The Effect of the Elemental Composition of Municipal Sewage Sludge on the Phosphorus Recycling during Pyrolysis, with a Focus on the Char Chemistry—Modeling and Experiments

Abstract

:1. Introduction

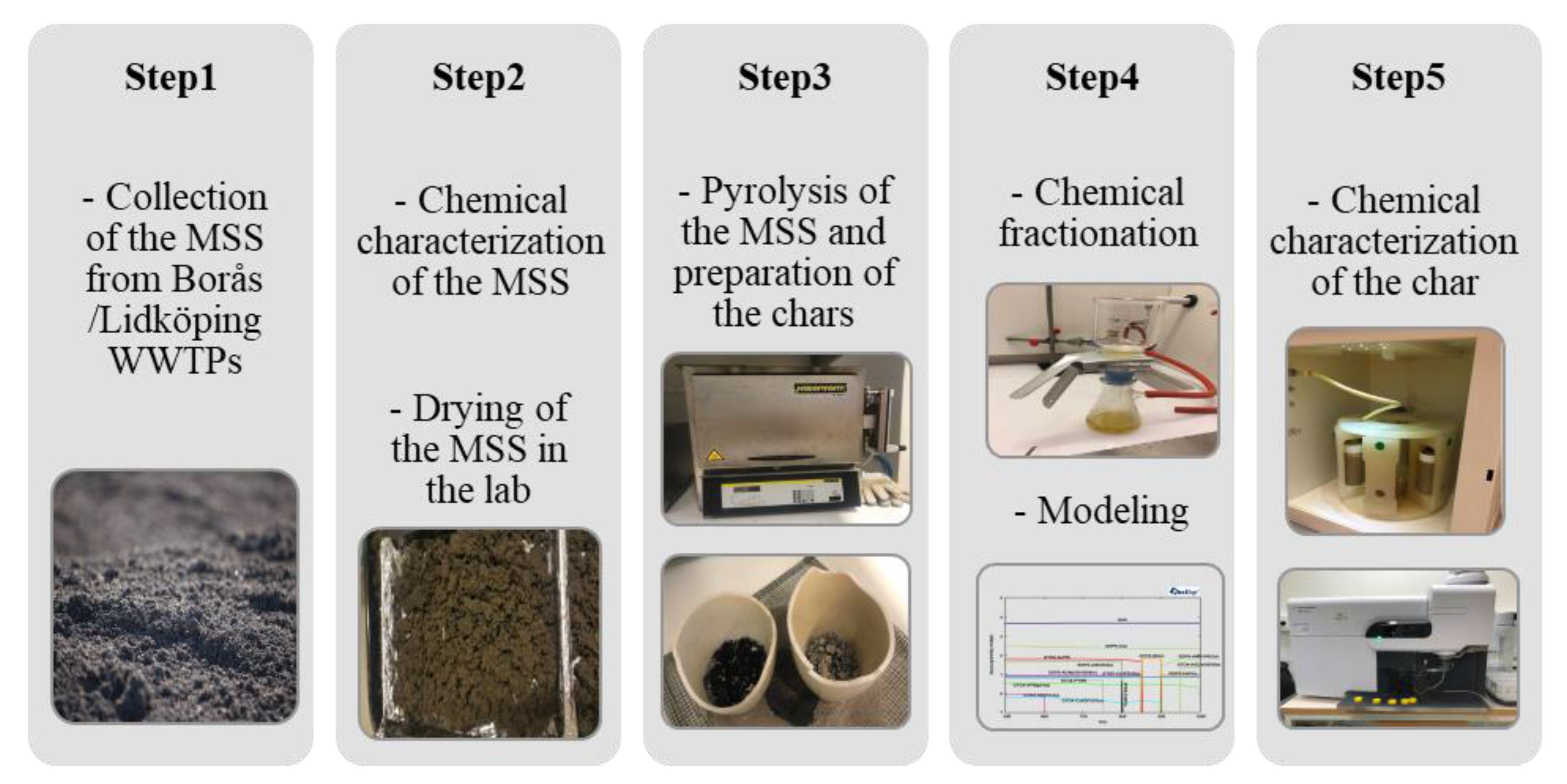

2. Materials and Methods

2.1. Sewage Sludge and Sample Preparation

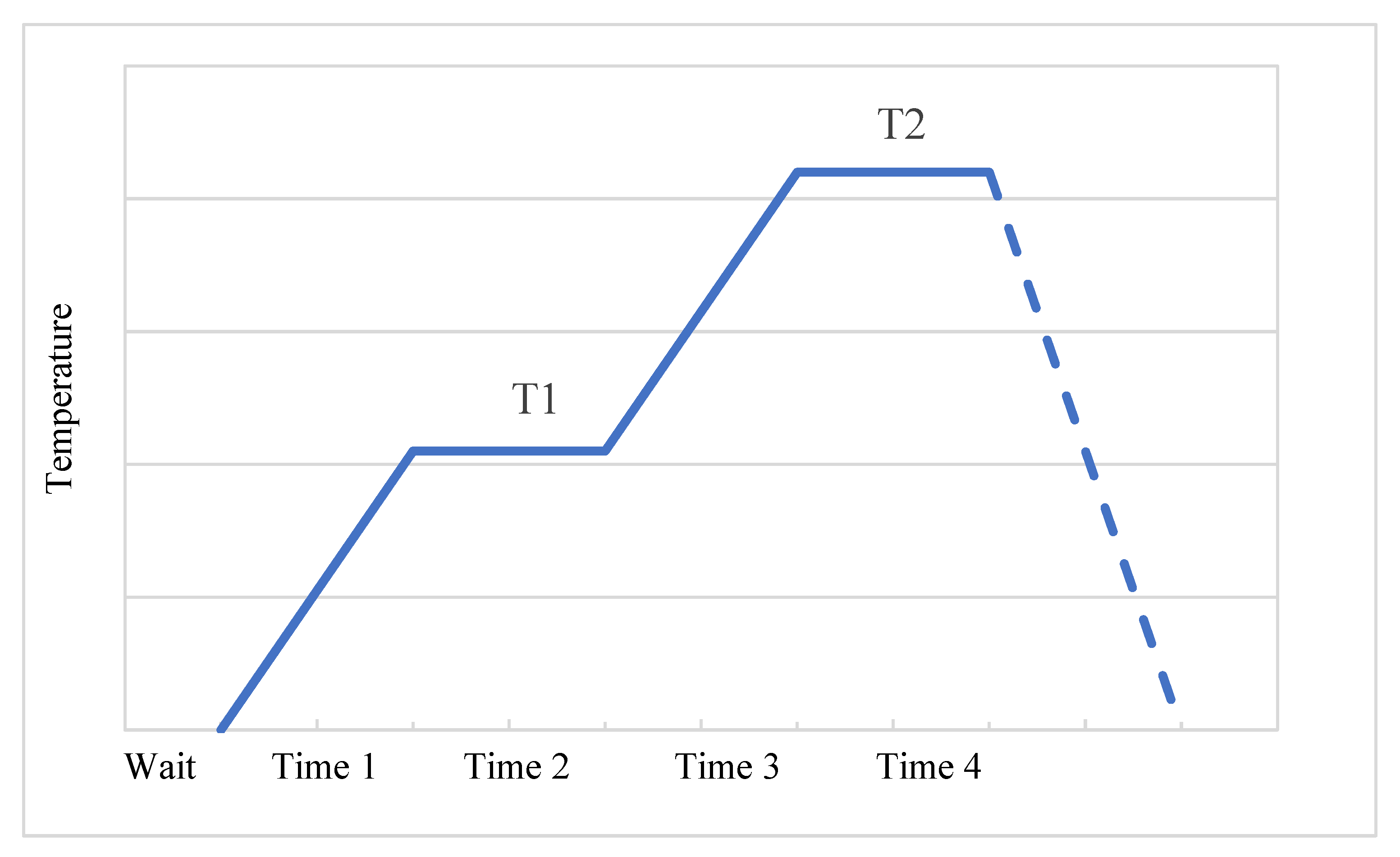

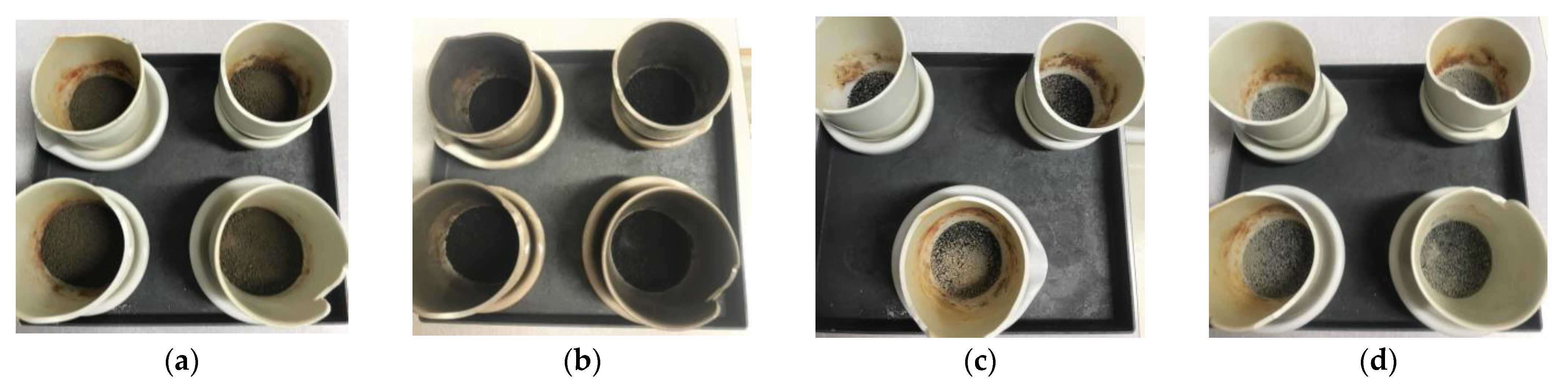

2.2. Pyrolysis Procedure and Preparation of Chars and Thermogravimetric Analysis (TGA)

2.3. Heating Value Measurements with a Bomb Calorimeter

2.4. Chemical Treatments and MP-AES Analysis

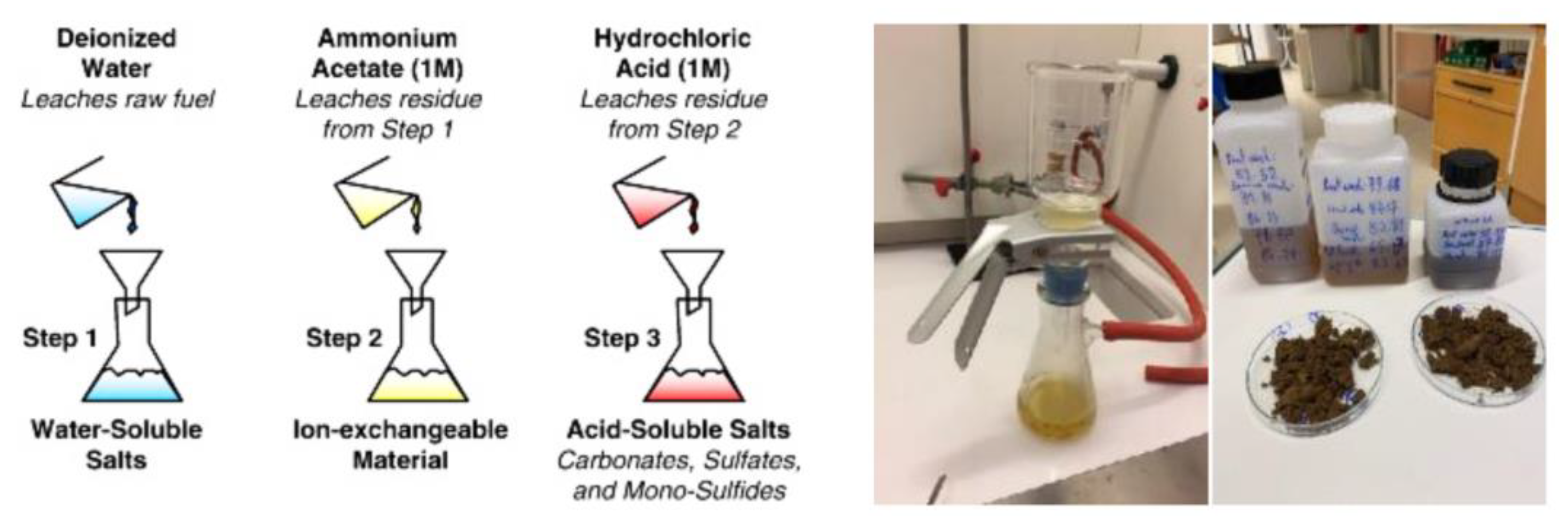

2.5. Chemical Fractionations of the Dried Municipal Sewage Sludge (DMSS)

2.6. Thermodynamic Modeling

3. Results and Discussion

3.1. Characteristics of the Sewage Sludge and the Char Residues

3.2. Elemental Analysis

3.3. Thermogravimetric Analysis

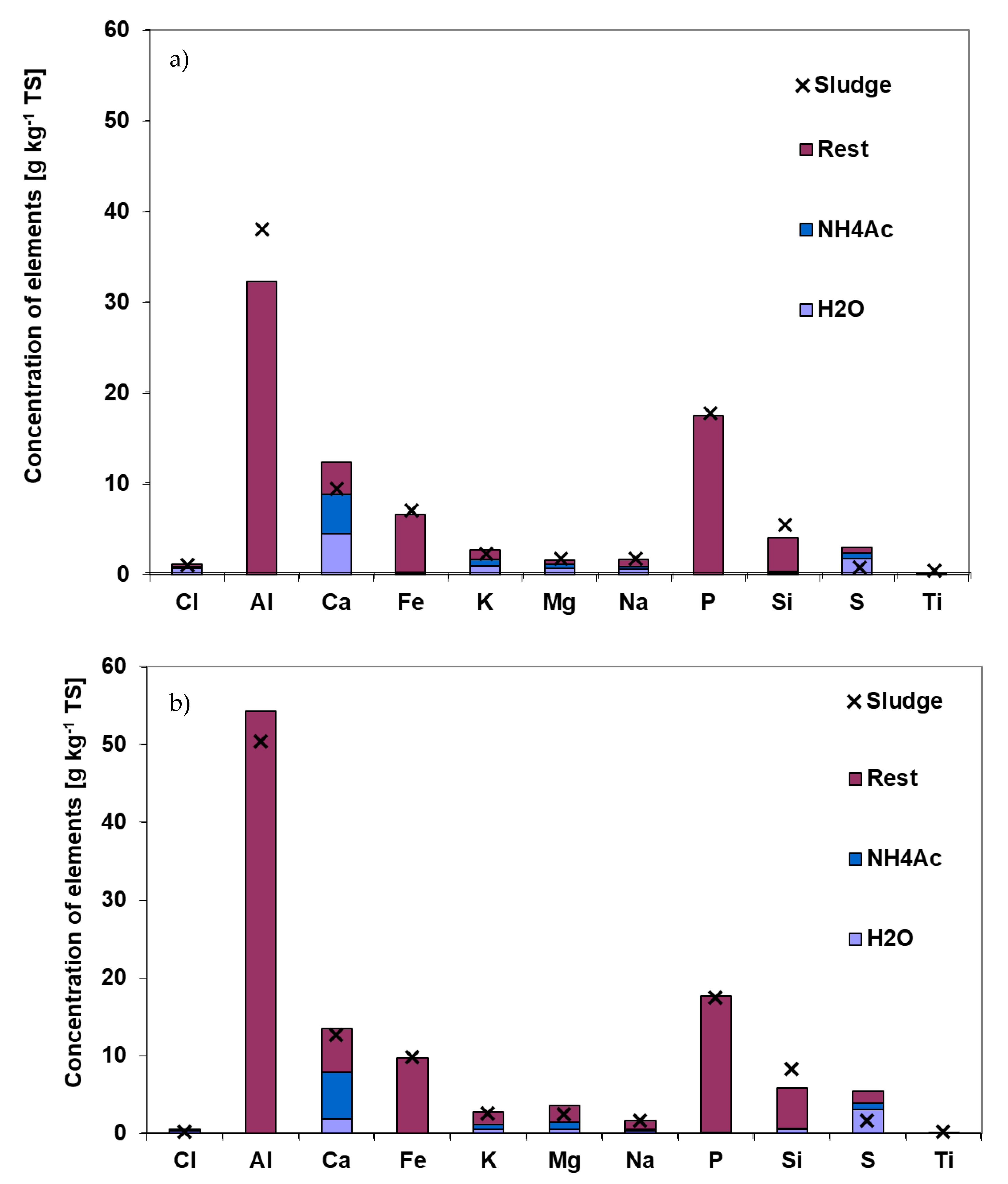

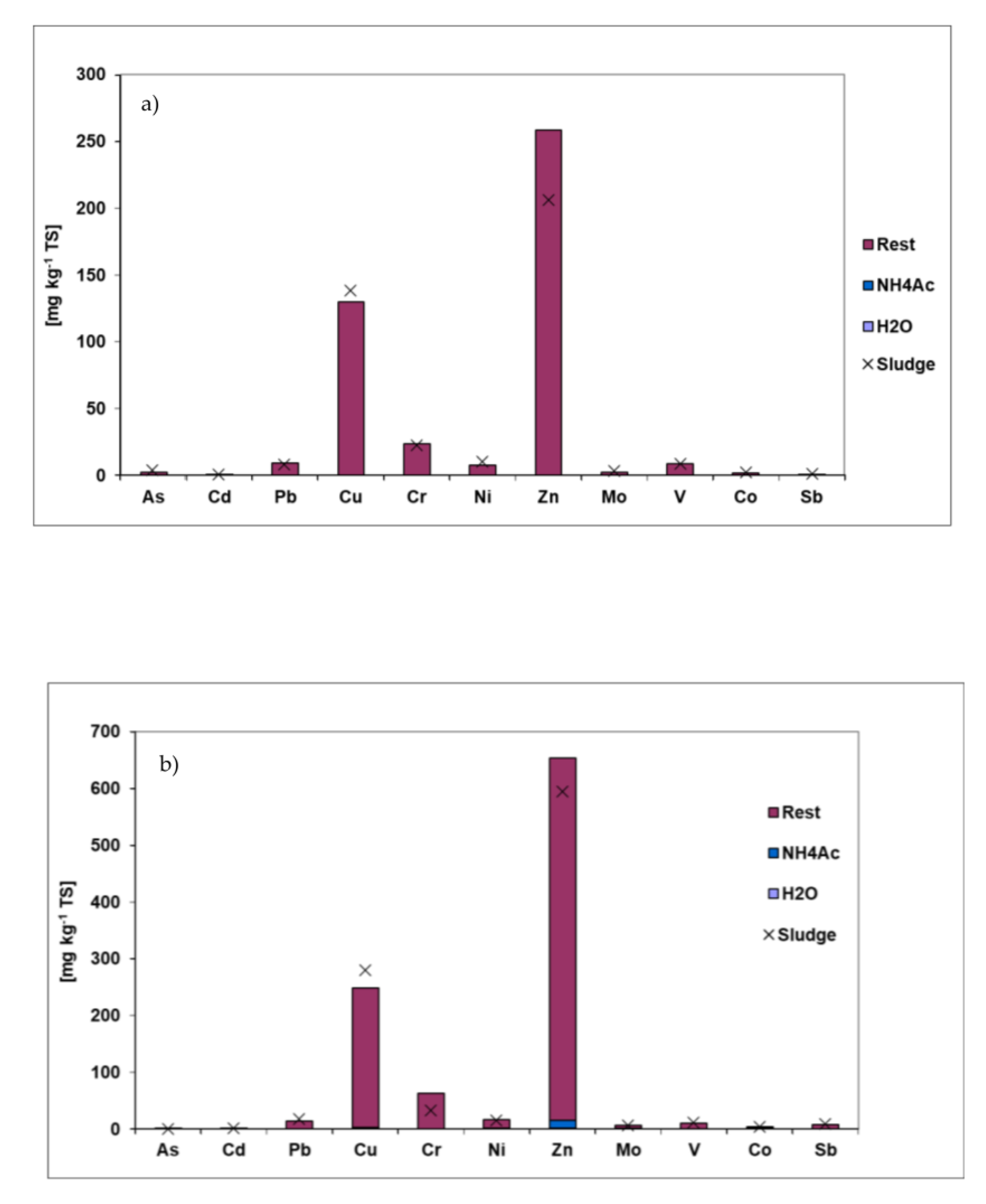

3.4. Chemical Fractionation Analysis and Modeling Results

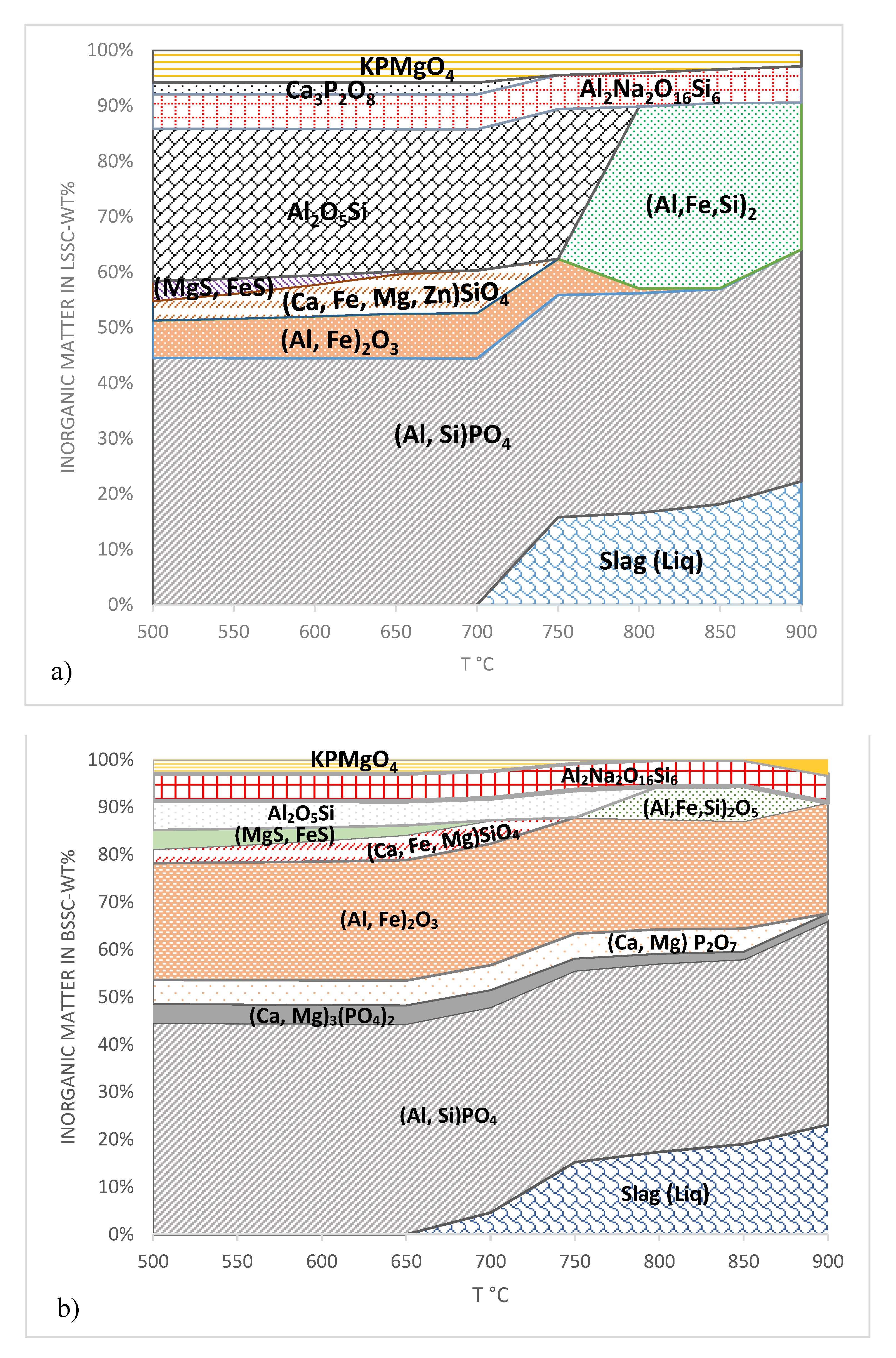

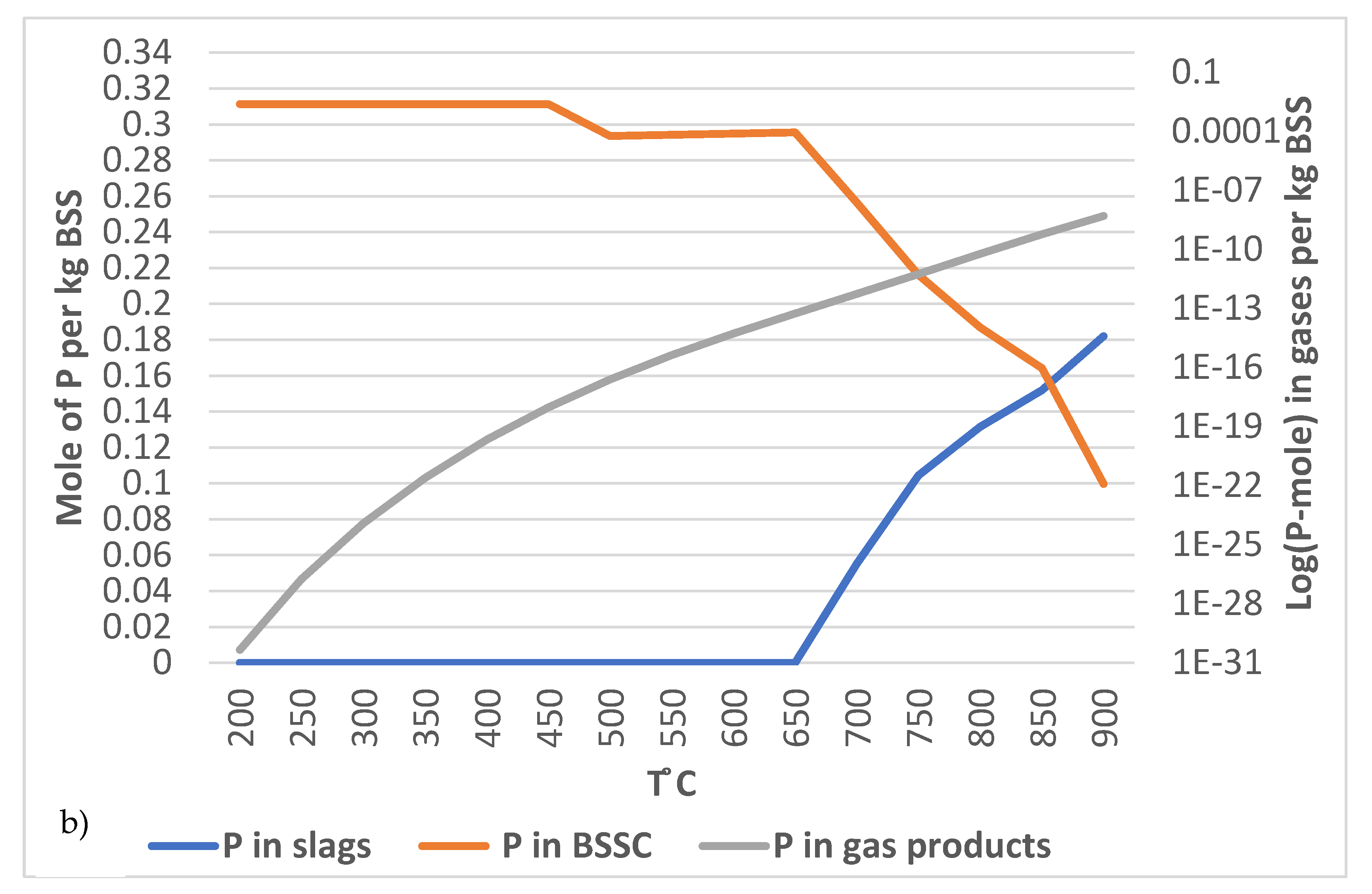

3.4.1. The Prediction of Reactivity of Ash-Forming Elements during Pyrolysis

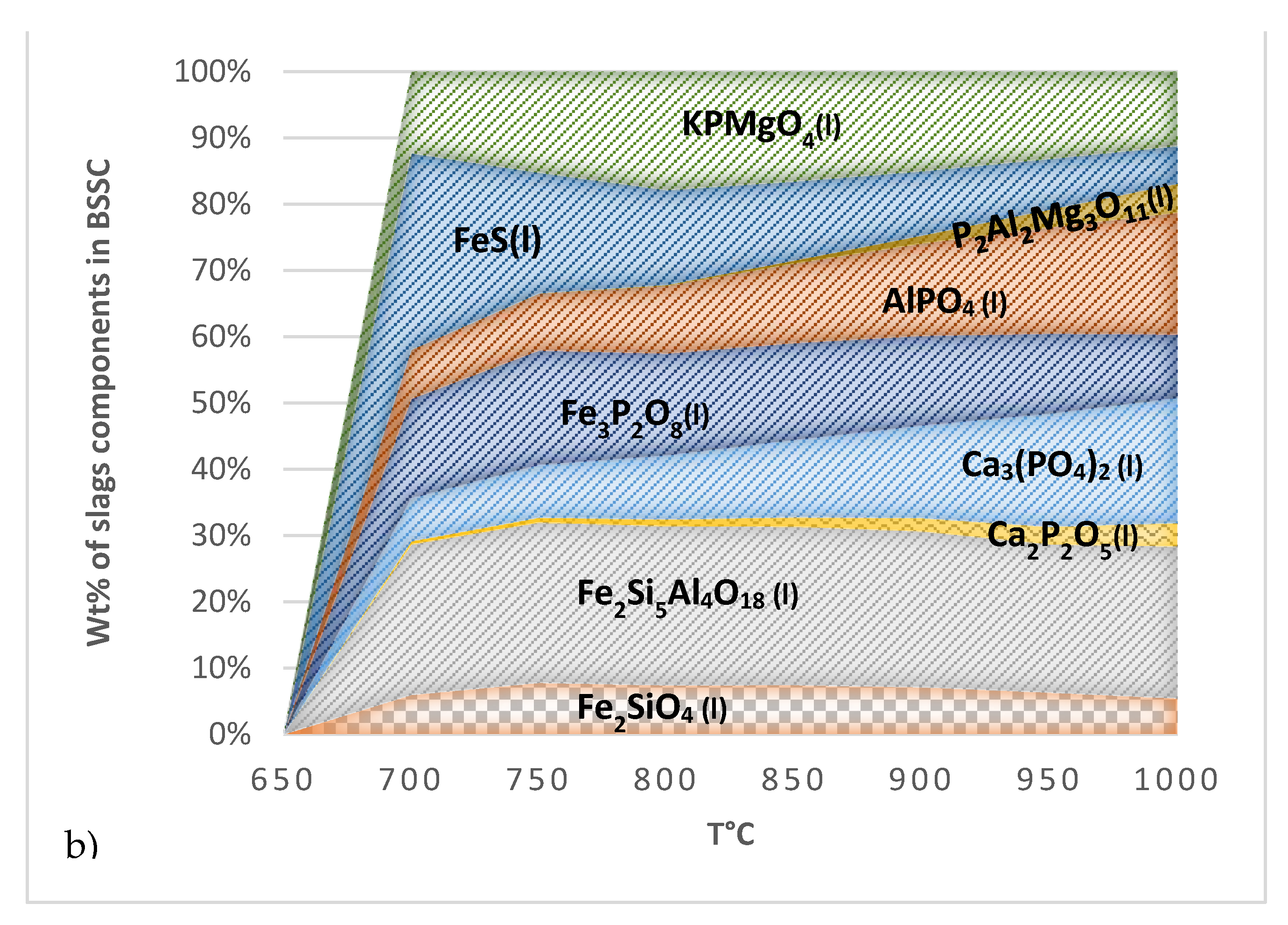

3.4.2. Initial Melt Formation (IMF) Obtained by Thermodynamics Modeling

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shaddel, S.; Bakhtiary-Davijany, H.; Kabbe, C.; Dadgar, F.; Østerhus, S.W. Sustainable Sewage Sludge Management: From Current Practices to Emerging Nutrient Recovery Technologies. Sustainability 2019, 11, 3435. [Google Scholar] [CrossRef] [Green Version]

- Kelessidis, A.; Stasinakis, A.S. Comparative study of the methods used for treatment and final disposal of sewage sludge in European countries. Waste Manag. 2012, 32, 1186–1195. [Google Scholar] [CrossRef] [PubMed]

- Smol, M.; Adam, C.; Kugler, S.A. Thermochemical Treatment of Sewage Sludge Ash (SSA)-Potential and Perspective in Poland. Energies 2020, 13, 5461. [Google Scholar] [CrossRef]

- Hannl, T.K.; Sefidari, H.; Kuba, M.; Skoglund, N.; Öhman, M. Thermochemical equilibrium study of ash transformation during combustion and gasification of sewage sludge mixtures with agricultural residues with focus on the phosphorus speciation. Biomass Convers. Biorefinery 2021, 11, 57–68. [Google Scholar] [CrossRef]

- Hedayati, A.; Lindgren, R.; Skoglund, N.; Boman, C.; Kienzl, N.; Öhman, M. Ash Transformation during Single-Pellet Combustion of Agricultural Biomass with a Focus on Potassium and Phosphorus. Energy Fuels 2021, 35, 1449–1464. [Google Scholar] [CrossRef]

- Hosseinian, A.; Ylä-Mella, J.; Pongrácz, E. Current Status of Circular Economy Research in Finland. Resources 2021, 10, 40. [Google Scholar] [CrossRef]

- Hoffman, T.C.; Zitomer, D.H.; McNamara, P.J. Pyrolysis of wastewater biosolids significantly reduces estrogenicity. J. Hazard. Mater. 2016, 317, 579–584. [Google Scholar] [CrossRef] [Green Version]

- Moško, J.; Pohořelý, M.; Cajthaml, T.; Jeremiáš, M.; Robles-Aguilar, A.A.; Skoblia, S.; Beňo, Z.; Innemanová, P.; Linhartová, L.; Michalíková, K.; et al. Effect of pyrolysis temperature on removal of organic pollutants present in anaerobically stabilized sewage sludge. Chemosphere 2021, 265, 129082. [Google Scholar] [CrossRef]

- Jeon, S.; Kim, D.-J. Enhanced phosphorus bioavailability and heavy metal removal from sewage sludge ash through thermochemical treatment with chlorine donors. J. Ind. Eng. Chem. 2018, 58, 216–221. [Google Scholar] [CrossRef]

- Gorazda, K.; Tarko, B.; Werle, S.; Wzorek, Z. Sewage sludge as a fuel and raw material for phosphorus recovery: Combined process of gasification and P extraction. Waste Manag. 2018, 73, 404–415. [Google Scholar] [CrossRef]

- Xia, Y.; Tang, Y.; Shih, K.; Li, B. Enhanced phosphorus availability and heavy metal removal by chlorination during sewage sludge pyrolysis. J. Hazard. Mater. 2020, 382, 121110. [Google Scholar] [CrossRef] [PubMed]

- Han, H.; Hu, S.; Syed-Hassan, S.S.A.; Xiao, Y.; Wang, Y.; Xu, J.; Jiang, L.; Su, S.; Xiang, J. Effects of reaction conditions on the emission behaviors of arsenic, cadmium and lead during sewage sludge pyrolysis. Bioresour. Technol. 2017, 236, 138–145. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Zhang, Y.; Wang, H.; Lu, W.; Zhou, Z.; Zhang, Y.; Ren, L. Influence of pyrolysis temperature on characteristics and heavy metal adsorptive performance of biochar derived from municipal sewage sludge. Bioresour. Technol. 2014, 164, 47–54. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Huang, Q.; Xu, J.; Gao, H.; Yan, J. A review of phosphorus recovery from different thermal treatment products of sewage sludge. Waste Dispos. Sustain. Energy 2019, 1, 99–115. [Google Scholar] [CrossRef] [Green Version]

- Skoglund, N. Ash Chemistry and Fuel Design Focusing on Combustion of Phosphorus-Rich Biomass. Ph.D. Thesis, Comprehensive Summary. Umeå Universitet, Umea, Sweden, 2014. [Google Scholar]

- Skoglund, N.; Grimm, A.; Ohman, M.; Boström, D. Effects on Ash Chemistry when Co-firing Municipal Sewage Sludge and Wheat Straw in a Fluidized Bed: Influence on the Ash Chemistry by Fuel Mixing. Energy Fuels 2013, 27, 5725–5732. [Google Scholar] [CrossRef]

- Khiari, B.; Marias, F.; Zagrouba, F.; Vaxelaire, J. Analytical study of the pyrolysis process in a wastewater treatment pilot station. Desalination 2004, 167, 39–47. [Google Scholar] [CrossRef]

- Miller, S.F.; Miller, B.G. The occurrence of inorganic elements in various biofuels and its effect on ash chemistry and behavior and use in combustion products. Fuel Process. Technol. 2007, 88, 1155–1164. [Google Scholar] [CrossRef]

- Zevenhoven, M.; Yrjas, P.; Skrifvars, B.-J.; Hupa, M. Characterization of Ash-Forming Matter in Various Solid Fuels by Selective Leaching and Its Implications for Fluidized-Bed Combustion. Energy Fuels 2012, 26, 6366–6386. [Google Scholar] [CrossRef]

- Pettersson, A. Characterisation of Fuels and Fly Ashes from Co-Combustion of Biofuels and Waste Fuels in a Fluidised Bed Boiler. A Phosphorus and Alkali Perspective. Ph.D. Thesis, Chalmers Tekniska Högskola, Göteborg, Sweden, 2008. [Google Scholar]

- Moradian, F.; Tchoffor, P.A.; Davidsson, K.O.; Pettersson, A.; Backman, R. Thermodynamic equilibrium prediction of bed agglomeration tendency in dual fluidized-bed gasification of forest residues. Fuel Process. Technol. 2016, 154, 82–90. [Google Scholar] [CrossRef]

- Bale, C.W.; Bélisle, E.; Chartrand, P.; Decterov, S.A.; Eriksson, G.; Gheribi, A.E.; Hack, K.; Jung, I.H.; Kang, Y.B.; Melançon, J.; et al. FactSage thermochemical software and databases, 2010–2016. Calphad 2016, 54, 35–53. [Google Scholar] [CrossRef]

- Vali, N.; Lars-Erik, A.; Combres, A.; Richards, T.; Pettersson, A. Pyrolysis of Municipal Sewage Sludge to Investigate Char and Phosphorous Yield together with Heavy-Metal Removal-Experimental and by Thermodynamic Calculations. Energies 2021, 14, 1477. [Google Scholar] [CrossRef]

- Gascó, G.; Paz-Ferreiro, J.; Méndez, A. Thermal analysis of soil amended with sewage sludge and biochar from sewage sludge pyrolysis. J. Anal. Calor. 2012, 108, 769–775. [Google Scholar] [CrossRef]

- Lidman Olsson, E.O.; Glarborg, P.; Leion, H.; Dam-Johansen, K.; Wu, H. Release of P from Pyrolysis, Combustion, and Gasification of BiomassA Model Compound Study. Energy Fuels 2021, 35, 15817–15830. [Google Scholar] [CrossRef]

- Häggström, G.; Hannl, T.K.; Hedayati, A.; Kuba, M.; Skoglund, N.; Öhman, M. Single Pellet Combustion of Sewage Sludge and Agricultural Residues with a Focus on Phosphorus. Energy Fuels 2021, 35, 10009–10022. [Google Scholar] [CrossRef]

- Raboy, V. Approaches and challenges to engineering seed phytate and total phosphorus. Plant Sci. 2009, 177, 281–296. [Google Scholar] [CrossRef]

- Pedersen, A.J.; van Lith, S.C.; Frandsen, F.J.; Steinsen, S.D.; Holgersen, L.B. Release to the gas phase of metals, S and Cl during combustion of dedicated waste fractions. Fuel Process. Technol. 2010, 91, 1062–1072. [Google Scholar] [CrossRef]

- Han, J.; Xu, M.; Yao, H.; Furuuchi, M.; Sakano, T.; Kanchanapiya, P.; Kanaoka, C. Partition of Heavy and Alkali Metals during Sewage Sludge Incineration. Energy Fuels 2006, 20, 583–590. [Google Scholar] [CrossRef]

- Kumpiene, J.; Brännvall, E.; Wolters, M.; Skoglund, N.; Čirba, S.; Aksamitauskas, V.Č. Phosphorus and cadmium availability in soil fertilized with biosolids and ashes. Chemosphere 2016, 151, 124–132. [Google Scholar] [CrossRef]

- Hupa, M. Ash-Related Issues in Fluidized-Bed Combustion of Biomasses: Recent Research Highlights. Energy Fuels 2012, 26, 4–14. [Google Scholar] [CrossRef]

| Wastewater Treatment Plant Location | Lidköping, Sweden | Borås, Sweden |

|---|---|---|

| P Removal Method in WWTP | Undigested, Chemical P removal | Anaerobic Digested, biological P removal |

| Ash content in dry matter 1 | 21.5 | 38.0 |

| Moisture content (wt%) 1,2 | 79 | 71 |

| Ash analysis (g/kg DSS 2) | ||

| Al | 38 ± 6.7 | 50.5 ± 14 |

| Ca | 9.9 ± 1.8 | 12.7 ± 3 |

| Fe | 7.1 ± 1.4 | 9.8 ± 2 |

| K | 2.1 ± 0.5 | 2.5 ± 0.5 |

| Mg | 1.7 ± 0.6 | 2.4 ± 0.5 |

| Na | 1.6 ± 0.2 | 1.6 ± 0.2 |

| P | 17.6 ± 2.7 | 29.1 ± 5 |

| Si | 17.8 ± 3.2 | 17.5 ± 5.2 |

| Ti | 0.6 ± 0.1 | 1.6 ± 0.3 |

| Cl | 0.3 | 0.19 |

| Trace elements (mg/kg DSS 3) | ||

| As | 3 ± 0.7 | |

| Cd | 3.2 ± 1.25 | 0.6 ± 0.195 |

| Co | 0.3 ± 0.069 | 3.7 ± 1.6 |

| Cr | 2.2 ± 0.70 | 32.9 ± 11.4 |

| Cu | 24.5 ± 5.4 | 280 ± 70 |

| V | 139 ± 30 | 10.5 ± 2.7 |

| Mo | 8.3 ± 1.21 | 6.3 ± 1 |

| Ni | 2.9 ± 0.62 | 14.8 ± 3.5 |

| Pb | 9.2 2.06 | 16.8 ± 4 |

| Zn | 7.4 1.85 | 596 ± 25 |

| Elements | |

|---|---|

| H, C, N, O, Na, Mg, Al, Si, P, K, Ca, Fe, Zn, S | |

| Database—GTOX (solution models) | |

| Slag (liquid phase containing oxides, metals, sulphides, sulphates of existing elements) | |

| ALPM (Al, Si)(P, Si)O4 | C3PL (Ca, Mg, Zn)3(PO4)2 |

| CORU (Al, Fe)2O3 | PYRR (MgS, FeS) |

| MEO CaO, MgO, K2O, Al2O3, FeO, ZnO | MULL Al2(Al, Fe, Si)O5 |

| OLIV (Ca, Fe, Mg, Zn)SiO4 | CMP (Ca, Mg) CaP2O7 |

| Gases: CO2, H2O, H2 | Stoichiometric solid compounds |

| Database—SGPS Gas compounds Stoichiometric solid compounds | |

| Percentage of Char Residue | Heating Value (kJ/g) | Average of Heating Value (kJ/g) | Average% of Heating Value | |

|---|---|---|---|---|

| LSS | Non-applicable | 19.4 | 19.4 | Non-applicable |

| LSSC 500 °C, 1 | 41 | 13.8 | ||

| LSSC 500 °C, 2 | 44 | 13.6 | 13.7 | 71 |

| LSSC 500 °C, 3 | 44 | 13.8 | ||

| LSSC 700 °C, 1 | 34 | 12.3 | ||

| LSSC 700 °C, 2 | 34 | 12.5 | 12.4 | 64 |

| LSSC 700 °C, 3 | 34 | 12.5 | ||

| LSSC 900 °C, 1 | 29 | 10.2 | ||

| LSSC 900 °C, 2 | 31 | 11.8 | 11.4 | 59 |

| LSSC 900 °C, 3 | 31 | 12.1 | ||

| BSS | Non-applicable | 12.7 | 12.6 | Non-applicable |

| Borås 500 °C, 1 | 59.4 | 10.1 | ||

| Borås 500 °C, 2 | 59.1 | 10.1 | 9.6 | 76 |

| Borås 500 °C, 3 | 61.1 | 9.1 | ||

| Borås 700 °C, 1 | 51.7 | 8.3 | ||

| Borås 700 °C, 2 | 52.1 | 8.8 | 8.6 | 68 |

| Borås 700 °C, 3 | 52.0 | 8.9 | ||

| Borås 900 °C, 1 | 47.9 | 7.4 | ||

| Borås 900 °C, 2 | 47.9 | 7.4 | 7.1 | 56 |

| Borås 900 °C, 3 | 46.0 | 6.6 |

| Element | P [g × (kg TS)−1] | Fe [g × (kg TS)−1] | Mg [g × (kg TS)−1] | Na [g × (kg TS)−1] | Mn [g × (kg TS)−1] | K [g × (kg TS)−1] | Ca [g × (kg TS)−1] |

|---|---|---|---|---|---|---|---|

| LSS | 17.5 | 6.9 | 1.5 | 1570 | 0.15 ± 0.01 | 2.2 ± 0.1 | 9.3 ± 1.0 |

| LSSC 500 °C | 36 ± 0.5 | 15 ± 0.5 | 0.40 ± 0.01 | 24 ± 0.7 | 0.23 ± 0.01 | 9.8 ±1.0 | 7.5 ± 0.5 |

| LSSC 700 °C | 44 ± 0.3 | 17 ± 0.5 | 0.40 ± 0.01 | 24 ± 0.6 | 0.28 ± 0.05 | 10 ± 1.0 | 6.5 ± 1.0 |

| LSSC 900 °C | 46 ± 0.2 | 18 ± 1 | 0.80 ± 0.40 | 24 ± 0.5 | 0.3± 0.05 | 11 ± 0.5 | 8.5 ± 0.5 |

| BSS | 29 | 9.8 | 2.4 | 1.6 | 2.8 | 2.6 | 12.7 |

| BSSC 500 °C | 44 ± 0.6 | 18 ± 0.1 | 0.51 ± 0.01 | 32 ± 0.2 | 0.4 ± 0.01 | 14 ± 1.0 | 10 ± 1.1 |

| BSSC 700 °C | 53 ± 1.0 | 21 ± 1.4 | 0.52 ± 0.01 | 31 ± 0.4 | 0.4 ± 0.02 | 14 ±1.0 | 9.4 ± 1.2 |

| BSSC 900 °C | 61 ± 0.5 | 25 ± 2.0 | 0.91 ± 0.16 | 31 ± 0.5 | 0.5 ± 0.02 | 15 ± 0.5 | 12 ± 1.2 |

| Element | Cu [mg × (kg TS)−1] | Cr [mg × (kg TS)−1] | Pb [mg × (kg TS)−1] | Ni [mg × (kg TS)−1] | Zn [mg × (kg TS)−1] | Cd [mg × (kg TS)−1] |

|---|---|---|---|---|---|---|

| LSS | 140 ± 3.0 | 22 ± 2 | 8 | 10 ± 1 | 206 ± 6 | |

| LSSC 500 °C | 300 ± 3.0 | 50 ± 5 | 30 ± 3 | 20 ± 3 | 190 ± 27 | 0 |

| LSSC 700 °C | 370 ± 5.0 | 55 ± 3 | 40 ± 1 | 24 ± 1 | 280 ± 17 | 0 |

| LSSC 900 °C | 450 ± 4.0 | 170 ± 20 | 75 ± 13 | 99 ± 11 | 300 ± 20 | 0 |

| BSS | 280 | 33 | 17 | 15 | 596 | |

| BSSC 500 °C | 440 ± 5.0 | 60 ± 5 | 60 ± 9 | 11 ± 5 | 500 ± 72 | ~0 |

| BSSC 700 °C | 500 ± 6.0 | 65 ± 2 | 65 ± 4 | 13 ± 5 | 580 ± 74 | ~0 |

| BSSC 900 °C | 540 ± 4.0 | 100 ± 6 | 70 ± 3 | 40 ± 4 | 550 ± 72 | ~0 |

| 1 EU 2019/1009 | 600 | 2 | 120 | 100 | 1500 | 3 |

| 2 Sweden farmland regulation SFS 1998:994 | 600 | 100 | 100 | 50 | 800 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vali, N.; Combres, A.; Hosseinian, A.; Pettersson, A. The Effect of the Elemental Composition of Municipal Sewage Sludge on the Phosphorus Recycling during Pyrolysis, with a Focus on the Char Chemistry—Modeling and Experiments. Separations 2023, 10, 31. https://doi.org/10.3390/separations10010031

Vali N, Combres A, Hosseinian A, Pettersson A. The Effect of the Elemental Composition of Municipal Sewage Sludge on the Phosphorus Recycling during Pyrolysis, with a Focus on the Char Chemistry—Modeling and Experiments. Separations. 2023; 10(1):31. https://doi.org/10.3390/separations10010031

Chicago/Turabian StyleVali, Naeimeh, Aurélie Combres, Aida Hosseinian, and Anita Pettersson. 2023. "The Effect of the Elemental Composition of Municipal Sewage Sludge on the Phosphorus Recycling during Pyrolysis, with a Focus on the Char Chemistry—Modeling and Experiments" Separations 10, no. 1: 31. https://doi.org/10.3390/separations10010031