Revolutionary Integration of Artificial Intelligence with Meta-Optics-Focus on Metalenses for Imaging

Abstract

:1. Introduction

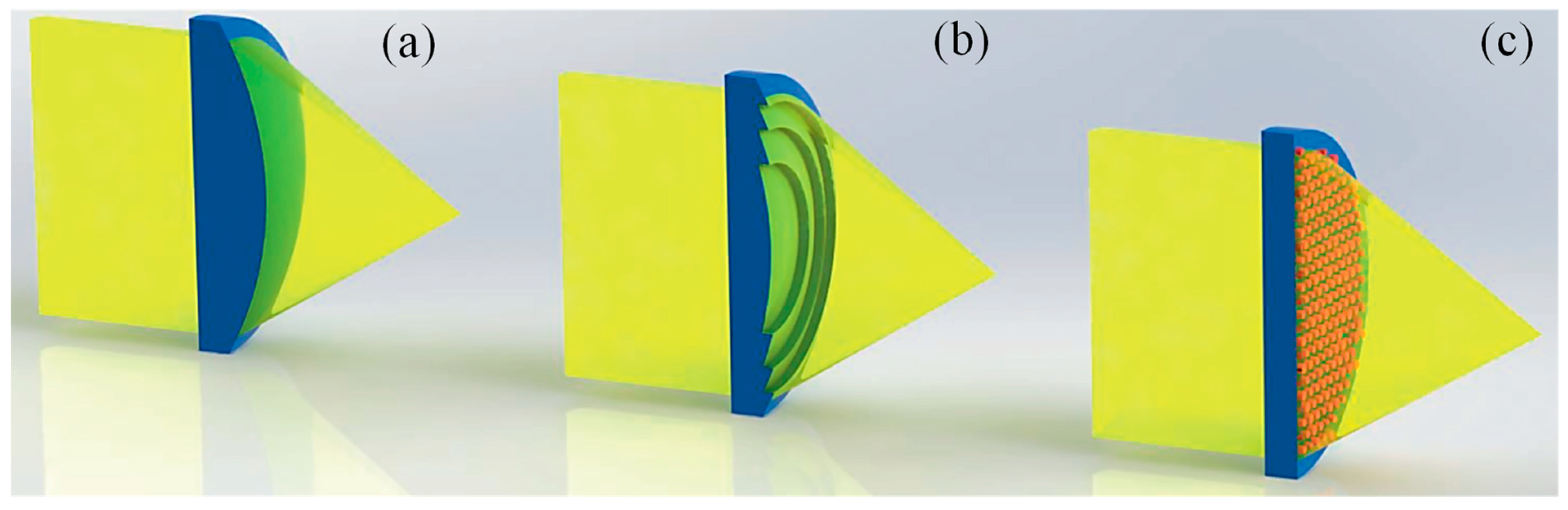

2. Standard Refractive Lenses, Diffractive Lenses and Metalenses

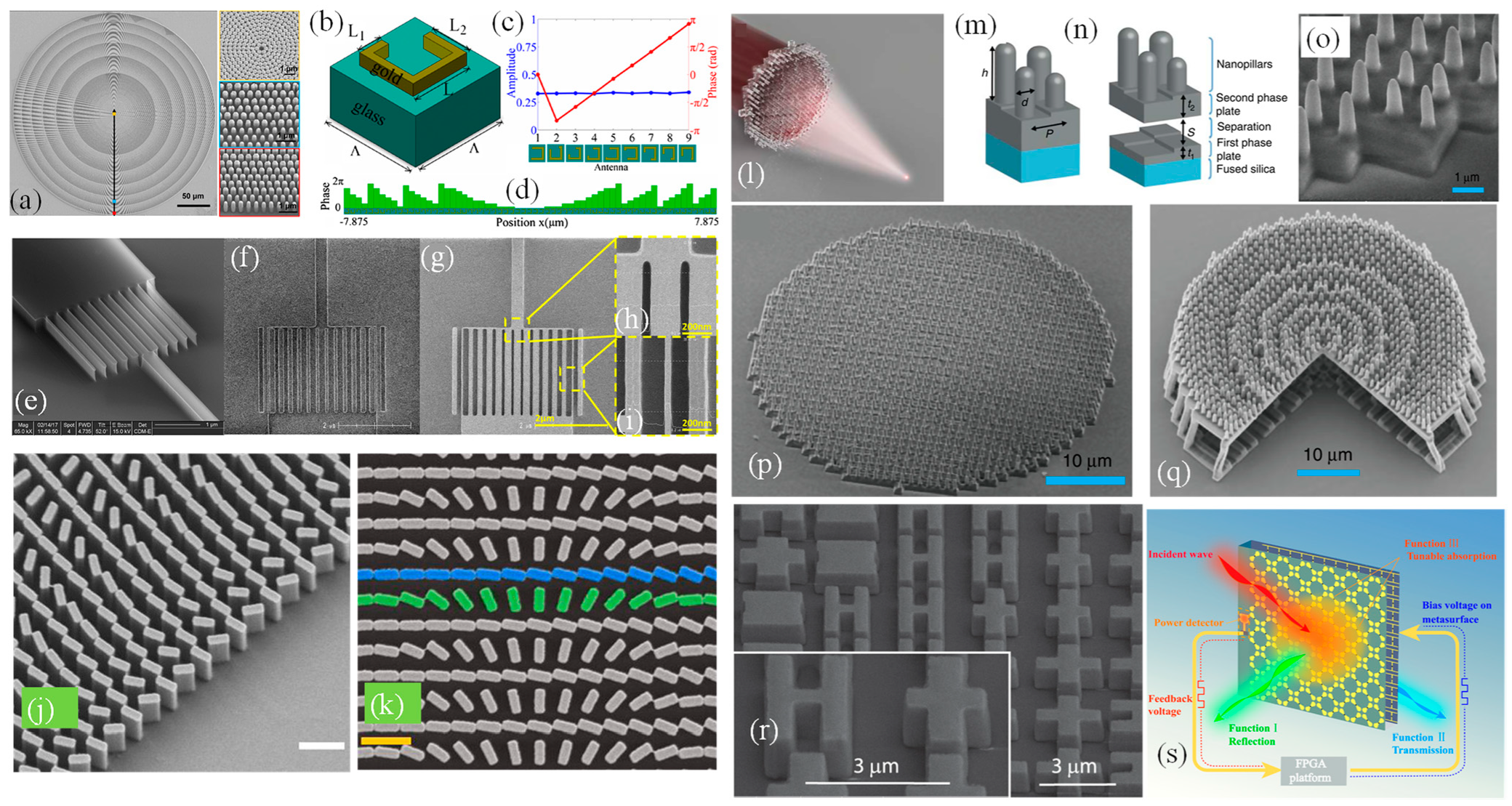

3. Types of Metalenses

3.1. Dielectric Metalenses

3.2. Plasmonic Metalenses

3.3. Gradient Index (GRIN) Metalenses

3.4. Chiral Metalens

3.5. Parabolic Metalenses

3.6. Hybrid Metalenses

3.7. Reconfigurable Metalenses

3.8. Binocular and Metalens Array

| Type of Metalens | Material | Mechanism | Advantages | Disadvantages | Applications |

|---|---|---|---|---|---|

| Dielectric Metalenses | High-index dielectrics (e.g., TiO2, Si) | Phase control through geometric phase or propagation phase | High efficiency, low loss, compatibility with visible light | Fabrication complexity, requires high precision | Imaging, microscopy, AR/VR devices [66,151] |

| Plasmonic Metalenses | Metals (e.g., Au, Ag) | Surface plasmon resonances to control light | Compact, capable of sub-wavelength focusing | High loss, limited efficiency, typically for near-IR or visible | Sensing, imaging, nano-optics [88,152] |

| GRIN Metalenses | Gradient refractive index materials | Spatial variation of refractive index [153] | Broad wavelength range, reduced CA | Complex fabrication, limited material choices | Imaging systems, optical communication [154,155] |

| Chiral Metalens | Chiral metamaterials | Circular dichroism and birefringence | Polarization control, circular dichroism | Limited efficiency, complex design | Polarization optics, spectroscopy [114,156,157] |

| Reflective parabolic metalenses | TiO2, SiO2 | Parabolic phase profile, Bragg reflector | High reflectivity, efficient focusing | Limited to reflective applications | Telescopes, optical communication [124] |

| Hybrid Metalenses | Combination of dielectric and plasmonic materials | Integrates benefits of both dielectric and plasmonic mechanisms | Enhanced functionality, improved efficiency and bandwidth | Increased design and fabrication complexity | Multifunctional optical devices, sensing [19,130] |

| Reconfigurable Metalenses | Tunable materials (e.g., liquid crystals, phase-change materials) | Dynamically controlled phase shift | Tunable focal length and beam shaping, adaptable to varying conditions | Slow response time, material stability, fabrication challenges | Adaptive optics, dynamic imaging systems [140,158] |

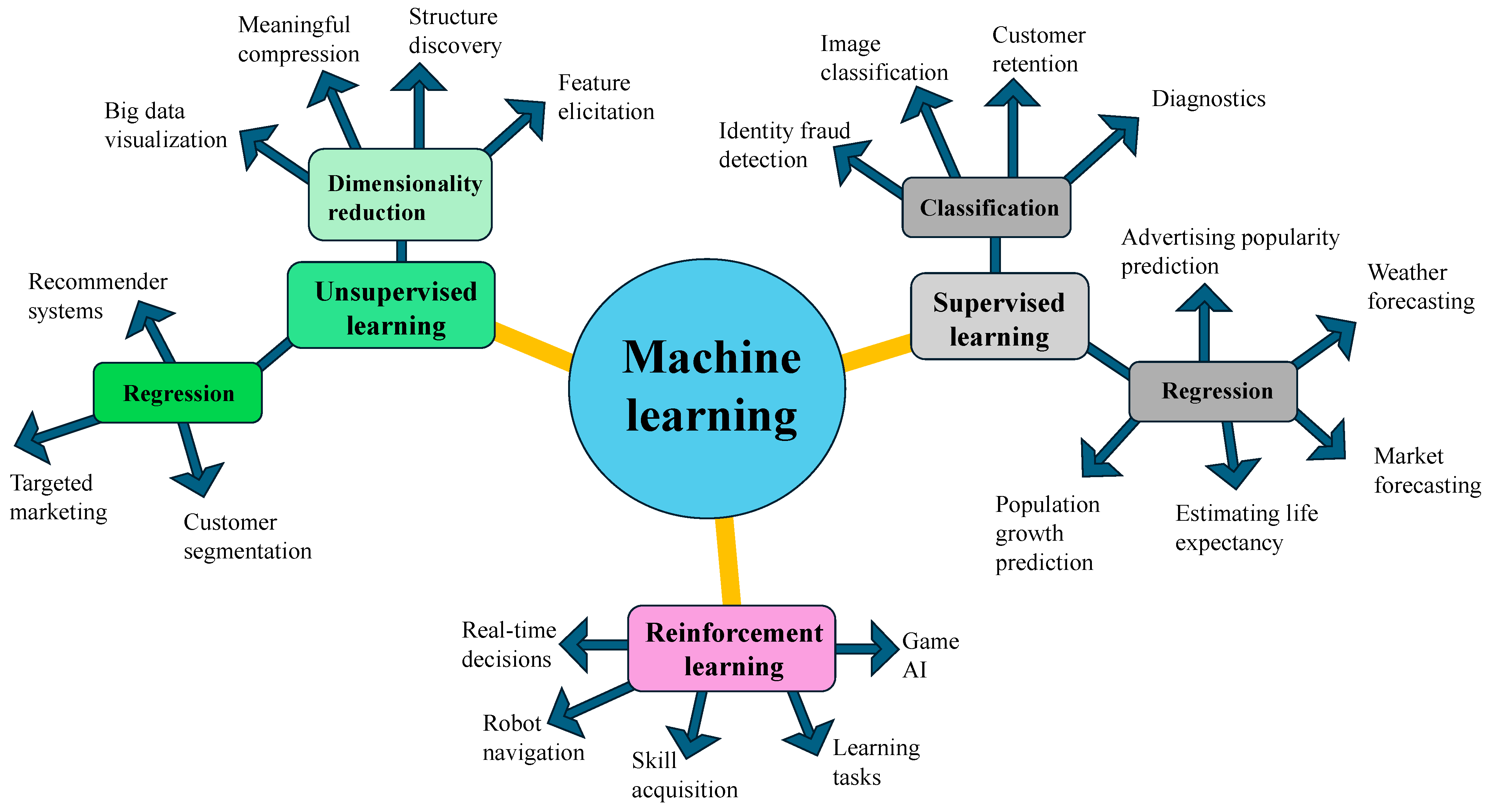

4. Synergy between AI and MOs

4.1. Brief History of AI

- The Initial Stage (1950s–1960s): focused on creating heuristic algorithms and programs designed to solve artistic and intellectual difficulties.

- The Intermediate Stage (Late 1960s–1970s): aimed at developing intelligent robots skilled at modeling the external world, identifying and evaluating situations, making decisions, forming behavioral plans, and engaging in natural language communication.

- The Modern Stage (Mid-1970s–Present): characterized by the enhancement of intelligent human–computer systems that combine human intelligence with computational abilities.

4.2. Role of AI in MOs-Focus on Metalenses

4.3. Examples of Recently Developed AI-Powered Metalenses for Imaging

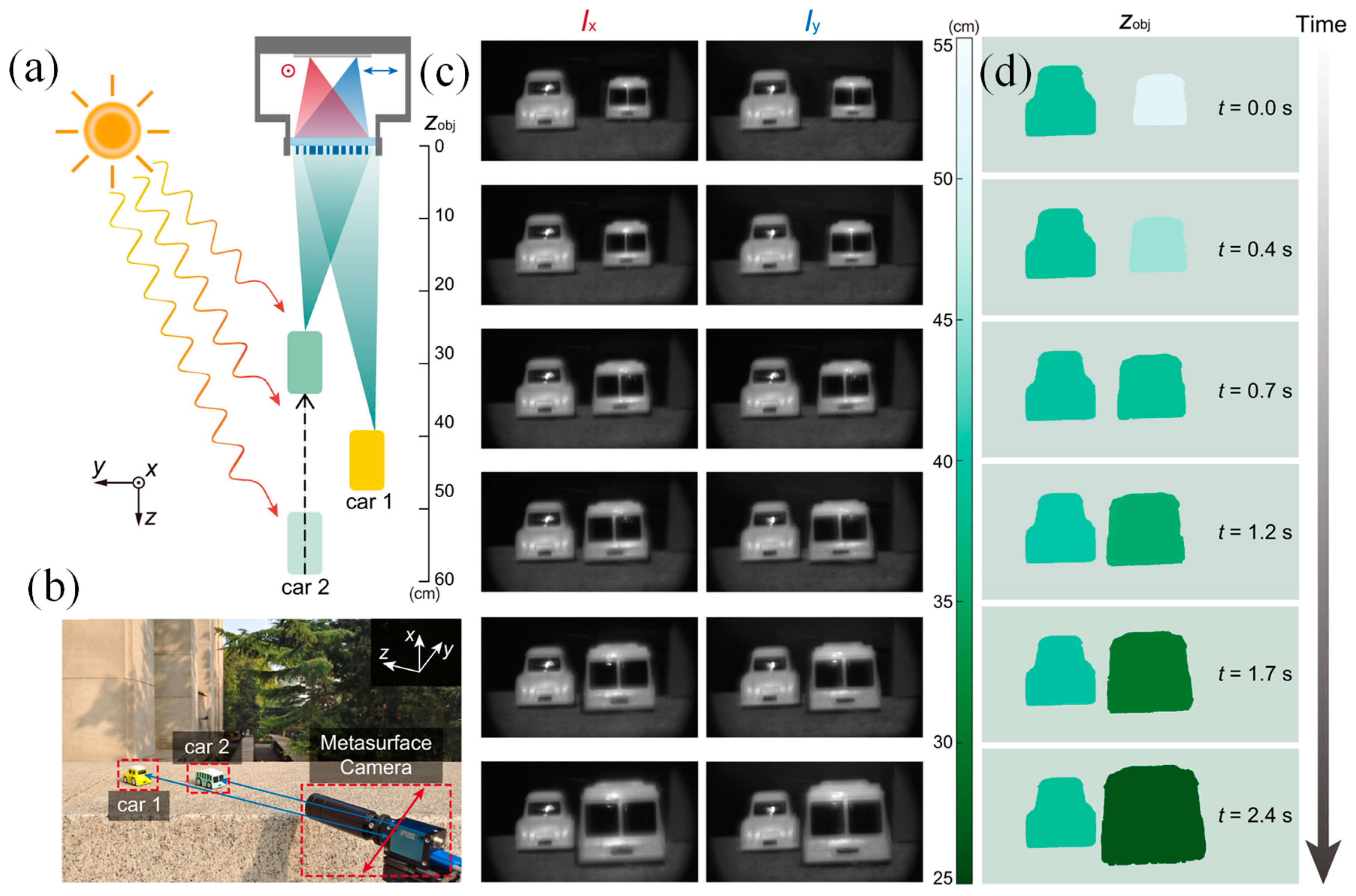

4.3.1. Monocular Camera

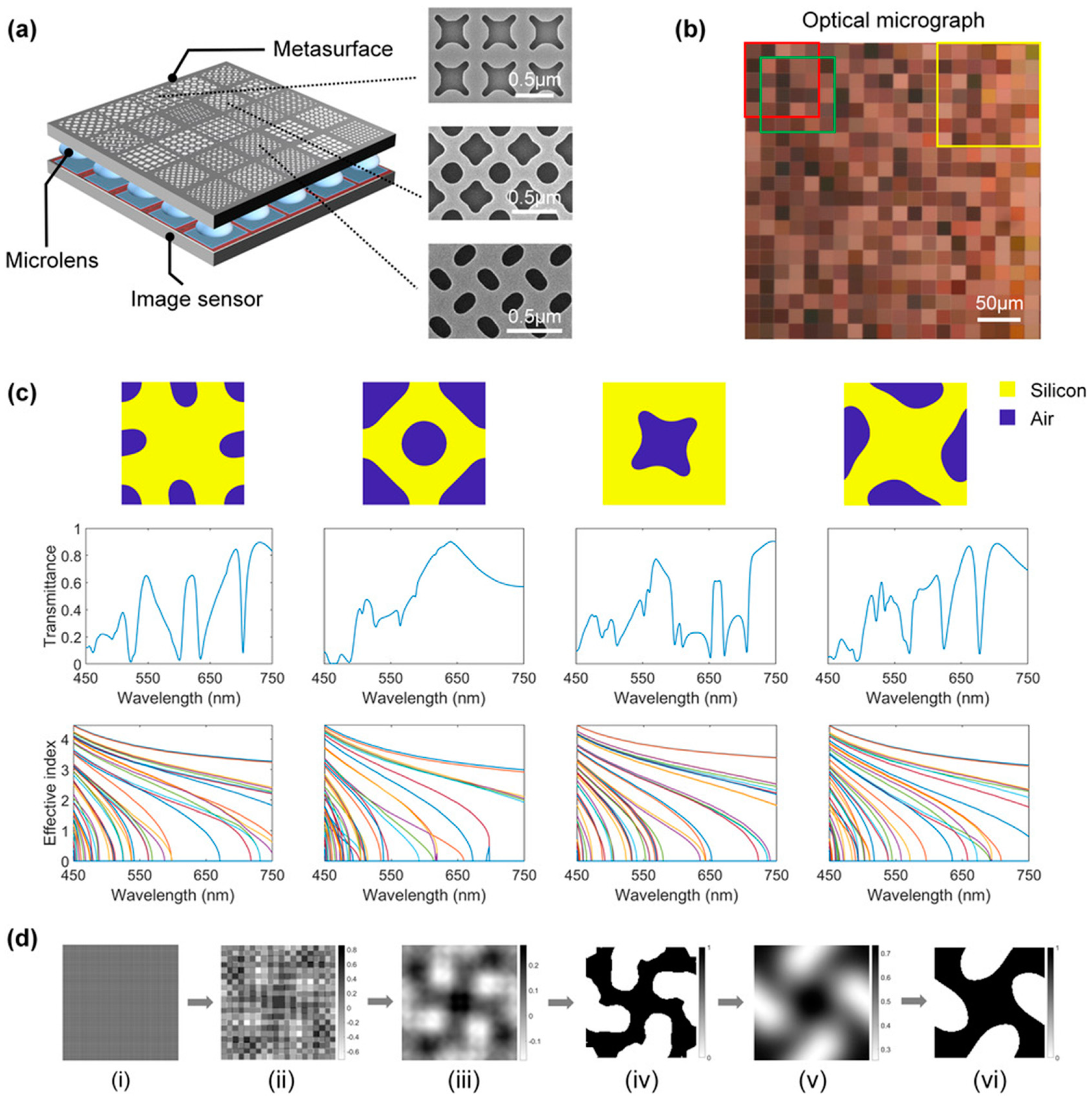

4.3.2. Ultraspectral Imaging

4.3.3. Virtual Reality (VR)

5. Challenges and Future Prospectives

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Full Form |

| MO | Meta-optics |

| ML | Machine learning |

| DL | Deep learning |

| MS | Metasurface |

| VR | Virtual reality |

| AR | Augmented reality |

| EA | Evolutionary algorithm |

| GRIN | Graded index |

| AI | Artificial intelligence |

| TL | Transfer learning |

| RL | Reinforcement learning |

| BO | Bayesian optimization |

| GA | Genetic algorithms |

| CA | Chromatic aberration |

| SL | Supervised learning |

| USL | Unsupervised learning |

References

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Metasurfaces: Shaping the future of photonics. Sci. Bull. 2024, 69, 1607–1611. [Google Scholar] [CrossRef] [PubMed]

- Ou, K.; Wan, H.; Wang, G.; Zhu, J.; Dong, S.; He, T.; Yang, H.; Wei, Z.; Wang, Z.; Cheng, X. Advances in Meta-Optics and Metasurfaces: Fundamentals and Applications. Nanomaterials 2023, 13, 1235. [Google Scholar] [CrossRef] [PubMed]

- Arbabi, A.; Arbabi, E.; Mansouree, M.; Han, S.; Kamali, S.M.; Horie, Y.; Faraon, A. Increasing efficiency of high numerical aperture metasurfaces using the grating averaging technique. Sci. Rep. 2020, 10, 7124. [Google Scholar] [CrossRef] [PubMed]

- Khonina, S.N.; Butt, M.A.; Kazanskiy, N.L. A Review on Reconfigurable Metalenses Revolutionizing Flat Optics. Adv. Opt. Mater. 2023, 12, 2302794. [Google Scholar] [CrossRef]

- Butt, M.A.; Kazansky, N.L. Narrowband perfect metasurface absorber based on impedance matching. Photonics Lett. Pol. 2020, 12, 88–90. [Google Scholar] [CrossRef]

- Li, Z.; Pestourie, R.; Park, J.-S.; Huang, Y.-W.; Johnson, S.G.; Capasso, F. Inverse design enables large-scale high-performance meta-optics reshaping virtual reality. Nat. Commun. 2022, 13, 2409. [Google Scholar] [CrossRef]

- Neshev, D.; Aharonovich, I. Optical metasurfaces: New generation building blocks for multi-functional optics. Light Sci. Appl. 2018, 7, 58. [Google Scholar] [CrossRef]

- Basiri, A.; Rafique, Z.E.; Bai, J.; Choi, S.; Yao, Y. Ultrafast low-pump fluence all-optical modulation based on graphene-metal hybrid metasurfaces. Light Sci. Appl. 2022, 11, 102. [Google Scholar] [CrossRef]

- Ali, F.; Aksu, S. A hybrid broadband metalens operating at ultraviolet frequencies. Sci. Rep. 2021, 11, 2313. [Google Scholar] [CrossRef]

- Decker, M.; Chen, W.T.; Nobis, T.; Zhu, A.Y.; Khorasaninejad, M.; Bharwani, Z.; Capasso, F.; Petschulat, J. Imaging Performance of Polarization-Insensitive Metalenses. ACS Photonics 2019, 6, 1493–1499. [Google Scholar] [CrossRef]

- Pahlevaninezhad, M.; Huang, Y.-W.; Pahlevani, M.; Bouma, B.; Suter, M.J.; Capasso, F.; Pahlevaninezhad, H. Metasurface-based bijective illumination collection imaging provides high-resolution tomography in three dimensions. Nat. Photonics 2022, 16, 203–211. [Google Scholar] [CrossRef] [PubMed]

- Bouchal, P.; Dvořák, P.; Babocký, J.; Bouchal, Z.; Ligmajer, F.; Hrtoň, M.; Křápek, V.; Faßbender, A.; Linden, S.; Chmelík, R.; et al. High-Resolution Quantitative Phase Imaging of Plasmonic Metasurfaces with Sensitivity down to a Single Nanoantenna. Nano Lett. 2019, 19, 1242–1250. [Google Scholar] [CrossRef]

- Intaravanne, Y.; Ansari, M.A.; Ahmed, H.; Bileckaja, N.; Yin, H.; Chen, X. Metasurface-Enabled 3-in-1 Microscopy. ACS Photonics 2023, 10, 544–551. [Google Scholar] [CrossRef]

- Degtyarev, S.A.; Volotovsky, S.G.; Khonina, S.N. Sublinearly chirped metalenses for forming abruptly autofocusing cylindrically polarized beams. J. Opt. Soc. Am. B 2018, 35, 1963–1969. [Google Scholar] [CrossRef]

- Huang, L.; Han, Z.; Wirth-Singh, A.; Saragadam, V.; Mukherjee, S.; Fröch, J.E.; Tanguy, Q.A.A.; Rollag, J.; Gibson, R.; Hendrickson, J.R.; et al. Broadband thermal imaging using meta-optics. Nat. Commun. 2024, 15, 1662. Available online: https://www.nature.com/articles/s41467-024-45904-w (accessed on 29 June 2024). [CrossRef] [PubMed]

- Khonina, S.N.; Tukmakov, K.N.; Degtyarev, S.A.; Reshetnikov, A.S.; Pavelyev, V.S.; Knyazev, B.A.; Choporova, Y.Y. Design, fabrication and investigation of a subwavelength axicon for terahertz beam polarization transforming. Comput. Opt. 2019, 43, 756–764. [Google Scholar] [CrossRef]

- Lan, F.; Wang, L.; Zeng, H.; Liang, S.; Song, T.; Liu, W.; Mazumder, P.; Yang, Z.; Zhang, Y.; Mittleman, D.M. Real-time programmable metasurface for terahertz multifunctional wave front engineering. Light Sci. Appl. 2023, 12, 191. [Google Scholar] [CrossRef]

- Zou, X.; Zheng, G.; Yuan, Q.; Zang, W.; Chen, R.; Li, T.; Li, L.; Wang, S.; Wang, Z.; Zhu, S. Imaging based on metalenses. PhotoniX 2020, 1, 2. [Google Scholar] [CrossRef]

- Jeon, D.; Shin, K.; Moon, S.-W.; Rho, J. Recent advancements of metalenses for functional imaging. Nano Converg. 2023, 10, 24. [Google Scholar] [CrossRef]

- Vogliardi, A.; Ruffato, G.; Bonaldo, D.; Zilio, S.D.; Romanato, F. Silicon metaoptics for the compact generation of perfect vector beams in the telecom infrared. Opt. Lett. 2023, 48, 4925–4928. [Google Scholar] [CrossRef]

- Damgaard-Carstensen, C.; Bozhevolnyi, S.I. Nonlocal electro-optic metasurfaces for free-space light modulation. Nanophotonics 2023, 12, 2953–2962. [Google Scholar] [CrossRef]

- Ren, H.; Jang, J.; Li, C.; Aigner, A.; Plidschun, M.; Kim, J.; Rho, J.; Schmidt, M.A.; Maier, S.A. An achromatic metafiber for focusing and imaging across the entire telecommunication range. Nat. Commun. 2022, 13, 4183. [Google Scholar] [CrossRef]

- Ding, F.; Bozhevolnyi, S.I. Advances in quantum meta-optics. Mater. Today Proc. 2023, 71, 63–72. [Google Scholar] [CrossRef]

- Kan, Y.; Liu, X.; Kumar, S.; Bozhevolnyi, S.I. Multichannel Quantum Emission with On-Chip Emitter-Coupled Holographic Metasurfaces. ACS Nano 2023, 17, 20308–20314. [Google Scholar] [CrossRef]

- Liu, J.; Shi, M.; Chen, Z.; Wang, S.; Wang, Z.; Zhu, S. Quantum photonics based on metasurfaces. Opto-Electron. Adv. 2021, 4, 200092. [Google Scholar] [CrossRef]

- Li, Z.; Lin, P.; Huang, Y.-W.; Park, J.-S.; Chen, W.T.; Shi, Z.; Qiu, C.-W.; Cheng, J.-X.; Capasso, F. Meta-optics achieves RGB-achromatic focusing for virtual reality. Sci. Adv. 2021, 7, eabe4458. [Google Scholar] [CrossRef]

- Seong, J.; Jeon, Y.; Yang, Y.; Badloe, T.; Rho, J. Cost-Effective and Environmentally Friendly Mass Manufacturing of Optical Metasurfaces Towards Practical Applications and Commercialization. Int. J. Precis. Eng. Manuf. Technol. 2023, 11, 685–706. [Google Scholar] [CrossRef]

- Wong, W.W.; Wang, N.; Jagadish, C.; Tan, H.H. Directional Lasing in Coupled InP Microring/Nanowire Systems. Laser Photonics Rev. 2022, 17, 2200658. [Google Scholar] [CrossRef]

- Wei, J. Research Progress and Application of Computer Artificial Intelligence Technology. MATEC Web Conf. 2018, 176, 01043. [Google Scholar] [CrossRef]

- The Future of AI: How AI Is Changing the World|Built In. Available online: https://builtin.com/artificial-intelligence/artificial-intelligence-future (accessed on 6 July 2024).

- Alowais, S.A.; Alghamdi, S.S.; Alsuhebany, N.; Alqahtani, T.; Alshaya, A.I.; Almohareb, S.N.; Aldairem, A.; Alrashed, M.; Bin Saleh, K.; Badreldin, H.A.; et al. Revolutionizing healthcare: The role of artificial intelligence in clinical practice. BMC Med. Educ. 2023, 23, 689. [Google Scholar] [CrossRef]

- Amisha; Malik, P.; Pathania, M.; Rathaur, V.K. Overview of artificial intelligence in medicine. J. Fam. Med. Prim. Care 2019, 8, 2328–2331. [Google Scholar] [CrossRef]

- Davydov, N.S.; Evdokimova, V.V.; Serafimovich, P.G.; Protsenko, V.I.; Khramov, A.G.; Nikonorov, A.V. Neural network for step anomaly detection in head motion during fMRI using me-ta-learning adaptation. Comput. Opt. 2023, 47, 991–1001. [Google Scholar] [CrossRef]

- Khonina, S.N.; Kazanskiy, N.L.; Skidanov, R.V.; Butt, M.A. Exploring Types of Photonic Neural Networks for Imaging and Computing—A Review. Nanomaterials 2024, 14, 697. [Google Scholar] [CrossRef]

- Gad, A.G. Particle Swarm Optimization Algorithm and Its Applications: A Systematic Review. Arch. Comput. Methods Eng. 2022, 29, 2531–2561. [Google Scholar] [CrossRef]

- Ahmad, M.F.; Isa, N.A.M.; Lim, W.H.; Ang, K.M. Differential evolution: A recent review based on state-of-the-art works. Alex. Eng. J. 2022, 61, 3831–3872. [Google Scholar] [CrossRef]

- Jafar-Zanjani, S.; Inampudi, S.; Mosallaei, H. Adaptive Genetic Algorithm for Optical Metasurfaces Design. Sci. Rep. 2018, 8, 11040. [Google Scholar] [CrossRef]

- Rahmat-Samii, Y. Genetic algorithm (GA) and particle swarm optimization (PSO) in engineering electromagnetics. In Proceedings of the 17th International Conference on Applied Electromagnetics and Communications, 2003, ICECom 2003, Dubrovnik, Croatia, 1–3 October 2003; pp. 1–5. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. Artificial Bee Colony (ABC) Optimization Algorithm for Solving Constrained Optimization Problems. In Foundations of Fuzzy Logic and Soft Computing; Melin, P., Castillo, O., Aguilar, L.T., Kacprzyk, J., Pedrycz, W., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2007; Volume 4529, pp. 789–798. [Google Scholar] [CrossRef]

- Yang, X. Firefly Algorithms for Multimodal Optimization. Stoch. Algorithms Found. Appl. 2009, 5792, 169–178. [Google Scholar]

- Chen, M.K.; Liu, X.; Sun, Y.; Tsai, D.P. Artificial Intelligence in Meta-optics. Chem. Rev. 2022, 122, 15356–15413. [Google Scholar] [CrossRef]

- Alzubaidi, L.; Zhang, J.; Humaidi, A.J.; Al-Dujaili, A.; Duan, Y.; Al-Shamma, O.; Santamaría, J.; Fadhel, M.A.; Al-Amidie, M.; Farhan, L. Review of deep learning: Concepts, CNN architectures, challenges, applications, future directions. J. Big Data 2021, 8, 53. [Google Scholar] [CrossRef] [PubMed]

- Palmer, P.B.; O’Connell, D.G. Regression analysis for prediction: Understanding the process. Cardiopulm. Phys. Ther. J. 2009, 20, 23–26. [Google Scholar] [CrossRef]

- Banchhor, C.; Srinivasu, N. Analysis of Bayesian optimization algorithms for big data classification based on Map Reduce framework. J. Big Data 2021, 8, 81. [Google Scholar] [CrossRef]

- Faria, R.d.R.; Capron, B.D.O.; Secchi, A.R.; de Souza, M.B., Jr. Where Reinforcement Learning Meets Process Control: Review and Guidelines. Processes 2022, 10, 2311. [Google Scholar] [CrossRef]

- Griffiths, L.J. A simple adaptive algorithm for real-time processing in antenna arrays. IEEE J. Mag. 1969, 57, 1696–1704. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, L.; Zhang, Y.; Han, X.; Deveci, M.; Parmar, M. A review of convolutional neural networks in computer vision. Artif. Intell. Rev. 2024, 57, 99. [Google Scholar] [CrossRef]

- Peng, L.; Fang, S.; Fan, Y.; Wang, M.; Ma, Z. A Method of Noise Reduction for Radio Communication Signal Based on RaGAN. Sensors 2023, 23, 475. [Google Scholar] [CrossRef] [PubMed]

- Mumuni, A.; Mumuni, F. Automated data processing and feature engineering for deep learning and big data applications: A survey. J. Inf. Intell. 2024; in press. [Google Scholar] [CrossRef]

- Simpson, J.E.; Haider, S.; Giddings, L. Development of a virtual reality simulation for practitioners. Soc. Work. Educ. 2023, 2023, 2258136. [Google Scholar] [CrossRef]

- Ogunleye, J.O. Predictive Data Analysis Using Linear Regression and Random Forest; IntechOpen: London, UK, 2022; Available online: https://www.intechopen.com/chapters/84394 (accessed on 9 July 2024).

- Kang, C.; Seo, D.; Boriskina, S.V.; Chung, H. Adjoint method in machine learning: A pathway to efficient inverse design of photonic devices. Mater. Des. 2024, 239, 112737. [Google Scholar] [CrossRef]

- Seo, D.; Kang, C.; Chung, H. Adjoint Method for Data Augmentation of Photonic Structures. In Optica Imaging Congress (3D, COSI, DH, FLatOptics, IS, pcAOP); Optica Publishing Group: Boston, MA, USA, 2023; p. FTu5G.2. [Google Scholar] [CrossRef]

- A Tutorial on the Adjoint Method for Inverse Problems—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0045782521001468 (accessed on 12 August 2024).

- Hughes, T.W.; Minkov, M.; Williamson, I.A.D.; Fan, S. Adjoint Method and Inverse Design for Nonlinear Nanophotonic Devices. ACS Photonics 2018, 5, 4781–4787. [Google Scholar] [CrossRef]

- Fekete, I.; Molnár, A.; Simon, P.L. A Functional Approach to Interpreting the Role of the Adjoint Equation in Machine Learning. Results Math. 2023, 79, 43. [Google Scholar] [CrossRef]

- Lin, J.-M.; Lin, C.-H. A novel intelligent neural guidance law design by using adjoint method. In Proceedings of the 2014 International Conference on Machine Learning and Cybernetics, Lanzhou, China, 13–16 July 2014; pp. 303–308. [Google Scholar] [CrossRef]

- Pan, Z.; Pan, X. Deep Learning and Adjoint Method Accelerated Inverse Design in Photonics: A Review. Photonics 2023, 10, 852. [Google Scholar] [CrossRef]

- Hu, J.; Mengu, D.; Tzarouchis, D.C.; Edwards, B.; Engheta, N.; Ozcan, A. Diffractive optical computing in free space. Nat. Commun. 2024, 15, 1525. [Google Scholar] [CrossRef] [PubMed]

- Shih, K.-H.; Renshaw, C.K. Hybrid meta/refractive lens design with an inverse design using physical optics. Appl. Opt. 2024, 63, 4032–4043. [Google Scholar] [CrossRef] [PubMed]

- Banerji, S.; Meem, M.; Majumder, A.; Vasquez, F.G.; Sensale-Rodriguez, B.; Menon, R. Imaging with flat optics: Metalenses or diffractive lenses? Optica 2019, 6, 805–810. [Google Scholar] [CrossRef]

- Aguiam, D.E.; Santos, J.D.; Silva, C.; Gentile, F.; Ferreira, C.; Garcia, I.S.; Cunha, J.; Gaspar, J. Fabrication and optical characterization of large aperture diffractive lenses using greyscale lithography. Micro Nano Eng. 2022, 14, 100111. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Butt, M.A.; Khonina, S.N. Optical Computing: Status and Perspectives. Nanomaterials 2022, 12, 2171. [Google Scholar] [CrossRef] [PubMed]

- Levy, U.; Mendlovic, D.; Marom, E. Efficiency analysis of diffractive lenses. J. Opt. Soc. Am. A 2001, 18, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Doskolovich, L.L.; Skidanov, R.V.; Bezus, E.A.; Ganchevskaya, S.V.; Bykov, D.A.; Kazanskiy, N.L. Design of diffractive lenses operating at several wavelengths. Opt. Express 2020, 28, 11705–11720. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Chen, Q.; Tang, D.; Liu, K.; Zhang, H.; Shi, L.; He, M.; Guo, Y.; Xiao, S. Broadband high-efficiency dielectric metalenses based on quasi-continuous nanostrips. Opto-Electron. Adv. 2024, 7, 230126. [Google Scholar] [CrossRef]

- Ladino, A.I.; Mendoza-Hernández, J.; Arroyo-Carrasco, M.L.; Salas-Montiel, R.; García-Méndez, M.; Coello, V.; Tellez-Limon, R. Large depth of focus plasmonic metalenses based on Fresnel biprism. AIP Adv. 2020, 10, 045025. [Google Scholar] [CrossRef]

- Balli, F.; Sultan, M.; Lami, S.K.; Hastings, J.T. A hybrid achromatic metalens. Nat. Commun. 2020, 11, 3892. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, C.E.; Sabra, A. Chromatic aberration in metalenses. Adv. Appl. Math. 2020, 124, 102134. [Google Scholar] [CrossRef]

- Hu, T.; Wen, L.; Li, H.; Wang, S.; Xia, R.; Mei, Z.; Yang, Z.; Zhao, M. Aberration-corrected hybrid metalens for longwave infrared thermal imaging. Nanophotonics 2024, 13, 3059–3066. [Google Scholar] [CrossRef]

- Yu, X.; Shen, Y.; Dai, G.; Zou, L.; Zhang, T.; Deng, X. Phase-Controlled Planar Metalenses for High-Resolution Terahertz Focusing. Photonics 2021, 8, 143. [Google Scholar] [CrossRef]

- Engelberg, J.; Levy, U. The advantages of metalenses over diffractive lenses. Nat. Commun. 2020, 11, 103981. [Google Scholar] [CrossRef]

- Deep Learning-Based Imaging Using Single-Lens and Multi-Aperture Diffractive Optical Systems|IEEE Conference Publication|IEEE Xplore. Available online: https://ieeexplore.ieee.org/document/9022384 (accessed on 18 July 2024).

- At the Intersection of Optics and Deep Learning: Statistical Inference, Computing, and Inverse Design. Available online: https://opg.optica.org/aop/abstract.cfm?uri=aop-14-2-209 (accessed on 18 July 2024).

- Khonina, S.N.; Volotovsky, S.G.; Ustinov, A.V.; Kharitonov, S.I. Analysis of focusing light by a harmonic diffractive lens with regard for the refractive index dispersion. Comput. Opt. 2017, 43, 338–347. [Google Scholar] [CrossRef]

- Moon, S.-W.; Kim, Y.; Yoon, G.; Rho, J. Recent Progress on Ultrathin Metalenses for Flat Optics. iScience 2020, 23, 101877. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Chen, C.; Wang, Y.; Fang, D.; Li, K.; Zhang, B.; Wei, Z. High-efficiency all-dielectric metalenses for multi-focus with arbitrary polarization. Results Phys. 2021, 23, 103981. [Google Scholar] [CrossRef]

- Pan, M.; Fu, Y.; Zheng, M.; Chen, H.; Zang, Y.; Duan, H.; Li, Q.; Qiu, M.; Hu, Y. Dielectric metalens for miniaturized imaging systems: Progress and challenges. Light Sci. Appl. 2022, 11, 195. [Google Scholar] [CrossRef]

- Khonina, S.N.; Degtyarev, S.A.; Ustinov, A.V.; Porfirev, A.P. Metalenses for the generation of vector Lissajous beams with a complex Poynting vector density. Opt. Express 2021, 29, 18634–18645. [Google Scholar] [CrossRef]

- Zuo, H.; Choi, D.; Gai, X.; Ma, P.; Xu, L.; Neshev, D.N.; Zhang, B.; Luther-Davies, B. High-Efficiency All-Dielectric Metalenses for Mid-Infrared Imaging. Adv. Opt. Mater. 2017, 5, 1700585. [Google Scholar] [CrossRef]

- He, F.; Feng, Y.; Pi, H.; Yan, J.; MacDonald, K.F.; Fang, X. Coherently switching the focusing characteristics of all-dielectric metalenses. Opt. Express 2022, 30, 27683–27693. [Google Scholar] [CrossRef]

- Kim, S.-J.; Kim, C.; Kim, Y.; Jeong, J.; Choi, S.; Han, W.; Kim, J.; Lee, B. Dielectric Metalens: Properties and Three-Dimensional Imaging Applications. Sensors 2021, 21, 4584. [Google Scholar] [CrossRef]

- Zhou, Y.; Gan, F.; Wang, R.; Lan, D.; Shang, X.; Li, W. Doublet Metalens with Simultaneous Chromatic and Monochromatic Correction in the Mid-Infrared. Sensors 2022, 22, 6175. [Google Scholar] [CrossRef] [PubMed]

- Li, S.-H.; Sun, C.; Tang, P.-Y.; Liao, J.-H.; Hsieh, Y.-H.; Fung, B.-H.; Fang, Y.-H.; Kuo, W.-H.; Wu, M.-H.; Chang, H.-C.; et al. Augmented reality system based on the integration of polarization-independent metalens and micro-LEDs. Opt. Express 2024, 32, 11463–11473. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Ren, H. Beyond the lab: A nanoimprint metalens array-based augmented reality. Light Sci. Appl. 2024, 13, 102. [Google Scholar] [CrossRef] [PubMed]

- Khonina, S.N.; Kazanskiy, N.L.; Butt, M.A. Exploring diffractive optical elements and their potential in free space optics and imaging- A comprehensive review. Laser Photonics Rev. 2024, 2024, 2400377. [Google Scholar] [CrossRef]

- Quan, D.; Liu, X.; Tang, Y.; Liu, H.; Min, S.; Li, G.; Srivastava, A.K.; Cheng, X. Dielectric Metalens by Multilayer Nanoimprint Lithography and Solution Phase Epitaxy. Adv. Eng. Mater. 2023, 25, 2201824. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, X.; Xu, Y.; Li, Q.; Li, Y.; Ouyang, C.; Tian, Z.; Gu, J.; Zhang, W.; Zhang, X.; et al. Plasmonic metalens based on coupled resonators for focusing of surface plasmons. Sci. Rep. 2016, 6, 37861. [Google Scholar] [CrossRef]

- Guay, J.-M.; Lesina, A.C.; Côté, G.; Charron, M.; Poitras, D.; Ramunno, L.; Berini, P.; Weck, A. Laser-induced plasmonic colours on metals. Nat. Commun. 2017, 8, 16095. [Google Scholar] [CrossRef]

- Liu, A.; Cai, P.; Zhang, J.; Wang, B.; Hao, L.; Wu, Q.; Ying, Y.; Zhou, D.; Gao, L. High-speed road sign detection scheme based on ultrafast single-pixel scanning LiDAR. Opt. Lasers Eng. 2024, 176, 108111. [Google Scholar] [CrossRef]

- Huang, H.; Song, S.; Liu, Y.; Liu, Z.; Xiao, Z.; Li, Y.; Wang, Y.; Li, R.; Zhao, Q.; Wang, X.; et al. Near-Field-Regulated Ultrafast Laser Supra-Wavelength Structuring Directly on Ultrahard Metallic Glasses. Adv. Mater. 2024, 2024, e2405766. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, L.; Lu, X.; Lü, H.; Han, Y.; Wang, S.; Teng, S. Spatial multiplexing plasmonic metalenses based on nanometer cross holes. New J. Phys. 2018, 20, 123009. [Google Scholar] [CrossRef]

- Ni, X.; Ishii, S.; Kildishev, A.V.; Shalaev, V.M. Ultra-thin, planar, Babinet-inverted plasmonic metalenses. Light Sci. Appl. 2013, 2, e72. [Google Scholar] [CrossRef]

- Sosa-Sánchez, C.T.; Téllez-Limón, R. Plasmonic Metalens to Generate an Airy Beam. Nanomaterials 2023, 13, 2576. [Google Scholar] [CrossRef] [PubMed]

- Zeisberger, M.; Schneidewind, H.; Hübner, U.; Wieduwilt, T.; Plidschun, M.; Schmidt, M.A. Plasmonic Metalens-Enhanced Single-Mode Fibers: A Pathway Toward Remote Light Focusing. Adv. Photonics Res. 2021, 2, 2100100. [Google Scholar] [CrossRef]

- Liu, Y.-Q.; Chen, W.; Du, X.; Shu, Y.; Wu, L.; Ren, Z.; Yin, H.; Sun, J.; Qi, K.; Che, Y.; et al. An ultra-thin high-efficiency plasmonic metalens with symmetric split ring transmitarray metasurfaces. Results Phys. 2023, 47, 106366. [Google Scholar] [CrossRef]

- Kuchmizhak, A.; Pustovalov, E.; Syubaev, S.; Vitrik, O.; Kulchin, Y.; Porfirev, A.; Khonina, S.; Kudryashov, S.; Danilov, P.; Ionin, A. On-Fly Femtosecond-Laser Fabrication of Self-Organized Plasmonic Nanotextures for Chemo- and Biosensing Applications. ACS Appl. Mater. Interfaces 2016, 8, 24946–24955. [Google Scholar] [CrossRef]

- Nelson, D.; Kim, S.; Crozier, K.B. Inverse Design of Plasmonic Nanotweezers based on Nanoapertures with Multiple Resonances. In Frontiers in Optics + Laser Science 2023 (FiO, LS); Optica Publishing Group: Tacoma, WA, USA, 2023; p. JW4A.38. [Google Scholar] [CrossRef]

- Li, N.; Cadusch, J.; Crozier, K.B. Optical Trapping of Nanoparticles with Plasmonic Apertures Generated by Algorithm. In Proceedings of the 2021 Conference on Lasers and Electro-Optics (CLEO), San Jose, CA, USA, 9–14 May 2021; pp. 1–2. Available online: https://ieeexplore.ieee.org/document/9572793 (accessed on 12 August 2024).

- Zaman, M.A.; Ren, W.; Wu, M.; Padhy, P.; Hesselink, L. Topological visualization of the plasmonic resonance of a nano C-aperture. Appl. Phys. Lett. 2023, 122, 081107. [Google Scholar] [CrossRef]

- Nelson, D.; Kim, S.; Crozier, K.B. Inverse Design of Plasmonic Nanotweezers by Topology Optimization. ACS Photonics 2024, 11, 85–92. [Google Scholar] [CrossRef]

- Zaman, M.A.; Hesselink, L. Dynamically controllable plasmonic tweezers using C-shaped nano-engravings. Appl. Phys. Lett. 2022, 121, 181108. [Google Scholar] [CrossRef] [PubMed]

- Hesselink, L.; Zaman, M.A. Plasmonic C-Shaped Structures and their Applications in Photonics and Biotechnology. In Encyclopedia of Materials: Electronics; Haseeb, A.S.M.A., Ed.; Academic Press: Oxford, UK, 2023; pp. 382–396. [Google Scholar] [CrossRef]

- Williams, C.; Montelongo, Y.; Wilkinson, T.D. Plasmonic Metalens for Narrowband Dual-Focus Imaging. Adv. Opt. Mater. 2017, 5, 1700811. [Google Scholar] [CrossRef]

- Chang, C.-K.; Yeh, W.-T. Beaming effect of the plasmonic metalens structured with concentric elliptical nanohole arrays. Opt. Mater. 2022, 134, 113084. [Google Scholar] [CrossRef]

- Wang, W.; Guo, Z.; Li, R.; Zhang, J.; Liu, Y.; Wang, X.; Qu, S. Ultra-thin, planar, broadband, dual-polarity plasmonic metalens. Photonics Res. 2015, 3, 68–71. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, Y.; Dong, Y.; Xu, Z.; Xu, J.; Quan, X.; Zou, X.; Su, Y. Ultra-broadband on-chip beam focusing enabled by GRIN metalens on silicon-on-insulator platform. Nanophotonics 2022, 11, 3603–3612. [Google Scholar] [CrossRef]

- Chen, M.-H.; Chou, W.-N.; Su, V.-C.; Kuan, C.-H.; Lin, H.Y. High-performance gallium nitride dielectric metalenses for imaging in the visible. Sci. Rep. 2021, 11, 6500. [Google Scholar] [CrossRef]

- Lu, D.; Liu, Z. Hyperlenses and metalenses for far-field super-resolution imaging. Nat. Commun. 2012, 3, 1205. [Google Scholar] [CrossRef] [PubMed]

- Hassan, K.; Dallery, J.-A.; Brianceau, P.; Boutami, S. Integrated photonic guided metalens based on a pseudo-graded index distribution. Sci. Rep. 2020, 10, 1123. [Google Scholar] [CrossRef]

- He, Y.; Song, B.; Tang, J. Optical metalenses: Fundamentals, dispersion manipulation, and applications. Front. Optoelectron. 2022, 15, 24. [Google Scholar] [CrossRef]

- He, C.; Sun, T.; Guo, J.; Cao, M.; Xia, J.; Hu, J.; Yan, Y.; Wang, C. Chiral Metalens of Circular Polarization Dichroism with Helical Surface Arrays in Mid-Infrared Region. Adv. Opt. Mater. 2019, 7, 1901129. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C. Interference-enhanced chirality-reversible dichroism metalens imaging using nested dual helical surfaces. Optica 2021, 8, 502–510. [Google Scholar] [CrossRef]

- Liu, H.; Duan, S.; Chen, C.; Cui, H.; Gao, P.; Dai, Y.; Gao, Z.; Wang, X.; Zhou, T. Graphene-enabled chiral metasurface for terahertz wavefront manipulation and multiplexing holographic imaging. Opt. Mater. 2024, 147, 114654. [Google Scholar] [CrossRef]

- Yu, H.; Xie, Z.; Li, C.; Li, C.; Menezes, L.d.S.; Maier, S.A.; Ren, H. Dispersion engineering of metalenses. Appl. Phys. Lett. 2023, 123, 240503. [Google Scholar] [CrossRef]

- Zhang, J.; Liang, Y.; Wu, S.; Xu, W.; Zheng, S.; Zhang, L. Single-layer dielectric metasurface with giant chiroptical effects combining geometric and propagation phase. Opt. Commun. 2021, 478, 126405. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Chen, W.T.; Zhu, A.Y.; Oh, J.; Devlin, R.C.; Roques-Carmes, C.; Mishra, I.; Capasso, F. Visible Wavelength Planar Metalenses Based on Titanium Dioxide. IEEE J. Sel. Top. Quantum Electron. 2016, 23, 43–58. [Google Scholar] [CrossRef]

- Syubaev, S.; Zhizhchenko, A.; Vitrik, O.; Porfirev, A.; Fomchenkov, S.; Khonina, S.; Kudryashov, S.; Kuchmizhak, A. Chirality of laser-printed plasmonic nanoneedles tunable by tailoring spiral-shape pulses. Appl. Surf. Sci. 2019, 470, 526–534. [Google Scholar] [CrossRef]

- Syubaev, S.; Mitsai, E.; Porfirev, A.; Khonina, S.; Kudryashov, S.; Katkus, T.; Juodkazis, S.; Gurevich, E.; Kuchmizhak, A. Silicon microprotrusions with tailored chirality enabled by direct femtosecond laser ablation. Opt. Lett. 2020, 45, 3050–3053. [Google Scholar] [CrossRef] [PubMed]

- Zhu, A.Y.; Chen, W.-T.; Khorasaninejad, M.; Oh, J.; Zaidi, A.; Mishra, I.; Devlin, R.C.; Capasso, F. Ultra-compact visible chiral spectrometer with meta-lenses. APL Photon. 2017, 2, 036103. [Google Scholar] [CrossRef]

- Tang, F.; Ye, X.; Li, Q.; Wang, Y.; Yu, H.; Wu, W.; Li, B.; Zheng, W. Dielectric metalenses at long-wave infrared wavelengths: Multiplexing and spectroscope. Results Phys. 2020, 18, 103215. [Google Scholar] [CrossRef]

- Liu, W.; Cheng, H.; Tian, J.; Chen, S. Diffractive metalens: From fundamentals, practical applications to current trends. Adv. Phys. X 2020, 5, 1742584. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Chen, W.T.; Zhu, A.Y.; Oh, J.; Devlin, R.C.; Rousso, D.; Capasso, F. Multispectral Chiral Imaging with a Metalens. Nano Lett. 2016, 16, 4595–4600. [Google Scholar] [CrossRef] [PubMed]

- Alnakhli, Z.; Lin, R.; Liao, C.-H.; El Labban, A.; Li, X. Reflective metalens with an enhanced off-axis focusing performance. Opt. Express 2022, 30, 34117–34128. [Google Scholar] [CrossRef]

- Johansen, V.E.; Gür, U.M.; Martínez-Llinás, J.; Hansen, J.F.; Samadi, A.; Larsen, M.S.V.; Nielsen, T.; Mattinson, F.; Schmidlin, M.; Mortensen, N.A.; et al. Nanoscale precision brings experimental metalens efficiencies on par with theoretical promises. Commun. Phys. 2024, 7, 123. [Google Scholar] [CrossRef]

- Zhang, K.; Yuan, Y.; Ding, X.; Ratni, B.; Burokur, S.N.; Wu, Q. High-Efficiency Metalenses with Switchable Functionalities in Microwave Region. ACS Appl. Mater. Interfaces 2019, 11, 28423–28430. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Bai, W.; Jia, H.; Han, J.; Guo, P.; Wu, J.; Yang, J. Multifocal co-plane metalens based on computer-generated holography for multiple visible wavelengths. Results Phys. 2020, 17, 103085. [Google Scholar] [CrossRef]

- Liu, Y.-Q.; Zhu, Y.; Wang, Y.; Ren, Z.; Yin, H.; Qi, K.; Sun, J. Monolithically integrated wide field-of-view metalens by angular dispersionless metasurface. Mater. Des. 2024, 240, 112879. [Google Scholar] [CrossRef]

- Chu, Y.; Xiao, X.; Ye, X.; Chen, C.; Zhu, S.; Li, T. Design of achromatic hybrid metalens with secondary spectrum correction. Opt. Express 2023, 31, 21399–21406. [Google Scholar] [CrossRef] [PubMed]

- Go, G.-H.; Park, C.H.; Woo, K.Y.; Choi, M.; Cho, Y.-H. Scannable Dual-Focus Metalens with Hybrid Phase. Nano Lett. 2023, 23, 3152–3158. [Google Scholar] [CrossRef]

- Degtyarev, S.; Savelyev, D.; Khonina, S.; Kazanskiy, N. Metasurfaces with continuous ridges for inverse energy flux generation. Opt. Express 2019, 27, 15129–15135. [Google Scholar] [CrossRef]

- Pavelyev, V.; Khonina, S.; Degtyarev, S.; Tukmakov, K.; Reshetnikov, A.; Gerasimov, V.; Osintseva, N.; Knyazev, B. Subwavelength Diffractive Optical Elements for Generation of Terahertz Coherent Beams with Pre-Given Polarization State. Sensors 2023, 23, 1579. [Google Scholar] [CrossRef]

- Hu, J.; Wang, D.; Bhowmik, D.; Liu, T.; Deng, S.; Knudson, M.P.; Ao, X.; Odom, T.W. Lattice-Resonance Metalenses for Fully Reconfigurable Imaging. ACS Nano 2019, 13, 4613–4620. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Dong, S.; Dun, X.; Wei, Z.; Wang, Z.; Cheng, X. Reconfigurable Metalens with Phase-Change Switching between Beam Acceleration and Rotation for 3D Depth Imaging. Micromachines 2022, 13, 607. [Google Scholar] [CrossRef] [PubMed]

- Eskandari, M.R.; Shameli, M.A.; Safian, R. Analysis of an electrically reconfigurable metasurface for manipulating polarization of near-infrared light. J. Opt. Soc. Am. B 2021, 39, 145–154. [Google Scholar] [CrossRef]

- Jung, J.; Kim, H.; Shin, J. Three-dimensionally reconfigurable focusing of laser by mechanically tunable metalens doublet with built-in holograms for alignment. Nanophotonics 2023, 12, 1373–1385. [Google Scholar] [CrossRef]

- Archetti, A.; Lin, R.J.; Restori, N.; Kiani, F.; Tsoulos, T.V.; Tagliabue, G. Thermally reconfigurable metalens. Nanophotonics 2022, 11, 3969–3980. [Google Scholar] [CrossRef]

- Wang, Q.; Rogers, E.T.F.; Gholipour, B.; Wang, C.-M.; Yuan, G.; Teng, J. Optically reconfigurable metasurfaces and photonic devices based on phase change materials. Nat. Photonics 2016, 10, 60–65. [Google Scholar] [CrossRef]

- Shalaginov, M.Y.; An, S.; Zhang, Y.; Yang, F.; Su, P.; Liberman, V.; Chou, J.B.; Roberts, C.M.; Kang, M.; Rios, C.; et al. Reconfigurable all-dielectric metalens with diffraction-limited performance. Nat. Commun. 2021, 12, 1225. [Google Scholar] [CrossRef]

- She, Y.; Ji, C.; Huang, C.; Zhang, Z.; Liao, J.; Wang, J.; Luo, X. Intelligent reconfigurable metasurface for self-adaptively electromagnetic functionality switching. Photonics Res. 2022, 10, 769–776. [Google Scholar] [CrossRef]

- Liu, X.; Chen, M.K.; Chu, C.H.; Zhang, J.; Leng, B.; Yamaguchi, T.; Tanaka, T.; Tsai, D.P. Underwater Binocular Meta-lens. ACS Photonics 2023, 10, 2382–2389. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Leng, B.; Zhou, Y.; Cheng, J.; Yamaguchi, T.; Tanaka, T.; Chen, M.K. Edge enhanced depth perception with binocular meta-lens. Opto-Electron. Sci. 2024, 3, 230033. [Google Scholar] [CrossRef]

- Fan, Z.-B.; Cheng, Y.-F.; Chen, Z.-M.; Liu, X.; Lu, W.-L.; Li, S.-H.; Jiang, S.-J.; Qin, Z.; Dong, J.-W. Integral imaging near-eye 3D display using a nanoimprint metalens array. eLight 2024, 4, 3. [Google Scholar] [CrossRef]

- Machine Vision with Binocular Meta-Lens|SPIE Optics + Photonics. Available online: https://spie.org/optics-photonics/presentation/Machine-vision-with-binocular-meta-lens/13111-59#_=_ (accessed on 12 August 2024).

- Hu, J.; Yang, W. Metalens array miniaturized microscope for large-field-of-view imaging. Opt. Commun. 2024, 555, 130231. [Google Scholar] [CrossRef]

- Hu, J.; Yang, W. Metalens Array with Controllable Angle of View for Compact, Large Field-of-View Microscopy. In Proceedings of the Conference on Lasers and Electro-Optics (2021), Munich, Germany, 21–25 June 2021; Optica Publishing Group: San Jose, CA, USA, 2021; p. FTu4H.1. [Google Scholar] [CrossRef]

- Hu, T.; Feng, X.; Yang, Z.; Zhao, M. Design of scalable metalens array for optical addressing. Front. Optoelectron. 2022, 15, 32. [Google Scholar] [CrossRef]

- Fan, Z.-B.; Qiu, H.-Y.; Zhang, H.-L.; Pang, X.-N.; Zhou, L.-D.; Liu, L.; Ren, H.; Wang, Q.-H.; Dong, J.-W. A broadband achromatic metalens array for integral imaging in the visible. Light Sci. Appl. 2019, 8, 67. [Google Scholar] [CrossRef]

- Li, L.; Liu, Z.; Ren, X.; Wang, S.; Su, V.-C.; Chen, M.-K.; Chu, C.H.; Kuo, H.Y.; Liu, B.; Zang, W.; et al. Metalens-array–based high-dimensional and multiphoton quantum source. Science 2020, 368, 1487–1490. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, J.; Yuan, H.; Wang, Z.; Deng, Y.; Zhang, Z.; Lin, G.; Yang, J. A vortex-focused beam metalens array in the visible light range based on computer-generated holography. Results Phys. 2021, 25, 104211. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Chen, W.T.; Devlin, R.C.; Oh, J.; Zhu, A.Y.; Capasso, F. Metalenses at visible wavelengths: Diffraction-limited focusing and subwavelength resolution imaging. Science 2016, 352, 1190–1194. [Google Scholar] [CrossRef]

- Wang, Y.; Min, C.; Zhang, Y.; Feng, F.; Si, G.; Li, L.; Yuan, X. Drawing structured plasmonic field with on-chip metalens. Nanophotonics 2022, 11, 1969–1976. [Google Scholar] [CrossRef]

- Bayati, E.; Zhan, A.; Colburn, S.; Zhelyeznyakov, M.V.; Majumdar, A. Role of refractive index in metalens performance. Appl. Opt. 2019, 58, 1460–1466. [Google Scholar] [CrossRef]

- Zhou, S.; Xi, K.; Zhuang, S.; Cheng, Q. Spherical Aberration-Corrected Metalens for Polarization Multiplexed Imaging. Nanomaterials 2021, 11, 2774. [Google Scholar] [CrossRef]

- Datta, S.; Tamburrino, A.; Udpa, L. Gradient Index Metasurface Lens for Microwave Imaging. Sensors 2022, 22, 8319. [Google Scholar] [CrossRef] [PubMed]

- Asefa, S.A.; Shim, S.; Seong, M.; Lee, D. Chiral Metasurfaces: A Review of the Fundamentals and Research Advances. Appl. Sci. 2023, 13, 10590. [Google Scholar] [CrossRef]

- Hada, M.; Adegawa, H.; Aoki, K.; Ikezawa, S.; Iwami, K. Polarization-separating Alvarez metalens. Opt. Express 2024, 32, 6672–6683. [Google Scholar] [CrossRef] [PubMed]

- Ullah, N.; Khalid, A.U.R.; Ahmed, S.; Iqbal, S.; Khan, M.I.; Rehman, M.U.; Mehmood, A.; Hu, B.; Tian, X.-Q. Tunable metalensing based on plasmonic resonators embedded on thermosresponsive hydrogel. Opt. Express 2023, 31, 12789–12801. [Google Scholar] [CrossRef] [PubMed]

- Wiener, N. ‘Cybernetics’, Scientific American. Available online: https://www.scientificamerican.com/article/cybernetics/ (accessed on 8 July 2024).

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Metamaterials Meet AI: Crafting the Future of Material Science|by Oluwafemidiakhoa|Medium. Available online: https://oluwafemidiakhoa.medium.com/metamaterials-meet-ai-crafting-the-future-of-material-science-36613a65d3e6 (accessed on 30 June 2024).

- Fu, Y.; Zhou, X.; Yu, Y.; Chen, J.; Wang, S.; Zhu, S.; Wang, Z. Unleashing the potential: AI empowered advanced metasurface research. Nanophotonics 2024, 13, 1239–1278. [Google Scholar] [CrossRef]

- Sarker, I.H. Machine Learning: Algorithms, Real-World Applications and Research Directions. SN Comput. Sci. 2021, 2, 160. [Google Scholar] [CrossRef]

- Gupta, V.; Mishra, V.K.; Singhal, P.; Kumar, A. An Overview of Supervised Machine Learning Algorithm. In Proceedings of the 2022 11th International Conference on System Modeling & Advancement in Research Trends (SMART), Moradabad, India, 16–17 December 2022; pp. 87–92. [Google Scholar] [CrossRef]

- Tchio, G.M.T.; Kenfack, J.; Kassegne, D.; Menga, F.-D.; Ouro-Djobo, S.S. A Comprehensive Review of Supervised Learning Algorithms for the Diagnosis of Photovoltaic Systems, Proposing a New Approach Using an Ensemble Learning Algorithm. Appl. Sci. 2024, 14, 2072. [Google Scholar] [CrossRef]

- Kaelbling, L.P.; Littman, M.L.; Moore, A.W. Reinforcement Learning: A Survey. J. Artif. Intell. Res. 1996, 4, 237–285. [Google Scholar] [CrossRef]

- Jin, Z.; Mei, S.; Chen, S.; Li, Y.; Zhang, C.; He, Y.; Yu, X.; Yu, C.; Yang, J.K.W.; Luk’yanchuk, B.; et al. Complex Inverse Design of Meta-optics by Segmented Hierarchical Evolutionary Algorithm. ACS Nano 2019, 13, 821–829. [Google Scholar] [CrossRef]

- Machine Learning and Evolutionary Algorithm Studies of Graphene Metamaterials for Optimized Plasmon-Induced Transparency. Available online: https://opg.optica.org/oe/fulltext.cfm?uri=oe-28-13-18899&id=432535 (accessed on 1 July 2024).

- Candeias, J.; de Araújo, D.R.; Miranda, P.; Bastos-Filho, C.J. Memetic evolutionary algorithms to design optical networks with a local search that improves diversity. Expert Syst. Appl. 2023, 232, 120805. [Google Scholar] [CrossRef]

- Phase-Controlled Metasurface Design via Optimized Genetic Algorithm. Available online: https://www.degruyter.com/document/doi/10.1515/nanoph-2020-0132/html (accessed on 1 July 2024).

- An, S.; Zheng, B.; Shalaginov, M.Y.; Tang, H.; Li, H.; Zhou, L.; Ding, J.; Agarwal, A.M.; Rivero-Baleine, C.; Kang, M.; et al. Deep learning modeling approach for metasurfaces with high degrees of freedom. Opt. Express 2020, 28, 31932–31942. [Google Scholar] [CrossRef] [PubMed]

- Lin, A. A Meta-Learning Reinforcement Training Method for Machine Learning Image-to-Image Optical Proximity Correction. Engineering Archive. Available online: https://engrxiv.org/preprint/view/3197/version/4499 (accessed on 1 July 2024).

- Zhang, D.; Qin, F.; Zhang, Q.; Liu, Z.; Wei, G.; Xiao, J.J. Segmented Bayesian optimization of meta-gratings for sub-wavelength light focusing. J. Opt. Soc. Am. B 2020, 37, 181–187. [Google Scholar] [CrossRef]

- Sun, M.; Kovanis, V.; Lončar, M.; Lin, Z. Bayesian optimization of Fisher Information in nonlinear multiresonant quantum photonics gyroscopes. Nanophotonics 2024, 13, 2401–2416. [Google Scholar] [CrossRef]

- Abu, M.; Zahri, N.A.H.; Amir, A.; Ismail, M.I.; Yaakub, A.; Fukumoto, F.; Suzuki, Y. Analysis of the Effectiveness of Metaheuristic Methods on Bayesian Optimization in the Classification of Visual Field Defects. Diagnostics 2023, 13, 1946. [Google Scholar] [CrossRef]

- Tunio, M.H.; Li, J.P.; Zeng, X.; Akhtar, F.; Shah, S.A.; Ahmed, A.; Yang, Y.; Bin Heyat, B. Meta-knowledge guided Bayesian optimization framework for robust crop yield estimation. J. King Saud Univ.-Comput. Inf. Sci. 2024, 36, 101895. [Google Scholar] [CrossRef]

- Schneider, P.-I.; Santiago, X.G.; Soltwisch, V.; Hammerschmidt, M.; Burger, S.; Rockstuhl, C. Benchmarking Five Global Optimization Approaches for Nano-optical Shape Optimization and Parameter Reconstruction. ACS Photonics 2019, 6, 2726–2733. [Google Scholar] [CrossRef]

- Ji, W.; Chang, J.; Xu, H.-X.; Gao, J.R.; Gröblacher, S.; Urbach, H.P.; Adam, A.J.L. Recent advances in metasurface design and quantum optics applications with machine learning, physics-informed neural networks, and topology optimization methods. Light Sci. Appl. 2023, 12, 169. [Google Scholar] [CrossRef]

- Elsawy, M.M.R.; Lanteri, S.; Duvigneau, R.; Brière, G.; Mohamed, M.S.; Genevet, P. Global optimization of metasurface designs using statistical learning methods. Sci. Rep. 2019, 9, 17918. [Google Scholar] [CrossRef]

- Hosna, A.; Merry, E.; Gyalmo, J.; Alom, Z.; Aung, Z.; Azim, M.A. Transfer learning: A friendly introduction. J. Big Data 2022, 9, 102. [Google Scholar] [CrossRef]

- Weiss, K.; Khoshgoftaar, T.M.; Wang, D.D. A survey of transfer learning. J. Big Data 2016, 3, 1345–1459. [Google Scholar] [CrossRef]

- Xu, D.; Luo, Y.; Luo, J.; Pu, M.; Zhang, Y.; Ha, Y.; Luo, X. Efficient design of a dielectric metasurface with transfer learning and genetic algorithm. Opt. Mater. Express 2021, 11, 1852–1862. [Google Scholar] [CrossRef]

- Huisman, M.; Plaat, A.; van Rijn, J.N. Understanding transfer learning and gradient-based meta-learning techniques. Mach. Learn. 2023, 113, 4113–4132. [Google Scholar] [CrossRef]

- Peng, R.; Ren, S.; Malof, J.; Padilla, W.J. Transfer learning for metamaterial design and simulation. Nanophotonics 2024, 13, 2323–2334. [Google Scholar] [CrossRef]

- Lv, J.; Zhang, R.; Gu, Q.; Uddin, H.; Jiang, X.; Qi, J.; Si, G.; Ou, Q. Metasurfaces and their intelligent advances. Mater. Des. 2023, 237, 112610. [Google Scholar] [CrossRef]

- Jia, Y.; Qian, C.; Fan, Z.; Cai, T.; Li, E.-P.; Chen, H. A knowledge-inherited learning for intelligent metasurface design and assembly. Light Sci. Appl. 2023, 12, 82. [Google Scholar] [CrossRef]

- Fan, Z.; Qian, C.; Jia, Y.; Chen, M.; Zhang, J.; Cui, X.; Li, E.-P.; Zheng, B.; Cai, T.; Chen, H. Transfer-Learning-Assisted Inverse Metasurface Design for 30% Data Savings. Phys. Rev. Appl. 2022, 18, 024022. [Google Scholar] [CrossRef]

- Cockerham, A.; Horton, C.; Kuebler, S.M.; Touma, J. Using AI-Assisted Inverse Design for Metalens Performance Optimization. In Proceedings of the 2023 IEEE Research and Applications of Photonics in Defense Conference (RAPID), Miramar Beach, FL, USA, 11–13 September 2023; pp. 1–2. [Google Scholar] [CrossRef]

- Shen, Z.; Zhao, F.; Jin, C.; Wang, S.; Cao, L.; Yang, Y. Monocular metasurface camera for passive single-shot 4D imaging. Nat. Commun. 2023, 14, 1035. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Y.; Huang, C.; Zhou, Z.-W.; Li, M.; Zhang, Z.; Chen, J. Deep-learning enhanced high-quality imaging in metalens-integrated camera. Opt. Lett. 2024, 49, 2853–2856. [Google Scholar] [CrossRef]

- Colburn, S.; Zhan, A.; Majumdar, A. Metasurface optics for full-color computational imaging. Sci. Adv. 2018, 4, eaar2114. [Google Scholar] [CrossRef]

- Yang, J.; Cui, K.; Cai, X.; Xiong, J.; Zhu, H.; Rao, S.; Xu, S.; Huang, Y.; Liu, F.; Feng, X.; et al. Ultraspectral Imaging Based on Metasurfaces with Freeform Shaped Meta-Atoms. Laser Photonics Rev. 2022, 16, 2100663. [Google Scholar] [CrossRef]

- Hsu, W.-L.; Huang, C.-F.; Tan, C.-C.; Liu, N.Y.-C.; Chu, C.H.; Huang, P.-S.; Wu, P.C.; Yiin, S.J.; Tanaka, T.; Weng, C.-J.; et al. High-Resolution Metalens Imaging with Sequential Artificial Intelligence Models. Nano Lett. 2023, 23, 11614–11620. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Yan, W.; Qu, Y.; Ma, S.; Li, S.Z.; Qiu, M. Intelligent designs in nanophotonics: From optimization towards inverse creation. PhotoniX 2021, 2, 22. [Google Scholar] [CrossRef]

- Alagappan, G.; Ong, J.R.; Yang, Z.; Ang, T.Y.L.; Zhao, W.; Jiang, Y.; Zhang, W.; Png, C.E. Leveraging AI in Photonics and Beyond. Photonics 2022, 9, 75. [Google Scholar] [CrossRef]

- Liu, X.; Chen, M.K.; Tsai, D.P. Photonic Meta-Neurons. Laser Photonics Rev. 2024, 18, 2300456. [Google Scholar] [CrossRef]

- Wright, L.G.; Onodera, T.; Stein, M.M.; Wang, T.; Schachter, D.T.; Hu, Z. Deep physical neural networks trained with backpropagation. Nature 2022, 601, 549–555. [Google Scholar] [CrossRef]

- Zhelyeznyakov, M.; Fröch, J.; Wirth-Singh, A.; Noh, J.; Rho, J.; Brunton, S.; Majumdar, A. Large area optimization of meta-lens via data-free machine learning. Commun. Eng. 2023, 2, 60. [Google Scholar] [CrossRef]

- Khonina, S.; Kazanskiy, N.; Efimov, A.; Nikonorov, A.; Oseledets, I.; Skidanov, R.; Butt, M. A perspective on the artificial intelligence’s transformative role in advancing diffractive optics. iScience 2024, 27, 110270. [Google Scholar] [CrossRef]

- Optical Transformers|OpenReview. Available online: https://openreview.net/forum?id=Xxw0edFFQC (accessed on 18 July 2024).

| Benefit | Description | AI Techniques Involved |

|---|---|---|

| Design optimization | AI can optimize the design parameters of meta-optical components to achieve desired properties, such as minimizing aberrations or enhancing resolution. | Machine learning (ML), Genetic algorithms (GAs) [38] |

| Inverse design | AI algorithms can assist in the inverse design process, where desired optical responses are specified, and the system computes the necessary meta-structure to achieve these responses. | Deep learning (DL), Neural networks [42] |

| Performance prediction | AI can predict the performance of meta-optical devices under various conditions, reducing the need for extensive simulations and experimental trials. | Predictive modeling, Regression analysis [43] |

| Material discovery | AI can help discover new materials with specific properties suitable for MOs applications by analyzing large datasets of material properties. | Data mining, Bayesian optimization (BO) [44] |

| Fabrication process optimization | AI can optimize the fabrication processes of meta-optical components, improving yield and reducing defects. | Reinforcement learning (RL), Process control algorithms [45] |

| Real-time adaptive optics | AI can enable real-time adjustments and corrections in adaptive optical systems, improving image quality and system performance in dynamic environments. | Real-time data processing, Adaptive algorithms [46] |

| Pattern recognition and classification | AI can enhance pattern recognition and classification in imaging systems, improving the accuracy of optical sensing and imaging applications. | Computer vision, convolutional neural networks [47] |

| Enhanced sensing | AI can enhance the capabilities of meta-optical sensors by improving signal processing and noise reduction, leading to more accurate and reliable measurements. | Signal processing, Noise reduction techniques [48] |

| Automated data analysis | AI can automate the analysis of large datasets generated by meta-optical systems, extracting meaningful insights and reducing the need for manual analysis. | Big data analytics, Automated feature extraction [49] |

| Virtual prototyping | AI can create virtual prototypes of meta-optical devices, allowing for extensive testing and optimization before physical prototypes are built. | Simulation, Virtual reality techniques [50] |

| Performance prediction | AI can predict the performance of meta-optical devices under various conditions, reducing the need for extensive simulations and experimental trials. | Predictive modeling, Regression analysis [51] |

| Characteristic | Refractive Lens | Diffractive Lens | Metalens |

|---|---|---|---|

| Working mechanism | Bending of light rays through refraction | Diffraction and interference | Manipulation of light using nanostructures |

| Material | Typically glass or plastic | Typically plastic or glass with microstructures | Dielectrics or metals with nanoscale structures |

| Thickness | Generally thick, especially for high power | Can be very thin | Ultra-thin (sub-wavelength scale) |

| Weight | Relatively heavy | Lighter compared to refractive lenses | Extremely lightweight |

| Aberrations | Susceptible to CA | High CA but can be designed to minimize it | Can be engineered to correct aberrations, including chromatic |

| Manufacturing Complexity | Moderate to high | High due to precise microstructure fabrication | Very high due to nanoscale fabrication requirements |

| Focal Length Variation | Fixed for a given lens shape | Fixed for a given structure | Can be dynamically varied using external stimuli (e.g., voltage) |

| Applications | Common in cameras, eyeglasses, microscopes | Used in diffractive optical elements (DOE), holography | Advanced imaging systems, compact optical devices, AR |

| Efficiency | High | Moderate (efficiency can decrease with diffraction orders) | High efficiency can be achieved, but depends on design and material |

| Scalability | Scalable, but size affects weight and thickness | Scalable with microfabrication techniques | Highly scalable with advanced nanofabrication techniques |

| Wavelength Dependency | Less wavelength dependent (broadband) | Strong wavelength dependence | Can be designed for specific wavelengths or broadband operation |

| Technique | Definition | Key Characteristics | Applications |

|---|---|---|---|

| ML | Algorithms that learn patterns from data | SL, USL, and semi-supervised learning. Focus on predictive accuracy. Requires labeled data for SL | Image and speech recognition, predictive analytics, natural language processing |

| DL | Subset of ML using NNs | Hierarchical learning architecture. Automated feature extraction. State-of-the-art performance in many domains. Requires large amounts of data and computational resources | Computer vision, natural language processing, robotics |

| EAs | Optimization techniques inspired by natural selection | Population-based optimization. Uses genetic operators (mutation, crossover). Suitable for complex, nonlinear problems | Engineering design, financial modeling, game-playing strategies |

| RL | Learning through interaction with an environment | Agent learns by trial and error. Maximizes cumulative reward. Markov Decision Processes (MDPs) are often used as a framework | Game playing (e.g., AlphaGo), robotics, Autonomous driving |

| BO | Optimization technique based on BO | Uses prior information and observations to guide the search. Efficient for expensive, black-box functions. Balances exploration and exploitation | Hyperparameter tuning, experimental design, robotics motion planning |

| TL | Leveraging knowledge from one domain for another | Transfers knowledge learned from one task to improve learning in another task. Reduces the need for large amounts of labeled data in new domains | Image classification, natural language understanding, medical diagnosis |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazanskiy, N.L.; Khonina, S.N.; Oseledets, I.V.; Nikonorov, A.V.; Butt, M.A. Revolutionary Integration of Artificial Intelligence with Meta-Optics-Focus on Metalenses for Imaging. Technologies 2024, 12, 143. https://doi.org/10.3390/technologies12090143

Kazanskiy NL, Khonina SN, Oseledets IV, Nikonorov AV, Butt MA. Revolutionary Integration of Artificial Intelligence with Meta-Optics-Focus on Metalenses for Imaging. Technologies. 2024; 12(9):143. https://doi.org/10.3390/technologies12090143

Chicago/Turabian StyleKazanskiy, Nikolay L., Svetlana N. Khonina, Ivan V. Oseledets, Artem V. Nikonorov, and Muhammad A. Butt. 2024. "Revolutionary Integration of Artificial Intelligence with Meta-Optics-Focus on Metalenses for Imaging" Technologies 12, no. 9: 143. https://doi.org/10.3390/technologies12090143

APA StyleKazanskiy, N. L., Khonina, S. N., Oseledets, I. V., Nikonorov, A. V., & Butt, M. A. (2024). Revolutionary Integration of Artificial Intelligence with Meta-Optics-Focus on Metalenses for Imaging. Technologies, 12(9), 143. https://doi.org/10.3390/technologies12090143