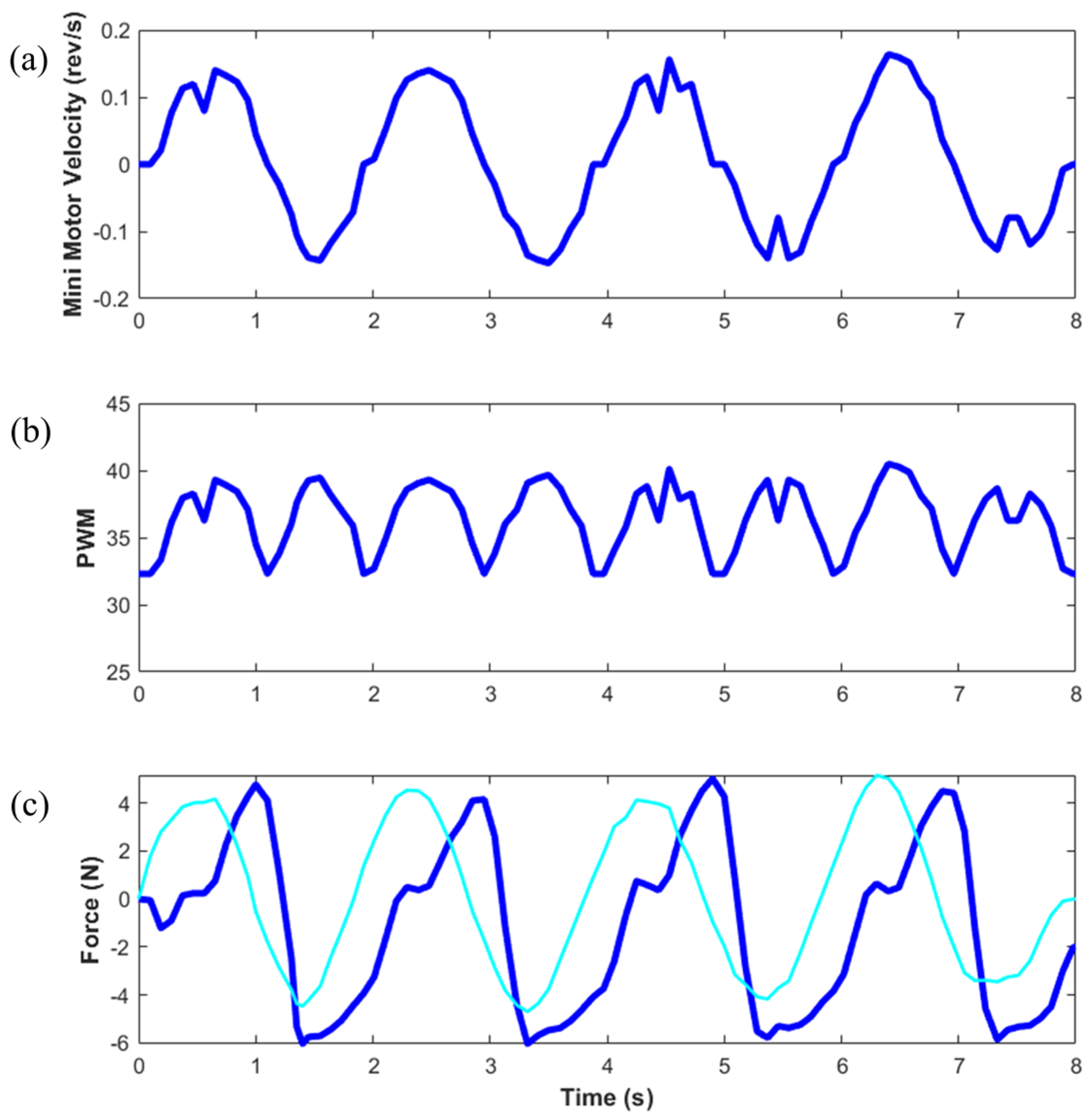

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Frey, M.; Colombo, G.; Vaglio, M.; Bucher, R.; Jorg, M.; Riener, R. A novel mechatronic body weight support system. IEEE Trans. Neural Syst. Rehab. Eng. 2006, 14, 311–321. [Google Scholar] [CrossRef] [PubMed]

- Wessels, M.; Lucas, C.; Eriks, I.; de Groot, S. Body weight-supported gait training for restoration of walking in people with an incomplete spinal cord injury: A systematic review. J. Rehabil. Med. 2010, 42, 513–519. [Google Scholar] [CrossRef] [PubMed]

- Lu, Q.; Liang, J.; Qiao, B.; Ma, O. A New Active Body Weight Support System Capable of Virtually Offloading Partial Body Mass. IEEE ASME Trans. Mechatron. 2013, 18, 11–20. [Google Scholar] [CrossRef]

- Van Thuc, T.; Yamamoto, S.-I. Development of a body weight support system using pneumatic muscle actuators: Controlling and validation. Adv. Mech. Eng. 2016, 8, 1–13. [Google Scholar] [CrossRef]

- Jungwon, Y.; Novandy, B.; Chul-Ho, Y.; Ki-Jong, P. A 6-DOF Gait Rehabilitation Robot with Upper and Lower Limb Connections That Allows Walking Velocity Updates on Various Terrains. IEEE ASME Trans. Mechatron. 2010, 15, 201–215. [Google Scholar] [CrossRef]

- Stienen, A.H.A.; Hekman, E.E.G.; ter Braak, H.; Aalsma, A.M.M.; van der Helm, F.C.T.; van der Kooij, H. Design of a Rotational Hydroelastic Actuator for a Powered Exoskeleton for Upper Limb Rehabilitation. IEEE Trans. Biomed. Eng. 2010, 57, 728–735. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Yang, Y. Nonlinear-Observer-Based Neural Fault-Tolerant Control for a Rehabilitation Exoskeleton Joint with Electro-Hydraulic Actuator and Error Constraint. Appl. Sci. 2023, 13, 8294. [Google Scholar] [CrossRef]

- Yap, H.K.; Lim, J.H.; Nasrallah, F.; Goh, J.C.; Yeow, R.C. A soft exoskeleton for hand assistive and rehabilitation application using pneumatic actuators with variable stiffness. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 4967–4972. [Google Scholar]

- Chen, H.; Ma, Y.; Chen, W. Design and Optimization of an Origami-Inspired Foldable Pneumatic Actuator. IEEE Robot. Autom. Lett. 2024, 9, 1278–1285. [Google Scholar] [CrossRef]

- Davidson, J.R.; Krebs, H.I. An electrorheological fluid actuator for rehabilitation robotics. IEEE ASME Trans. Mechatron. 2018, 23, 2156–2167. [Google Scholar] [CrossRef]

- Kong, K.; Bae, J.; Tomizuka, M. Control of rotary series elastic actuator for ideal force-mode actuation in human–robot interaction applications. IEEE ASME Trans. Mechatron. 2009, 14, 105–118. [Google Scholar] [CrossRef]

- Kong, K.; Bae, J.; Tomizuka, M. A compact rotary series elastic actuator for human assistive systems. IEEE ASME Trans. Mechatron. 2011, 17, 288–297. [Google Scholar] [CrossRef]

- Abdullahi, A.M.; Haruna, A.; Chaichaowarat, R. Hybrid Adaptive Impedance and Admittance Control Based on the Sensorless Estimation of Interaction Joint Torque for Exoskeletons: A Case Study of an Upper Limb Rehabilitation Robot. J. Sens. Actuator Netw. 2024, 13, 24. [Google Scholar] [CrossRef]

- Arents, J.; Abolins, V.; Judvaitis, J.; Vismanis, O.; Oraby, A.; Ozols, K. Human–robot collaboration trends and safety aspects: A systematic review. J. Sens. Actuator Netw. 2021, 10, 48. [Google Scholar] [CrossRef]

- Yuan, W.; Hang, K.; Song, H.; Kragic, D.; Wang, M.Y.; Stork, J.A. Reinforcement learning in topology-based representation for human body movement with whole arm manipulation. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 2153–2160. [Google Scholar]

- Hirzinger, G.; Bals, J.; Otter, M.; Stelter, J. The DLR-KUKA success story: Robotics research improves industrial robots. IEEE Robot. Autom. Mag. 2005, 12, 16–23. [Google Scholar] [CrossRef]

- Wolf, S.; Hirzinger, G. A new variable stiffness design: Matching requirements of the next robot generation. In Proceedings of the IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 1741–1746. [Google Scholar]

- Tsagarakis, N.G.; Sardellitti, I.; Caldwell, D.G. A new variable stiffness actuator (CompAct-VSA): Design and modelling. In Proceedings of the IEEE/RSJ international conference on intelligent robots and systems, San Francisco, CA, USA, 25–30 September 2011; pp. 378–383. [Google Scholar]

- Javadi, A.; Haghighi, H.; Pornpipatsakul, K.; Chaichaowarat, R. Data-Driven Position and Stiffness Control of Antagonistic Variable Stiffness Actuator Using Nonlinear Hammerstein Models. J. Sens. Actuator Netw. 2024, 13, 29. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z.; Lv, Y.; Na, J.; Liu, C.; Zhao, Z. Data-driven learning for H∞ control of adaptive cruise control systems. IEEE Trans. Veh. Technol. 2024, 1–15. [Google Scholar] [CrossRef]

- Kim, H.K.; Kang, B.; Kim, B.; Park, S. Estimation of multijoint stiffness using electromyogram and artificial neural network. IEEE Trans. Syst. Man Cybern.-Part A Syst. Hum. 2009, 39, 972–980. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Yang, C. Adaptive neural network based variable stiffness control of uncertain robotic systems using disturbance observer. IEEE Trans. Ind. Electron. 2016, 64, 2236–2245. [Google Scholar] [CrossRef]

- Seshia, A.A.; Palaniapan, M.; Roessig, T.A.; Howe, R.T.; Gooch, R.W.; Schimert, T.R.; Montague, S. A vacuum packaged surface micromachined resonant accelerometer. J. Microelectromech. Syst. 2002, 11, 784–793. [Google Scholar] [CrossRef]

- Azevedo, R.G.; Jones, D.G.; Jog, A.V.; Jamshidi, B.; Myers, D.R.; Chen, L.; Fu, X.-A.; Mehregany, M.; Wijesundara, M.B.; Pisano, A.P. A SiC MEMS resonant strain sensor for harsh environment applications. IEEE Sens. J. 2007, 7, 568–576. [Google Scholar] [CrossRef]

- Petersen, K.; Pourahmadi, F.; Brown, J.; Parsons, P.; Skinner, M.; Tudor, J. Resonant beam pressure sensor fabricated with silicon fusion bonding. In Proceedings of the TRANSDUCERS’91: 1991 International Conference on Solid-State Sensors and Actuators, Digest of Technical Papers, San Francisco, CA, USA, 24–27 June 1991; pp. 664–667. [Google Scholar]

- Dürig, U.; Gimzewski, J.; Pohl, D. Experimental observation of forces acting during scanning tunneling microscopy. Phys. Rev. Lett. 1986, 57, 2403. [Google Scholar] [CrossRef] [PubMed]

- Sardellitti, I.; Park, J.; Shin, D.; Khatib, O. Air muscle controller design in the distributed macro-mini (DM 2) actuation approach. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 1822–1827. [Google Scholar]

- Sensinger, J.W.; Weir, R.F.F. Improvements to series elastic actuators. In Proceedings of the IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications, Beijing, China, 13–16 August 2006; pp. 1–7. [Google Scholar]

- Paine, N.; Oh, S.; Sentis, L. Design and Control Considerations for High-Performance Series Elastic Actuators. IEEE ASME Trans. Mechatron. 2014, 19, 1080–1091. [Google Scholar] [CrossRef]

- Lee, H.; Lee, J.; Keppler, M.; Oh, S. Robust Elastic Structure Preserving Control for High Impedance Rendering of Series Elastic Actuator. IEEE Robot. Autom. Lett. 2024, 9, 3601–3608. [Google Scholar] [CrossRef]

- Zhou, W.; Chew, C.-M.; Hong, G.-S. Design of series damper actuator. Robotica 2009, 27, 379–387. [Google Scholar] [CrossRef]

- Scibilia, A.; Pedrocchi, N.; Fortuna, L. Human control model estimation in physical human–machine interaction: A survey. Sensos 2022, 22, 1732. [Google Scholar] [CrossRef]

- Goncalves, R.S.; Krebs, H.I. MIT-Skywalker: Considerations on the Design of a Body Weight Support System. J. Neuroeng. Rehab. 2017, 14, 88. [Google Scholar] [CrossRef]

- Abdullahi, A.M.; Chaichaowarat, R. Sensorless estimation of human joint torque for robust tracking control of lower-limb exoskeleton assistive gait rehabilitation. J. Sens. Actuator Netw. 2023, 12, 53. [Google Scholar] [CrossRef]

- Chaichaowarat, R.; Nishimura, S.; Nozaki, T.; Krebs, H.I. Work in the Time of COVID-19: Actuators and Sensors for Rehabilitation Robotics. IEEJ J. Ind. Appl. 2022, 11, 256–265. [Google Scholar] [CrossRef]

- Nishimura, S.; Chaichaowarat, R.; Krebs, H.I. Human-robot interaction: Controller design and stability. In Proceedings of the IEEE RAS/EMBS International Conference for Biomedical Robotics and Biomechatronics, New York, NY, USA, 29 November–1 December 2020; pp. 1096–1101. [Google Scholar]

- Chaichaowarat, R.; Nishimura, S.; Krebs, H.I. Design and modeling of a variable-stiffness spring mechanism for impedance modulation in physical human–robot interaction. In Proceedings of the IEEE International Conference on Robotics and Automation, Xi’an, China, 30 May–5 June 2021; pp. 7052–7057. [Google Scholar]

- Braun, D.J.; Chalvet, V.; Chong, T.; Apte, S.S.; Hogan, N. Variable stiffness spring actuators for low-energy-cost human augmentation. IEEE Trans. Robot. 2019, 35, 1435–1449. [Google Scholar] [CrossRef]

- Wu, Y.; Lan, C. Linear variable-stiffness mechanisms based on preloaded curved beams. J. Mech. Des. 2014, 136, 122302. [Google Scholar] [CrossRef]

- Choi, J.; Hong, S.; Lee, W.; Kang, S. A variable stiffness joint using leaf springs for robot manipulators. In Proceedings of the IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 4363–4368. [Google Scholar]

- Groothuis, S.S.; Carloni, R.; Stramigioli, S. A novel variable stiffness mechanism capable of an infinite stiffness range and unlimited decoupled output motion. Actuators 2014, 3, 107–123. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, Z.; Wang, J.; Xu, D.; Chen, W. A novel design of variable stiffness linkage with distributed leaf springs. In Proceedings of the 2016 IEEE Conference Industrial Electronics and Applications, San Francisco, CA, USA, 27 June–2 July 2016; pp. 789–794. [Google Scholar]

- Chaichaowarat, R.; Macha, V.; Wannasuphoprasit, W. Passive knee exoskeleton using brake torque to assist stair ascent. In Proceedings of the 2020 IEEE Region 10 Conference (TENCON), Osaka, Japan, 16–19 November 2020; pp. 1165–1170. [Google Scholar]

- Chaichaowarat, R.; Nishimura, S.; Krebs, H.I. Macro-Mini Linear Actuator Using Electrorheological-Fluid Brake for Impedance Modulation in Physical Human–Robot Interaction. IEEE Robot. Autom. Lett. 2022, 7, 2945–2952. [Google Scholar] [CrossRef]

- Ullah, Z.; Chaichaowarat, R.; Wannasuphoprasit, W. Variable Damping Actuator Using an Electromagnetic Brake for Impedance Modulation in Physical Human–Robot Interaction. Robotics 2023, 12, 80. [Google Scholar] [CrossRef]

- Jleilaty, S.; Ammounah, A.; Abdulmalek, G.; Nouveliere, L.; Su, H.; Alfayad, S. Distributed real-time control architecture for electrohydraulic humanoid robots. Robot. Intell. Autom. 2024, 4, 607–620. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, Z.; Sermsrisuwan, T.; Pornpipatsakul, K.; Chaichaowarat, R.; Wannasuphoprasit, W. High-Transparency Linear Actuator Using an Electromagnetic Brake for Damping Modulation in Physical Human–Robot Interaction. J. Sens. Actuator Netw. 2024, 13, 65. https://doi.org/10.3390/jsan13050065

Ullah Z, Sermsrisuwan T, Pornpipatsakul K, Chaichaowarat R, Wannasuphoprasit W. High-Transparency Linear Actuator Using an Electromagnetic Brake for Damping Modulation in Physical Human–Robot Interaction. Journal of Sensor and Actuator Networks. 2024; 13(5):65. https://doi.org/10.3390/jsan13050065

Chicago/Turabian StyleUllah, Zahid, Thachapan Sermsrisuwan, Khemwutta Pornpipatsakul, Ronnapee Chaichaowarat, and Witaya Wannasuphoprasit. 2024. "High-Transparency Linear Actuator Using an Electromagnetic Brake for Damping Modulation in Physical Human–Robot Interaction" Journal of Sensor and Actuator Networks 13, no. 5: 65. https://doi.org/10.3390/jsan13050065