Temperature Sensors Based on Organic Field-Effect Transistors

Abstract

:1. Introduction

2. Small-Molecule Semiconductor-Based OFET Temperature Sensors

2.1. OFET Semiconductor Channel as Sensing Element

2.2. OFET Dielectric Layer as Sensing Element

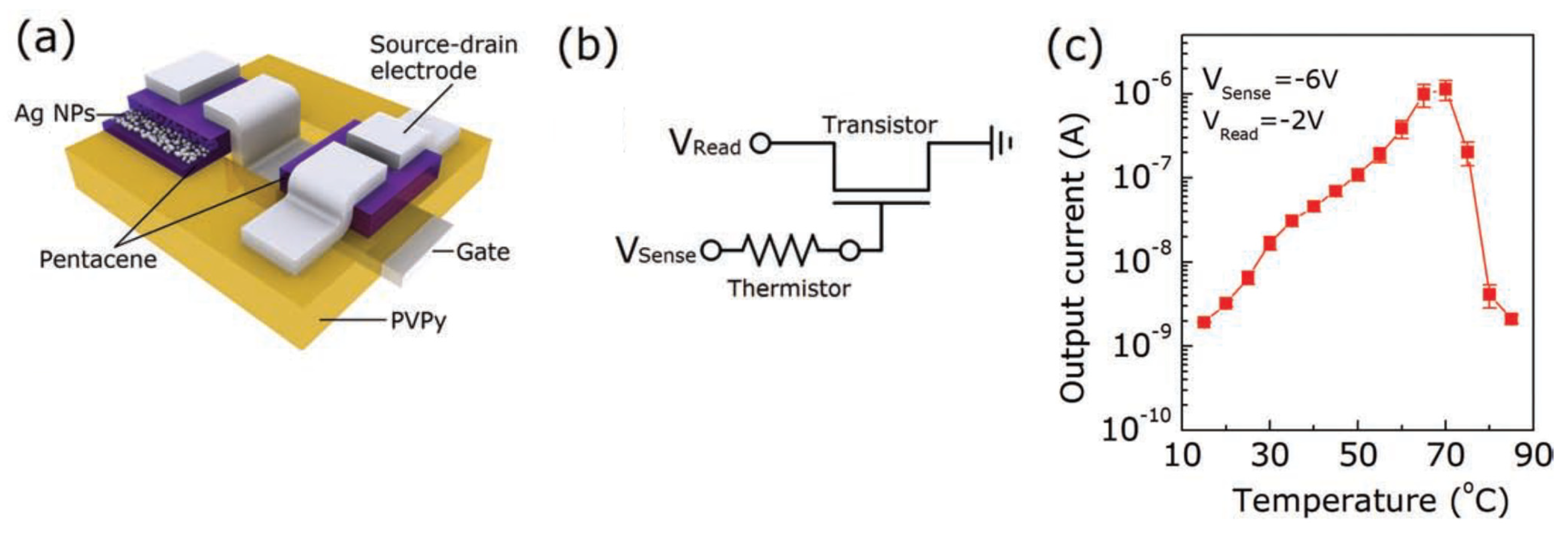

2.3. Thermistor as Sensing Element

2.4. Other Types of Sensing Elements

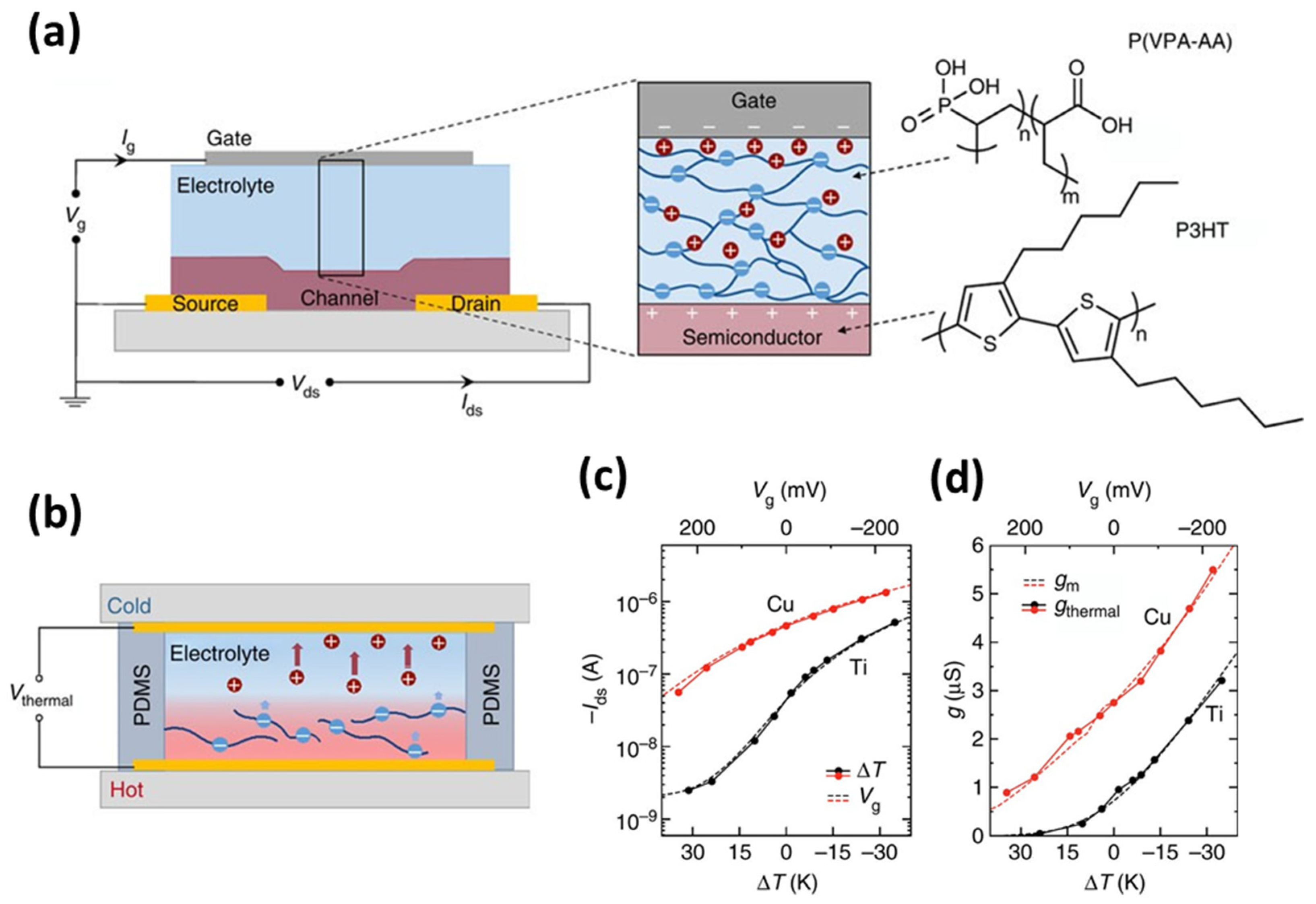

3. Polymer Semiconductor-Based OFET Temperature Sensors

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klauk, H. Organic Thin-Film Transistors. Chem. Soc. Rev. 2010, 39, 2643. [Google Scholar] [CrossRef]

- Huang, Y.; Kramer, E.J.; Heeger, A.J.; Bazan, G.C. Bulk Heterojunction Solar Cells: Morphology and Performance Relationships. Chem. Rev. 2014, 114, 7006–7043. [Google Scholar] [CrossRef]

- van de Burgt, Y.; Melianas, A.; Keene, S.T.; Malliaras, G.; Salleo, A. Organic Electronics for Neuromorphic Computing. Nat. Electron. 2018, 1, 386–397. [Google Scholar] [CrossRef]

- Lee, Y.H.; Kweon, O.Y.; Kim, H.; Yoo, J.H.; Han, S.G.; Oh, J.H. Recent Advances in Organic Sensors for Health Self-Monitoring Systems. J. Mater. Chem. C 2018, 6, 8569–8612. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, W.; Xu, H.; Liu, S.; Huang, W.; Zhao, Q. Fabrication of Ultra-Thin 2D Covalent Organic Framework Nanosheets and Their Application in Functional Electronic Devices. Coord. Chem. Rev. 2021, 429, 213616. [Google Scholar] [CrossRef]

- Freund, R.; Zaremba, O.; Arnauts, G.; Ameloot, R.; Skorupskii, G.; Dincă, M.; Bavykina, A.; Gascon, J.; Ejsmont, A.; Goscianska, J.; et al. The Current Status of MOF and COF Applications. Angew. Chem. Int. Ed. 2021, 60, 23975–24001. [Google Scholar] [CrossRef]

- Elkington, D.; Cooling, N.; Belcher, W.; Dastoor, P.C.; Zhou, X. Organic Thin-Film Transistor (OTFT)-Based Sensors. Electronics 2014, 3, 234–254. [Google Scholar] [CrossRef] [Green Version]

- Inal, S.; Malliaras, G.G.; Rivnay, J. Benchmarking Organic Mixed Conductors for Transistors. Nat. Commun. 2017, 8, 1767. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.Y.; Lee, H.R.; Park, C.H.; Han, S.G.; Oh, J.H. Organic Transistor-Based Chemical Sensors for Wearable Bioelectronics. Acc. Chem. Res. 2018, 51, 2829–2838. [Google Scholar] [CrossRef]

- Wang, N.; Yang, A.; Fu, Y.; Li, Y.; Yan, F. Functionalized Organic Thin Film Transistors for Biosensing. Acc. Chem. Res. 2019, 52, 277–287. [Google Scholar] [CrossRef]

- Fang, X.; Zong, B.; Mao, S. Metal–Organic Framework-Based Sensors for Environmental Contaminant Sensing. Nano-Micro Lett. 2018, 10, 64. [Google Scholar] [CrossRef] [Green Version]

- Urban, G.; Jachimowicz, A.; Kohl, F.; Kuttner, H.; Olcaytug, F.; Kamper, H.; Pittner, F.; Mann-Buxbaum, E.; Schalkhammer, T.; Prohaska, O.; et al. High-Resolution Thin-Film Temperature Sensor Arrays for Medical Applications. Sens. Actuators A Phys. 1990, 22, 650–654. [Google Scholar] [CrossRef]

- Khan, Y.; Ostfeld, A.E.; Lochner, C.M.; Pierre, A.; Arias, A.C. Monitoring of Vital Signs with Flexible and Wearable Medical Devices. Adv. Mater. 2016, 28, 4373–4395. [Google Scholar] [CrossRef]

- Mansor, H.; Shukor, M.H.A.; Meskam, S.S.; Rusli, N.Q.A.M.; Zamery, N.S. Body Temperature Measurement for Remote Health Monitoring System. In Proceedings of the 2013 IEEE International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA), Kuala Lumpur, Malaysia, 25–27 November 2013; pp. 1–5. [Google Scholar]

- Harada, S.; Kanao, K.; Yamamoto, Y.; Arie, T.; Akita, S.; Takei, K. Fully Printed Flexible Fingerprint-like Three-Axis Tactile and Slip Force and Temperature Sensors for Artificial Skin. ACS Nano 2014, 8, 12851–12857. [Google Scholar] [CrossRef]

- Kanao, K.; Harada, S.; Yamamoto, Y.; Honda, W.; Arie, T.; Akita, S.; Takei, K. Highly Selective Flexible Tactile Strain and Temperature Sensors against Substrate Bending for an Artificial Skin. RSC Adv. 2015, 5, 30170–30174. [Google Scholar] [CrossRef]

- Mansoor, M.; Haneef, I.; Akhtar, S.; De Luca, A.; Udrea, F. Silicon Diode Temperature Sensors—A Review of Applications. Sens. Actuators A Phys. 2015, 232, 63–74. [Google Scholar] [CrossRef]

- Newman, C.R.; Frisbie, C.D.; da Silva Filho, D.A.; Brédas, J.-L.; Ewbank, P.C.; Mann, K.R. Introduction to Organic Thin Film Transistors and Design of N-Channel Organic Semiconductors. Chem. Mater. 2004, 16, 4436–4451. [Google Scholar] [CrossRef]

- Zaumseil, J.; Sirringhaus, H. Electron and Ambipolar Transport in Organic Field-Effect Transistors. Chem. Rev. 2007, 107, 1296–1323. [Google Scholar] [CrossRef]

- Schafft, H.A.; Suehle, J.S. The Measurement, Use and Interpretation of the Temperature Coefficient of Resistance of Metallizations. Solid-State Electron. 1992, 35, 403–410. [Google Scholar] [CrossRef]

- Torsi, L.; Dodabalapur, A.; Sabbatini, L.; Zambonin, P.G. Multi-Parameter Gas Sensors Based on Organic Thin-Film-Transistors. Sens. Actuators B 2000, 67, 312–316. [Google Scholar] [CrossRef]

- Poghossian, A.; Schultze, J.W.; Schöning, M.J. Multi-Parameter Detection of (Bio-)Chemical and Physical Quantities Using an Identical Transducer Principle. Sens. Actuators B Chem. 2003, 91, 83–91. [Google Scholar] [CrossRef]

- Horowitz, G. Organic Field-Effect Transistors. Adv. Mater. 1998, 10, 365–377. [Google Scholar] [CrossRef]

- Stallinga, P. Electronic Transport in Organic Materials: Comparison of Band Theory with Percolation/(Variable Range) Hopping Theory. Adv. Mater. 2011, 23, 3356–3362. [Google Scholar] [CrossRef]

- Coropceanu, V.; Cornil, J.; da Silva Filho, D.A.; Olivier, Y.; Silbey, R.; Brédas, J.-L. Charge Transport in Organic Semiconductors. Chem. Rev. 2007, 107, 926–952. [Google Scholar] [CrossRef]

- Mei, Y.; Diemer, P.J.; Niazi, M.R.; Hallani, R.K.; Jarolimek, K.; Day, C.S.; Risko, C.; Anthony, J.E.; Amassian, A.; Jurchescu, O.D. Crossover from Band-like to Thermally Activated Charge Transport in Organic Transistors Due to Strain-Induced Traps. Proc. Natl. Acad. Sci. USA 2017, 114, E6739–E6748. [Google Scholar] [CrossRef] [Green Version]

- Lee, J. Physical Modeling of Charge Transport in Conjugated Polymer Field-Effect Transistors. J. Phys. D Appl. Phys. 2021, 54, 143002. [Google Scholar] [CrossRef]

- de Boer, R.W.I.; Gershenson, M.E.; Morpurgo, A.F.; Podzorov, V. Organic Single-Crystal Field-Effect Transistors. Phys. Status Solidi A 2004, 201, 1302–1331. [Google Scholar] [CrossRef] [Green Version]

- Minder, N.A.; Ono, S.; Chen, Z.; Facchetti, A.; Morpurgo, A.F. Band-Like Electron Transport in Organic Transistors and Implication of the Molecular Structure for Performance Optimization. Adv. Mater. 2012, 24, 503–508. [Google Scholar] [CrossRef] [Green Version]

- Yamashita, Y.; Tsurumi, J.; Hinkel, F.; Okada, Y.; Soeda, J.; Zajączkowski, W.; Baumgarten, M.; Pisula, W.; Matsui, H.; Müllen, K.; et al. Transition Between Band and Hopping Transport in Polymer Field-Effect Transistors. Adv. Mater. 2014, 26, 8169–8173. [Google Scholar] [CrossRef]

- Rani, V.; Kumar, P.; Sharma, A.; Yadav, S.; Singh, B.; Ray, N.; Ghosh, S. Carrier Induced Hopping to Band Conduction in Pentacene. Sci. Rep. 2019, 9, 20193. [Google Scholar] [CrossRef]

- Senanayak, S.P.; Ashar, A.Z.; Kanimozhi, C.; Patil, S.; Narayan, K.S. Room-Temperature Bandlike Transport and Hall Effect in a High-Mobility Ambipolar Polymer. Phys. Rev. B 2015, 91, 115302. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Chung, J.W.; Kim, D.H.; Lee, B.-L.; Park, J.-I.; Lee, S.; Häusermann, R.; Batlogg, B.; Lee, S.-S.; Choi, I.; et al. Thin Films of Highly Planar Semiconductor Polymers Exhibiting Band-like Transport at Room Temperature. J. Am. Chem. Soc. 2015, 137, 7990–7993. [Google Scholar] [CrossRef]

- Schott, S.; Gann, E.; Thomsen, L.; Jung, S.; Lee, J.; McNeill, C.R.; Sirringhaus, H. Charge--Transport Anisotropy in a Uniaxially Aligned Diketopyrrolopyrrole--Based Copolymer. Adv. Mater. 2015, 27, 7356–7364. [Google Scholar] [CrossRef] [Green Version]

- Yamashita, Y.; Hinkel, F.; Marszalek, T.; Zajaczkowski, W.; Pisula, W.; Baumgarten, M.; Matsui, H.; Müllen, K.; Takeya, J. Mobility Exceeding 10 cm2/(V·s) in Donor–Acceptor Polymer Transistors with Band-like Charge Transport. Chem. Mater. 2016, 28, 420–424. [Google Scholar] [CrossRef]

- Podzorov, V.; Menard, E.; Borissov, A.; Kiryukhin, V.; Rogers, J.A.; Gershenson, M.E. Intrinsic Charge Transport on the Surface of Organic Semiconductors. Phys. Rev. Lett. 2004, 93, 086602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Merlo, J.A.; Frisbie, C.D. Field Effect Transport and Trapping in Regioregular Polythiophene Nanofibers. J. Phys. Chem. B 2004, 108, 19169–19179. [Google Scholar] [CrossRef]

- Hulea, I.N.; Fratini, S.; Xie, H.; Mulder, C.L.; Iossad, N.N.; Rastelli, G.; Ciuchi, S.; Morpurgo, A.F. Tunable Fröhlich Polarons in Organic Single-Crystal Transistors. Nat. Mater. 2006, 5, 982–986. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.; Ji, T.; Varadan, V.K. Point-of-Care Temperature and Respiration Monitoring Sensors for Smart Fabric Applications. Smart Mater. Struct. 2006, 15, 1872–1876. [Google Scholar] [CrossRef]

- Wu, X.; Ma, Y.; Zhang, G.; Chu, Y.; Du, J.; Zhang, Y.; Li, Z.; Duan, Y.; Fan, Z.; Huang, J. Thermally Stable, Biocompatible, and Flexible Organic Field-Effect Transistors and Their Application in Temperature Sensing Arrays for Artificial Skin. Adv. Funct. Mater. 2015, 25, 2138–2146. [Google Scholar] [CrossRef]

- Someya, T.; Kato, Y.; Sekitani, T.; Iba, S.; Noguchi, Y.; Murase, Y.; Kawaguchi, H.; Sakurai, T. Conformable, Flexible, Large-Area Networks of Pressure and Thermal Sensors with Organic Transistor Active Matrixes. Proc. Natl. Acad. Sci. USA 2005, 102, 12321–12325. [Google Scholar] [CrossRef] [Green Version]

- Ren, X.; Chan, P.K.L.; Lu, J.; Huang, B.; Leung, D.C.W. High Dynamic Range Organic Temperature Sensor. Adv. Mater. 2013, 25, 1291–1295. [Google Scholar] [CrossRef]

- Cosseddu, P.; Viola, F.; Lai, S.; Raffo, L.; Bonfiglio, A. A Temperature Transducer Based on a Low-Voltage Organic Thin-Film Transistor Detecting Pyroelectric Effect. IEEE Electron Device Lett. 2014, 35, 1296–1298. [Google Scholar] [CrossRef]

- Yang, S.Y.; Kim, S.H.; Shin, K.; Jeon, H.; Park, C.E. Low-Voltage Pentacene Field-Effect Transistors with Ultrathin Polymer Gate Dielectrics. Appl. Phys. Lett. 2006, 88, 173507. [Google Scholar] [CrossRef] [Green Version]

- Yamamoto, T.; Takimiya, K. Facile Synthesis of Highly π-Extended Heteroarenes, Dinaphtho[2,3-b:2‘,3‘-f]Chalcogenopheno[3,2-b]Chalcogenophenes, and Their Application to Field-Effect Transistors. J. Am. Chem. Soc. 2007, 129, 2224–2225. [Google Scholar] [CrossRef]

- Takimiya, K.; Shinamura, S.; Osaka, I.; Miyazaki, E. Thienoacene-Based Organic Semiconductors. Adv. Mater. 2011, 23, 4347–4370. [Google Scholar] [CrossRef] [PubMed]

- Quinn, J.T.E.; Zhu, J.; Li, X.; Wang, J.; Li, Y. Recent Progress in the Development of N-Type Organic Semiconductors for Organic Field Effect Transistors. J. Mater. Chem. C 2017, 5, 8654–8681. [Google Scholar] [CrossRef]

- Lin, P.; Yan, F. Organic Thin-Film Transistors for Chemical and Biological Sensing. Adv. Mater. 2012, 24, 34–51. [Google Scholar] [CrossRef]

- Li, H.; Shi, W.; Song, J.; Jang, H.-J.; Dailey, J.; Yu, J.; Katz, H.E. Chemical and Biomolecule Sensing with Organic Field-Effect Transistors. Chem. Rev. 2019, 119, 3–35. [Google Scholar] [CrossRef]

- Yuvaraja, S.; Nawaz, A.; Liu, Q.; Dubal, D.; Surya, S.G.; Salama, K.N.; Sonar, P. Organic Field-Effect Transistor-Based Flexible Sensors. Chem. Soc. Rev. 2020, 49, 3423–3460. [Google Scholar] [CrossRef]

- Baeg, K.-J.; Noh, Y.-Y.; Ghim, J.; Kang, S.-J.; Lee, H.; Kim, D.-Y. Organic Non-Volatile Memory Based on Pentacene Field-Effect Transistors Using a Polymeric Gate Electret. Adv. Mater. 2006, 18, 3179–3183. [Google Scholar] [CrossRef]

- Schroeder, R.; Majewski, L.A.; Grell, M. A Study of the Threshold Voltage in Pentacene Organic Field-Effect Transistors. Appl. Phys. Lett. 2003, 83, 3201–3203. [Google Scholar] [CrossRef]

- Shi, W.; Yu, J.; Katz, H.E. Sensitive and Selective Pentacene-Guanine Field-Effect Transistor Sensing of Nitrogen Dioxide and Interferent Vapor Analytes. Sens. Actuators B Chem. 2018, 254, 940–948. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, L.; Liu, Z.; Wan, Z.; Yin, J.; Gao, X.; Xia, Y.; Liu, Z. Enhancement of Memory Properties of Pentacene Field-Effect Transistor by the Reconstruction of an Inner Vertical Electric Field with an n-Type Semiconductor Interlayer. ACS Appl. Mater. Interfaces 2021, 13, 13452–13458. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.; Ji, T.; Varadan, V.K. Temperature Sensor Using Thermal Transport Properties in the Subthreshold Regime of an Organic Thin Film Transistor. Appl. Phys. Lett. 2007, 90, 062105. [Google Scholar] [CrossRef]

- Kawakami, D.; Yasutake, Y.; Nishizawa, H.; Majima, Y. Bias Stress Induced Threshold Voltage Shift in Pentacene Thin-Film Transistors. Jpn. J. Appl. Phys. 2006, 45, L1127–L1129. [Google Scholar] [CrossRef]

- Kwak, T.H.; Kang, H.S.; Kim, K.; Cho, M.Y.; Lee, J.W.; Joo, J. Copper-Phthalocyanine Based Organic Thin Film Transistor. In Proceedings of the 2006 IEEE Nanotechnology Materials and Devices Conference, Gyeongju, Korea, 22–25 October 2006; pp. 630–631. [Google Scholar]

- Ye, R.; Baba, M.; Ohishi, Y.; Mori, K.; Suzuki, K. On the Correlation between Morphology and Electronic Properties of Fluorinated Copper Phthalocyanine (F16CuPc) Thin Films. Mol. Cryst. Liq. Cryst. 2006, 444, 203–210. [Google Scholar] [CrossRef]

- Boileau, N.T.; Melville, O.A.; Mirka, B.; Cranston, R.; Lessard, B.H. P and N Type Copper Phthalocyanines as Effective Semiconductors in Organic Thin-Film Transistor Based DNA Biosensors at Elevated Temperatures. RSC Adv. 2019, 9, 2133–2142. [Google Scholar] [CrossRef] [Green Version]

- Ye, R.; Ohta, K.; Baba, M. Temperature Dependence of Electrical Properties of Organic Thin Film Transistors Based on Pn Heterojuction and Their Applications in Temperature Sensors. J. Comput. Commun. 2016, 4, 10–15. [Google Scholar] [CrossRef] [Green Version]

- Ye, R.; Baba, M.; Oishi, Y.; Mori, K.; Suzuki, K. Air-Stable Ambipolar Organic Thin-Film Transistors Based on an Organic Homostructure. Appl. Phys. Lett. 2005, 86, 253505. [Google Scholar] [CrossRef]

- Ye, R.; Baba, M.; Suzuki, K.; Mori, K. Improved Performance of Fluorinated Copper Phthalocyanine Thin Film Transistors Using an Organic Pn Junction: Effect of Copper Phthalocyanine Film Thickness. Thin Solid Film. 2009, 517, 3001–3004. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Yan, X.; Huang, H.; Yan, D. Organic Heterojunction and Its Application for Double Channel Field-Effect Transistors. Appl. Phys. Lett. 2005, 87, 093507. [Google Scholar] [CrossRef]

- Xiang, L.; Ying, J.; Han, J.; Zhang, L.; Wang, W. High Reliable and Stable Organic Field-Effect Transistor Nonvolatile Memory with a Poly(4-Vinyl Phenol) Charge Trapping Layer Based on a Pn-Heterojunction Active Layer. Appl. Phys. Lett. 2016, 108, 173301. [Google Scholar] [CrossRef]

- Yu, S.H.; Kang, B.; An, G.; Kim, B.; Lee, M.H.; Kang, M.S.; Kim, H.; Lee, J.H.; Lee, S.; Cho, K.; et al. Pn-Heterojunction Effects of Perylene Tetracarboxylic Diimide Derivatives on Pentacene Field-Effect Transistor. ACS Appl. Mater. Interfaces 2015, 7, 2025–2031. [Google Scholar] [CrossRef] [PubMed]

- Ye, R.; Ohta, K.; Baba, M. In-Situ Study of Pn-Heterojunction Interface States in Organic Thin Film Transistors. Thin Solid Film. 2014, 554, 137–140. [Google Scholar] [CrossRef]

- Haque, F.; Lim, S.; Lee, S.; Park, Y.; Mativenga, M. Highly Sensitive and Ambient Air-Processed Hybrid Perovskite TFT Temperature Sensor. IEEE Electron Device Lett. 2020, 41, 1086–1089. [Google Scholar] [CrossRef]

- Shao, M.; He, Y.; Hong, K.; Rouleau, C.M.; Geohegan, D.B.; Xiao, K. A Water-Soluble Polythiophene for Organic Field-Effect Transistors. Polym. Chem. 2013, 4, 5270. [Google Scholar] [CrossRef]

- Subbarao, N.V.V.; Mandal, S.; Gedda, M.; Iyer, P.K.; Goswami, D.K. Effect of Temperature on Hysteresis of Dipolar Dielectric Layer Based Organic Field-Effect Transistors: A Temperature Sensing Mechanism. Sens. Actuators A Phys. 2018, 269, 491–499. [Google Scholar] [CrossRef]

- Mandal, S.; Banerjee, M.; Roy, S.; Mandal, A.; Ghosh, A.; Satpati, B.; Goswami, D.K. Organic Field-Effect Transistor-Based Ultrafast, Flexible, Physiological-Temperature Sensors with Hexagonal Barium Titanate Nanocrystals in Amorphous Matrix as Sensing Material. ACS Appl. Mater. Interfaces 2019, 11, 4193–4202. [Google Scholar] [CrossRef]

- Rullyani, C.; Singh, M.; Li, S.-H.; Sung, C.-F.; Lin, H.-C.; Chu, C.-W. Stimuli-Responsive Polymer as Gate Dielectric for Organic Transistor Sensors. Org. Electron. 2020, 85, 105818. [Google Scholar] [CrossRef]

- Ren, X.; Pei, K.; Peng, B.; Zhang, Z.; Wang, Z.; Wang, X.; Chan, P.K.L. A Low-Operating-Power and Flexible Active-Matrix Organic-Transistor Temperature-Sensor Array. Adv. Mater. 2016, 28, 4832–4838. [Google Scholar] [CrossRef] [PubMed]

- Yokota, T.; Inoue, Y.; Terakawa, Y.; Reeder, J.; Kaltenbrunner, M.; Ware, T.; Yang, K.; Mabuchi, K.; Murakawa, T.; Sekino, M.; et al. Ultraflexible, Large-Area, Physiological Temperature Sensors for Multipoint Measurements. Proc. Natl. Acad. Sci. USA 2015, 112, 14533–14538. [Google Scholar] [CrossRef] [Green Version]

- Ishaku, A.A.; Gleskova, H. Potential of Low-Voltage Organic Transistors with High on-State Drain Current for Temperature Sensor Development. Org. Electron. 2021, 93, 106152. [Google Scholar] [CrossRef]

- Jang, S.; Son, D.; Hwang, S.; Kang, M.; Lee, S.-K.; Jeon, D.-Y.; Bae, S.; Lee, S.H.; Lee, D.S.; Kim, T.-W. Hybrid Dielectrics Composed of Al2O3 and Phosphonic Acid Self-Assembled Monolayers for Performance Improvement in Low Voltage Organic Field Effect Transistors. Nano Converg. 2018, 5, 20. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nakayama, K.; Cha, B.-S.; Kanaoka, Y.; Isahaya, N.; Omori, M.; Uno, M.; Takeya, J. Organic Temperature Sensors and Organic Analog-to-Digital Converters Based on p-Type and n-Type Organic Transistors. Org. Electron. 2016, 36, 148–152. [Google Scholar] [CrossRef]

- Ozgun, R.; Katz, H.E.; Andreou, A.G. Organic Diode Implementations in Configurable Architectures and Temperature Sensors. In Proceedings of the 2013 Microsystems for Measurement and Instrumentation: Fulfilling the Promise (MAMNA), Gaithersburg, MD, USA, 14 May 2013; pp. 24–27. [Google Scholar]

- Dudhe, R.S.; Sinha, J.; Kumar, A.; Rao, V.R. Polymer Composite-Based OFET Sensor with Improved Sensitivity towards Nitro Based Explosive Vapors. Sens. Actuators B Chem. 2010, 148, 158–165. [Google Scholar] [CrossRef]

- Graz, I.; Krause, M.; Bauer-Gogonea, S.; Bauer, S.; Lacour, S.P.; Ploss, B.; Zirkl, M.; Stadlober, B.; Wagner, S. Flexible Active-Matrix Cells with Selectively Poled Bifunctional Polymer-Ceramic Nanocomposite for Pressure and Temperature Sensing Skin. J. Appl. Phys. 2009, 106, 034503. [Google Scholar] [CrossRef]

- Guo, X.; Baumgarten, M.; Müllen, K. Designing π-Conjugated Polymers for Organic Electronics. Prog. Polym. Sci. 2013, 38, 1832–1908. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, L.; You, W. Rational Design of High Performance Conjugated Polymers for Organic Solar Cells. Macromolecules 2012, 45, 607–632. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Hendriks, K.H.; Wienk, M.M.; Janssen, R.A.J. Diketopyrrolopyrrole Polymers for Organic Solar Cells. Acc. Chem. Res. 2016, 49, 78–85. [Google Scholar] [CrossRef] [Green Version]

- Sekine, C.; Tsubata, Y.; Yamada, T.; Kitano, M.; Doi, S. Recent Progress of High Performance Polymer OLED and OPV Materials for Organic Printed Electronics. Sci. Technol. Adv. Mater. 2014, 15, 034203. [Google Scholar] [CrossRef]

- Pivrikas, A.; Sariciftci, N.S.; Juška, G.; Österbacka, R. A Review of Charge Transport and Recombination in Polymer/Fullerene Organic Solar Cells. Prog. Photovolt. Res. Appl. 2007, 15, 677–696. [Google Scholar] [CrossRef]

- Yeh, N.; Yeh, P. Organic Solar Cells: Their Developments and Potentials. Renew. Sustain. Energy Rev. 2013, 21, 421–431. [Google Scholar] [CrossRef]

- Sirringhaus, H.; Brown, P.J.; Friend, R.H.; Nielsen, M.M.; Bechgaard, K.; Langeveld-Voss, B.M.W.; Spiering, A.J.H.; Janssen, R.A.J.; Meijer, E.W.; Herwig, P.; et al. Two-Dimensional Charge Transport in Self-Organized, High-Mobility Conjugated Polymers. Nature 1999, 401, 685–688. [Google Scholar] [CrossRef]

- Ong, B.S.; Wu, Y.; Liu, P.; Gardner, S. High-Performance Semiconducting Polythiophenes for Organic Thin-Film Transistors. J. Am. Chem. Soc. 2004, 126, 3378–3379. [Google Scholar] [CrossRef]

- Ong, B.S.; Wu, Y.; Li, Y.; Liu, P.; Pan, H. Thiophene Polymer Semiconductors for Organic Thin-Film Transistors. Chem. Eur. J. 2008, 14, 4766–4778. [Google Scholar] [CrossRef] [PubMed]

- McCulloch, I.; Heeney, M.; Bailey, C.; Genevicius, K.; MacDonald, I.; Shkunov, M.; Sparrowe, D.; Tierney, S.; Wagner, R.; Zhang, W.; et al. Liquid-Crystalline Semiconducting Polymers with High Charge-Carrier Mobility. Nat. Mater. 2006, 5, 328–333. [Google Scholar] [CrossRef] [PubMed]

- Ohmori, Y.; Muro, K.; Yoshino, K. Gas-Sensitive and Temperature-Dependent Schottky Gated Field Effect Transistors Utilizing Poly(3-Alkylthiophene)s. Synth. Met. 1993, 57, 4111–4116. [Google Scholar] [CrossRef]

- Song, M.; Seo, J.; Kim, H.; Kim, Y. Flexible Thermal Sensors Based on Organic Field-Effect Transistors with Polymeric Channel/Gate-Insulating and Light-Blocking Layers. ACS Omega 2017, 2, 4065–4070. [Google Scholar] [CrossRef] [Green Version]

- Zhu, C.; Wu, H.-C.; Nyikayaramba, G.; Bao, Z.; Murmann, B. Intrinsically Stretchable Temperature Sensor Based on Organic Thin-Film Transistors. IEEE Electron Device Lett. 2019, 40, 1630–1633. [Google Scholar] [CrossRef]

- Zhao, D.; Fabiano, S.; Berggren, M.; Crispin, X. Ionic Thermoelectric Gating Organic Transistors. Nat. Commun. 2017, 8, 14214. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Sensor Structure | OFET Channel | Sensing Element | Working Range | Sensor Parameter | Sensitivity | Year [Ref.] |

|---|---|---|---|---|---|---|

| Sensing element: OFET active layer | ||||||

| OFET | Pentacene | OFET channel | 0–80 °C | IDS,sub | ~0.1 nA/°C 1 | 2006 [39] |

| OFET | Pentacene | OFET channel | 0–180 °C | IDS,sub, VT | - | 2007 [55] |

| OFET | CuPc | OFET channel | 25–90 °C | VT | 0.11 V/°C | 2019 [59] |

| OFET | F16CuPc | OFET channel | 25–90 °C | VT | −0.25 V/°C | 2019 [72] |

| OFET | α6T/F16CuPc pn junction | OFET channel | −173–27 °C | VT | −0.090 V/°C (<–73 °C) −0.185 V/°C (>–73 °C) | 2016 [60] |

| Organic-inorganic FET | MAPbI3 | FET channel | 20–45 °C | VT | −200 mV/°C | 2020 [67] |

| Sensing element: dielectric layer | ||||||

| OFET | 6PTTP6 8-3-NTCDI DNTT | Dielectric (PLA) | −25–200 °C | IDS | 0.29 μA/°C 1 | 2015 [40] |

| OFET | CuPc | Dielectric (PVA) | −20–0 °C | IDS | 0.45 nA/°C (<300 K) 8 nA/°C (>300 K) | 2018 [69] |

| OFET | Pentacene | Dielectric (h-BTNC) | 27–45 °C | IDS | 20 nA/°C | 2019 [70] |

| OFET | Pentacene | Dielectric (PNIPAM) | 30–45 °C | IDS | 2.58 µA/°C | 2020 [71] |

| Sensing element: thermistor | ||||||

| OFET-thermistor | Pentacene | Thermistor (Pentacene/AgNPs) | 15–70 °C | IDS | DR = 10 bits | 2013 [42] |

| OFET-thermistor | DNTT | Thermistor (Pentacene/AgNPs) | 20–100 °C | TCR | −4.40%/°C | 2016 [72] |

| OFET-thermistor | DNTT | PTC thermistor (copolymer-graphite) | 29.8–37.0 °C | IDS or R | 20 mK | 2015 [73] |

| OFET-thermistor | DNTT | Thermistor (commercial) | 20–50 °C | TCR | −2.44%/°C | 2021 [74] |

| OFET-thermistor ADC | C10-DNBDT (p) GSID 104031-1 (n) | Thermistors (PEDOT:PSS; Cr/Au) | 33–67 °C | Binary codes | - | 2016 [76] |

| Sensing element: other types | ||||||

| OFET-diode | Pentacene | Diode (CuPc/PTCDI) | 30–80 °C | IDS | ~20 nA/°C | 2005 [41] |

| OFET-diode | Pentacene | OFET& Diode | 27.2–59.0 °C | VDS | 16.3 mV/°C | 2013 [77] |

| OFET-capacitor | Pentacene | Capacitor (polymer composite) | ~r. t. | IDS | ~30 nA/°C 1 | 2009 [79] |

| OFET-capacitor | TIPS | Pyroelectric (PVDF) | 10–42 °C | IDS | ~0.14 μA/°C 1 | 2014 [43] |

| Sensor Structure | OFET Channel | Sensing Element | Working Range | Sensor Parameter | Sensitivity | Year [Ref.] |

|---|---|---|---|---|---|---|

| OFET | P3ET | OFET channel | 14–75 °C | μh | 9 × 10−5 (cm2/V·s)/°C 1 | 1993 [90] |

| OFET | P3HT | OFET channel | 25–100 °C | μh | 2.34 × 10−5 (cm2/V·s)/°C | 2017 [91] |

| OFET | PDPPFT4 | OFET channel | 25–55 °C | TCR | –2.89%/°C | 2019 [92] |

| OFET | PII2T | OFET channel | 25–55 °C | TCR | –4.23%/°C | 2019 [92] |

| OFET/capacitor | P3HT | Capacitor (PEO-NaOH) | 15–45 °C | IDS gthermal | 20 nA/°C 0.08 μS/°C 1 | 2017 [93] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polena, J.; Afzal, D.; Ngai, J.H.L.; Li, Y. Temperature Sensors Based on Organic Field-Effect Transistors. Chemosensors 2022, 10, 12. https://doi.org/10.3390/chemosensors10010012

Polena J, Afzal D, Ngai JHL, Li Y. Temperature Sensors Based on Organic Field-Effect Transistors. Chemosensors. 2022; 10(1):12. https://doi.org/10.3390/chemosensors10010012

Chicago/Turabian StylePolena, John, Daniel Afzal, Jenner H. L. Ngai, and Yuning Li. 2022. "Temperature Sensors Based on Organic Field-Effect Transistors" Chemosensors 10, no. 1: 12. https://doi.org/10.3390/chemosensors10010012

APA StylePolena, J., Afzal, D., Ngai, J. H. L., & Li, Y. (2022). Temperature Sensors Based on Organic Field-Effect Transistors. Chemosensors, 10(1), 12. https://doi.org/10.3390/chemosensors10010012