Feasibility Study of a Table Prototype Made of High-Performance Fiber-Reinforced Concrete

Abstract

:1. Introduction

2. High-Performance Fiber-Reinforced Concrete: Mix Design and Mechanical Properties

- -

- Commercial Portland-limestone blended cement type CEM I 52.5 R, according to the European Standards EN-197/1, is used at a dosage of 720 kg/m3 of concrete (its Blaine fineness is 470 m2/kg and its relative specific gravity is 3.14).

- -

- As aggregate, 1350 kg/m3 of well-graded very fine natural sand has been used with particle size up to 2.0 mm. The percentage of material passing the sieve with 1.0 mm opening is 97%, while the percentage passing the 0.25 mm sieve is 7%. The maximum particle size is chosen so small in order to allow the introduction of a huge amount of fibers. In fact, the higher the maximum grain size of the aggregate particles, the more difficult it is for the fibers to matrix bond in the mixture [11].

- -

- As filler, silica fume with grain size smaller than 1 µm, obtained as industrial by-product of the silicon processing, has been used at a dosage of 120 kg/m3 of concrete. Silica fume powder has a specific surface area of about 18 m2/g, evaluated by means of BET surface method, and a relative specific gravity of 2.21. Its chemical composition is 98% silica.

- -

- Metallic glass fibers are used for FRC at a dosage of 55 kg/m3 (corresponding to 0.75 vol %). They are flat and flexible amorphous metallic fibers, obtained by quenching a molten alloy (Fe, Cr)80 (P, C, S)20, falling on a water-cooled wheel rotating at high speed (15 mm long, 1.0 mm wide, 0.029 mm thick). Fiber aspect ratio is 80, and relative specific gravity is 7.25. Fibers have a high resistance to corrosion due to the chromium content of the alloy. The elastic modulus is about 218 GPa and tensile strength is about 320 MPa. Their effectiveness on reinforcing cement-based matrix was proven in previous experimental works [12,13].

- -

- Polycarboxylate-based superplasticizers have been employed, constituted of a carboxylic acrylic ester polymer in the form of 26.8 ± 1.3% aqueous solution at a dosage of 2.0% by weight of cement.

- -

- -

- Density of 2340 kg/m3;

- -

- 122 MPa compressive strength, evaluated according to EN 1015-11;

- -

- 20 MPa maximum flexural strength, evaluated according to EN 14651 (i.e., three-point bending test) on three prism specimens for each mixture and curing time with a nominal size (width and depth) of 40 mm, 160 mm long;

- -

- Young modulus of about 43 GPa in compression, and Poisson modulus of 0.25.

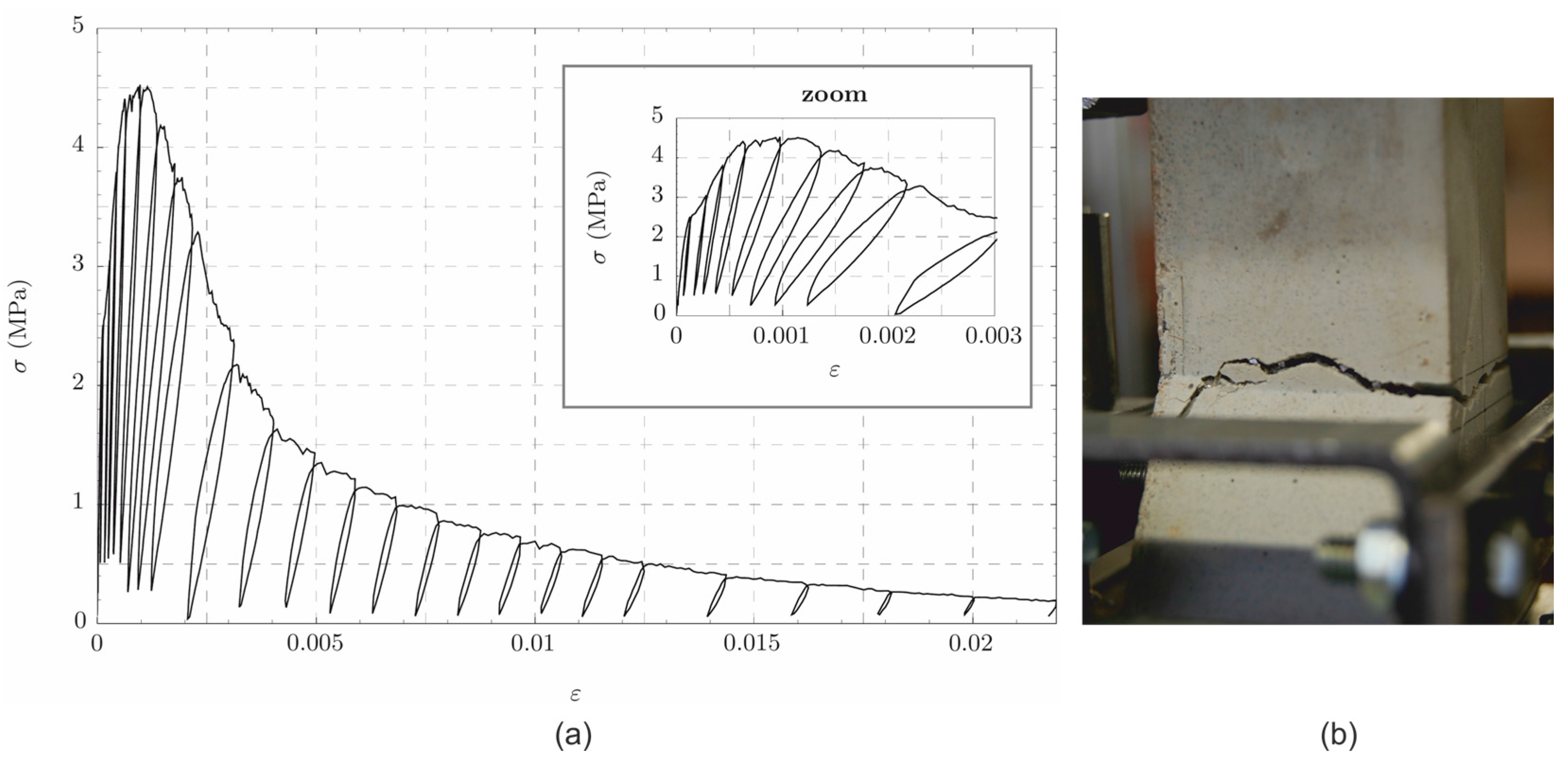

3. Tensile Tests

3.1. Experimental Setup

3.2. Experimental Results

4. Finite Element Modelling

4.1. Numerical Model

4.2. Simulations: Tensile Tests

4.3. Simulations: Nervi Table

5. Conclusions

- (i)

- development of a fiber-reinforced concrete with specific properties, that is, large workability, very low surface roughness, and large mechanical strength to tensile stresses;

- (ii)

- experimental testing, to characterize the material mechanical properties, and to calibrate the numerical model;

- (iii)

- numerical analysis, where accurate numerical simulations were conducted in order to determine the table capability of bearing different loadings, under different boundary conditions. It was found that the worst mechanical responses are registered when the table is simply supported over a horizontal surface. In this case, the maximum vertical and horizontal loads, that lead to the table collapse, are around 0.9–1.0 KN and 0.5–0.6 KN, respectively. Furthermore, it was found that the most stressed cross-sections of the table top, where damage and plastic strains localize, are the midsection and the sections adjacent to the supporting legs. Localized inelastic phenomena initiates when the stress σ = 9–10 MPa is reached, which represents the maximum stress that concrete can sustain under bending loadings, and it is two times larger than the maximum stress of pure tensile tests. Analogous differences were found in experimental studies (see [30]). This suggests to reinforce the table top in these sections, and, in this regard, the ribs at the intrados of the Nervi table (see Figure 1), adjacent to the legs, represent useful strengthening elements.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Swamy, R.N. Fiber Reinforced Cement and Concrete. In Proceedings of the 4th RILEM International Symposium, Sheffield, UK, 20–23 July 1992. [Google Scholar]

- Cheyrezy, M.; Deniel, J.I.; Krenciel, H.; Mihashi, H.; Pera, J.; Rossi, P.; Xi, Y. Specific Production and manufacturing issue. In High Performance Fiber Reinforced Cement Composite, Proceedings of the 2nd International Workshop (HPFRCC2), Ann Arbor, MI, USA, 11–14 June 1995; Naaman, A.E., Reinhardt, H.W., Eds.; E.&F.N. Spon: London, UK, 1995; Volume 2, pp. 25–41. [Google Scholar]

- Di Prisco, M.; Plizzari, G.; Vandewalle, L. Fibre reinforced concrete: New design perspectives. Mater. Struct. 2009, 42, 1261–1281. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile behavior of Ultra High Performance Hybrid Fiber Reinforced Concrete. Cem Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Compos. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Jungwirth, J.; Muttoni, A. Structural behavior of tension members in UHPC. In Proceedings of the International Symposium on UHPC 2004, Kassel, Germany, 13–15 September 2004; pp. 1–12. [Google Scholar]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef]

- Website Kristalia srl. Available online: www.kristalia.it/design-tables/boiacca/outdoor-concrete-table/ (accessed on 1 January 2013).

- Abaqus Theory Manual, Version 6.10; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2010.

- Collepardi, M. The New Concrete; Grafiche Tintoretto: Villorba (Treviso), Italy, 2006. [Google Scholar]

- Corinaldesi, V.; Nardinocchi, A.; Donnini, J. The Influence of Expansive Agent on the Performance of Fiber Reinforced Cement-Based Composites. Constr. Build. Mater. 2015, 91, 171–191. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Nardinocchi, A. Mechanical characterization of Engineered Cement-based Composites prepared with hybrid fibres and expansive agent. Compos. Part B Eng. 2016, 98, 389–396. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Donnini, J.; Nardinocchi, A. The Influence of Calcium Oxide Addition on Properties of Fiber Reinforced Cement-Based Composites. J. Build. Eng. 2015, 4, 14–20. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Nardinocchi, A. Influence of type of fibers on the properties of high performance cement-based composites. Constr. Build. Mater. 2016, 107, 321–331. [Google Scholar] [CrossRef]

- CNR. Istruzioni per la Progettazione, l’Esecuzione ed il Controllo di Strutture di Calcestruzzo Fibrorinforzato. Technical Report; Consiglio Nazionale delle Ricerche: Rome, Italy, 2006. [Google Scholar]

- Akita, H.; Koide, H.; Mihashi, H. Specimen Geometry in Uniaxial Tension Test of Concrete; FraMCoS-6; Carpinteri, A., Ed.; Taylor & Francis: London, UK, 2007. [Google Scholar]

- Bensaid Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Flowability of fibre-reinforced concrete and its effect on the mechanical properties of the material. Constr. Build. Mater. 2010, 24, 1664–1671. [Google Scholar] [CrossRef]

- Herrmann, H.; Lees, A. On the influence of the rheological boundary conditions on the fibre orientations in the production of steel fibre reinforced concrete elements. Proc. Estonian Acad. Sci. 2016, 65, 408–413. [Google Scholar] [CrossRef]

- Choi, J.I.; Lee, B.Y.; Ranade, R.; Li, V.C.; Lee, Y.; Composites, C.; York, N. Ultra-high-ductile behavior of apolyethylene fiber-reinforced alkali-activated slag-based composite. Cem. Concr. Compos. 2016, 70, 153–158. [Google Scholar] [CrossRef]

- Paschalis, S.A.; Lampropoulos, A.P. Ultra-high-performance fiber-reinforced concrete under cyclic loading. ACI Mater. J. 2016, 113, 419–427. [Google Scholar] [CrossRef]

- Zwick/Roell. AllroundLine Z250 SW Materials Testing Machines. Available online: https://www.zwick.com/en/universal-testing-machines/allroundline-test-machine (accessed on 2017).

- Lubliner, J.; Oliver, J.; Oller, S.; Onate, E. A Plastic-Damage Model for Concrete. Int. J. Solids Struct. 1989, 25, 299–329. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-Damage Model for Cyclic Loading of Concrete Structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- Ramm, E. Strategies for Tracing the Nonlinear Response Near Limit Points, Nonlinear Finite Element Analysis in Structural Mechanics; Wunderlich, E., Stein, E., Bathe, K.J., Eds.; Springer-Verlag: Berlin, Germany, 1981. [Google Scholar]

- Crisfield, M.A. Snap-Through and Snap-Back Response in Concrete Structures and the Dangers of Under-Integration. Int. J. Numer. Methods Eng. 1986, 22, 751–767. [Google Scholar] [CrossRef]

- Powell, G.; Simons, J. Improved Iterative Strategy for Nonlinear Structures. Int. J. Numer.Methods Eng. 1981, 17, 1455–1467. [Google Scholar] [CrossRef]

- Baioni, E. Plasticity and Fracture Models for the Study of High Performance Fibre-Reinforced Concretes: Numerical Applications to Design Objects, Master Degree Thesis in Building Engineering; Università Politecnica delle Marche: Piazza Roma, Italy, 2017. [Google Scholar]

- Lancioni, G.; Corinaldesi, V. Variational modelling of diffused and localized damage with applications to fiber-reinforced concretes. Meccanica 2017. [Google Scholar] [CrossRef]

- Maca, P.; Savjac, R.; Vavrinik, T. Experimental investigation of mechanical properties of UHPFRC. Proc. Eng. 2013, 65, 14–419. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baioni, E.; Alessi, R.; Corinaldesi, V.; Lancioni, G.; Rizzini, R. Feasibility Study of a Table Prototype Made of High-Performance Fiber-Reinforced Concrete. Technologies 2017, 5, 41. https://doi.org/10.3390/technologies5030041

Baioni E, Alessi R, Corinaldesi V, Lancioni G, Rizzini R. Feasibility Study of a Table Prototype Made of High-Performance Fiber-Reinforced Concrete. Technologies. 2017; 5(3):41. https://doi.org/10.3390/technologies5030041

Chicago/Turabian StyleBaioni, Elisa, Roberto Alessi, Valeria Corinaldesi, Giovanni Lancioni, and Robin Rizzini. 2017. "Feasibility Study of a Table Prototype Made of High-Performance Fiber-Reinforced Concrete" Technologies 5, no. 3: 41. https://doi.org/10.3390/technologies5030041

APA StyleBaioni, E., Alessi, R., Corinaldesi, V., Lancioni, G., & Rizzini, R. (2017). Feasibility Study of a Table Prototype Made of High-Performance Fiber-Reinforced Concrete. Technologies, 5(3), 41. https://doi.org/10.3390/technologies5030041