Overview of Recent Solar Photovoltaic Cooling System Approach

Abstract

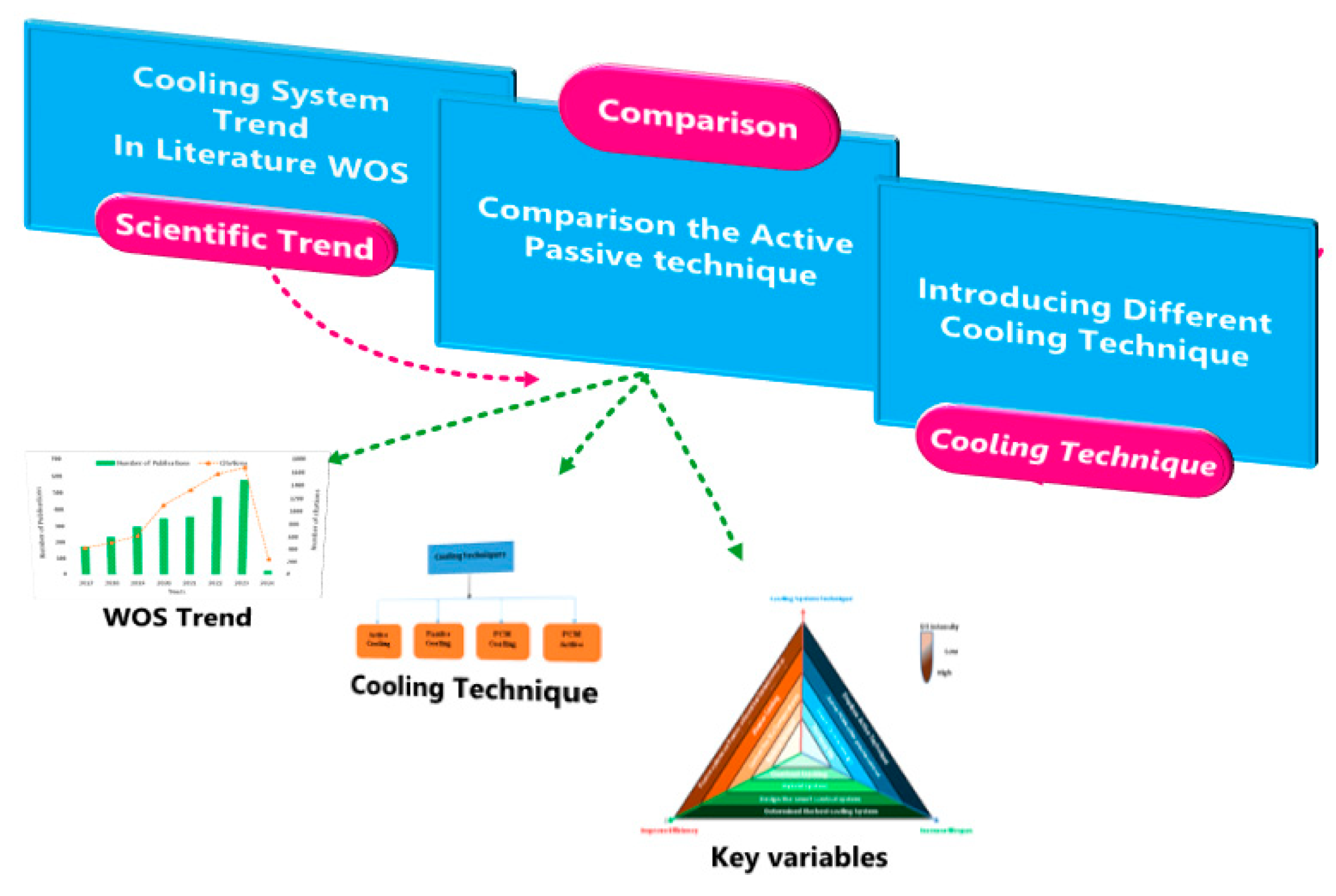

:1. Introduction

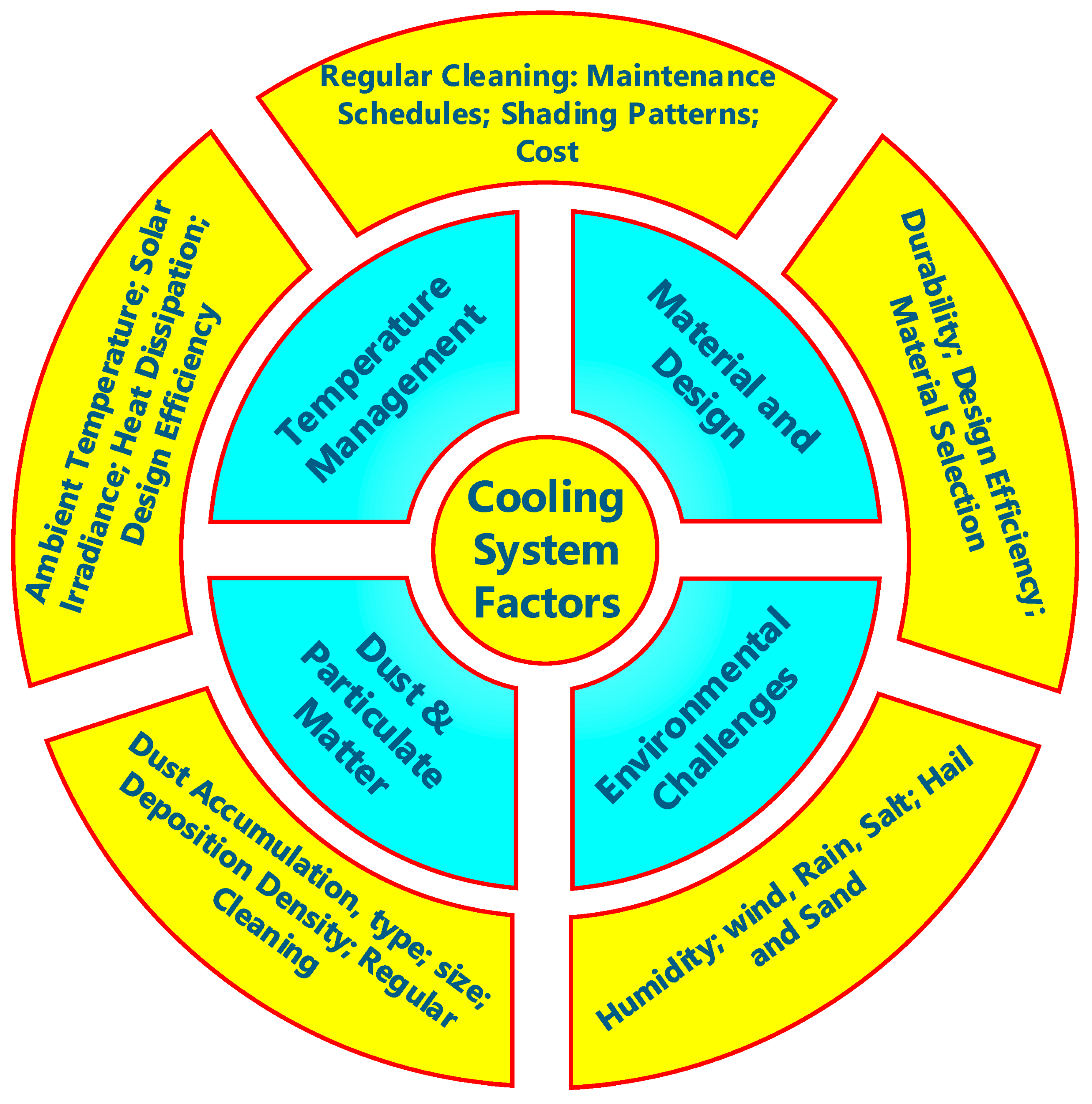

2. The Factors Affecting Cooling Performance

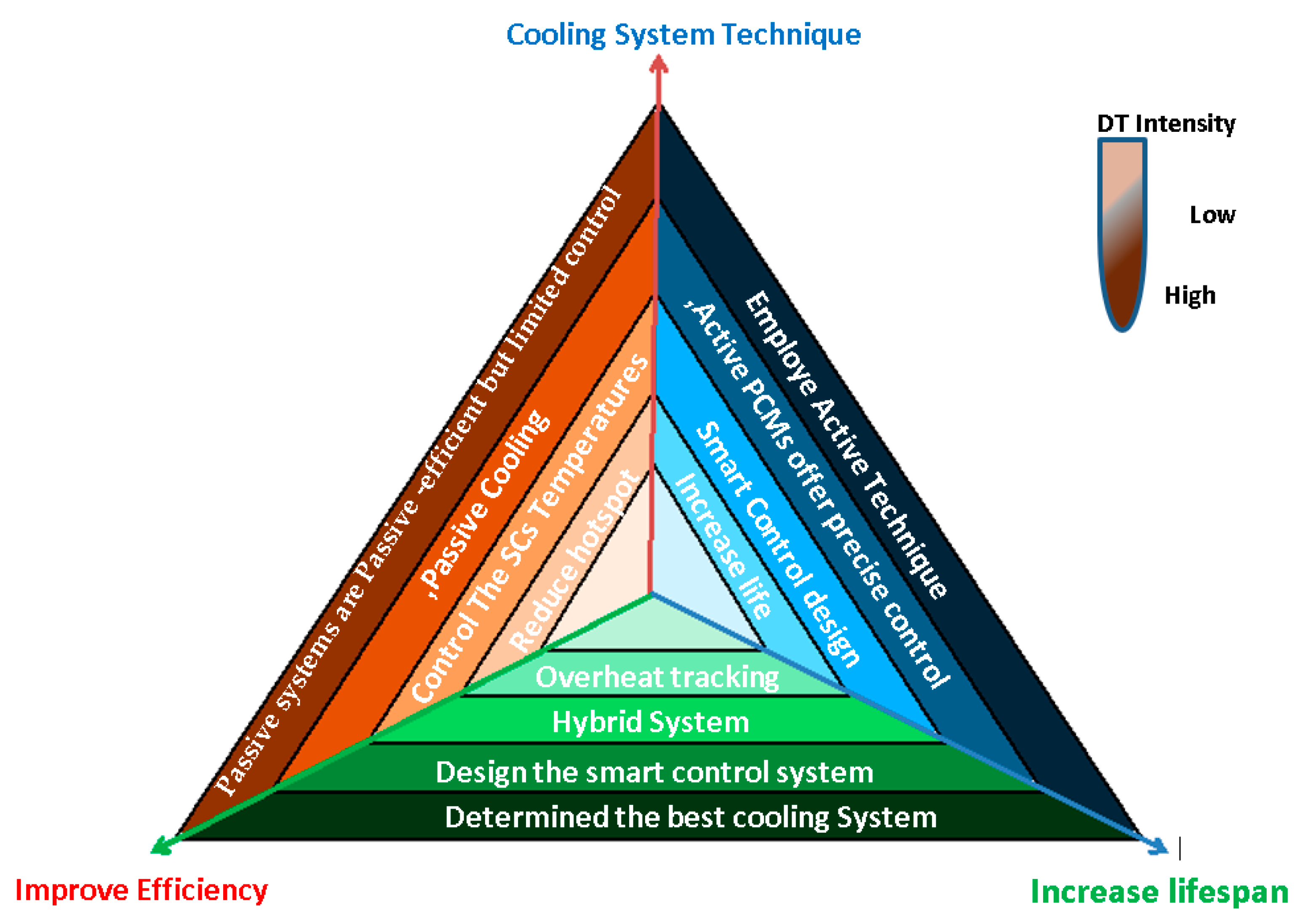

3. Overview of Cooling System Technique

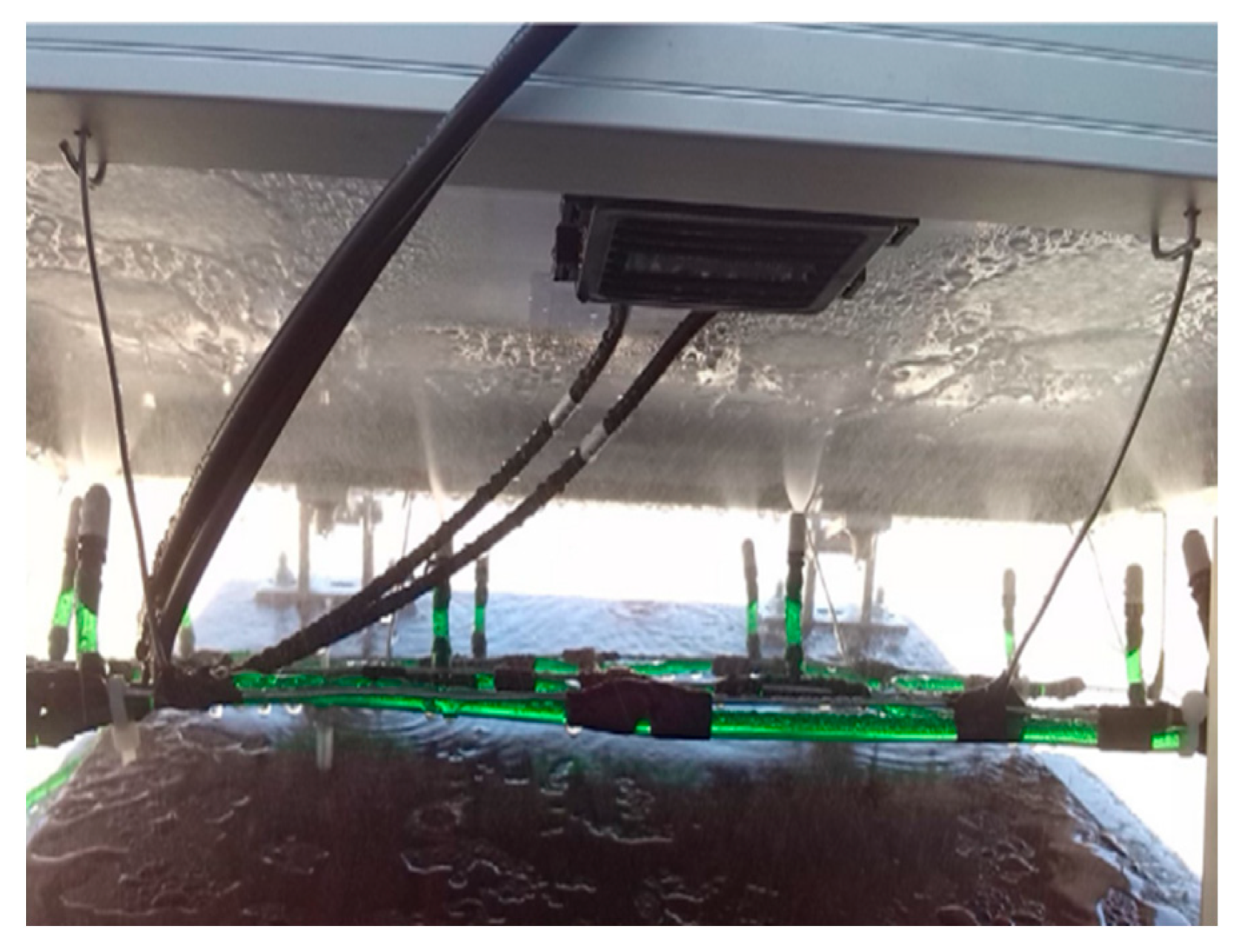

4. Active Cooling

5. Passive Cooling

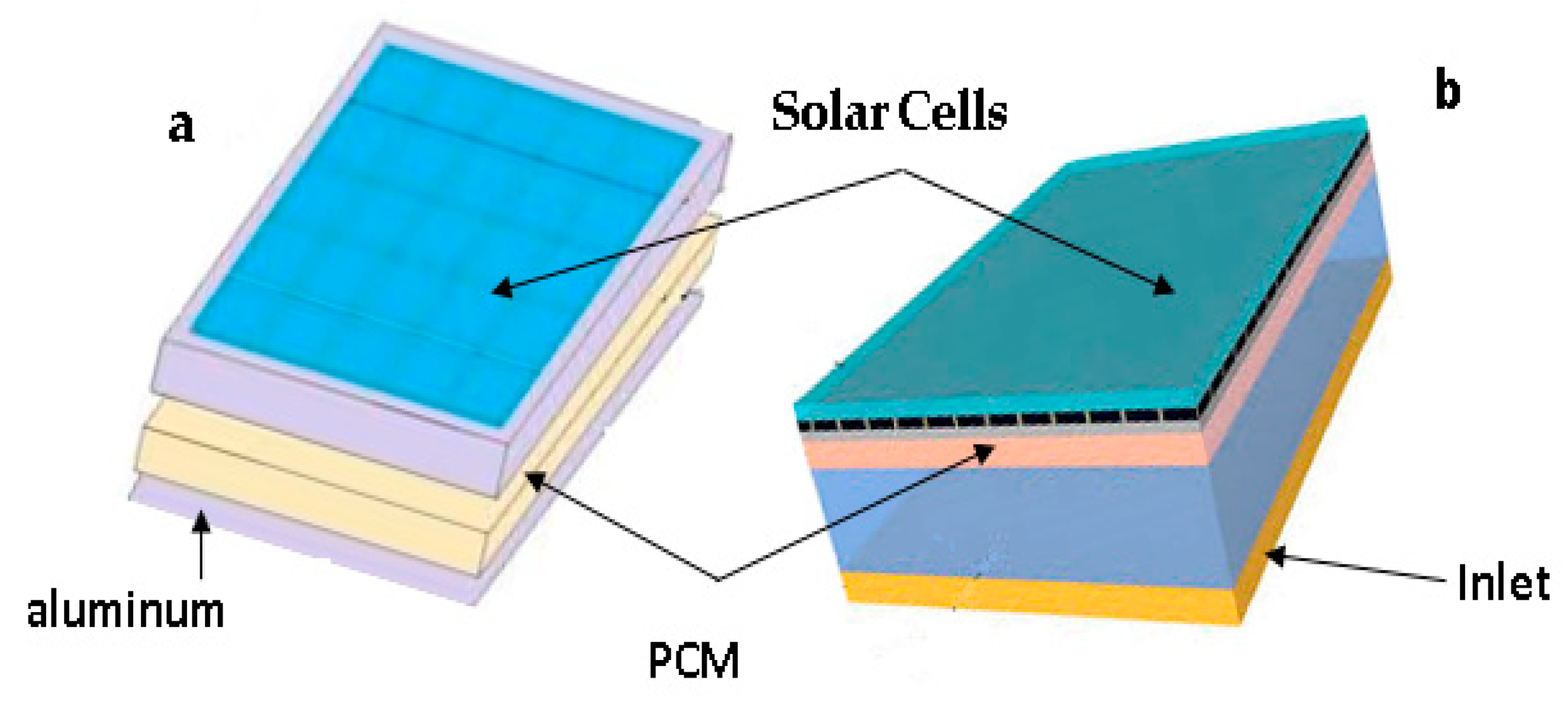

6. Passive PCM Cooling System

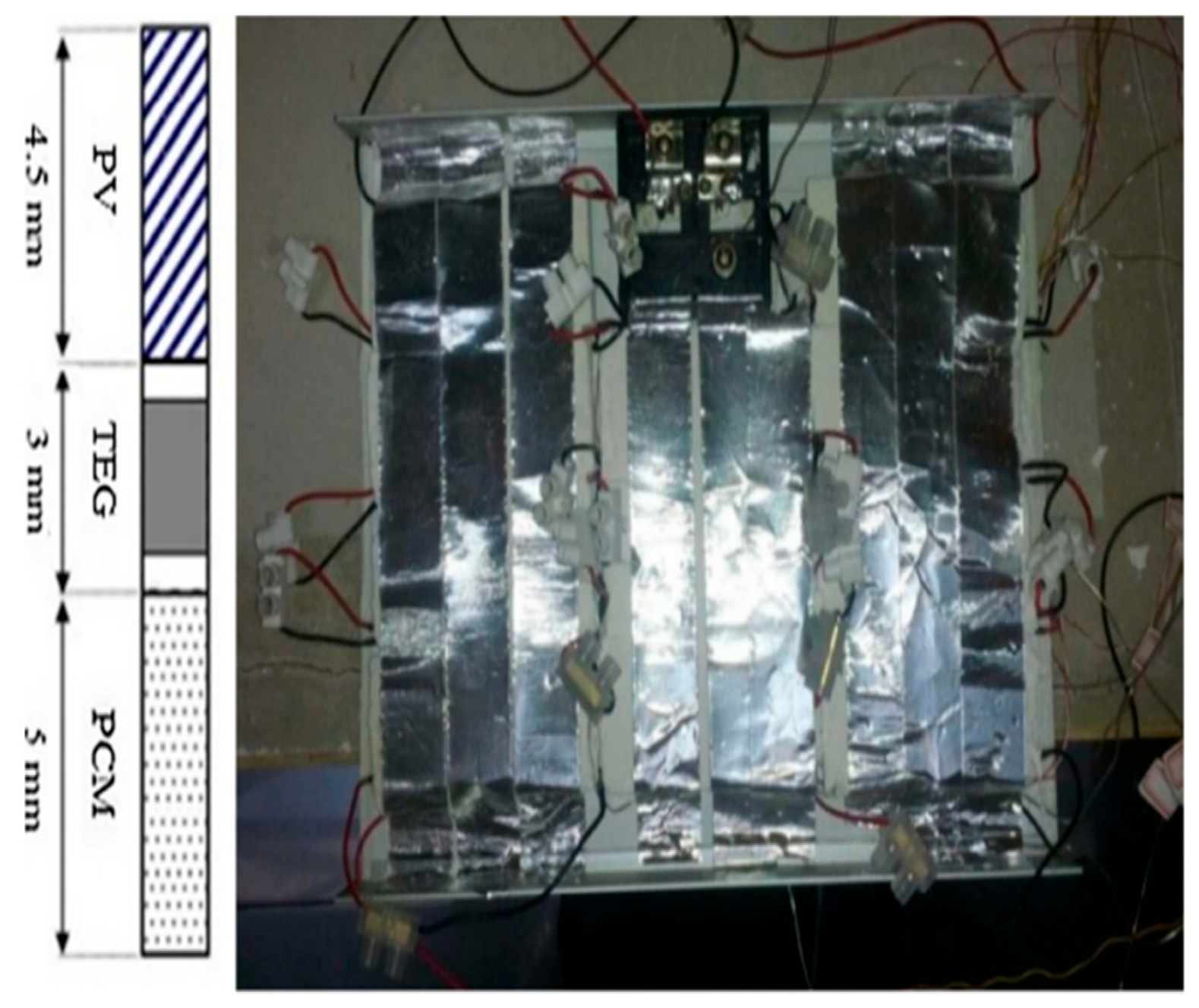

7. Active PCM Cooling System

8. Comparison of the Cooling Systems

9. Conclusions and Future Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moharram, K.A.; Abd-Elhady, M.; Kandil, H.; El-Sherif, H. Enhancing the performance of photovoltaic panels by water cooling. Ain Shams Eng. J. 2013, 4, 869–877. [Google Scholar] [CrossRef]

- Maghami, M.R.; Hizam, H.; Gomes, C.; Radzi, M.A.; Rezadad, M.I.; Hajighorbani, S. Power loss due to soiling on solar panel: A review. Renew. Sustain. Energy Rev. 2016, 59, 1307–1316. [Google Scholar] [CrossRef]

- Zareian-Jahromi, M.; Fadaeinedjad, R.; Hosseini-Biyouki, M.M.; Askarian-Abyaneh, H. Investigation of Solar Irradiance Impact on Electro-Thermo-Mechanical Characteristics of a Dish-Stirling Engine Power Generation System. In Proceedings of the 2014 IEEE Electrical Power and Energy Conference, Washington, DC, USA, 12–14 November 2014; pp. 196–201. [Google Scholar]

- Libra, M.; Petrík, T.; Poulek, V.; Tyukhov, I.I.; Kouřím, P. Changes in the efficiency of photovoltaic energy conversion in temperature range with extreme limits. IEEE J. Photovolt. 2021, 11, 1479–1484. [Google Scholar] [CrossRef]

- Zhu, L.; Boehm, R.F.; Wang, Y.; Halford, C.; Sun, Y. Water immersion cooling of PV cells in a high concentration system. Sol. Energy Mater. Sol. Cells 2011, 95, 538–545. [Google Scholar] [CrossRef]

- An, Q.; Bagheritabar, M.; Basem, A.; Ghabra, A.A.; Li, Y.; Tang, M.; Sabri, L.S.; Sabetvand, R. The effect of size of copper oxide nanoparticles on the thermal behavior of silica aerogel/paraffin nanostructure in a duct using molecular dynamics simulation. Case Stud. Therm. Eng. 2024, 60, 104666. [Google Scholar] [CrossRef]

- Dubey, S.; Sarvaiya, J.N.; Seshadri, B. Temperature dependent photovoltaic (PV) efficiency and its effect on PV production in the world–a review. Energy Procedia 2013, 33, 311–321. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, J.; Liang, R.; Zhou, C. Refrigeration characteristics of a hybrid heat dissipation photovoltaic-thermal heat pump under various ambient conditions on summer night. Renew. Energy 2020, 146, 2524–2534. [Google Scholar] [CrossRef]

- Larciprete, M.C.; Passeri, D.; Michelotti, F.; Paoloni, S.; Sibilia, C.; Bertolotti, M.; Belardini, A.; Sarto, F.; Somma, F.; Lo Mastro, S. Second order nonlinear optical properties of zinc oxide films deposited by low temperature dual ion beam sputtering. J. Appl. Phys. 2005, 97, 023501. [Google Scholar] [CrossRef]

- Horschig, T.; Adams, P.W.; Röder, M.; Thornley, P.; Thrän, D. Reasonable potential for GHG savings by anaerobic biomethane in Germany and UK derived from economic and ecological analyses. Appl. Energy 2016, 184, 840–852. [Google Scholar] [CrossRef]

- Benkahoul, M.; Chaker, M.; Margot, J.; Haddad, E.; Kruzelecky, R.; Wong, B.; Jamroz, W.; Poinas, P. Thermochromic VO2 film deposited on Al with tunable thermal emissivity for space applications. Sol. Energy Mater. Sol. Cells 2011, 95, 3504–3508. [Google Scholar] [CrossRef]

- Browne, M.; Norton, B.; McCormack, S. Phase change materials for photovoltaic thermal management. Renew. Sustain. Energy Rev. 2015, 47, 762–782. [Google Scholar] [CrossRef]

- Maghami, M.R.; Asl, S.N.; Rezadad, M.E.; Ale Ebrahim, N.; Gomes, C. Qualitative and quantitative analysis of solar hydrogen generation literature from 2001 to 2014. Scientometrics 2015, 105, 759–771. [Google Scholar] [CrossRef] [PubMed]

- Maghami, M.R.; Hizam, H.; Gomes, C. Mathematical Relationship Identification for Photovoltaic Systems under Dusty Condition. In Proceedings of the 2015 IEEE European Modelling Symposium (EMS), Madrid, Spain, 6–8 October 2015; pp. 288–292. [Google Scholar]

- Rusănescu, C.O.; Rusănescu, M.; Istrate, I.A.; Constantin, G.A.; Begea, M. The effect of dust deposition on the performance of photovoltaic panels. Energies 2023, 16, 6794. [Google Scholar] [CrossRef]

- Maghami, M.; Hizam, H.; Gomes, C.; Hajighorbani, S.; Rezaei, N. Evaluation of the 2013 southeast asian haze on solar generation performance. PLoS ONE 2015, 10, e0135118. [Google Scholar] [CrossRef] [PubMed]

- Xiao, M.; Tang, L.; Zhang, X.; Lun, I.Y.F.; Yuan, Y. A review on recent development of cooling technologies for concentrated photovoltaics (CPV) systems. Energies 2018, 11, 3416. [Google Scholar] [CrossRef]

- Kumari, S.; Pandit, A.; Bhende, A.; Rayalu, S. Thermal management of solar panels for overall efficiency enhancement using different cooling techniques. Int. J. Environ. Res. 2022, 16, 53. [Google Scholar] [CrossRef]

- Maghami, M.; Hizam, H.; Gomes, C.; AG, I. Characterization of dust materials on the surface of solar panel. Life Sci. J. 2014, 11, 387–390. [Google Scholar]

- Nižetić, S.; Čoko, D.; Yadav, A.; Grubišić-Čabo, F. Water spray cooling technique applied on a photovoltaic panel: The performance response. Energy Convers. Manag. 2016, 108, 287–296. [Google Scholar] [CrossRef]

- Mehrotra, S.; Rawat, P.; Debbarma, M.; Sudhakar, K. Performance of a solar panel with water immersion cooling technique. Int. J. Sci. Environ. Technol. 2014, 3, 1161–1172. [Google Scholar]

- Nižetić, S.; Papadopoulos, A.; Giama, E. Comprehensive analysis and general economic-environmental evaluation of cooling techniques for photovoltaic panels, Part I: Passive cooling techniques. Energy Convers. Manag. 2017, 149, 334–354. [Google Scholar] [CrossRef]

- Darkwa, J.; Calautit, J.; Du, D.; Kokogianakis, G. A numerical and experimental analysis of an integrated TEG-PCM power enhancement system for photovoltaic cells. Appl. Energy 2019, 248, 688–701. [Google Scholar] [CrossRef]

- Dwivedi, P.; Sudhakar, K.; Soni, A.; Solomin, E.; Kirpichnikova, I. Advanced cooling techniques of PV modules: A state of art. Case Stud. Therm. Eng. 2020, 21, 100674. [Google Scholar] [CrossRef]

- Hadipour, A.; Zargarabadi, M.R.; Rashidi, S. An efficient pulsed-spray water cooling system for photovoltaic panels: Experimental study and cost analysis. Renew. Energy 2021, 164, 867–875. [Google Scholar] [CrossRef]

- Nižetić, S.; Giama, E.; Papadopoulos, A. Comprehensive analysis and general economic-environmental evaluation of cooling techniques for photovoltaic panels, Part II: Active cooling techniques. Energy Convers. Manag. 2018, 155, 301–323. [Google Scholar] [CrossRef]

- Teo, H.; Lee, P.; Hawlader, M. An active cooling system for photovoltaic modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Elminshawy, N.A.; El-Ghandour, M.; Elhenawy, Y.; Bassyouni, M.; El-Damhogi, D.; Addas, M.F. Experimental investigation of a V-trough PV concentrator integrated with a buried water heat exchanger cooling system. Sol. Energy 2019, 193, 706–714. [Google Scholar] [CrossRef]

- Maleki, A.; Ngo, P.T.T.; Shahrestani, M.I. Energy and exergy analysis of a PV module cooled by an active cooling approach. J. Therm. Anal. Calorim. 2020, 141, 2475–2485. [Google Scholar] [CrossRef]

- Siecker, J.; Kusakana, K.; Numbi, E.B. A review of solar photovoltaic systems cooling technologies. Renew. Sustain. Energy Rev. 2017, 79, 192–203. [Google Scholar] [CrossRef]

- Castanheira, A.F.; Fernandes, J.F.; Branco, P.C. Demonstration project of a cooling system for existing PV power plants in Portugal. Appl. Energy 2018, 211, 1297–1307. [Google Scholar] [CrossRef]

- Tang, L.; Zhou, Y.; Zheng, S.; Zhang, G. Exergy-based optimisation of a phase change materials integrated hybrid renewable system for active cooling applications using supervised machine learning method. Sol. Energy 2020, 195, 514–526. [Google Scholar] [CrossRef]

- Kane, A.; Verma, V.; Singh, B. Optimization of thermoelectric cooling technology for an active cooling of photovoltaic panel. Renew. Sustain. Energy Rev. 2017, 75, 1295–1305. [Google Scholar] [CrossRef]

- Colţ, G. Performance evaluation of a PV panel by rear surface water active cooling. In Proceedings of the 2016 International Conference on Applied and Theoretical Electricity (ICATE), Craiova, Romania, 6–8 October 2016; pp. 1–5. [Google Scholar]

- Zubeer, S.A.; Ali, O.M. Performance analysis and electrical production of photovoltaic modules using active cooling system and reflectors. Ain Shams Eng. J. 2021, 12, 2009–2016. [Google Scholar] [CrossRef]

- Cuce, E.; Bali, T.; Sekucoglu, S.A. Effects of passive cooling on performance of silicon photovoltaic cells. Int. J. Low-Carbon Technol. 2011, 6, 299–308. [Google Scholar] [CrossRef]

- Elbreki, A.; Muftah, A.; Sopian, K.; Jarimi, H.; Fazlizan, A.; Ibrahim, A. Experimental and economic analysis of passive cooling PV module using fins and planar reflector. Case Stud. Therm. Eng. 2021, 23, 100801. [Google Scholar] [CrossRef]

- Dida, M.; Boughali, S.; Bechki, D.; Bouguettaia, H. Experimental investigation of a passive cooling system for photovoltaic modules efficiency improvement in hot and arid regions. Energy Convers. Manag. 2021, 243, 114328. [Google Scholar] [CrossRef]

- Abdollahi, N.; Rahimi, M. Potential of water natural circulation coupled with nano-enhanced PCM for PV module cooling. Renew. Energy 2020, 147, 302–309. [Google Scholar] [CrossRef]

- Hernandez-Perez, J.; Carrillo, J.; Bassam, A.; Flota-Banuelos, M.; Patino-Lopez, L. Thermal performance of a discontinuous finned heatsink profile for PV passive cooling. Appl. Therm. Eng. 2021, 184, 116238. [Google Scholar] [CrossRef]

- Wongwuttanasatian, T.; Sarikarin, T.; Suksri, A. Performance enhancement of a photovoltaic module by passive cooling using phase change material in a finned container heat sink. Sol. Energy 2020, 195, 47–53. [Google Scholar] [CrossRef]

- Li, H.; Zhao, J.; Li, M.; Deng, S.; An, Q.; Wang, F. Performance analysis of passive cooling for photovoltaic modules and estimation of energy-saving potential. Sol. Energy 2019, 181, 70–82. [Google Scholar] [CrossRef]

- Hernandez-Perez, J.; Carrillo, J.; Bassam, A.; Flota-Banuelos, M.; Patino-Lopez, L. A new passive PV heatsink design to reduce efficiency losses: A computational and experimental evaluation. Renew. Energy 2020, 147, 1209–1220. [Google Scholar] [CrossRef]

- Čabo, F.G.; Nižetić, S.; Giama, E.; Papadopoulos, A. Techno-economic and environmental evaluation of passive cooled photovoltaic systems in Mediterranean climate conditions. Appl. Therm. Eng. 2020, 169, 114947. [Google Scholar] [CrossRef]

- Kalaiselvan, S.; Karthikeyan, V.; Rajesh, G.; Kumaran, A.S.; Ramkiran, B.; Neelamegam, P. Solar PV active and passive cooling technologies-a review. In Proceedings of the 2018 International Conference on Computation of Power, Energy, Information and Communication (ICCPEIC), Chennai, India, 28–29 March 2018; pp. 166–169. [Google Scholar]

- Elminshawy, N.A.; El-Damhogi, D.; Ibrahim, I.; Elminshawy, A.; Osama, A. Assessment of floating photovoltaic productivity with fins-assisted passive cooling. Appl. Energy 2022, 325, 119810. [Google Scholar] [CrossRef]

- Wu, S.; Xiong, C. Passive cooling technology for photovoltaic panels for domestic houses. Int. J. Low-Carbon Technol. 2014, 9, 118–126. [Google Scholar] [CrossRef]

- Ramkiran, B.; Sundarabalan, C.; Sudhakar, K. Sustainable passive cooling strategy for PV module: A comparative analysis. Case Stud. Therm. Eng. 2021, 27, 101317. [Google Scholar]

- Chandrasekar, M.; Suresh, S.; Senthilkumar, T. Passive cooling of standalone flat PV module with cotton wick structures. Energy Convers. Manag. 2013, 71, 43–50. [Google Scholar] [CrossRef]

- Elbreki, A.; Sopian, K.; Fazlizan, A.; Ibrahim, A. An innovative technique of passive cooling PV module using lapping fins and planner reflector. Case Stud. Therm. Eng. 2020, 19, 100607. [Google Scholar] [CrossRef]

- Agyekum, E.B.; PraveenKumar, S.; Alwan, N.T.; Velkin, V.I.; Shcheklein, S.E.; Yaqoob, S.J. Experimental investigation of the effect of a combination of active and passive cooling mechanism on the thermal characteristics and efficiency of solar PV module. Inventions 2021, 6, 63. [Google Scholar] [CrossRef]

- Gupta, N.; Tiwari, G. Parametric study to understand the effect of various passive cooling concepts on building integrated semitransparent photovoltaic thermal system. Sol. Energy 2019, 180, 391–400. [Google Scholar] [CrossRef]

- Sarafraz, M.; Safaei, M.R.; Leon, A.S.; Tlili, I.; Alkanhal, T.A.; Tian, Z.; Goodarzi, M.; Arjomandi, M. Experimental investigation on thermal performance of a PV/T-PCM (photovoltaic/thermal) system cooling with a PCM and nanofluid. Energies 2019, 12, 2572. [Google Scholar] [CrossRef]

- Sudhakar, P.; Santosh, R.; Asthalakshmi, B.; Kumaresan, G.; Velraj, R. Performance augmentation of solar photovoltaic panel through PCM integrated natural water circulation cooling technique. Renew. Energy 2021, 172, 1433–1448. [Google Scholar] [CrossRef]

- Sharaf, M.; Huzayyin, A.; Yousef, M.S. Performance enhancement of photovoltaic cells using phase change material (PCM) in winter. Alex. Eng. J. 2022, 61, 4229–4239. [Google Scholar] [CrossRef]

- Díaz, F.A.; Moraga, N.O.; Cabrales, R.C. Computational modeling of a PV-PCM passive cooling system during a day–night cycle at arid and semi-arid climate zones. Energy Convers. Manag. 2022, 270, 116202. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Liu, M.; Saman, W.; Bruno, F. Review on storage materials and thermal performance enhancement techniques for high temperature phase change thermal storage systems. Renew. Sustain. Energy Rev. 2012, 16, 2118–2132. [Google Scholar] [CrossRef]

- Sarı, A.; Karaipekli, A. Thermal conductivity and latent heat thermal energy storage characteristics of paraffin/expanded graphite composite as phase change material. Appl. Therm. Eng. 2007, 27, 1271–1277. [Google Scholar] [CrossRef]

- Kyaligonza, S.; Cetkin, E. Photovoltaic System Efficiency Enhancement with Thermal Management: Phase Changing Materials (PCM) with High Conductivity Inserts. Int. J. Smart Grid 2021, 5, 138–148. [Google Scholar]

- Ahmadi, R.; Monadinia, F.; Maleki, M. Passive/active photovoltaic-thermal (PVT) system implementing infiltrated phase change material (PCM) in PS-CNT foam. Sol. Energy Mater. Sol. Cells 2021, 222, 110942. [Google Scholar] [CrossRef]

- Nasef, H.; Nada, S.; Hassan, H. Integrative passive and active cooling system using PCM and nanofluid for thermal regulation of concentrated photovoltaic solar cells. Energy Convers. Manag. 2019, 199, 112065. [Google Scholar] [CrossRef]

- Said, Z.; Ahmad, F.F.; Radwan, A.M.; Hachicha, A.A. New thermal management technique for PV module using Mist/PCM/Husk: An experimental study. J. Clean. Prod. 2023, 401, 136798. [Google Scholar] [CrossRef]

- Radwan, A.; Emam, M.; Ahmed, M. Comparative study of active and passive cooling techniques for concentrated photovoltaic systems. In Exergetic, Energetic and Environmental Dimensions; Elsevier: Amsterdam, The Netherlands, 2018; pp. 475–505. [Google Scholar]

- Atyabi, S.A.; Afshari, E.; Udemu, C. Comparison of active and passive cooling of proton exchange membrane fuel cell using a multiphase model. Energy Convers. Manag. 2022, 268, 115970. [Google Scholar] [CrossRef]

- Aldaghi, A.; Banejad, A.; Kalani, H.; Sardarabadi, M.; Passandideh-Fard, M. An experimental study integrated with prediction using deep learning method for active/passive cooling of a modified heat sink. Appl. Therm. Eng. 2023, 221, 119522. [Google Scholar] [CrossRef]

- Bria, A.; Raillani, B.; Chaatouf, D.; Salhi, M.; Amraqui, S.; Mezrhab, A. Effect of PCM thickness on the performance of the finned PV/PCM system. Mater. Today Proc. 2023, 72, 3617–3625. [Google Scholar] [CrossRef]

- Prakash, K.B.; Amarkarthik, A. Energy analysis of a novel butterfly serpentine flow-based PV/T and PV/T heat pump system with phase change material–an experimental comparative study. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 5494–5507. [Google Scholar]

- Ma, T.; Li, Z.; Zhao, J. Photovoltaic panel integrated with phase change materials (PV-PCM): Technology overview and materials selection. Renew. Sustain. Energy Rev. 2019, 116, 109406. [Google Scholar] [CrossRef]

- Stritih, U. Increasing the efficiency of PV panel with the use of PCM. Renew. Energy 2016, 97, 671–679. [Google Scholar]

- Nižetić, S.; Jurčević, M.; Čoko, D.; Arıcı, M. A novel and effective passive cooling strategy for photovoltaic panel. Renew. Sustain. Energy Rev. 2021, 145, 111164. [Google Scholar] [CrossRef]

- Salem, M.; Elsayed, M.; Abd-Elaziz, A.; Elshazly, K. Performance enhancement of the photovoltaic cells using Al2O3/PCM mixture and/or water cooling-techniques. Renew. Energy 2019, 138, 876–890. [Google Scholar] [CrossRef]

- Velmurugan, K.; Kumarasamy, S.; Wongwuttanasatian, T.; Seithtanabutara, V. Review of PCM types and suggestions for an applicable cascaded PCM for passive PV module cooling under tropical climate conditions. J. Clean. Prod. 2021, 293, 126065. [Google Scholar] [CrossRef]

- Akhtar, M.; Arendt, C.; Das, U. A review on active cooling techniques of photovoltaic modules. Renew. Sustain. Energy Rev. 2015, 50, 724–742. [Google Scholar]

- Kargarian, A.; Bahaidarah, H.M.; Gandhidasan, P. Cooling techniques and design considerations for photovoltaic modules: A review. Sol. Energy 2019, 183, 278–305. [Google Scholar]

- Padullés, J.; Ramírez, L.; Escobar, R.; Roca, J. Analysis of the impact of active cooling strategies on the electrical performance of a photovoltaic module under real working conditions. Energy 2018, 152, 206–216. [Google Scholar]

- Luo, Z.; Zhu, N.; Hu, P.; Lei, F.; Zhang, Y. Simulation study on performance of PV-PCM-TE system for year-round analysis. Renew. Energy 2022, 195, 263–273. [Google Scholar] [CrossRef]

- Stalin, P.M.J.; Prasad, K.S.; Kumar, K.P.; Hemadri, G.; Rajesh, M.; Kumar, K.P. Performance improvement of solar PV through the thermal management using a nano-PCM. Mater. Today Proc. 2022, 50, 1553–1558. [Google Scholar]

- Abdulmunem, A.R.; Samin, P.M.; Rahman, H.A.; Hussien, H.A.; Ghazali, H. A novel thermal regulation method for photovoltaic panels using porous metals filled with phase change material and nanoparticle additives. J. Energy Storage 2021, 39, 102621. [Google Scholar] [CrossRef]

- Sharaf, M.; Yousef, M.S.; Huzayyin, A. Year-round energy and exergy performance investigation of a photovoltaic panel coupled with metal foam/phase change material composite. Renew. Energy 2022, 189, 777–789. [Google Scholar] [CrossRef]

- Lu, W.; Liu, Z.; Flor, J.-F.; Wu, Y.; Yang, M. Investigation on designed fins-enhanced phase change materials system for thermal management of a novel building integrated concentrating PV. Appl. Energy 2018, 225, 696–709. [Google Scholar] [CrossRef]

- Ahmed, A.; Shanks, K.; Sundaram, S.; Mallick, T.K. Theoretical investigation of the temperature limits of an actively cooled high concentration photovoltaic system. Energies 2020, 13, 1902. [Google Scholar] [CrossRef]

- Chandavar, A.U. Quantifying the performance advantage of using passive solar air heater with chimney for photovoltaic module cooling. Int. J. Energy Res. 2021, 45, 1576–1586. [Google Scholar] [CrossRef]

- Gad, R.; Mahmoud, H.; Ookawara, S.; Hassan, H. Impact of PCM type on photocell performance using heat pipe-PCM cooling system: A numerical study. J. Energy Syst. 2023, 7, 67–88. [Google Scholar] [CrossRef]

- Al Miaari, A.; Ali, H.M. Technical method in passive cooling for photovoltaic panels using phase change material. Case Stud. Therm. Eng. 2023, 49, 103283. [Google Scholar] [CrossRef]

- Elarga, H.; Goia, F.; Zarrella, A.; Dal Monte, A.; Benini, E. Thermal and electrical performance of an integrated PV-PCM system in double skin façades: A numerical study. Sol. Energy 2016, 136, 112–124. [Google Scholar] [CrossRef]

| Year | References | Techniques | Type | Result | Objective |

|---|---|---|---|---|---|

| (2019) | [28] | Active cooling | Forced-water cooling; forced-water cooling with buried water | The study demonstrated a 12.20% enhancement in the relative levelized cost of energy as a result of the suggested cooling system. Additionally, this system contributed to a reduction of around 49,209 g CO2/summer sea in global average CO2 emissions. | To evaluate the efficiency of a photovoltaic cooling mechanism that combines a V-trough configuration with an underground water heat exchanger. |

| (2020) | [29] | Active cooling | Forced-water cooling | The results indicated that augmenting the mass flow rate of cooling water has negligible effects. However, under ideal conditions, with a solar irradiance of 1000 W m−2, an ambient temperature of 45 °C, and a water velocity of 0.9 m s−1, the cell’s efficiency improved by 17.12%. | To explore how changes in ambient temperature, the flow rate of cooling water, and solar irradiance affect cell efficiency and temperature. |

| (2017) | [30] | Active cooling | Forced-water cooling | Improves electrical efficiency; yet, with a steady flow rate, it cannot achieve maximal efficiency. If you want maximum efficiency, it is best to modify the flow rate when the temperature changes. | To reduce the negative effects of increased temperature using various techniques. |

| (2018) | [31] | Active cooling | Forced-water cooling | Experiments were conducted to determine the ideal cooling cycle, which was 20%/80%. The cooling system had an initial startup temperature of 30 °C. We anticipate a two-year payback period for the system. | To cool many photovoltaic chains simultaneously, both on and off, and to consider different facets of its potential as a product for commercial use. |

| (2020) | [32] | Active cooling | Forced-water cooling | The research demonstrated that the peak exergy of the hybrid renewable system amounts to 872.06 kWh, representing a 2.6% increase compared to the maximum exergy achieved using the Taguchi standard orthogonal array (849.9 kWh). | To maximize the overall exergy, with the integration of an advanced optimization algorithm. |

| (2012) | [27] | Active cooling | Hybrid photovoltaic/thermal (PV/T) | Solar cell efficiency went up from 12% to 14% as a result of the precipitous drop in temperature. | To connect a series of ducts to the back of the panel, each with its inlet and output manifold to distribute airflow evenly to cool the PV cells efficiently. |

| (2017) | [33] | Active cooling | Thermoelectric module (TEM) | Research indicated that the temperature of photovoltaic panels decreased by 6–26% when a temperature-based “Maximum Power Point Tracking (MPPT)” controller was employed under solar insolation levels ranging from 0.8 to 1 kW/m2 and temperatures between 25 and 45 °C. | To improve the effectiveness and durability of photovoltaic systems. By utilizing thermoelectric technologies to construct and model the PV module |

| (2020) | [29] | Active cooling | Water flow (forced) | The study revealed that this cooling technique is most efficient in conditions characterized by elevated ambient temperatures and intense sun radiation. | To scrutinize how the mass flow rate of cooling water, ambient room temperature, and variations in solar irradiance affect both the temperature and efficiency of the cell. |

| (2016) | [34] | Active cooling | Forced-water heat exchanger | The effectiveness of the PV panel augmented by 57%, going from 7 W to 11 W, and the module temperature decreased by 32%, from 50 °C. | To study the cooling impact of the PV panel, a forced water heat exchanger will be incorporated through numerical simulation and experimental investigation. |

| (2016) | [35] | Active cooling | Water flow (forced), reflectors | The cooling system reduces the working temperature of the PV module to 30–35 °C, resulting in an 18.5% increase in power output for water-cooled CPV and an 8% increase for CPV. | To utilize a technique that focuses on and lowers the temperature of sunlight to enhance the electrical performance of the photovoltaic (PV) module. |

| Year | References | Techniques | Type | Result | Objective |

|---|---|---|---|---|---|

| (2018) | [45] | Passive cooling | Convection or conduction | Passive technology is more advanced than other technologies but requires additional maintenance. Passive technology is more economically efficient when considering the factors that limit it. | To enhance the efficiency of a photovoltaic panel by employing various methods to lower its temperature. |

| (2021) | [38] | Passive cooling | Cooling by natural water evaporation | An evaporative cooling system helped achieve a substantial 26% drop in temperature. The operational temperature of the reference module fluctuated between 54.2 °C and 76.4 °C, averaging at approximately 66.4 °C. | To scrutinize the efficacy of water-based passive cooling mechanisms in enhancing the efficiency of photovoltaic (PV) modules in hot, arid environments. |

| (2020) | [39] | Passive cooling | Natural water circulation | The introduction of nano-composed oil resulted in the greatest augmentation of the maximum generated power compared to the reference condition. The percentage enhancements were 44.74%, 46.63%, and 48.23% at radiation intensities of 410, 530, and 690 W/m2, respectively. | To insert nano-composed oil to increase the maximum generated power compared to the baseline condition. The percentage improvements were 44.74%, 46.63%, and 48.23% at radiation intensities of 410, 530, and 690 W/m2, respectively. |

| (2022) | [46] | Passive cooling | Floating photovoltaic system | The research demonstrated that the improved floating PV system featuring a finned heatsink outperforms the conventional floating photovoltaic system, decreasing the operating temperature by roughly 19.07%. | To improve the efficacy of a floating PV system, a novel partially floating system is combined with a passive arrangement of finned heatsinks to lower the operating temperature and sustain the module’s productivity. |

| (2019) | [47] | Passive cooling | Evaporative cooling and natural water mass | Raising the water mass from 0 kg to 600 kg (heat capacity) leads to a 4.67% increase in electrical efficiency, attributed to a 4.79 °C decrease in solar cell temperature at midday. | To comprehend the impacts of different passive cooling methods on integrated semitransparent photovoltaic thermal systems. |

| (2014) | [48] | Passive cooling | Rainwater, gas expansion device | On a design day, the research indicates a reduction in cell temperature along with an 8.3% upsurge in the electrical efficiency of the PV panel attributed to the passive cooling system. | To employ rainwater for passive cooling in a solar system to enhance its performance by distributing it through a gas expansion mechanism. |

| (2021) | [36] | Passive cooling | Plant cooling, greenhouse cooling, coir pith | Examples of net cooling within greenhouses and cooling plants using greenhouse structures demonstrate that temperature reduction does not consistently lead to increased power. Nations in tropical regions with agriculture-based economies stand to gain the most from employing this cooling technique. | To measure a 50 W polycrystalline photovoltaic module’s power generation and temperature drop. |

| (2011) | [49] | Passive cooling | Aluminum heat sink | Under conditions of 800 W/m2 radiation, the PV cell’s power production increases by around 20%. The cooling effect is most pronounced at an intensity level of 600 W/m2. Photovoltaic cell efficiency increases when temperature decreases, regardless of the presence of fins. | To understand how passive cooling with an aluminum heat sink affects the performance of silicon photovoltaic systems under various radiation settings. |

| (2013) | [37] | Passive cooling | Cotton wick | A 30% enhanced cooling system has a 1.4% increase in module efficiency, resulting in a 15.61% increase in PV module output power and a module temperature. | To propose a passive cooling system for flat PV modules using cotton wick structures. |

| (2021) | [50] | Passive cooling | Fin heat sinks namely | The payback period for different types of PV modules was determined to be 4.2 years for longitudinal fins, 5 years for lapping fins, and 8.4 years for exposed PV modules. The electrical efficiency and power output achieved were 10. | To evaluate the efficiency of passive cooling in a concentrated solar module experimentally by using two different types of passive fin heat sinks: pounding and long-term. |

| (2020) | [51] | Passive cooling | Lapping fin, wind speed | Increasing the fin pitch from 20 to 60 mm reduced the number of fins from 20 to 10 and raised the PV module temperature from 44.13 to 54.01 °C. | To improve the efficiency of the PV module, they incorporated a planar reflector and expand the surface of the back plate. |

| (2021) | [38] | Passive cooling | Heat sink, aluminum fins, ultrasonic humidifier | The study employed a cooling technique that reduced the temperature of the panel by an average of 14.61 °C. This lessening resulted in a 6.8% upgrade in the electrical efficiency of the module. | To improve the electrical output of the photovoltaic module by employing an aluminum fin heat sink and an ultrasonic humidifier. |

| (2021) | [52] | Passive cooling | Water evaporation, capillary action, and burlap fabric | The research demonstrated that the proposed evaporative cooling system efficiently lessened the temperature of the PV module by 20 degrees Celsius, marking a 26% reduction. Consequently, there was a significant 14.7% increase in electricity efficiency. | To create a passive cooling system aimed at averting overheating of solar modules while enhancing their efficiency. |

| Year | References | Techniques | Type | Result | Objective |

|---|---|---|---|---|---|

| (2016) | 103 | PCM cooling | PV/CS6P-M, PCM | The simulation’s final results indicate that the power generation of the PV–PCM panel in Ljubljana exceeded the previous year’s output by 7.3%. | To boost the electrical efficiency and power generation of a photovoltaic panel by integrating a phase-change material (PCM). |

| (2021) | [57] | PCM cooling | PV–PCM cooling systems | The power generated by the PV system rose by 2.5% when utilizing a full PCM container in contrast to a typical PV panel. The innovative PV–PCM passive cooling technology, featuring numerous dissimilar PCM containers, elevated performance by 10.7% compared to the use of a solitary PCM container. | To review the traditional passive cooling method frequently utilized in photovoltaic systems by integrating phase-change material for cooling (PV–PCM cooling systems). |

| (2021) | [58] | PCM cooling | Water (natural), nano-PCM, PV | The results indicate that utilizing nano-composed PCMs derives superior results compared with using traditional PCMs. The most notable improvement in maximum power output was observed with nano-composed oil, reaching 44.74%, 46.63%, and 48.23% at radiation intensities of 410, 530, and 690 W/m2, respectively. | To propose a novel passive cooling arrangement for photovoltaic modules that utilizes natural water flow for cooling, supplemented with a nano-enhanced cooling system. |

| (2019) | [59] | PCM cooling | PV/T-PCM, nanofluid | Increasing coolant concentration boosted electricity and power generation, while higher nanofluid concentration increased pumping power but decreased thermal–electrical equivalent power. | To measure the thermal and electrical efficiency of a photovoltaic solar panel utilizing a nano-suspension containing multi-walled carbon nanotubes in a water/ethylene glycol (50:50) solution. |

| (2019) | [60] | PCM cooling | PV, natural water, Al2O3/PCM mixture | The results show that including Al2O3 nanoparticles at a concentration of γ = 1% enhances the effectiveness of the compound approach (Al2O3/PCM combination + water) compared to using 100% water for cooling. The compound strategy using Al2O3 (=1%)/PCM mixture (thermal conductivity of PCM = 25%) with 75% water yields the highest photovoltaic performance among all cooling techniques examined. | To implement a compound improvement approach to achieve a cooling effect on PV modules. |

| (2021) | [61] | PCM cooling | Water/ethylene glycol with PCM | By adjusting the coolant concentration, there was an improvement in electricity and power generation. Similarly, increasing the nanofluid concentration led to higher pumping power but a decrease in thermal–electrical equivalent power. | To assess the thermal of cooling photovoltaic solar panels and electrical efficiency using a combination of multi-walled carbon nanotubes, water/ethylene glycol, and phase-change material. |

| (2019) | [62] | PCM cooling | PCM, natural water circulation | Incorporating phase-change material (PCM) and using natural water circulation improved the performance of a PV panel. A top-to-bottom continuous water supply cooling method was found to be more effective than previous methods, leading to increased electricity generation. | To evaluate the effectiveness of solar panels in cold climates by employing phase-change material (PCM) with natural water circulation. |

| (2017) | [63] | PCM cooling | Paraffin, PCM, melting range | PCM cooling efficiency decreases in extreme temperatures due to incomplete melting and solidification processes, but in hot climates, the PV–PCM system boosts the annual electrical energy output of the PV system by 5.9%. | To measure the sustained energy-saving efficiency through incorporating paraffin-based PCM with a melting range of 38–43 °C behind the PV plate, while monitoring the cooling effects. |

| (2023) | [45] | PCM cooling | Nano-emulsions PCM | The mean overall thermal-equivalent energy efficiency reached 84.41%, with a peak of 89.23% when employing nano-emulsion within the module, in contrast to 79.95% and 83.23% observed in the water-cooled system. The collective exergy efficiency stood at 10.69% with nano-emulsion, slightly lower than the 11.66% attained with water. | To evaluate the application of nano-emulsion phase-change materials as advanced coolants to improve the overall efficiency of liquid-cooled PV/thermal systems. |

| (2022) | [64] | PCM cooling | Foam (AMF), PCM | The PV–PCM/AFM system exhibited lower PV surface temperatures by 4%, 7.4%, and 13.12% compared to standard PV, while achieving higher power outputs by 1.85%, 3.38%, and 4.14%. | To develop a method for passively regulating the temperature of a photovoltaic system using aluminum metal foam and PCM |

| (2022) | [65] | PCM cooling | PV–PCM cooling, (ECM) | Findings show that PCM can reduce PV temperature by up to 17.5 °C when used as a cooling system, leading to less efficiency losses and more power output. The usage of a 40 mm thick coating of CaCl2-6H2O boosts the electrical generation for Vicuña by 5.8% and for Calame by 4.5% in a 1-year period. | To upsurge efficiency in silicon photovoltaic (PV) systems, this study compares several PV–PCM cooling system configurations according to PCM material |

| Year | References | Techniques | Type | Result | Objective |

|---|---|---|---|---|---|

| (2022) | [70] | PCM active | PV–PCM-TE system | Research findings show that in a PV–PCM-TE system, solar cells cooled from 79.72 °C to 57.39 °C, while in a PV-TE system, the temperature remained at 73.62 °C. The yearly average efficiencies were 17.57% for PVs. | To boost power output through the optimization of thermoelectric (TE) module attachment and phase-change material (PCM) to photovoltaic (PV) cells. |

| (2022) | [71] | PCM active | Nano-PCM, PV | Using nano-PCM resulted in augmented electrical efficiency and lower panel surface temperature | To expand the productivity of photovoltaic panels by utilizing nano-phase-change material (nano-PCM) to enhance heat radiation absorption. |

| (2021) | [39] | PCM active | PCM, nanoparticle | The results indicate that incorporating twisted bundles of multi-walled carbon nanotubes (MWCNTs) into the PCM/CFM at a concentration ratio of 0.2% significantly improved the material’s heat absorption and rejection capabilities. Throughout the test, the solar panel’s average electrical efficiency surged from 4% to 21% owing to the enhanced electrical performance of the cells. | To examine how empirically dispersing nanoparticles within porous materials and phase-change materials (PCMs) affects the electrical efficiency of photovoltaic (PV) panels in hot climate conditions. |

| (2022) | [53] | PCM active | PV–PCM/AMF system | Experimental results show significant temperature decreases in July for PV/PCM-AMF and PV/PCM solar cells, with reductions of 8.1% and 13.4% respectively. In contrast, November had the smallest temperature decreases at 3.8% and 5% for the same cells. The annual exergy and energy productivities of the PV–PCM. | To compare the energy and exergy efficiency of a proposed PV–PCM/AMF system with conventional PV systems and PV–PCM systems without metal foam. |

| (2018) | [72] | PCM active | CPV/PCM, fins | Studies show that both vertical and horizontal fins improve the thermal efficiency of PCM systems. Vertical fins are especially effective in controlling the temperature of PV cells and exhibit better performance than horizontal fins, particularly under a solar irradiation level of 670 W/m2. | To implement aluminum fins of varying thicknesses in both horizontal and vertical orientations to enhance heat transfer within the PCM. |

| (2021) | [73] | PCM active | Convection (PVT/PCM-III) | Experimental findings from existing literature were used to validate the outcomes of a numerical model. After 120 min, the conversion efficiency of PV cells in different setups was recorded, ranging from 16.84% to 18.98%, with an inflow velocity of 3 m/s. | To securitize four solar module configurations to ensure a consistent cell temperature for optimal efficiency: a standard PV module (PVT module) and a traditional module featuring a PCM layer beneath (PVT/PCM-I). |

| (2021) | [74] | PCM active | Solar simulator, PCM | Studies have shown that PCM composites can reduce PV cell temperature by 6.8% and recuperate electrical efficiency by 14%. Implementing active cooling techniques involved flowing water through a cooling block underneath the PVT system at flow rates varying from 0.3 to 1 liter per minute. | To find out the effects of the effectiveness of active PCM on solar panels/experimental study. |

| (2019) | [75] | PCM active | Nanofluid, PCM | A new technology reduces the average temperature of concentrated photovoltaic (CPV) systems by 60% compared to traditional cooling methods. With specific settings, the cell temperature remains below 78 °C. | To evaluate and improve system efficiency by employing nanofluid as the heat transfer fluid (HTF) in a PCM active cooling system. |

| (2023) | [76] | PCM active | Coconut husk and paraffin wax (PCM) | The outcomes display that the rear surface temperature of a PV panel can reach 69.02 °C under an irradiance of 752 W/m2. The cooling effect of PCM reduces this temperature by 12.83% compared to a standard PV panel. | To recover photovoltaic output performance and mitigate thermal stress in PV panels, the implementation of active fog phase-change material (PCM) will be conducted. A comprehensive applied study will assess its effectiveness. |

| Type | References/ Year | Advantage | Disadvantage | Impact |

|---|---|---|---|---|

| Active Cooling | [26,82] (2020,2018) | Efficient heat transfer, precise temperature control, suitable for high heat loads, flexibility, higher cooling capacity, adaptability, highly effective in maintaining a specific temperature, suitable for applications where precise temperature control is critical, can handle large heat loads. | High energy consumption, complexity, environmental impact, noise generation, size and space requirements, consumes electricity and can be costly to operate, requires maintenance and can be noisy, may not be ideal for portable or off-grid applications. | Enhanced performance and efficiency heat, dissipation in high-power applications, thermal management in vehicles medical, applications aerospace and space exploration, environmental control in buildings |

| Passive Cooling | [38,83] (2021,2021) | High effectiveness, energy efficiency, simplicity, reliability, cost-effective, quiet operation, natural ventilation, longevity, suitable for remote or off-grid locations, environmentally friendly. | Slower heat dissipation, limited cooling capacity, lack of precise control, adaptation challenges, insufficient heat dissipation, design complexity, less effective than active cooling for precise temperature control, may not be appropriate for high heat loads or harsh circumstances. | Energy efficiency, cost savings, environmental benefits, low maintenance, resilience, architectural integration, natural ventilation, sustainable design. |

| PCM Cooling | [84,85] (2023,2023) | Energy-efficient and environmentally friendly, lower operating costs, reduce the average temperature, reduced peak load, thermal inertia, space-efficient design, maintenance reduction, remote and off-grid applications, compatibility with renewable energy, thermal energy storage. | Limited cooling capacity, limited temperature range, thermal cycling fatigue, thermal management, long charging times, volume and weight constraints, thermal conductivity, material compatibility, limited material selection, maintenance complexity, initial cost, limited control over the exact temperature (it stabilizes around the melting/freezing point of the PCM), slower response to temperature changes compared to active systems. | Quiet operation, renewable energy integration, improved thermal comfort, energy efficiency, peak load reduction, temperature regulation, environmental benefits, space efficiency. |

| PCM Active | [69,86] (2019,2016) | Extract thermal energy stored, thermal energy storage, energy efficiency, temperature regulation, reduced peak loads, thermal stability, space-efficient design, environmental benefits, precise temperature control. Suitable for applications with varying heat loads, can store and release thermal energy efficiently. | Requires energy input for phase change control, complex systems may require maintenance, limited by the specific properties of the pCm used, limited temperature range, thermal conductivity, volume expansion, limited energy density, durability, initial cost, complexity of system, integration, regulatory and safety concerns. | Integration with renewable energy, improved thermal, comfort efficient, thermal storage, energy savings, reduced peak loads, temperature regulation, environmental benefits, space-efficient design. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, Y.E.; Maghami, M.R.; Pasupuleti, J.; Danook, S.H.; Basim Ismail, F. Overview of Recent Solar Photovoltaic Cooling System Approach. Technologies 2024, 12, 171. https://doi.org/10.3390/technologies12090171

Ahmed YE, Maghami MR, Pasupuleti J, Danook SH, Basim Ismail F. Overview of Recent Solar Photovoltaic Cooling System Approach. Technologies. 2024; 12(9):171. https://doi.org/10.3390/technologies12090171

Chicago/Turabian StyleAhmed, Yaareb Elias, Mohammad Reza Maghami, Jagadeesh Pasupuleti, Suad Hassan Danook, and Firas Basim Ismail. 2024. "Overview of Recent Solar Photovoltaic Cooling System Approach" Technologies 12, no. 9: 171. https://doi.org/10.3390/technologies12090171

APA StyleAhmed, Y. E., Maghami, M. R., Pasupuleti, J., Danook, S. H., & Basim Ismail, F. (2024). Overview of Recent Solar Photovoltaic Cooling System Approach. Technologies, 12(9), 171. https://doi.org/10.3390/technologies12090171