Advanced Precision Cutting Titanium Alloy Methods: A Critical Review Considering Cost, Efficiency, and Quality

Abstract

1. Introduction

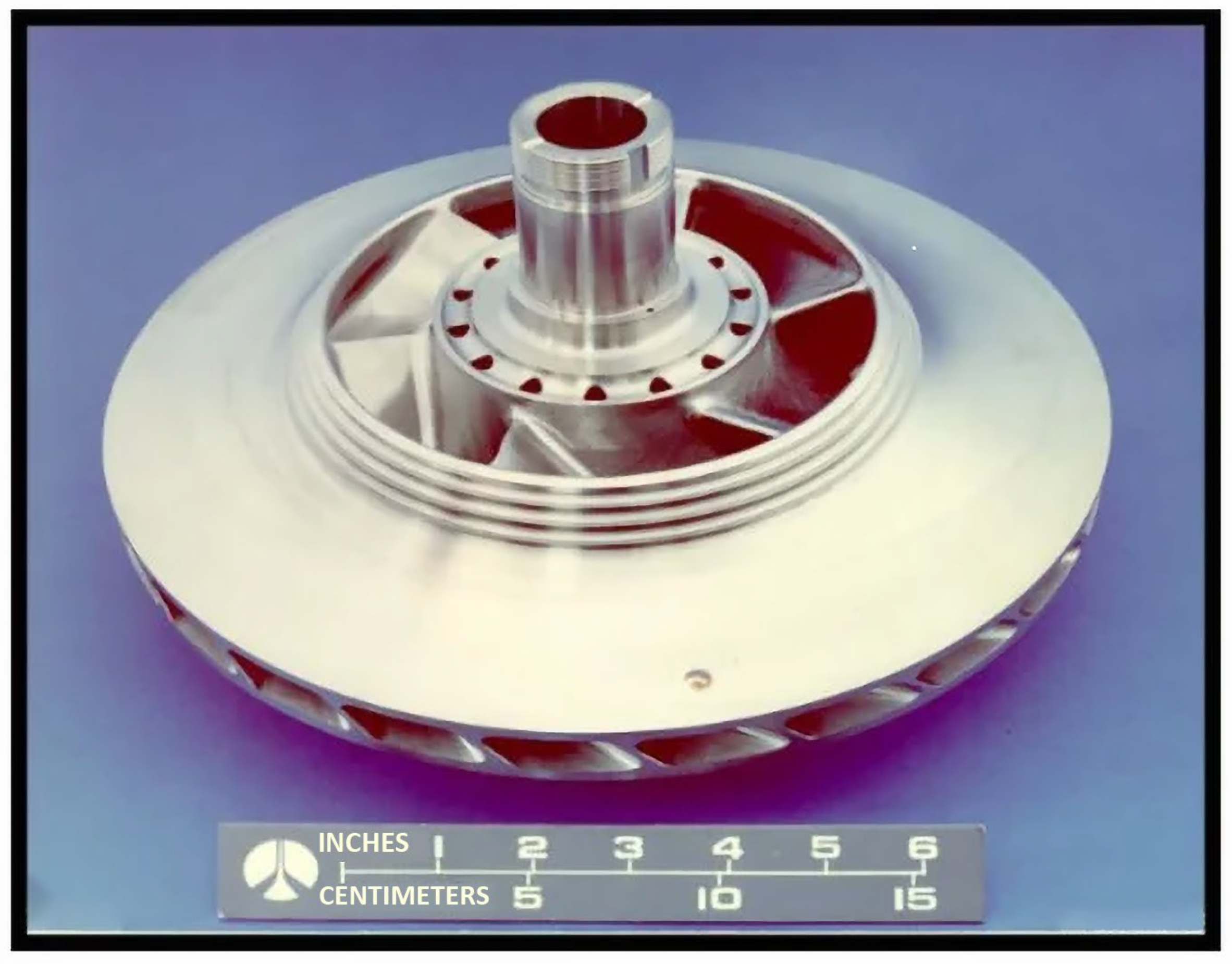

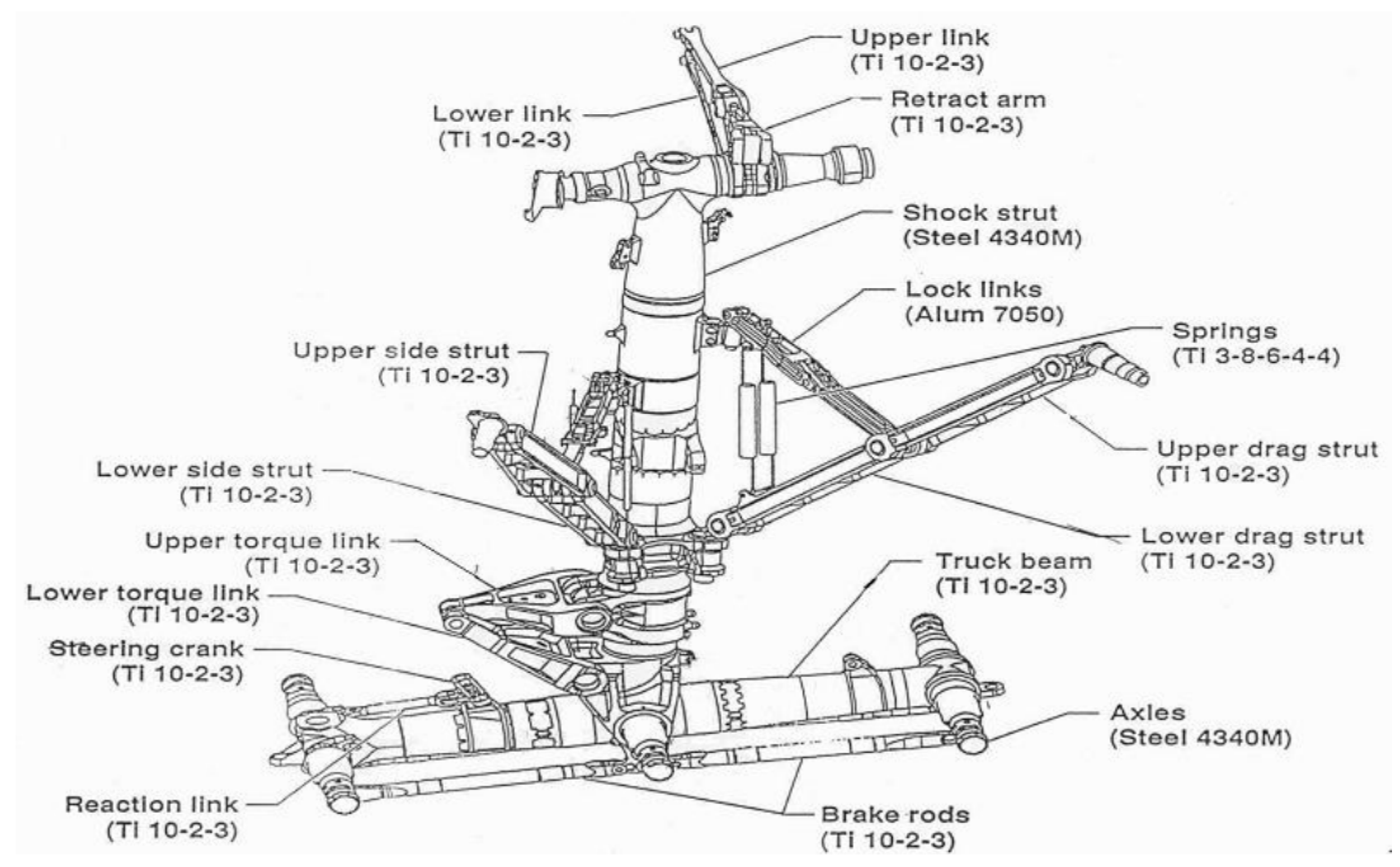

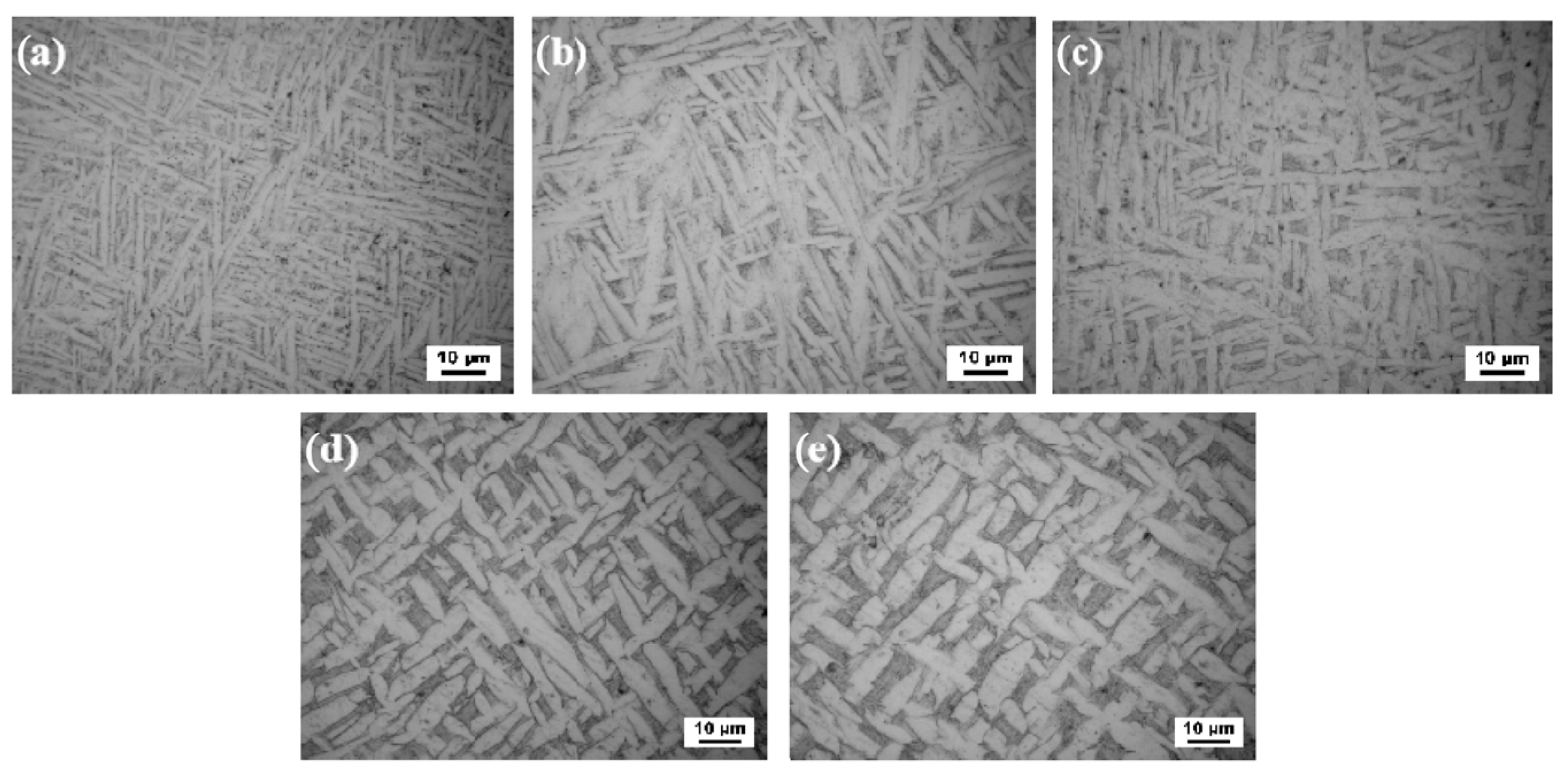

2. Titanium Alloys

3. Advanced Cutting Methods

3.1. Innovated Tool Design

3.1.1. Tool Matrix Material

3.1.2. Tool Shape

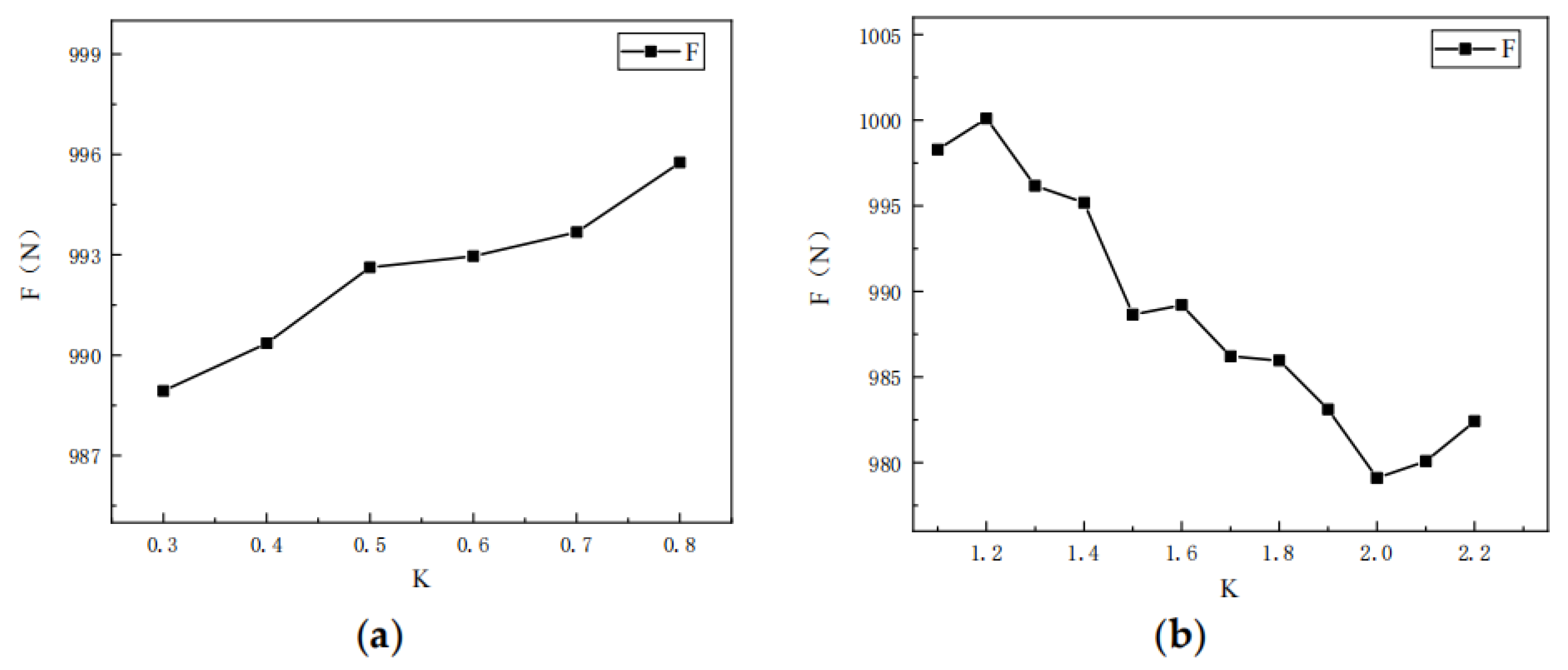

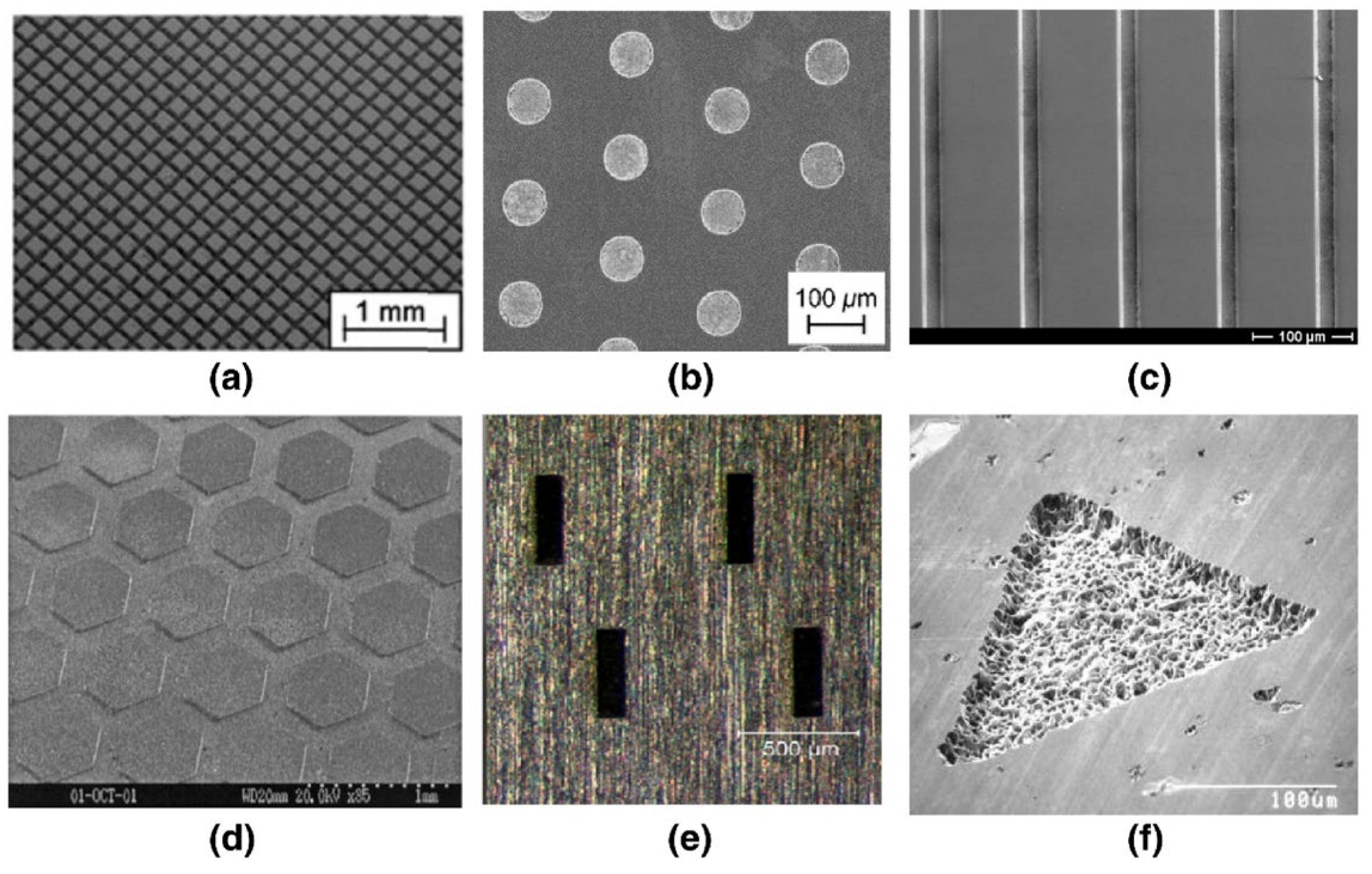

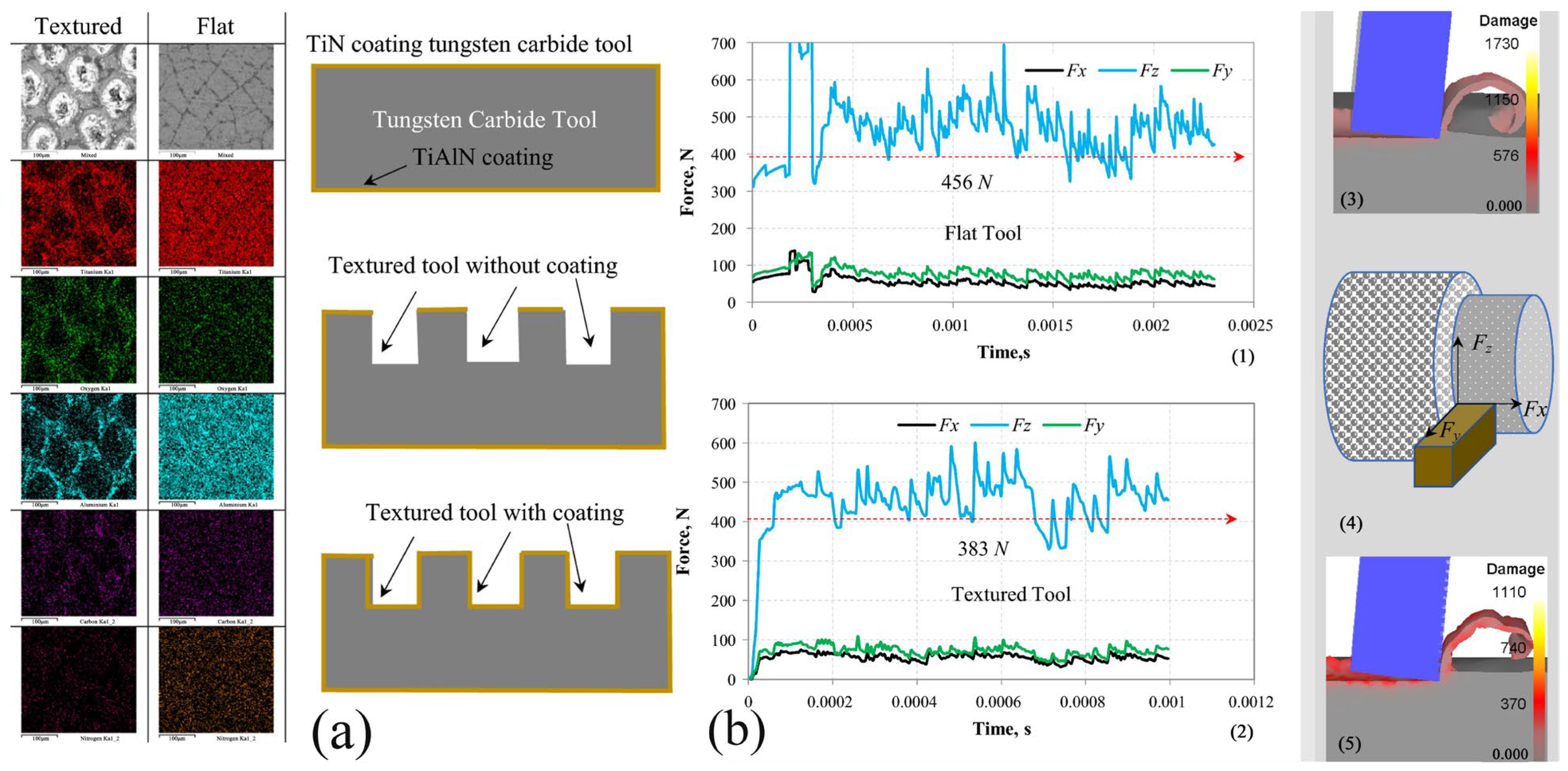

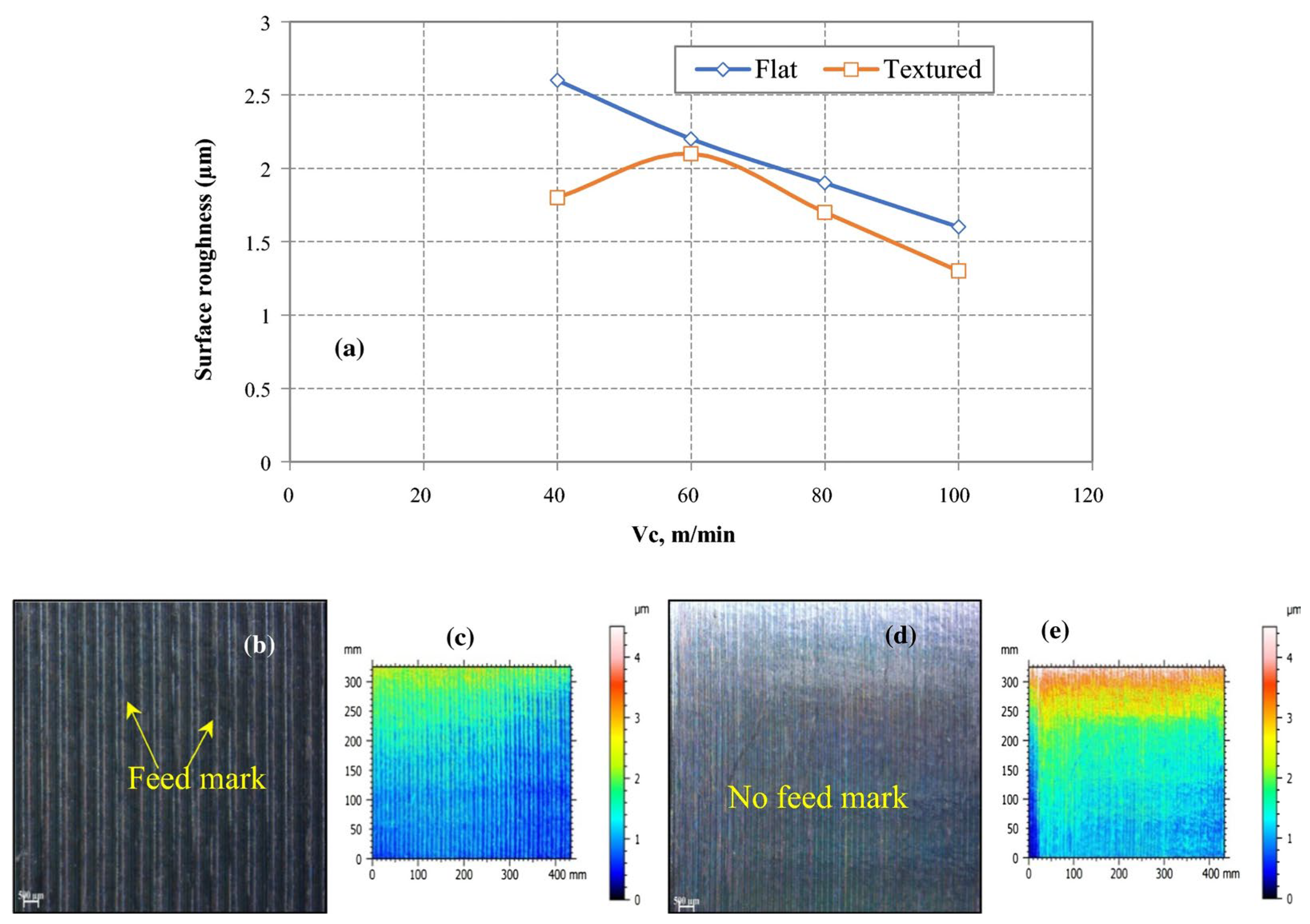

3.1.3. Tool Texture

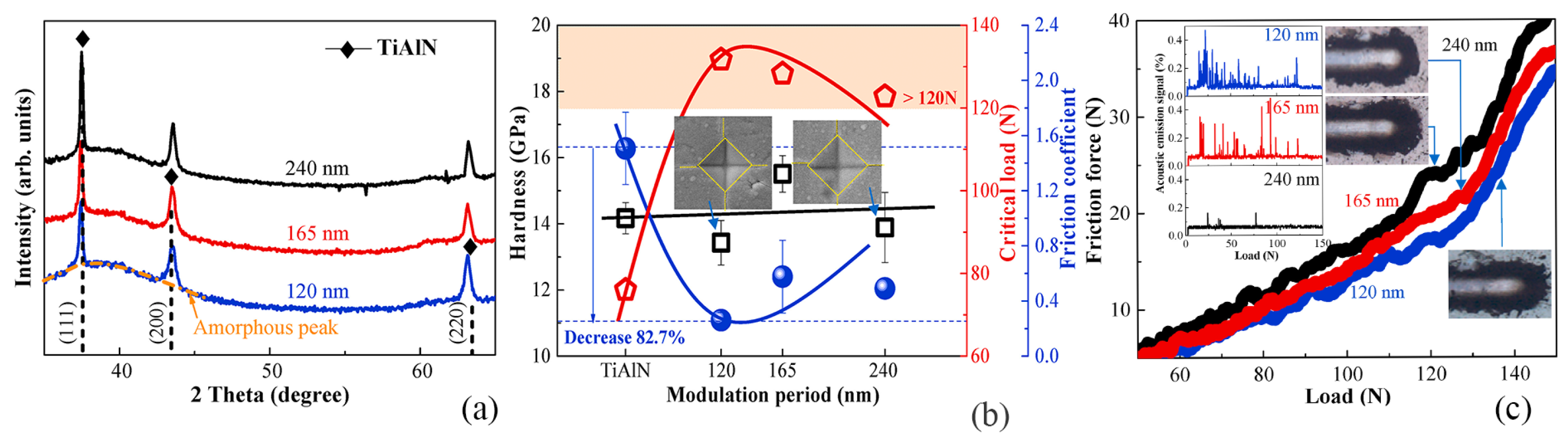

3.1.4. Advanced Coatings

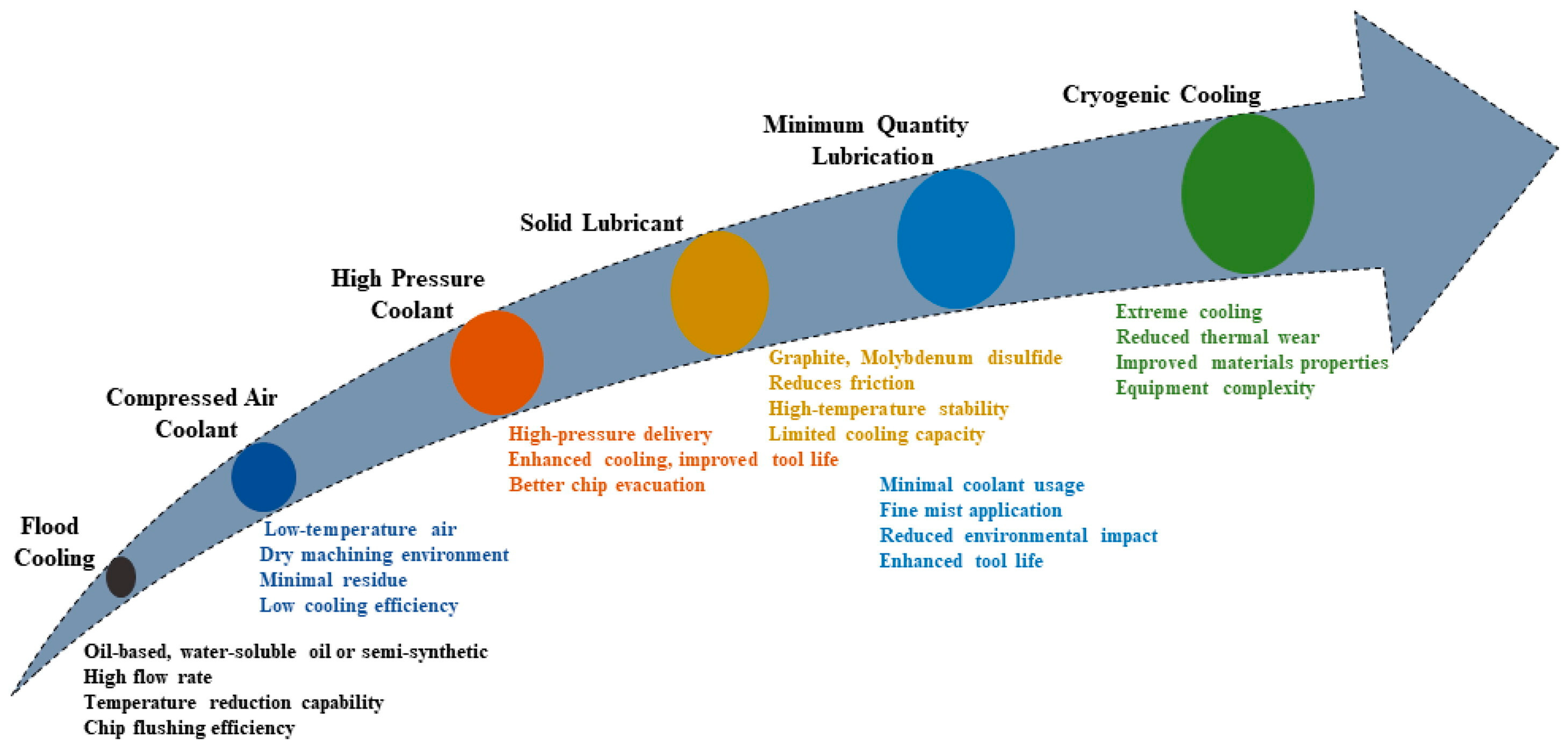

3.2. High-Efficiency Coolant

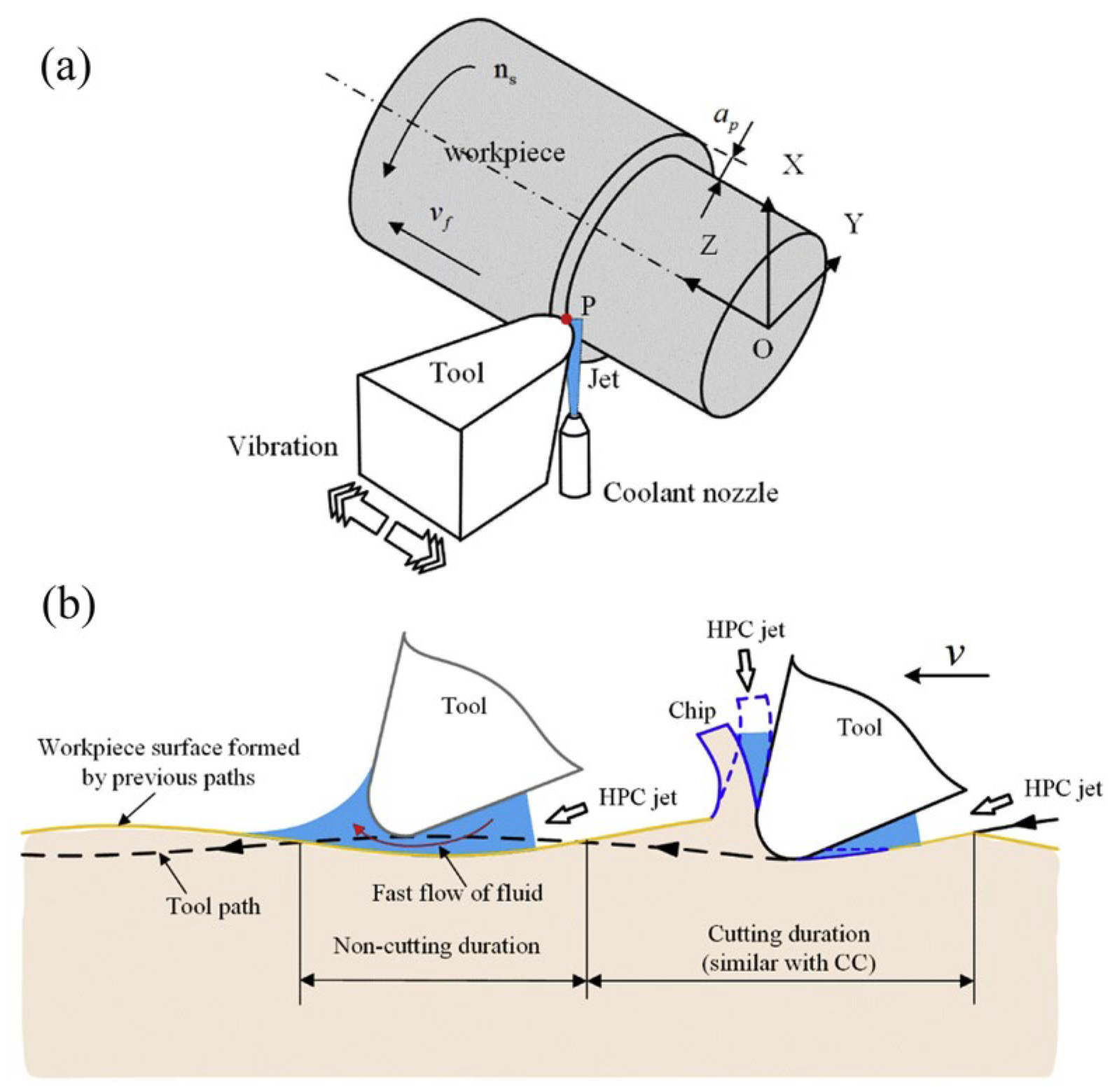

3.2.1. High-Pressure Coolant

3.2.2. Minimum Quantity Lubrication

3.2.3. Cryogenic Cooling

3.2.4. Hybrid Cooling

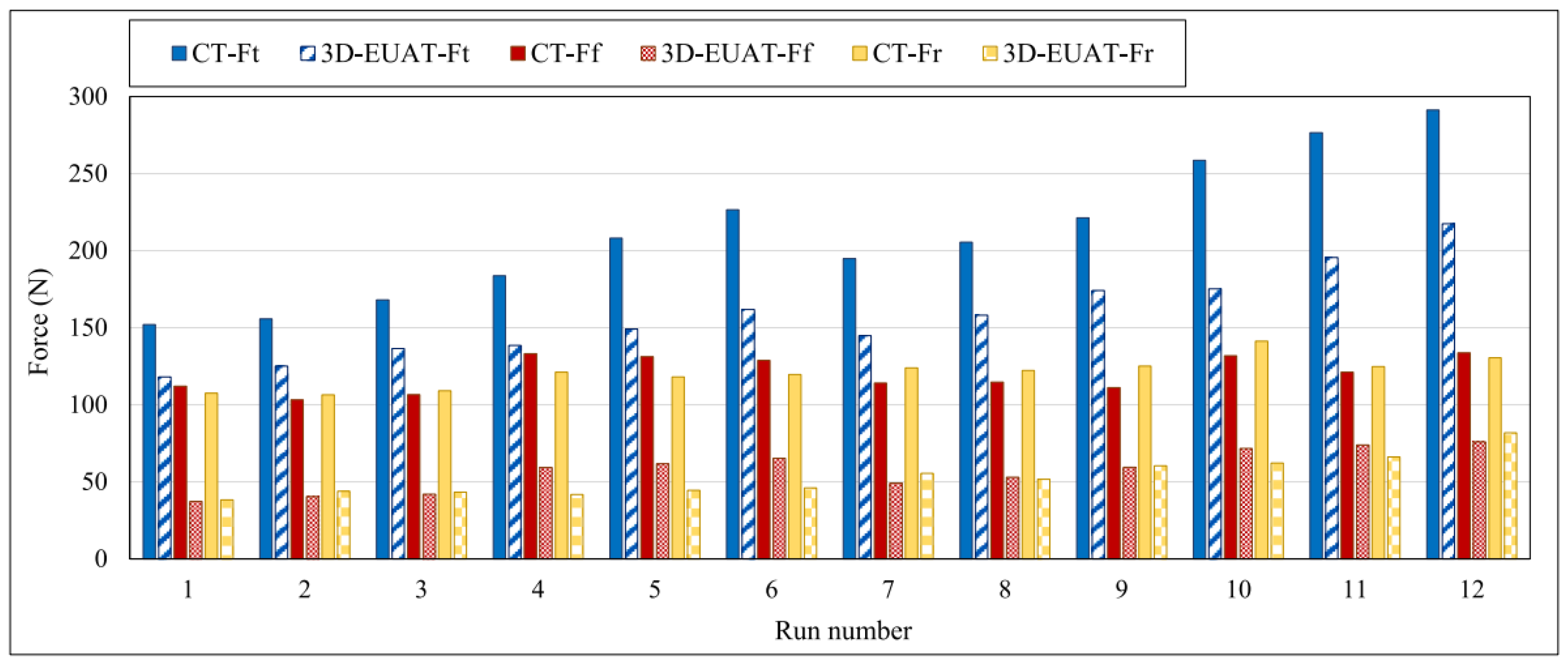

3.3. Ultrasonic Vibration Cutting

3.3.1. Turning

3.3.2. Milling

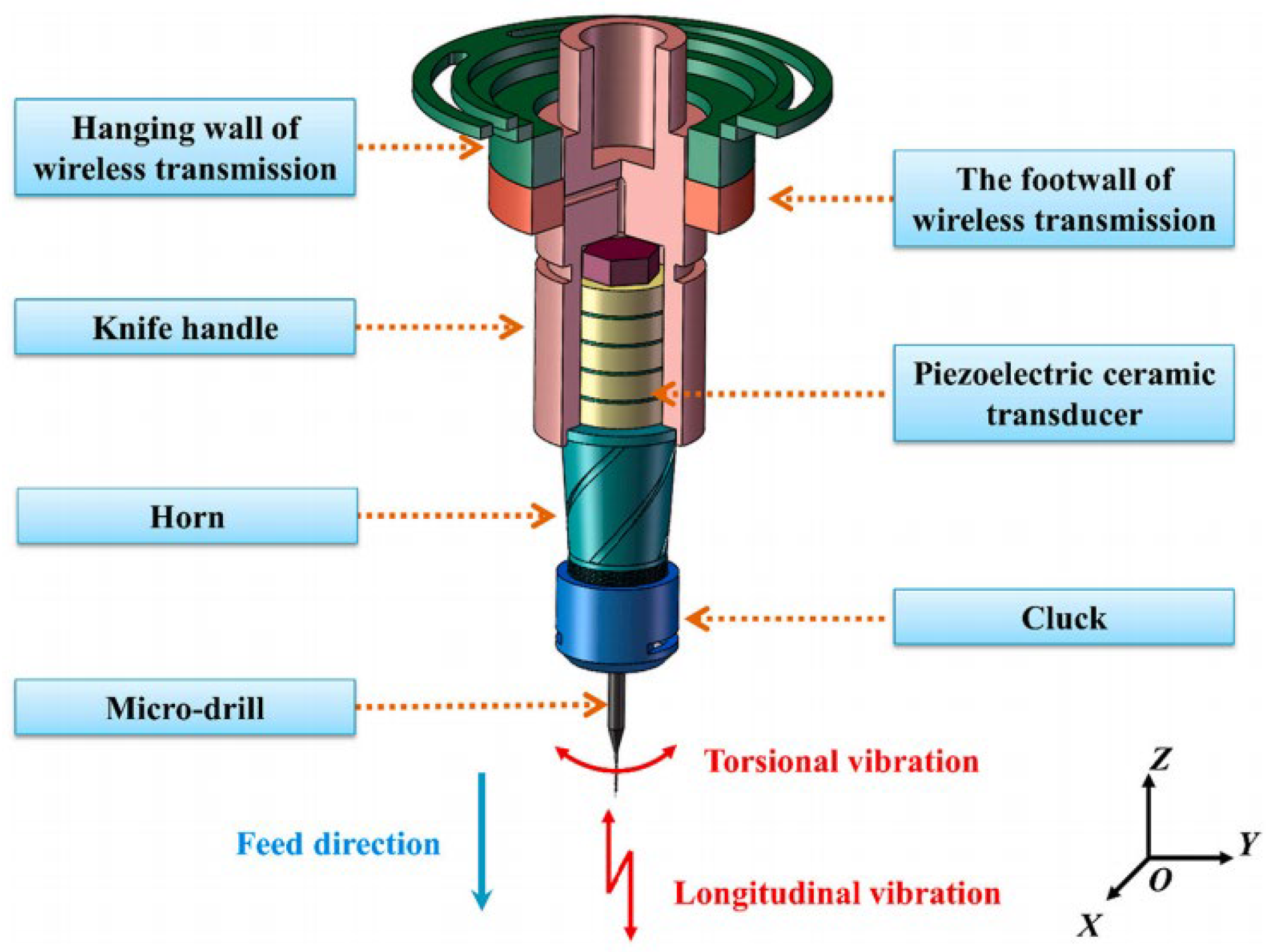

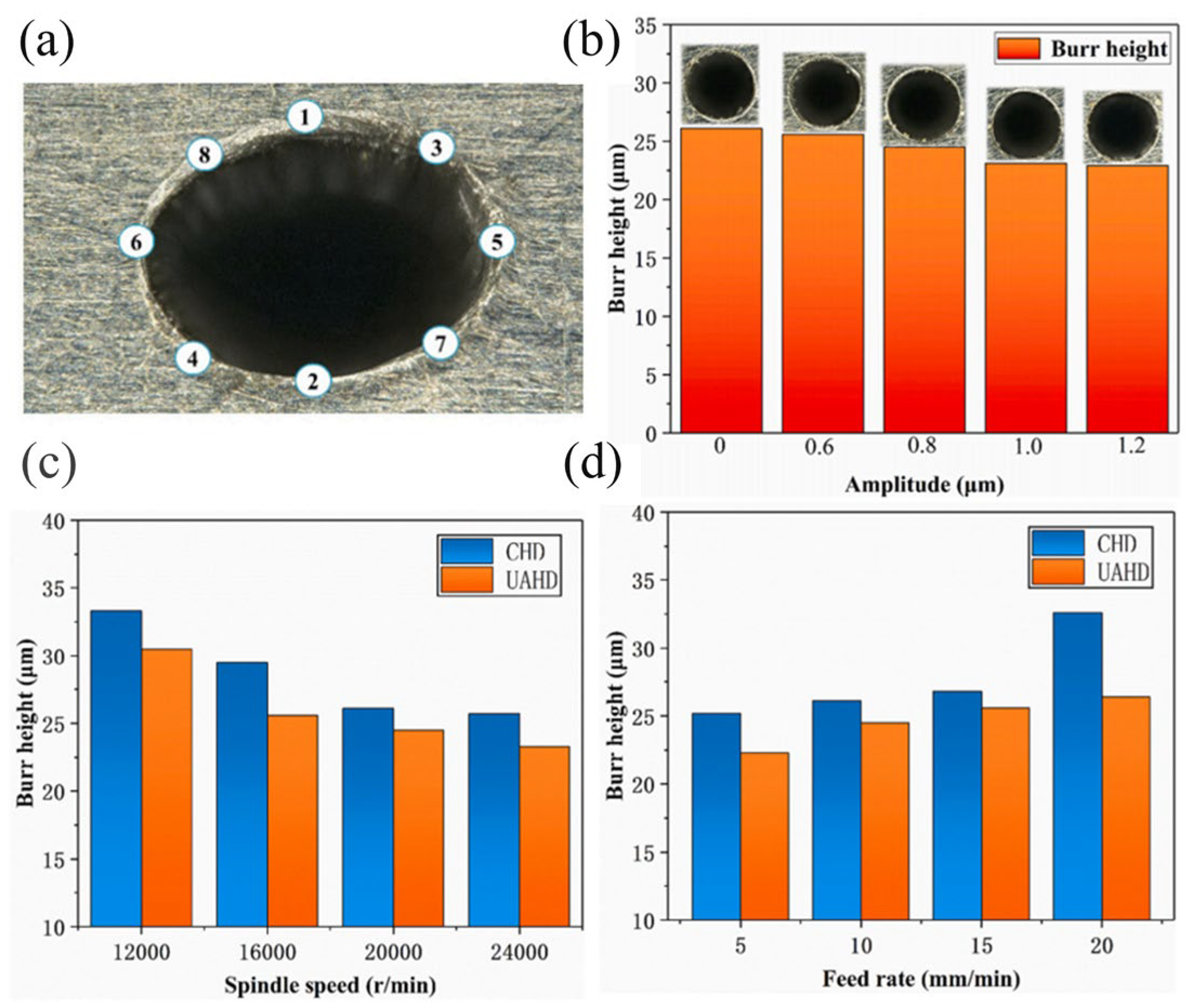

3.3.3. Drilling

3.3.4. Grinding

4. Comprehensive Analysis of the Relationship Between Cost, Efficiency, and Quality

4.1. Low Cost

4.2. High Efficiency

4.3. High Quality

4.4. Summary

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Wang, X.N.; Liu, K.; Cao, G.H.; Li, M.B.; Zhu, Z.S.; Wu, S.J. Hierarchical structure and deformation behavior of a novel multicomponent β titanium alloy with ultrahigh strength. J. Mater. Sci. Technol. 2022, 107, 227–242. [Google Scholar] [CrossRef]

- Xie, B.; Gao, K. Research Progress of Surface Treatment Technologies on Titanium Alloys: A Mini Review. Coatings 2023, 13, 1486. [Google Scholar] [CrossRef]

- Wang, M.H.; Liu, Z.H.; Wang, W. Study on Precision Machining Titanium Alloy Thin-walled Parts. Adv. Mater. Res. 2011, 314–316, 1778–1782. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic Tial alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Qu, S.; Tang, S.; Feng, A.; Feng, C.; Shen, J.; Chen, D. Microstructural evolution and high-temperature oxidation mechanisms of a titanium aluminide based alloy. Acta Mater. 2018, 148, 300–310. [Google Scholar] [CrossRef]

- Appel, F.; Clemens, H.; Fischer, F. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Gong, S.K.; Shang, Y.; Zhang, J.; Guo, X.P.; Lin, J.P.; Zhao, X.H. Application and research of typical intermetal-lics-based high temperature structural materials in China. Acta Metall. Sin. 2019, 55, 1067–1076. [Google Scholar] [CrossRef]

- Wu, X. Review of alloy and process development of TiAl alloys. Intermetallics 2006, 14, 1114–1122. [Google Scholar] [CrossRef]

- Du, Y.; Shen, J.; Xiong, Y.; Shang, Z.; Qin, L.; Fu, H. Microstructural development and room temperature tensile property of directionally solidified Ti–47Al alloys by electromagnetic confinement and directional solidification. J. Mater. Res. 2018, 33, 958–966. [Google Scholar] [CrossRef]

- Rack, H.; Qazi, J. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- Sarraf, M.; Ghomi, E.R.; Alipour, S.; Ramakrishna, S.; Sukiman, N.L. A state-of-the-art review of the fabrication and characteristics of titanium and its alloys for biomedical applications. Bio-Des. Manuf. 2022, 5, 371–395. [Google Scholar] [CrossRef] [PubMed]

- Mahmoud, A.; Wakabayashi, N.; Takahashi, H.; Ohyama, T. Deflection fatigue of Ti-6Al-7Nb, Co-Cr, and gold alloy cast clasps. J. Prosthet. Dent. 2005, 93, 183–188. [Google Scholar] [CrossRef] [PubMed]

- Grubova, I.Y.; Surmenev, R.A.; Neyts, E.C.; Koptyug, A.V.; Volkova, A.P.; Surmeneva, M.A. Combined first-principles and experimental study on the microstructure and mechanical characteristics of the multicomponent additive-manufactured Ti–35Nb–7Zr–5Ta alloy. ACS Omega 2023, 8, 27519–27533. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Zhang, W.; He, L.; Wang, J.; Zhao, D.; Wu, Z. Novel (Ti-15Mo)-xNb alloys with low elastic modulus and high strength for bio-medical applications. Chin. J. Nonferrous Met. 2023, 33, 3733–3743. [Google Scholar] [CrossRef]

- Hua, N.; Wang, W.; Wang, Q.; Ye, Y.; Lin, S.; Zhang, L.; Guo, Q.; Brechtl, J.; Liaw, P.K. Mechanical, corrosion, and wear properties of biomedical Ti–Zr–Nb–Ta–Mo high entropy alloys. J. Alloys Compd. 2021, 861, 157997. [Google Scholar] [CrossRef]

- Khan, A.; Maity, K. Statistical modelling and machinability assessment of commercially pure titanium (CP-Ti) grade II: An experimental investigation. Measurement 2019, 137, 664–672. [Google Scholar] [CrossRef]

- del Risco-Alfonso, R.; Siller, H.R.; Pérez-Rodríguez, R.; Molina, A. Study of a Novel Ceramic Tool Performance in the Machining of Ti-6Al-7Nb Alloys. MRS Adv. 2019, 4, 3007–3015. [Google Scholar] [CrossRef]

- Polini, W.; Turchetta, S. Cutting force, tool life and surface integrity in milling of titanium alloy Ti-6Al-4V with coated carbide tools. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 694–700. [Google Scholar] [CrossRef]

- Gariani, S.; Shyha, I.; Inam, F.; Huo, D. Evaluation of a Novel Controlled Cutting Fluid Impinging Supply System When Machining Titanium Alloys. Appl. Sci. 2017, 7, 560. [Google Scholar] [CrossRef]

- Hojati, F.; Daneshi, A.; Soltani, B.; Azarhoushang, B.; Biermann, D. Study on machinability of additively manufactured and conventional titanium alloys in micro-milling process. Precis. Eng. 2020, 62, 1–9. [Google Scholar] [CrossRef]

- Polishetty, A.; Shunmugavel, M.; Goldberg, M.; Littlefair, G.; Singh, R.K. Cutting force and surface finish analysis of machining additive manufactured titanium alloy Ti-6Al-4V. Procedia Manuf. 2017, 7, 284–289. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Y.F.; Sun, C.Y.; Wu, Q.Y.; Liu, J.; Yao, Y.F.; Zhang, J.H.; Wu, W. Processing of titanium alloys with improved efficiency and accuracy by laser and electrochemical machining. Int. J. Adv. Manuf. Technol. 2024, 130, 4013–4025. [Google Scholar] [CrossRef]

- Ganesan, G.; Malayath, G.; Mote, R.G. A review of cutting tools for ultra-precision machining. Mach. Sci. Technol. 2022, 26, 923–976. [Google Scholar] [CrossRef]

- Wang, S.; Yu, L.; Qin, C. Machinability improvement of titanium alloys in ultra-precision machining with mi-cro-structured surface. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2023, 238, 1362–1373. [Google Scholar] [CrossRef]

- Yip, W.S.; To, S. Sustainable Ultra-Precision Machining of Titanium Alloy Using Intermittent Cutting. Int. J. Precis. Eng. Manuf. Technol. 2020, 7, 361–373. [Google Scholar] [CrossRef]

- Li, Q.; Yang, Y.; Yang, Y.; Li, P.; Yang, G.; Liu, J.; Wu, M. Enhancing the wear performance of WC-6Co tool by pulsed magnetic field in Ti-6Al-4V machining. J. Manuf. Process. 2022, 80, 898–908. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Dong, J.; Zhao, P. Discussion on the economics and low-cost methods of titanium and titanium alloy materials. China Mater. Prog. 2015, 34, 401–406. [Google Scholar] [CrossRef]

- Kalienko, M.S.; Zhelnina, A.V.; Volkov, A.V.; Leder, M.O.; Tolstykh, N.A.; Bocharov, A.I. A New approach to estimation of the thermal conductivity of titanium alloys. Crystallogr. Rep. 2020, 65, 844–848. [Google Scholar] [CrossRef]

- Sweet, J.N.; Roth, E.P.; Moss, M. Thermal conductivity of Inconel 718 and 304 stainless steel. Int. J. Thermophys. 1987, 8, 593–606. [Google Scholar] [CrossRef]

- Nguyen, V.C.; Nguyen, T.D.; Tien, D.H. Cutting Parameter Optimization in Finishing Milling of Ti-6Al-4V Titanium Alloy under MQL Condition using TOPSIS and ANOVA Analysis. Eng. Technol. Appl. Sci. Res. 2021, 11, 6775–6780. [Google Scholar] [CrossRef]

- Kimura, T.; Sawa, T.; Kamijyo, T. Study on high speed milling of steam turbine blade materials. Adv. Mater. Res. 2016, 1136, 251–256. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhao, W.; Sun, G.B.; Zhang, A.Z. Study on surface quality of titanium alloy by ultrasonic-electrical discharge composite machining. Electromach. Mould. 2009, 299, 117334. [Google Scholar]

- Zha, X.; Yuan, Z.; Qin, H. Research status and development trends of ultrasonic impact strengthening for titanium alloys. China Mech. Eng. 2023, 34, 2269–2287. [Google Scholar] [CrossRef]

- Cai, D.; Zhao, X.; Yang, L.; Wang, R.; Qin, G.; Chen, D.-F.; Zhang, E. A novel biomedical titanium alloy with high antibacterial property and low elastic modulus. J. Mater. Sci. Technol. 2021, 81, 13–25. [Google Scholar] [CrossRef]

- Xiong, Y.; Huang, X.; Lu, B.; Wu, B.; Lu, L.; Liu, J.; Peng, K. Acceleration of floc-water separation and floc reduction with magnetic nano-particles during demulsification of complex waste cutting emulsions. J. Environ. Sci. 2020, 89, 83–92. [Google Scholar] [CrossRef]

- Qiu, M.; Wu, E.; Guo, C.; Yao, Z.; Li, J.; Zhang, Y.; Liu, Z. Research on efficient electrical discharge machining trepanning technology of TC4 titanium alloy hole. Int. J. Adv. Manuf. Technol. 2024, 132, 1497–1509. [Google Scholar] [CrossRef]

- Liu, C.-C.; Li, Y.-H.-Z.; Gu, J.; Song, M. Phase transformation in titanium alloys: A review. Trans. Nonferrous Met. Soc. China 2024, 34, 3093–3117. [Google Scholar] [CrossRef]

- Jia, C.L.; Wu, L.H.; Xue, P.; Zhang, H.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. Static spheroidization and its effect on superplasticity of fine lamellae in nugget of a friction stir welded Ti-6Al-4V joint. J. Mater. Sci. Technol. 2022, 119, 1–10. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A. Biomedical applications of titanium alloys: A comprehensive review. Materials 2024, 17, 114. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and Issues in the Application of Titanium Alloys for Aerospace Components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Moiseyev, V.N. Titanium Alloys: Russian Aircraft and Aerospace Applications; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar]

- Peters, M.; Kumpfert, J.; Ward, C.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Tabie, V.M.; Li, C.; Saifu, W.; Li, J.; Xu, X. Mechanical properties of near alpha titanium alloys for high-temperature applications—A review. Aircr. Eng. Aerosp. Technol. 2020, 92, 521–540. [Google Scholar] [CrossRef]

- Dong, R.; Li, J.; Kou, H.; Fan, J.; Tang, B. Dependence of mechanical properties on the microstructure characteristics of a near β titanium alloy Ti-7333. J. Mater. Sci. Technol. 2019, 35, 48–54. [Google Scholar] [CrossRef]

- Boyer, R.R.; Rosenberg, H.W. Beta Titanium Alloys in the 80’s; TMS-AIME Publications: Warrendale, PA, USA, 1984. [Google Scholar]

- Jamhari, F.I.; Foudzi, F.M.; Buhairi, M.A.; Sulong, A.B.; Radzuan, N.A.M.; Muhamad, N.; Mohamed, I.F.; Jamadon, N.H.; Tan, K.S. Influence of heat treatment parameters on microstructure and mechanical performance of titanium alloy in LPBF: A brief review. J. Mater. Res. Technol. 2023, 24, 4091–4110. [Google Scholar] [CrossRef]

- Fan, J.; Lai, M.; Tang, B.; Kou, H.; Li, J. Research progress of dynamic phase transformation behavior of titanium alloy under thermo-mechanical coupling process. J. Aeronaut. Mater. 2020, 40, 25–44. [Google Scholar] [CrossRef]

- Hourmand, M.; Sarhan, A.A.D.; Sayuti, M.; Hamdi, M. A comprehensive review on machining of titanium alloys. Arab. J. Sci. Eng. 2021, 46, 7087–7123. [Google Scholar] [CrossRef]

- Vajpai, S.K.; Sharma, B.; Ota, M.; Ameyama, K. Effect of cold rolling and heat-treatment on the microstructure and mechanical properties of β-titanium Ti-25Nb-25Zr alloy. Mater. Sci. Eng. A 2018, 736, 323–328. [Google Scholar] [CrossRef]

- Wang, W.; Xu, X.; Ma, R.; Xu, G.; Liu, W.; Xing, F. The Influence of Heat Treatment Temperature on Microstructures and Mechanical Properties of Titanium Alloy Fabricated by Laser Melting Deposition. Materials 2020, 13, 4087. [Google Scholar] [CrossRef]

- Velay, V.; Matsumoto, H.; Vidal, V.; Chiba, A. Behavior modeling and microstructural evolutions of Ti–6Al–4V alloy under hot forming conditions. Int. J. Mech. Sci. 2016, 108–109, 1–13. [Google Scholar] [CrossRef]

- Chen, G.; Ren, C.; Qin, X.; Li, J. Temperature dependent work hardening in Ti–6Al–4V alloy over large temperature and strain rate ranges: Experiments and constitutive modeling. Mater. Des. 2015, 83, 598–610. [Google Scholar] [CrossRef]

- He, D.; Zhu, J.; Lai, Z.; Liu, Y.; Yang, X. An experimental study of deformation mechanism and microstructure evolution during hot deformation of Ti–6Al–2Zr–1Mo–1V alloy. Mater. Des. 2013, 46, 38–48. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, H.; Zheng, J.; Ji, J.; Shi, Y.; Jia, L.; Yan, Z.; Dong, B.; Xue, Y. Microstructure of Hot Isostatically Pressed Ti-6Al-4V Alloy after Hot Deformation. Rare Met. Mater. Eng. 2019, 48, 820–826. [Google Scholar]

- Tang, X.; Ren, M.; Bu, F.; Chen, G.; Li, G.; Li, T. Strain rate dependent behaviors of a hot isotropically processed Ti-6Al-4V: Mechanisms and material model. J. Mech. Sci. Technol. 2016, 30, 661–665. [Google Scholar] [CrossRef]

- Markovsky, P.E.; Janiszewski, J.; Bondarchuk, V.I.; Stasyuk, O.O.; Savvakin, D.G.; Skoryk, M.A.; Cieplak, K.; Dziewit, P.; Prikhodko, S.V. Effect of Strain Rate on Microstructure Evolution and Mechanical Behavior of Titanium-Based Materials. Metals 2020, 10, 1404. [Google Scholar] [CrossRef]

- Pragatheswaran, T.; Rajakumar, S.; Balasubramanian, V.; Petley, V.; Verma, S. Effect of holding time on microstructural characteristics and mechanical properties of Ti64 diffusion bonds. In Advances in Additive Manufacturing And Joining; Shunmugam, M., Kanthababu, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 793–805. [Google Scholar]

- Min, W.; Darong, H.; Ya, F.; YongQuan, N.; Hongzhen, G.; Zekun, Y. Influence of heat treatment on the microstructure and mechanical properties of TC17 titanium alloy. MATEC Web Conf. 2018, 190, 07002. [Google Scholar] [CrossRef]

- Campanella, D.; Buffa, G.; El Hassanin, A.; Squillace, A.; Gagliardi, F.; Filice, L.; Fratini, L. Mechanical and microstructural characterization of titanium gr.5 parts produced by different manufacturing routes. Int. J. Adv. Manuf. Technol. 2022, 122, 741–759. [Google Scholar] [CrossRef]

- Topolski, K.; Garbacz, H.; Pachla, W.; Kurzydlowski, K.J. The Influence of the Initial State on Microstructure and Mechanical Properties of Hydrostatically Extruded Titanium. Solid State Phenom. 2008, 140, 191–196. [Google Scholar] [CrossRef]

- Muroga, T.; Nagasaka, T.; Zheng, P.F.; Chen, J. Microstructural Control for Improving Properties of V-4Cr-4Ti Alloys. In Advances in Science and Technology. In Materials Challenges for Future Nuclear Fission and Fusion Technologies; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2010. [Google Scholar]

- Wang, B.; Liu, Z. Influences of tool structure, tool material and tool wear on machined surface integrity during turning and milling of titanium and nickel alloys: A review. Int. J. Adv. Manuf. Technol. 2018, 98, 1925–1975. [Google Scholar] [CrossRef]

- Li, M.; Yue, C.; Liu, X.; Chen, Z.; Jiang, Z.; Yue, D.; Steven, Y.L. Research on design and application of endmill for milling titanium alloy frame parts. J. Mech. Eng. 2023, 59, 283–309. [Google Scholar] [CrossRef]

- Li, C.; Qiao, J.; Zheng, Q.; Xiong, T.; Zeng, Z.; Guo, Z.; Yang, T. Research Progress on the Application of Rare Metal Elements in Cemented Carbides. Rare Met. Cem. Carbides 2024, 52, 69–74. [Google Scholar] [CrossRef]

- Bose, A.; Reidy, J.P.; Pötschke, J. Sinter-based additive manufacturing of hardmetals: Review. Int. J. Refract. Met. Hard Mater. 2024, 119, 106493. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, Z.; Qin, Y.; Bao, Z.; Luo, L. Ultrafine/nano WC-Co cemented carbide: Overview of preparation and key technologies. J. Mater. Res. Technol. 2023, 27, 5822–5839. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, H.; Zhao, C.; Hu, H.; Liu, X.; Song, X. Nanocrystalline WC-Co composite with ultrahigh hardness and toughness. Compos. Part B Eng. 2020, 197, 108161. [Google Scholar] [CrossRef]

- Walbrühl, M.; Linder, D.; Bonvalet, M.; Ågren, J.; Borgenstam, A. ICME guided property design: Room temperature hardness in cemented carbides. Mater. Des. 2019, 161, 35–43. [Google Scholar] [CrossRef]

- Zhao, X.; Ke, W.; Zhang, S.; Zheng, W. Potential failure cause analysis of tungsten carbide end mills for titanium alloy machining. Eng. Fail. Anal. 2016, 66, 321–327. [Google Scholar] [CrossRef]

- Kumar, T.S.; Prabu, S.B.; Vasu, K.; Krishna, M.G. Metallurgical characteristics and machining performance of nanostructured TNN-coated tungsten carbide tool. Int. J. Mater. Res. 2015, 106, 378–390. [Google Scholar] [CrossRef]

- Liu, H.; Tang, J.; Yan, Z.; Li, W.; Tang, D.; Hong, N.; Teng, F. Research on the correlation mechanism between powder characteristics, alloy proper-ties, and tool cutting life of cemented carbide. China Tungsten Ind. 2024, 39, 64–71. [Google Scholar] [CrossRef]

- Huang, S.; Xiong, J.; Guo, Z.; Wan, W.; Tang, L.; Zhong, H.; Zhou, W.; Wang, B. Oxidation of WC-TiC-TaC-Co hard materials at relatively low temperature. Int. J. Refract. Met. Hard Mater. 2015, 48, 134–140. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, H.; Wang, Q.; Ma, Z.; Chen, L. Effects of carbide inhibitor on microstructures and mechanical properties of ultrafine grained carbide cement WC-2.5TiC-10Co. Chin. J. Mater. Res. 2015, 29, 881–888. [Google Scholar]

- Guo, S.; Yan, W.; Yi, J.; Wang, S.; Huang, X.; Yang, S.; Zhang, M.; Ye, Y. The optimization of mechanical property and corrosion resistance of WC-6Co cemented carbide by Mo2C content. Ceram. Int. 2020, 46, 17243–17251. [Google Scholar] [CrossRef]

- Guo, S.; Bao, R.; Li, S.; Ye, Y.; Zhu, E.; Wang, W.; Zhang, Y.; Chen, H.; Ye, Y. The role of Y2O3, Cu, Mo and Mo2C additives on optimizing the corrosion resistance of WC-6Co cemented carbide in HCl and NaOH solutions. J. Alloys Compd. 2020, 827, 154269. [Google Scholar] [CrossRef]

- Harouz, R.; Zelmatı, D.; Khelil, K. Machine learning application for wear rate prediction of WC/Co-based cermet with different content of Ni, Cr, TiC, TaC, and NbC. Int. J. Adv. Manuf. Technol. 2024, 135, 5945–5959. [Google Scholar] [CrossRef]

- Lin, T.; Li, Q.; Han, Y.; Song, K.; Wang, X.; Shao, H.; Dong, J.; Wang, H.; Deng, X. Effects of Nb and NbC additives on microstructure and properties of WC-Co-Ni cemented carbides. Int. J. Refract. Met. Hard Mater. 2022, 103, 595–602. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, J.; Yang, Y.; Xiong, X.; Xu, T.; Zhang, J.; Liu, X.; Yao, P. Effect of additives on high-temperature oxidation resistance of extra-coarse grained and ultra-coarse grained cemented carbides. Powder Metall. Mater. Sci. Eng. 2015, 20, 595–602. [Google Scholar]

- Chandru, M.; Selladurai, V.; Venkatesh, C. Experimental evaluation of machinability performance of CNT coated HSS tool during turning of titanium alloy. J. Mech. Sci. Technol. 2021, 35, 2141–2150. [Google Scholar] [CrossRef]

- Dang, M.N.; Singh, S.; King, H.J.; Navarro-Devia, J.H.; Le, H.; Pattison, T.G.; Hocking, R.K.; Wade, S.A.; Stephens, G.; Papageorgiou, A.; et al. Surface Enhancement of Titanium-Based Coatings on Commercial Hard Steel Cutting Tools. Crystals 2024, 14, 470. [Google Scholar] [CrossRef]

- Sun, J.; He, R.; Niu, G.; Xie, L.; Chen, X.; Fang, L. Sound velocities, elasticity and thermal properties of cBN com-posite with AlN binder at high pressure. Ceram. Int. 2024, 50, 27080–27085. [Google Scholar] [CrossRef]

- Xiao, C.; Zheng, H.; Tao, H.; Ma, J.; Zhang, Q.; Tang, L. Effect of particle size of cubic boron nitride powders on the properties of polycrystalline cubic boron nitride composites. Bull. Mater. Sci. 2024, 47, 1–9. [Google Scholar] [CrossRef]

- Rumiantseva, Y.; Laszkiewicz-Łukasik, J.; Podsiadło, M.; Chat-Wilk, K.; Momot, K.; Boroń, Ł.; Klimczyk, P. Development of two-layer whisker-reinforced PcBN materials for cutting tool applications. Ceram. Int. 2025, 51, 1271–1280. [Google Scholar] [CrossRef]

- Nayeri, M.R.; Abootorabi, M.M. New generation nano-cbn cutting tool for increasing sustainability of hard turning process. Surf. Rev. Lett. 2022, 29, 2250139. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Zhang, G.; Huo, Z.; Huang, Z.; Wu, L. A review of diamond synthesis, modification technology, and cutting tool application in ultra-precision machining. Mater. Des. 2024, 237, 112577. [Google Scholar] [CrossRef]

- Khmelnitskiy, R.A. Prospects for the synthesis of large single-crystal diamonds. Physics-Uspekhi 2015, 58, 134–149. [Google Scholar] [CrossRef]

- Chen, D.; Lin, H.; Chen, Y.; Yan, C.; Xu, J. Wear behaviors of PCD and diamond-coated tools during low-frequency vibration-assisted drilling CFRP/Ti stacks. Int. J. Adv. Manuf. Technol. 2023, 128, 595–609. [Google Scholar] [CrossRef]

- Childerhouse, T.; M’saoubi, R.; Franca, L.F.; Crawforth, P.; Jackson, M. Machining performance and wear behaviour of polycrystalline diamond and coated carbide tools during milling of titanium alloy Ti-54M. Wear 2023, 523, 204791. [Google Scholar] [CrossRef]

- Kong, F.; Zhao, W.; Li, H.; He, N. Effect of grain size and cobalt content on machining performance during milling tungsten carbide with PCD tool. Int. J. Refract. Met. Hard Mater. 2024, 123, 106780. [Google Scholar] [CrossRef]

- Denkena, B.; Köhler, J.; Ventura, C. Customized cutting edge preparation by means of grinding. Precis. Eng. 2013, 37, 590–598. [Google Scholar] [CrossRef]

- You, Z.; Yuan, H.; Ye, X. Numerical Investigation on the Effect of Cutting-Edge Shape Factor on the Cutting Performance of Titanium Alloy. Coatings 2023, 13, 1048. [Google Scholar] [CrossRef]

- Shokrani, A.; Newman, S.T. A new cutting tool design for cryogenic machining of Ti–6Al–4V titanium alloy. Materials 2019, 12, 477. [Google Scholar] [CrossRef]

- Tran, H.N.; Tran, A.S.; Nguyen, T.H.; Nguyen, T.P. Design of 2D wave booster ultrasonic vibration-assisted cutting tool in small size surface machining. Key Eng. Mater. 2022, 923, 75–83. [Google Scholar] [CrossRef]

- Cheng, Y.; Yang, J.; Qin, C.; Zuo, D. Tool design and cutting parameter optimization for side milling blisk. Int. J. Adv. Manuf. Technol. 2018, 100, 2495–2508. [Google Scholar] [CrossRef]

- Zhao, G.; Zhao, B.; Ding, W.; Xin, L.; Nian, Z.; Peng, J.; He, N.; Xu, J. Nontraditional energy-assisted mechanical machining of difficult-to-cut materials and components in aerospace community: A comparative analysis. Int. J. Extreme Manuf. 2024, 6, 022007. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, B.; Khan, A.M.; Liu, Z.; Cai, Y.; Song, Q. Integrating textured tools and diverse lubricooling approaches in machining performance of Ti and Ni-base alloys—A comprehensive review. Mach. Sci. Technol. 2024, 28, 323–391. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, Z.; Kuriyagawa, T.; Gonda, H. Fabricating micro-structured surface by using single-crystalline diamond endmill. Int. J. Adv. Manuf. Technol. 2010, 51, 957–964. [Google Scholar] [CrossRef]

- Dhage, S.; Jayal, A.D.; Sarkar, P. Effects of surface texture parameters of cutting tools on friction conditions at tool-chip interface during dry machining of AISI 1045 steel. Procedia Manuf. 2019, 33, 794–801. [Google Scholar] [CrossRef]

- Parida, A.K.; Rao, P.V.; Ghosh, S. Performance of textured tool in turning of Ti–6Al–4V alloy: Numerical analysis and experimental validation. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 255. [Google Scholar] [CrossRef]

- Fouathiya, A.; Meziani, S.; Sahli, M.; Barrière, T. Experimental investigation of microtextured cutting tool performance in titanium alloy via turning. J. Manuf. Process. 2021, 69, 33–46. [Google Scholar] [CrossRef]

- Zheng, K.; Yang, F.; Zhang, N.; Liu, Q.; Jiang, F. Study on the Cutting Performance of Micro Textured Tools on Cutting Ti-6Al-4V Titanium Alloy. Micromachines 2020, 11, 137. [Google Scholar] [CrossRef]

- Li, Q.; Yang, S.; Zhang, Y.; Zhou, Y.; Cui, J. Evaluation of the machinability of titanium alloy using a micro-textured ball end milling cutter. Int. J. Adv. Manuf. Technol. 2018, 98, 2083–2092. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Z.; Wang, B.; Wang, C.; Cheung, C.F. Friction behaviors in the metal cutting process: State of the art and future perspectives. Int. J. Extreme Manuf. 2023, 5, 012002. [Google Scholar] [CrossRef]

- Pham, H.-V.; Nguyen, H.-P.; Shailesh, S.; Nguyen, D.-T.; Bui, N.-T. Improving micro-Edm machining efficiency for titanium alloy fabrication with advanced coated electrodes. Micromachines 2024, 15, 692. [Google Scholar] [CrossRef]

- Cheng, Y.; Browne, T.; Heckerman, B.; Meletis, E. Influence of the C content on the mechanical and tribological properties of the TiCN coatings deposited by LAFAD technique. Surf. Coat. Technol. 2011, 205, 4024–4029. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Zhu, X.F.; Zhang, J.J.; Li, J.Y. Microstructure and cutting performance of TiCN and TiN tool coatings deposited by ion plating. Tool Eng. 2010, 44, 18–21. [Google Scholar] [CrossRef]

- Abdullah, R.I.R.; Redzuwan, B.I.; Aziz, M.S.A.; Kasim, M.S. Comparative study of tool wear in milling titanium alloy (Ti-6Al-4V) using PVD and CVD coated cutting tool. Ind. Lubr. Tribol. 2017, 69, 363–370. [Google Scholar] [CrossRef]

- Chen, L.; Du, Y.; Yin, F.; Li, J. Mechanical properties of (Ti, Al)N monolayer and TiN/(Ti, Al)N multilayer coatings. Int. J. Refract. Met. Hard Mater. 2007, 25, 72–76. [Google Scholar] [CrossRef]

- Uddin, G.M.; Joyia, F.M.; Ghufran, M.; Khan, S.A.; Raza, M.A.; Faisal, M.; Arafat, S.M.; Zubair, S.W.H.; Jawad, M.; Zafar, M.Q.; et al. Comparative performance analysis of cemented carbide, TiN, TiAlN, and PCD coated inserts in dry machining of Al 2024 alloy. Int. J. Adv. Manuf. Technol. 2021, 112, 1461–1481. [Google Scholar] [CrossRef]

- Thepsonthi, T.; Özel, T. Experimental and finite element simulation based investigations on micro-milling Ti-6Al-4V titanium alloy: Effects of cBN coating on tool wear. J. Mech. Work. Technol. 2013, 213, 532–542. [Google Scholar] [CrossRef]

- Ali, A.; Younas, M.; Khan, M.; Jaffery, S.H.I.; Khan, Z. Machinability performance of single coated and multicoated carbide tools during turning Ti6Al4V Alloy. Int. J. Precis. Eng. Manuf. 2025, 26, 43–58. [Google Scholar] [CrossRef]

- Fan, G.; Zhang, J.; Chen, H.; Xiao, G.; Chen, Z.; Yi, M.; Xu, C.; Fan, L.; Li, G. Analysis of tool wear of TiAlN coated tool, machined surface morphology and chip during titanium alloy milling. Tribol. Int. 2024, 197, 109751. [Google Scholar] [CrossRef]

- He, Q.; Saciotto, V.; DePaiva, J.M.; Guimaraes, M.C.; Kohlscheen, J.; Martins, M.M.; Veldhuis, S.C. Enhancing tool performance in high-speed end milling of Ti-6Al-4V alloy: The role of AlCrN PVD coatings and resistance to chipping wear. J. Manuf. Mater. Process. 2024, 8, 68. [Google Scholar] [CrossRef]

- Vereschaka, A.; Gurin, V.; Oganyan, M.; Oganyan, G.; Bublikov, J.; Shein, A. Increase in tool life for end milling titanium alloys using tools with multilayer composite nanostructured modified coatings. Procedia CIRP 2019, 81, 1412–1416. [Google Scholar] [CrossRef]

- Li, G.; Lü, W.; Liu, S.; Li, C.; Zhou, Y.; Wang, Q. Multilayer-growth of TiAlN/WS self-lubricating composite coatings with high adhesion and their cutting performance on titanium alloy. Compos. Part B Eng. 2021, 211, 108620. [Google Scholar] [CrossRef]

- Kaminski, J.; Alvelid, B. Temperature reduction in the cutting zone in water-jet assisted turning. J. Mater. Process. Technol. 2000, 106, 68–73. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J. Effect of high-pressure coolant supply when machining nickel-base, Inconel 718, alloy with coated carbide tools J. Mater. Process. Technol. 2004, 153, 1045–1050. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J.; Da Silva, R.B.; Çakir, O. Surface integrity of finished turned Ti–6Al–4V alloy with PCD tools using conventional and high pressure coolant supplies. Int. J. Mach. Tools Manuf. 2007, 47, 884–891. [Google Scholar] [CrossRef]

- Masek, P.; Maly, J.; Zeman, P.; Heinrich, P.; Alagan, N.T. Turning of titanium alloy with PCD tool and high-pressure cooling. J. Manuf. Process. 2022, 84, 871–885. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, D.; Zhang, X.; Peng, Z. Effects of high-pressure coolant on cutting performance of high-speed ultrasonic vibration cutting titanium alloy. J. Mech. Work. Technol. 2020, 279, 116584. [Google Scholar] [CrossRef]

- Mao, J.; Usuki, H.; Tanaka, R.; Morigo, C.; Yukinari, S. Research on effect of ultra-high pressure coolant supplied from flank face in end milling of Ti-6Al-4V supported by CFD simulations. J. Manuf. Process. 2024, 118, 15–31. [Google Scholar] [CrossRef]

- Ezugwu, E.; Da Silva, R.; Bonney, J.; Machado, Á. Evaluation of the performance of CBN tools when turning Ti–6Al–4V alloy with high pressure coolant supplies. Int. J. Mach. Tools Manuf. 2005, 45, 1009–1014. [Google Scholar] [CrossRef]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S.; Jamil, M.; Pimenov, D.Y.; Khanna, N. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Process. 2021, 62, 179–201. [Google Scholar] [CrossRef]

- Sharma, V.S.; Singh, G.; Sørby, K. A Review on Minimum Quantity Lubrication for Machining Processes. Mater. Manuf. Process. 2015, 30, 935–953. [Google Scholar] [CrossRef]

- Sun, J.; Wong, Y.S.; Rahman, M.; Wang, Z.G.; Neo, K.S.; Tan, C.H.; Onozuka, H. Effects of coolant supply methods and cutting conditions on tool life in end milling titanium alloy. Mach. Sci. Technol. 2006, 10, 355–370. [Google Scholar] [CrossRef]

- Yuan, S.; Yan, L.; Liu, W.; Liu, Q. Effects of cooling air temperature on cryogenic machining of Ti–6Al–4V alloy. J. Mech. Work. Technol. 2011, 211, 356–362. [Google Scholar] [CrossRef]

- Sivarupan, T.; Bermingham, M.; Ng, C.-H.; Sun, S.; Dargusch, M. A review of the use of cryogenic coolant during machining titanium alloys. Sustain. Mater. Technol. 2024, 40, e00946. [Google Scholar] [CrossRef]

- Sartori, S.; Moro, L.; Ghiotti, A.; Bruschi, S. On the tool wear mechanisms in dry and cryogenic turning Additive Manufactured titanium alloys. Tribol. Int. 2017, 105, 264–273. [Google Scholar] [CrossRef]

- Hong, S.Y.; Markus, I.; Jeong, W.-C. New cooling approach and tool life improvement in cryogenic machining of titanium alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2001, 41, 2245–2260. [Google Scholar] [CrossRef]

- Bermingham, M.; Kirsch, J.; Sun, S.; Palanisamy, S.; Dargusch, M. New observations on tool life, cutting forces and chip morphology in cryogenic machining Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2011, 51, 500–511. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Palanisamy, S.; Dargusch, M.S. Effect of cryogenic compressed air on the evolution of cutting force and tool wear during machining of Ti–6Al–4V alloy. J. Mech. Work. Technol. 2015, 221, 243–254. [Google Scholar] [CrossRef]

- Busch, K.; Hochmuth, C.; Pause, B.; Stoll, A.; Wertheim, R. Investigation of cooling and lubrication strategies for machining high-temperature alloys. Procedia CIRP 2016, 41, 835–840. [Google Scholar] [CrossRef]

- Gupta, M.K.; Niesłony, P.; Sarikaya, M.; Korkmaz, M.E.; Kuntoğlu, M.; Królczyk, G.; Jamil, M. Tool wear patterns and their promoting mechanisms in hybrid cooling assisted machining of titanium Ti-3Al-2.5V/grade 9 alloy. Tribol. Int. 2022, 174, 107773. [Google Scholar] [CrossRef]

- Chen, G.; Caudill, J.; Chen, S.; Jawahir, I. Machining-induced surface integrity in titanium alloy Ti-6Al-4V: An investigation of cutting edge radius and cooling/lubricating strategies. J. Manuf. Process. 2022, 74, 353–364. [Google Scholar] [CrossRef]

- Bagherzadeh, A.; Kuram, E.; Budak, E. Experimental evaluation of eco-friendly hybrid cooling methods in slot milling of titanium alloy. J. Clean. Prod. 2021, 289, 125817. [Google Scholar] [CrossRef]

- Khan, A.M.; Zhao, W.; Li, L.; Alkahtani, M.; Hasnain, S.; Jamil, M.; He, N. Assessment of cumulative energy demand, production cost, and CO2 emission from hybrid CryoMQL assisted machining. J. Clean. Prod. 2021, 292, 125952. [Google Scholar] [CrossRef]

- Grguraš, D.; Sterle, L.; Pušavec, F. Cutting forces and chip morphology in LCO2 + MQL assisted robotic drilling of Ti6Al4V. Procedia CIRP 2021, 102, 299–302. [Google Scholar] [CrossRef]

- Kalsi, N.S.; Sehgal, R.; Sharma, V.S. Cryogenic Treatment of Tool Materials: A Review. Mater. Manuf. Process. 2010, 25, 1077–1100. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, D.; Zhang, X. Chatter stability and precision during high-speed ultrasonic vibration cutting of a thin-walled titanium cylinder. Chin. J. Aeronaut. 2020, 33, 3535–3549. [Google Scholar] [CrossRef]

- Kurniawan, R.; Ahmed, F.; Ali, S.; Park, G.C.; Ko, T.J. Analytical, FEA, and experimental research of 2D-vibration assisted cutting (2D-VAC) in titanium alloy Ti6Al4V. Int. J. Adv. Manuf. Technol. 2021, 117, 1739–1764. [Google Scholar] [CrossRef]

- Sun, Z.; Shuang, F.; Ma, W. Investigations of vibration cutting mechanisms of Ti6Al4V alloy. Int. J. Mech. Sci. 2018, 148, 510–530. [Google Scholar] [CrossRef]

- Xie, H.; Wang, Z. Study of cutting forces using FE, ANOVA, and BPNN in elliptical vibration cutting of titanium alloy Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 105, 5105–5120. [Google Scholar] [CrossRef]

- Kurniawan, R.; Kumaran, S.T.; Ali, S.; Nurcahyaningsih, D.A.; Kiswanto, G.; Ko, T.J. Experimental and analytical study of ultrasonic elliptical vibration cutting on AISI 1045 for sustainable machining of round-shaped microgroove pattern. Int. J. Adv. Manuf. Technol. 2018, 98, 2031–2055. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K.; Bertolini, R.; Krolczyk, G.M.; Khanna, N. Sustainable cooling strategies to reduce tool wear, power consumption and surface roughness during ultrasonic assisted turning of Ti-6Al-4V. Tribol. Int. 2022, 169, 107494. [Google Scholar] [CrossRef]

- Llanos, I.; Campa, Á.; Iturbe, A.; Arrazola, P.J.; Zelaieta, O. Experimental Analysis of Cutting Force Reduction During Ultrasonic Assisted Turning of Ti6Al4V. Procedia CIRP 2018, 77, 86–89. [Google Scholar] [CrossRef]

- Bejjani, R.; Bachir, E.; Salame, C. Advanced Manufacturing of Titanium Alloy Ti-6Al-4V by Combining Cryogenic Machining and Ultrasonic-Assisted Turning. J. Mater. Eng. Perform. 2024, 33, 6507–6527. [Google Scholar] [CrossRef]

- Gürgen, S.; Çakır, F.H.; Sofuoğlu, M.A.; Orak, S.; Kuşhan, M.C.; Li, H. Multi-criteria decision-making analysis of different non-traditional machining operations of Ti6Al4V. Soft Comput. 2019, 23, 5259–5272. [Google Scholar] [CrossRef]

- Hu, K.; Lo, S.-L.; Wu, H.; To, S. Study on Influence of Ultrasonic Vibration on the Ultra-Precision Turning of Ti6Al4V Alloy Based on Simulation and Experiment. IEEE Access 2019, 7, 33640–33651. [Google Scholar] [CrossRef]

- Lotfi, M.; Amini, S.; Akbari, J. Surface integrity and microstructure changes in 3D elliptical ultrasonic assisted turning of Ti–6Al–4V: FEM and experimental examination. Tribol. Int. 2020, 151, 106492. [Google Scholar] [CrossRef]

- Bachir, E.; Bejjani, R. An experimental and FEM study on ultrasonic-assisted turning of titanium alloy. Mach. Sci. Technol. 2023, 27, 350–379. [Google Scholar] [CrossRef]

- Geng, D.; Sun, Z.; Liu, Y.; Liu, L.; Ying, E.; Cai, J.; Jiang, X.; Zhang, D. Unravelling the influence of vibration on material removal and microstructure evolution in ultrasonic transversal vibration-assisted helical milling of Ti-6Al-4V holes. J. Mech. Work. Technol. 2024, 326, 118320. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, X.; Han, X.; Gao, Z.; Zhang, D. Effects of rotary ultrasonic elliptical machining for side milling on the surface integrity of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 101, 1451–1465. [Google Scholar] [CrossRef]

- Qin, S.; Zhu, L.; Qin, D.; Yang, Z.; Lu, H. Tool–workpiece separation characteristic and surface generation in ultrasonic assisted milling. Mech. Based Des. Struct. Mach. 2024, 52, 3182–3209. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, D.; Guo, H.; Gao, Z.; Geng, D.; Liu, J.; Jiang, X. High-Speed Rotary Ultrasonic Elliptical Milling of Ti-6Al-4V Using High-Pressure Coolant. Metals 2020, 10, 500. [Google Scholar] [CrossRef]

- Zarchi, M.M.A.; Razfar, M.R.; Abdullah, A. Investigation of the effect of cutting speed and vibration amplitude on cutting forces in ultrasonic-assisted milling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 1185–1191. [Google Scholar] [CrossRef]

- Lü, Q.; Yang, S.; Yang, L.; Liu, E.; Li, G.; Xiang, D. Optimization milling force and surface roughness of ti-6al-4v based on ultrasonic-assisted milling (UAM): An Experimental Study. Micromachines 2023, 14, 1699. [Google Scholar] [CrossRef] [PubMed]

- Ying, N.; Feng, J.; Bo, Z. A novel 3D finite element simulation method for longitudinal-torsional ultrasonic-assisted milling. Int. J. Adv. Manuf. Technol. 2020, 106, 385–400. [Google Scholar] [CrossRef]

- Namlu, R.H.; Sadigh, B.L.; Kiliç, S.E. An experimental investigation on the effects of combined application of ultrasonic assisted milling (UAM) and minimum quantity lubrication (MQL) on cutting forces and surface roughness of Ti-6AL-4V. Mach. Sci. Technol. 2021, 25, 738–775. [Google Scholar] [CrossRef]

- Ko, J.H.; Shaw, K.C.; Chua, H.K.; Lin, R.M. The Effect of One Directional Ultrasonic Vibration Assistance in High Speed Meso-Scale Milling Process. Key Eng. Mater. 2010, 447–448, 41–45. [Google Scholar] [CrossRef]

- Su, Y.; Li, L. An investigation of cutting performance and action mechanism in ultrasonic vibration-assisted milling of ti6al4v using a PCD tool. Micromachines 2021, 12, 1319. [Google Scholar] [CrossRef]

- Yang, H.; Ding, W.; Chen, Y.; Laporte, S.; Xu, J.; Fu, Y. Drilling Force Model for Forced Low Frequency Vibration Assisted Drilling of Ti-6Al-4V Titanium Alloy. Int. J. Mach. Tools Manuf. 2019, 146, 103438. [Google Scholar] [CrossRef]

- Cong, W.; Pei, Z.; Treadwell, C. Preliminary Study on Rotary Ultrasonic Machining of CFRP/Ti Stacks. Ultrasonics 2014, 54, 1594–1602. [Google Scholar] [CrossRef]

- Moghaddas, M.A.; Graff, K.F. On the effect of load on vibration amplitude in ultrasonic-assisted drilling. Int. J. Adv. Manuf. Technol. 2020, 106, 3081–3094. [Google Scholar] [CrossRef]

- Iqbal, A.; Zhao, G.; Zaini, J.; Gupta, M.K.; Jamil, M.; He, N.; Nauman, M.M.; Mikolajczyk, T.; Pimenov, D.Y. Between-the-Holes Cryogenic Cooling of the Tool in Hole-Making of Ti-6Al-4V and CFRP. Materials 2021, 14, 795. [Google Scholar] [CrossRef]

- Liu, F.; Chen, T.; Duan, Z.; Suo, Y.; Zhang, C. Ultrasonic assisted pecking drilling process for CFRP/Ti laminated materials. J. Manuf. Process. 2023, 108, 834–851. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, Z.; Wang, X.; Jiao, F.; Li, Y. Research on the Entrance Damage of Carbon Fiber-Reinforced Polymer/Ti6Al4V Stacks in Six-Degrees-of-Freedom Robot Drilling. Machines 2024, 12, 881. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, D.; Jiang, X.; Qin, W.; Geng, D. Study on rotary ultrasonic-assisted drilling of titanium alloys (Ti6Al4V) using 8-facet drill under no cooling condition. Int. J. Adv. Manuf. Technol. 2017, 90, 3249–3264. [Google Scholar] [CrossRef]

- Zai, P.; Tong, J.; Liu, Z.; Zhang, Z.; Song, C.; Zhao, B. Analytical model of exit burr height and experimental investigation on ultrasonic-assisted high-speed drilling micro-holes. J. Manuf. Process. 2021, 68, 807–817. [Google Scholar] [CrossRef]

- Namlu, R.H.; Lotfi, B.; Kılıç, S.E.; Yılmaz, O.D.; Akar, S. Combined use of ultrasonic-assisted drilling and minimum quantity lubrication for drilling of NiTi shape memory alloy. Mach. Sci. Technol. 2023, 27, 325–349. [Google Scholar] [CrossRef]

- Gao, G.; Yuan, Z.; Xia, Z.; Fu, Z.; Xiang, D.; Zhao, B. Study on thrust force of ultrasonic-assisted vibration micro-hole drilling of titanium alloy. Int. J. Adv. Manuf. Technol. 2021, 112, 3399–3413. [Google Scholar] [CrossRef]

- Wang, P.; Wang, D. Evaluation of different tool geometries in the finite element simulation of ultrasonic-assisted drilling of Ti6A14V. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 181. [Google Scholar] [CrossRef]

- Chaudhari, A.; Yusufzai, M.Z.K.; Vashista, M. Grindability study of hard to cut AISI D2 steel upon ultrasonic vibration-assisted dry grinding. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2022, 236, 915–925. [Google Scholar] [CrossRef]

- Wu, H.; Duan, W.; Sun, L.; Zeng, J.; Li, S.; Wang, Q.; Wu, Y.; Chen, Y. Effect of ultrasonic vibration on the machining performance and mechanism of hybrid ultrasonic vibration/plasma oxidation assisted grinding. J. Manuf. Process. 2023, 94, 466–478. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, J.Q.; Chen, Q.; Lu, Z.M. Research on Dynamic Grinding Force in Ultrasonic Honing Chatter. Key Eng. Mater. 2011, 487, 433–437. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, J.; Cao, Y. Parameter Optimization of Surface Roughness in Ultrasonic Vibration Cutting Process. In Proceeding of the 2019 2nd International Conference on Mechanical, Electrical and Material Application (MEMA) 2019, Xi’an, China, 25–27 October 2019. [Google Scholar]

- Li, S.; Wang, L.; Li, G.; Zhang, S.; Wu, S.; Qiao, J.; Zeng, J.; Xue, Y.; Wu, Y. Small hole drilling of Ti–6Al–4V using ultrasonic-assisted plasma electric oxidation grinding. Precis. Eng. 2021, 67, 189–198. [Google Scholar] [CrossRef]

- Lavrinenko, V.I.; Solod, V.Y. Oxidation or oxide materials in the machining zone in superabrasive grinding—A factor of influence on the grinding performance. J. Superhard Mater. 2016, 38, 417–422. [Google Scholar] [CrossRef]

- Duan, Z.; Chen, T.; Li, H.; Zhang, C.; Liu, F. Longitudinal ultrasonic vibration effects on grinding mechanism in side and end grinding of 2.5D Cf/SiC composites. Int. J. Adv. Manuf. Technol. 2023, 129, 4185–4199. [Google Scholar] [CrossRef]

- Kan, Z.; Wenhe, L.; Lianjun, S.; Heng, M. Investigation on grinding temperature in ultrasonic vibration-assisted grinding of zirconia ceramics. Mach. Sci. Technol. 2019, 23, 612–628. [Google Scholar] [CrossRef]

- Akhonin, S.V.; Belous, V.Y.; Selin, R.V.; Schwab, S.L. Effect of TIG-Welding on the Structure and Mechanical Prop-erties of Low-Cost Titanium Alloy Ti-2.8Al-5.1Mo-4.9Fe Welded Joints. Mater. Sci. Forum 2023, 1095, 105–110. [Google Scholar] [CrossRef]

- Yang, F.; Raynova, S.; Singh, A.; Zhao, Q.; Romero, C.; Bolzoni, L. Producing High-Quality Titanium Alloy by a Cost-Effective Route Combining Fast Heating and Hot Processing. JOM 2018, 70, 632–637. [Google Scholar] [CrossRef]

- Lisowicz, J.; Habrat, W.; Krupa, K.; Janocha, P. The effect of different MQL supply strategies into the cutting zone on the tool wear when turning of Ti-6Al-4V alloy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1037, 012004. [Google Scholar] [CrossRef]

- Grzesik, W.; Niesłony, P.; Habrat, W. Investigation of the tribological performance of AlTiN coated cutting tools in the machining of Ti6Al4V titanium alloy in terms of demanded tool life. Eksploat. i Niezawodn.—Maint. Reliab. 2018, 21, 153–158. [Google Scholar] [CrossRef]

- Dredge, C.; M’saoubi, R.; Thomas, B.; Hatt, O.; Thomas, M.; Jackson, M. A low-cost machinability approach to accelerate titanium alloy development. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 235, 1618–1632. [Google Scholar] [CrossRef]

- Kaynak, Y.; Gharibi, A. The effects of cutting parameters on machining performance of titanium alloy Ti-5553. Adv. Mater. Process. Technol. 2019, 5, 317–328. [Google Scholar] [CrossRef]

- Sutowski, P.; Święcik, R. The estimation of machining results and efficiency of the abrasive electro-discharge grinding process of Ti6Al4V titanium alloy using the high-frequency acoustic emission and force signals. Int. J. Adv. Manuf. Technol. 2018, 94, 1263–1282. [Google Scholar] [CrossRef]

- Yang, S.; He, C.; Zheng, M.; Wan, Q.; Zhang, Y. Temperature Field of Tool Engaged Cutting Zone for Milling of Titanium Alloy with Ball-End Milling. Micromachines 2018, 9, 672. [Google Scholar] [CrossRef] [PubMed]

- Das, A. Correction to: Ultrasonic-Assisted Fracture Appearance of Titanium. J. Mater. Eng. Perform. 2024, 33, 1495. [Google Scholar] [CrossRef]

- Słodki, B.; Zębala, W.; Struzikiewicz, G. Turning titanium alloy, grade 5 ELI, with the implementation of high pressure coolant. Materials 2019, 12, 768. [Google Scholar] [CrossRef]

- Wu, G.; Mao, X.; Pan, W.; Li, G.; Ding, S. The machinability of titanium alloy thin-wall parts in cooling minimum quantity lubrication (CMQL) environments. Int. J. Adv. Manuf. Technol. 2023, 129, 2875–2895. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Chen, X.; Xu, Z.; Feng, F.; Zhang, J.; Zhang, X.; Feng, P. Advanced Precision Cutting Titanium Alloy Methods: A Critical Review Considering Cost, Efficiency, and Quality. Technologies 2025, 13, 172. https://doi.org/10.3390/technologies13050172

Wang G, Chen X, Xu Z, Feng F, Zhang J, Zhang X, Feng P. Advanced Precision Cutting Titanium Alloy Methods: A Critical Review Considering Cost, Efficiency, and Quality. Technologies. 2025; 13(5):172. https://doi.org/10.3390/technologies13050172

Chicago/Turabian StyleWang, Guangping, Xiaoxuan Chen, Zhipeng Xu, Feng Feng, Jianfu Zhang, Xiangyu Zhang, and Pingfa Feng. 2025. "Advanced Precision Cutting Titanium Alloy Methods: A Critical Review Considering Cost, Efficiency, and Quality" Technologies 13, no. 5: 172. https://doi.org/10.3390/technologies13050172

APA StyleWang, G., Chen, X., Xu, Z., Feng, F., Zhang, J., Zhang, X., & Feng, P. (2025). Advanced Precision Cutting Titanium Alloy Methods: A Critical Review Considering Cost, Efficiency, and Quality. Technologies, 13(5), 172. https://doi.org/10.3390/technologies13050172