The Impact of Agri-Food Supply Channels on the Efficiency and Links in Supply Chains

Abstract

:1. Introduction

2. Literature Review

3. Methodology and Data

- (1)

- The coefficient of efficiency (profitability) (CE) in supply chains of food products (SC FP), defined as the ratio of gross profit to revenue (income) or as the ratio of gross turnover to total costs.The efficiency coefficient (profitability) is determined (Table 1) for (a) manufactured products; (b) sold products; (c) processed and manufactured products in industry; (d) sold food products in industry; (e) trade.

- (2)

- The coefficient of product connectivity in supply chains (SCr) is an indicator that characterizes how many links on average products pass on their way from the sphere of production to the final consumer.SCr is determined by the ratio of gross turnover and the product sold, or it can be determined through wholesale turnover to retail turnover. The SCr could be calculated both in the economy as a whole, and in the context of individual consumer goods or products, as well as for individual parts of the supply chain (SC).SCr is defined for agricultural products sold, wholesale trade, FP producers, for trade and their average values (Table 2).

- (3)

- Turnover characterizes inventories, which are determined by the level of availability of inventories (Il), and is determined by the formulawhere Ilb, Ile—inventories at the beginning and end of the period, respectively, Vtt—gross turnover of FP.

- (4)

- The purchasing power of monetary income on average per capita, the number of sets of subsistence minimum (SM), i.e., the ability to buy a living wage, times.

- (5)

- Food price index compared to last year, %

- (1)

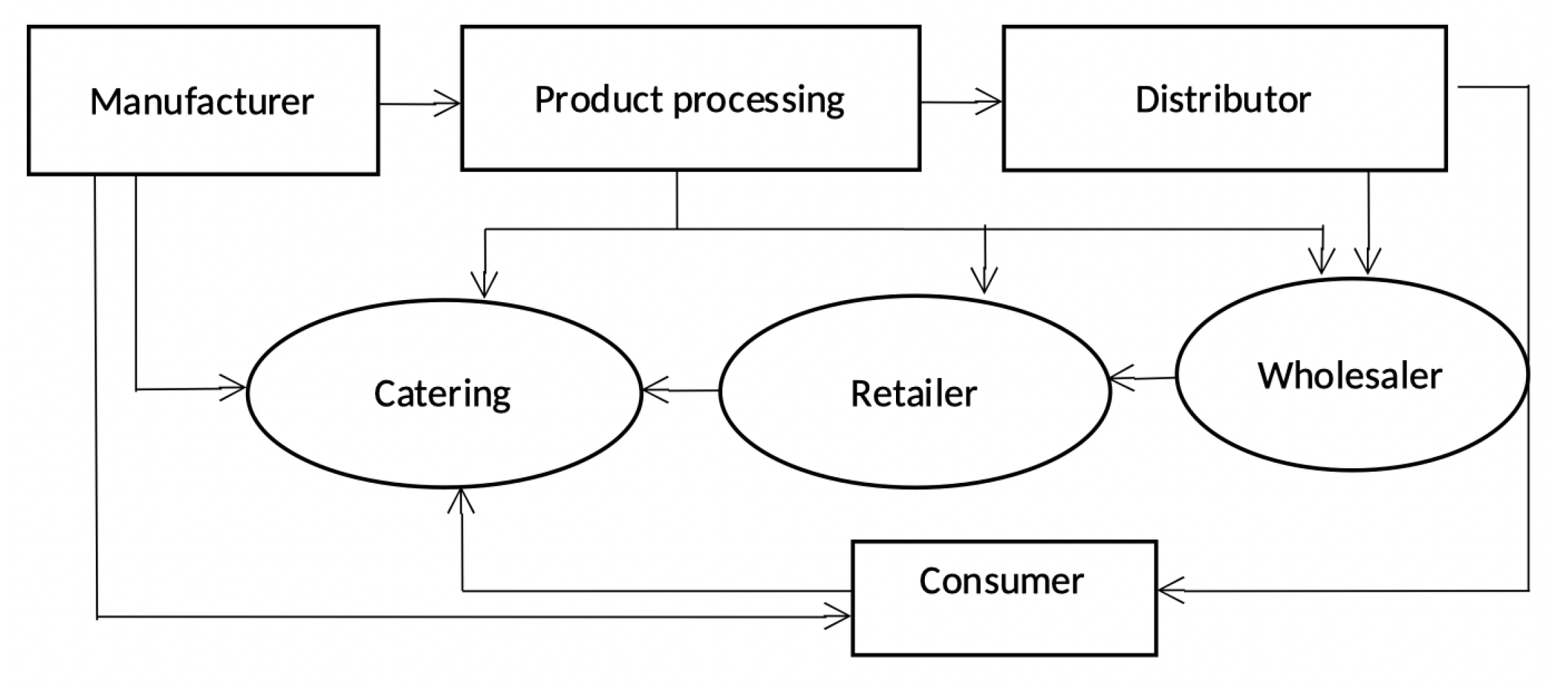

- Selection of the scheme of movement (supply channels) of agri-food products according to Figure 1;

- (2)

- Collection of statistical data on each supply channel of agri-food products for the industry according to Table 2: Vag, Vin, Vs.ag.m, Vs.in., and Vtt;

- (3)

- Calculation of supply chain indicators for each channel and in the system as a whole, according to Table 1 and according to Il, PP, and PI, indicators that affect the efficiency and links of supply chains;

- (4)

- Definition and description of statistical characteristics of variables (Table 3);

- (5)

- Description of the dynamics of changes in indicators of production, processing, sales, and trade through supply channels (Table 4);

- (6)

- Modeling and evaluation of the influence of factors on the efficiency and security of supply chains (Table 5). The following is a description of the methodology for evaluating efficiency and linkage in the production and sales supply chain (PS SC):

- Definition of variables: production and processing volumes, sales, and trade of agri-food products, their total costs, and profitability (Table 2):

- Determination of total costs (cost of products sold and services rendered) and profitability in each link and in the whole system for indicators 1–5 in Table 2.

- Calculation of the efficiency in supply chains in each link (Table 1).

- Calculation of the connectivity ratio of supply chains in each link (Table 1).

- Assessment of factors affecting the efficiency and connectivity in the supply chain.

- Analysis, identification of problems.

- Recommendations for improving distribution channels in agri-food supply chains.

4. Results And Discussion

4.1. Analysis of Efficiency and Connectivity in the Supply Chains of Agri-Food Products

4.2. Assessment of Factors Affecting Efficiency and Connectivity in Food Supply Chains

5. Discussion

- -

- the main trends inherent in the process of trade development in Kazakhstan are identified; the factors that significantly affect the efficiency in supply chains and the links in the commodity distribution system are identified;

- -

- it is established that, for the formation and development of an effective supply chain and civilized trade, further integration of supply chains into the commodity distribution system is necessary, which helps to optimally load the distribution channels of goods, reduce costs, reduce the number of intermediaries, and improve the quality of service and product safety;

- -

- based on the results of the analysis of the efficiency in supply chains, it was determined that increasing the sustainability of commodity-carrying food supply chains at all stages—from production to consumption—requires an integrated and coordinated approach (infrastructure, warehouses, financial resources, etc.) in their management;

- -

- formation of more stable and diverse distribution systems, including shorter distribution chains (by reducing the length of supply chains);

- -

- the uniform degree of concentration of commodity flows (production and consumption) in the regions of the country requires a differentiated approach to the creation of regional and interregional commodity distribution networks.

- (1)

- the close interaction of all market participants and more efficient use of existing wholesale, retail, and catering enterprises, which should help to reduce costs in the commodity distribution system when selling products by minimizing the number of intermediaries in the supply chain between the producer and consumer;

- (2)

- modernization of existing wholesale and retail trade enterprises as the infrastructure of the food market, which involves the maximum use of the capabilities of modern innovative technologies and logistics in order to speed up the process of delivering goods to the consumer with minimal costs and maximum preservation of product quality to meet the demand and needs of the population in goods and services;

- (3)

- the smooth functioning of food distribution chains on a well-established supply of basic food products. One of such measures is the close placement of production and consumers, an increase in the volume of production for delivery to local markets to the main sources of consumption, which is a condition for creating short commodity distribution chains with or without minimal intermediaries.

- (4)

- reduction in stocks and creation of wholesale and retail distribution centers at the locations of manufacturing enterprises (manufacturers), which makes it possible to respond more effectively to changing consumer demands;

- (5)

- improving the efficiency in each channel in the supply chains should move towards reducing costs, consolidating purchases and sales of agri-food products to ensure the volume of work performed, improving the quality of customer service.

6. Conclusions

- (1)

- stimulating activities to improve the efficiency in processing and food processing enterprises through the use of innovative and digital technologies, which will lead to an increase in the overall efficiency in the supply chain;

- (2)

- stimulation to increase the income of the population by increasing the number of self-employed and individual entrepreneurs in the field of agricultural production and trade, increasing their purchasing power;

- (3)

- increase in turnover and decrease in stock level due to optimization, monitoring, and implementation of automated logistics technologies, construction of warehouses, storage facilities, and distribution centers;

- (4)

- introduction of digital technologies for measuring, tracking, and controlling material flows in the supply chains of agri-food products;

- (5)

- an increase in the share of retail trade in the total volume of turnover using non-standard methods of sales in retail (online trade, mobile retail, etc.), which will lead to a decrease in the level of connectivity in commodity movement.

7. Limitation And Future Research

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

| 1 | On the approval of the national project on entrepreneurship development for 2021–2025 https://adilet.zan.kz/rus/docs/P2100000728 (in Russian) (accessed on 28 March 2023). |

| 2 | Bureau of National Statistics of the Agency for Strategic Planning and Reforms of the Republic of Kazakhstan http://stat.gov.kz (in Russian) (accessed on 10 March 2023). |

References

- Ableeva, Alisa, Guzel Salimova, and Nuria Rafikova. 2019. Economic evaluation of the efficiency of supply chain management in agricultural production based on multidimensional research methods. International Journal of Supply Chain Management 8: 328–38. [Google Scholar]

- Aramyan, Lusine H., Alfons Oude Lansink, Jack van der Vorst, and Olaf van Kooten. 2007. Performance measurement in agri-food supply chains: A case study. Supply Chain Management 12: 304–15. [Google Scholar] [CrossRef]

- Ardekani, Zahra Fozouni, Seyed Mohammad Javad Sobhani, Marcelo Werneck Barbosa, and Paulo Renato de Sousa. 2023. Transition to a sustainable food supply chain during disruptions: A study on the Brazilian food companies in the COVID-19 era. International Journal of Production Economics 257: 108782. [Google Scholar] [CrossRef] [PubMed]

- Baibardina, Tatyana, and Anna Yakimik. 2018. Trends in the development of network trade in the Republic of Belarus. Bulletin of the Belarusian State Economic University 3: 57–64. [Google Scholar]

- Barrett, Christopher, Thomas Reardon, Johan Swinnen, and David Zilberman. 2019. Structural Transformation and Economic Development: Insights from the Agri-food Value Chain Revolution, Working Paper, Dyson School of Applied Economics and Management. Cornell University, Ithaca, NY, USA.

- Bowersox, Donald J., David J. Closs, M. Bixby Cooper, and John C. Bowersox. 2014. Supply Chain Management Logistics Management. New York: McGraw-Hill Education. [Google Scholar]

- Bui, Lan Thi Hoang, and Dat Ngoc Nguyen. 2021. The distribution channel, strategic factor and firm performance: Evidence from FDI enterprises channel production. Journal of Distribution Science 19: 35–41. [Google Scholar]

- Callado, Antônio André Cunha, and Lisa Jack. 2017. Relations between usage patterns of performance indicators and the role of individual firms in fresh fruit agri-food supply chains. Journal of Applied Accounting Research 18: 375–98. [Google Scholar] [CrossRef] [Green Version]

- Chopra, Shweta, Chad Laux, Edie Schmidt, and Prashant Rajan. 2017. Perception of performance indicators in an agri-food supply chain: A case study of India’s Public Distribution System. International Journal on Food System Dynamics 8: 130–45. [Google Scholar]

- Closs, David J., Cheri Speier, and Nathan Meacham. 2011. Sustainability to support end-to-end value chains: The role of supply chain management. Journal of the Academy of Marketing Science 39: 101–16. [Google Scholar] [CrossRef]

- Constantin, Marius, Juan Sapena, Andreea Apetrei, and S. Roxana Pătărlăgeanu. 2023. Deliver Smart, Not More! Building Economically Sustainable Competitiveness on the Ground of High Agri-Food Trade Specialization in the EU. Foods 12: 232. [Google Scholar] [CrossRef]

- Cupertino, Sebastiano, Gianluca Vitale, and Angelo Riccaboni. 2021. Sustainability and short-term profitability in the agri-food sector, a cross-sectional time-series investigation on global corporations. British Food Journal 123: 317–36. [Google Scholar] [CrossRef]

- Despotovic, Danijela, Slobodan Cvetanovic, Vladimir Nedic, and Milan Despotovic. 2016. Economic, Social and Environmental Dimension of Sustainable Competitiveness of European Countries. Journal of Environmental Planning and Management 59: 1656–78. [Google Scholar] [CrossRef]

- European Commission, Directorate-General for Competition. 2019. Study on Producer Organisations and Their Activities in the Olive Oil, Beef and Veal, Arable Crops Sectors. Luxembourg: Publications Office. Available online: https://data.europa.eu/doi/10.2763/720686 (accessed on 20 March 2023).

- Fan, Xuemei, and Shujun Zhang. 2016. Performance Evaluation for the Sustainable Supply Chain Management. Chapters. In Sustainable Supply Chain Management. Edited by Evelin Krmac. Rijeka: IntechOpen. [Google Scholar]

- Gajdić, Dusanka, Herbert Kotzab, and Kristina Petljak. 2023. Collaboration, trust and performance in agri-food supply chains: A bibliometric analysis. British Food Journal 125: 752–78. [Google Scholar] [CrossRef]

- Grigoreva, Elena, Ekaterina Polovkina, and Liliya Zulfakarova. 2019. Economic and statistical analysis of the management efficiency by the supply chain strategy and grouping method. International Journal of Supply Chain Management 8: 916–22. [Google Scholar]

- Harrison, Alan, and Remko Van Hoek. 2008. Logistics Management and Strategy. Competing through the Supply Chain, 3rd ed. London: Pearson Education Limited, p. 368. [Google Scholar]

- Harrison Terry P., Hau L. Lee, and John J. Neale. 2005. Principles for the strategic design of supply chains. In The Practice of Supply Chain Management. New York: Springer, pp. 3–12. [Google Scholar]

- Ilyina, Zinaida. 2013. Formation of an Effective Marketing System for Agricultural Products. Minsk: Institute for System Research in the Agroindustrial Complex of the National Academy of Sciences of Belarus, p. 185. [Google Scholar]

- Kaplan, Robert S., and David P. Norton. 2005. The balanced scorecard: Measures that drive performance. Harvard Business Review 83. Available online: https://hbr.org/1992/01/the-balanced-scorecard-measures-that-drive-performance-2 (accessed on 20 March 2023).

- Kataike, Joanita, Lusine Aramyan, Oliver Schmidt, Adrienn Molnár, and Xavier Gellynck. 2019. Measuring chain performance beyond supplier-buyer relationships in agri-food chains. Supply Chain Management 24: 484–97. [Google Scholar] [CrossRef]

- Khadim, Zunaira, Irem Batool, Ahsan Akbar, Petra Poulova, and Minahs Akbar. 2021. Mapping the moderating role of logistics performance of logistics infrastructure on economic growth in developing countries. Economies 9: 177. [Google Scholar] [CrossRef]

- Kim, Dong-Hwan, and Jong-Ki Hyun. 2017. Development of Performance Indices for Agro-food Distribution Corporations Based on the AHP Method. Journal of Distribution Science 15: 95–110. [Google Scholar]

- Kireenko, Natalya. 2015. Marketing System for Agricultural Products Based on the Marketing Approach: Theory, Methodology, Practice. Minsk: Institute for System Research in the Agroindustrial Complex of the National Academy of Sciences of Belarus, p. 265. [Google Scholar]

- Kotler, Philip, and Gary Armstrong. 2005. Principles of Marketing. London: Pearson Education Limited, pp. 990–1010. [Google Scholar]

- Krasilnikova, Elena, and Venera Timiryanova. 2013. Analysis of existing management systems and indicators for evaluating the effectiveness of the process of product distribution. Bulletin of Economics, Law and Sociology 4: 33–37. [Google Scholar]

- Kumar, Mukesh, Mahak Sharma, Rakesh Raut, Sachina Mangla, and Vikas Choubey. 2022. Performance assessment of circular driven sustainable agri-food supply chain towards achieving sustainable consumption and production. Journal of Cleaner Production 372: 133698. [Google Scholar] [CrossRef]

- Majewski, Edward, Anna Komerska, Jerzy Kwiatkowski, and Agata Malak Rawlikowska. 2020. Are Short Food Supply Chains More Environmentally Sustainable than Long Chains? A Life Cycle Assessment (LCA) of the Eco-Efficiency of Food Chains in Selected EU Countries. Energies 13: 4853. [Google Scholar] [CrossRef]

- Makarevich, Elena. 2017. Statistical estimation of goods flow chains in wholesale and retail trade of the Republic of Belarus. Voprosy Statistiki 6: 80–83. [Google Scholar]

- McCullough, Ellen B., Prabhu L. Pingali, and Kostas G. Stamoulis. 2008. Small Farms and the Transformation of Food Systems: An Overview. Food and Agriculture Organization of the UN/Earthscan. London: Routledge, pp. 400–8. [Google Scholar]

- Moazzam, Muhammad, Pervaiz Akhtar, Elena Garnevska, and Norman E. Marr. 2018. Measuring agri-food supply chain performance and risk through a new analytical framework: A case study of New Zealand dairy. Production Planning and Control 29: 1258–74. [Google Scholar] [CrossRef]

- Mouritsen, Jan, Allan Hansen, and Carsten Ørts Hansen. 2001. Inter-organizational controls and organizational competencies: Episodes around target cost management/functional analysis and open book accounting. Management Accounting Research 12: 221–44. [Google Scholar] [CrossRef]

- National Trade Development Project for 2021–2025. 2021. Decree of the Government of the Republic of Kazakhstan dated October 12, 2021. No. 728. Available online: https://adilet.zan.kz/rus/docs/P2100000728 (accessed on 9 February 2023). (In Russian).

- Pagell, Mark, and Anton Shevchenko. 2014. Why research in sustainable supply chain management should have no future. J. Supply Chain Manag 50: 44–55. [Google Scholar] [CrossRef]

- Raimbekov, Zhanarys, Bakyt Syzdykbayeva, Darima Zhenskhan, and Aydar Mukanov. 2021. Regional distribution networks: Evaluation of the functioning and development efficiency. Economic Annals-XXI 191: 114–20. [Google Scholar] [CrossRef]

- Ramos, Edgar, Philip S. Coles, Melissa Chavez, and Benjamin Hazen. 2022. Measuring agri-food supply chain performance: Insights from the Peruvian kiwicha industry. Benchmarking: An International Journal 29: 1484–12. [Google Scholar] [CrossRef]

- To, Tha Hien, Thuy Trong Than, Duyen Thi Kim Nguyen, and Dat Ngoc Nguyen. 2021. Distribution of supply chain capabilities and firm’s sustainable development. Journal of Distribution Science 19: 5–12. [Google Scholar] [CrossRef]

- Touboulic, Anne, and Helen Walker. 2015. Theories in sustainable supply chain management: A structured literature review. International Journal of Physical Distribution and Logistics Management 45: 16–42. [Google Scholar] [CrossRef]

- Tyapukhin, Alexey, and Zhanna Ermakova. 2022. Options, structure, and digitalization of value chain management objects. Digital Transformation in Industry 54: 373–89. [Google Scholar]

- Van der Vorst, Jack, Carlos A. da Silva, and Jacques H. Trienekens. 2007. Agro-Industrial Supply Chain Management: Concepts and Applications. Rome: Food and Agriculture Organization of the United Nations, p. 71. [Google Scholar]

- Van Hoek, Remko, Alan Harrison, and Martin Christopher. 2001. Measuring agile capabilities in the supply chain. International Journal of Operations and Production Management 21: 126–47. [Google Scholar] [CrossRef]

- Vlasova, Margarita, Olga Ilyina, and Valentina Morokhina. 2012. Cost efficiency and its impact on the economic sustainability of the enterprise. Problems of Modern Economy 3: 123–25. [Google Scholar]

- Vinokurov, Evgeny, Arman Akhunbaev, Sergei Chuev, Nurbol Usmanov, A. Zaboev, Alexander Malakhov, Vladimir Pereboev, Mikhail Ksenofontov, Dmitry Polzikov, and Vadim Potapenko. 2023. Food Security and Unlocking the Agro-Industrial Potential of the Eurasian Region. Reports and Working Papers 23/1. Almaty: Eurasian Development Bank. [Google Scholar]

- Wang, Yu Chung William, Hing Kai Chan, and David J. Pauleen. 2009. Aligning Business Process Reengineering in Implementing Global Supply Chain Systems by the SCOR Model. International Journal of Production Research 48: 5647–69. [Google Scholar] [CrossRef] [Green Version]

- Woo, Donghyup, and Nallan C. Suresh. 2022. Voluntary agreements for sustainability, resource efficiency and firm performance under the supply chain cooperation policy in South Korea. International Journal of Production Economics 252: 108563. [Google Scholar] [CrossRef]

- Yeo, Alassane D., Aimin Deng, and Todine Y. Nadiedjoa. 2020. The Effect of Infrastructure and Logistics Performance on Economic Performance: The Mediation Role of International Trade. Foreign Trade Review 55: 450–65. [Google Scholar] [CrossRef]

- Zinovieva, Olga, Dmitry Klevtsov, and Alexey Savin. 2020. Supply chain management in the food industry as a factor in food security. International Agriculture Journal 2: 1–12. [Google Scholar] [CrossRef]

| No | Variable and Abbreviation | Formula |

|---|---|---|

| The coefficient of product distribution links in supply chains: | ||

| 1 | SCrag. Coefficient of links in the sale of agricultural products | Vr.t/Vs.ag.m |

| 2 | SCrwt. Coefficient of links of wholesale trade in agricultural food products | Vw.t/Vs.ag.m |

| 3 | SCrfm. The coefficient of linkage of food producers | Vt/Vs.ag.m |

| 4 | SCrft. The coefficient of linkage of trade in food products | Vtt/Vr.t |

| 5 | SCrav. Average link ratio of the food supply chain | (SCag. + SCwt. + SCfm. + SCft.)/4 |

| Efficiency (profitability) ratio: | ||

| 1 | CPag. Agricultural production efficiency coefficient | 1-Cag/Vag |

| 2 | CPi.p. Efficiency coefficient of industrial production of food products (FP) | 1-Cin/Vin |

| 3 | CPs.ag. Ratio of efficiency in sales of agricultural food products | 1-Cag/Vag |

| 4 | CPs.in. Efficiency ratio for the sale of industrial food products | 1- Cs.in/Vs.in. |

| 5 | CPt. Trade efficiency ratio | 1- Ct.t/(Vw.t + Vr.t + Vcat.) |

| 6 | CPav. Average Food Supply Chain Efficiency Ratio | (CPag. + CPi.p. + CPs.ag. + CPs.in. + CPt.)/5 |

| Supply Chains | Variables | Notation |

|---|---|---|

| Production and processing | 1. The volume of agricultural products produced | Vag |

| The cost of production in agriculture | Cag | |

| 2. The volume of industrial production of food products from raw materials and materials of agricultural products | Vin | |

| The cost of industrial production of food products | Cin | |

| Gross food production, (sum of lines 1 + 2) | Vg | |

| Sales | 3. Cost of sold agricultural products, billion KZT | Vs.ag.m |

| Cost of sold agricultural products | Cs.ag | |

| 4. The volume of sales of food products in the industry | Vs.in. | |

| The cost of selling food products in the industry | Cs.in | |

| Gross turnover of food producers (Sum of lines 3 + 4) | Vt | |

| Trade | 5.1. Volume of wholesale trade in food products, million KZT | Vw.t |

| 5.2. The volume of retail trade in food products, million KZT | Vr.t | |

| 5.3. Provision of services for the provision of food and drinks (public catering), million KZT | Vcat. | |

| Total cost of food trade | Ct.t | |

| Gross turnover of food products (Sum of lines 5.1-5.3) | Vtt |

| Variable | Mean | SD | Skewness | Kurtosis | Jarque–Bera Test | p-Value | CS |

|---|---|---|---|---|---|---|---|

| 1. The volume of gross food production (Vg) | |||||||

| 1.1. Vag | 799.9 | 353.7 | 0.80 | −0.67 | 1.88 | 0.39 | 65.8 |

| 1.2. Vin | 1347.2 | 662.0 | 1.03 | 0.72 | 2.96 | 0.23 | 62.9 |

| Vg, Total | 2147.1 | 1009.0 | 0.94 | 0.18 | 2.23 | 0.33 | 73.1 |

| 2. The volume of gross turnover of food producers (Vt) | |||||||

| 2.1. Vs.ag.m | 1326.0 | 869.8 | 1.01 | 0.07 | 2.56 | 0.28 | 69.4 |

| 2.2. Vs.in. | 1279.8 | 628.9 | 1.03 | 0.72 | 2.96 | 0.23 | 67.9 |

| Vt, Total | 2605.9 | 1494.3 | 1.02 | 0.33 | 2.64 | 0.27 | 66.3 |

| 3. Gross turnover (Vtt) | |||||||

| 3.1. Vw.t | 3715.3 | 1989.0 | 0.12 | −1.36 | 1.20 | 0.51 | 66.5 |

| 3.2 Vr.t | 2456.6 | 1494.1 | 0.91 | −0.16 | 2.10 | 0.35 | 69.2 |

| 3.3. Vcat. | 370.9 | 210.7 | 0.38 | −1.16 | 1.20 | 0.49 | 73.2 |

| Vtt, Total | 6542.8 | 3650.8 | 0.44 | −0.94 | 1.04 | 0.59 ** | 74.3 |

| Variable factors that affect CPav and SCav | |||||||

| GDP, billion KZT | 47,967.9 | 25,321.0 | 0.66 | −0.27 | 1.13 | 0.57 ** | 77.2 |

| PP, once | 3.2 | 0.3 | −0.73 | −1.05 | 1.04 | 0.36 | 90.0 |

| Il | 41.8 | 6.5 | 0.27 | −1.21 | 1.10 | 0.51 | 84.4 |

| PI, % | 108.2 | 3.4 | 1.86 | 0.91 | 2.34 | 0.05 | 97.8 |

| 2008 | 2010 | 2012 | 2014 | 2016 | 2018 | 2020 | 2022 | |

|---|---|---|---|---|---|---|---|---|

| 1. The volume of gross food production (VG FP) (Vg) | ||||||||

| Vag | 452.1 | 465.2 | 594.3 | 563.8 | 708.1 | 951.7 | 1222.4 | 1495.7 |

| Vin | 623.5 | 695.2 | 865.6 | 1103.5 | 1448.4 | 1527.7 | 1957.2 | 2914.4 |

| Vg, Total | 1075.6 | 1160.4 | 1459.9 | 1667.3 | 2156.5 | 2479.4 | 3179.6 | 4410.1 |

| 2. The volume of gross turnover of food producers (Vt): | ||||||||

| Vs.ag.m | 370.5 | 544.1 | 755.7 | 872.8 | 1182.0 | 1520.2 | 2304.1 | 3212.7 |

| Vs.in. | 592.3 | 660.5 | 822.3 | 1048.3 | 1376.0 | 1451.3 | 1859.4 | 2768.7 |

| Vt, Total | 962.8 | 1204.6 | 1578.0 | 1921.1 | 2557.9 | 2971.5 | 4163.5 | 5981.4 |

| 3. Gross turnover (Vtt) | ||||||||

| Vw.t | 982.8 | 1548.2 | 2057.5 | 3029.9 | 4448.2 | 5216.9 | 5333.1 | 7043.8 |

| Vr.t | 819.7 | 1050.2 | 1417.7 | 1820.8 | 2204.3 | 3035.8 | 4102.1 | 5614.6 |

| Vcat. | 103.3 | 156.0 | 220.5 | 269.3 | 415.8 | 524.8 | 536.6 | 751.5 |

| Vtt, Total | 1905.7 | 2754.4 | 3695.7 | 5120.0 | 7068.4 | 8777.5 | 9971.8 | 13,409.9 |

| Variables | ||||||||

| GDP | 16,052.9 | 21,815.5 | 30,177.5 | 38451.4 | 45,622.7 | 61,819.5 | 70,649.0 | 101,523 |

| Il | 0.152 | 0.135 | 0.159 | 0.122 | 0.110 | 0.109 | 0.107 | 0.095 |

| PP, once | 2.67 | 2.89 | 3.08 | 3.27 | 3.54 | 3.44 | 3.52 | 3.53 |

| PI,% | 108.2 | 107.1 | 105.1 | 106.7 | 114.6 | 107.5 | 108.8 | 110.7 |

| Calculation of the dynamics of changes in indicators | ||||||||

| Vt share in GDP | 0.12 | 0.13 | 0.12 | 0.13 | 0.15 | 0.14 | 0.14 | 0.13 |

| Vt/Vtt | 0.51 | 0.44 | 0.43 | 0.38 | 0.36 | 0.34 | 0.42 | 0.45 |

| Vtt/Vt | 1.98 | 2.29 | 2.34 | 2.67 | 2.76 | 2.95 | 2.40 | 2.24 |

| Vt/Vg | 0.90 | 1.04 | 1.08 | 1.15 | 1.19 | 1.20 | 1.31 | 1.36 |

| Vtt/Vg | 1.77 | 2.37 | 2.53 | 3.07 | 3.28 | 3.54 | 3.14 | 3.04 |

| Vr.t/Vtt (Srt) | 0.43 | 0.42 | 0.38 | 0.36 | 0.31 | 0.35 | 0.41 | 0.42 |

| Model 1 | Model 2 | Model 3 | |

|---|---|---|---|

| Dependent variables | CPav | CPav | SCrav |

| Independent variables | SCrft.; CPag.; CPi.p.; CPt.; PP; Il | SCrft.; PP | Srt; CPav.; PI |

| 2008 | 2010 | 2012 | 2014 | 2016 | 2018 | 2020 | 2022 | |

|---|---|---|---|---|---|---|---|---|

| 1. Production of agricultural products (Vag) | ||||||||

| Vag | 427.7 | 433.3 | 545.0 | 582.3 | 771.9 | 1031.8 | 1415.1 | 1759.7 |

| Cag | 337.2 | 396.4 | 463.9 | 504.7 | 625.9 | 837.6 | 1068.7 | 1318.3 |

| CPag, % | 14.37 | −3.45 | 5.42 | 1.86 | 5.54 | 6.45 | 18.95 | 25.3 |

| 2. Sales of agricultural products (Vs.ag.m) | ||||||||

| Vs.ag.m | 370.5 | 544.1 | 755.7 | 872.8 | 1182.0 | 1520.2 | 2304.1 | 3295.1 |

| Cs.ag | 281.6 | 408.1 | 553.4 | 631.5 | 855.1 | 1128.0 | 1639.2 | 2235.3 |

| CPs.ag, % | 24.0 | 25.0 | 26.8 | 27.7 | 27.7 | 25.8 | 28.9 | 27.1 |

| 3. Industrial food production (Vin) | ||||||||

| Vin | 623.5 | 695.2 | 865.6 | 1103.5 | 1448.4 | 1527.7 | 1957.2 | 2914.4 |

| Cin | 621.2 | 697.5 | 840.9 | 1069.6 | 1408.3 | 1507.6 | 1831.3 | 2681.3 |

| CPi.p., % | 0.41 | −0.33 | 2.91 | 3.24 | 2.81 | 1.35 | 6.96 | 8.72 |

| 4. Sales of food products in the industry (Vs.in.) | ||||||||

| Vs.in. | 592.3 | 660.4 | 822.3 | 1048.3 | 1375.9 | 1451.3 | 1859.3 | 2768.7 |

| Cs.in | 515.6 | 588.2 | 770.9 | 915.9 | 1152.2 | 1374.2 | 1655.3 | 2483.6 |

| CPs.in, % | 13.0 | 10.9 | 6.20 | 12.6 | 13.4 | 5.30 | 11.0 | 10.2 |

| 5. Trade in food products (Vtt) | ||||||||

| Vtt | 1905.7 | 2754.4 | 3695.7 | 5120.0 | 7068.4 | 8777.5 | 9971.8 | 13409.9 |

| Ct.t | 1385.6 | 1796.6 | 2757.5 | 2757.5 | 3547.6 | 5259.5 | 5513.2 | 7120.9 |

| CPt, % | 27.3 | 34.8 | 25.4 | 46.1 | 49.8 | 40.1 | 44.7 | 41.6 |

| 2008 | 2010 | 2012 | 2014 | 2016 | 2018 | 2020 | 2022 | Mean | SD | CV | CS | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Calculation of links in supply chains | ||||||||||||

| 1.SCrag | 2.21 | 1.93 | 1.88 | 2.09 | 1.86 | 2.00 | 1.78 | 1.70 | 1.90 | 0.15 | 7.90 | 92.1 |

| 2.SCrwt | 2.65 | 2.85 | 2.72 | 3.47 | 3.76 | 3.43 | 2.31 | 2.14 | 2.92 | 0.53 | 18.1 | 81.8 |

| 3.SCrfm | 5.14 | 5.06 | 4.89 | 5.87 | 5.98 | 5.77 | 4.33 | 4.07 | 5.12 | 0.64 | 12.5 | 87.5 |

| 4.SCrft | 2.33 | 2.62 | 2.61 | 2.81 | 3.21 | 2.89 | 2.43 | 2.39 | 2.69 | 0.28 | 10.4 | 89.6 |

| SCrav | 3.08 | 3.12 | 3.02 | 3.56 | 3.78 | 3.52 | 2.71 | 2.57 | 3.16 | 0.37 | 11.7 | 88.3 |

| Calculation of efficiency (profitability) in supply chains | ||||||||||||

| 1.CPag | 0.14 | −0.03 | 0.05 | 0.02 | 0.06 | 0.06 | 0.19 | 0.25 | 0.08 | 0.10 | 10.4 | 89.6 |

| 2.CPs.ag | 0.24 | 0.25 | 0.27 | 0.28 | 0.28 | 0.26 | 0.29 | 0.27 | 0.26 | 0.02 | 7.3 | 92.7 |

| 3.CPi.p | 0.00 | 0.00 | 0.03 | 0.03 | 0.03 | 0.01 | 0.06 | 0.08 | 0.03 | 0.03 | 30.4 | 69.6 |

| 4.CPs.in | 0.13 | 0.11 | 0.06 | 0.13 | 0.13 | 0.05 | 0.11 | 0.10 | 0.10 | 0.03 | 26.9 | 73.1 |

| 5.CPt | 0.27 | 0.35 | 0.25 | 0.46 | 0.50 | 0.40 | 0.55 | 0.42 | 0.41 | 0.08 | 19.1 | 80.9 |

| CPav | 0.16 | 0.13 | 0.13 | 0.18 | 0.20 | 0.16 | 0.24 | 0.22 | 0.18 | 0.03 | 19.1 | 80.9 |

| Variables and Their Characteristics | Model 1 | Model 2 | Variables | Model 3 |

|---|---|---|---|---|

| Dependent Variable CPav | Dependent Variable SCav | |||

| constant | 0.0536 ** | 0.0207 ** | SCav | 4.5275 *** |

| Independent variable | ||||

| SCav | −0.0117 ** | −0.0973 *** | CPav. | −3.3996 ** |

| CPag | 0.2018 *** | - | Srt | −8.5982 *** |

| CPi.p | 0.2604 ** | - | PI | 0.0227 ** |

| CPt. | 0.2831 *** | - | ||

| PP | 0.0528 *** | |||

| Il | −0.9189 ** | |||

| R-squared | 0.9669 | 0.7690 | 0.8470 | |

| Adjusted R-squared | 0.9537 | 0.7141 | 0.8053 | |

| F-statistic | 73.21 | 7.4112 | 20.30 | |

| p-value for the F test | 2.2904 × 10 | 0.0054 | 0.00008 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raimbekov, Z.; Syzdykbayeva, B.; Rakhmetulina, A.; Rakhmetulina, Z.; Abylaikhanova, T.; Ordabayeva, M.; Doltes, L. The Impact of Agri-Food Supply Channels on the Efficiency and Links in Supply Chains. Economies 2023, 11, 206. https://doi.org/10.3390/economies11080206

Raimbekov Z, Syzdykbayeva B, Rakhmetulina A, Rakhmetulina Z, Abylaikhanova T, Ordabayeva M, Doltes L. The Impact of Agri-Food Supply Channels on the Efficiency and Links in Supply Chains. Economies. 2023; 11(8):206. https://doi.org/10.3390/economies11080206

Chicago/Turabian StyleRaimbekov, Zhanarys, Bakyt Syzdykbayeva, Aigerim Rakhmetulina, Zhibek Rakhmetulina, Tana Abylaikhanova, Mainur Ordabayeva, and Lyubov Doltes. 2023. "The Impact of Agri-Food Supply Channels on the Efficiency and Links in Supply Chains" Economies 11, no. 8: 206. https://doi.org/10.3390/economies11080206

APA StyleRaimbekov, Z., Syzdykbayeva, B., Rakhmetulina, A., Rakhmetulina, Z., Abylaikhanova, T., Ordabayeva, M., & Doltes, L. (2023). The Impact of Agri-Food Supply Channels on the Efficiency and Links in Supply Chains. Economies, 11(8), 206. https://doi.org/10.3390/economies11080206