Open Sensor Manager for IIoT

Abstract

1. Introduction

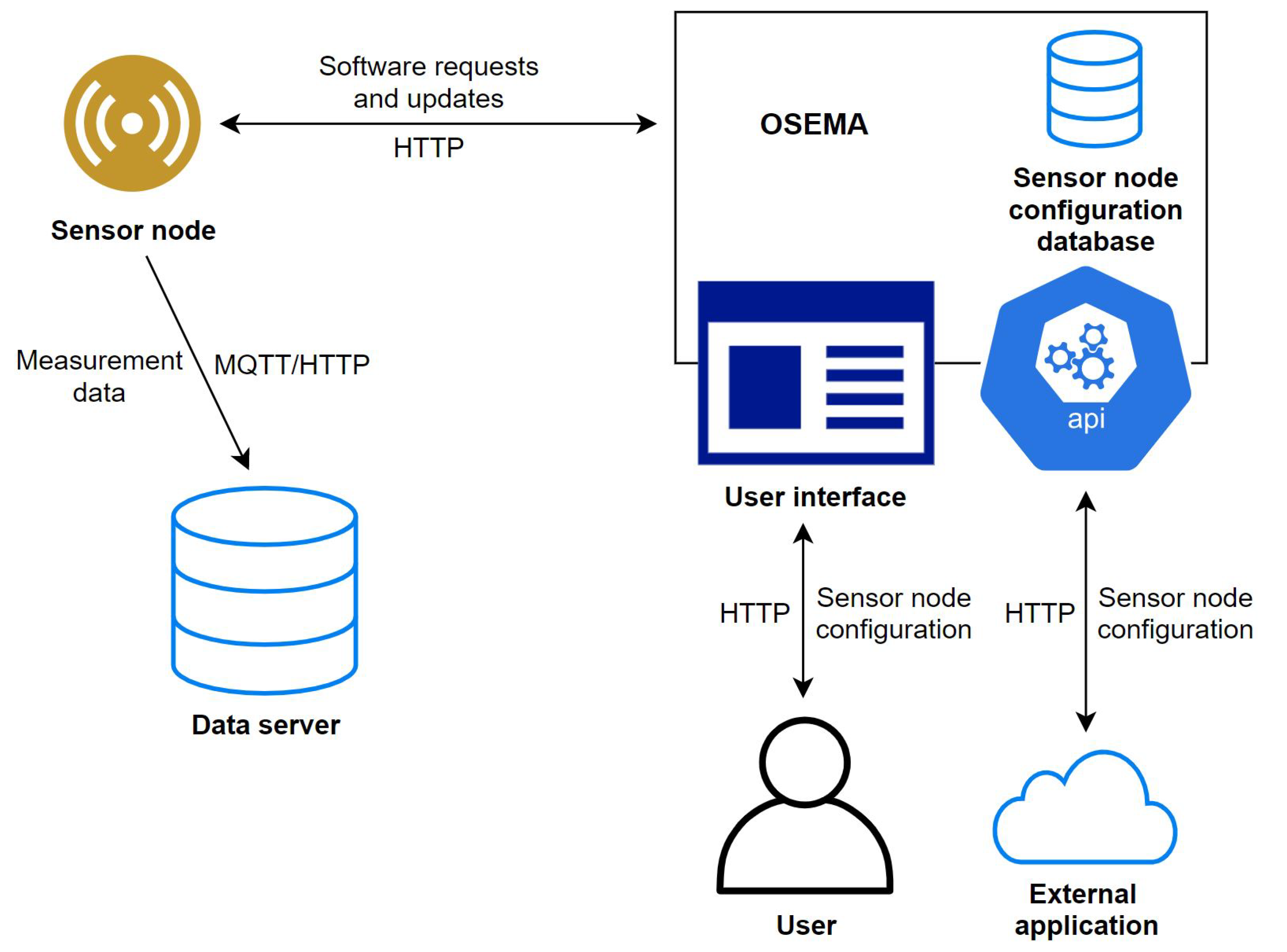

- Developing a sensor manager that allows remote software updates of sensor nodes via a web user interface and a REST API (Representational State Transfer Application Programming Interface);

- Introducing a software generation method for sensor nodes with minimal manual programming;

- Implementing the configuration of sensor nodes via remote software updates, which allows changing sensor settings via the I2C (Inter-Integrated Circuit) bus.

2. Related Work

3. Materials And Methods

3.1. Sensor Node

3.2. Programming, Frameworks and Tools

4. Open Sensor Manager

4.1. Generation of Software for a Sensor Node

4.2. Software Update Process

4.3. Measuring

4.4. Security

4.5. Application Layer Protocols

4.6. Web User Interface

5. Use Cases of OSEMA

5.1. Usage Roughness of an Overhead Crane

5.2. Position Tracking of an Overhead Crane

5.3. Laboratory Exercise

6. Discussion

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vitturi, S.; Zunino, C.; Sautor, T. Industrial Communication Systems and Their Future Challenges: Next-Generation Ethernet, IIoT, and 5G. Proc. IEEE 2019, 107, 944–961. [Google Scholar] [CrossRef]

- Carlsson, O.; Pereira, P.P.; Eliasson, J.; Delsing, J. Configuration service in cloud based automation systems. In Proceedings of the 42nd Annual Conference of the IEEE Industrial Electronics Society (IECON), Florence, Italy, 23–26 October 2016. [Google Scholar]

- Datta, S.K.; Bonnet, C. Smart M2M Gateway Based Architecture for M2M Device and Endpoint Management. In Proceedings of the IEEE International Conference on Internet of Things (iThings), and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom), Taipei, Taiwan, 1–3 September 2014. [Google Scholar]

- Pham, C.; Lim, Y.; Tan, Y. Management architecture for heterogeneous IoT devices in home network. In Proceedings of the IEEE 5th Global Conference on Consumer Electronics (GCCE), Kyoto, Japan, 11–14 October 2016. [Google Scholar]

- Haus, M.; Ding, A.Y.; Ott, J. Managing IoT at the Edge. In Proceedings of the 3rd Workshop on Experiences with the Design and Implementation of Smart Objects (SMARTOBJECTS), Snowbird, UT, USA, 16 October 2017. [Google Scholar]

- Rao, S.; Chendanda, D.; Deshpande, C.; Lakkundi, V. Implementing LWM2M in constrained IoT devices. In Proceedings of the IEEE Conference on Wireless Sensors (ICWiSe), Melaka, Malaysia, 24–26 August 2015. [Google Scholar]

- Ruckebusch, P.; De Poorter, E.; Fortuna, C.; Moerman, I. GITAR: Generic extension for Internet-of-Things ARchitectures enabling dynamic updates of network and application modules. Ad Hoc Netw. 2016, 36, 127–151. [Google Scholar] [CrossRef]

- Nikolov, N. Research Firmware Update Over the Air from the Cloud. In Proceedings of the IEEE XXVII International Scientific Conference Electronics (ET), Sozopol, Bulgaria, 13–15 September 2018. [Google Scholar]

- Yesilyurt, H.B.; Aksu, H.; Uluagac, S.; Beyah, R. SOTA: Secure Over-the-Air Programming of IoT Devices. In Proceedings of the IEEE Military Communications Conference (MILCOM), Los Angeles, CA, USA, 29–31 October 2018. [Google Scholar]

- Ala-Laurinaho, R. OSEMA: Open Sensor Manager. Available online: https://github.com/AaltoIIC/OSEMA (accessed on 24 April 2020).

- Ala-laurinaho, R. Sensor Data Transmission from a Physical Twin to a Digital Twin. Master’s Thesis, Aalto University, Espoo, Finland, 2019. Available online: Http://urn.fi/URN:NBN:fi:aalto-201905123028 (accessed on 14 April 2020).

- Doddapaneni, K.; Lakkundi, R.; Rao, S.; Kulkarni, S.G.; Bhat, B. Secure FoTA Object for IoT. In Proceedings of the IEEE 42nd Conference on Local Computer Networks Workshops (LCN Workshops), Singapore, 9–12 October 2017. [Google Scholar]

- Meddeb, M.; Alaya, M.B.; Monteil, T.; Dhraief, A.; Drira, K. M2M platform with autonomic device management service. Procedia Comput. Sci. 2014, 32, 1063–1070. [Google Scholar] [CrossRef]

- Elgazzar, M.H. Perspectives on M2M protocols. In Proceedings of the IEEE 7th International Conference on Intelligent Computing and Information Systems (ICICIS), Cairo, Egypt, 12–14 December 2015. [Google Scholar]

- Open Mobile Alliance. Lightweight Machine to Machine Technical Specification: Core 1.1.1. 2019. Available online: Http://www.openmobilealliance.org/release/LightweightM2M/V1_1_1-20190617-A/OMA-TS-LightweightM2M_Core-V1_1_1-20190617-A.pdf (accessed on 14 April 2020).

- Mohapatra, S.K.; Bhuyan, J.N.; Asundi, P.; Singh, A. A Solution Framework for Managing Internet of Things (IOT). Int. J. Comput. Netw. Commun. 2016, 8, 73–87. [Google Scholar] [CrossRef]

- Amazon Web Services, Inc. AWS IoT. Available online: https://aws.amazon.com/iot/ (accessed on 4 June 2020).

- Microsoft. Azure IoT. Available online: https://azure.microsoft.com/en-us/overview/iot/ (accessed on 4 June 2020).

- IBM. Watson IoT Platform. Available online: https://www.ibm.com/Internet-of-things/solutions/iot-platform/watson-iot-platform (accessed on 4 June 2020).

- KaaIoT Technologies, LLC. Enterprise IoT Platform, Cloud, and Analytics. Available online: https://www.kaaproject.org/ (accessed on 4 June 2020).

- DeviceHive. DeviceHive—Open Source IoT Data Platform with the Wide Range of Integration Options. Available online: https://devicehive.com/ (accessed on 4 June 2020).

- Thinger.io. Thinger.io—Open Source IoT Platform. Available online: https://thinger.io/ (accessed on 4 June 2020).

- Amazon Web Services, Inc. FreeRTOS Over-the-Air Updates. Available online: https://aws.amazon.com/iot-device-management/ (accessed on 4 June 2020).

- Amazon Web Services, Inc. AWS IoT Device Management. Available online: https://docs.aws.amazon.com/freertos/latest/userguide/freertos-ota-dev.html (accessed on 4 June 2020).

- Microsoft. Azure IoT Automatic Device Management Helps Deploying Firmware Updates at Scale. Available online: https://azure.microsoft.com/en-us/blog/azure-iot-automatic-device-management-helps-deploying-firmware-updates-at-scale/ (accessed on 4 June 2020).

- IBM. Device Management Protocol. Available online: https://www.ibm.com/support/knowledgecenter/SSQP8H/iot/platform/reference/devicemgmt/index.html (accessed on 4 June 2020).

- IBM. Device Management Requests. Available online: https://www.ibm.com/support/knowledgecenter/SSQP8H/iot/platform/reference/devicemgmt/requests.html (accessed on 4 June 2020).

- KaaIoT Technologies, LLC. Kaa IoT Platform—Enterprise and Open Source Development History. Available online: https://www.kaaproject.org/kaa-open-source.html (accessed on 4 June 2020).

- KaaIoT Technologies, LLC. OTAO. Available online: https://docs.kaaiot.io/KAA/docs/current/Features/Software-updates/OTAO/ (accessed on 4 June 2020).

- DeviceHive. 101 Overview. Available online: https://docs.devicehive.com/docs/101-overview (accessed on 4 June 2020).

- Thinger.io. Overview. Available online: https://docs.thinger.io/ (accessed on 5 June 2020).

- Thinger.io. Devices Administration. Available online: https://docs.thinger.io/features/devices-administration (accessed on 5 June 2020).

- Brown, S.; Sreenan, C. Software Updating in Wireless Sensor Networks: A Survey and Lacunae. J. Sens. Actuator Netw. 2013, 2, 717–760. [Google Scholar] [CrossRef]

- Reijers, N.; Langendoen, K. Efficient code distribution in wireless sensor networks. In Proceedings of the 2nd ACM International Conference on Wireless Sensor Networks and Applications (WSNA), San Diego, CA, USA, 19 September 2003. [Google Scholar]

- Chandra, H.; Anggadjaja, E.; Wijaya, P.S.; Gunawan, E. Internet of Things: Over-the-Air (OTA) firmware update in Lightweight mesh network protocol for smart urban development. In Proceedings of the 22nd Asia-Pacific Conference on Communications (APCC), Yogyakarta, Indonesia, 25–27 August 2016. [Google Scholar]

- NXP Semiconductors N.V. UM10204 I2C-Bus Specification and User Manual. 2014. Available online: https://www.nxp.com/docs/en/user-guide/UM10204.pdf (accessed on 14 April 2020).

- Analog Devices, Inc. ADXL345. Available online: https://www.analog.com/en/products/adxl345.html#product-overview (accessed on 14 April 2020).

- STMicroelectronics. LIS3DSH. Available online: https://www.st.com/en/mems-and-sensors/lis3dsh.html (accessed on 14 April 2020).

- Garmin Ltd. Lidar-Lite v3HP Operation Manual and Technical Specifications. Available online: Http://static.garmin.com/pumac/LIDAR-Lite_v3HP_Instructions_EN.pdf (accessed on 14 April 2020).

- Django Software Foundation. Why Django? Available online: https://www.djangoproject.com/start/overview/ (accessed on 14 April 2020).

- Django REST framework Home Page. Available online: https://www.django-rest-framework.org/ (accessed on 14 April 2020).

- Ian Foote. Rest Framework Generic Relations. Available online: https://github.com/Ian-Foote/rest-framework-generic-relations (accessed on 14 April 2020).

- Sanders, D. Simple JWT. Available online: https://github.com/davesque/django-rest-framework-simplejwt (accessed on 14 April 2020).

- Bootstrap Home Page. Available online: https://getbootstrap.com/ (accessed on 14 April 2020).

- jQuery Home Page. Available online: https://jquery.com/ (accessed on 14 April 2020).

- George Robotics Limited. MicroPython. Available online: Http://micropython.org/ (accessed on 14 April 2020).

- MicroPython FAQ. Available online: https://github.com/micropython/micropython/wiki/FAQ (accessed on 14 April 2020).

- Abdul-Ghani, H.A.; Konstantas, D. A comprehensive study of security and privacy guidelines, threats, and countermeasures: An IoT perspective. J. Sens. Actuator Netw. 2019, 8, 22. [Google Scholar] [CrossRef]

- Barker, E. Recommendation for Key Management Part 1: General. NIST Special Publication 800-57 Part 1, Rev. 4; 2016. Available online: https://nvlpubs.nist.gov/nistpubs/SpecialPublications/NIST.SP.800-57pt1r4.pdf (accessed on 14 April 2020).

- Chen, Y.; Kunz, T. Performance evaluation of IoT protocols under a constrained wireless access network. In Proceedings of the International Conference on Selected Topics in Mobile & Wireless Networking (MoWNeT), Cairo, Egypt, 11–13 April 2016. [Google Scholar]

- Talaminos-Barroso, A.; Estudillo-Valderrama, M.A.; Roa, L.M.; Reina-Tosina, J.; Ortega-Ruiz, F. A Machine-to- Machine protocol benchmark for eHealth applications—Use case: Respiratory rehabilitation. Comput. Methods Programs Biomed. 2016, 129, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Alani, M.M. Guide to OSI and TCP/IP Models; Springer: Cham, Switzerland, 2014; ISBN 978-3-319-05151-9. [Google Scholar]

- Kurose, J.F.; Ross, K.W. Computer Networking: A Top-Down Approach, 6th ed.; Pearson Education UK: Essex, UK, 2013; ISBN 978-0-273-77563-8. [Google Scholar]

- Naik, N. Choice of effective messaging protocols for IoT systems: MQTT, CoAP, AMQP and HTTP. In Proceedings of the IEEE International Symposium on Systems Engineering, ISSE, Vienna, Austria, 11–13 October 2017. [Google Scholar]

- Rescorla, E. HTTP Over TLS; RFC Editor. 2000. Available online: https://tools.ietf.org/html/rfc2818 (accessed on 14 April 2020).

- Altowaijri, S.; Ayari, M.; Touati, Y. El Impact of multi-sensor technology for enhancing global security in closed environments using cloud-based resources. J. Sens. Actuator Netw. 2019, 8, 4. [Google Scholar] [CrossRef]

- Autiosalo, J. Platform for Industrial Internet and Digital Twin Focused Education, Research, and Innovation: Ilmatar the Overhead Crane. In Proceedings of the IEEE 4th World Forum on Internet of Things (WF-IoT), Singapore, 5–8 February 2018. [Google Scholar]

- Sjöman, H.; Autiosalo, J.; Juhanko, J.; Kuosmanen, P.; Steinert, M. Using Low-Cost Sensors to Develop a High Precision Lifting Controller Device for an Overhead Crane—Insights and Hypotheses from Prototyping a Heavy Industrial Internet Project. Sensors 2018, 18, 3328. [Google Scholar] [CrossRef] [PubMed]

- insigh.io. microCoAPy. Available online: https://github.com/insighio/microCoAPy (accessed on 14 April 2020).

- Hwang, C.E.; Lee, S.H.; Jeong, J.W. VisKit: Web-based interactive IoT management with deep visual object detection. J. Sens. Actuator Netw. 2019, 8, 12. [Google Scholar] [CrossRef]

| Setting | Description | Example Value |

|---|---|---|

| Update URL | OSEMA server URL where updates are requested | www.example.com |

| Update port | Sensor node requests updates from this port | 443 |

| Update over HTTPS | Use HTTPS for sending updates (true/false) | True |

| Update check limit | How often a node requests updates | 3600 (s) |

| Sensor model | Which sensor model is used | ADXL345 |

| Sample rate | Sample rate of the sensor | 12.5 (Hz) |

| Sensitivity | Sensitivity of sensor | ±2 g |

| Burst length | Length of measurement when measured in bursts | 10 (s) |

| Burst rate | Time interval between bursts | 10 (s) |

| Data send rate | How often data are sent to the data server | 10 (s) |

| Connection close limit | If the data send rate are higher than this, the connection is closed after data transmission | 3 (s) |

| Network close limit | If the data send rate are higher than this, the network connection is closed after data transmission | 30 (s) |

| SSID | SSID of the Wi-Fi network | myHotspot |

| Security | The security method of the Wi-Fi network | WPA2 |

| Key | Password of the Wi-Fi network | secretpasswd |

| Protocol | Application layer protocols used for measurement data transmission | MQTT |

| Data server URL | Data server URL | www.example.com |

| Data server port | Data server port | 80 |

| Path | Path where the measurement data are sent (with HTTP/HTTPS) | /add-data |

| MQTT User | Username for MQTT | username |

| MQTT Key | Password for MQTT | secretpasswd |

| Topic | MQTT topic | example/topic |

| Broker URL | MQTT broker URL | io.adafruit.com |

| Broker port | MQTT broker port | 1883 |

| Data format | In which format measurement data are sent | JSON |

| Variable name | Each variable should be named | x_acceleration |

| Encrypt data | Encrypt the measurement data (true/false) | True |

| Key for data encryption | Key used to encrypt data as hex number | 3ba19f5c4192b1317123e993ca9dae21 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ala-Laurinaho, R.; Autiosalo, J.; Tammi, K. Open Sensor Manager for IIoT. J. Sens. Actuator Netw. 2020, 9, 30. https://doi.org/10.3390/jsan9020030

Ala-Laurinaho R, Autiosalo J, Tammi K. Open Sensor Manager for IIoT. Journal of Sensor and Actuator Networks. 2020; 9(2):30. https://doi.org/10.3390/jsan9020030

Chicago/Turabian StyleAla-Laurinaho, Riku, Juuso Autiosalo, and Kari Tammi. 2020. "Open Sensor Manager for IIoT" Journal of Sensor and Actuator Networks 9, no. 2: 30. https://doi.org/10.3390/jsan9020030

APA StyleAla-Laurinaho, R., Autiosalo, J., & Tammi, K. (2020). Open Sensor Manager for IIoT. Journal of Sensor and Actuator Networks, 9(2), 30. https://doi.org/10.3390/jsan9020030