Composites Based on CaCl2-CaBr2 Salt System for Adsorption Applications: Designing the Optimal Sorbent for Gas Drying and Air Conditioning

Abstract

:1. Introduction

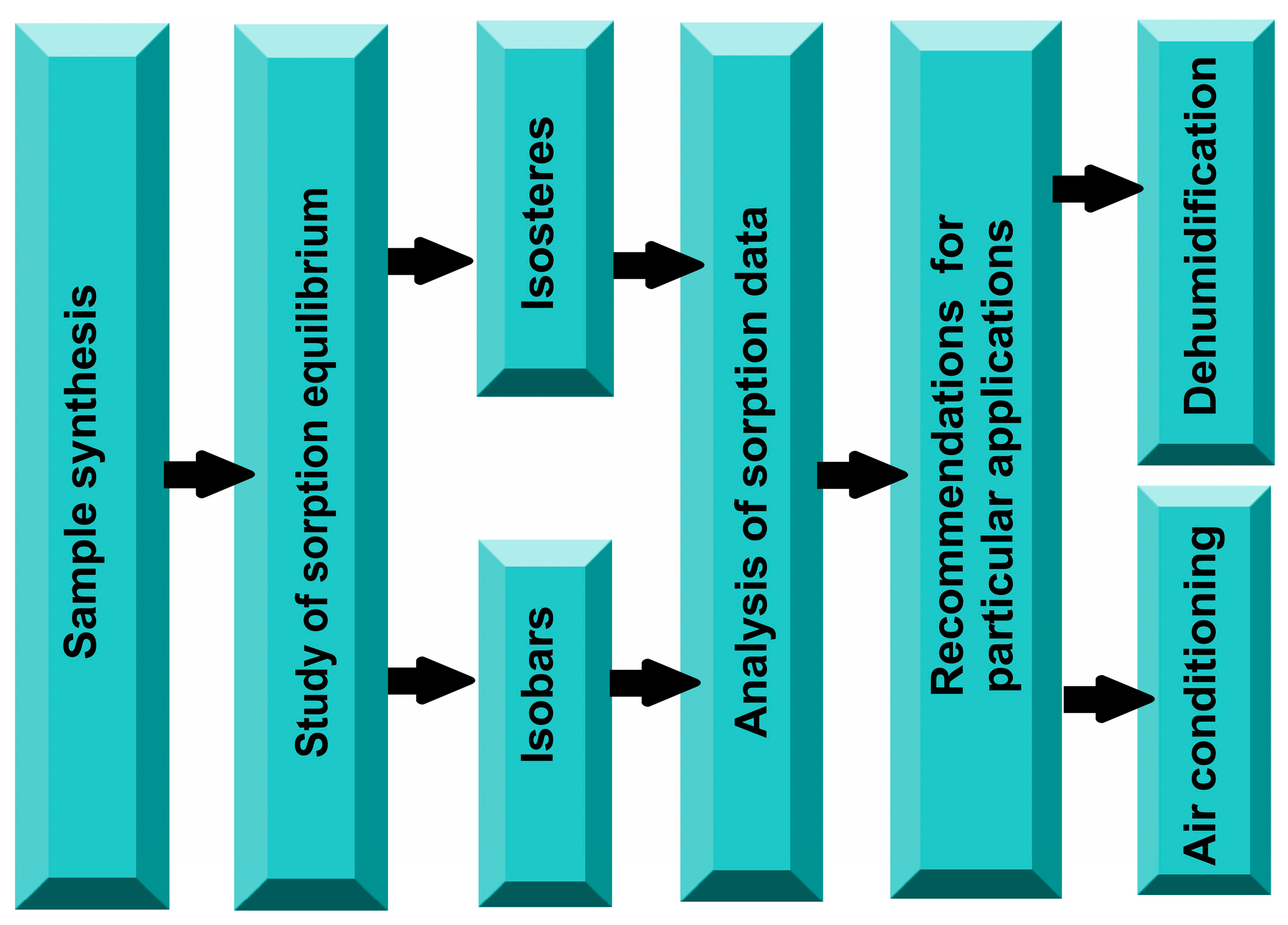

2. Materials and Methods

2.1. Materials and Synthesis

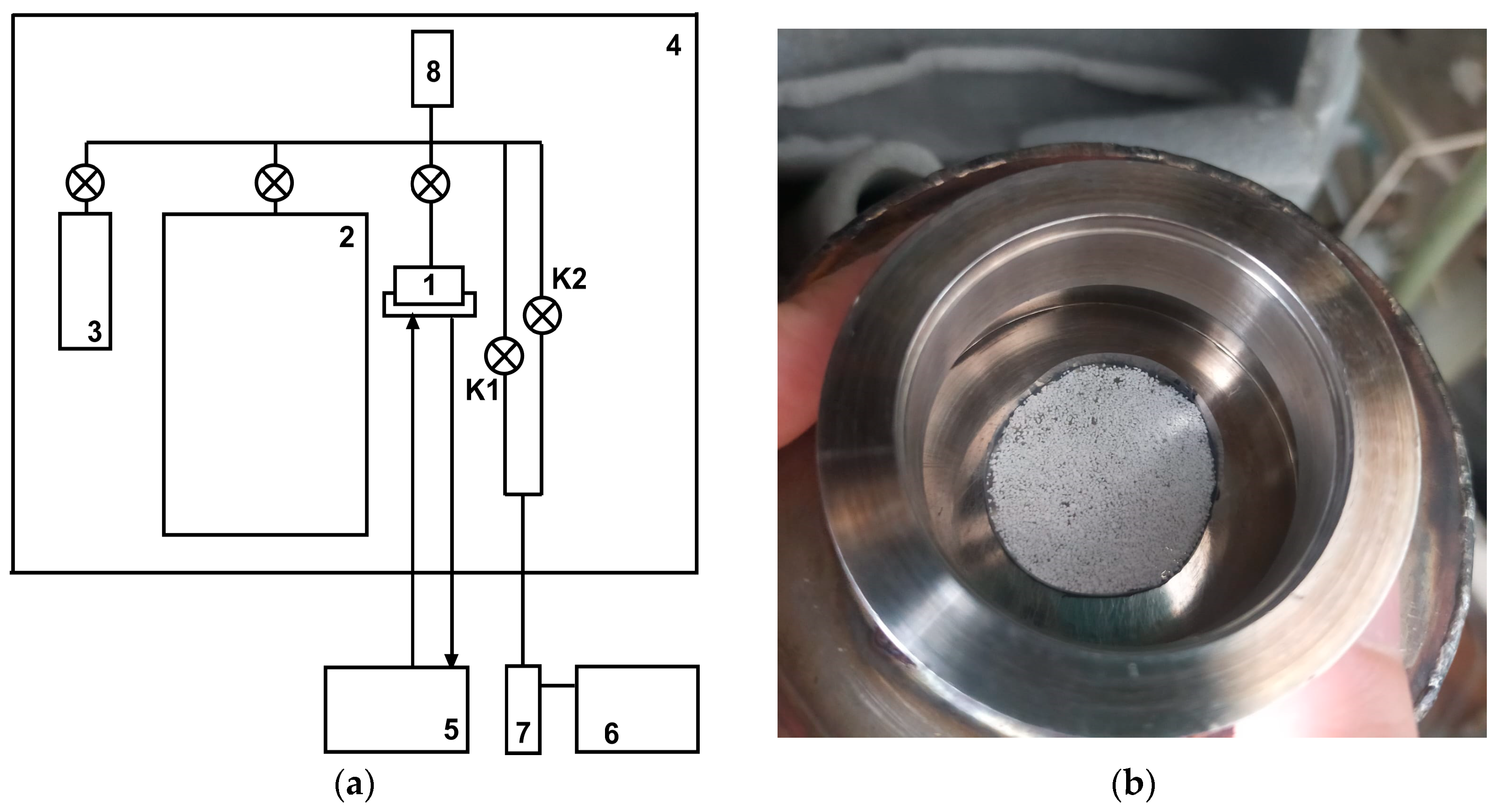

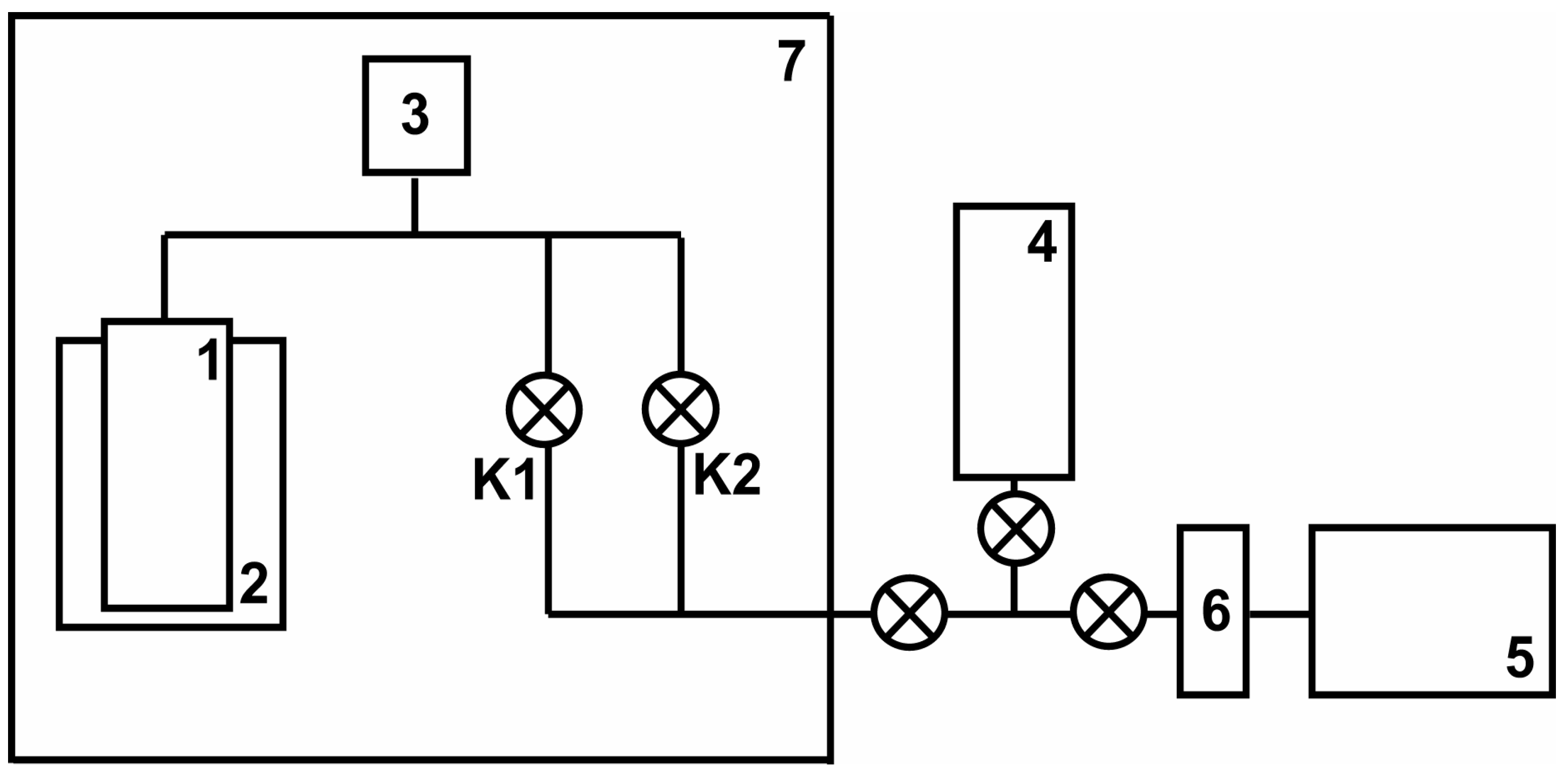

2.2. Sorption Isotherms’ Measurement

2.3. Sorption Isosteres’ Measurement

3. Results

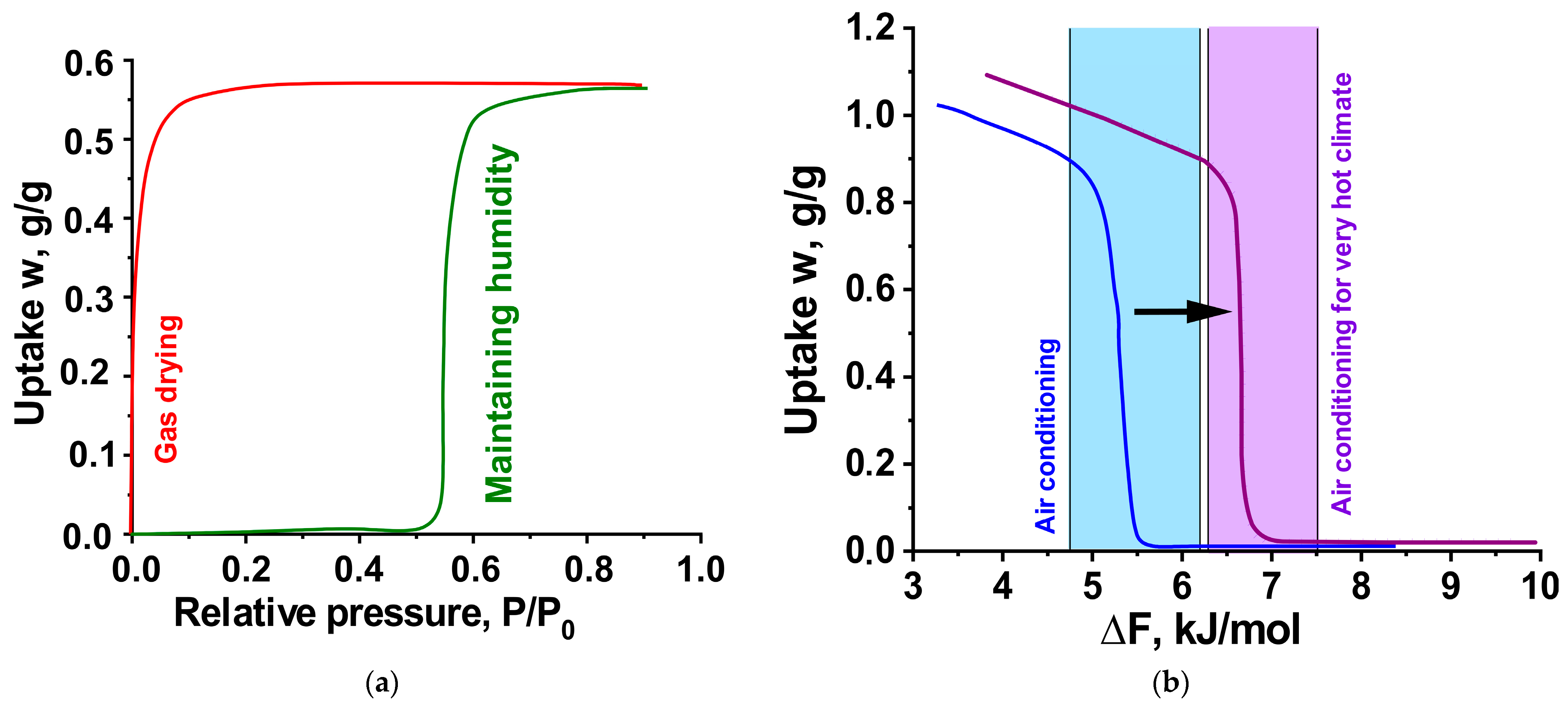

4. Discussion

4.1. Air Conditioning for Hot Climate

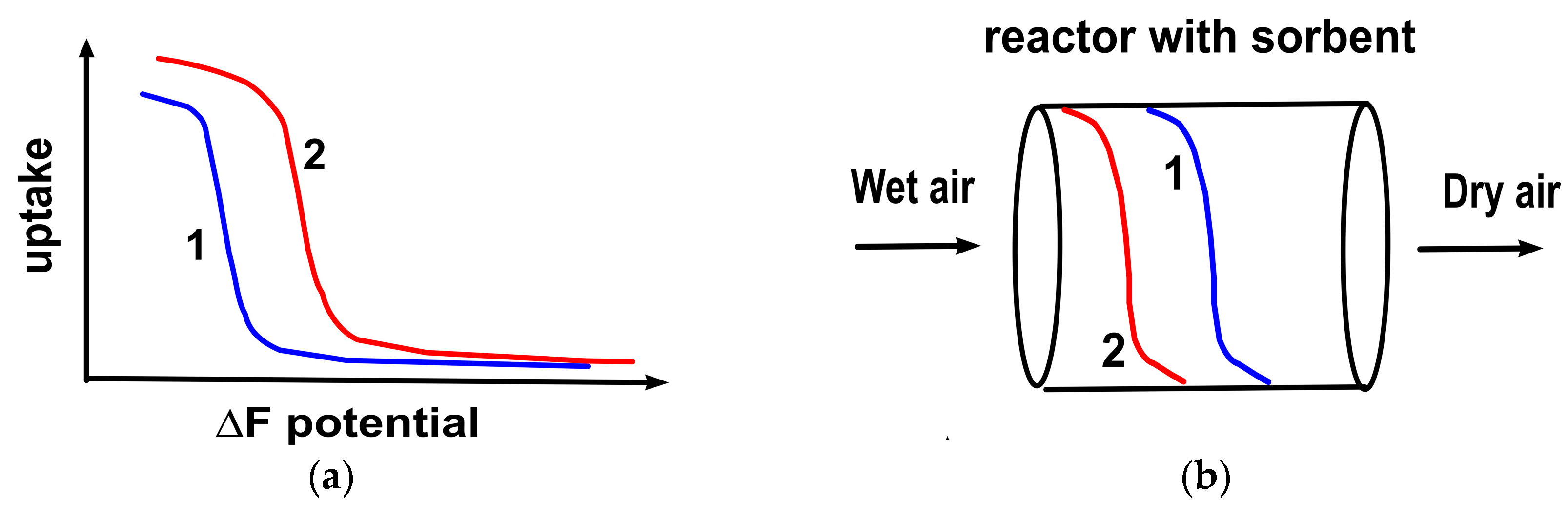

4.2. Dehumidification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dabrowski, A. Adsorption—From Theory to Practice. Adv. Colloid Interface Sci. 2001, 93, 135–224. [Google Scholar] [CrossRef] [PubMed]

- San, J.-Y.; Lin, W.M. Comparison among three adsorption pairs for using as the working substances in a multi-bed adsorption heat pump. Appl. Therm. Eng. 2008, 28, 988–997. [Google Scholar] [CrossRef]

- Gordeeva, L.G.; Aristov, Y.I. Adsorptive heat storage and amplification: New cycles and adsorbents. Energy 2019, 167, 440–453. [Google Scholar] [CrossRef]

- Aristov, Y.I. Novel materials for adsorptive heat pumping and storage: Screening and nanotailoring of sorption properties. J. Chem. Eng. Jpn. 2007, 40, 1242–1251. [Google Scholar] [CrossRef]

- Polanyi, M. Section III.—Theories of the adsorption of gases. A general survey and some additional remarks. Introductory paper to section III. Trans. Faraday Soc. 1932, 28, 316–333. [Google Scholar] [CrossRef]

- Pons, M.; Meunier, F.; Cacciola, G.; Critoph, R.E.; Groll, M.; Puigjaner, L.; Spinner, B.; Ziegler, F. Thermodynamic based comparison of sorption systems for cooling and heat pumping. Int. J. Refrig. 1999, 22, 5–17. [Google Scholar] [CrossRef]

- Critoph, R.E.; Zhong, Y. Review of trends in solid sorption refrigeration and heat pumping technology. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2005, 219, 285–300. [Google Scholar] [CrossRef]

- Wang, D.C.; Li, Y.H.; Li, D.; Xia, Y.Z.; Zhang, J.P. A review on adsorption refrigeration technology and adsorption deterioration in physical adsorption systems. Renew. Sustain. Energy Rev. 2010, 14, 344–353. [Google Scholar] [CrossRef]

- Aristov, Y.I. Challenging offers of material science for adsorption heat transformation. Appl. Therm. Eng. 2013, 50, 1610–1618. [Google Scholar] [CrossRef]

- Rahmadiawan, D.; Abral, H.; Railis, R.M.; Iby, I.C.; Mahardika, M.; Handayani, D.; Natrana, K.D.; Juliadmi, D.; Akbar, F. The Enhanced Moisture Absorption and Tensile Strength of PVA/Uncaria gambir Extract by Boric Acid as a Highly Moisture-Resistant, Anti-UV, and Strong Film for Food Packaging Applications. J. Compos. Sci. 2022, 6, 337. [Google Scholar] [CrossRef]

- Rahmadiawan, D.; Abral, H.; Kotodeli, R.A.; Sugiarti, E.; Muslimin, A.N.; Admi, R.I.; Arafat, A.; Kim, H.-J.; Sapuan, S.M.; Kosasih, E.A. A Novel Highly Conductive, Transparent, and Strong Pure-Cellulose Film from TEMPO-Oxidized Bacterial Cellulose by Increasing Sonication Power. Polymers 2023, 15, 643. [Google Scholar] [CrossRef] [PubMed]

- Nordin, A.H.; Norfarhana, A.S.; Noor, S.F.M.; Paiman, S.H.; Nordin, M.L.; Husna, S.M.N.; Ilyas, R.A.; Ngadi, N.; Bakar, A.A.; Ahmad, Z.; et al. Recent Advances in Using Adsorbent Derived from Agricultural Waste for Antibiotics and Non-Steroidal Anti-Inflammatory Wastewater Treatment: A Review. Separations 2023, 10, 300. [Google Scholar] [CrossRef]

- Wang, M.; Phillips, T.D. Green-Engineered Barrier Creams with Montmorillonite-Chlorophyll Clays as Adsorbents for Benzene, Toluene, and Xylene. Separations 2023, 10, 237. [Google Scholar] [CrossRef]

- Rodinkov, O.; Postnov, V.; Spivakovskyi, V.; Vlasov, A.; Bugaichenko, A.; Slastina, S.; Znamenskaya, E.; Shilov, R.; Lanin, S.; Nesterenko, P. Comparison of Adsorbents Containing Carbon Nanotubes for Express Pre-Concentration of Volatile Organic Compounds from the Air Flow. Separations 2021, 8, 50. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, X.; Xie, Y.; Hu, Y.; Jia, Z.; Ma, Y.; Wang, X. Facile Separation of Cu2+ from Water by Novel Sandwich NaY Zeolite Adsorptive Membrane. Separations 2023, 10, 171. [Google Scholar] [CrossRef]

- Singh, V.; Pant, N.; Sharma, R.K.; Padalia, D.; Rawat, P.S.; Goswami, R.; Singh, P.; Kumar, A.; Bhandari, P.; Tabish, A.; et al. Adsorption Studies of Pb(II) and Cd(II) Heavy Metal Ions from Aqueous Solutions Using a Magnetic Biochar Composite Material. Separations 2023, 10, 389. [Google Scholar] [CrossRef]

- Nguyen, M.H.; Zbair, M.; Dutournié, P.; Gervasini, A.; Vaulot, C.; Bennici, S. Toward new low-temperature thermochemical heat storage materials: Investigation of hydration/dehydration behaviors of MgSO4/Hydroxyapatite composite. Sol. Energy Mater. Sol. Cells 2022, 240, 111696. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, D. Investigation on pH/temperature-manipulated hydrothermally reduced graphene oxide aerogel impregnated with MgCl2 hydrates for low-temperature thermochemical heat storage. Sol. Energy Mater. Sol. Cells 2022, 241, 111740. [Google Scholar] [CrossRef]

- Jiang, L.; Lin, Y.C.; Liu, W.; Ma, Z.W.; Wang, R.Q.; Zhang, X.J.; Roskilly, A.P. Thermophysical characterization of magnesium chloride and its application in open sorption thermal energy storage system. Sol. Energy Mater. Sol. Cells 2022, 236, 111528. [Google Scholar] [CrossRef]

- Gordeeva, L.G.; Glaznev, I.S.; Savchenko, E.V.; Malakhov, V.V.; Aristov, Y.I. Impact of phase composition on water adsorption on inorganic hybrids “salt/silica”. J. Colloid Interface Sci. 2006, 301, 685–691. [Google Scholar] [CrossRef]

- Gordeeva, L.; Restuccia, G.; Freni, A.; Aristov, Y.I. Water sorption on composites “LiBr in a porous carbon”. Fuel Process. Technol. 2002, 79, 225–231. [Google Scholar] [CrossRef]

- Mrowiec-Białoń, J.; Lachowski, A.I.; Jarzȩbski, A.B.; Gordeeva, L.G.; Aristov, Y.I. SiO2–LiBr Nanocomposite Sol–Gel Adsorbents of Water Vapor: Preparation and Properties. J. Colloid Interface Sci. 1999, 218, 500–503. [Google Scholar] [CrossRef] [PubMed]

- Gordeeva, L.G.; Freni, A.; Krieger, T.A.; Restuccia, G.; Aristov, Y.I. Composites “lithium halides in silica gel pores”: Methanol sorption equilibrium. Microporous Mesoporous Mater. 2008, 112, 254–261. [Google Scholar] [CrossRef]

- Simonova, I.A.; Freni, A.; Restuccia, G.; Aristov, Y.I. Water sorption on composite “silica modified by calcium nitrate”. Microporous Mesoporous Mater. 2009, 122, 223–228. [Google Scholar] [CrossRef]

- Wei, S.; Zhou, W.; Han, R.; Gao, J.; Zhao, G.; Qin, Y.; Wang, C. Influence of minerals with different porous structures on thermochemical heat storage performance of CaCl2-based composite sorbents. Sol. Energy Mater. Sol. Cells 2022, 243, 111769. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Y.; Zhang, Y.; Su, Y.; Riffat, S. A study on vermiculite-based salt mixture composite materials for low-grade thermochemical adsorption heat storage. Energy 2023, 278, 127986. [Google Scholar] [CrossRef]

- Posern, K.; Kaps, C. Calorimetric studies of thermochemical heat storage materials based on mixtures of MgSO4 and MgCl2. Thermochim. Acta 2010, 502, 73–76. [Google Scholar] [CrossRef]

- Jiang, L.; Zhu, F.Q.; Wang, L.W.; Liu, C.Z.; Wang, R.Z. Experimental investigation on a MnCl2-CaCl2-NH3 thermal energy storage system. Renew. Energy 2016, 91, 130–136. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R. Sorption Thermal Energy Storage: Concept, Process, Applications and Perspectives. Energy Storage Mater. 2020, 27, 352–369. [Google Scholar] [CrossRef]

- Vegard, L. Die Konstitution der Mischkristalle und die Raumfüllung der Atome. Z. Für Phys. 1921, 5, 17–26. [Google Scholar] [CrossRef]

- Feilchenfeld, H.; Fuchs, J.; Kahana, F.; Sarig, S. The melting point adjustment of calcium chloride hexahydrate by addition of potassium chloride or calcium bromide hexahydrate. Solar Energy 1985, 34, 199–201. [Google Scholar] [CrossRef]

- Ghosh, S.; Sridharan, R.; Gnanasekaran, T. Studies on the phase diagram of CaCl2–CaBr2 system. Thermochim. Acta 2010, 505, 69–72. [Google Scholar] [CrossRef]

- Liu, C.Y.; Aika, K.-I. Ammonia absorption into alkiline earth metal halide mixtures as an ammonia storage material. Ind. Eng. Chem. Res. 2004, 43, 7484–7491. [Google Scholar] [CrossRef]

- Liu, C.Y.; Aika, K.-I. Effect of the Cl/Br ratio of a CaCl2–CaBr2 mixture used as an ammonia storage material. Ind. Eng. Chem. Res. 2004, 43, 6494–7000. [Google Scholar] [CrossRef]

- Gordeeva, L.; Grekova, A.; Krieger, T.; Aristov, Y. Composites “binary salts in porous matrix” for adsorption heat transformation. Appl. Therm. Eng. 2013, 50, 1633–1638. [Google Scholar] [CrossRef]

- Grekova, A.D.; Veselovskaya, J.V.; Tokarev, M.M.; Krieger, T.A.; Shmakov, A.N.; Gordeeva, L.G. Ammonia sorption on the composites “(BaCl2+BaBr2) inside vermiculite pores”. Colloids Surf. A Physicochem. Eng. Asp. 2014, 448, 169–174. [Google Scholar] [CrossRef]

- Veselovskaya, J.V.; Tokarev, M.M.; Grekova, A.D.; Gordeeva, L.G. Novel ammonia sorbents “porous matrix modified by active salt” for adsorptive heat transformation: 6. The ways of adsorption dynamics enhancement. Appl. Therm. Eng. 2012, 37, 87–94. [Google Scholar] [CrossRef]

- Grekova, A.D.; Veselovskaya, J.V.; Tokarev, M.M.; Gordeeva, L.G. Novel ammonia sorbents “porous matrix modified by active salt” for adsorptive heat transformation: 5. Designing the composite adsorbent for ice makers. Appl. Therm. Eng. 2012, 37, 80–86. [Google Scholar] [CrossRef]

- Gordeeva, L.G.; Grekova, A.D.; Krieger, T.A.; Aristov, Y.I. Adsorption properties of composite materials (LiCl + LiBr)/silica. Microporous Mesoporous Mater. 2009, 126, 262–267. [Google Scholar] [CrossRef]

- Bülow, M.; Shen, D.; Jale, S. Measurement of sorption equilibria under isosteric conditions: The principles, advantages and limitations. Appl. Surf. Sci. 2002, 196, 157–172. [Google Scholar] [CrossRef]

- Yanagi, H.; Okamoto, N.; Komatsu, F.; Ino, N.; Ogura, M.; Nishino, M.; Okamoto, Y. Development of Adsorption Refrigerator using Silicagel-Water Pairs. In Studies in Surface Science and Catalysis; Suzuki, M., Ed.; Elsevier: Amsterdam, The Netherlands, 1993; Volume 80, pp. 751–758. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Gordeeva, L.G. Combining the psychrometric chart of humid air with water adsorption isosters: Analysis of the Ventireg process. Energy 2022, 239, 122278. [Google Scholar] [CrossRef]

- Glaznev, I.S.; Aristov, Y.I. The effect of cycle boundary conditions and adsorbent grain size on the water sorption dynamics in adsorption chillers. Int. J. Heat Mass Transf. 2010, 53, 1893–1898. [Google Scholar] [CrossRef]

- Aristov, Y.I.; Tokarev, M.M.; Cacciola, G.; Restuccia, G. Selective water sorbents for multiple applications: 1. CaCl2 confined in mesopores of the silica gel: Sorption properties. React. Kinet. Catal. Lett. 1996, 59, 325–334. [Google Scholar] [CrossRef]

- Sapienza, A.; Glaznev, I.S.; Santamaria, S.; Freni, A.; Aristov, Y.I. Adsorption chilling driven by low temperature heat: New adsorbent and cycle optimization. Appl. Therm. Eng. 2012, 32, 141–146. [Google Scholar] [CrossRef]

- Freni, A.; Russo, F.; Vasta, S.; Tokarev, M.; Aristov, Y.I.; Restuccia, G. An advanced solid sorption chiller using SWS-1L. Appl. Therm. Eng. 2007, 27, 2200–2204. [Google Scholar] [CrossRef]

- Almohammadi, K.M.; Harby, K. Operational conditions optimization of a proposed solar-powered adsorption cooling system: Experimental, modeling, and optimization algorithm techniques. Energy 2020, 206, 118007. [Google Scholar] [CrossRef]

- Chen, Q.F.; Du, S.W.; Yuan, Z.X.; Sun, T.B.; Li, Y.X. Experimental study on performance change with time of solar adsorption refrigeration system. Appl. Therm. Eng. 2018, 138, 386–393. [Google Scholar] [CrossRef]

- Liu, Y.M.; Yuan, Z.X.; Wen, X.; Du, C.X. Evaluation on performance of solar adsorption cooling of silica gel and SAPO-34 zeolite. Appl. Therm. Eng. 2021, 182, 116019. [Google Scholar] [CrossRef]

- Tso, C.Y.; Chan, K.C.; Chao, C.Y.H.; Wu, C.L. Experimental performance analysis on an adsorption cooling system using zeolite 13X/CaCl2 adsorbent with various operation sequences. Int. J. Heat Mass Transf. 2015, 85, 343–355. [Google Scholar] [CrossRef]

- Roumpedakis, T.C.; Vasta, S.; Sapienza, A.; Kallis, G.; Karellas, S.; Wittstadt, U.; Tanne, M.; Harborth, N.; Sonnenfeld, U. Performance Results of a Solar Adsorption Cooling and Heating Unit. Energies 2020, 13, 1630. [Google Scholar] [CrossRef]

- Mohammed, R.H.; Mesalhy, O.; Elsayed, M.L.; Chow, L.C. Performance evaluation of a new modular packed bed for adsorption cooling systems. Appl. Therm. Eng. 2018, 136, 293–300. [Google Scholar] [CrossRef]

- Chan, K.C.; Tso, C.Y.; Wu, C.; Chao, C.Y.H. Enhancing the performance of a zeolite 13X/CaCl2–water adsorption cooling system by improving adsorber design and operation sequence. Energy Build. 2018, 158, 1368–1378. [Google Scholar] [CrossRef]

- Wang, R.Z. Performance improvement of adsorption cooling by heat and mass recovery operation. Int. J. of Refrig. 2001, 24, 602–611. [Google Scholar] [CrossRef]

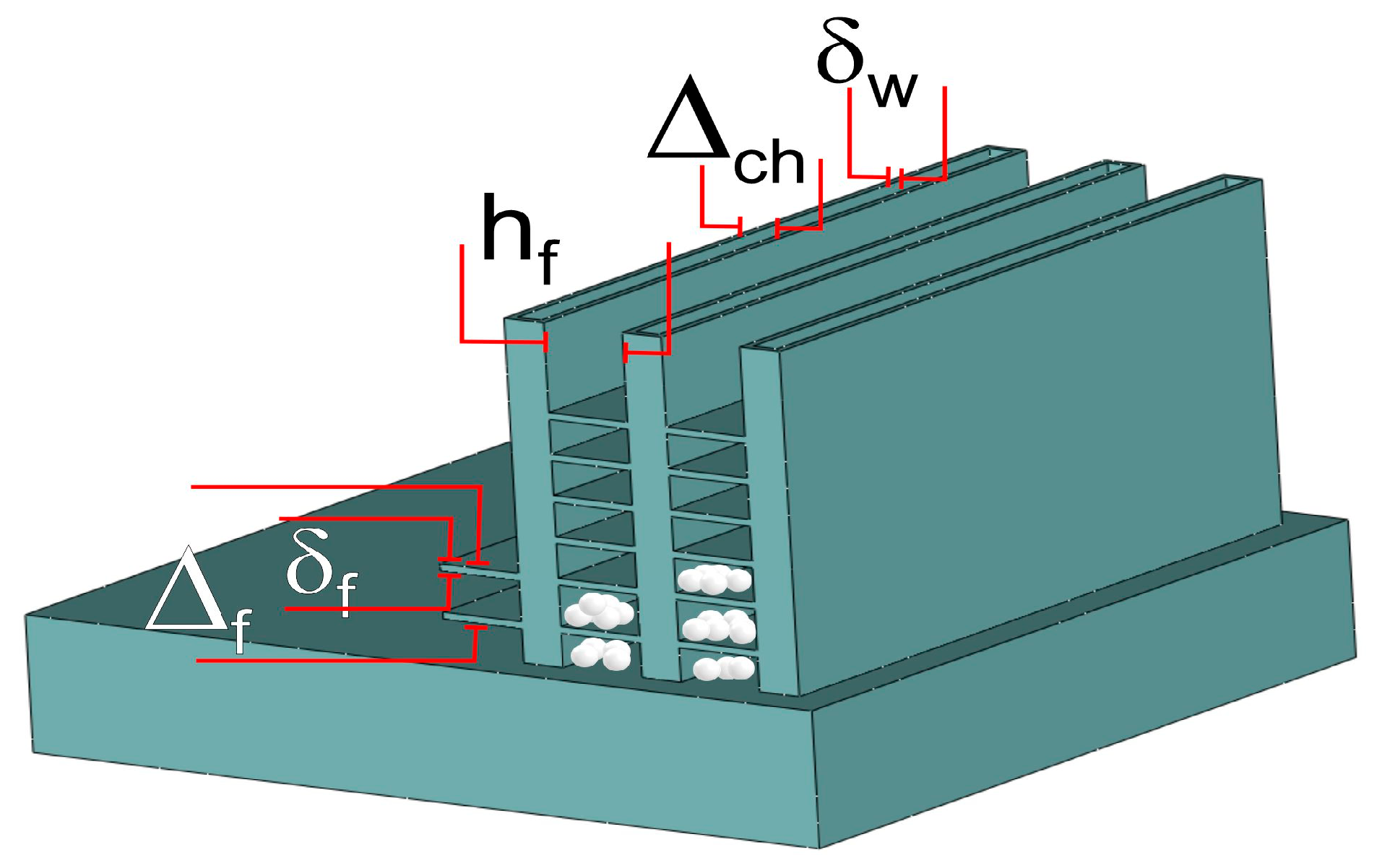

- Grekova, A.; Tokarev, M. An Optimal Plate Fin Heat Exchanger for Adsorption Chilling: Theoretical Consideration. Int. J. Thermofluids 2022, 16, 100221. [Google Scholar] [CrossRef]

- Grekova, A.; Krivosheeva, I.; Solovyeva, M.; Tokarev, M. Express Method for Assessing Optimality of Industrial Heat Exchangers for Adsorption Heat Transformation. Fluids 2023, 8, 14. [Google Scholar] [CrossRef]

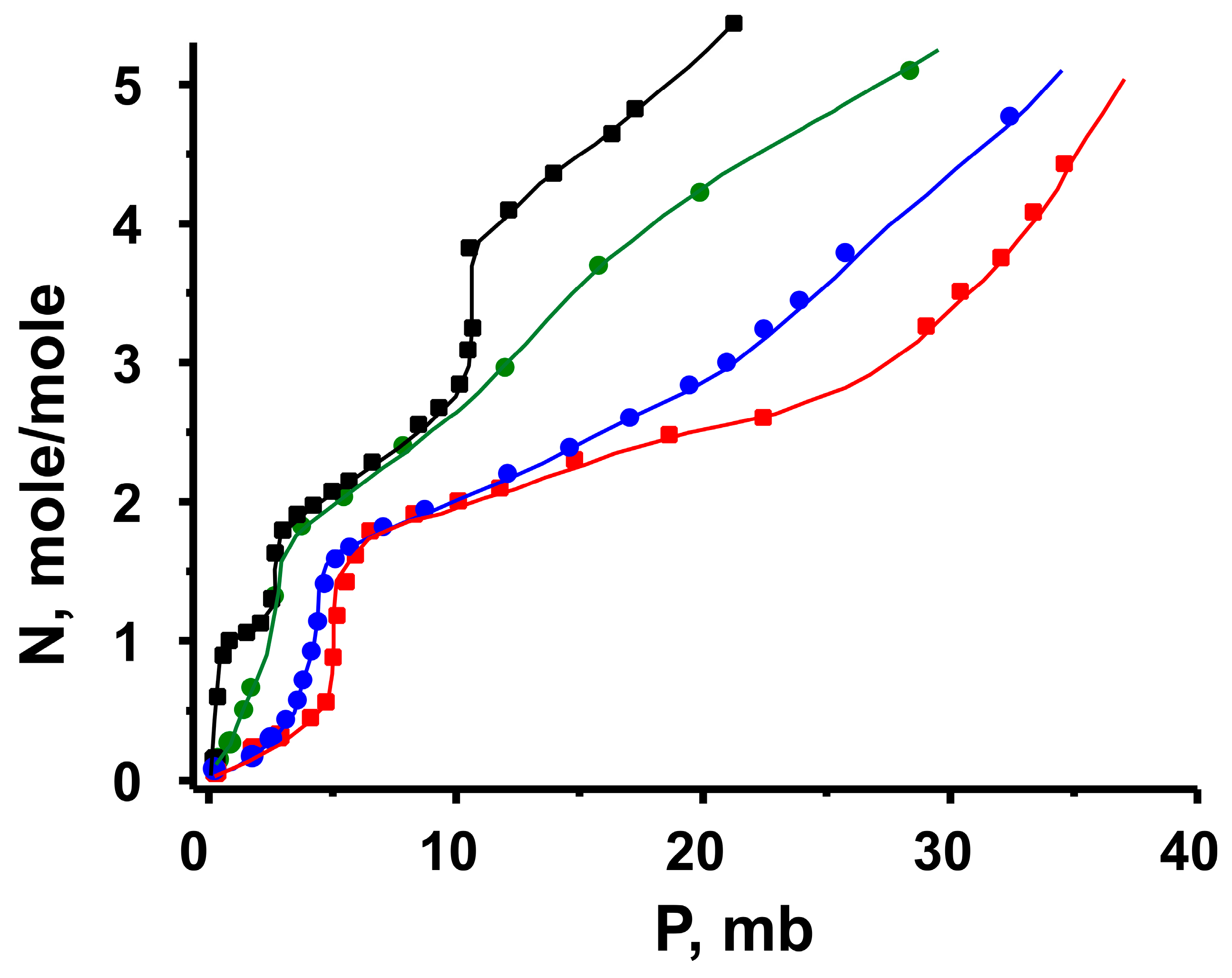

)—CaBr2/SiO2, (

)—CaBr2/SiO2, ( )—(CaCl2 + CaBr2 (1:1))/SiO2, (

)—(CaCl2 + CaBr2 (1:1))/SiO2, ( )—(CaCl2 + CaBr2 (3:1))/SiO2, (

)—(CaCl2 + CaBr2 (3:1))/SiO2, ( )—CaCl2/SiO2 obtained at T = 65 °C.

)—CaCl2/SiO2 obtained at T = 65 °C.

)—CaBr2/SiO2, (

)—CaBr2/SiO2, ( )—(CaCl2 + CaBr2 (1:1))/SiO2, (

)—(CaCl2 + CaBr2 (1:1))/SiO2, ( )—(CaCl2 + CaBr2 (3:1))/SiO2, (

)—(CaCl2 + CaBr2 (3:1))/SiO2, ( )—CaCl2/SiO2 obtained at T = 65 °C.

)—CaCl2/SiO2 obtained at T = 65 °C.

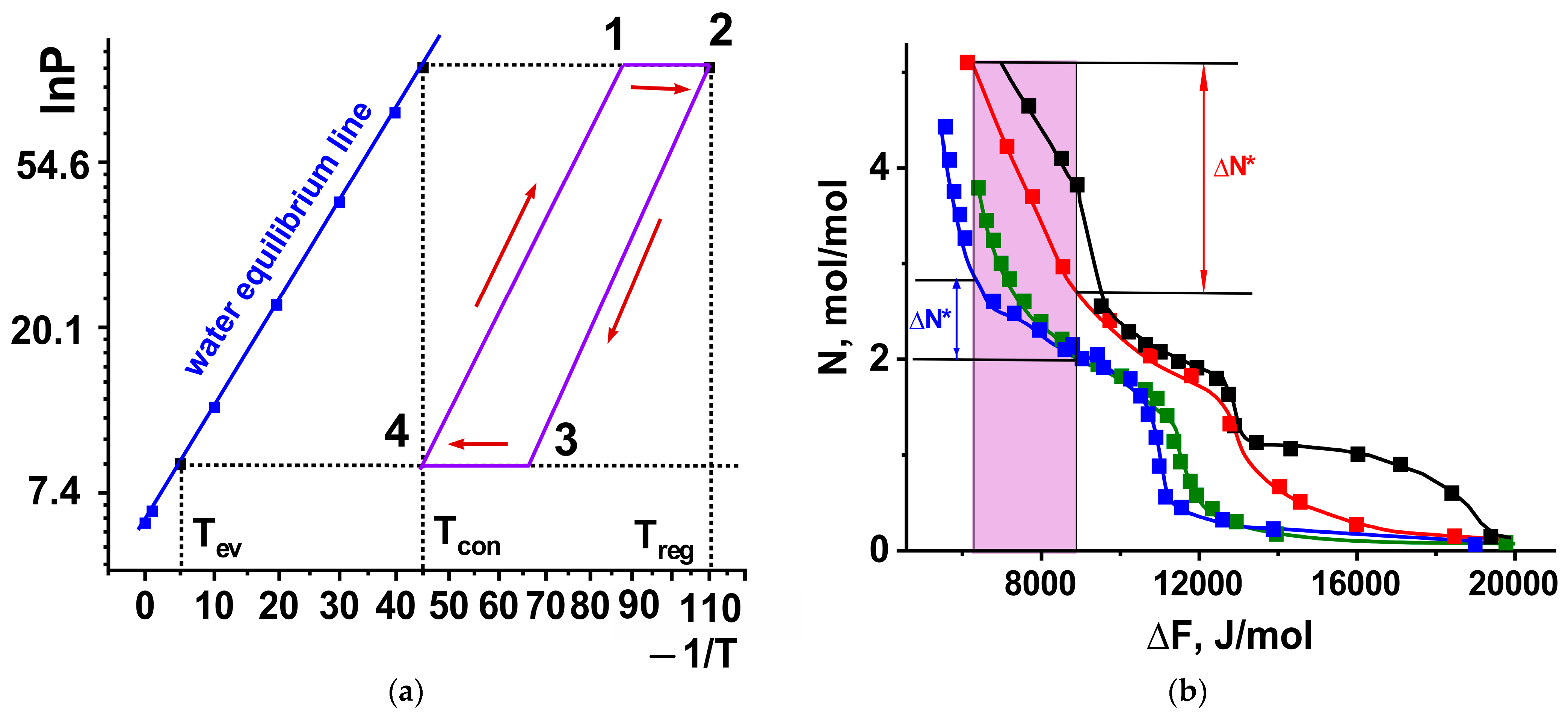

,

,  )—CaCl2/SiO2, (

)—CaCl2/SiO2, ( ,

,  )—(CaCl2 + CaBr2 (1:1))/SiO2, (

)—(CaCl2 + CaBr2 (1:1))/SiO2, ( ,

,  )—CaBr2/SiO2; N = 1.5 ± 0.05 mole/mole (

)—CaBr2/SiO2; N = 1.5 ± 0.05 mole/mole ( ,

,  )—CaBr2/SiO2, (

)—CaBr2/SiO2, ( ,

,  )—(CaCl2 + CaBr2 (1:1))/SiO2;

)—(CaCl2 + CaBr2 (1:1))/SiO2;  —water liquid–gas equilibrium line. Open symbols—data obtained by measuring the sorption isotherms.

—water liquid–gas equilibrium line. Open symbols—data obtained by measuring the sorption isotherms.

,

,  )—CaCl2/SiO2, (

)—CaCl2/SiO2, ( ,

,  )—(CaCl2 + CaBr2 (1:1))/SiO2, (

)—(CaCl2 + CaBr2 (1:1))/SiO2, ( ,

,  )—CaBr2/SiO2; N = 1.5 ± 0.05 mole/mole (

)—CaBr2/SiO2; N = 1.5 ± 0.05 mole/mole ( ,

,  )—CaBr2/SiO2, (

)—CaBr2/SiO2, ( ,

,  )—(CaCl2 + CaBr2 (1:1))/SiO2;

)—(CaCl2 + CaBr2 (1:1))/SiO2;  —water liquid–gas equilibrium line. Open symbols—data obtained by measuring the sorption isotherms.

—water liquid–gas equilibrium line. Open symbols—data obtained by measuring the sorption isotherms.

)—CaCl2/SiO2, (

)—CaCl2/SiO2, ( )—(CaCl2 + CaBr2(3:1))/SiO2, (

)—(CaCl2 + CaBr2(3:1))/SiO2, ( )—(CaCl2 + CaBr2(1:1))/SiO2, (

)—(CaCl2 + CaBr2(1:1))/SiO2, ( )—CaBr2/SiO2, pink area—window of cycle. Arrows show the consequence of the stages.

)—CaBr2/SiO2, pink area—window of cycle. Arrows show the consequence of the stages.

)—CaCl2/SiO2, (

)—CaCl2/SiO2, ( )—(CaCl2 + CaBr2(3:1))/SiO2, (

)—(CaCl2 + CaBr2(3:1))/SiO2, ( )—(CaCl2 + CaBr2(1:1))/SiO2, (

)—(CaCl2 + CaBr2(1:1))/SiO2, ( )—CaBr2/SiO2, pink area—window of cycle. Arrows show the consequence of the stages.

)—CaBr2/SiO2, pink area—window of cycle. Arrows show the consequence of the stages.

)—CaCl2/SiO2, (

)—CaCl2/SiO2, ( )—(CaCl2 + CaBr2 (1:1))/SiO2, (

)—(CaCl2 + CaBr2 (1:1))/SiO2, ( )—CaBr2/SiO2, (

)—CaBr2/SiO2, ( )—ΔF corresponding to different dew point values, (

)—ΔF corresponding to different dew point values, ( )—ΔF corresponding to different regeneration temperatures.

)—ΔF corresponding to different regeneration temperatures.

)—CaCl2/SiO2, (

)—CaCl2/SiO2, ( )—(CaCl2 + CaBr2 (1:1))/SiO2, (

)—(CaCl2 + CaBr2 (1:1))/SiO2, ( )—CaBr2/SiO2, (

)—CaBr2/SiO2, ( )—ΔF corresponding to different dew point values, (

)—ΔF corresponding to different dew point values, ( )—ΔF corresponding to different regeneration temperatures.

)—ΔF corresponding to different regeneration temperatures.

| Sample | Mole CaCl2/Mole CaBr2 | CCaCl2, wt % | CCaBr2, wt % | CSiO2, wt % |

|---|---|---|---|---|

| CaBr2/SiO2 | 0/1 | 0 | 41 | 59 |

| (CaCl2 + CaBr2 (1:1))/SiO2 | 1/1 | 11 | 21 | 68 |

| (CaCl2 + CaBr2 (3:1))/SiO2 | 3/1 | 17 | 10 | 73 |

| CaCl2/SiO2 | 1/0 | 23 | 0 | 77 |

| Sample | N, Mole/Mole ± 0.05 | ΔH, kJ/Mole | ΔS, J/(Mole∙K) |

|---|---|---|---|

| CaBr2/SiO2 | 3.6 | −51 ± 3 | −115 ± 3 |

| CaClxBr2−x/SiO2-1:1 | 3.6 | −48 ± 3 | −108 ± 3 |

| CaCl2/SiO2 | 3.6 | −46 ± 3 | −109 ± 3 |

| CaBr2/SiO2 | 1.5 | −55 ± 3 | −114 ± 3 |

| CaClxBr2−x/SiO2-1:1 | 1.5 | −55 ± 3 | −115 ± 3 |

| Working Pair | Cooling Temperature Tev, °C | Ambient Temperature Tcon, °C | Regeneration Temperature Treg, °C | Reference |

|---|---|---|---|---|

| Silica gel/water | 17 | 30 | 85 | [47] |

| SAPO34-water | 9 | 30 | 130 | [48] |

| SAPO34-water | 7 | 30 | 82 | [49] |

| Zeolite 13X/CaCl2)/water | 14 | 31 | 85 | [50] |

| Zeolite (SAPO-34)/water | 10 | 30 | 85 | [51] |

| Silica gel RD-2060; zeolite AQSOA-Z02 | 10 | 30 | 95 | [52] |

| Zeolite 13X/CaCl2 − water | 14 | 28 | 85 | [53] |

| activated carbon-methanol | 5 | 30 | 100 | [54] |

| δw, mm | Δch, mm | hf, mm | Δf, mm | δf, µm |

|---|---|---|---|---|

| 0.5 | 1.0 | 6.2 | 0.8 | 63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grekova, A.; Solovyeva, M.; Cherpakova, A.; Tokarev, M. Composites Based on CaCl2-CaBr2 Salt System for Adsorption Applications: Designing the Optimal Sorbent for Gas Drying and Air Conditioning. Separations 2023, 10, 473. https://doi.org/10.3390/separations10090473

Grekova A, Solovyeva M, Cherpakova A, Tokarev M. Composites Based on CaCl2-CaBr2 Salt System for Adsorption Applications: Designing the Optimal Sorbent for Gas Drying and Air Conditioning. Separations. 2023; 10(9):473. https://doi.org/10.3390/separations10090473

Chicago/Turabian StyleGrekova, Alexandra, Marina Solovyeva, Anastasiia Cherpakova, and Mikhail Tokarev. 2023. "Composites Based on CaCl2-CaBr2 Salt System for Adsorption Applications: Designing the Optimal Sorbent for Gas Drying and Air Conditioning" Separations 10, no. 9: 473. https://doi.org/10.3390/separations10090473

APA StyleGrekova, A., Solovyeva, M., Cherpakova, A., & Tokarev, M. (2023). Composites Based on CaCl2-CaBr2 Salt System for Adsorption Applications: Designing the Optimal Sorbent for Gas Drying and Air Conditioning. Separations, 10(9), 473. https://doi.org/10.3390/separations10090473