Temperature Sensors Based on Polymer Fiber Optic Interferometer

Abstract

:1. Introduction

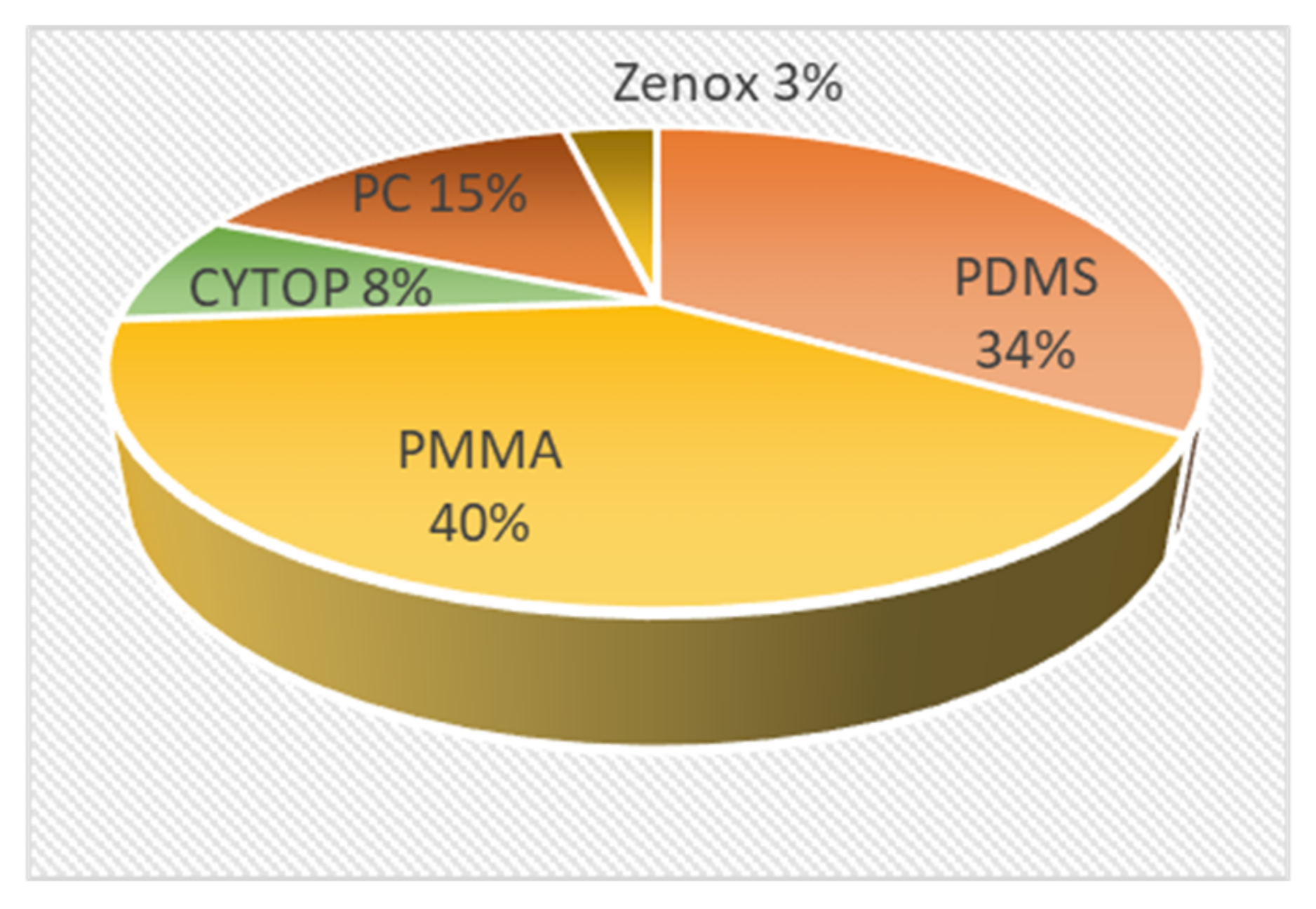

2. Polymer Fiber Optic Sensors

3. POF Temperature Sensing Principles

3.1. Intensity Modulation POF Temperature Sensor

3.2. Phase Modulation POF Temperature Sensor

4. Polymer Fiber Optic Sensors Based on Fabry–Pérot Configuration

4.1. Extrinsic POF FPI for Temperature Sensing

4.2. In-Line POF FPI for Temperature Sensing

4.3. Metrological Parameters of POF FPI for Temperature Sensing

5. Summary and Future Perspective

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deb Majumder, B.; Roy, J.K.; Padhee, S. Recent Advances in Multifunctional Sensing Technology on a Perspective of Multi-Sensor System: A Review. IEEE Sens. J. 2019, 19, 1204–1214. [Google Scholar] [CrossRef]

- Wang, K.; Dong, X.; Kohler, M.H.; Kienle, P.; Bian, Q.; Jakobi, M.; Koch, A.W. Advances in Optical Fiber Sensors Based on Multimode Interference (MMI): A Review. IEEE Sens. J. 2021, 21, 132–142. [Google Scholar] [CrossRef]

- Fernandez-Vallejo, M.; Lopez-Amo, M. Optical Fiber Networks for Remote Fiber Optic Sensors. Sensors 2012, 12, 3929–3951. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Listewnik, P.; Bechelany, M.; Jasinski, J.B.; Szczerska, M. ZnO ALD-Coated Microsphere-Based Sensors for Temperature Measurements. Sensors 2020, 20, 4689. [Google Scholar] [CrossRef] [PubMed]

- Li, J. A Review: Development of Novel Fiber-Optic Platforms for Bulk and Surface Refractive Index Sensing Applications. Sens. Actuators Rep. 2020, 2, 100018. [Google Scholar] [CrossRef]

- Wu, T.; Liu, G.; Fu, S.; Xing, F. Recent Progress of Fiber-Optic Sensors for the Structural Health Monitoring of Civil Infrastructure. Sensors 2020, 20, 4517. [Google Scholar] [CrossRef]

- Berardi, M.; Bielawski, K.; Rijnveld, N.; Gruca, G.; Aardema, H.; van Tol, L.; Wuite, G.; Akca, B.I. Optical Interferometry Based Micropipette Aspiration Provides Real-Time Sub-Nanometer Spatial Resolution. Commun. Biol. 2021, 4, 1–7. [Google Scholar] [CrossRef]

- Sun, D.; Ran, Y.; Wang, G. Label-Free Detection of Cancer Biomarkers Using an In-Line Taper Fiber-Optic Interferometer and a Fiber Bragg Grating. Sensors 2017, 17, 2559. [Google Scholar] [CrossRef] [Green Version]

- Camuffo, D. Evidence from the Archives of Societies: Early Instrumental Observations. In The Palgrave Handbook of Climate History; White, S., Pfister, C., Mauelshagen, F., Eds.; Palgrave Macmillan: London, UK, 2018; pp. 83–92. ISBN 978-1-137-43019-9. [Google Scholar]

- Liao, J.; Yang, L. Optical Whispering-Gallery Mode Barcodes for High-Precision and Wide-Range Temperature Measurements. Light Sci. Appl. 2021, 10, 32. [Google Scholar] [CrossRef]

- Mikolajek, M.; Martinek, R.; Koziorek, J.; Hejduk, S.; Vitasek, J.; Vanderka, A.; Poboril, R.; Vasinek, V.; Hercik, R. Temperature Measurement Using Optical Fiber Methods: Overview and Evaluation. J. Sens. 2020, 2020, e8831332. [Google Scholar] [CrossRef]

- Chiavaioli, F.; Gouveia, C.A.J.; Jorge, P.A.S.; Baldini, F. Towards a Uniform Metrological Assessment of Grating-Based Optical Fiber Sensors: From Refractometers to Biosensors. Biosensors 2017, 7, 23. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Su, Y.-D.; Preger, Y.; Burroughs, H.; Sun, C.; Ohodnicki, P. Fiber Optic Sensing Technologies for Battery Management Systems and Energy Storage Applications. Sensors 2021, 21, 1397. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Hu, X.; Hu, S.; Peng, Y. Applications of Fiber-Optic Biochemical Sensor in Microfluidic Chips: A Review. Biosens. Bioelectron. 2020, 166, 112447. [Google Scholar] [CrossRef] [PubMed]

- Zolfaghari, P.; Erden, O.K.; Ferhanoglu, O.; Tumer, M.; Yalcinkaya, A.D. MRI Compatible Fiber Optic Multi Sensor Platform for Real Time Vital Monitoring. J. Light. Technol. 2021, 39, 4138–4144. [Google Scholar] [CrossRef]

- Su, H.; Iordachita, I.I.; Tokuda, J.; Hata, N.; Liu, X.; Seifabadi, R.; Xu, S.; Wood, B.; Fischer, G.S. Fiber-Optic Force Sensors for MRI-Guided Interventions and Rehabilitation: A Review. IEEE Sens. J. 2017, 17, 1952–1963. [Google Scholar] [CrossRef] [Green Version]

- Schena, E.; Tosi, D.; Saccomandi, P.; Lewis, E.; Kim, T. Fiber Optic Sensors for Temperature Monitoring during Thermal Treatments: An Overview. Sensors 2016, 16, 1144. [Google Scholar] [CrossRef]

- Aliyu, F.; Sheltami, T. Development of an Energy-Harvesting Toxic and Combustible Gas Sensor for Oil and Gas Industries. Sens. Actuators B Chem. 2016, 231, 265–275. [Google Scholar] [CrossRef]

- López-Cardona, J.D.; Vázquez, C.; Montero, D.S.; Lallana, P.C. Remote Optical Powering Using Fiber Optics in Hazardous Environments. J. Light. Technol. 2018, 36, 748–754. [Google Scholar] [CrossRef] [Green Version]

- Truly Remote Fiber Optic Sensor Networks-IOP Science. Available online: https://iopscience.iop.org/article/10.1088/2515-7647/ab3f0e/meta (accessed on 30 May 2022).

- Jędrzejewska-Szczerska, M.; Majchrowicz, D.; Hirsch, M.; Struk, P.; Bogdanowicz, R.; Bechelany, M.; Tuchin, V.V. Nanolayers in Fiber-Optic Biosensing. In Nanotechnology and Biosensors; Elsevier: Amsterdam, The Netherlands, 2018; pp. 395–426. ISBN 978-0-12-813855-7. [Google Scholar]

- Cennamo, N.; Trigona, C.; Graziani, S.; Zeni, L.; Arcadio, F.; Di Pasquale, G.; Pollicino, A. An Eco-Friendly Disposable Plasmonic Sensor Based on Bacterial Cellulose and Gold. Sensors 2019, 19, 4894. [Google Scholar] [CrossRef] [Green Version]

- Gierej, A.; Geernaert, T.; Van Vlierberghe, S.; Dubruel, P.; Thienpont, H.; Berghmans, F. Challenges in the Fabrication of Biodegradable and Implantable Optical Fibers for Biomedical Applications. Materials 2021, 14, 1972. [Google Scholar] [CrossRef]

- Ahmad, H.; Alias, M.A.; Ismail, M.F.; Ismail, N.N.; Zaini, M.K.A.; Lim, K.S.; Brambilla, G.; Grattan, K.T.V.; Rahman, B.M.A. Strain Sensor Based on Embedded Fiber Bragg Grating in Thermoplastic Polyurethane Using the 3D Printing Technology for Improved Sensitivity. Photonic Sens. 2022, 12, 220302. [Google Scholar] [CrossRef]

- 3D Printing of Resilient Biogels for Omnidirectional and Exteroceptive Soft Actuators. Available online: https://www.science.org/doi/10.1126/scirobotics.abk2119 (accessed on 21 May 2022).

- Azkune, M.; Ruiz-Rubio, L.; Aldabaldetreku, G.; Arrospide, E.; Pérez-Álvarez, L.; Bikandi, I.; Zubia, J.; Vilas-Vilela, J. U-Shaped and Surface Functionalized Polymer Optical Fiber Probe for Glucose Detection. Sensors 2017, 18, 34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ye, F.; Tian, C.; Ma, C.; Zhang, Z.F. Fiber Optic Sensors Based on Circular and Elliptical Polymer Optical Fiber for Measuring Refractive Index of Liquids. Opt. Fiber Technol. 2022, 68, 102812. [Google Scholar] [CrossRef]

- Chen, C.-H.; Tsao, T.-C.; Tang, J.-L.; Wu, W.-T. A Multi-D-Shaped Optical Fiber for Refractive Index Sensing. Sensors 2010, 10, 4794–4804. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leal-Junior, A.G.; Frizera, A.; Avellar, L.M.; Pontes, M.J. Design Considerations, Analysis, and Application of a Low-Cost, Fully Portable, Wearable Polymer Optical Fiber Curvature Sensor. Appl. Opt. 2018, 57, 6927. [Google Scholar] [CrossRef]

- Min, R.; Hu, X.; Pereira, L.; Simone Soares, M.; Silva, L.C.B.; Wang, G.; Martins, L.; Qu, H.; Antunes, P.; Marques, C.; et al. Polymer Optical Fiber for Monitoring Human Physiological and Body Function: A Comprehensive Review on Mechanisms, Materials, and Applications. Opt. Laser Technol. 2022, 147, 107626. [Google Scholar] [CrossRef]

- Woyessa, G.; Rasmussen, H.K.; Bang, O. Zeonex–A Route towards Low Loss Humidity Insensitive Single-Mode Step-Index Polymer Optical Fibre. Opt. Fiber Technol. 2020, 57, 102231. [Google Scholar] [CrossRef]

- Woyessa, G.; Fasano, A.; Markos, C.; Stefani, A.; Rasmussen, H.K.; Bang, O. Zeonex Microstructured Polymer Optical Fiber: Fabrication Friendly Fibers for High Temperature and Humidity Insensitive Bragg Grating Sensing. Opt. Mater. Express 2017, 7, 286. [Google Scholar] [CrossRef] [Green Version]

- Theodosiou, A.; Lacraz, A.; Stassis, A.; Koutsides, C.; Komodromos, M.; Kalli, K. Plane-by-Plane Femtosecond Laser Inscription Method for Single-Peak Bragg Gratings in Multimode CYTOP Polymer Optical Fiber. J. Light. Technol. 2017, 35, 5404–5410. [Google Scholar] [CrossRef]

- Hu, X.; Chen, Y.; Gao, S.; Min, R.; Woyessa, G.; Bang, O.; Qu, H.; Wang, H.; Caucheteur, C. Direct Bragg Grating Inscription in Single Mode Step-Index TOPAS/ZEONEX Polymer Optical Fiber Using 520 Nm Femtosecond Pulses. Polymers 2022, 14, 1350. [Google Scholar] [CrossRef]

- Prasad, S.G.; Lal, C. Spectroscopic Investigations of Optical Bandgap and Search for Reaction Mechanism Chemistry Due to γ-Rays Irradiated PMMA Polymer. Biointerface Res. Appl. Chem. 2022, 13, 184. [Google Scholar] [CrossRef]

- Zuo, H.; Yu, S.; Gu, T.; Hu, J. Low Loss, Flexible Single-Mode Polymer Photonics. Opt. Express 2019, 27, 11152–11159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fiber Optic Fabry-Perot Micro-Displacement Sensor Based on Low-Cost Polymer Film|IEEE Journals & Magazine|IEEE Xplore. Available online: https://ieeexplore.ieee.org/abstract/document/8854178 (accessed on 21 May 2022).

- Chapalo, I.; Theodosiou, A.; Kalli, K.; Kotov, O. Multimode Fiber Interferometer Based on Graded-Index Polymer CYTOP Fiber. J. Light. Technol. 2020, 38, 1439–1445. [Google Scholar] [CrossRef]

- Woyessa, G.; Fasano, A.; Stefani, A.; Markos, C.; Nielsen, K.; Rasmussen, H.K.; Bang, O. Single Mode Step-Index Polymer Optical Fiber for Humidity Insensitive High Temperature Fiber Bragg Grating Sensors. Opt. Express 2016, 24, 1253–1260. [Google Scholar] [CrossRef] [Green Version]

- Broadway, C.; Min, R.; Leal-Junior, A.G.; Marques, C.; Caucheteur, C. Toward Commercial Polymer Fiber Bragg Grating Sensors: Review and Applications. J. Light. Technol. 2019, 37, 2605–2615. [Google Scholar] [CrossRef]

- Low Loss Polycarbonate Polymer Optical Fiber for High Temperature FBG Humidity Sensing|IEEE Journals & Magazine|IEEE Xplore. Available online: https://ieeexplore.ieee.org/document/7852502 (accessed on 20 May 2022).

- Bhowmik, K.; Peng, G.-D. Polymer Optical Fibers. In Handbook of Optical Fibers; Peng, G.-D., Ed.; Springer: Singapore, 2019; pp. 1–51. ISBN 978-981-10-1477-2. [Google Scholar]

- Min, R.; Pereira, L.; Paixão, T.; Woyessa, G.; André, P.; Bang, O.; Antunes, P.; Pinto, J.; Li, Z.; Ortega, B.; et al. Inscription of Bragg Gratings in Undoped PMMA MPOF with Nd:YAG Laser at 266 Nm Wavelength. Opt. Express 2019, 27, 38039. [Google Scholar] [CrossRef]

- Study on the Structure Design and Simulation of MPOF. Available online: https://ieeexplore-1ieee-1org-10000077t01ff.han.bg.pg.edu.pl/document/5252263/ (accessed on 26 May 2022).

- Fasano, A.; Woyessa, G.; Stajanca, P.; Markos, C.; Stefani, A.; Nielsen, K.; Rasmussen, H.K.; Krebber, K.; Bang, O. Fabrication and Characterization of Polycarbonate Microstructured Polymer Optical Fibers for High-Temperature-Resistant Fiber Bragg Grating Strain Sensors. Opt. Mater. Express 2016, 6, 649–659. [Google Scholar] [CrossRef] [Green Version]

- Mei, S.; Kong, D.; Mu, Q.; Li, W.; He, Z.; Wang, L.; Zhang, Y. A Porous Core Zeonex THz Fiber with Low Loss and Small Dispersion. Opt. Fiber Technol. 2022, 69, 102834. [Google Scholar] [CrossRef]

- Wang, S.; Echeverry, J.; Trevisi, L.; Prather, K.; Xiang, L.; Liu, Y. Ultrahigh Resolution Pulsed Laser-Induced Photoacoustic Detection of Multi-Scale Damage in CFRP Composites. Appl. Sci. 2020, 10, 2106. [Google Scholar] [CrossRef] [Green Version]

- Niu, D.; Wang, L.; Xu, Q.; Jiang, M.; Wang, X.; Sun, X.; Wang, F.; Zhang, D. Ultra-Sensitive Polymeric Waveguide Temperature Sensor Based on Asymmetric Mach–Zehnder Interferometer. Appl. Opt. 2019, 58, 1276. [Google Scholar] [CrossRef]

- Oliveira, R.; Marques, T.H.R.; Bilro, L.; Nogueira, R.; Cordeiro, C.M.B. Multiparameter POF Sensing Based on Multimode Interference and Fiber Bragg Grating. J. Light. Technol. 2017, 35, 3–9. [Google Scholar] [CrossRef]

- LaNasa, J.A.; Neuman, A.; Riggleman, R.A.; Hickey, R.J. Investigating Nanoparticle Organization in Polymer Matrices during Reaction-Induced Phase Transitions and Material Processing. ACS Appl. Mater. Interfaces 2021, 13, 42104–42113. [Google Scholar] [CrossRef] [PubMed]

- Sampath, U.; Kim, D.; Kim, H.; Song, M. Polymer-Coated FBG Sensor for Simultaneous Temperature and Strain Monitoring in Composite Materials under Cryogenic Conditions. Appl. Opt. 2018, 57, 492. [Google Scholar] [CrossRef] [PubMed]

- Paulson, B.; Jung, H.; Hwang, J.; Hong, S.; Lee, S.; Kim, J.K.; Oh, K. High Sensitivity Temperature Measurement via Mask-Free Hybrid Polymer Long Period Fiber Grating. Opt. Express 2018, 26, 16125–16137. [Google Scholar] [CrossRef] [PubMed]

- Webb, D.J. Fibre Bragg Grating Sensors in Polymer Optical Fibres. Meas. Sci. Technol. 2015, 26, 092004. [Google Scholar] [CrossRef]

- Bonefacino, J.; Tam, H.-Y.; Glen, T.S.; Cheng, X.; Pun, C.-F.J.; Wang, J.; Lee, P.-H.; Tse, M.-L.V.; Boles, S.T. Ultra-Fast Polymer Optical Fibre Bragg Grating Inscription for Medical Devices. Light Sci. Appl. 2018, 7, 17161. [Google Scholar] [CrossRef]

- Min, R.; Pereira, L.; Paixao, T.; Woyessa, G.; Hu, X.; Antunes, P.; Marques, C. Chirped POF Bragg Grating Production Utilizing UV Cure Adhesive Coating for Multiparameter Sensing. Opt. Fiber Technol. 2021, 65, 102593. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, N.; Min, R.; Cheng, X.; Qu, H.; Hu, X. Recent Achievements on Grating Fabrications in Polymer Optical Fibers with Photosensitive Dopants: A Review. Polymers 2022, 14, 273. [Google Scholar] [CrossRef]

- Hu, X.; Hu, X.; Chen, Z.; Chen, Z.; Cheng, X.; Min, R.; Qu, H.; Qu, H.; Caucheteur, C.; Tam, H.-Y. Femtosecond Laser Point-by-Point Bragg Grating Inscription in BDK-Doped Step-Index PMMA Optical Fibers. Opt. Lett. 2022, 47, 249–252. [Google Scholar] [CrossRef]

- Xu, Q.; Li, K.; Copner, N.; Lin, S. An Ultrashort Wavelength Multi/Demultiplexer via Rectangular Liquid-Infiltrated Dual-Core Polymer Optical Fiber. Materials 2019, 12, 1709. [Google Scholar] [CrossRef] [Green Version]

- Cheng, X.; Gunawardena, D.S.; Pun, C.-F.J.; Bonefacino, J.; Tam, H.-Y. Single Nanosecond-Pulse Production of Polymeric Fiber Bragg Gratings for Biomedical Applications. Opt. Express 2020, 28, 33573. [Google Scholar] [CrossRef] [PubMed]

- Pereira, L.; Min, R.; Paixão, T.; Marques, C.; Woyessa, G.; Bang, O.; Pinto, J.L.; da Costa Antunes, P.F. Compact Dual-Strain Sensitivity Polymer Optical Fiber Grating for Multi-Parameter Sensing. J. Light. Technol. 2021, 39, 2230–2240. [Google Scholar] [CrossRef]

- Leffers, L.; Locmelis, J.; Bremer, K.; Roth, B.; Overmeyer, L. Optical Bend Sensor Based on Eccentrically Micro-Structured Multimode Polymer Optical Fibers. IEEE Photonics J. 2021, 13, 1–7. [Google Scholar] [CrossRef]

- Mizuno, Y.; Hayashi, N.; Tanaka, H.; Nakamura, K.; Todoroki, S. Observation of Polymer Optical Fiber Fuse. Appl. Phys. Lett. 2014, 104, 043302. [Google Scholar] [CrossRef] [Green Version]

- Leal-Junior, A.G.; Marques, C.; Lee, H.; Nakamura, K.; Mizuno, Y. Sensing Applications of Polymer Optical Fiber Fuse. Adv. Photonics Res. 2021, 3, 2100210. [Google Scholar] [CrossRef]

- Talataisong, W.; Ismaeel, R.; Beresna, M.; Brambilla, G. Suspended-Core Microstructured Polymer Optical Fibers and Potential Applications in Sensing. Sensors 2019, 19, 3449. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Berganza, A.; Arrospide, E.; Amorebieta, J.; Zubia, J.; Durana, G. Fabrication Quality Assessment Based on the Coupling of a Dual-Core Microstructured Polymer Optical Fiber. Sensors 2021, 21, 7435. [Google Scholar] [CrossRef]

- He, R.; Teng, C.; Kumar, S.; Marques, C.; Min, R. Polymer Optical Fiber Liquid Level Sensor: A Review. IEEE Sens. J. 2022, 22, 1081–1091. [Google Scholar] [CrossRef]

- SMF-28® Ultra Optical Fibers|Single Mode Optical Fiber|Corning. Available online: https://www.corning.com/optical-communications/worldwide/en/home/products/fiber/optical-fiber-products/smf-28-ultra.html (accessed on 24 May 2022).

- Mizuno, Y.; Theodosiou, A.; Kalli, K.; Liehr, S.; Lee, H.; Nakamura, K. Distributed Polymer Optical Fiber Sensors: A Review and Outlook. Photonics Res. 2021, 9, 1719. [Google Scholar] [CrossRef]

- Lethien, C.; Loyez, C.; Vilcot, J.-P.; Rolland, N.; Rolland, P.A. Exploit the Bandwidth Capacities of the Perfluorinated Graded Index Polymer Optical Fiber for Multi-Services Distribution. Polymers 2011, 3, 1006–1028. [Google Scholar] [CrossRef] [Green Version]

- Ulep, T.-H.; Yoon, J.-Y. Challenges in Paper-Based Fluorogenic Optical Sensing with Smartphones. Nano Converg. 2018, 5, 14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Frka-Petesic, B.; Vignolini, S. So Much More than Paper. Nat. Photonics 2019, 13, 365–367. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Tian, J.; Hu, L.; Yao, Y. High Sensitivity Humidity Fiber-Optic Sensor Based on All-Agar Fabry–Perot Interferometer. IEEE Sens. J. 2018, 18, 4879–4885. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Aisyah, H.A.; Nordin, A.H.; Ngadi, N.; Zuhri, M.Y.M.; Asyraf, M.R.M.; Sapuan, S.M.; Zainudin, E.S.; Sharma, S.; Abral, H.; et al. Natural-Fiber-Reinforced Chitosan, Chitosan Blends and Their Nanocomposites for Various Advanced Applications. Polymers 2022, 14, 874. [Google Scholar] [CrossRef]

- Gierej, A.; Vagenende, M.; Filipkowski, A.; Siwicki, B.; Buczynski, R.; Thienpont, H.; Van Vlierberghe, S.; Geernaert, T.; Dubruel, P.; Berghmans, F. Poly(D,L-Lactic Acid) (PDLLA) Biodegradable and Biocompatible Polymer Optical Fiber. J. Light. Technol. 2019, 37, 1916–1923. [Google Scholar] [CrossRef]

- Theodosiou, A.; Kalli, K. Recent Trends and Advances of Fibre Bragg Grating Sensors in CYTOP Polymer Optical Fibres. Opt. Fiber Technol. 2020, 54, 102079. [Google Scholar] [CrossRef]

- Jędrzejewska-Szczerska, M. Response of a New Low-Coherence Fabry-Perot Sensor to Hematocrit Levels in Human Blood. Sensors 2014, 14, 6965–6976. [Google Scholar] [CrossRef] [Green Version]

- Leal-Junior, A.; Frizera, A.; Lee, H.; Mizuno, Y.; Nakamura, K.; Paixão, T.; Leitão, C.; Domingues, M.F.; Alberto, N.; Antunes, P.; et al. Strain, Temperature, Moisture, and Transverse Force Sensing Using Fused Polymer Optical Fibers. Opt. Express 2018, 26, 12939–12947. [Google Scholar] [CrossRef]

- Irawati, N.; Harun, S.W.; Rahman, H.A.; Chong, S.S.; Hamizi, N.A.; Ahmad, H. Temperature Sensing Using CdSe Quantum Dot Doped Poly(Methyl Methacrylate) Microfiber. Appl. Opt. 2017, 56, 4675–4679. [Google Scholar] [CrossRef]

- Shahzad, M.K.; Zhang, Y.; Khan, M.U.; Sun, X.; Liu, L.; Li, H. Upconversion Thermometer through Novel PMMA Fiber Containing Nanocrystals. Opt. Mater. Express 2018, 8, 2321–2329. [Google Scholar] [CrossRef]

- Sánchez-Escobar, S.; Hernández-Cordero, J. Fiber Optic Fluorescence Temperature Sensors Using Up-Conversion from Rare-Earth Polymer Composites. Opt. Lett. 2019, 44, 1194–1197. [Google Scholar] [CrossRef] [PubMed]

- Moraleda, A.T.; García, C.V.; Zaballa, J.Z.; Arrue, J. A Temperature Sensor Based on a Polymer Optical Fiber Macro-Bend. Sensors 2013, 13, 13076–13089. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tapetado, A.; Pinzon, P.J.; Zubia, J.; Vazquez, C. Polymer Optical Fiber Temperature Sensor with Dual-Wavelength Compensation of Power Fluctuations. J. Light. Technol. 2015, 33, 2716–2723. [Google Scholar] [CrossRef] [Green Version]

- Zhong, N.; Liao, Q.; Zhu, X.; Zhao, M.; Huang, Y.; Chen, R. Temperature-Independent Polymer Optical Fiber Evanescent Wave Sensor. Sci. Rep. 2015, 5, 11508. [Google Scholar] [CrossRef]

- Zhong, N.; Zhao, M.; Liao, Q.; Zhu, X.; Li, Y.; Xiong, Z. Effect of Heat Treatments on the Performance of Polymer Optical Fiber Sensor. Opt. Express 2016, 24, 13394–13409. [Google Scholar] [CrossRef]

- Sampath, U.; Kim, D.-G.; Song, M. Side-Polished Fiber-Optic Temperature Sensor for Cryogenic Conditions. In Proceedings of the 26th International Conference on Optical Fiber Sensors, Lausanne, Switzerland, 24–28 September 2018; OSA: Lausanne, Switzerland, 2018; p. ThE89. [Google Scholar]

- Grattan, L.S.; Meggitt, B.T. Optical Fiber Sensor Technology: Fundamentals; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 978-1-4757-6081-1. [Google Scholar]

- Hariharan, P. Basics of Interferometry; Elsevier: Amsterdam, The Netherlands, 2007; ISBN 978-0-12-373589-8. [Google Scholar]

- Sun, B.; Wang, Y.; Qu, J.; Liao, C.; Yin, G.; He, J.; Zhou, J.; Tang, J.; Liu, S.; Li, Z.; et al. Simultaneous Measurement of Pressure and Temperature by Employing Fabry-Perot Interferometer Based on Pendant Polymer Droplet. Opt. Express 2015, 23, 1906. [Google Scholar] [CrossRef] [Green Version]

- Ma, C.-T.; Chang, Y.-W.; Yang, Y.-J.; Lee, C.-L. A Dual-Polymer Fiber Fizeau Interferometer for Simultaneous Measurement of Relative Humidity and Temperature. Sensors 2017, 17, 2659. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.-L.; You, Y.-W.; Dai, J.-H.; Hsu, J.-M.; Horng, J.-S. Hygroscopic Polymer Microcavity Fiber Fizeau Interferometer Incorporating a Fiber Bragg Grating for Simultaneously Sensing Humidity and Temperature. Sens. Actuators B Chem. 2016, 222, 339–346. [Google Scholar] [CrossRef]

- Born, M.; Wolf, E. Principles of Optics: Electromagnetic Theory of Propagation, Interference and Diffraction of Light, 7th ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Tan, X.; Li, X.; Geng, Y.; Yin, Z.; Wang, L.; Wang, W.; Deng, Y. Polymer Microbubble-Based Fabry–Perot Fiber Interferometer and Sensing Applications. IEEE Photonics Technol. Lett. 2015, 27, 2035–2038. [Google Scholar] [CrossRef]

- Ge, M.; Li, Y.; Han, Y.; Xia, Z.; Guo, Z.; Gao, J.; Qu, S. High-Sensitivity Double-Parameter Sensor Based on the Fibre-Tip Fabry–Pérot Interferometer. J. Mod. Opt. 2016, 64, 1–5. [Google Scholar] [CrossRef]

- Cao, K.; Liu, Y.; Qu, S. Highly Sensitive Temperature Sensor Based on Cascaded Polymer-Microbubble Cavities by Employing a Subtraction between Reciprocal Thermal Responses. Opt. Express 2016, 24, 20655–20662. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.-Q.; Zhao, Y.; Xia, F.; Peng, Y.; Tong, R.-J. High Sensitivity Temperature Sensor Based on Fiber Air-Microbubble Fabry-Perot Interferometer with PDMS-Filled Hollow-Core Fiber. Sens. Actuators Phys. 2018, 275, 60–66. [Google Scholar] [CrossRef]

- Wang, C.; Yan, G.; Lian, Z.; Chen, X.; Wu, S.; He, S. Hybrid-Cavity Fabry-Perot Interferometer for Multi-Point Relative Humidity and Temperature Sensing. Sens. Actuators B Chem. 2018, 255, 1937–1944. [Google Scholar] [CrossRef]

- Pawar, D.; Kumar, A.; Kanawade, R.; Mondal, S.; Sinha, R.K. Negative Axicon Tip Micro-Cavity with a Polymer Incorporated Optical Fiber Temperature Sensor. OSA Contin. 2019, 2, 2353. [Google Scholar] [CrossRef]

- Li, M.; Liu, Y.; Zhao, X.; Qu, S.; Li, Y. Miniature ⊓-Shaped Polymer Fiber Tip for Simultaneous Measurement of the Liquid Refractive Index and Temperature with High Sensitivities. J. Opt. 2015, 17, 105701. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.-X.; Zhang, W.-G.; Kong, L.-X.; Yan, T.-Y. Micro-Cap on 2-Core-Fiber Facet Hybrid Interferometer for Dual-Parameter Sensing. J. Light. Technol. 2019, 37, 6114–6120. [Google Scholar] [CrossRef]

- Gao, H.; Xu, D.; Ye, Y.; Zhang, Y.; Shen, J.; Li, C. Fiber-Tip Polymer Filled Probe for High-Sensitivity Temperature Sensing and Polymer Refractometers. Opt. Express 2022, 30, 8104–8114. [Google Scholar] [CrossRef]

- Flores-Hernández, S.; Torres-Cisneros, M.; López-Cortés, D.; Monzón-Hernández, D.; May-Arrioja, D.A.; Hernández-Romano, I. Polymer Comparison on Temperature Sensors Based on Fiber-Optic Fabry-Perot Interferometer. In Proceedings of the Latin America Optics and Photonics Conference, Lima, Peru, 12–15 November 2018; OSA: Lima, Peru, 2018; p. Tu5B.5. [Google Scholar]

- Pan, R.; Yang, W.; Li, L.; Yang, Y.; Zhang, L.; Yu, X.; Fan, J.; Yu, S.; Xiong, Y. A High-Sensitive Fiber-Optic Fabry-Perot Sensor with Parallel Polymer-Air Cavities Based on Vernier Effect for Simultaneous Measurement of Pressure and Temperature. IEEE Sens. J. 2021, 21, 21577–21585. [Google Scholar] [CrossRef]

- Hernández-Romano, I.; Cruz-Garcia, M.A.; Moreno-Hernández, C.; Monzón-Hernández, D.; López-Figueroa, E.O.; Paredes-Gallardo, O.E.; Torres-Cisneros, M.; Villatoro, J. Optical Fiber Temperature Sensor Based on a Microcavity with Polymer Overlay. Opt. Express 2016, 24, 5654–5661. [Google Scholar] [CrossRef]

- Li, X.; Tanyan, S.; Xie, S.; Chen, R.; Liao, Q.; Zhu, X.; He, X. A 3D Porous PDMS Sponge Embedded with Carbon Nanoparticles for Solar Driven Interfacial Evaporation. Sep. Purif. Technol. 2022, 292, 120985. [Google Scholar] [CrossRef]

- Lu, J.; Yu, Y.; Qin, S.; Li, M.; Bian, Q.; Lu, Y.; Hu, X.; Yang, J.; Meng, Z.; Zhang, Z. High-Performance Temperature and Pressure Dual-Parameter Sensor Based on a Polymer-Coated Tapered Optical Fiber. Opt. Express 2022, 30, 9714–9726. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liao, M.; Xiao, H.; Han, X.; Jiang, Y.; Tan, J.; Zhang, P.; Shao, J.; Tian, Y.; Yang, J. High Sensitivity Temperature Sensor Based on a PDMS-Assisted Bow-Shaped Fiber Structure. Opt. Commun. 2021, 481, 126536. [Google Scholar] [CrossRef]

- Statkiewicz-Barabach, G.; Mergo, P.; Urbanczyk, W. Bragg Grating-Based Fabry–Perot Interferometer Fabricated in a Polymer Fiber for Sensing with Improved Resolution. J. Opt. 2016, 19, 015609. [Google Scholar] [CrossRef]

- Domínguez-Flores, C.E.; Monzón-Hernández, D.; Moreno-Basulto, J.I.; Rodríguez-Quiroz, O.; Minkovich, V.P.; López-Cortés, D.; Hernández-Romano, I. Real-Time Temperature Sensor Based on In-Fiber Fabry–Perot Interferometer Embedded in a Resin. J. Light. Technol. 2019, 37, 1084–1090. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Yang, J.; Zhang, Y.; Ren, C. Microfiber Fabry-Perot Interferometer Used as a Temperature Sensor and an Optical Modulator. Opt. Laser Technol. 2020, 129, 106296. [Google Scholar] [CrossRef]

- Fu, X.; Ran, R.; Li, Q.; Huang, Z.; Li, D.; Zhang, R.; Fu, G.; Jin, W.; Qi, Y.; Bi, W. A Few Mode Fiber Temperature Sensor Filled With PDMS Based on Vernier Effect. IEEE Photonics J. 2021, 13, 1–5. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Y.; Cai, L. Hybrid Fiber-Optic Sensor for Seawater Temperature and Salinity Simultaneous Measurements. J. Light. Technol. 2022, 40, 880–886. [Google Scholar] [CrossRef]

- Santiago-Hernández, H.; Bravo-Medina, B.; Mora-Nuñez, A.; Flores, J.L.; García-Torales, G.; Pottiez, O. All-POF Coupling Ratio-Imbalanced Sagnac Interferometer as a Refractive Index Sensor. Appl. Opt. 2021, 60, 7145. [Google Scholar] [CrossRef]

- Liu, Y.; He, K.; Chen, G.; Leow, W.; Chen, X. Nature-Inspired Structural Materials for Flexible Electronic Devices. Chem. Rev. 2017, 117, 12893–12941. [Google Scholar] [CrossRef]

- Li, X.; Chen, N.; Zhou, X.; Gong, P.; Wang, S.; Zhang, Y.; Zhao, Y. A Review of Specialty Fiber Biosensors Based on Interferometer Configuration. J. Biophotonics 2021, 14, e202100068. [Google Scholar] [CrossRef]

- Hao, Y.; Zhang, S.; Fang, B.; Sun, F.; Liu, H.; Li, H. A Review of Smart Materials for the Boost of Soft Actuators, Soft Sensors, and Robotics Applications. Chin. J. Mech. Eng. 2022, 35, 37. [Google Scholar] [CrossRef]

- Fang, G.; Chow, M.C.K.; Ho, J.D.L.; He, Z.; Wang, K.; Ng, T.C.; Tsoi, J.K.H.; Chan, P.-L.; Chang, H.-C.; Chan, D.T.-M.; et al. Soft Robotic Manipulator for Intraoperative MRI-Guided Transoral Laser Microsurgery. Sci. Robot. 2021, 6, eabg5575. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wang, H.; Li, B.; Guo, Z.; Luo, J.; Huang, X.; Gao, J. Highly Electrically Conductive Polymer Composite with a Novel Fiber-Based Segregated Structure. J. Mater. Sci. 2020, 55, 11727–11738. [Google Scholar] [CrossRef]

| Type | PFFPI Construction | Multiparameter Sensing | Measurement Range [°C] | Sensitivity | Linearity | Reference |

|---|---|---|---|---|---|---|

| Exctrinicis POF FPI | Two beam FPI based on microbubble | Temperature and pressure | 25 ÷ 50 | 5.99 degree/°C | No data | [91] |

| Multibeam FPI based on microbubble | Temperature | 25 ÷ 50 | 5.013 nm/°C | 0.996 | [93] | |

| SMF + HCF filled with polymer | Temperature, refractometer, and pressure | 25 ÷ 50 | 1226.64 pm/°C 2.2 nm/°C | 0.997 No data | [100] [101] | |

| PDMS cavity | Temperature | 22 ÷ 60 | 0.13 dB/°C | No data | [103] | |

| Multibeam FPI based on the polymer-coated NCF | Temperature and saline | 15 ÷ 35 | −3.784 nm/°C | 0.9961 | [111] | |

| Two beam FPI SMF PDMS | Temperature and pressure | 40 ÷ 50 | 1.01 nm/°C | 0.9992 | [102] | |

| Multibeam FPI based on a two-layered cap | Temperature, refractive index | 20 ÷ 75 | 689.68 pm/°C | No data | [92] | |

| Multibeam FPI based on the cap within Π-shape | Temperature, refractive index | 25 ÷ 45 | 451 pm/°C | 0.996 | [98] | |

| Multibeam FPI based on air bubble into PDMS cylinder | Temperature | 51.2 ÷ 70.5 | 2.7035 nm/℃ | 0.9962 | [94] | |

| Multipoint FPI based on multi-core fiber and polymer cap | Temperature and humidity | 15 ÷ 40 | −0.115 rad/°C | No data | [95] | |

| FPI based on the polymer cap and 2-core-fiber | Temperature and humidity | 20 ÷ 60 | 385.8 pm/°C | No data | [99] | |

| Intrinsic POF FPI | FPI based on Bragg FPI based on two SMF and air gap | Temperature Temperature | 20 ÷ 70 10 ÷ 30 | −25.1 pm/°C 6.386 nm/°C 3.98 nm/°C | No data 0.9990 0.99829 | [107] [109] [110] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szczerska, M. Temperature Sensors Based on Polymer Fiber Optic Interferometer. Chemosensors 2022, 10, 228. https://doi.org/10.3390/chemosensors10060228

Szczerska M. Temperature Sensors Based on Polymer Fiber Optic Interferometer. Chemosensors. 2022; 10(6):228. https://doi.org/10.3390/chemosensors10060228

Chicago/Turabian StyleSzczerska, Malgorzata. 2022. "Temperature Sensors Based on Polymer Fiber Optic Interferometer" Chemosensors 10, no. 6: 228. https://doi.org/10.3390/chemosensors10060228

APA StyleSzczerska, M. (2022). Temperature Sensors Based on Polymer Fiber Optic Interferometer. Chemosensors, 10(6), 228. https://doi.org/10.3390/chemosensors10060228