Highly Polarized SERS Based on Random Working Domains Composed of Nanorod Arrays for Self-Referenced Detection

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

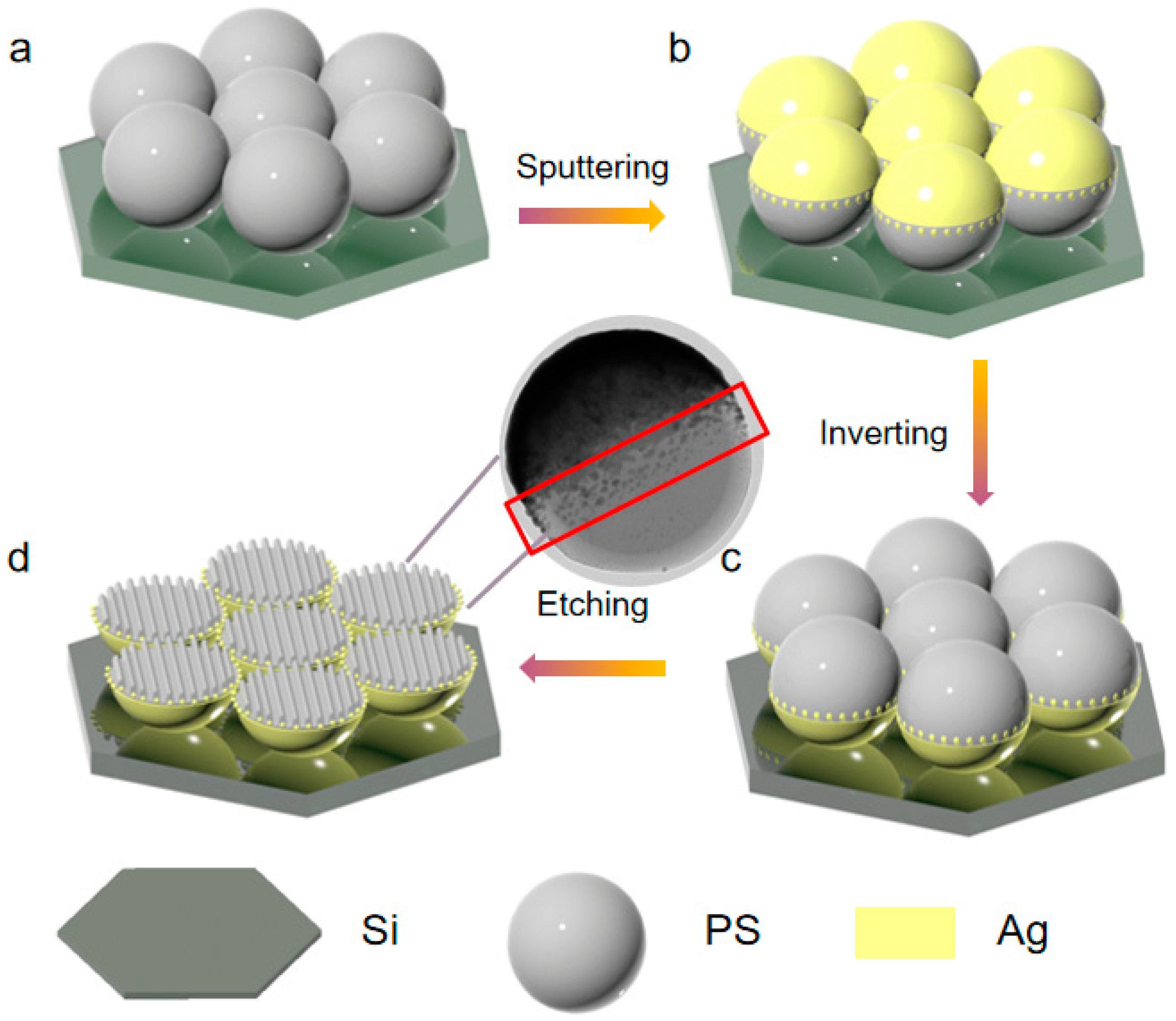

2.2. Methods

2.3. FDTD Simulation

3. Results

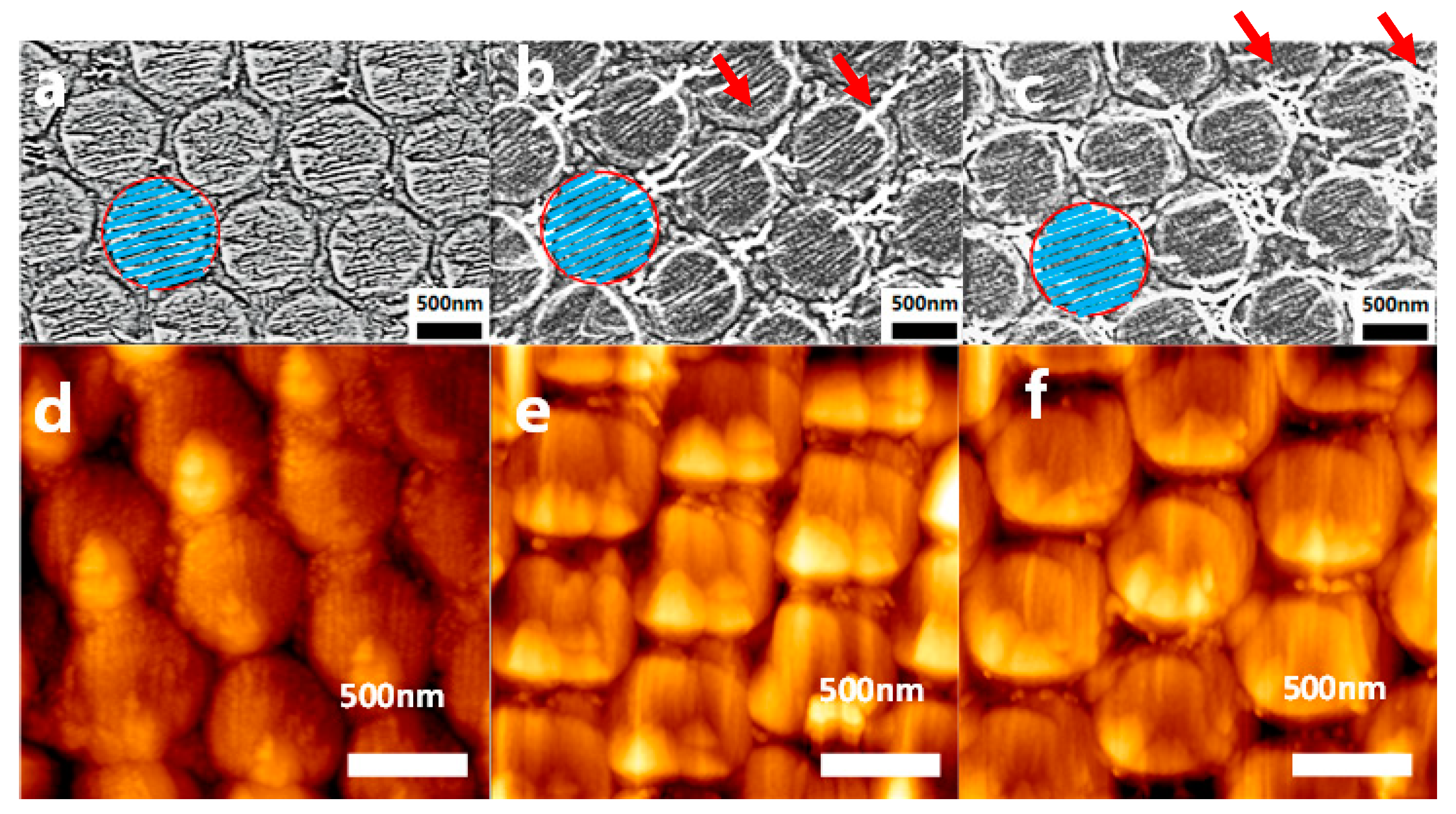

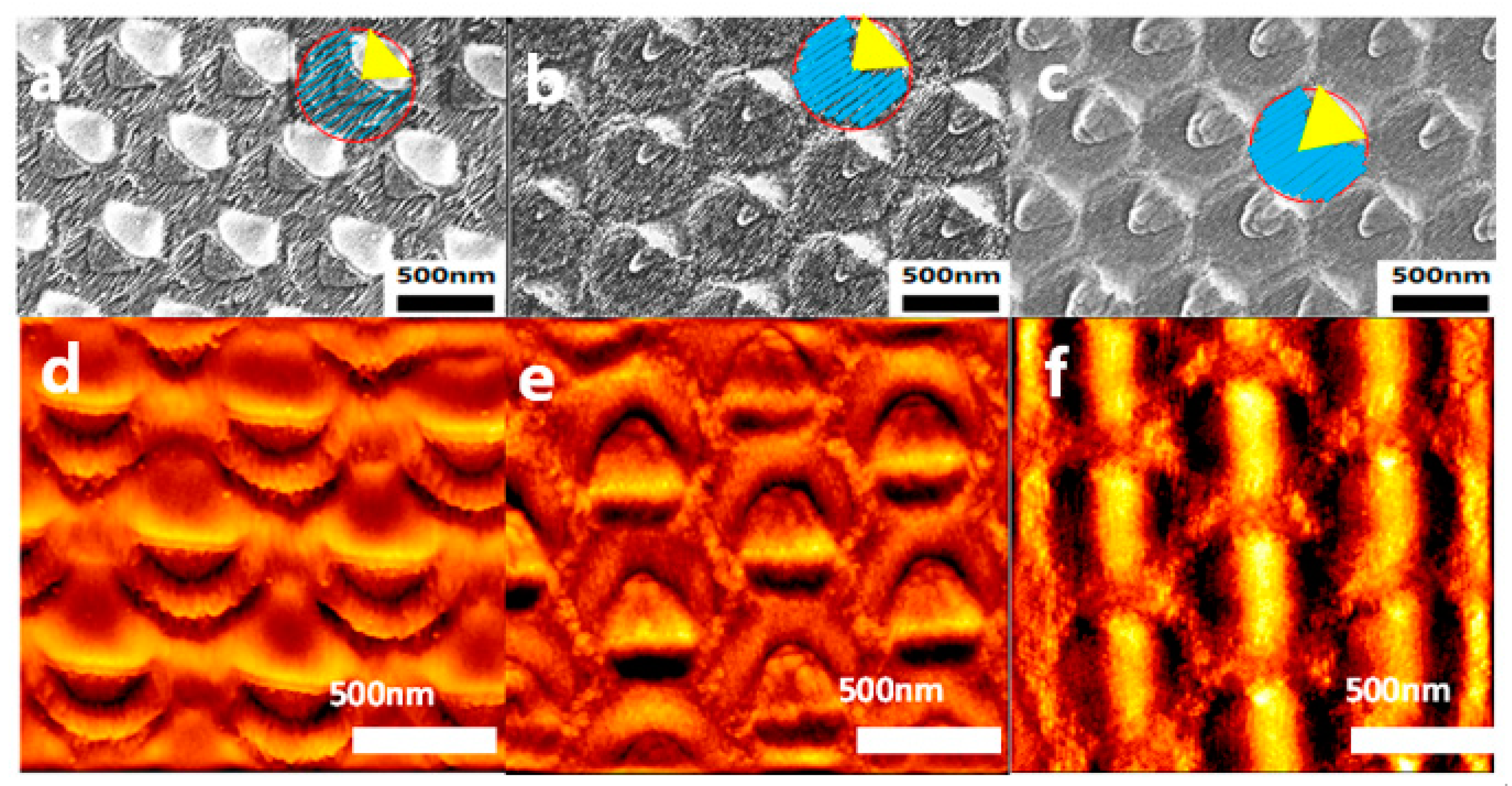

3.1. Microstructure Characterization

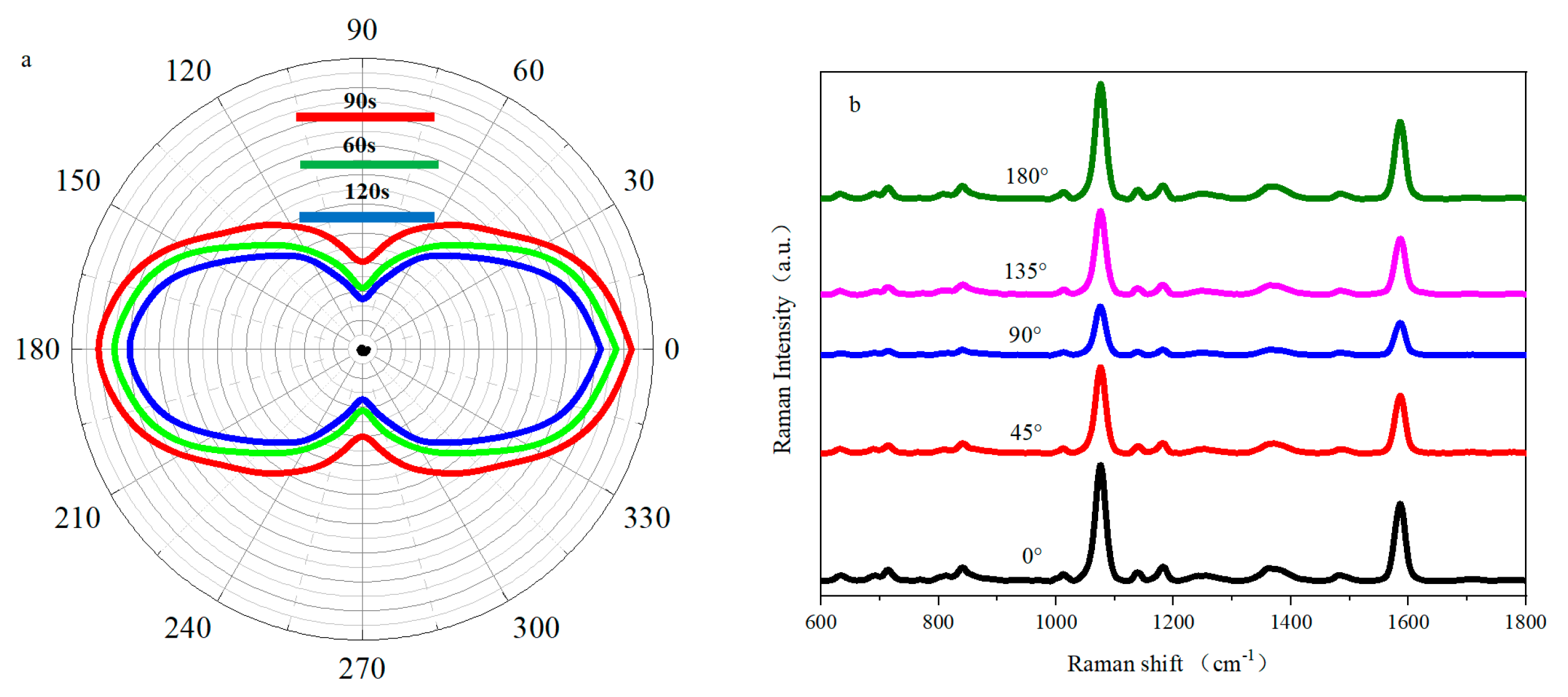

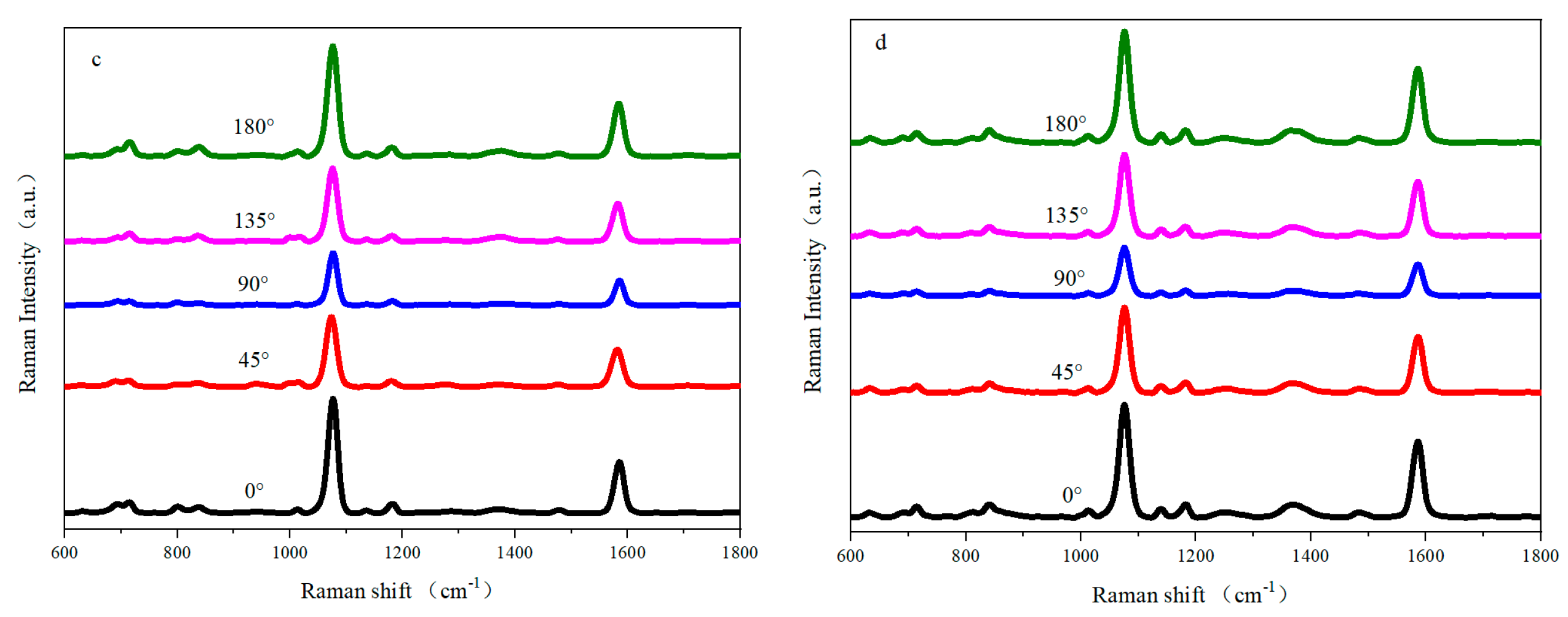

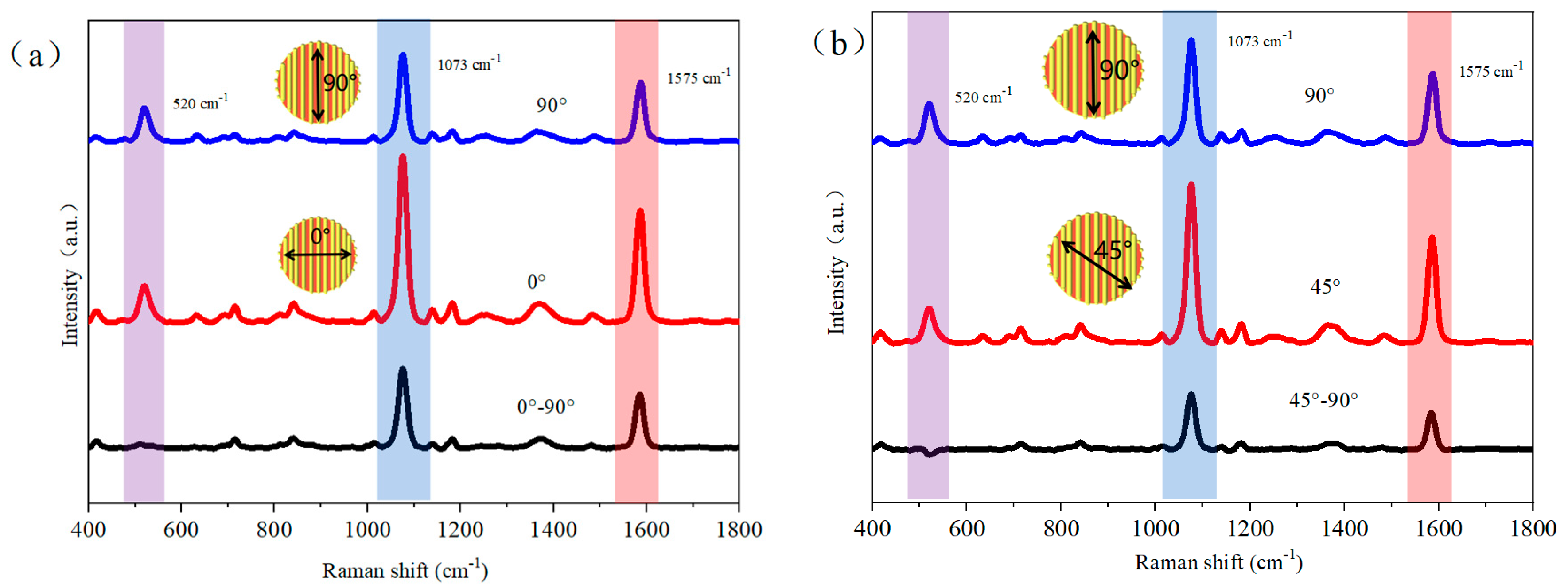

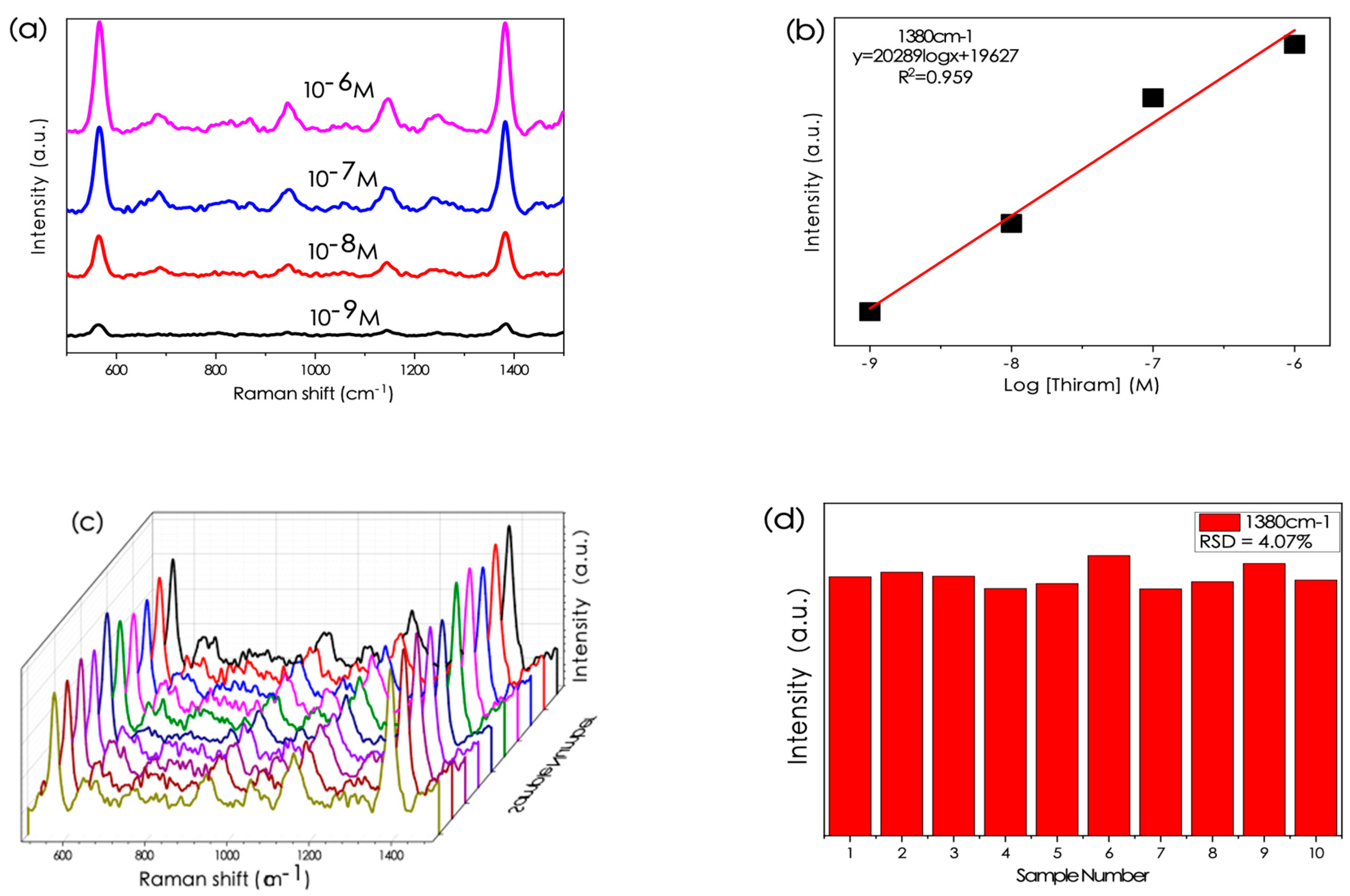

3.2. Optical Properties

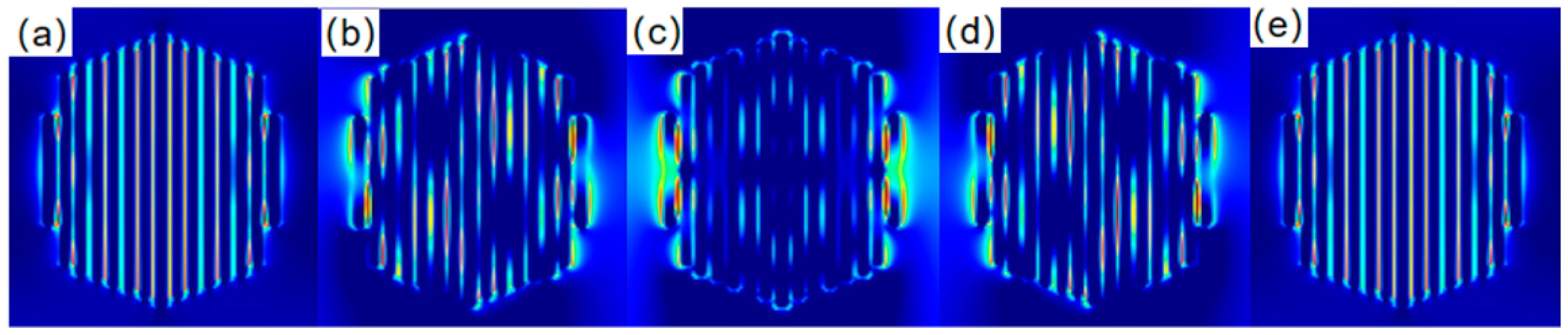

3.3. FDTD Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Linic, S.; Aslam, U.; Boerigter, C.; Morabito, M. Photochemical transformations on plasmonic metal nanoparticles. Nat. Mater. 2015, 14, 567–576. [Google Scholar] [CrossRef] [PubMed]

- Kherbouche, I.; Luo, Y.; Félidj, N.; Mangeney, C. Plasmon-Mediated surface functionalization: New horizons for the control of surface chemistry on the nanoscale. Chem. Mater. 2020, 32, 5442–5454. [Google Scholar] [CrossRef]

- Chen, W.; Shi, H.; Wan, F.; Wang, P.; Gu, Z.; Li, W.; Huang, Y. Substrate influence on the polarization dependence of SERS in crossed metal nanowires. J. Mater. Chem. C 2017, 5, 7028–7034. [Google Scholar] [CrossRef]

- Lee, H.; Kim, G.H.; Lee, J.H.; Kim, N.H.; Nam, J.M.; Suh, Y.D. Quantitative plasmon mode and Surface-Enhanced Raman Scattering analyses of strongly coupled plasmonic nanotrimers with diverse geometries. Nano Lett. 2015, 15, 4628–4636. [Google Scholar] [CrossRef] [PubMed]

- Tumkur, T.U.; Yang, X.; Cerjan, B.; Halas, N.J.; Nordlander, P.; Thomann, I. Photoinduced force mapping of plasmonic nanostructures. Nano Lett. 2016, 16, 7942–7949. [Google Scholar] [CrossRef] [PubMed]

- Vasista, A.B.; Jog, H.; Heilpern, T.; Sykes, M.E.; Tiwari, S.; Sharma, D.K.; Kumar, G.V.P. Differential wavevector distribution of Surface-Enhanced Raman Scattering and fluorescence in a film-coupled plasmonic nanowire cavity. Nano Lett. 2017, 18, 650–655. [Google Scholar] [CrossRef]

- Pal, S.; Harmsen, S.; Oseledchyk, A.; Hsu, H.T.; Kircher, M.F. MUC1 aptamer targeted SERS nanoprobes. Adv. Funct. Mater. 2017, 27, 1606632. [Google Scholar] [CrossRef]

- Wang, X.; Guo, L. SERS activity of semiconductors: Crystalline and amorphous nanomaterials. Angew. Chem. Int. Ed. 2019, 59, 4231–4239. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, H.; Yan, L.; Zhang, X.; Falak, A.; Guo, Y.; Chu, W. A generalized methodology of designing 3D SERS probes with superior detection limit and uniformity by maximizing multiple coupling effects. Adv. Sci. 2019, 6, 1900177. [Google Scholar] [CrossRef]

- McLellan, J.M.; Li, Z.; Siekkinen, A.R.; Xia, Y. The SERS activity of a supported Ag nanocube strongly depends on its orientation relative to laser polarization. Nano Lett. 2007, 7, 1013–1017. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, J.; Li, Z.; Yuan, Y.; Liu, A.; Huang, Y. Coherent enhancement of dual-path-excited remote SERS. ACS Appl. Mater. Interfaces 2020, 12, 32746–32751. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.Y.; Yin, P.; Hu, Y.; Szydzik, C.; Khan, M.W.; Xu, K.; Thurgood, P.; Mahmood, N.; Dekiwadia, C.; Afrin, S.; et al. Highly accurate and label-free discrimination of single cancer cell using a plasmonic oxide-based nanoprobe. Biosens. Bioelectron. 2021, 198, 113814. [Google Scholar] [CrossRef]

- Alsaif, M.M.Y.A.; Haque, F.; Alkathiri, T.; Krishnamurthi, V.; Walia, S.; Hu, Y.; Jannat, A.; Mohiuddin; Xu, K.; Khan, M.W.; et al. 3D Visible-Light-Driven Plasmonic Oxide Frameworks Deviated from Liquid Metal Nanodroplets. Adv. Funct. Mater. 2021, 31, 2106397. [Google Scholar] [CrossRef]

- Bai, S.; Serien, D.; Hu, A.; Sugioka, K. 3D Microfluidic Surface-Enhanced Raman Spectroscopy (SERS) Chips Fabricated by All-Femtosecond-Laser-Processing for Real-Time Sensing of Toxic Substances. Adv. Funct. Mater. 2018, 28, 1706262. [Google Scholar] [CrossRef]

- Zhang, D.; Xia, C.; Li, S.; Liu, H.; Ding, L.; Liu, X.; Li, Y. Detection of off-resonance single-walled carbon nanotubes by enormous Surface-Enhanced Raman Scattering. Adv. Opt. Mater. 2021, 9, 2100559. [Google Scholar] [CrossRef]

- Langer, J.; Jimenez, D.; Aizpurua, J.; Alvarez, R.A.; Auguie, B.; Baumberg, J.J.; Liz-Marzan, L.M. Present and future of Surface-Enhanced Raman Scattering. ACS Nano 2020, 14, 28–117. [Google Scholar] [CrossRef]

- Wei, H.; Hao, F.; Huang, Y.; Wang, W.; Nordlander, P.; Xu, H. Polarization dependence of Surface-Enhanced Raman Scattering in gold nanoparticle-nanowire systems. Nano Letter 2008, 8, 2497–2502. [Google Scholar] [CrossRef]

- Lee, S.Y.; Hung, L.; Lang, G.S.; Cornett, J.E.; Mayergoyz, I.D.; Rabin, O. Dispersion in the SERS Enhancement with Silver Nanocube Dimers. ACS Nano 2010, 4, 5763–5772. [Google Scholar] [CrossRef]

- Tian, C.; Ding, C.; Liu, S.; Yang, S.; Song, X.; Ding, B.; Li, Z.; Fang, J. Nanoparticle Attachment on Silver Corrugated-Wire Nanoantenna for Large Increases of Surface-Enhanced Raman Scattering. ACS Nano 2011, 5, 9442–9449. [Google Scholar] [CrossRef]

- Eom, G.; Kim, H.; Hwang, A.; Son, H.Y.; Choi, Y.; Moon, J.; Kim, B. Nanogap-rich Au nanowire SERS sensor for ultrasensitive telomerase activity detection: Application to gastric and breast cancer tissues diagnosis. Adv. Funct. Mater. 2017, 27, 1701832. [Google Scholar] [CrossRef]

- Pissuwan, D.; Hattori, Y. Detection of Adhesion Molecules on Inflamed Macrophages at Early-Stage Using SERS Probe Gold Nanorods. Nano-Micro Lett. 2016, 9, 8–17. [Google Scholar] [CrossRef] [PubMed]

- Niu, R.; Song, C.; Gao, F.; Fang, W.; Jiang, X.; Ren, S.; Zhu, D.; Su, S.; Chao, J.; Chen, S.; et al. DNA Origami-Based Nanoprinting for the Assembly of Plasmonic Nanostructures with Single-Molecule Surface-Enhanced Raman Scattering. Angew. Chem. Int. Ed. 2021, 60, 11695–11701. [Google Scholar] [CrossRef] [PubMed]

- Andrea, C.D.; Bochterle, J.; Toma, A.; Huck, C.; Neubrech, F.; Messina, E.; Fazio, B.; Marago, O.M.; Fabrizio, E.D.; Chapelle, M.; et al. Optical nanoantennas for multiband surface-enhanced infrared and raman spectroscopy. ACS Nano 2019, 494, 87–93. [Google Scholar]

- Hao, N.; Pei, Z.; Liu, P.; Bachman, H.; Naquin, T.D.; Zhang, P.; Huang, T.J. Acoustofluidics-assisted fluorescence-SERS bimodal biosensors. Small 2020, 16, 2005179. [Google Scholar] [CrossRef]

- Cheng, M.; Zhang, F.; Zhu, A.; Zhang, X.; Wang, Y.; Zhao, X.; Zhang, X. Bridging the neighbor plasma coupling on curved surface array for early hepatocellular carcinoma detection. Sens. Actuators B Chem. 2020, 309, 127759. [Google Scholar] [CrossRef]

- Kasani, S.; Curtin, K.; Wu, N. A review of 2D and 3D plasmonic nanostructure array patterns: Fabrication, light management and sensing applications. Nanophotonics 2019, 8, 2065–2089. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhao, X.; Zhang, X.; Zhu, A.; Gao, R.; Zhang, Y.; Chen, L. Au nanocone array with 3D hotspots for biomarker chips. CrystEngComm 2020, 22, 5191–5199. [Google Scholar] [CrossRef]

- Zhu, A.; Zhang, F.; Gao, R.; Zhao, X.; Chen, L.; Zhang, Y.; Wang, Y. Increasing polarization-dependent SERS effects by optimizing the axial symmetry of plasmonic nanostructures. Appl. Surf. Sci. 2019, 494, 87–93. [Google Scholar] [CrossRef]

- Gao, R.; Zhang, Y.; Zhang, F.; Guo, S.; Wang, Y.; Chen, L.; Yang, J. SERS polarization-dependent effects for an ordered 3D plasmonic tilted silver nanorod array. Nanoscale 2018, 10, 8106–8114. [Google Scholar] [CrossRef]

- Agrawal, A.; Cho, S.H.; Zandi, O.; Ghosh, S.; Johns, R.W.; Milliron, D.J. Localized Surface Plasmon Resonance in semiconductor nanocrystals. Chem. Rev. 2018, 118, 3121–3207. [Google Scholar] [CrossRef]

- Mao, D.; Zhao, X.; Wen, J.; Wang, A.; Gao, R.; Wang, Y. Enhanced Electromagnetic Coupling in the Walnut-Shaped Nanostructure Array. Chemosensors 2022, 10, 445. [Google Scholar] [CrossRef]

| Raman Shift (cm−1) | Vibrational Modes |

|---|---|

| 719 | γ(CCC) out-of-plane ring vibration |

| 846 | δ(COO-) bending vibration |

| 1296 | Ring in-plane C-H bending mode |

| 1318 | C-O stretching mode |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Mao, D.; Zhao, S.; Wang, Y.; Guo, X.; Wang, Y.; Gao, R.; Zhang, Y. Highly Polarized SERS Based on Random Working Domains Composed of Nanorod Arrays for Self-Referenced Detection. Chemosensors 2023, 11, 462. https://doi.org/10.3390/chemosensors11080462

Zhao X, Mao D, Zhao S, Wang Y, Guo X, Wang Y, Gao R, Zhang Y. Highly Polarized SERS Based on Random Working Domains Composed of Nanorod Arrays for Self-Referenced Detection. Chemosensors. 2023; 11(8):462. https://doi.org/10.3390/chemosensors11080462

Chicago/Turabian StyleZhao, Xiaoyu, Deyuan Mao, Shuangshuang Zhao, Yuxia Wang, Xiaojie Guo, Yaxin Wang, Renxian Gao, and Yongjun Zhang. 2023. "Highly Polarized SERS Based on Random Working Domains Composed of Nanorod Arrays for Self-Referenced Detection" Chemosensors 11, no. 8: 462. https://doi.org/10.3390/chemosensors11080462

APA StyleZhao, X., Mao, D., Zhao, S., Wang, Y., Guo, X., Wang, Y., Gao, R., & Zhang, Y. (2023). Highly Polarized SERS Based on Random Working Domains Composed of Nanorod Arrays for Self-Referenced Detection. Chemosensors, 11(8), 462. https://doi.org/10.3390/chemosensors11080462