Improved Flotation of Fine Flake Graphite Using a Modified Thickening Process

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Reagents

2.2. Experimental Tests

2.3. Characterization

3. Results and Discussion

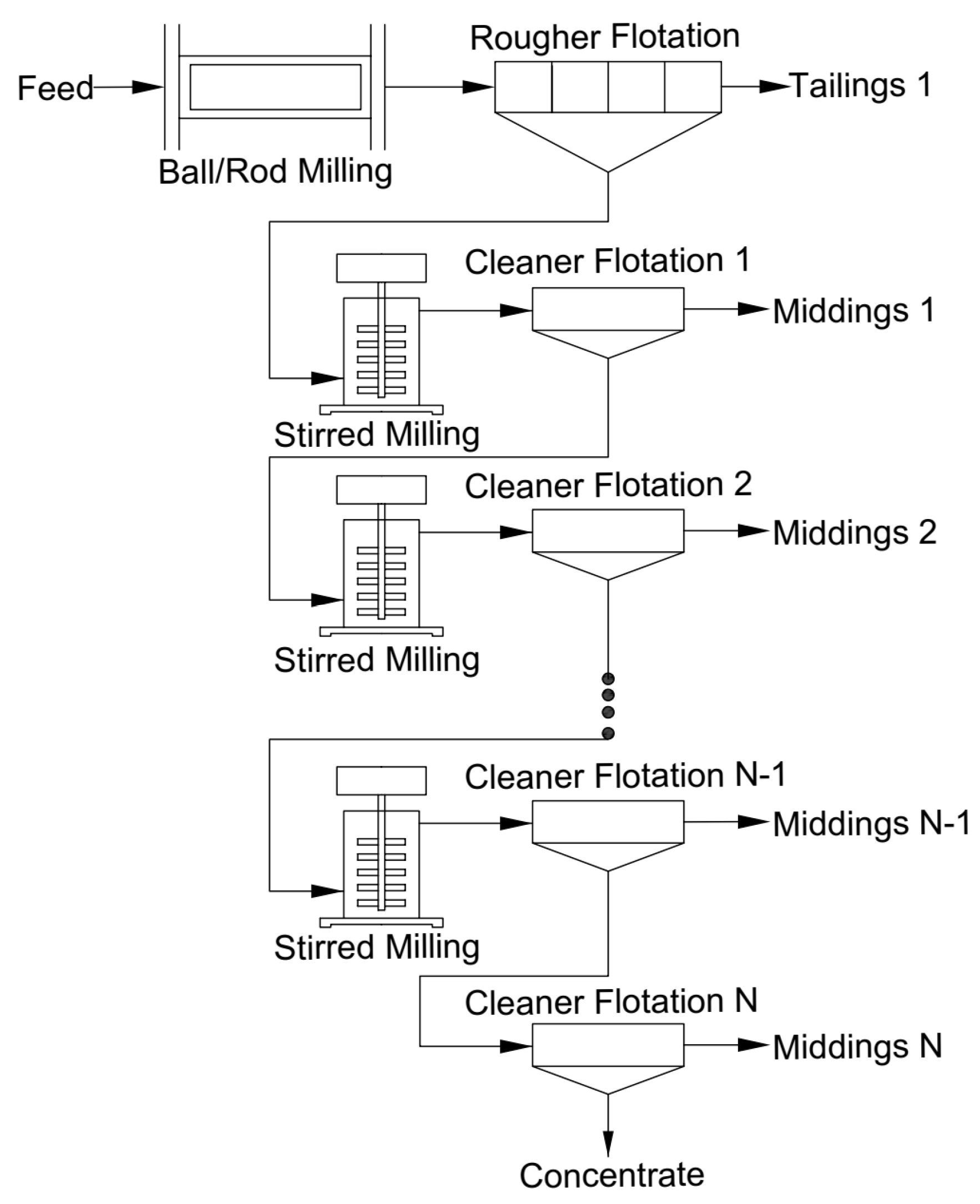

3.1. Optimizing the Roughing Flotation Conditions

3.2. Optimizing the First Regrinding Condition

3.3. Comparing the Flotation Performance with and without the Thickening Stage

3.4. Mechanism of the Thickening and Regrinding Process

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, H.; Feng, Q.; Liu, K.; Zuo, K.; Tang, X. A novel technique for microcrystalline graphite beneficiation based on alkali-acid leaching process. Sep. Sci. Technol. 2017, 53, 982–989. [Google Scholar] [CrossRef]

- Jara, A.D.; Betemariam, A.; Woldetinsae, G.; Kim, J.Y. Purification, application and current market trend of natural graphite: A review. Int. J. Min. Sci. Technol. 2019, 29, 671–689. [Google Scholar] [CrossRef]

- Wakamatsu, T.; Numata, Y. Flotation of graphite. Miner. Eng. 1991, 4, 975–982. [Google Scholar] [CrossRef]

- Chelgani, S.C.; Rudolph, M.; Kratzsch, R.; Sandmann, D.; Gutzmer, J. A Review of Graphite Beneficiation Techniques. Miner. Process. Extr. Metall. Rev. 2016, 37, 58–68. [Google Scholar] [CrossRef]

- Öney, Ö.; Samanli, S. Determination of optimal flotation conditions of low-grade graphite ore. E3S Web Conf. 2016, 8, 1002. [Google Scholar] [CrossRef]

- Florena, F.F.; Syarifuddin, F.; Hanam, E.S.; Trisko, N.; Kustiyanto, E.; Enilisiana; Rianto, A.; Arinton, G. Floatability study of graphite ore from southeast Sulawesi (Indonesia). In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2016; Volume 1712, p. 050005. [Google Scholar] [CrossRef]

- Lai, Q.; Liao, Y.; An, M.; Liu, Z.; Qiu, Y.; Ma, L. Enhanced graphite recovery by optimising flotation energy input. Sep. Sci. Technol. 2018, 54, 766–774. [Google Scholar] [CrossRef]

- Qiu, Y.; Yu, Y.; Zhang, L.; Qian, Y.; Ouyang, Z. An Investigation of Reverse Flotation Separation of Sericite from Graphite by Using a Surfactant: MF. Minerals 2016, 6, 57. [Google Scholar] [CrossRef]

- Ni, C.; Zhang, Q.; Jin, M.; Xie, G.; Peng, Y.; Yu, H.; Bu, X. Effect of high-speed shear flocculation on the flotation kinetics of ultrafine microcrystalline graphite. Powder Technol. 2021, 396, 345–353. [Google Scholar] [CrossRef]

- Ma, F.; Tao, D.; Tao, Y.; Liu, S. An innovative flake graphite upgrading process based on HPGR, stirred grinding mill, and nanobubble column flotation. Int. J. Min. Sci. Technol. 2021, 31, 1063–1074. [Google Scholar] [CrossRef]

- Li, J.-H.; Hou, S.-Y.; Su, J.-R.; Li, K.; Wei, L.-B.; Ma, L.-Q.; Shen, W.-C.; Kang, F.-Y.; Huang, Z.-H. Beneficiation of ultra-large flake graphite and the preparation of flexible graphite sheets from it. New Carbon Mater. 2019, 34, 205–210. [Google Scholar] [CrossRef]

- Jara, A.D.; Woldetinsae, G.; Betemariam, A.; Kim, J.Y. Mineralogical and petrographic analysis on the flake graphite ore from Saba Boru area in Ethiopia. Int. J. Min. Sci. Technol. 2020, 30, 715–721. [Google Scholar] [CrossRef]

- Gao, J.; Bu, X.; Zhou, S.; Wang, X.; Alheshibri, M.; Peng, Y.; Xie, G. Graphite flotation by β-cyclodextrin/kerosene Pickering emulsion as a novel collector. Miner. Eng. 2022, 178, 107412. [Google Scholar] [CrossRef]

- Sun, K.; Qiu, Y.; Zhang, L.; Liu, Q.; Mao, Z.; Qian, Y. Enhanced fine flake graphite flotation and reduced carbon emission by a novel water-in-oil kerosene emulsion. Colloids Surf. A Physicochem. Eng. Asp. 2022, 650, 129603. [Google Scholar] [CrossRef]

- Sun, K.; Qiu, Y.; Zhang, L. Preserving Flake Size in an African Flake Graphite Ore Beneficiation Using a Modified Grinding and Pre-Screening Process. Minerals 2017, 7, 115. [Google Scholar] [CrossRef]

- Li, H.; Feng, Q.; Yang, S.; Ou, L.; Lu, Y. The entrainment behaviour of sericite in microcrystalline graphite flotation. Int. J. Miner. Process. 2014, 127, 1–9. [Google Scholar] [CrossRef]

- Weng, X.; Li, H.; Song, S.; Liu, Y. Reducing the Entrainment of Gangue Fines in Low Grade Microcrystalline Graphite Ore Flotation Using Multi-Stage Grinding-Flotation Process. Minerals 2017, 7, 38. [Google Scholar] [CrossRef]

- Xu, W.; Sun, K.; Qiu, Y.; Zhang, L.; Yang, L.; Wei, S.; Ding, D. Understanding the collection behavior of gangue minerals in fine flake graphite flotation. Physicochem. Probl. Miner. Process. 2021, 58, 101–112. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, L.; Cao, M.; Liu, Q. Slime coatings in froth flotation: A review. Miner. Eng. 2017, 114, 26–36. [Google Scholar] [CrossRef]

- Peng, W.; Qiu, Y.; Zhang, L.; Guan, J.; Song, S. Increasing the Fine Flaky Graphite Recovery in Flotation via a Combined MultipleTreatments Technique of Middlings. Minerals 2017, 7, 208. [Google Scholar] [CrossRef]

- Wang, X.; Bu, X.; Alheshibri, M.; Bilal, M.; Zhou, S.; Ni, C.; Peng, Y.; Xie, G. Effect of scrubbing medium’s particle size distribution and scrubbing time on scrubbing flotation performance and entrainment of microcrystalline graphite. Int. J. Coal Prep. Util. 2022, 42, 3032–3053. [Google Scholar] [CrossRef]

- Wang, X.; Bu, X.; Ni, C.; Zhou, S.; Yang, X.; Zhang, J.; Alheshibri, M.; Peng, Y.; Xie, G. Effect of scrubbing medium’s particle size on scrubbing flotation performance and mineralogical charac-teristics of microcrystalline graphite. Miner. Eng. 2021, 163, 106766. [Google Scholar] [CrossRef]

- Barma, S.D.; Baskey, P.K.; Rao, D.S.; Sahu, S.N. Ultrasonic-assisted flotation for enhancing the recovery of flaky graphite from low-grade graphite ore. Ultrason. Sonochem. 2019, 56, 386–396. [Google Scholar] [CrossRef] [PubMed]

- Kang, W.; Li, H. Enhancement of flaky graphite cleaning by ultrasonic treatment. R. Soc. Open. Sci. 2019, 6, 191160. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Li, X.; Xu, M.; Zhang, H. Effect of ultrasonication on the flotation of fine graphite particles: Nanobubbles or not? Ultrason. Sonochem. 2020, 69, 105243. [Google Scholar] [CrossRef] [PubMed]

- Bu, X.N.; Zhang, T.; Chen, Y.; Peng, Y.; Xie, G.; Wu, E. Comparison of mechanical flotation cell and cyclonic microbubble flotation column in terms of separation performance for fine graphite. Physicochem. Probl. Miner. Process. 2018, 54, 732–740. [Google Scholar]

- Bu, X.; Zhang, T.; Peng, Y.; Xie, G.; Wu, E. Multi-Stage Flotation for the Removal of Ash from Fine Graphite Using Mechanical and Centrifugal Forces. Minerals 2018, 8, 15. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Feng, A.; Guo, Z.; Zhang, Y. Application of stirred mill to upgrading of graphite concentrate by flotation. Can. Met. Q. 2017, 57, 245–251. [Google Scholar] [CrossRef]

- Ma, F.; Tao, D. A Study of Mechanisms of Nanobubble-Enhanced Flotation of Graphite. Nanomaterials 2022, 12, 3361. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Li, C.; Zhang, H.; Kupka, N.; Peuker, U.A.; Rudolph, M. A contribution to exploring the importance of surface air nucleation in froth flotation—The effects of dissolved air on graphite flotation. Colloids Surf. A Physicochem. Eng. Asp. 2022, 633, 127866. [Google Scholar] [CrossRef]

- Gálvez, E.D.; Cruz, R.; Robles, P.A.; Cisternas, L.A. Optimization of dewatering systems for mineral processing. Miner. Eng. 2014, 63, 110–117. [Google Scholar] [CrossRef]

- Chaedir, B.A.; Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. Advances in dewatering and drying in mineral processing. Dry. Technol. 2021, 39, 1667–1684. [Google Scholar] [CrossRef]

- Rezaei, A.; Abdollahi, H.; Gharabaghi, M.; Mohammadzadeh, A.A. Effects of Flocculant, Surfactant, Coagulant, and Filter Aid on Efficiency of Filtration Processing of Copper Concentrate: Mechanism and Optimization. J. Min. Environ. 2020, 11, 119–141. [Google Scholar] [CrossRef]

| Composition | SiO2 | Al2O3 | CaO | Fe2O3 | SO3 | K2O | MgO | TiO2 | Na2O | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| Content/% | 46.662 | 9.645 | 8.397 | 5.292 | 4.186 | 1.417 | 1.409 | 0.502 | 0.286 | 0.280 |

| Composition | V2O5 | MnO | Cr2O3 | SrO | ZrO2 | Rb2O | Y2O3 | MoO3 | LOI | FC |

| Content/% | 0.185 | 0.128 | 0.043 | 0.019 | 0.017 | 0.008 | 0.005 | 0.005 | 21.515 | 17.870 |

| Processes | Process 1 | Process 2 | Process 3 |

|---|---|---|---|

| Coarse grinding | 65.00 | 65.00 | 65.00 |

| Rougher flotation | 25.14 | 25.02 | 25.21 |

| Regrinding 1 | 30.31 | 31.47 | 31.82 |

| Cleaner flotation 1 | 10.25 | 10.29 | 10.71 |

| Regrinding 2 | 11.96 | 20.64 | 58.30 |

| Cleaner flotation 2 | 5.61 | 5.46 | 5.62 |

| Regrinding 3 | 10.28 | 9.56 | 10.32 |

| Cleaner flotation 3 | 4.48 | 4.49 | 4.17 |

| Regrinding 4 | 8.87 | 8.64 | 8.69 |

| Cleaner flotation 4 | 3.94 | 4.07 | 3.94 |

| Cleaner flotation 5 | 3.67 | 3.91 | 3.84 |

| Products | Process 1 | Process 2 | Process 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Yield % | FC % | Recovery % | Yield % | FC % | Recovery % | Yield % | FC % | Recovery % | |

| Conc | 14.33 | 95.86 | 83.88 | 15.48 | 96.78 | 88.18 | 15.13 | 97.12 | 87.53 |

| M1 | 18.56 | 2.24 | 2.54 | 19.35 | 2.73 | 3.11 | 20.37 | 2.21 | 2.68 |

| M2 | 4.51 | 10.92 | 3.00 | 3.88 | 7.96 | 1.82 | 5.79 | 7.23 | 2.50 |

| M3 | 2.15 | 21.29 | 2.79 | 1.67 | 11.72 | 1.15 | 0.93 | 26.01 | 1.44 |

| M4 | 1.09 | 42.04 | 2.79 | 0.63 | 31.93 | 1.18 | 0.39 | 54.39 | 1.28 |

| M5 | 0.36 | 66.90 | 1.47 | 0.17 | 64.02 | 0.65 | 0.22 | 85.35 | 1.13 |

| Tailing | 59.00 | 0.98 | 3.53 | 58.83 | 1.13 | 3.91 | 57.16 | 1.01 | 3.44 |

| Raw Ore | 100.00 | 16.38 | 100.00 | 100.00 | 16.98 | 100.00 | 100.00 | 16.78 | 100.00 |

| Map Sum Spectrum | Spectrum 1 | Spectrum 2 | ||||||

|---|---|---|---|---|---|---|---|---|

| Element | Wt% | Atomic % | Element | Wt% | Atomic % | Element | Wt% | Atomic % |

| C | 91.81 | 97.82 | C | 26.10 | 47.74 | C | 100.00 | 100.00 |

| O | - | - | O | 14.66 | 20.13 | O | - | - |

| Si | 1.86 | 0.85 | Si | 22.76 | 17.80 | Si | - | - |

| S | - | - | S | 0.46 | 0.32 | S | - | - |

| Fe | 3.64 | 0.84 | Fe | 33.90 | 13.34 | Fe | - | - |

| Ga | 2.69 | 0.49 | Ga | 2.13 | 0.67 | Ga | - | - |

| Total: | 100.00 | 100.00 | Total: | 100.00 | 100.00 | Total: | 100.00 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Z.; Li, D.; Fang, W.; Zhang, J.; Zhang, R.; Qiu, Y.; Sun, K. Improved Flotation of Fine Flake Graphite Using a Modified Thickening Process. Separations 2023, 10, 275. https://doi.org/10.3390/separations10050275

Peng Z, Li D, Fang W, Zhang J, Zhang R, Qiu Y, Sun K. Improved Flotation of Fine Flake Graphite Using a Modified Thickening Process. Separations. 2023; 10(5):275. https://doi.org/10.3390/separations10050275

Chicago/Turabian StylePeng, Ziming, Dianshun Li, Wenjie Fang, Juan Zhang, Rongyan Zhang, Yangshuai Qiu, and Kangkang Sun. 2023. "Improved Flotation of Fine Flake Graphite Using a Modified Thickening Process" Separations 10, no. 5: 275. https://doi.org/10.3390/separations10050275