1. Introduction

The rising global need for the reduction of greenhouse gas emissions has prompted the development of alternative and sustainable applications in industry and society in general. Carbon capture and utilization (CCU) technologies are among the necessary tools applied towards the carbon circularity of the industry [

1,

2,

3]. Technologies such as synthesis of methanol (MeOH) and dimethyl ether (DME) brings the CCU benefits to the front, allowing the direct utilization of CO

2 towards a sustainable alternative fuel and chemical feedstock [

4,

5]. It is noteworthy to mention that DME has become a molecule of interest because of its notable properties such as being a non-corrosive, non-carcinogenic, non-toxic colorless gas, environmentally friendly and easy to liquefy [

6]. These properties make DME usable in various applications either as a building block for higher carbon molecules or as an end use product; green aerosol propellant that can replace the hazardous chlorofluorocarbons (CFCs) or substituent for petroleum-based diesel fuel (cetane numbers varies between 55 and 60) [

7] or in combustion cells. In the latter applications—DME as a clean fuel—it produces minimal NO

x and CO and no SO

x emissions. Besides, due to its high oxygen content, it leads to soot-free combustion [

8]. Moreover, DME can be blended up to 20–30% with LPG for its replacement for domestic and transportation usage.

Conventionally, DME is produced in the two-step method that includes synthesis of methanol from syngas (a mixture of CO, H

2 and CO

2) over copper-based catalysts, and the subsequent dehydration step over solid acid catalysts such as γ-alumina, HZSM-5, silica-alumina and fluorinated alumina. The industrial standard for methanol dehydration takes place in a fixed-bed catalytic reactor, followed by downstream processing using distillation to deliver highly pure DME (>99.99 wt%). The conventional distillation separation process for purification of DME and recovery of unconverted methanol is still state of the art, but can be outperformed by dividing wall column distillation [

9] or even reactive distillation; process intensification by integration of the methanol dehydration reaction with the separation of the DME product [

10].

The key opportunity in DME production is the flexibility of utilizing various feedstocks. The stretch of the process comes partially from its base mixture; syngas. It can be either biomass-based or from different fossil-based raw materials such as oil, naphtha, coal (bed methane), shale gas or natural gas. Moreover, hydrogenation of the captured CO

2 using renewable hydrogen has currently become an interesting topic in circular industry, which is forecasted to play a key role in the energy transition. In fact, the CO

2 recycling to methanol and subsequently to DME has been thoroughly discussed by George Olah [

11], whereby he prescribes its key role in what he has coined the methanol economy. Therefore, DME can be called a multisource and multipurpose molecule that is future-proof.

In the pursuit of finding innovative methods for DME production, one of the research lines is the direct or one-step conversion of the syngas to DME in a single reactor. Other research studies focused on using reactive distillation for the dehydration of methanol to DME in one column and the subsequent distillation for the recovery of methanol. Moreover, in a reactive-dividing-wall column methanol is fed to the reactive zone where a heterogenous catalyst is incorporated. The DME is separated as top distillate; water leaves the column as a bottom product and the methanol as a side product that is ideally recycled without further purification [

8].

Methane dry reforming is a well-established procedure for the production of syngas [

12,

13,

14]. The subsequent conversion of syngas to MeOH and/or DME is strongly correlated with the ratio of H

2/CO. MeOH conversion requires H

2/CO ratios of 2, while direct DME synthesis from syngas can be performed at ratios of approximately 1 [

15]. Synthesis of DME from syngas produced from methane is represented by the following catalytic reactions:

| Dry reforming | | | (1) |

| Methanol synthesis | | | (2a) |

| | | (2b) |

| Water–Gas shift | | | (3) |

| Methanol dehydration | | | (4) |

| Direct DME synthesis | | | (5) |

Reaction (1) is the dry reforming of methane, (2a) and (2b) are the synthesis of methanol from CO2 and CO, respectively, (3) is the water-gas shift reaction, (4) is the DME synthesis from methanol dehydration and (5) is the direct conversion of syngas into DME.

Novel DME synthesis routes, such as DME synthesis integrated with dry reforming (DIDR) and sorption enhanced DME synthesis (SEDMES) are examples of effective direct DME synthesis routes. DIDR process consists of initial dry or tri-reforming of natural gas (i.e., reaction of methane with CO

2, O

2 and H

2O) to produce syngas that is directly converted into DME in a single reactor [

12,

16,

17].

The SEDMES process, on the other hand, allows for the direct conversion of CO

2 (6) in a multicolumn adsorption system in which water is removed in situ. In this process, two commercial catalysts and an adsorbent material are applied: CZA for MeOH synthesis, γ-alumina for dehydration of MeOH and LTA 3A solid adsorbent for the in situ removal of water [

18,

19,

20]. This selective H

2O adsorption shifts the reaction equilibrium towards higher reactant conversion and increased DME production.

| Direct DME synthesis from CO2 | | | (6) |

Both conversion routes yield a DME product that requires further processing, which typically comprises several distillation steps. The most difficult separation task in this case comes within the first distillation step where CO

2 and residual gases are separated from DME and heavier components (mainly H

2O and MeOH). The difficulty in separating CO

2 from DME comes from the high affinity of the two components, and proximity and shape of their VLE curves within a full pressure spectrum in the Henry’s law region (see

Figure 1).

The technological developments in a conversion domain exemplified by SEDMES and DIDR facilitate the development and conjoint optimization with the purification techniques. Stripping enhanced distillation (SED) presents such a development, whereby two established methods, distillation and stripping, are combined to improve the separation efficiency and reduce the capital and operating costs. In this study, the advantages of using SED in two different processes for direct DME synthesis are shown: (i) CO2–DME separation after the sorption enhanced DME synthesis (SEDMES) process utilizing hydrogen as stripping gas, and (ii) CO2–DME separation after direct DME synthesis utilizing methane as stripping gas. In case (i), the impact of column design parameters such as reflux ratio and number of equilibrium stages on minimizing the energy consumption and product losses was studied. Moreover, in case (ii), a sensitivity analysis was carried out with as variables, the flow rate of the stripping agent and the reflux ratio in the SED column for the same aim; minimizing the energy consumption and product losses. For the studied cases, it is demonstrated that with minor changes to the existing facilities, introducing SED reduces energy consumption and cuts down the product losses.

2. SED Method and Application

Stripping enhanced distillation (SED) is a distillation process that utilizes a gaseous component, either inert or (preferably) a feedstock constituent, as a stripping medium to increase the separation efficiency comparatively to the conventional routes. The stripping medium or clearing gas needs to have low affinity towards the heavy component or the bottom product of the distillation process.

SED implementation into the process benefits from the integration of the feedstock and downstream recycle stream of the unconverted gaseous components to the conversion unit. First, it removes the requirements for the addition of an external stripping medium, as the clearing gas will be obtained directly from the feedstock. Second, by using the feedstock component, the vapor distillate, which primarily consists of unreacted components, can be recycled to the conversion unit. Third, it can reduce the conversion demands on the reaction unit. This is due to the multi-pass approach of the unconverted components; the demand for the existing system but also design requirements can be reduced.

3. Process Simulation

The stripping enhanced distillation concept was evaluated in the Aspen Plus simulator (V10 and V12). The thermophysical properties of the components involved (e.g., DME, MeOH, CO

2, CO, H

2 and H

2O) are available in the Aspen Plus database. The process simulations are solved in the sequential modular mode. In order to sufficiently describe the physical interaction inside the DME mixtures, more specifically CO

2–DME and CO

2–H

2O, several thermodynamic models were tested to describe their vapor-liquid-equilibria (VLE). The model predictions were compared to the experimental data available in the open literature [

21,

22] to verify the reliability of the simulation results. The predictive Soave-Redlich Kwong equation of state (PSRK EoS) provided highest level of matching with the experimental data (see

Figure 1), and was adopted as a default method for future simulation and analysis. The PSRK EoS combines the UNIFAC model and Huron-Vidal mixing rules with the SRK EoS. The merit of this combination is that it allows prediction of the VLE data over a notable larger pressure and temperature ranges than the UNIFAC model and can be applied for mixtures containing supercritical compounds [

23].

The rigorous (RadFrac) fractionation module was utilized as a primary tool in the evaluation of stripping enhanced distillation and in comparative studies with the conventional methods. RadFrac is a rigorous model for simulating multistage vapor-liquid fractionation operation. In the conventional approach, the feed from the DME synthesis reactor is first led via a heat exchanger to a flash vessel to primarily remove H

2 and CO. However, moderate losses of DME and CO

2 are encountered. Afterwards, the bottom stream of the flash drum is sent to the distillation column where a CO

2 rich stream is obtained as the distillate, while the bottom stream containing a mixture of DME, MeOH and H

2O is sent to the subsequent distillation column. There DME is further purified to meet the set purity objective (e.g., >98.5wt%). Unlike the conventional methods, the SED is an intensified process where distillation and gas stripping are combined in one unit. This allows for an efficient separation in one operation section, making the flash tank and heat exchanger, which would be required in the conventional process, redundant (see

Figure 2). The SED column was designed with two inlets. The feed enters the column around the middle point of the column, while the stripping gas enters the column below the bottom tray. The column’s bottoms primarily consist of DME and residual MeOH and H

2O. The top product leaving the column contains mainly CO

2, unconverted gases and the stripping gas.

The goal of this study was to design a column that meets a specific product purity according to international standards for DME as a fuel (ISO 16861:2015(E) [

24]), production capacity that reaches the scale of a demonstration plant and a reduction of product losses. The basis of the simulation was a product flow rate of 100 kmol∙hour

−1 from a DME synthesis reactor. Tools like design specs, calculator blocks and sensitivity analysis were applied in order to find optimal design conditions for the above-mentioned constraints. The DME purity and maximum allowed impurities are listed in

Table 1.

Moreover, the SED and conventional separation processes were compared on the basis of energy consumption, DME losses, number of equilibrium stages and required reflux ratio. The distillate rate was fixed in all cases. The aforementioned parameters are co-dependent; hence, the results should be evaluated cumulatively. Typical compositions of the SEDMES and DIDR product streams are listed in

Table 2.

3.1. Case (i): CO2–DME Separation after the Sorption Enhanced DME Synthesis (SEDMES) Process Utilizing Hydrogen as Clearing Gas

The SEDMES process enables utilization of industrial carbon in conjunction with hydrogen in a direct CO

2 to DME synthesis route. This is done during the cyclic operation in the multicolumn reactive-adsorption and regeneration system. During a single cycle, each of the columns continuously go through the different steps of the SEDMES cycle, consecutively (i.e., adsorption, blowdown, purge and repressurization). Initially, CO

2 and H

2 are fed to the column during the reactive adsorption step producing DME, while H

2O is selectively adsorbed shifting the equilibrium towards higher DME production. Subsequently, a steam saturated column is regenerated by feeding a purge gas, repressurized/depressurized for a pressure swing cycle, or heated/cooled for a temperature swing regeneration. This complex behavior, characteristic to sorption enhanced processes, requires a detailed approach to design and system optimization. Therefore, a robust downstream section with the recycle can reduce the design requirements and further optimize the system. Moreover, the high temperature and pressure SEDMES product stream requires an extensive treatment in order to obtain highly pure DME. Conventionally, the SEDMES product purification consists of three steps (see

Figure 3). Initially, the bulk of residual gases is removed in the flash vessel. This primarily includes H

2 and CO; part of CO

2 is also removed with small DME losses. Following the flash vessel, the DME–CO

2 distillation column is utilized to remove the CO

2 from the mixture of DME, water and methanol. A second distillation column is used to obtain pure DME as the distillate product. The bottom products of the second column consists of water and methanol.

Stripping enhanced distillation enables single-step separation of DME and CO

2 (and other unconverted gases) coming from the SEDMES multicolumn system (see

Figure 4). The column consists of two feed intakes, one for the SEDMES DME product and the other one for the hydrogen stripping gas. The DME product stream enters the column around the middle section, depending on the separation requirements of the column. The hydrogen feed enters below the bottom stage of the column and can be supplied in several ways. In the larger SEDMES infrastructure, an electrolyzer unit will provide the H

2 as a feed for the SEDMES unit and stripping gas for the SED column.

In this case study, two different SEDMES product streams with high and low CO

2 content were investigated (see

Table 2). The difference in composition can be explained with the conversion degree of CO

2. Simulations were run at different pressures (i.e., 15, 20, 30 and 50 bar). The column size, the reflux ratio and the amount of required H

2 stripping gas were varied independently to fulfill the requirements set in

Table 1. Aforementioned parameters were used as a basis of comparison between SED and the conventional process under the same process conditions and feed composition.

3.2. Case (ii): CO2–DME Separation after Direct DME Synthesis via Dry Reforming Utilizing Methane as Clearing Gas

In the conventional DIDR process, the tri-reformer is used for the reaction of natural gas with steam, carbon dioxide and oxygen to produce syngas with the desired H

2:CO ratio (see

Figure 5). The unreacted and by-product CO

2 is removed via absorption using chilled methanol and recovered in the stripper before recycling it to the tri-reformer. Moreover, the methanol absorber is also used to remove water from the syngas before feeding it to the DME reactors. Direct DME synthesis in the DIDR process (via reaction 5) produces equimolar amounts of DME and CO

2. Furthermore, due to the thermodynamic limitations, the downstream separation results in large recycle streams. After the DME synthesis, the purification train separates and recycles the syngas to the DME reactor, separates the CO

2 and directs it back to the reformer and removes the by-product methanol to obtain a product stream with predefined purity.

Similarly to the SEDMES process, the DIDR stripping enhanced distillation enables efficient separation of DME and CO

2, and other unconverted gases. Substitution of the downstream CO

2 separation column (removal of CO

2 from the DME product stream) with SED allows for a more efficient purification while using methane as a clearing gas. The SED column consists of two feed intakes, one for the DIDR DME product stream and the other one for the methane stripping gas (see

Figure 6). The DME product stream enters the column around the middle section, depending on the separation requirements of the column. The methane feed enters at the bottom stage of the column. Part of the methane that is used as clearing gas in the SED will be recycled with unconverted gasses and CO

2 to the reformer unit where it is converted to syngas again. The composition of the DME product stream of a pilot scale DIDR reactor [

25] is listed in

Table 2. We have assumed that 95 mol% of the syngas is recovered using a knock-out vessel and recycled to the reactor prior to the CO

2–DME separation.

In this case study, a sensitivity analysis was performed wherein the reflux ratio (range 0.2–3) and the flow rate of the methane stripping gas (0–20 kmol∙h−1, 0 means no SED was utilized) were varied. The number of equilibrium stages was fixed at 12. A lower number of stages resulted in higher DME losses (>1wt%).

4. Results and Discussion

In order to compare the simulation results for the two cases mentioned in

Section 3, the feed composition and the operational conditions of the product streams leaving the reactor are kept constant. The synthesis step is out of scope of this study. Instead, the focus is on the separation of the gases and the final purification of the DME from the condensables (i.e., methanol and water) to meet the predefined specifications.

As discussed, in DME purification following direct DME synthesis, the most challenging separation is of CO

2 from DME. This is because CO

2 dissolves very well in liquid DME (cf.

Figure 1). The concept of SED is based on the introduction of a light gas that does not readily dissolve in the heavy product DME. Specifically, hydrogen and methane are introduced into the system, because they both allow easy recycling to the upstream synthesis section. By the introduction of the additional light component, the partial pressure of light product CO

2 is reduced, hence lower quantities are dissolved in the liquid DME. The clearing gas is readily recovered at the top of the distillation column together with the other light components (H

2, CO, CO

2, CH

4) while heavy components (DME, methanol, water) are recovered as the bottom product. The concept thus gives rise to some very favorable characteristics in the distillation process, as described below for the two use cases.

4.1. Case (i): CO2–DME Separation after the Sorption Enhanced DME Synthesis (SEDMES) Process Utilizing Hydrogen as Clearing Gas

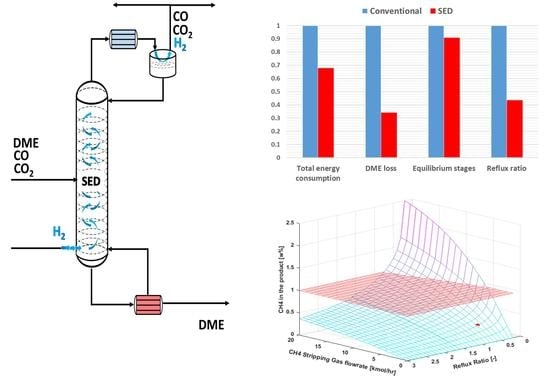

A qualitative comparison of the performance of SED and conventional purification of the SEDMES product stream is presented in

Figure 7 and listed in

Table 3. For the sake of completion, both feed compositions listed in

Table 2 are investigated. In addition, the values of the conventional process are normalized. As mentioned before, the presented process parameters are interconnected and should be evaluated as such. As can be seen from the obtained results, the SED performance significantly exceeds that of the conventional process for all the parameters:

Reflux ratio—Intensified stripping effect of H2 clearing gas results in a reduction of reflux flow requirements;

Total energy consumption—SED implementation results in moderately to significantly lower energy consumption (up to 30% circa 200–800 kW case dependent) due to reduced fluid loads on the column because of intensified H2 stripping activity and the lack of flash vessel energy requirements;

Total DME losses—Even though both processes were optimized, the reduction of DME losses in a conventional process is a challenging task due to the presence of the non-selective flash vessel. On the other hand, the SED process can achieve minimal DME losses;

Equilibrium stages—Due to the stripping effect of the clearing gas, the SED process requires a lower number of equilibrium stages.

Figure 7.

Comparison of the results for the conventional SEDMES product stream purification (red bars) and SEDMES with SED incorporated in the downstream separation train (blue bars). The comparison parameters are: total energy consumption; DME product losses; number of equilibrium stages and reflux ratio.

Figure 7.

Comparison of the results for the conventional SEDMES product stream purification (red bars) and SEDMES with SED incorporated in the downstream separation train (blue bars). The comparison parameters are: total energy consumption; DME product losses; number of equilibrium stages and reflux ratio.

Table 3.

Numerical values of the parameters presented in the graphs in

Figure 7 for the comparison of the conventional SEDMES product stream purification with and without SED incorporated in downstream processing.

Table 3.

Numerical values of the parameters presented in the graphs in

Figure 7 for the comparison of the conventional SEDMES product stream purification with and without SED incorporated in downstream processing.

| Cases | 15 Bar |

|---|

| | High CO2 Content | Low CO2 Content |

|---|

| | Conventional | SED | Conventional | SED |

|---|

| Total energy consumption [kW] | 1253 | 850 | 1059 | 886 |

| DME loss [wt%] | 1.36 | 0.46 | 1.43 | 0.43 |

| Equilibrium stages [-] | 11 | 10 | 16 | 8 |

| Reflux ratio [-] | 1.70 | 0.74 | 3.35 | 0.62 |

| Cases | 20 Bar |

| | High CO2 Content | Low CO2 Content |

| | Conventional | SED | Conventional | SED |

| Total energy consumption [kW] | 1164 | 888 | 1065 | 912 |

| DME loss [wt%] | 1.36 | 0.59 | 0.90 | 0.59 |

| Equilibrium stages [-] | 11 | 10 | 15 | 8 |

| Reflux ratio [-] | 1.70 | 0.65 | 2.80 | 0.50 |

| Cases | 30 Bar |

| | High CO2 Content | Low CO2 Content |

| | Conventional | SED | Conventional | SED |

| Total energy consumption [kW] | 1381 | 1187 | 1122 | 1034 |

| DME loss [wt%] | 1.36 | 0.10 | 0.91 | 0.75 |

| Equilibrium stages [-] | 11 | 11 | 19 | 8 |

| Reflux ratio [-] | 1.70 | 1.0 | 3.70 | 0.50 |

| Cases | 50 Bar |

| | High CO2 Content | Low CO2 Content |

| | Conventional | SED | Conventional | SED |

| Total energy consumption [kW] | 1673 | 1054 | 1260 | 1190 |

| DME loss [wt%] | 1.11 | 0.35 | 1.07 | 0.11 |

| Equilibrium stages [-] | 25 | 18 | 25 | 14 |

| Reflux ratio [-] | 6.10 | 0.50 | 6.20 | 0.50 |

The use of a flash vessel in the conventional process inevitably causes higher losses of DME; for this reason, the DME losses in the flash vessel were limited to 1%. This creates a difference in the total molar flow rate and amount of non-condensable gases going to the first distillation column. Consequently, it results in the reduction of the stripping effect in the region of low CO

2 concentration and higher separation requirements in the low CO

2 content case compared to the high CO

2 content case (see

Table 3). However, this is not observed with the SED, due to the lack of flash vessel and addition of the non-condensable gas in the stripping region of the column.

4.2. Case: (ii) CO2–DME Separation after Direct DME Synthesis via Dry Reforming Utilizing Methane as Clearing Gas

In this process, methane and CO

2 are combined with a recycled stream of methane in the reformer. The recycle stream of methane comes from the off gas of the condenser on top of the SED column (see

Figure 6). In the case of using a tri-reformer, the streams are further combined with steam before entering the burner of the tri-reformer. Using the DME product stream listed in

Table 2, a process simulation of the SED column using steady state models is conducted in Aspen Plus. The simulation reflects the results of real operation data of a demo scale plant [

25]. Moreover, the presence of the tri-reformer in the DIDR process adds an additional degree of freedom to the choice of the clearing gas. One could think of using oxygen or nitrogen instead of methane. However, preliminary results showed that using oxygen led to high concentrations of oxygen in the gas stream (~41 wt%) and contamination above (~1 wt%) the max allowed limit in DME as fuel. To meet the product specifications, oxygen adds complexity to the process layout in terms of CAPEX (e.g., more stages) and OPEX (e.g., higher reflux ratio) in addition to safety precautions. Using nitrogen, on the other hand, contaminates the DME stream (~0.4 wt%) and the gas stream is diluted with nitrogen (~40 wt%), requiring additional operational steps for nitrogen removal. The best option in this case is still using methane as stripping gas; methane is both feed to the reformers and a functional clearing gas. The clearing gas along with other unconverted gases is recycled to the reformer with a small purge to avoid accumulation of inert gases. Moreover, from the sensitivity analysis, it can be concluded that using SED leads to:

Reduction in the total energy consumption compared to the conventional method;

A drop in the reflux ratio of ~30%;

The stripping gas flow rate is an additional variable to ensure the DME purity meets the specified product purity, ISO 16861:2015(E).

The results of the sensitivity analysis are shown in

Figure 8. The red surface in the figures denotes the design boundaries of the system, i.e., the DME purity, CH

4 and CO

2 content in the product as given in

Table 1. Cases where all the design boundaries are satisfied were compared with the conventional distillation in terms of energy consumption, and the optimal SED case was chosen. The optimal parameters for the SED column are represented by the closed red circles in the figures. Moreover, their numerical values, along with those for conventional distillation, are listed in

Table 4. It should be noted that the graphs are orientated differently to allow for the better clarity and presentation of the plotted data and the optimal point.

5. Conclusions

Stripping enhanced distillation is a novel application in the separation of CO2 and DME. CO2 utilization as a carbon source for synthesis of valuable products that are conventionally produced from fossil fuels plays an important role in the energy transition. Due to thermodynamic limitations of CO2 conversion to DME, the product stream tends to contain substantial amounts of CO2. The high affinity of CO2 towards DME complicates the purification step. The concept of SED relies on the introduction of an additional light component (e.g., H2, CH4) into the distillation column in order to facilitate the separation, resulting in significant operating cost savings. This is in part due to the configuration of the process, as the stripping gas hydrogen is readily available for the reduction of CO2 to DME. In addition, the vapor distillate which now includes the stripping gas does not need to be further purified, but it can be directly recycled to the conversion unit after a small purge stream.

In this work, the results of two distinct case studies of the SED performance are presented: (i) SEDMES process, using hydrogen as clearing gas; and (ii) dry reforming process (DIDR) utilizing methane as a clearing gas. In general, the addition of the stripping gas allows for the reduction of the reflux ratio in both cases compared to the conventional processes. This can be ascribed to the higher stripping effect, which directly influences the column load and consequently the required reflux ratio necessary for the desired purity. Similarly, the number of equilibrium stages could be reduced, which is also correlated to the required reflux ratio, as increasing one value influences the reduction of the second.

In the SEDMES case study, the process simulation results show that at all the process relevant pressures and two compositions (related to degree of CO2 conversion) studied, the reduction in the total energy consumption by around 30%, DME losses and number of required equilibrium stages is achieved.

In the DIDR case study, a sensitivity analysis of the process including SED was conducted. The reflux ratio and flow rate of methane clearing gas were varied while the number of column equilibrium stages was fixed. By utilizing methane, purification enhancement was observed due to its stripping effect in which SED outperformed conventional distillation. Energy savings by up to 20% were observed while maintaining the desired product quality and minimizing product losses.