Green Synthesis of Magnetite Nanoparticles Mediated Fumaria officinalis L. Plant as Sustainable and Renewable Adsorbing Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Experiments in Batch

2.2. Spectroscopic Measurements

2.3. Instruments for Characterization of Green Synthesized Magnetite NPs

2.4. Plant Material

2.5. Preparation of Fumaria officinalis L. Aqueous Extract

2.6. Extraction for Antioxidants, Total Phenol, and Flavonoids

2.6.1. Total Phenol Content

2.6.2. Total Flavonoid Content

2.7. Evaluation of Antioxidant Activity

2.8. Green Synthesis of Magnetite NPs Using Fumaria officinalis L.

2.9. In Vitro Biological (Antibacterial) Activity of Fumaria officinalis L. and Green

2.10. Experimental and Establishment of RSM

2.11. Adsorption Isotherms

2.12. Adsorption Kinetics

3. Results and Discussion

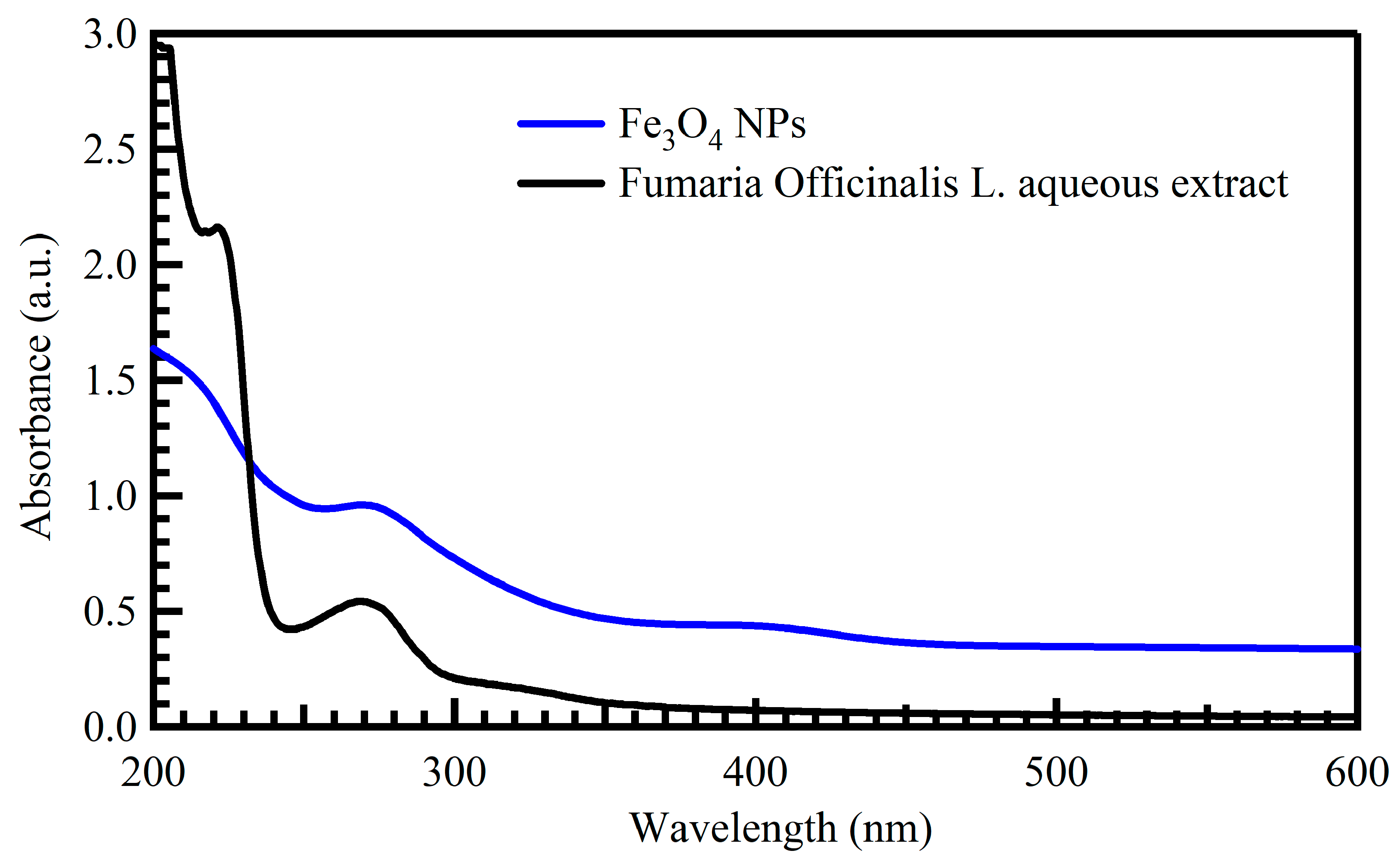

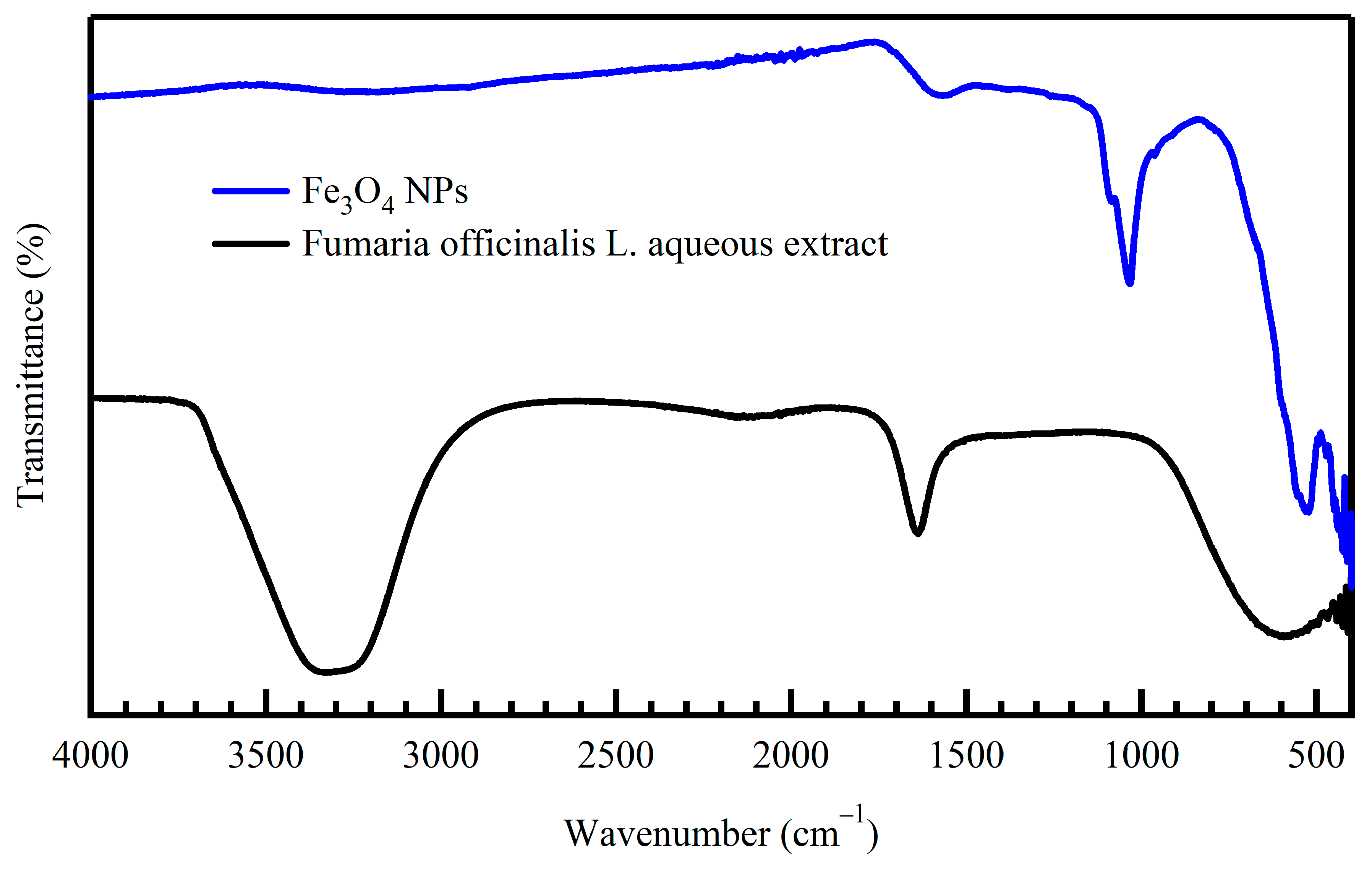

3.1. Spectroscopic Study of Fumaria officinalis L. Plant Extract and Green NPs

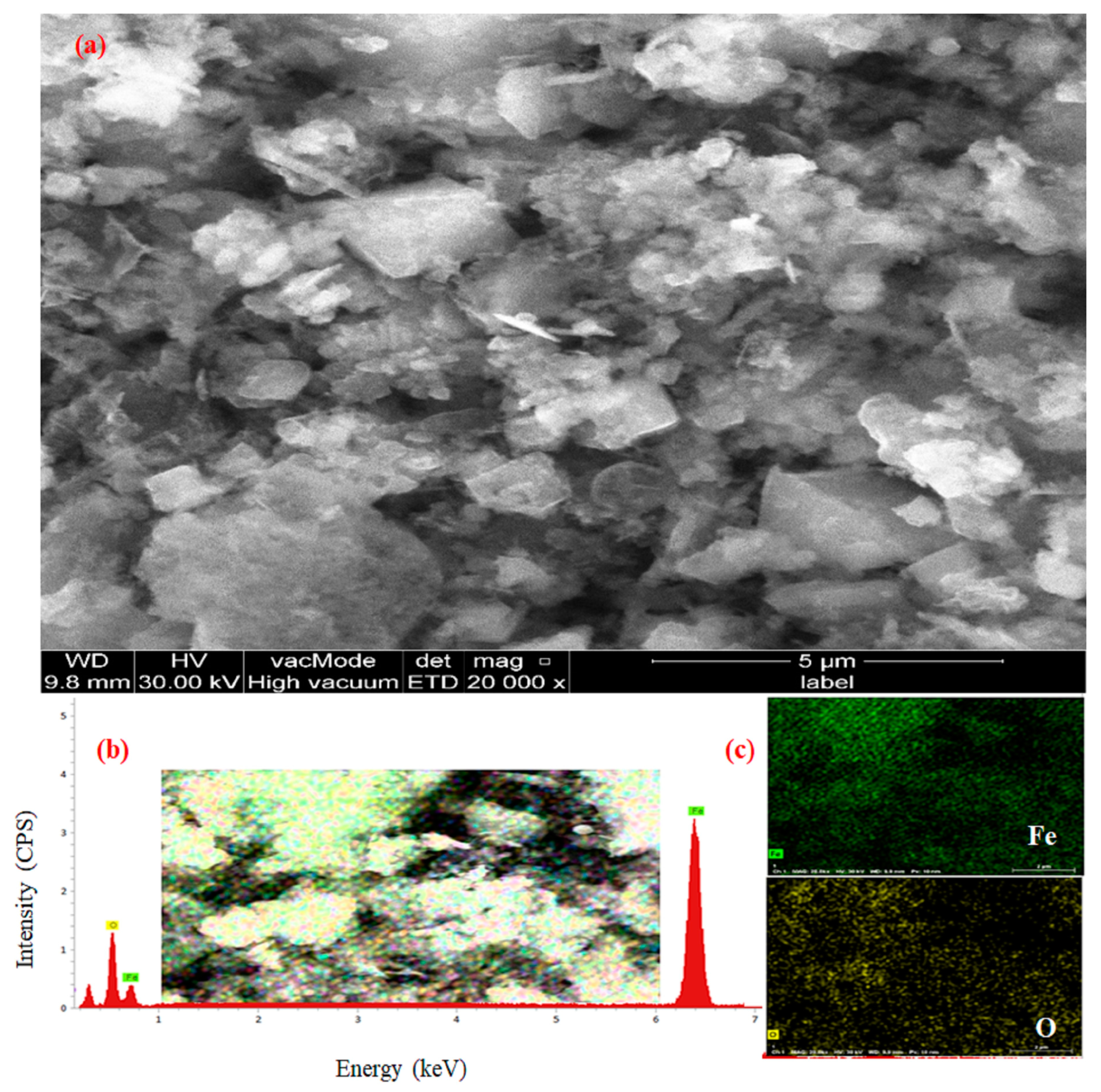

3.2. Characterization of Green Synthesized Magnetite NPs

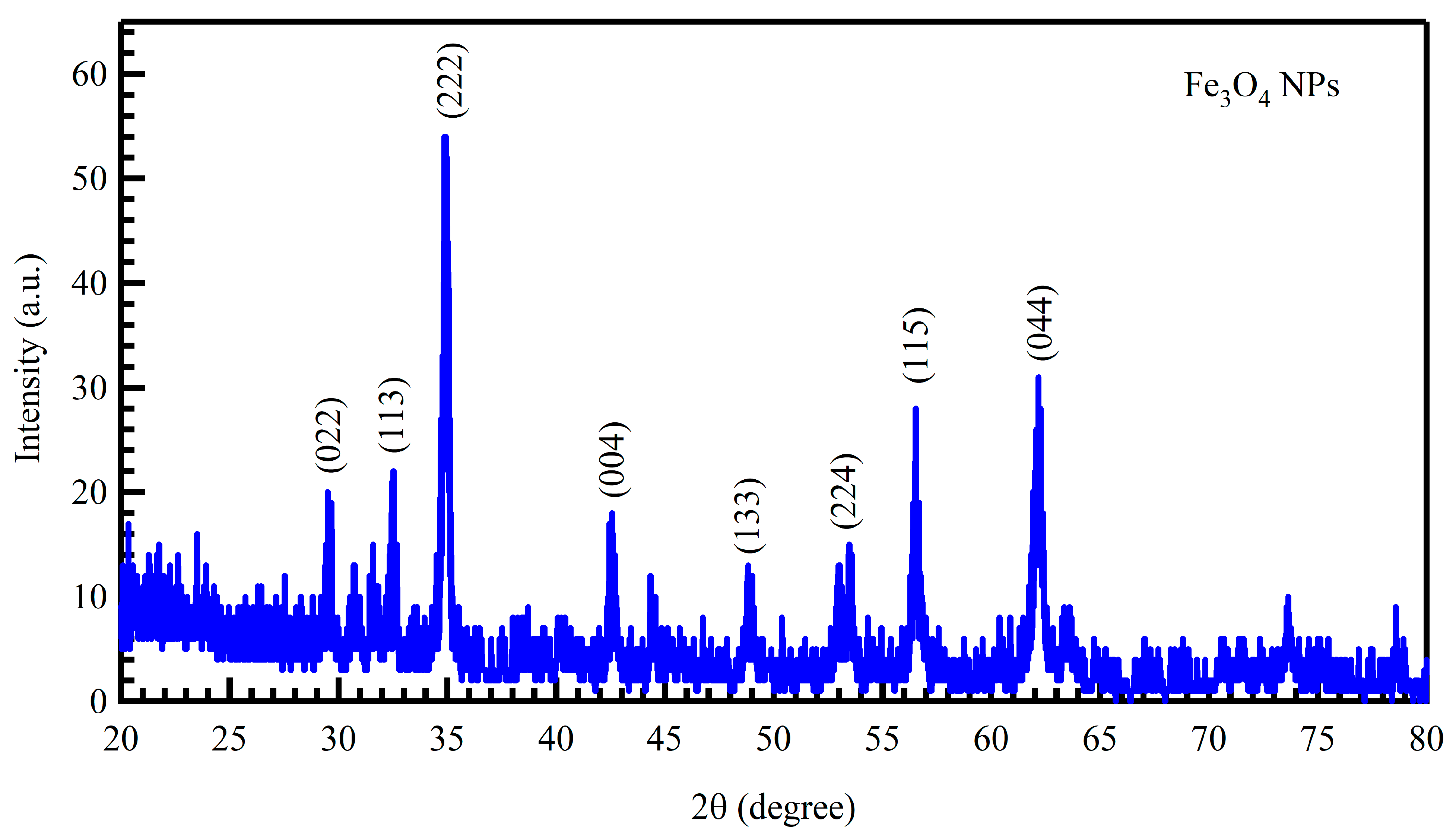

3.3. X-ray Diffraction

3.4. Polyphenol Profile of Fumaria officinalis L. (Papaveraceae) Plant

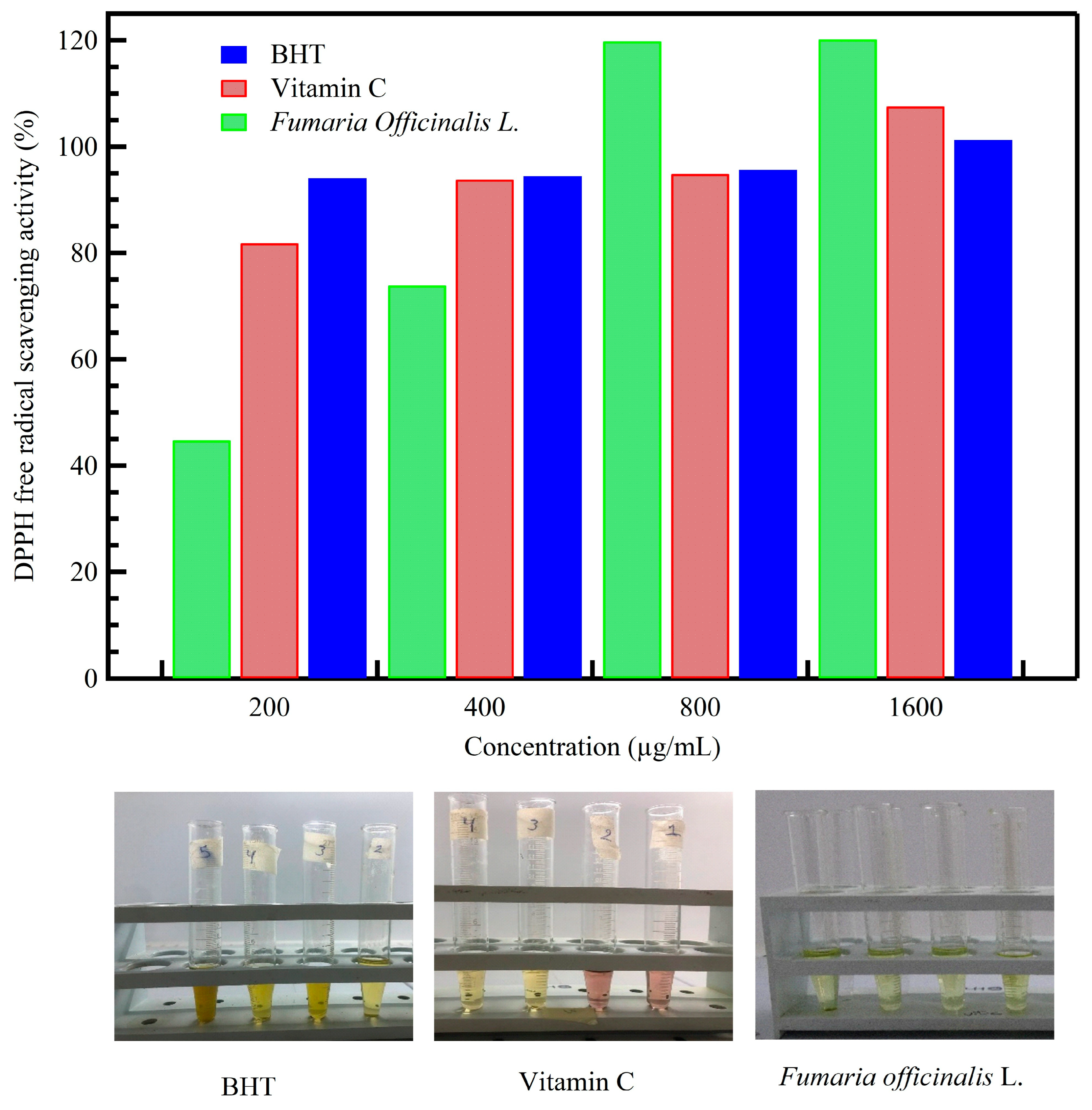

3.5. Antioxidant Activity Fumaria officinalis L. (Papaveraceae) Plant Extract

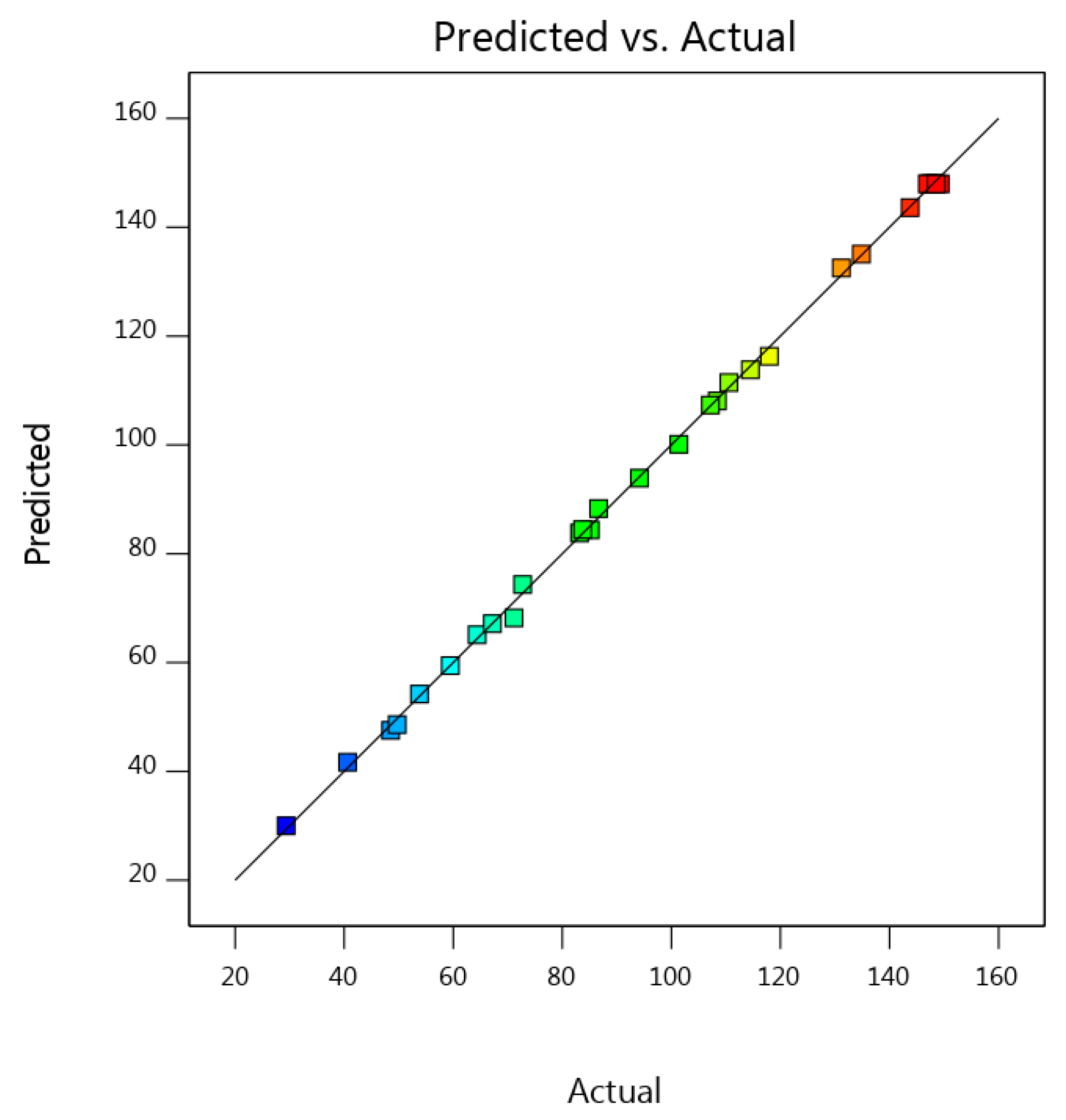

3.6. Central Composite Design

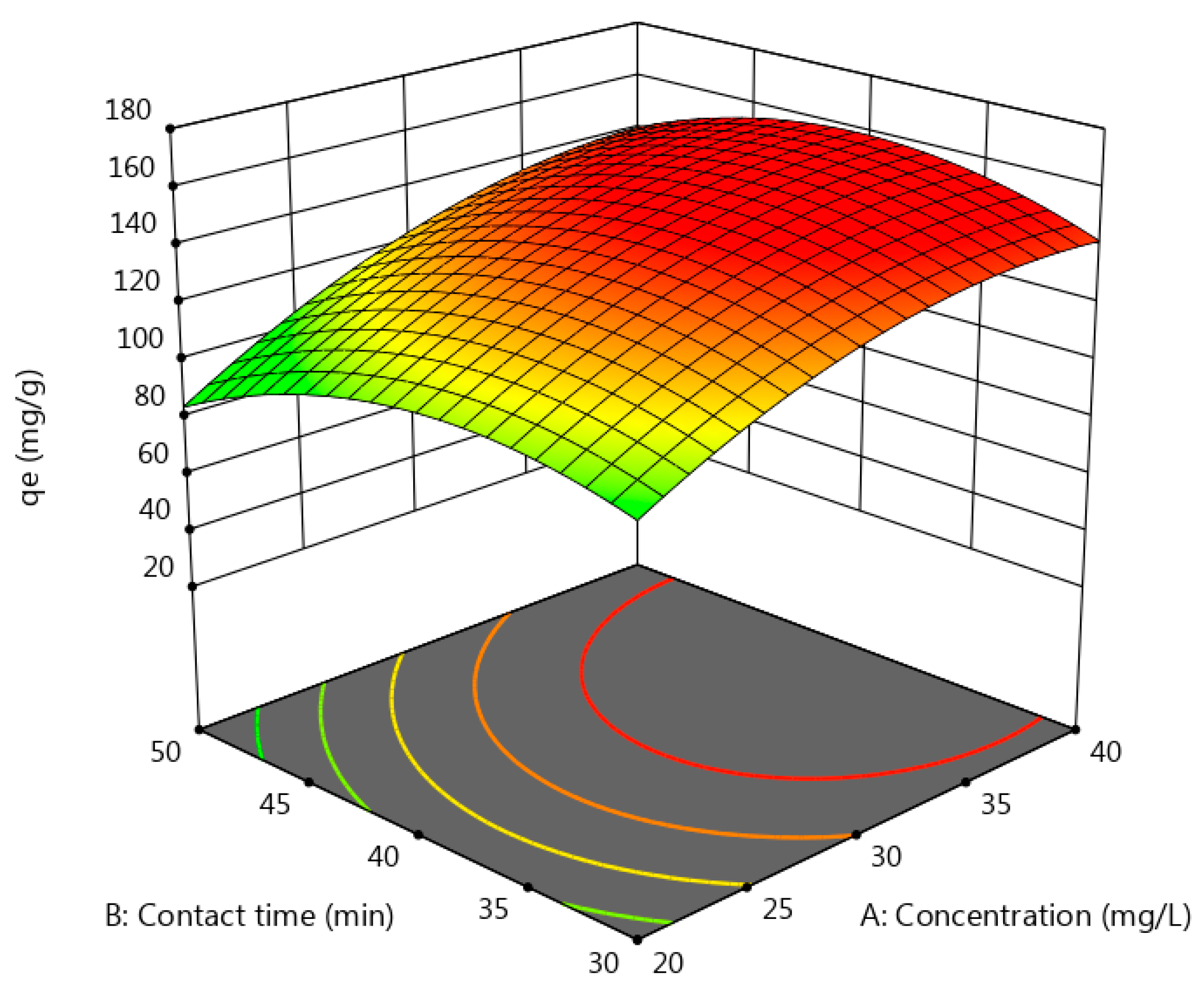

3.7. Effect of Initial Concentration

3.8. Effect of Contact Time

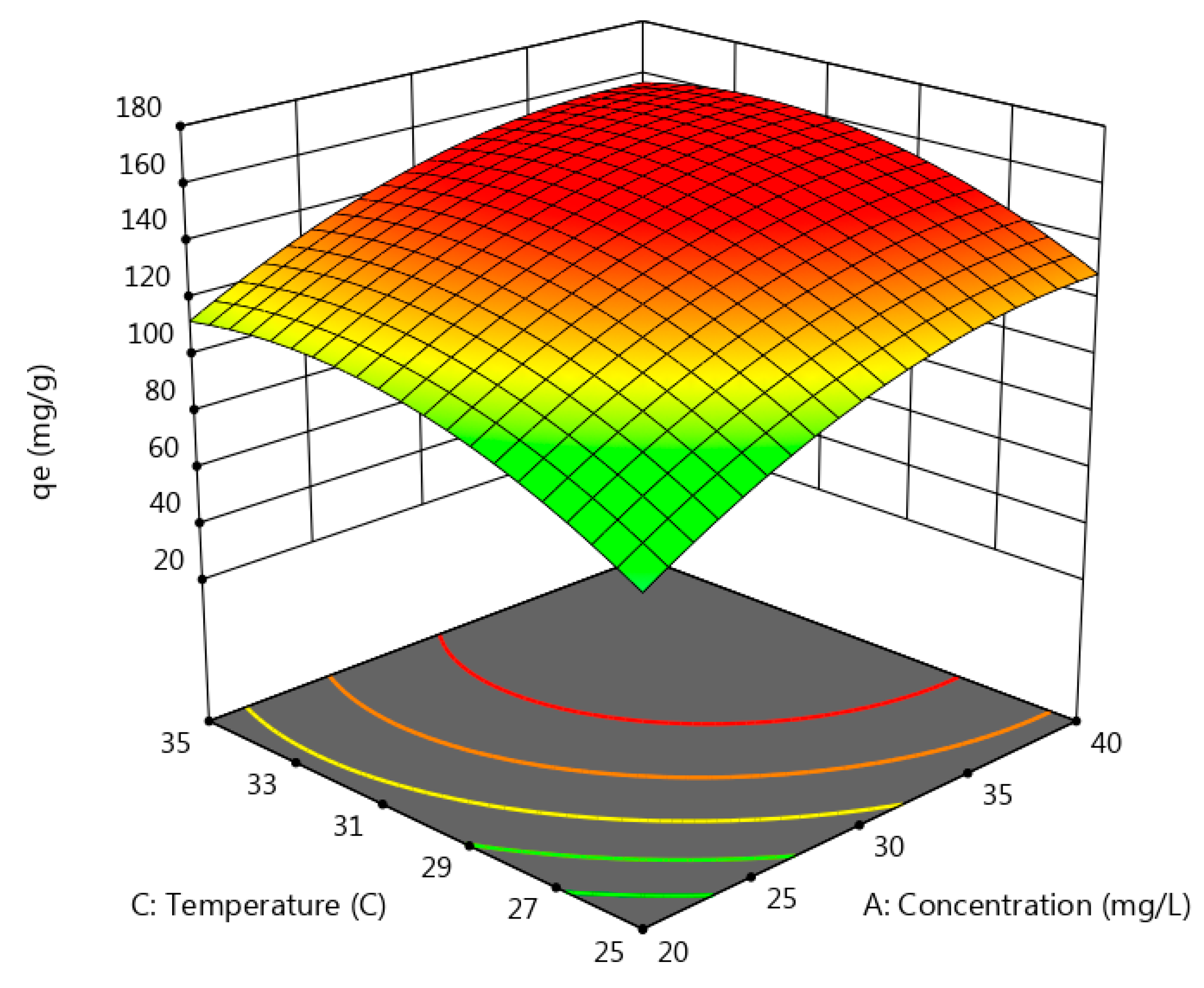

3.9. Effect of Temperature

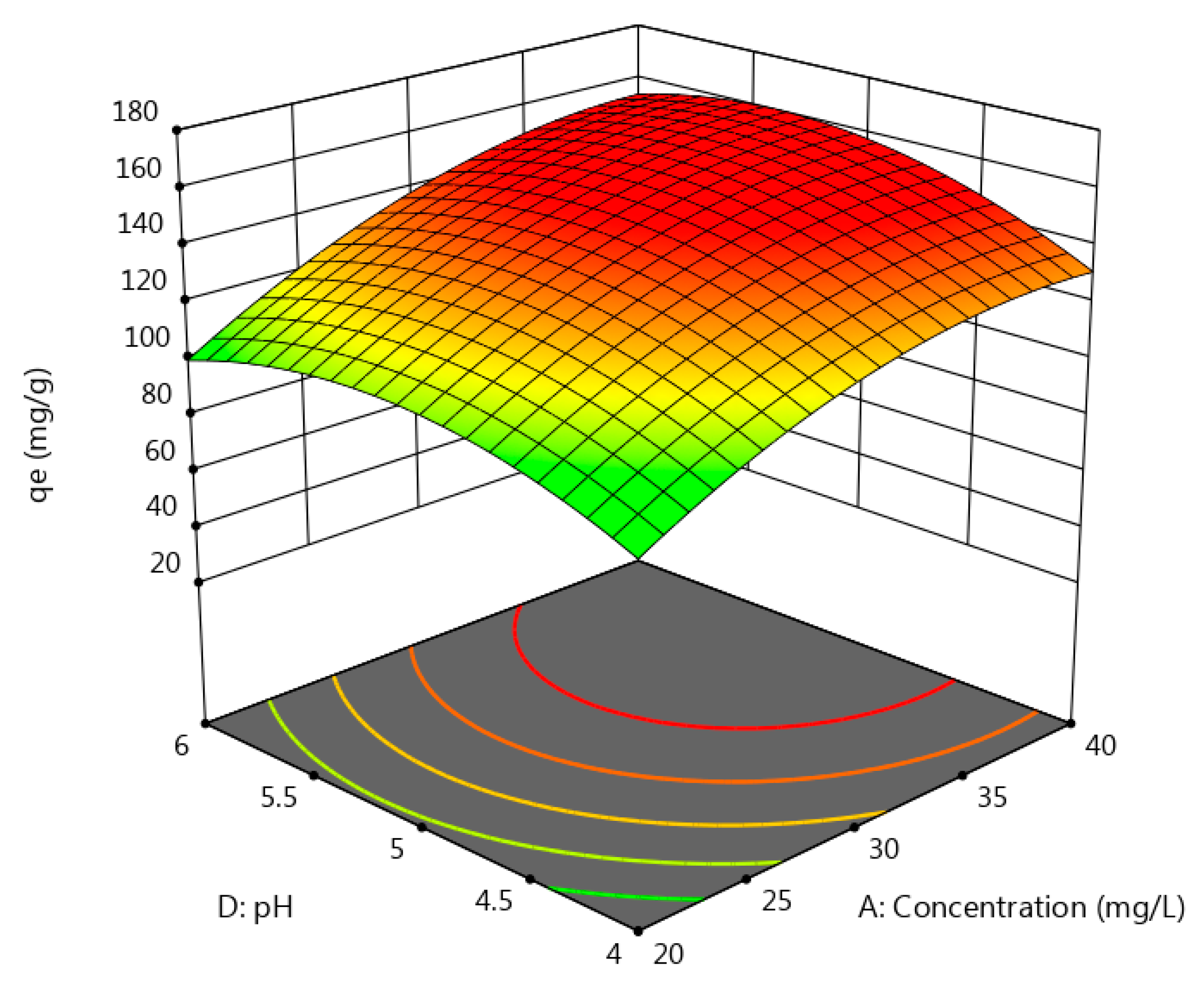

3.10. Effect of pH

3.11. Optimization Conditions Using Desirability Function

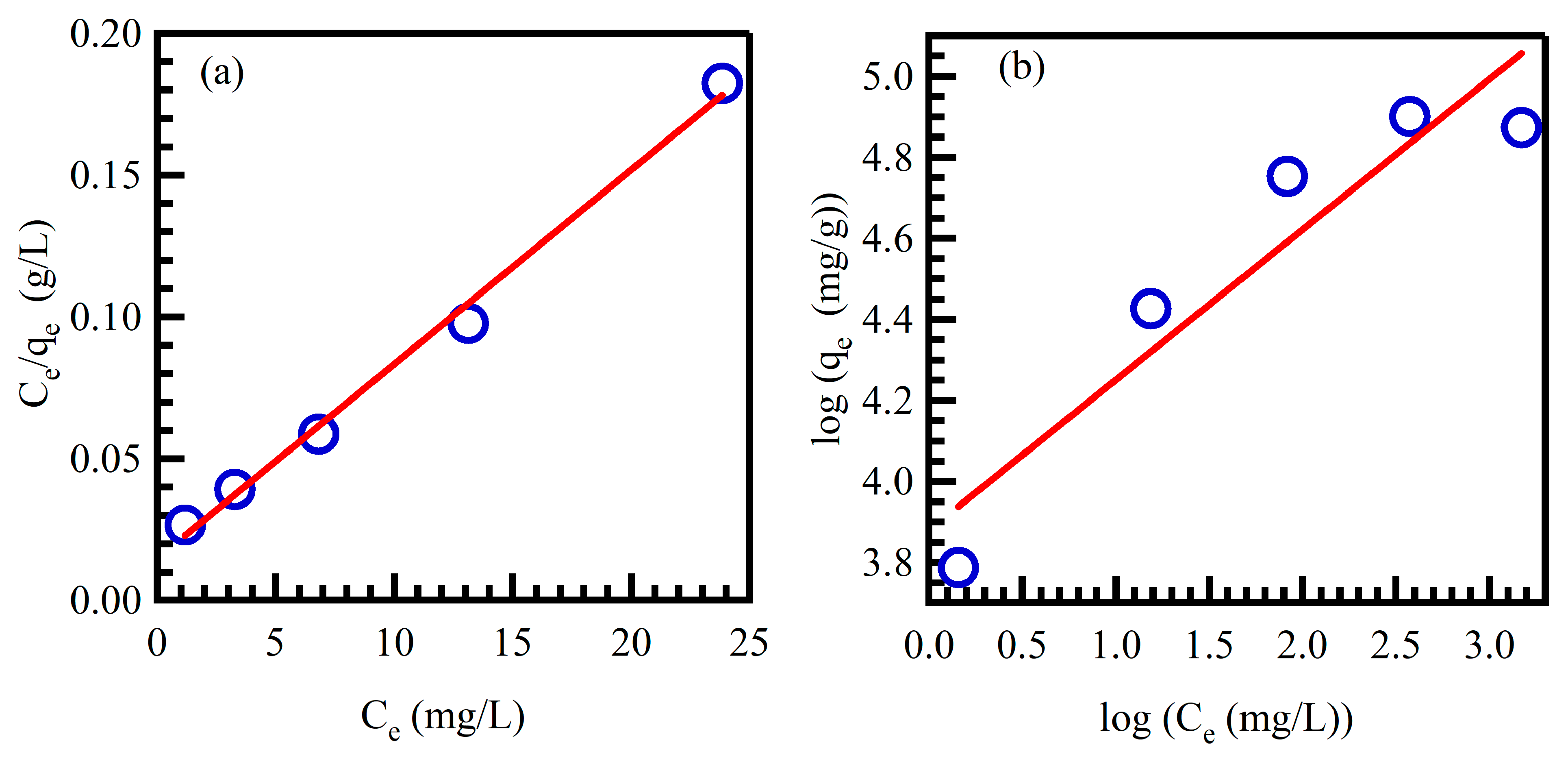

3.12. Adsorption Isotherms

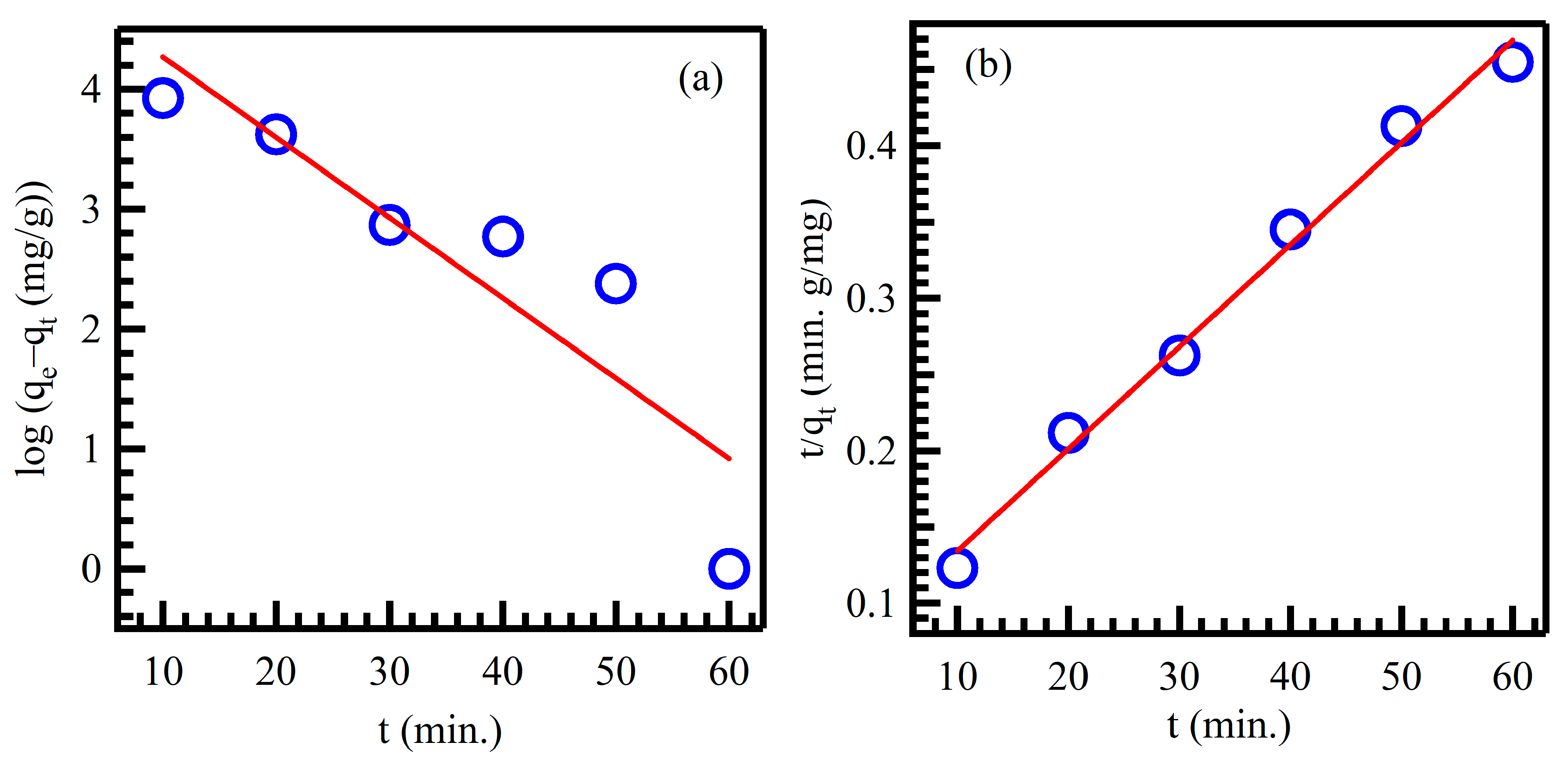

3.13. Adsorption Kinetics

3.14. Adsorption Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, L.; Zeng, Y.; Cheng, Z. Removal of heavy metal ions using chitosan and modified chitosan: A review. J. Mol. Liq. 2016, 214, 175–191. [Google Scholar] [CrossRef]

- Essa, W.K.; Yasin, S.A.; Abdullah, A.H.; Thalji, M.R.; Saeed, I.A.; Assiri, M.A.; Chong, K.F.; Ali, G.A.M. Taguchi L25 (54) Approach for Methylene Blue Removal by Polyethylene Terephthalate Nanofiber-Multi-Walled Carbon Nanotube Composite. Water 2022, 14, 1242. [Google Scholar] [CrossRef]

- Zhu, S.; Khan, M.A.; Wang, F.; Bano, Z.; Xia, M. Exploration of adsorption mechanism of 2-phosphonobutane-1,2,4-tricarboxylic acid onto kaolinite and montmorillonite via batch experiment and theoretical studies. J. Hazard. Mater. 2021, 403, 123810. [Google Scholar] [CrossRef]

- Carolin, C.F.; Kumar, P.S.; Saravanan, A.; Joshiba, G.J.; Naushad, M. Efficient techniques for the removal of toxic heavy metals from aquatic environment: A review. J. Environ. Chem. Eng. 2017, 5, 2782–2799. [Google Scholar] [CrossRef]

- Lee, S.P.; Ali, G.A.M.; Algarni, H.; Chong, K.F. Flake size-dependent adsorption of graphene oxide aerogel. J. Mol. Liq. 2019, 277, 175–180. [Google Scholar] [CrossRef]

- Mao, S.; Shen, T.; Han, T.; Ding, F.; Zhao, Q.; Gao, M. Adsorption and co-adsorption of chlorophenols and Cr(VI) by functional organo-vermiculite: Experiment and theoretical calculation. Sep. Purif. Technol. 2021, 277, 119638. [Google Scholar] [CrossRef]

- Sharma, S.K. Heavy Metals in Water: Presence, Removal and Safety; Royal Society of Chemistry: London, UK, 2014. [Google Scholar]

- Shayegan, H.; Ali, G.A.M.; Safarifard, V. Amide-Functionalized Metal–Organic Framework for High Efficiency and Fast Removal of Pb(II) from Aqueous Solution. J. Inorg. Organomet. Polym. Mater. 2020, 30, 3170–3178. [Google Scholar] [CrossRef]

- Acharya, J.; Sahu, J.; Mohanty, C.; Meikap, B. Removal of lead (II) from wastewater by activated carbon developed from Tamarind wood by zinc chloride activation. Chem. Eng. J. 2009, 149, 249–262. [Google Scholar] [CrossRef]

- Sharma, S.K.; Sanghi, R. Advances in Water Treatment and Pollution Prevention; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Ethiraj, A.S.; Rhen, D.S.; Soldatov, A.V.; Ali, G.A.M.; Bakr, Z.H. Efficient and recyclable Cu incorporated TiO2 nanoparticle catalyst for organic dye photodegradation. Int. J. Thin Film Sci. Technol. 2021, 10, 169–182. [Google Scholar]

- Li, P.; Zhang, H.; Xia, M.; Wang, F.; Zhu, S.; Lei, W. The synergistic effect and microscopic mechanism of co-adsorption of three emerging contaminants and copper ion on gemini surfactant modified montmorillonite. Ecotoxicol. Environ. Saf. 2019, 184, 109610. [Google Scholar] [CrossRef]

- Yew, Y.P.; Shameli, K.; Miyake, M.; Khairudin, N.B.B.A.; Mohamad, S.E.B.; Naiki, T.; Lee, K.X. Green biosynthesis of superparamagnetic magnetite Fe3O4 nanoparticles and biomedical applications in targeted anticancer drug delivery system: A review. Arab. J. Chem. 2020, 13, 2287–2308. [Google Scholar] [CrossRef]

- Golabiazar, R.; Omar, Z.A.; Ahmad, R.N.; Hasan, S.A.; Sajadi, S.M. Synthesis and characterization of antibacterial magnetite-activated carbon nanoparticles. J. Chem. Res. 2020, 44, 80–87. [Google Scholar] [CrossRef]

- Elshazly, E.H.; Mohamed, A.K.S.H.; Aboelmagd, H.A.; Gouda, G.A.; Abdallah, M.H.; Ewais, E.A.; Assiri, M.A.; Ali, G.A.M. Phytotoxicity and Antimicrobial Activity of Green Synthesized Silver Nanoparticles Using Nigella sativa Seeds on Wheat Seedlings. J. Chem. 2022, 2022, 9609559. [Google Scholar] [CrossRef]

- Lukman, A.I.; Gong, B.; Marjo, C.E.; Roessner, U.; Harris, A.T. Facile synthesis, stabilization, and anti-bacterial performance of discrete Ag nanoparticles using Medicago sativa seed exudates. J. Colloid Interface Sci. 2011, 353, 433–444. [Google Scholar] [CrossRef] [PubMed]

- Padil, V.V.T.; Černík, M. Green synthesis of copper oxide nanoparticles using gum karaya as a biotemplate and their antibacterial application. Int. J. Nanomed. 2013, 8, 889–898. [Google Scholar]

- Salam, H.A.; Rajiv, P.; Kamaraj, M.; Jagadeeswaran, P.; Gunalan, S.; Sivaraj, R. Plants: Green route for nanoparticle synthesis. Int. Res. J. Biol. Sci. 2012, 1, 85–90. [Google Scholar]

- Shameli, K.; Ahmad, M.B.; Zamanian, A.; Sangpour, P.; Shabanzadeh, P.; Abdollahi, Y.; Zargar, M. Green biosynthesis of silver nanoparticles using Curcuma longa tuber powder. Int. J. Nanomed. 2012, 7, 5603–5610. [Google Scholar] [CrossRef]

- Bouafia, A.; Laouini, S.E.; Tedjani, M.L.; Ali, G.A.M.; Barhoum, A. Green biosynthesis and physicochemical characterization of Fe3O4 nanoparticles using Punica granatum L. fruit peel extract for optoelectronic applications. Text. Res. J. 2022, 92, 2685–2696. [Google Scholar] [CrossRef]

- Laouini, S.E.; Bouafia, A.; Soldatov, A.V.; Algarni, H.; Tedjani, M.L.; Ali, G.A.M.; Barhoum, A. Green Synthesized of Ag/Ag2O Nanoparticles Using Aqueous Leaves Extracts of Phoenix dactylifera L. and Their Azo Dye Photodegradation. Membranes 2021, 11, 468. [Google Scholar] [CrossRef]

- Prasad, C.; Karlapudi, S.; Venkateswarlu, P.; Bahadur, I.; Kumar, S. Green arbitrated synthesis of Fe3O4 magnetic nanoparticles with nanorod structure from pomegranate leaves and Congo red dye degradation studies for water treatment. J. Mol. Liq. 2017, 240, 322–328. [Google Scholar] [CrossRef]

- Mahdavi, M.; Namvar, F.; Ahmad, M.B.; Mohamad, R. Green biosynthesis and characterization of magnetic iron oxide (Fe3O4) nanoparticles using seaweed (Sargassum muticum) aqueous extract. Molecules 2013, 18, 5954–5964. [Google Scholar] [CrossRef]

- Revati, K.; Pandey, B. Microbial synthesis of iron-based nanomaterials-A review. Bull. Mater. Sci. 2011, 34, 191–198. [Google Scholar]

- Guo, J.; Wang, R.; Tjiu, W.W.; Pan, J.; Liu, T. Synthesis of Fe nanoparticles@ graphene composites for environmental applications. J. Hazard. Mater. 2012, 225, 63–73. [Google Scholar] [CrossRef] [PubMed]

- Habeeb, O.A.; Ramesh, K.; Ali, G.A.M.; Yunus, R.M. Isothermal modelling based experimental study of dissolved hydrogen sulfide adsorption from waste water using eggshell based activated carbon. Malays. J. Anal. Sci. 2017, 21, 334–345. [Google Scholar]

- Habeeb, O.A.; Ramesh, K.; Ali, G.A.M.; Yunus, R.M. Application of response surface methodology for optimization of palm kernel shell activated carbon preparation factors for removal of H2S from industrial wastewater. J. Teknol. 2017, 79, 1–10. [Google Scholar] [CrossRef]

- Habeeb, O.A.; Ramesh, K.; Ali, G.A.M.; Yunus, R.M. Experimental design technique on removal of hydrogen sulfide using CaO-eggshells dispersed onto palm kernel shell activated carbon: Experiment, optimization, equilibrium and kinetic studies. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2017, 32, 305–320. [Google Scholar]

- Habeeb, O.A.; Ramesh, K.; Ali, G.A.M.; Yunus, R.M.; Olalere, O.A. Kinetic, Isotherm and Equilibrium Study of Adsorption of Hydrogen Sulfide From Wastewater Using Modified Eggshells. IIUM Eng. J. 2017, 18, 13–25. [Google Scholar] [CrossRef]

- Habeeb, O.A.; Ramesh, K.; Ali, G.A.M.; Yunus, R.M. Low-cost and eco-friendly activated carbon from modified palm kernel shell for hydrogen sulfide removal from wastewater: Adsorption and kinetic studies. Desalin. Water Treat. 2017, 84, 205–214. [Google Scholar] [CrossRef]

- Nwabueze, T.U. Basic steps in adapting response surface methodology as mathematical modelling for bioprocess optimisation in the food systems. Int. J. Food Sci. Technol. 2010, 45, 1768–1776. [Google Scholar] [CrossRef]

- Fazeli-Nasab, B.; Ghafari, M.; Jahantigh, M.; Beigomi, Z.; Saeidi, S. Evaluation of Phenolic and Flavonoid Content, Alkaloids, Antioxidant Capacity and Antibacterial Properties of Methanolic Extract of Zahak Native Medicinal Plants Against Seven Pathogens. J. Med. Plants By-Prod. 2023, in press. [Google Scholar]

- Rakotondramasy-Rabesiaka, L.; Havet, J.L.; Porte, C.; Fauduet, H. Solid-liquid extraction of protopine from Fumaria officinalis L.-Kinetic modelling of influential parameters. Ind. Crops Prod. 2009, 29, 516–523. [Google Scholar] [CrossRef]

- Păltinean, R.; Mocan, A.; Vlase, L.; Gheldiu, A.-M.; Crișan, G.; Ielciu, I.; Voștinaru, O.; Crișan, O. Evaluation of polyphenolic content, antioxidant and diuretic activities of six Fumaria species. Molecules 2017, 22, 639. [Google Scholar] [CrossRef] [PubMed]

- Bibi, N.; Shah, M.H.; Khan, N.; Al-Hashimi, A.; Elshikh, M.S.; Iqbal, A.; Ahmad, S.; Abbasi, A.M. Variations in total phenolic, total flavonoid contents, and free radicals’ scavenging potential of onion varieties planted under diverse environmental conditions. Plants 2022, 11, 950. [Google Scholar] [CrossRef]

- Baliyan, S.; Mukherjee, R.; Priyadarshini, A.; Vibhuti, A.; Gupta, A.; Pandey, R.P.; Chang, C.M. Determination of Antioxidants by DPPH Radical Scavenging Activity and Quantitative Phytochemical Analysis of Ficus religiosa. Molecules 2022, 27, 1326. [Google Scholar] [CrossRef]

- Rassem, H.H.A.; Nour, A.H.; Ali, G.A.M.; Masood, N.; Al-Bagawi, A.H.; Alanazi, T.Y.A.; Magam, S.; Assiri, M.A. Essential Oil from Hibiscus Flowers through Advanced Microwave-Assisted Hydrodistillation and Conventional Hydrodistillation. J. Chem. 2022, 2022, 2000237. [Google Scholar] [CrossRef]

- Haji, A.A.; Mohammed, N.M.S. Optimization of Arsenic Adsorption onto Activated Carbon of Potato Peel Using Response Surface Methodology. Sci. J. Univ. Zakho 2019, 7, 37–44. [Google Scholar]

- Van Thuan, T.; Quynh, B.T.P.; Nguyen, T.D.; Bach, L.G. Response surface methodology approach for optimization of Cu2+, Ni2+ and Pb2+ adsorption using KOH-activated carbon from banana peel. Surf. Interfaces 2017, 6, 209–217. [Google Scholar] [CrossRef]

- Davarnejad, R.; Panahi, P. Cu (II) removal from aqueous wastewaters by adsorption on the modified Henna with Fe3O4 nanoparticles using response surface methodology. Sep. Purif. Technol. 2016, 158, 286–292. [Google Scholar] [CrossRef]

- Samadi, N.; Hasanzadeh, R.; Rasad, M. Adsorption isotherms, kinetic, and desorption studies on removal of toxic metal ions from aqueous solutions by polymeric adsorbent. J. Appl. Polym. Sci. 2015, 132, 41642. [Google Scholar] [CrossRef]

- Chaudhry, S.A.; Zaidi, Z.; Siddiqui, S.I. Isotherm, kinetic and thermodynamics of arsenic adsorption onto Iron-Zirconium Binary Oxide-Coated Sand (IZBOCS): Modelling and process optimization. J. Mol. Liq. 2017, 229, 230–240. [Google Scholar] [CrossRef]

- Mashhadi, S.; Sohrabi, R.; Javadian, H.; Ghasemi, M.; Tyagi, I.; Agarwal, S.; Gupta, V.K. Rapid removal of Hg (II) from aqueous solution by rice straw activated carbon prepared by microwave-assisted H2SO4 activation: Kinetic, isotherm and thermodynamic studies. J. Mol. Liq. 2016, 215, 144–153. [Google Scholar] [CrossRef]

- Patterson, A. The Scherrer formula for X-ray particle size determination. Phys. Rev. 1939, 56, 978. [Google Scholar] [CrossRef]

- Tavan, M.; Azizi, A.; Sarikhani, H.; Mirjalili, M.H.; Rigano, M.M. Phenolics diversity among wild populations of Salvia multicaulis: As a precious source for antimicrobial and antioxidant applications. Nat. Prod. Res. 2022, 36, 1332–1336. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, S.V.; Bozorgian, A.; Mokhtari, N.; Gabris, M.A.; Nodeh, H.R.; Ibrahim, W.A.W. A novel cyanopropylsilane-functionalized titanium oxide magnetic nanoparticle for the adsorption of nickel and lead ions from industrial wastewater: Equilibrium, kinetic and thermodynamic studies. Microchem. J. 2019, 145, 914–920. [Google Scholar] [CrossRef]

- Park, D.; Yun, Y.-S.; Park, J.M. The past, present, and future trends of biosorption. Biotechnol. Bioprocess Eng. 2010, 15, 86–102. [Google Scholar] [CrossRef]

- Shahabuddin, S.; Tashakori, C.; Kamboh, M.A.; Korrani, Z.S.; Saidur, R.; Nodeh, H.R.; Bidhendi, M.E. Kinetic and equilibrium adsorption of lead from water using magnetic metformin-substituted SBA-15. Environ. Sci. Water Res. Technol. 2018, 4, 549–558. [Google Scholar] [CrossRef]

- Lung, I.; Stan, M.; Opris, O.; Soran, M.-L.; Senila, M.; Stefan, M. Removal of Lead(II), Cadmium(II), and Arsenic(III) from Aqueous Solution Using Magnetite Nanoparticles Prepared by Green Synthesis with Box–Behnken Design. Anal. Lett. 2018, 51, 2519–2531. [Google Scholar] [CrossRef]

- Venkateswarlu, S.; Kumar, B.N.; Prathima, B.; SubbaRao, Y.; Jyothi, N.V.V. A novel green synthesis of Fe3O4 magnetic nanorods using Punica Granatum rind extract and its application for removal of Pb(II) from aqueous environment. Arab. J. Chem. 2019, 12, 588–596. [Google Scholar] [CrossRef]

- Lingamdinne, L.P.; Koduru, J.R.; Rao Karri, R. Green synthesis of iron oxide nanoparticles for lead removal from aqueous solutions. Key Eng. Mater. 2019, 805, 122–127. [Google Scholar] [CrossRef]

- Ali, A.A.; Ahmed, I.S.; Elfiky, E.M. Auto-combustion Synthesis and Characterization of Iron Oxide Nanoparticles (α-Fe2O3) for Removal of Lead Ions from Aqueous Solution. J. Inorg. Organomet. Polym. Mater. 2021, 31, 384–396. [Google Scholar] [CrossRef]

- Taqui, M.; Das, S.; Kamilya, T.; Mondal, S.; Chaudhuri, S. Green synthesis of iron-oxide nanoparticles using scrap iron as precursor for the removal of Pb (II) from aqueous medium. J. Environ. Eng. Landsc. Manag. 2022, 30, 308–320. [Google Scholar] [CrossRef]

- Hu, R.; Wang, X.; Dai, S.; Shao, D.; Hayat, T.; Alsaedi, A. Application of graphitic carbon nitride for the removal of Pb(II) and aniline from aqueous solutions. Chem. Eng. J. 2015, 260, 469–477. [Google Scholar] [CrossRef]

- Tan, Y.; Chen, M.; Hao, Y. High efficient removal of Pb (II) by amino-functionalized Fe3O4 magnetic nano-particles. Chem. Eng. J. 2012, 191, 104–111. [Google Scholar] [CrossRef]

- Zhao, J.; Niu, Y.; Ren, B.; Chen, H.; Zhang, S.; Jin, J.; Zhang, Y. Synthesis of Schiff base functionalized superparamagnetic Fe3O4 composites for effective removal of Pb(II) and Cd(II) from aqueous solution. Chem. Eng. J. 2018, 347, 574–584. [Google Scholar] [CrossRef]

- Xie, Y.; Yuan, X.; Wu, Z.; Zeng, G.; Jiang, L.; Peng, X.; Li, H. Adsorption behavior and mechanism of Mg/Fe layered double hydroxide with Fe3O4-carbon spheres on the removal of Pb(II) and Cu(II). J. Colloid Interface Sci. 2019, 536, 440–455. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Yuvaraja, G.; Liu, C.; Kong, L.; Guo, K.; Reddy, G.M.; Zyryanov, G.V. Removal of Pb(II) ions from aqueous media using epichlorohydrin crosslinked chitosan Schiff’s base@Fe3O4 (ECCSB@Fe3O4). Int. J. Biol. Macromol. 2018, 117, 1305–1313. [Google Scholar] [CrossRef]

- Li, J.; Hu, Z.; Chen, Y.; Deng, R. Removal of Pb(II) by Adsorption of HCO–(Fe3O4)x Composite Adsorbent: Efficacy and Mechanism. Water 2023, 15, 1857. [Google Scholar] [CrossRef]

- Giraldo, L.; Erto, A.; Moreno-Piraján, J. Magnetite nanoparticles for removal of heavy metals from aqueous solutions: Synthesis and characterization. Adsorption 2013, 19, 465–474. [Google Scholar] [CrossRef]

| Sample | Total Phenol Content (mg GAE/g dry wt) | Total Flavonoid Content (mg QE/g dry wt) |

|---|---|---|

| Fumaria officinalis L. | 596.55 ± 0.05 | 18.25 ± 0.05 |

| Concentration μg/mL | RSA (%) | ||

|---|---|---|---|

| BHT | Vitamin C | Fumaria officinalis L. | |

| 200 | 81.800 ± 0.05 | 94.040 ± 0.05 | 44.735 ± 0.05 |

| 400 | 93.766 ± 0.05 | 94.403 ± 0.05 | 73.861 ± 0.05 |

| 600 | 94.840 ± 0.05 | 95.581 ± 0.05 | 119.791 ± 0.05 |

| 800 | 107.540 ± 0.05 | 101.250 ± 0.05 | 120.164 ± 0.05 |

| IC50 | 3.182 ± 0.05 | 18.440 ± 0.05 | 1.136 ± 0.05 |

| Factor | Name | Units | −α | −1 | 0 | 1 | +α |

|---|---|---|---|---|---|---|---|

| A | Concentration | mg/L | 10 | 20 | 30 | 40 | 50 |

| B | Contact time | min | 20 | 30 | 40 | 50 | 60 |

| C | Temperature | °C | 20 | 25 | 30 | 35 | 40 |

| D | pH | 3 | 4 | 5 | 6 | 7 |

| No. of Run | Concentration | Contact Time | Temperature | pH | Actual (qe) |

|---|---|---|---|---|---|

| (mg/L) | (min) | (°C) | (mg/g) | ||

| 1 | 20 | 30 | 25 | 4 | 48.520 |

| 2 | 20 | 30 | 25 | 6 | 59.460 |

| 3 | 20 | 50 | 25 | 4 | 29.350 |

| 4 | 40 | 30 | 25 | 4 | 85.120 |

| 5 | 40 | 30 | 25 | 6 | 108.41 |

| 6 | 40 | 50 | 25 | 4 | 83.150 |

| 7 | 20 | 30 | 35 | 4 | 83.720 |

| 8 | 20 | 50 | 25 | 6 | 40.630 |

| 9 | 20 | 30 | 35 | 6 | 94.150 |

| 10 | 40 | 30 | 35 | 4 | 114.48 |

| 11 | 20 | 50 | 35 | 4 | 64.380 |

| 12 | 40 | 50 | 35 | 4 | 110.54 |

| 13 | 30 | 40 | 30 | 5 | 148.18 |

| 14 | 40 | 50 | 25 | 6 | 107.16 |

| 15 | 40 | 50 | 35 | 6 | 131.16 |

| 16 | 40 | 30 | 35 | 6 | 134.84 |

| 17 | 20 | 50 | 35 | 6 | 72.730 |

| 18 | 30 | 40 | 30 | 5 | 146.93 |

| 19 | 10 | 40 | 30 | 5 | 49.720 |

| 20 | 50 | 40 | 30 | 5 | 143.78 |

| 21 | 30 | 40 | 30 | 5 | 147.67 |

| 22 | 30 | 20 | 30 | 5 | 86.660 |

| 23 | 30 | 60 | 30 | 5 | 71.150 |

| 24 | 30 | 40 | 30 | 5 | 149.31 |

| 25 | 30 | 40 | 20 | 5 | 53.810 |

| 26 | 30 | 40 | 40 | 5 | 117.96 |

| 27 | 30 | 40 | 30 | 5 | 147.24 |

| 28 | 30 | 40 | 30 | 3 | 67.180 |

| 29 | 30 | 40 | 30 | 7 | 101.37 |

| 30 | 30 | 40 | 30 | 5 | 148.56 |

| Source | SS | Df | MS | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 40,937.8 | 14 | 2924.1 | 1386.1 | <0.0001 | significant |

| A-Concentration | 13,539.4 | 1 | 13,539 | 6418.1 | <0.0001 | |

| B-Contact time | 606.22 | 1 | 606.22 | 287.37 | <0.0001 | |

| C-Temperature | 5781.51 | 1 | 5781.5 | 2740.6 | <0.0001 | |

| D-pH | 1627.89 | 1 | 1627.9 | 771.67 | <0.0001 | |

| AB | 288.32 | 1 | 288.32 | 136.67 | <0.0001 | |

| AC | 55.65 | 1 | 55.65 | 26.38 | 0.0001 | |

| AD | 139.71 | 1 | 139.71 | 66.23 | <0.0001 | |

| BC | 3.2 | 1 | 3.2 | 1.52 | 0.2368 | |

| BD | 0.0361 | 1 | 0.0361 | 0.0171 | 0.8977 | |

| CD | 5.95 | 1 | 5.95 | 2.82 | 0.1137 | |

| A2 | 4613.32 | 1 | 4613.3 | 2186.9 | <0.0001 | |

| B2 | 8333.13 | 1 | 8333.1 | 3950.2 | <0.0001 | |

| C2 | 6748.14 | 1 | 6748.1 | 3198.8 | <0.0001 | |

| D2 | 7098.91 | 1 | 7098.9 | 3365.1 | <0.0001 | |

| Residual | 31.64 | 15 | 2.11 | |||

| Lack of Fit | 27.75 | 10 | 2.78 | 3.57 | 0.0866 | not significant |

| Pure Error | 3.89 | 5 | 0.7783 | |||

| Cor Total | 40,969.4 | 29 | ||||

| SS = Sum of Squares | MS = Mean Square | |||||

| Metal Ion | Initial Concentration (mg/L) | Temperature (°C) | Contact Time (min) | pH | Adsorption Capacity (mg/g) | Max Adsorption (%) |

|---|---|---|---|---|---|---|

| Pb(II) | 35 | 31 | 35 | 5.5 | 149.3 | 99% |

| Langmuir | Freundlich | |||||

|---|---|---|---|---|---|---|

| qmax | KL | RL | R2 | Kf | 1/n | R2 |

| 147.1 | 0.456 | 0.042 | 0.994 | 48.37 | 0.37 | 0.887 |

| Adsorbate | Characteristics | Removal of Pb(II) | Ref. |

|---|---|---|---|

| Magnetite nanoparticles (Fe3O4) using Fumaria officinalis L. plant extract | Cubic shape with size of 23 nm | 147.1 mg/g (1.79 mmol/g) 99% at pH 5.5 and 25 °C | This work |

| Fe3O4 nanoparticles using Citrus limon aqueous peel extract | Nanoporous structure with a surface area of 137.4 m2/g, and particles size of 8 nm | 9.01 mg/g 98.8% at pH 5.5 and 28 °C | [49] |

| Conventional Fe3O4 nanoparticles | Nanoparticles with a surface area of 89.6 m2/g | 0.16 mg/g 59.4% at pH 5.5 and 28 °C | [49] |

| Fe3O4 magnetic nanorods using Punica Granatum rind extract | Nanorods with average diameter of 40 nm and length above 200 nm | 46.18 mg/g 96.68% at pH 5.0 and 28 °C | [50] |

| Fe3O4 nanoparticles modified with tangerine peel extract | Hexagonal shape with mesoporous nature | 101.20 mg/g 99% at pH 5.0 and 25 °C | [51] |

| Iron Oxide Nanoparticles (hematite, α-Fe2O3) | Aspherical and aspherical-like shaped with a size of 36 nm | 29.93 mg/g 97.5% at pH 5.5 and 25 °C | [52] |

| Magnetic Fe3O4 nanoparticles | Nanoparticles with a size of 31 nm and surface area of 46.856 m2/g | 68.07 mg/g 98% at pH 5.7 and 25 °C | [53] |

| Graphitic carbon nitride | g-C3N4 contains small flat sheets with irregular wrinkles with a surface area of 150.5 m2/g and a pore diameter of 16.39 nm | 65.6 mg/g at pH 5.0 and 25 °C | [54] |

| Amino-functionalized Fe3O4 magnetic nanoparticles | Spherical particles with a size of 50–100 nm and a mean diameter of 78.7 nm | 40.10 mg/g 98% at pH 5.0 and 25 °C | [55] |

| Schiff base functionalized Fe3O4 | Uniform spherical morphology with lattice fringes spacing of 0.297–0.485 nm and surface area of 42.02 m2/g | 0.56 mmol/g 98% at pH 6.0 and 25 °C | [56] |

| Layered double hydroxide loaded with magnetic (Fe3O4) carbon spheres | Small plate-like units with surface area of 4.38 m2/g | 3.66 mmol/g at pH 6.3 and 298 K | [57] |

| Epichlorohydrin crosslinked chitosan Schiff’s base@Fe3O4 | Spherical particles with about 10 and 50 nm in size | 86.20 mg/g 97% at pH 4.0 and 25 °C | [58] |

| First Order Kinetic | Second Order Kinetic | ||||

|---|---|---|---|---|---|

| qe | k1 | R2 | qe | k2 | R2 |

| 139.66 | 0.067 | 0.800 | 149.25 | 0.00067 | 0.990 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haji, A.A.; Abduljabar, R.S.; Yasin, S.A.; Omar, Z.A.; Ahmed, H.A.; Assiri, M.A.; Ali, G.A.M. Green Synthesis of Magnetite Nanoparticles Mediated Fumaria officinalis L. Plant as Sustainable and Renewable Adsorbing Materials. Separations 2023, 10, 518. https://doi.org/10.3390/separations10090518

Haji AA, Abduljabar RS, Yasin SA, Omar ZA, Ahmed HA, Assiri MA, Ali GAM. Green Synthesis of Magnetite Nanoparticles Mediated Fumaria officinalis L. Plant as Sustainable and Renewable Adsorbing Materials. Separations. 2023; 10(9):518. https://doi.org/10.3390/separations10090518

Chicago/Turabian StyleHaji, Akram A., Rihan S. Abduljabar, Suhad A. Yasin, Zagros A. Omar, Hozan A. Ahmed, Mohammed A. Assiri, and Gomaa A. M. Ali. 2023. "Green Synthesis of Magnetite Nanoparticles Mediated Fumaria officinalis L. Plant as Sustainable and Renewable Adsorbing Materials" Separations 10, no. 9: 518. https://doi.org/10.3390/separations10090518

APA StyleHaji, A. A., Abduljabar, R. S., Yasin, S. A., Omar, Z. A., Ahmed, H. A., Assiri, M. A., & Ali, G. A. M. (2023). Green Synthesis of Magnetite Nanoparticles Mediated Fumaria officinalis L. Plant as Sustainable and Renewable Adsorbing Materials. Separations, 10(9), 518. https://doi.org/10.3390/separations10090518