Influences of Impurity Gases in Air on Room-Temperature Hydrogen-Sensitive Pt–SnO2 Composite Nanoceramics: A Case Study of H2S

Abstract

:1. Introduction

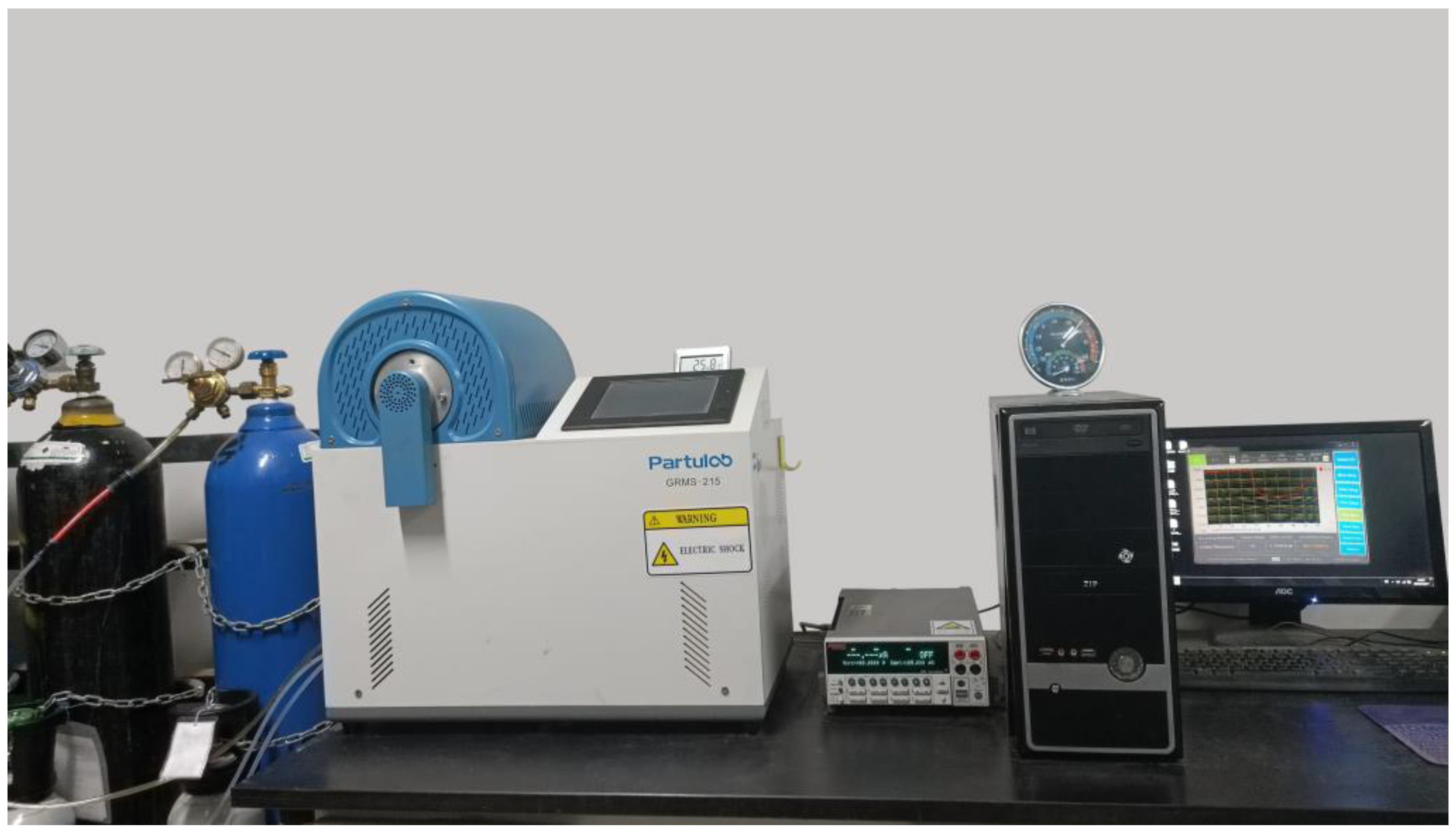

2. Materials and Methods

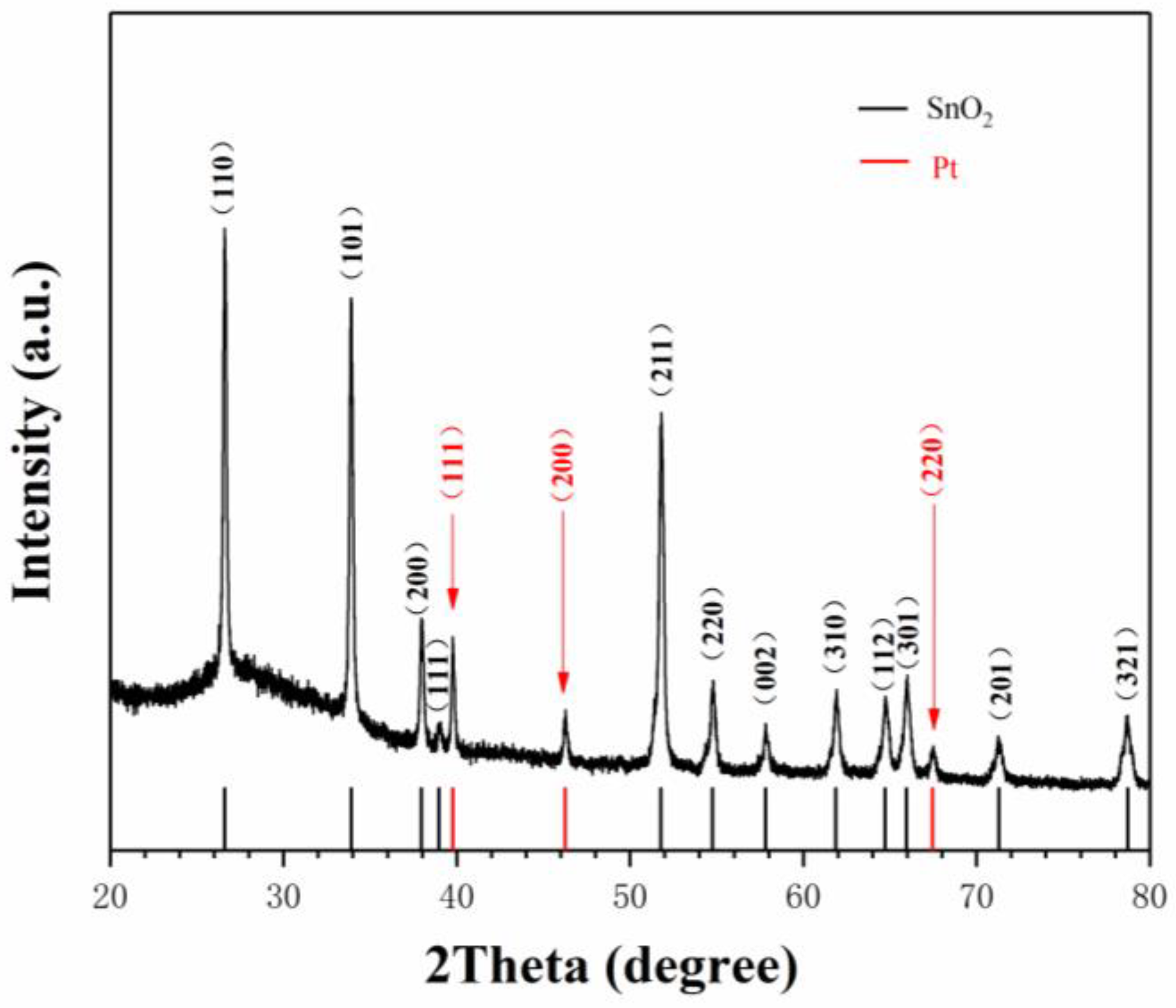

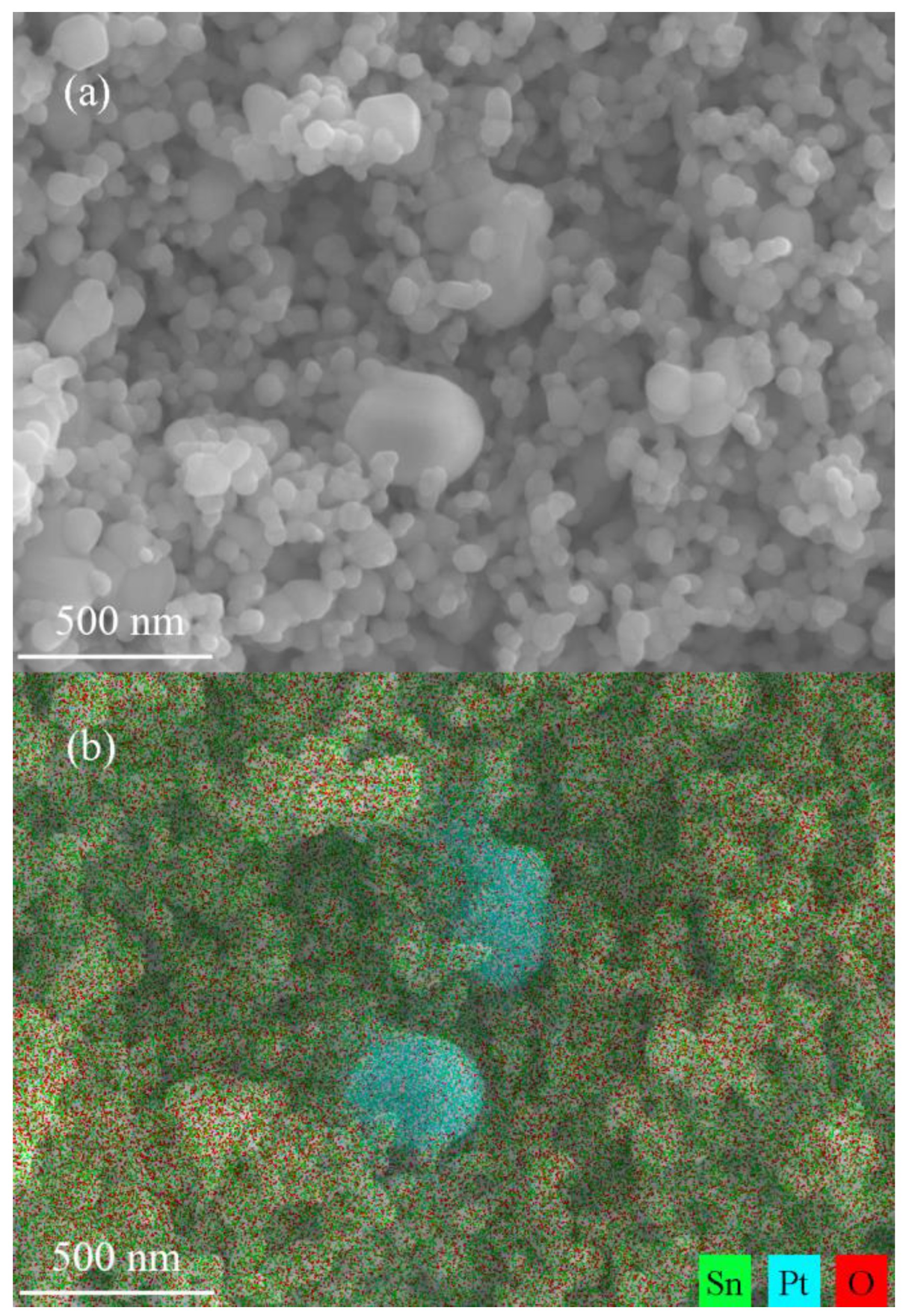

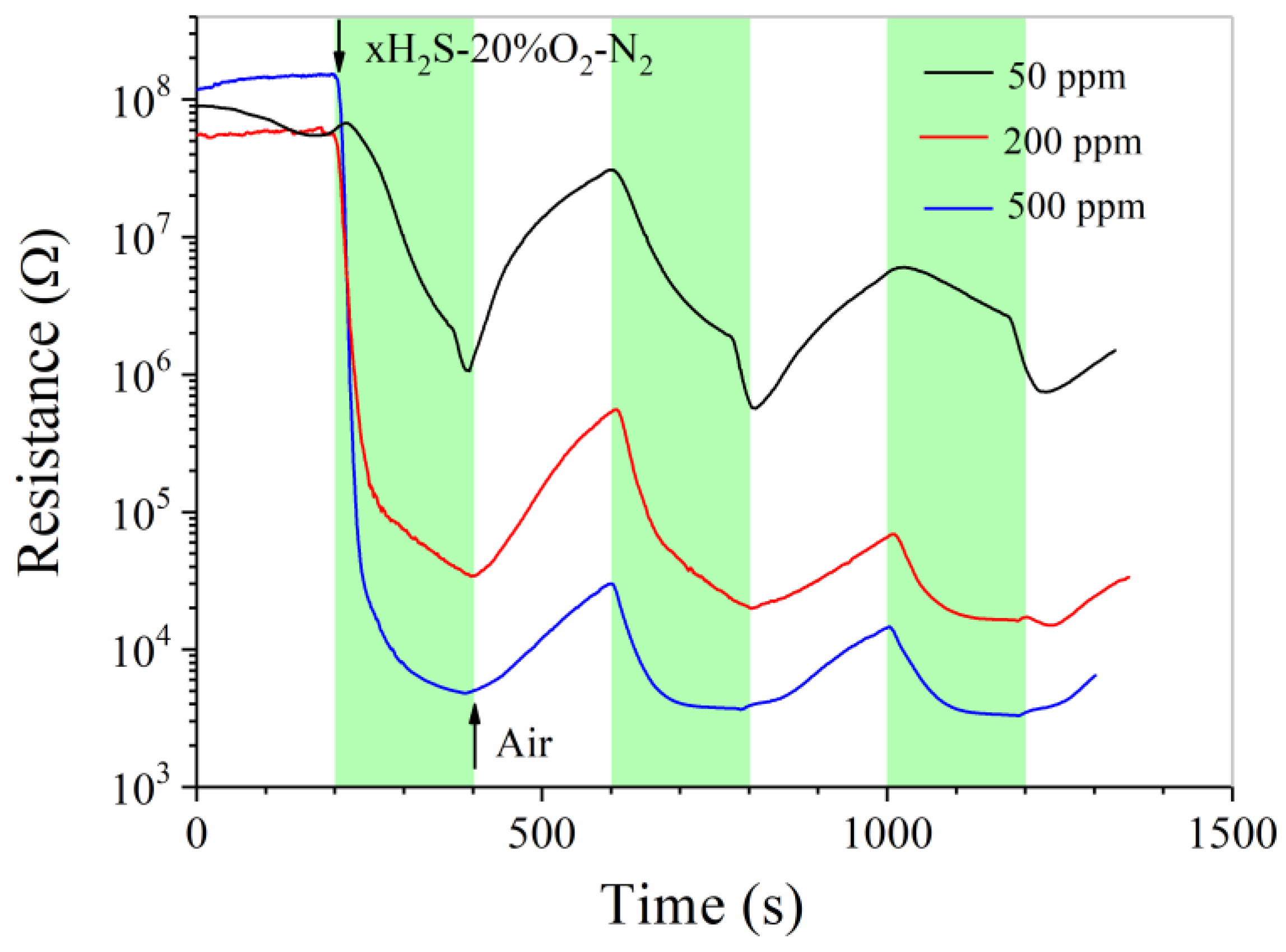

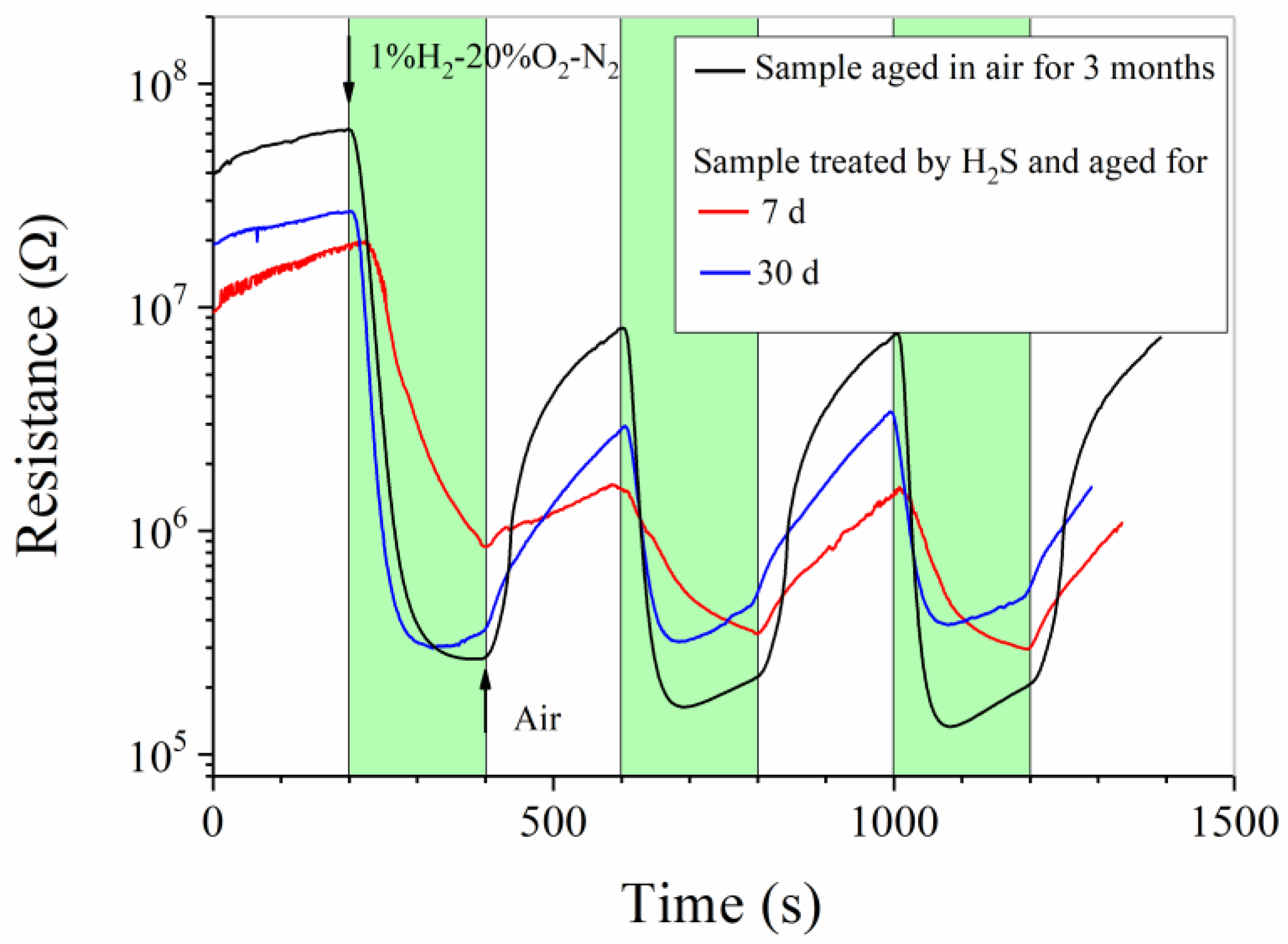

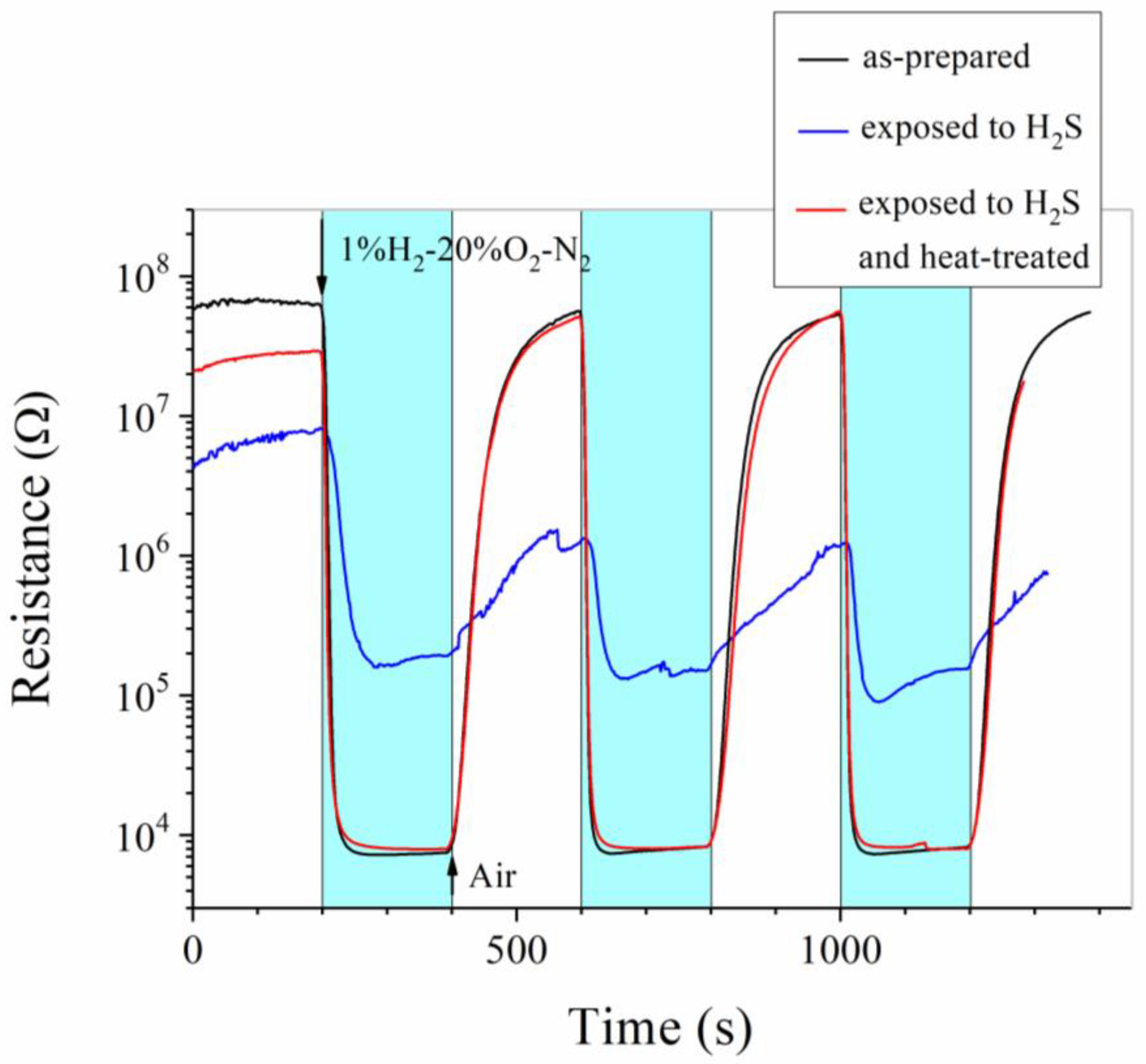

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kong, J.; Franklin, N.R.; Zhou, C.W.; Chapline, M.G.; Peng, S.; Cho, K.J.; Dai, H.J. Nanotube molecular wires as chemical sensors. Science 2000, 287, 622–625. [Google Scholar] [CrossRef] [PubMed]

- Jung, G.; Hong, S.; Jeong, Y.; Shin, W.; Park, J.; Kim, D.; Lee, J.-H. Highly Selective and Low-Power Carbon Monoxide Gas Sensor Based on the Chain Reaction of Oxygen and Carbon Monoxide to WO3. ACS Appl. Mater. Interfaces 2022, 14, 17950–17958. [Google Scholar] [CrossRef] [PubMed]

- Paliwal, A.; Sharma, A.; Tomar, M.; Gupta, V. Carbon monoxide (CO) optical gas sensor based on ZnO thin films. Sens. Actuators B 2017, 250, 679–685. [Google Scholar] [CrossRef]

- Yamazoe, N. Toward innovations of gas sensor technology. Sens. Actuators B 2005, 108, 2–14. [Google Scholar] [CrossRef]

- Moy, R. Liability and the hydrogen economy. Science 2003, 301, 47. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Y.; Maeng, B.; Jung, D.G.; Lee, J.; Kim, Y.; Kwon, J.; An, H.K.; Jung, D. Annealing Effects on SnO2 Thin Film for H2 Gas Sensing. Nanomaterials 2022, 12, 3277. [Google Scholar] [CrossRef]

- Cho, S.H.; Suh, J.M.; Jeong, B.; Lee, T.H.; Choi, K.S.; Eom, T.H.; Kim, T.; Jang, H.W. Fast responding and highly reversible gasochromic H2 sensor using Pd-decorated amorphous WO3 thin films. Chem. Eng. J. 2022, 446, 136862. [Google Scholar]

- Palla-Papavlu, A.; Voicu, S.I.; Dinescu, M. Sensitive Materials and Coating Technologies for Surface Acoustic Wave Sensors. Chemosensors 2021, 9, 105. [Google Scholar] [CrossRef]

- Brunet, E.; Maier, T.; Mutinati, G.C.; Steinhauer, S.; Koeck, A.; Gspan, C.; Grogger, W. Comparison of the gas sensing performance of SnO2 thin film and SnO2 nanowire sensors. Sens. Actuators B 2012, 165, 110–118. [Google Scholar] [CrossRef]

- Korotcenkov, G. Handbook of Gas Sensor Materials: Properties, Advantages and Shortcomings for Applications; Springer: New York, NY, USA, 2013. [Google Scholar]

- Boon-Brett, L.; Bousek, J.; Black, G.; Moretto, P.; Castello, P.; Huebert, T.; Banach, U. Identifying performance gaps in hydrogen safety sensor technology for automotive and stationary applications. Int. J. Hydrogen Energy 2010, 35, 373–384. [Google Scholar] [CrossRef]

- Nelli, P.; Faglia, G.; Sberveglieri, G.; Cereda, E.; Gabetta, G.; Dieguez, A.; Romano-Rodriguez, A.; Morante, J.R. The aging effect on SnO2-Au thin film sensors: Electrical and structural characterization. Thin Solid Films 2000, 371, 249–253. [Google Scholar] [CrossRef]

- Choi, K.J.; Jang, H.W. One-Dimensional Oxide Nanostructures as Gas-Sensing Materials: Review and Issues. Sensors 2010, 10, 4083–4099. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luo, X.; You, K.; Hu, Y.; Yang, S.; Pan, X.; Wang, Z.; Chen, W.; Gu, H. Rapid hydrogen sensing response and aging of a-MoO3 nanowires paper sensor. Int. J. Hydrogen Energy 2017, 42, 8399–8405. [Google Scholar] [CrossRef]

- Wang, M.-Y.; Sun, B.; Jiang, Z.; Liu, Y.; Wang, X.; Tang, Z.; Wang, Y.; Chen, W.-P. Preparation and Extraordinary Room-Temperature CO Sensing Capabilities of Pd-SnO2 Composite Nanoceramics. J. Nanosci. Nanotechnol. 2018, 18, 4176–4181. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Li, P.-C.; Huang, Y.; Cheng, L.; Hu, Y.-M.; Tang, Z.; Chen, W.-P. Room-Temperature Hydrogen-Sensing Capabilities of Pt-SnO2 and Pt-ZnO Composite Nanoceramics Occur via Two Different Mechanisms. Nanomaterials 2021, 11, 504. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Liu, Y.; Wu, G.; Fei, L.; Zhang, S.; Hu, Y.-M.; Yan, Z.; Wang, Y.; Gu, H.; Chen, W.-P. Mechanism study on extraordinary room-temperature CO sensing capabilities of Pd-SnO2 composite nanoceramics. Sens. Actuators B 2019, 285, 49–55. [Google Scholar] [CrossRef]

- Zhu, S.; Li, P.-C.; Wu, G.; Li, Z.; Wu, P.; Hu, Y.-M.; Gu, H.; Chen, W.-P. Extraordinary room-temperature hydrogen sensing capabilities with high humidity tolerance of Pt-SnO2 composite nanoceramics prepared using SnO2 agglomerate powder. Int. J. Hydrogen Energy 2018, 43, 21177–21185. [Google Scholar] [CrossRef]

- Huang, Y.; Li, P.; Xu, L.; Yu, Y.; Chen, W. Ultrahigh humidity tolerance of room-temperature hydrogen sensitive Pt-WO3 porous composite ceramics with ultra-large WO3 grains. Appl. Phys. A 2021, 127, 952. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, F.; Meng, L.; Hu, Y.-M.; Chen, W.-P. Aging and activation of room temperature hydrogen sensitive Pt-SnO2 composite nanoceramics. J. Mater. Sci. 2022, 57, 15267–15275. [Google Scholar] [CrossRef]

- Wu, M.-H.; Gui, F.-B.; Lu, X.-L.; Yan, Z.; Chen, F.; Jiang, Y.; Luo, X.; Chen, W.-P. Achieving a high long-term stability for room temperature CO-sensitive Pt-SnO2 composite nanoceramics through two strategies. Mater. Sci. Eng. B 2022, 286, 116070. [Google Scholar] [CrossRef]

- Ali, F.I.M.; Awwad, F.; Greish, Y.E.; Mahmoud, S.T. Hydrogen Sulfide (H2S) Gas Sensor: A Review. IEEE Sens. J. 2019, 19, 2394–2407. [Google Scholar] [CrossRef]

- Wang, R. Physiological implications of hydrogen sulfide: A whiff exploration that blossomed. Physiol. Rev. 2012, 92, 791–896. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, J.; Sokolovskij, R.; Chen, G.; Zhu, Y.; Qi, Y.; Lin, X.; Li, W.; Zhang, G.Q.; Jiang, Y.-L.; Yu, H. Impact of high temperature H2 pre-treatment on Pt-AlGaN/GaN HEMT sensor for H2S detection. Sens. Actuators B 2019, 280, 138–143. [Google Scholar] [CrossRef]

- Abu Haija, M.; Abu-Hani, A.F.S.; Hamdan, N.; Stephen, S.; Ayesh, A.I. Characterization of H2S gas sensor based on CuFe2O4 nanoparticles. J. Alloys Compd. 2017, 690, 461–468. [Google Scholar] [CrossRef]

- Liu, M.; Wang, C.; Li, P.; Cheng, L.; Hu, Y.; Xiong, Y.; Guo, S.; Gu, H.; Chen, W. Transforming Pt-SnO2 Nanoparticles into Pt-SnO2 Composite Nanoceramics for Room-Temperature Hydrogen-Sensing Applications. Materials 2021, 14, 2123. [Google Scholar] [CrossRef]

- He, F.; Muliane, U.; Weon, S.; Choi, W. Substrate-specific mineralization and deactivation behaviors of TiO2 as an air-cleaning photocatalyst. Appl. Catal. B 2020, 275, 119145. [Google Scholar] [CrossRef]

- Maki-Arvela, P.; Martin, G.; Simakova, I.; Tokarev, A.; Warna, J.; Hemming, J.; Holmbom, B.; Salmi, T.; Murzin, D.Y. Kinetics, catalyst deactivation and modeling in the hydrogenation of beta-sitosterol to beta-sitostanol over microporous and mesoporous carbon supported Pd catalysts. Chem. Eng. J. 2009, 154, 45–51. [Google Scholar] [CrossRef]

- Ravanchi, M.T.; Sahebdelfar, S.; Fard, M.R.; Fadaeerayeni, S.; Bigdeli, P. Pd-Ag/-Al2O3 Catalyst Deactivation in Acetylene Selective Hydrogenation Process. Chem. Eng. Technol. 2016, 39, 301–310. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Wu, M.; Huang, Y.; Song, J.; Liu, Y.; Yan, Z.; Chen, F.; Zhao, J.; Chen, W. Influences of Impurity Gases in Air on Room-Temperature Hydrogen-Sensitive Pt–SnO2 Composite Nanoceramics: A Case Study of H2S. Chemosensors 2023, 11, 31. https://doi.org/10.3390/chemosensors11010031

Lu X, Wu M, Huang Y, Song J, Liu Y, Yan Z, Chen F, Zhao J, Chen W. Influences of Impurity Gases in Air on Room-Temperature Hydrogen-Sensitive Pt–SnO2 Composite Nanoceramics: A Case Study of H2S. Chemosensors. 2023; 11(1):31. https://doi.org/10.3390/chemosensors11010031

Chicago/Turabian StyleLu, Xilai, Menghan Wu, Yong Huang, Jiannan Song, Yong Liu, Zhiqiao Yan, Feng Chen, Jieting Zhao, and Wanping Chen. 2023. "Influences of Impurity Gases in Air on Room-Temperature Hydrogen-Sensitive Pt–SnO2 Composite Nanoceramics: A Case Study of H2S" Chemosensors 11, no. 1: 31. https://doi.org/10.3390/chemosensors11010031

APA StyleLu, X., Wu, M., Huang, Y., Song, J., Liu, Y., Yan, Z., Chen, F., Zhao, J., & Chen, W. (2023). Influences of Impurity Gases in Air on Room-Temperature Hydrogen-Sensitive Pt–SnO2 Composite Nanoceramics: A Case Study of H2S. Chemosensors, 11(1), 31. https://doi.org/10.3390/chemosensors11010031