Elemental Determination in Stainless Steel via Laser-Induced Breakdown Spectroscopy and Back-Propagation Artificial Intelligence Network with Spectral Pre-Processing

Abstract

1. Introduction

2. Experiments and Methods

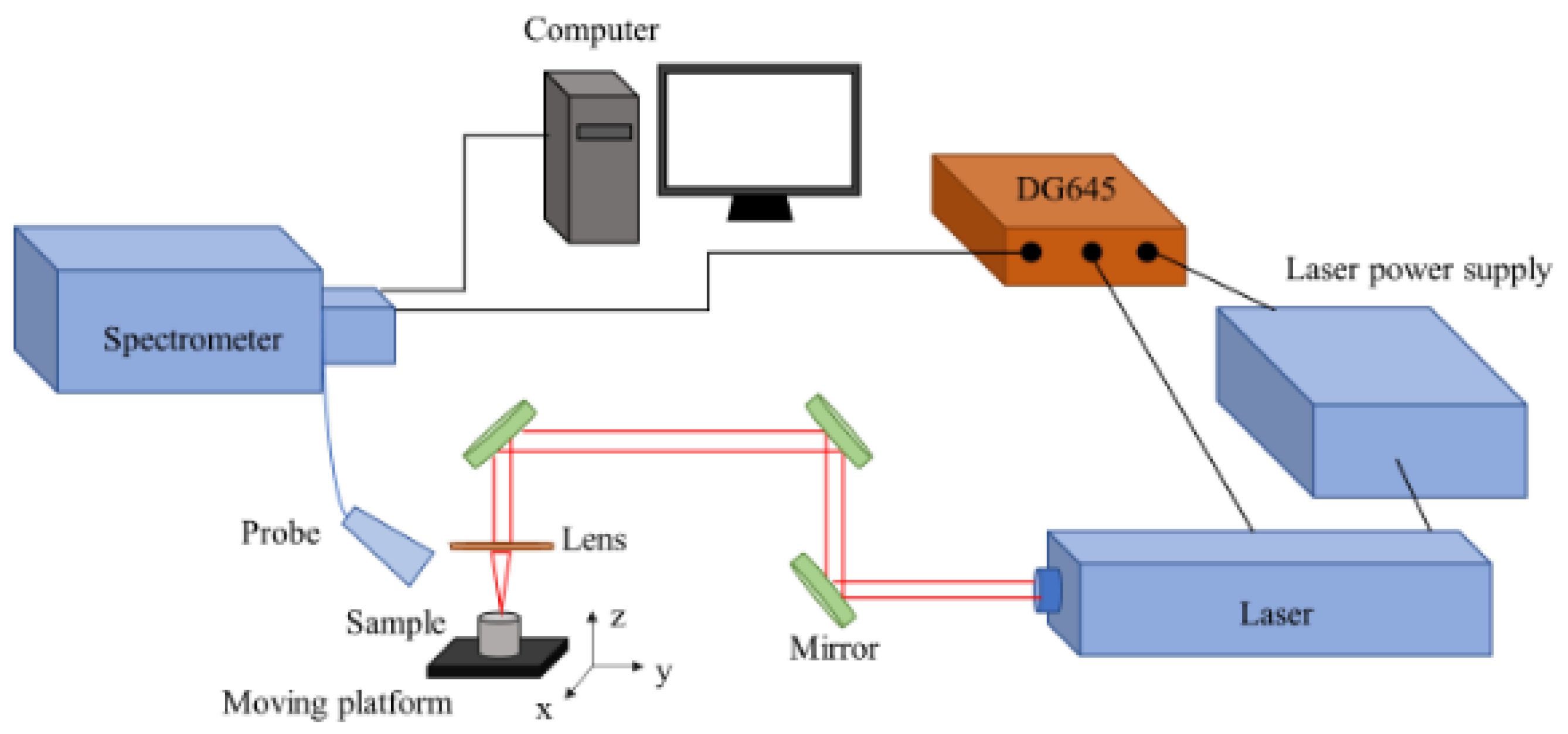

2.1. Experiments

2.2. Methods of LIBS Element Content Calibration

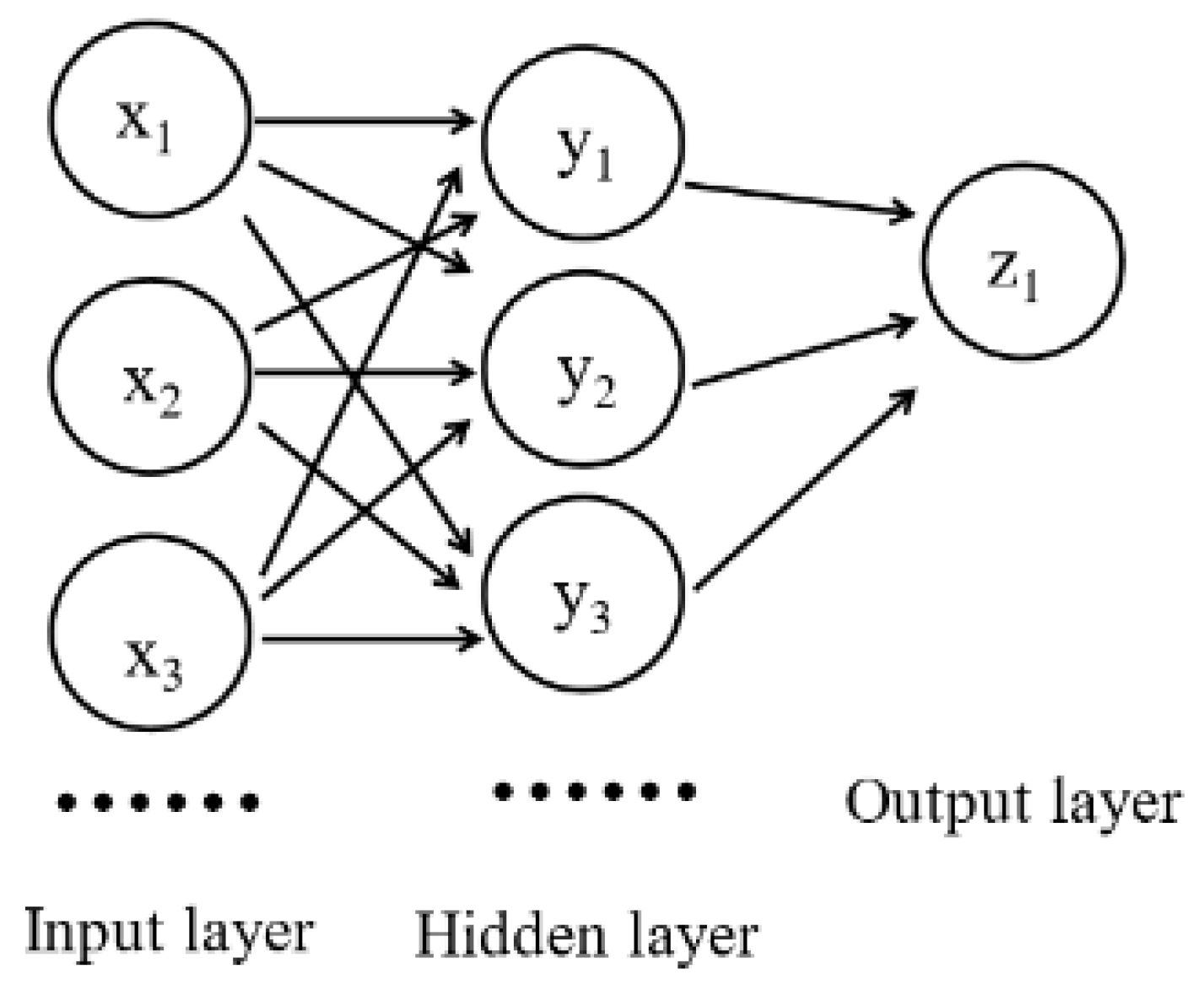

2.3. BP-ANN and Quantitative Analysis

2.4. Data Pre-Processing Methods

3. Results

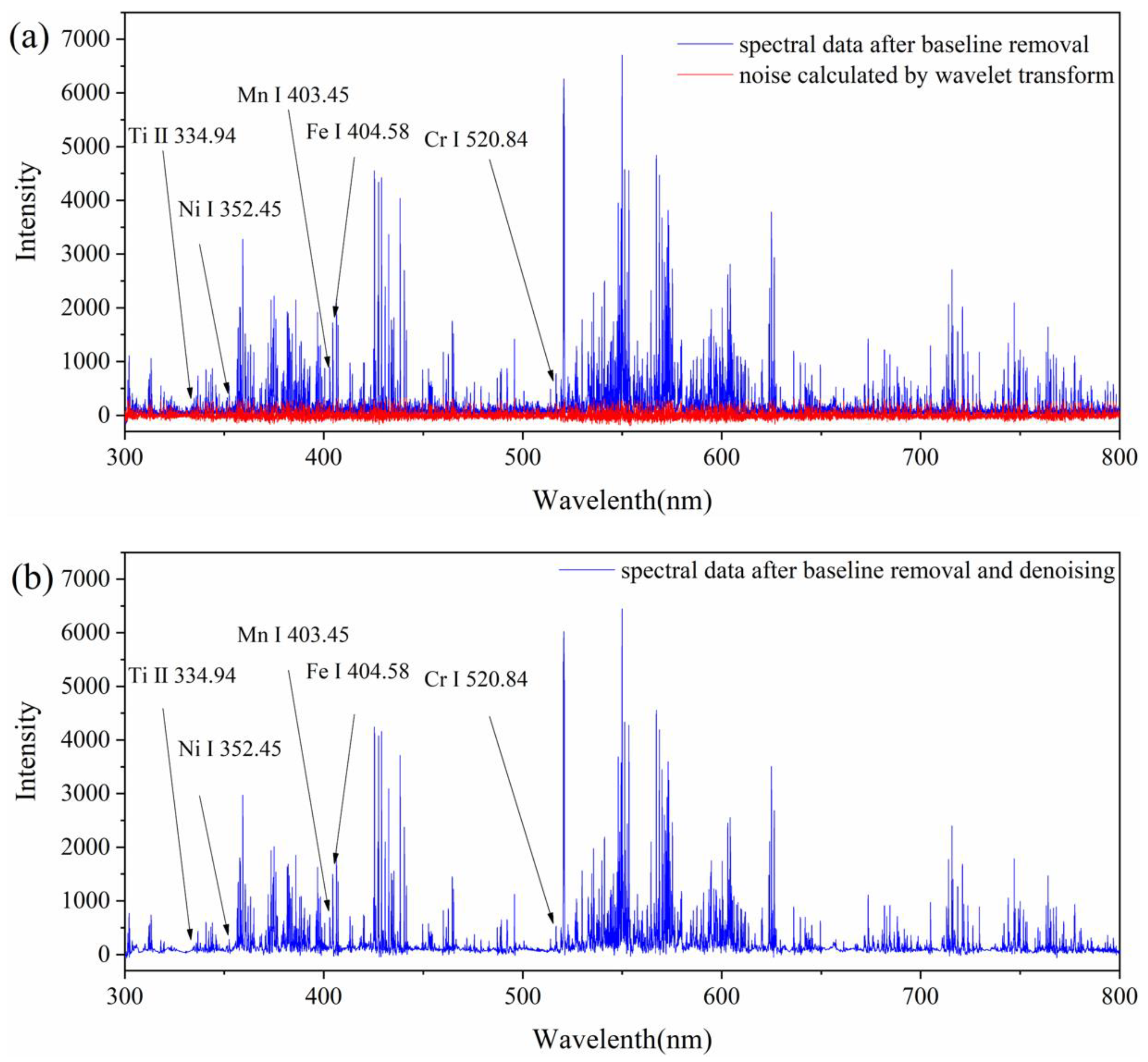

3.1. Result of Data Pre-Processing

3.2. Feature Selection

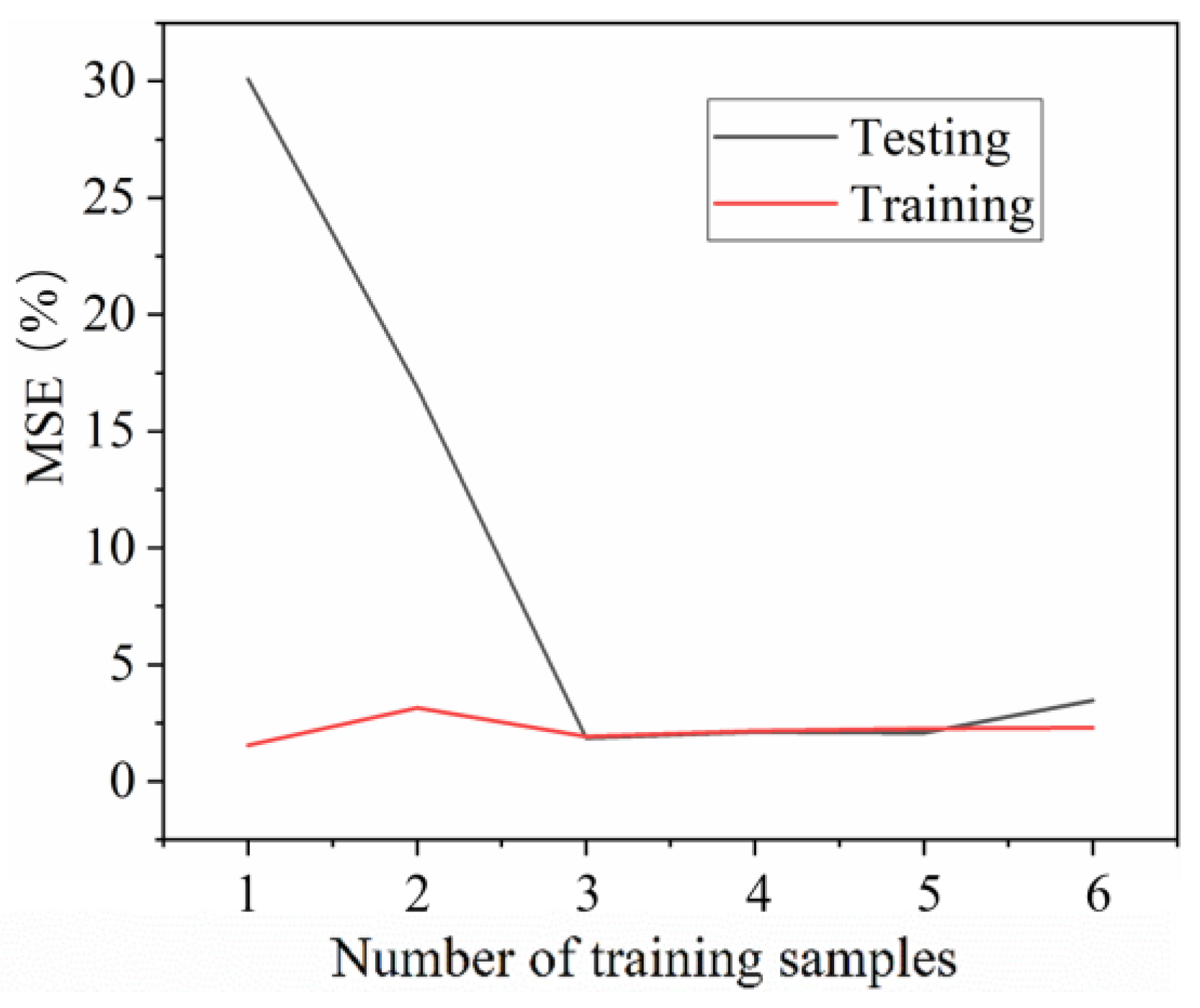

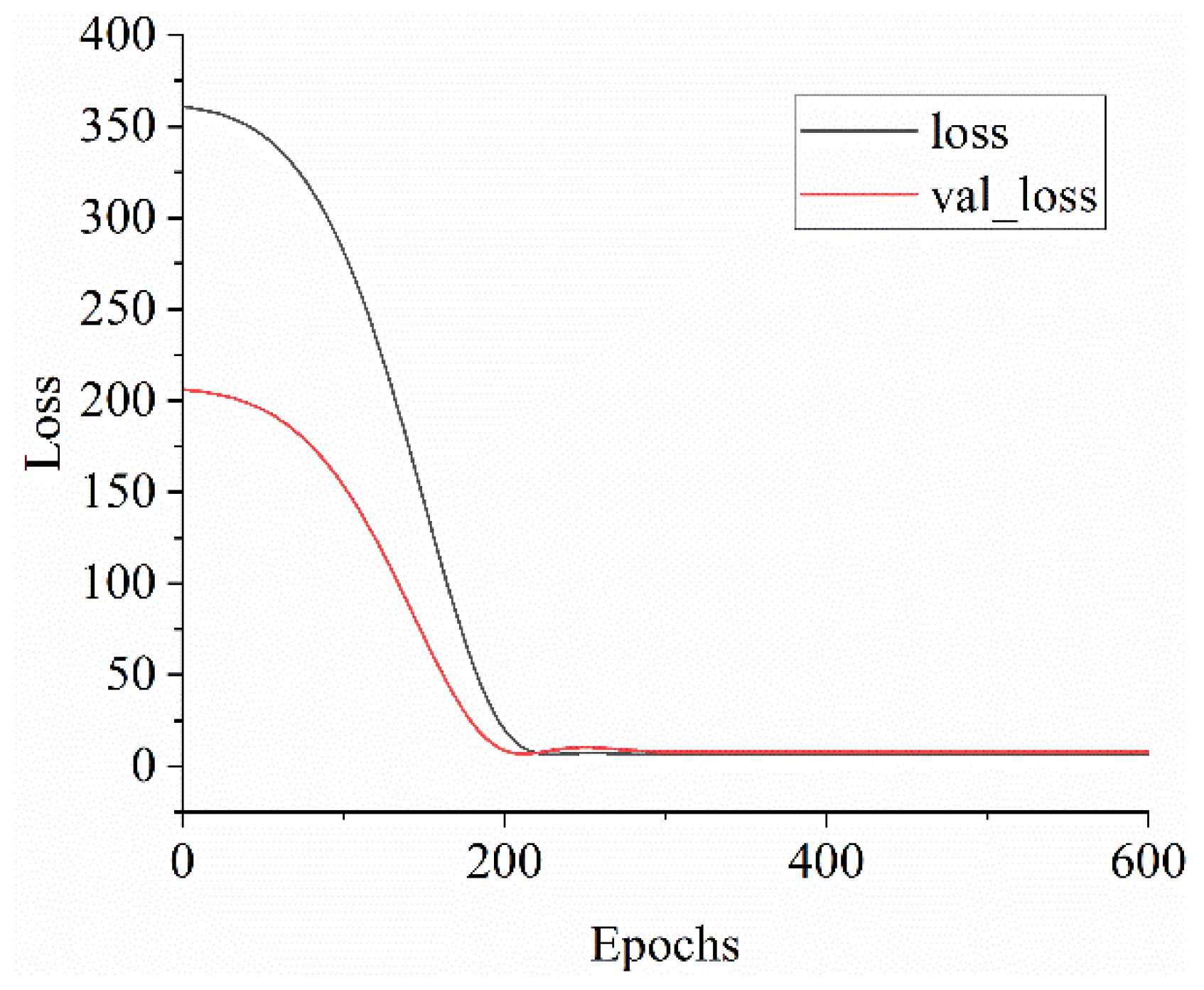

3.3. Element Content Calibration by BP-ANN

3.4. Comparison of Quantitative Methods

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rusak, D.; Castle, B.; Smith, B.; Winefordner, J. Fundamentals and applications of laser-induced breakdown spectroscopy. Crit. Rev. Anal. Chem. 1997, 27, 257–290. [Google Scholar] [CrossRef]

- Brech, F.; Cross, L. Optical microemission stimulated by a ruby maser. Appl. Spectmsc. 1962, 16, 59–64. [Google Scholar]

- Hu, Y.; Li, Z.; Lü, T. Determination of elemental concentration in geological samples using nanosecond laser-induced breakdown spectroscopy. J. Anal. At. Spectrom. 2017, 32, 2263–2270. [Google Scholar] [CrossRef]

- Tucker, J.; Dyar, M.; Schaefer, M.; Clegg, S.; Wiens, R. Optimization of laser-induced breakdown spectroscopy for rapid geochemical analysis. Chem. Geol. 2010, 277, 137–148. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, T.; Li, H. Applications of laser-induced breakdown spectroscopy (LIBS) combined with machine learning in geochemical and environmental resources exploration. Trends Anal. Chem. 2020, 133, 116113. [Google Scholar] [CrossRef]

- De Lucia, F.C., Jr.; Gottfried, J.L. Influence of variable selection on partial least squares discriminant analysis models for explosive residue classification. Spectrochim. Acta Part B 2011, 66, 122–128. [Google Scholar] [CrossRef]

- Horňáčková, M.; Grolmusová, Z.; Horňáček, M.; Rakovský, J.; Hudec, P.; Veis, P. Calibration analysis of zeolites by laser induced breakdown spectroscopy. Spectrochim. Acta Part B 2012, 74, 119–123. [Google Scholar] [CrossRef]

- Kondo, H.; Aimoto, M.; Yamamura, H.; Toh, T. Rapid defect characterization of steel by laser induced breakdown spectroscopy. Metall. Anal. 2009, 29, 13–16. [Google Scholar]

- Hamzaoui, S.; Khleifia, R.; Jaïdane, N.; Lakhdar, Z.B. Quantitative analysis of pathological nails using laser-induced breakdown spectroscopy (LIBS) technique. Lasers Med. Sci. 2011, 26, 79–83. [Google Scholar] [CrossRef]

- Nicolodelli, G.; Cabral, J.; Menegatti, C.R.; Marangoni, B.; Senesi, G.S. Recent advances and future trends in LIBS applications to agricultural materials and their food derivatives: An overview of developments in the last decade (2010–2019). Part I. Soils and fertilizers. Trends Anal. Chem. 2019, 115, 70–82. [Google Scholar] [CrossRef]

- Qi, J.; Zhang, T.; Tang, H.; Li, H. Rapid classification of archaeological ceramics via laser-induced breakdown spectroscopy coupled with random forest. Spectrochim. Acta Part B 2018, 149, 288–293. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, T.; Li, H. Application of laser-induced breakdown spectroscopy (LIBS) in environmental monitoring. Spectrochim. Acta Part B 2021, 181, 106218. [Google Scholar] [CrossRef]

- Hsu, P.S.; Gragston, M.; Wu, Y.; Zhang, Z.; Patnaik, A.K.; Kiefer, J.; Roy, S.; Gord, J.R. Sensitivity, stability, and precision of quantitative Ns-LIBS-based fuel-air-ratio measurements for methane-air flames at 1–11 bar. Appl. Opt. 2016, 55, 8042–8048. [Google Scholar] [CrossRef] [PubMed]

- Stipe, C.B.; Hensley, B.D.; Boersema, J.L.; Buckley, S.G. Laser-induced breakdown spectroscopy of steel: A comparison of univariate and multivariate calibration methods. Appl. Spectmsc. 2010, 64, 154–160. [Google Scholar] [CrossRef]

- Xu, X.; Du, C.; Ma, F.; Shen, Y.; Zhou, J. Fast and simultaneous determination of soil properties using laser-induced breakdown spectroscopy (LIBS): A case study of typical farmland soils in China. Soil Syst. 2019, 3, 66. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, C.; Gao, L.; Yue, Z.; Shabbir, S.; Xu, W.; Wu, M.; Yu, J. Determination of minor metal elements in steel using laser-induced breakdown spectroscopy combined with machine learning algorithms. Spectrochim. Acta Part B 2020, 166, 105802. [Google Scholar] [CrossRef]

- Li, L.-N.; Liu, X.-F.; Yang, F.; Xu, W.-M.; Wang, J.-Y.; Shu, R. A review of artificial neural network based chemometrics applied in laser-induced breakdown spectroscopy analysis. Spectrochim. Acta Part B 2021, 180, 106183. [Google Scholar] [CrossRef]

- Li, K.; Guo, L.; Li, C.; Li, X.; Shen, M.; Zheng, Z.; Yu, Y.; Hao, R.; Hao, Z.; Zeng, Q. Analytical-performance improvement of laser-induced breakdown spectroscopy for steel using multi-spectral-line calibration with an artificial neural network. J. Anal. At. Spectrom. 2015, 30, 1623–1628. [Google Scholar] [CrossRef]

- Rezaei, F.; Karimi, P.; Tavassoli, S. Effect of self-absorption correction on LIBS measurements by calibration curve and artificial neural network. Appl. Phys. B 2014, 114, 591–600. [Google Scholar] [CrossRef]

- Sirven, J.-B.; Bousquet, B.; Canioni, L.; Sarger, L. Laser-induced breakdown spectroscopy of composite samples: Comparison of advanced chemometrics methods. Anal. Chem. 2006, 78, 1462–1469. [Google Scholar] [CrossRef]

- M Motto-Ros, V.; Koujelev, A.S.; Osinski, G.R.; Dudelzak, A.E. Quantitative Multi-Elemental Laser-Induced Breakdown Spectroscopy Using Artificial Neural Networks. J. Eur. Opt. Soc. Rapid Publ. 2008, 3, 8011. [Google Scholar] [CrossRef]

- Inakollu, P.; Philip, T.; Rai, A.K.; Yueh, F.-Y.; Singh, J.P. A comparative study of laser induced breakdown spectroscopy analysis for element concentrations in aluminum alloy using artificial neural networks and calibration methods. Spectrochim. Acta Part B 2009, 64, 99–104. [Google Scholar] [CrossRef]

- D’Andrea, E.; Pagnotta, S.; Grifoni, E.; Lorenzetti, G.; Legnaioli, S.; Palleschi, V.; Lazzerini, B. An artificial neural network approach to laser-induced breakdown spectroscopy quantitative analysis. Spectrochim. Acta Part B 2014, 99, 52–58. [Google Scholar] [CrossRef]

- Moncayo, S.; Manzoor, S.; Rosales, J.; Anzano, J.; Caceres, J. Qualitative and quantitative analysis of milk for the detection of adulteration by Laser Induced Breakdown Spectroscopy (LIBS). Food Chem. 2017, 232, 322–328. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.; Li, X.; Nie, Z. Determination of the nutrient profile in plant materials using laser-induced breakdown spectroscopy with partial least squares-artificial neural network hybrid models. Opt. Express 2020, 28, 23037–23047. [Google Scholar] [CrossRef] [PubMed]

- Safi, A.; Campanella, B.; Grifoni, E.; Legnaioli, S.; Lorenzetti, G.; Pagnotta, S.; Poggialini, F.; Ripoll-Seguer, L.; Hidalgo, M.; Palleschi, V. Multivariate calibration in Laser-Induced Breakdown Spectroscopy quantitative analysis: The dangers of a ‘black box’approach and how to avoid them. Spectrochim. Acta Part B 2018, 144, 46–54. [Google Scholar] [CrossRef]

- ZHANG, T.-L.; Shan, W.; Hong-Sheng, T.; Kang, W.; Yi-Xiang, D.; Hua, L. Progress of chemometrics in laser-induced breakdown spectroscopy analysis. Chin. J. Anal. Chem. 2015, 43, 939–948. [Google Scholar] [CrossRef]

- Tan, Z.; Tao, Z.; Liu, J.; Wang, G. Baseline correction of roman spectrum based on piecewise linear fitting. Spectrosc. Spectr. Anal. 2013, 33, 383–386. [Google Scholar] [CrossRef]

- Weakley, A.T.; Griffiths, P.R.; Aston, D.E. Automatic baseline subtraction of vibrational spectra using minima identification and discrimination via adaptive, least-squares thresholding. Appl. Spectmsc. 2012, 66, 519–529. [Google Scholar] [CrossRef]

- Sun, L.; Yu, H. Automatic estimation of varying continuum background emission in laser-induced breakdown spectroscopy. Spectrochim. Acta Part B 2009, 64, 278–287. [Google Scholar] [CrossRef]

- Tan, B.; Huang, M.; Zhu, Q.; Guo, Y.; Qin, J. Detection and correction of laser induced breakdown spectroscopy spectral background based on spline interpolation method. Spectrochim. Acta Part B 2017, 138, 64–71. [Google Scholar] [CrossRef]

- Zhang, B.; Sun, L.; Yu, H.; Xin, Y.; Cong, Z. A method for improving wavelet threshold denoising in laser-induced breakdown spectroscopy. Spectrochim. Acta Part B 2015, 107, 32–44. [Google Scholar] [CrossRef]

- Yuan, T.; Wang, Z.; Li, Z.; Ni, W.; Liu, J. A partial least squares and wavelet-transform hybrid model to analyze carbon content in coal using laser-induced breakdown spectroscopy. Anal. Chim. Acta 2014, 807, 29–35. [Google Scholar] [CrossRef]

- Swindeman, R.; Sikka, V.; Klueh, R. Residual and trace element effects on the high-temperature creep strength of austenitic stainless steels. Metall. Trans. A 1983, 14, 581–593. [Google Scholar] [CrossRef]

- Melford, D. The influence of residual and trace elements on hot shortness and high temperature embrittlement. Philos. Trans. R. Soc. Lond. Ser. A 1980, 295, 89–103. [Google Scholar] [CrossRef]

- Senesi, G.S.; De Pascale, O.; Bove, A.; Marangoni, B.S. Quantitative Analysis of Pig Iron from Steel Industry by Handheld Laser-Induced Breakdown Spectroscopy and Partial Least Square (PLS) Algorithm. Appl. Sci. 2020, 10, 8461. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Li, X.; Ma, Q.; Zhao, N.; Zhang, Q.; Guo, L.; Lu, Y. Investigation of excitation interference in laser-induced breakdown spectroscopy assisted with laser-induced fluorescence for chromium determination in low-alloy steels. Opt. Lasers Eng. 2020, 124, 105834. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, R.; Liu, K.; Li, Q.; Tang, Z.; Zhu, C.; Li, X.; Zeng, X.; He, C. Silicon determination in steel with molecular emission using laser-induced breakdown spectroscopy combined with laser-induced molecular fluorescence. J. Anal. At. Spectrom. 2021, 36, 375–379. [Google Scholar] [CrossRef]

- Cui, M.; Guo, H.; Chi, Y.; Tan, L.; Yao, C.; Zhang, D.; Deguchi, Y. Quantitative analysis of trace carbon in steel samples using collinear long-short double-pulse laser-induced breakdown spectroscopy. Spectrochim. Acta Part B 2022, 191, 106398. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, J.; Li, L.; Ni, W.; Li, Z. A multivariate model based on dominant factor for laser-induced breakdown spectroscopy measurements. J. Anal. At. Spectrom. 2011, 26, 2289–2299. [Google Scholar] [CrossRef]

- Chun-Long, W.; Jian-Guo, L.; Nan-Jing, Z.; Ming-Jun, M.; Yin, W.; Li, H.; Da-Hai, Z.; Yang, Y.; De-Shuo, M.; Wei, Z. Comparative analysis of quantitative method on heavy metal detection in water with laser-induced breakdown spectroscopy. Acta Phys. Sin. 2013, 62, 125201. [Google Scholar] [CrossRef]

- Guo, Y.-M.; Guo, L.-B.; Li, J.-M.; Liu, H.-D.; Zhu, Z.-H.; Li, X.-Y.; Lu, Y.-F.; Zeng, X.-Y. Research progress in Asia on methods of processing laser-induced breakdown spectroscopy data. Front. Phys. 2016, 11, 114212. [Google Scholar] [CrossRef]

- Kouibia, A.; Pasadas, M. An approximation problem of noisy data by cubic and bicubic splines. Appl. Math. Model. 2012, 36, 4135–4145. [Google Scholar] [CrossRef]

- Lu, P.; Zhuo, Z.; Zhang, W.; Tang, J.; Tang, H.; Lu, J. Accuracy improvement of quantitative LIBS analysis of coal properties using a hybrid model based on a wavelet threshold de-noising and feature selection method. Appl. Opt. 2020, 59, 6443–6451. [Google Scholar] [CrossRef]

- Ciucci, A.; Corsi, M.; Palleschi, V.; Rastelli, S.; Salvetti, A.; Tognoni, E. New procedure for quantitative elemental analysis by laser-induced plasma spectroscopy. Appl. Spectmsc. 1999, 53, 960–964. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, T.; Sun, Y.; Tang, H.; Li, H. A hybrid variable selection method based on wavelet transform and mean impact value for calorific value determination of coal using laser-induced breakdown spectroscopy and kernel extreme learning machine. Spectrochim. Acta Part B 2019, 154, 75–81. [Google Scholar] [CrossRef]

- Adler, J.; Parmryd, I. Quantifying colocalization by correlation: The Pearson correlation coefficient is superior to the Mander’s overlap coefficient. Cytom. Part A 2010, 77, 733–742. [Google Scholar] [CrossRef]

| Year | Author | Sample | Brief Introduction |

|---|---|---|---|

| 2006 | Sirven et al. [20] | soil samples | Cr concentration in soil samples was quantitatively analyzed. By comparing the prediction accuracy and the detection limit of BP-ANN, PLSR and the standard calibration curve, the superiority of BP-ANN in LIBS analysis is proved. |

| 2008 | Motto-Ros et al. [21] | natural rock and soil samples | Simultaneous measurement of multiple element concentrations has been demonstrated and is of great significance in planetary science. |

| 2009 | Inakollu et al. [22] | Al alloy samples | The measurement results of artificial neural networks with the traditional one-way calibration method were compared, and it was determined that in most cases, BP-ANN exhibits better measurement performance and accuracy. |

| 2010 | Rezaei et al. [19] | aluminum standards | The effect of self-absorption on concentration prediction of the aluminum standard samples via two approaches—calibration curve and ANN—in the LIBS experiment is studied. |

| 2014 | D’Andrea et al. [23] | bronze alloys samples | Forward feature selection has been adopted to reduce the number of input variables to the neural network to the minimum number of variables, providing a viable, fast, and robust method for LIBS quantitative analysis. |

| 2017 | Moncayo et al. [24] | milk samples | The results demonstrate that LIBS/BP-ANN combination, supported by its speed of analysis, reduced cost, and ease of use, has the potential to serve as a useful screening tool in the quality control of milk. |

| 2017 | Hu et al. [3] | geological standard samples from USGS | The concentration of iron in the concentrations of BCR-1G, BHVO-2G, BIR-1G, GSD-1G, and GSE-1G was determined, and the relative error of the results is less than 6%. |

| 2020 | Yang et al. [25] | vegetables samples | Combined with the advantages of reducing the multiple collinearities of PLS independent variables and the nonlinear processing ability of ANN, the accuracy of LIBS quantitative analysis is significantly improved. |

| Sample | Ni | Cr | Ti |

|---|---|---|---|

| GBW 01659a | 4.76 | 28.00 | 0.053 |

| GBW 01660a | 14.58 | 14.37 | 0.475 |

| GBW 01661a | 19.13 | 10.66 | 0.577 |

| GBW 01662a | 11.24 | 19.73 | 0.253 |

| GBW 01663a | 22.77 | 7.65 | 0.774 |

| GBW 01664a | 7.34 | 24.40 | 0.170 |

| GBW 01665a | 8.72 | 17.57 | 0.336 |

| Species | Characteristic Spectral Lines |

|---|---|

| Ni | 352.4536, 349.2956, 338.0569, 351.0335, 339.1043. |

| Cr | 520.8426, 520.6037, 425.4336, 520.4511, 428.9717. |

| Ti | 334.9402, 334.9033, 349.1049, 338.0277, 323.6572. |

| Species | Characteristic Spectral Lines |

|---|---|

| Ni | 385.8297, 361.9391, 356.6372, 352.4536, 361.0462, 351.5052, 341.4764, 345.846, 346.1652, 343.3556. |

| Cr | 520.8426, 520.6037, 520.4511, 425.4336, 427.4797, 428.9717, 357.8686, 359.3485. |

| Ti | 375.7685, 375.9292, 390.0539, 345.6384, 346.1496, 344.4306, 349.1049, 338.027, 430.0042, 453.396. |

| Test Set Sample | Average Relative Error (%) | Relative Standard Deviation (%) | Root Mean Square Error (RSME) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Ti | Ni | Cr | Ti | Ni | Cr | Ti | |

| GBW 1659a | 4.62 | 13.50 | 31.45 | 22.08 | 12.14 | 12.01 | 1.95 | 4.67 | 0.056 |

| GBW 1660a | 0.88 | 3.82 | 2.07 | 12.68 | 12.58 | 15.21 | 1.77 | 1.86 | 0.068 |

| GBW 1661a | 7.25 | 4.17 | 12.94 | 19.08 | 20.12 | 19.21 | 3.50 | 2.16 | 0.12 |

| GBW 1662a | 5.64 | 6.87 | 12.52 | 20.28 | 9.40 | 15.43 | 2.13 | 2.12 | 0.045 |

| GBW 1663a | 8.57 | 4.64 | 22.43 | 12.67 | 18.30 | 14.80 | 3.17 | 1.43 | 0.19 |

| GBW 1664a | 3.61 | 6.01 | 23.37 | 22.25 | 10.65 | 13.10 | 1.52 | 2.74 | 0.048 |

| GBW 1665a | 1.97 | 1.53 | 1.88 | 14.03 | 16.27 | 12.19 | 1.15 | 2.68 | 0.040 |

| Test Set Sample | Average Relative Error (%) | Relative Standard Deviation (%) | Root Mean Square Error (RSME) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ni | Cr | Ti | Ni | Cr | Ti | Ni | Cr | Ti | |

| GBW 1659a | 8.37 | 15.08 | 26.70 | 25.76 | 9.67 | 28.11 | 1.48 | 2.72 | 0.038 |

| GBW 1660a | 5.78 | 8.49 | 10.03 | 17.46 | 18.88 | 22.16 | 2.69 | 3.05 | 0.10 |

| GBW 1661a | 15.91 | 4.42 | 42.36 | 21.01 | 17.36 | 24.48 | 4.42 | 1.74 | 0.26 |

| GBW 1662a | 9.39 | 11.68 | 22.43 | 20.24 | 8.03 | 19.58 | 2.58 | 2.85 | 0.081 |

| GBW 1663a | 13.61 | 11.89 | 28.93 | 23.40 | 22.80 | 13.94 | 3.11 | 2.13 | 0.24 |

| GBW 1664a | 10.70 | 8.27 | 61.54 | 26.57 | 9.70 | 18.38 | 2.19 | 2.88 | 0.12 |

| GBW 1665a | 8.79 | 2.18 | 16.73 | 29.31 | 15.78 | 17.52 | 1.73 | 2.60 | 0.086 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Y.; Fan, B.; Fang, B.; Meng, J.; Zhang, Y.; Lü, T. Elemental Determination in Stainless Steel via Laser-Induced Breakdown Spectroscopy and Back-Propagation Artificial Intelligence Network with Spectral Pre-Processing. Chemosensors 2022, 10, 472. https://doi.org/10.3390/chemosensors10110472

Ni Y, Fan B, Fang B, Meng J, Zhang Y, Lü T. Elemental Determination in Stainless Steel via Laser-Induced Breakdown Spectroscopy and Back-Propagation Artificial Intelligence Network with Spectral Pre-Processing. Chemosensors. 2022; 10(11):472. https://doi.org/10.3390/chemosensors10110472

Chicago/Turabian StyleNi, Yang, Bowen Fan, Bin Fang, Jiuling Meng, Yubo Zhang, and Tao Lü. 2022. "Elemental Determination in Stainless Steel via Laser-Induced Breakdown Spectroscopy and Back-Propagation Artificial Intelligence Network with Spectral Pre-Processing" Chemosensors 10, no. 11: 472. https://doi.org/10.3390/chemosensors10110472

APA StyleNi, Y., Fan, B., Fang, B., Meng, J., Zhang, Y., & Lü, T. (2022). Elemental Determination in Stainless Steel via Laser-Induced Breakdown Spectroscopy and Back-Propagation Artificial Intelligence Network with Spectral Pre-Processing. Chemosensors, 10(11), 472. https://doi.org/10.3390/chemosensors10110472