Isotherm, Kinetics, and Adsorption Mechanism Studies of Coal Gasification Coarse Slag as Highly Efficient Phosphate Adsorbents

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Materials

2.3. Characterizations

2.4. Batch Experiments

2.5. Leaching Test

2.6. Column Adsorption Experiments

2.7. Reusability Experiments

3. Results and Discussion

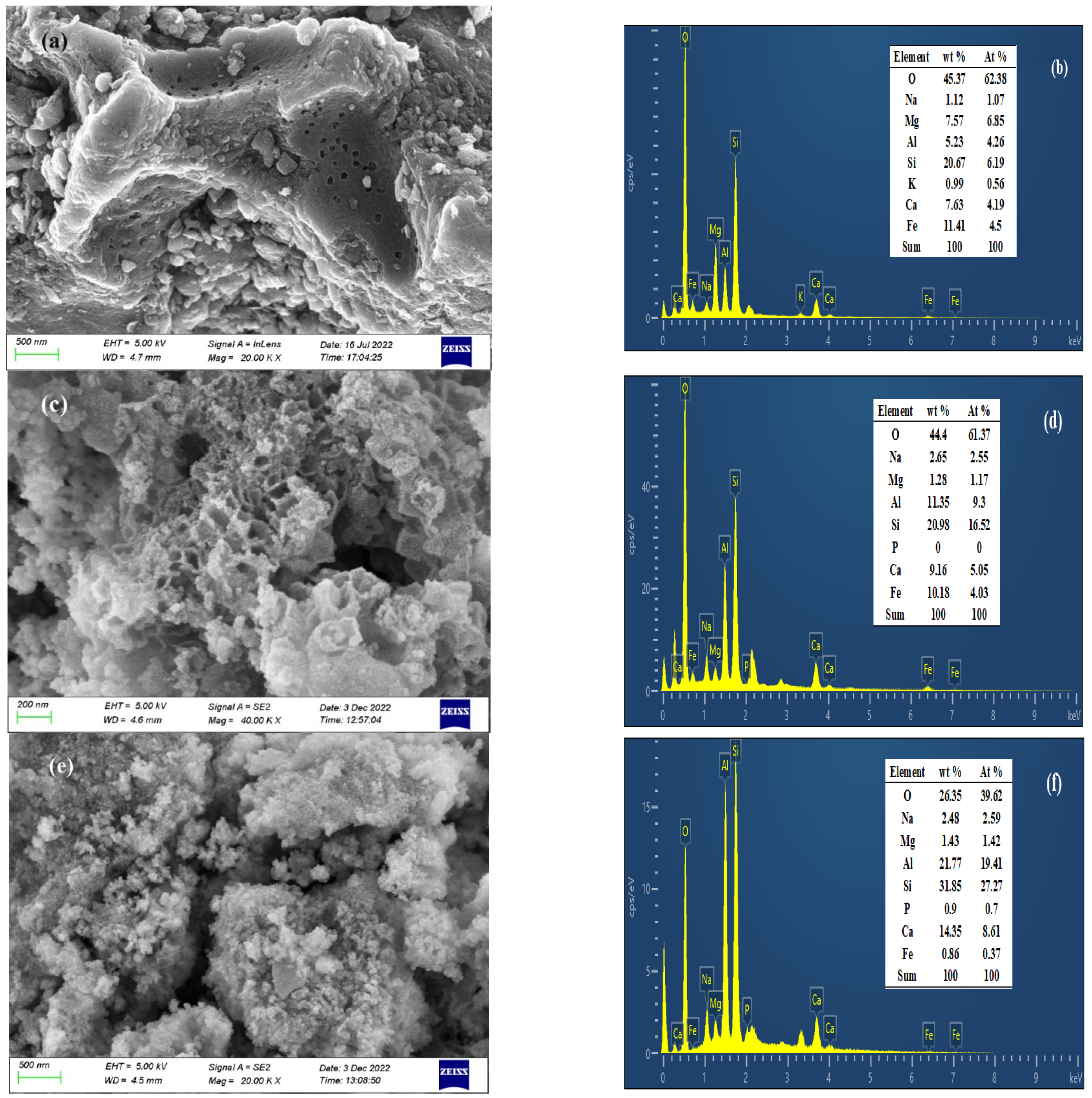

3.1. Characterization

3.2. Phosphate Adsorption

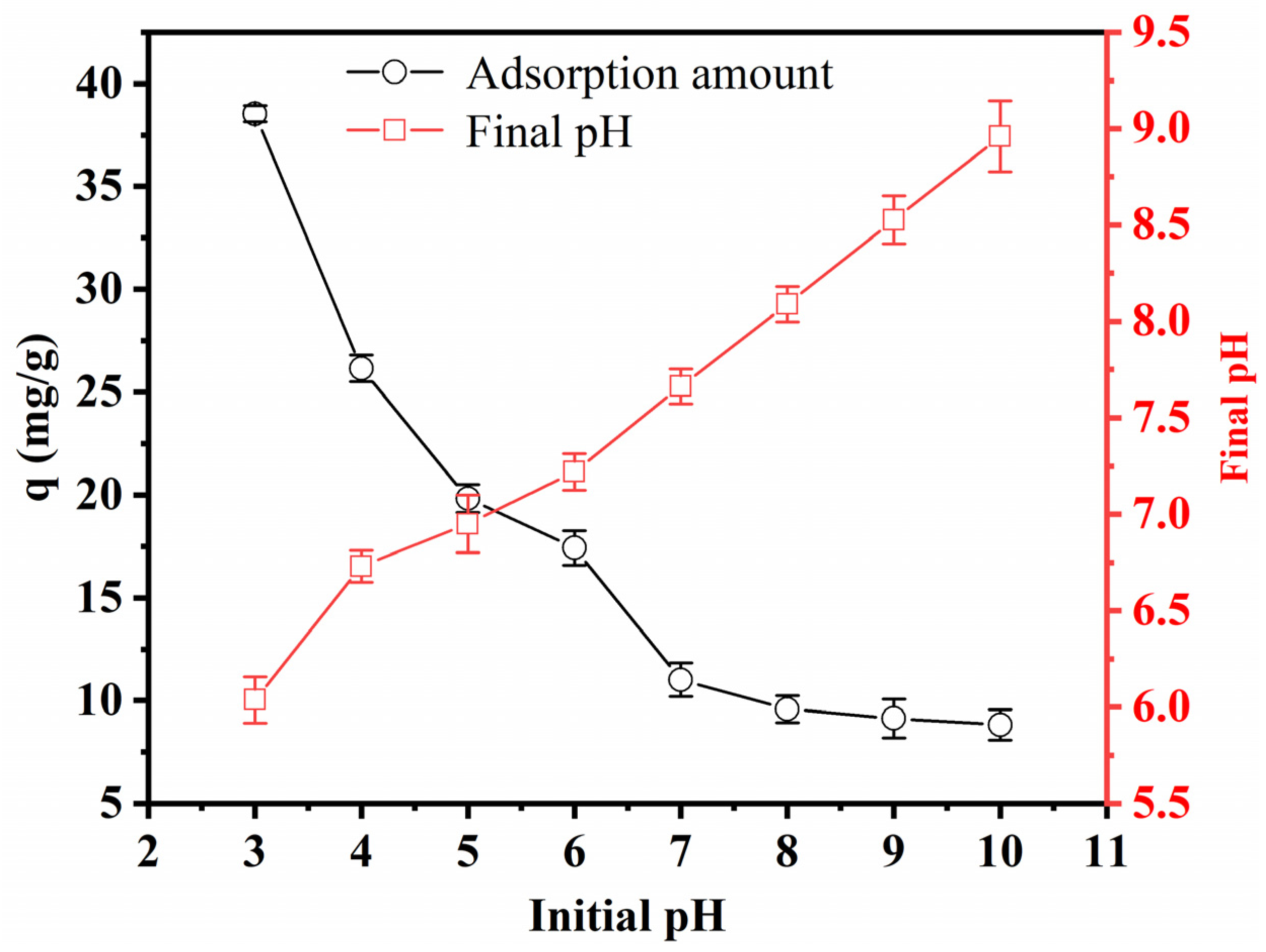

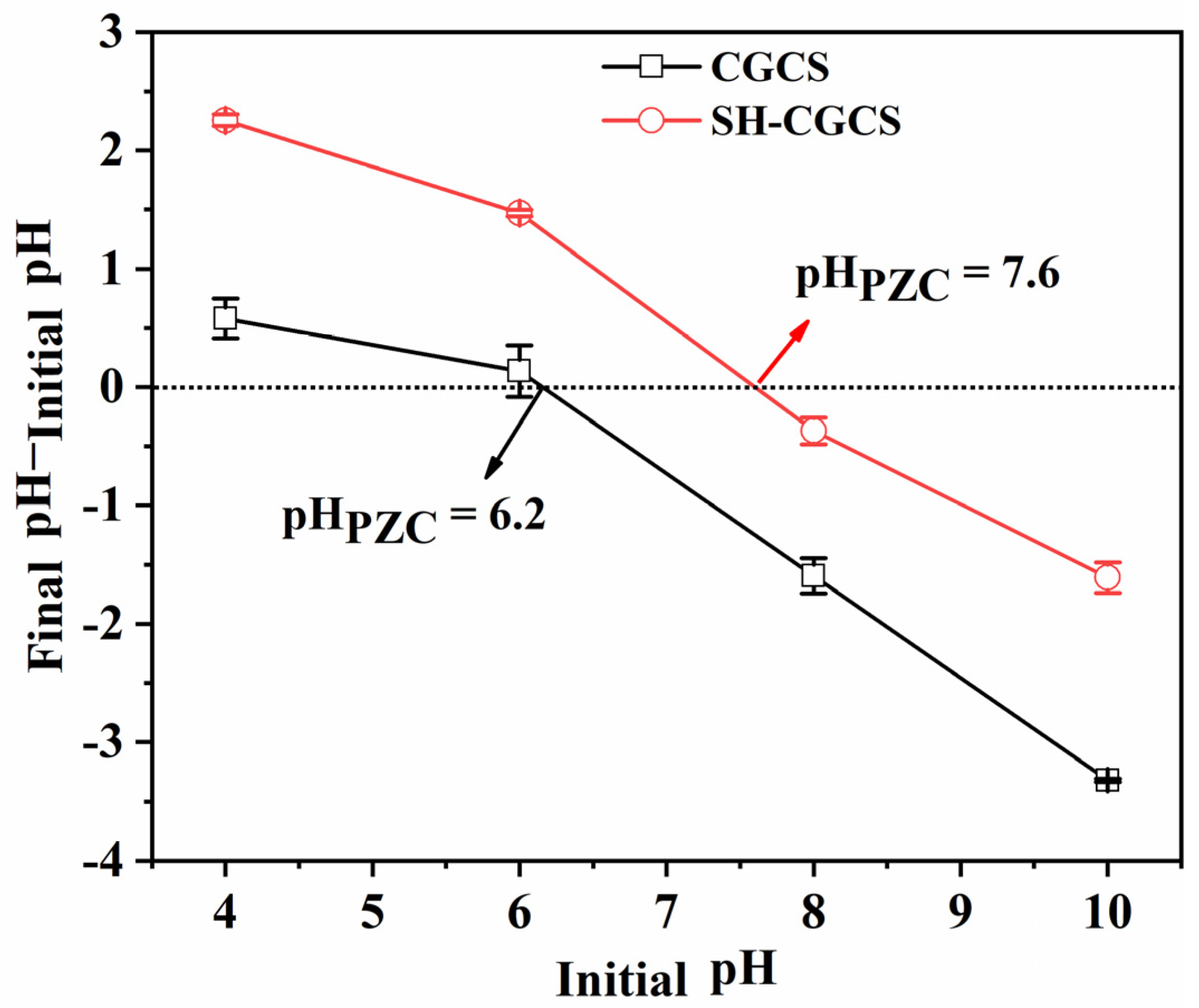

3.2.1. Effects of pH on Phosphate Adsorption

3.2.2. Effects of Coexisting Anions and HA

3.2.3. Adsorption Isotherms

3.2.4. Adsorption Kinetic Studies

3.2.5. Metal Leaching

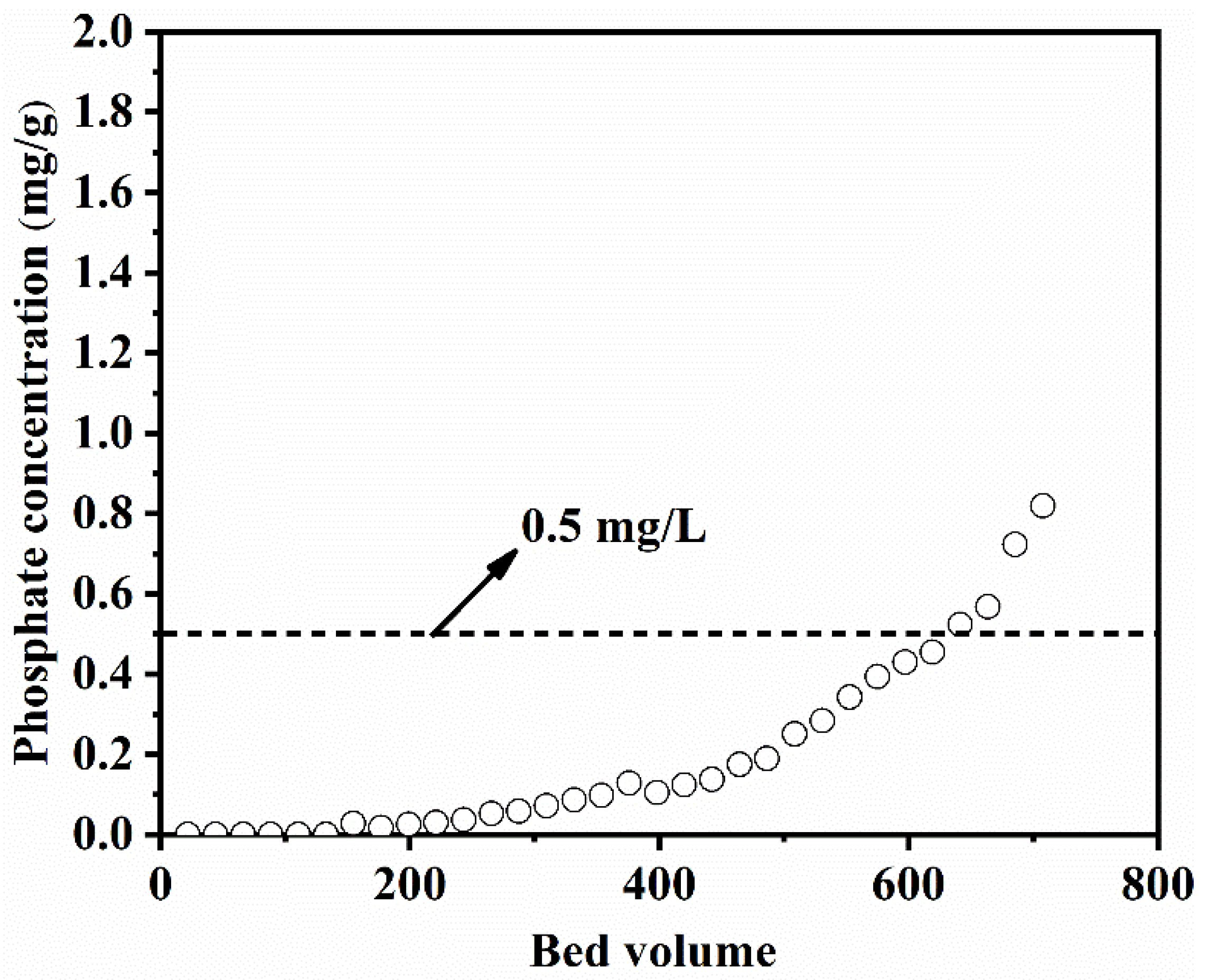

3.2.6. Column Adsorption Experiments

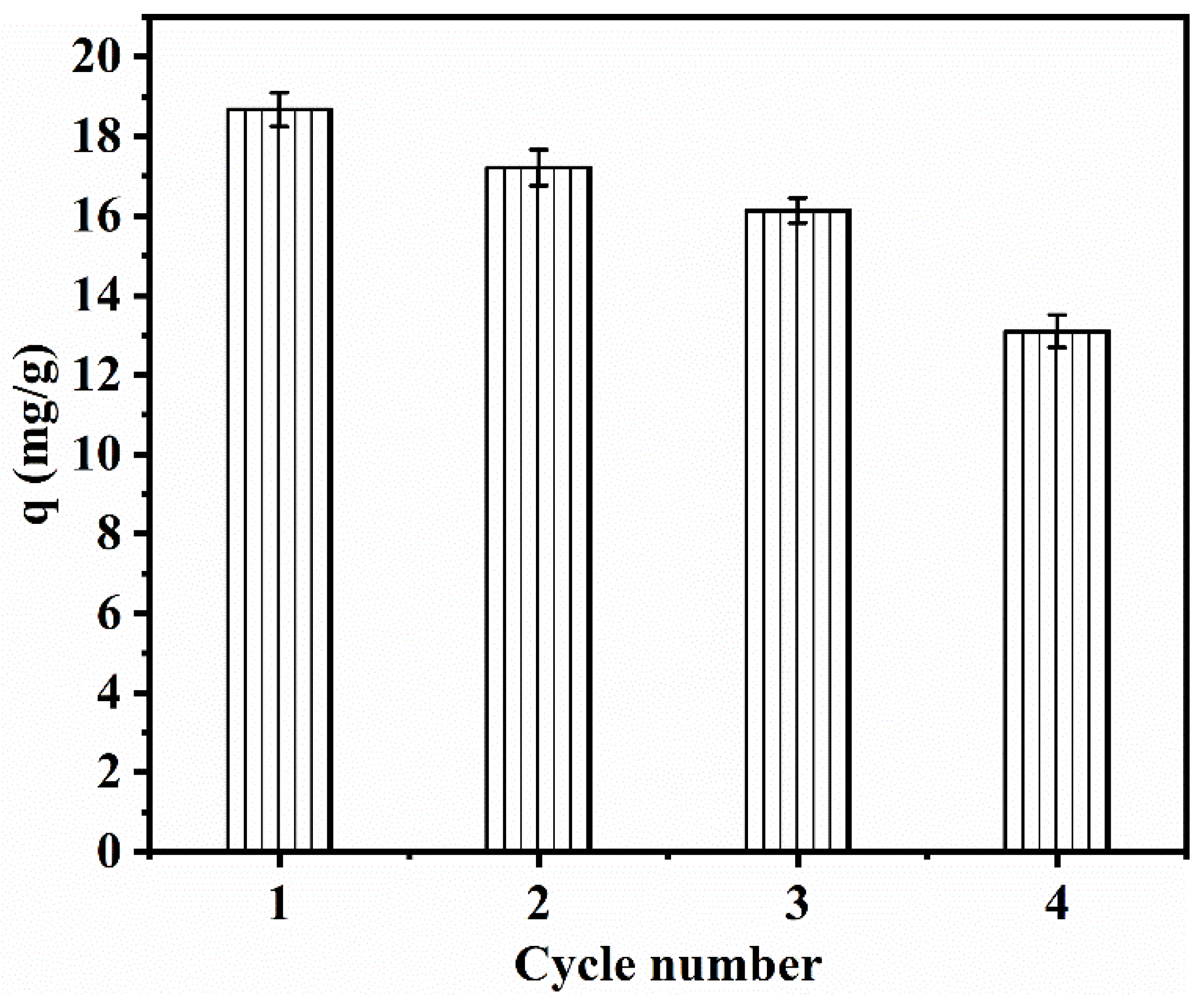

3.2.7. Reusability

3.3. Adsorption Mechanism

3.3.1. XRD

3.3.2. FTIR

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qu, J.; Zhang, J.; Li, H.; Li, S. A high value utilization process for coal gasification slag: Preparation of high modulus sodium silicate by mechano-chemical synergistic activation. Sci. Total Environ. 2021, 801, 149761. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Han, F.; Bai, Y.; Xie, Z.; Shi, T.; Wang, J.; Li, Y. Phosphate removal performance and mechanism of magnesium–lanthanum-modified coal gasification coarse slag. Mater. Today Sustain. 2023, 22, 100357. [Google Scholar] [CrossRef]

- Yang, B.; Han, F.; Li, Y.; Bai, Y.; Xie, Z.; Yang, J.; Liu, T. Phosphate removal mechanism of a novel magnesium slag-modified coal gasification coarse slag adsorbent. Environ. Sci. Pollut. Res. Int. 2023, 30, 60607–60617. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Li, Y.; Han, F.; Bai, Y.; Zhang, Y.; Yu, J.; Fu, Z. Novel composite in situ obtained from coal gasification coarse slag and its mechanism of removing phosphate. Arab. J. Chem. 2023, 16, 104512. [Google Scholar] [CrossRef]

- Ma, X.; Li, Y.; Xu, D.; Tian, H.; Yang, H. Simultaneous adsorption of ammonia and phosphate using ferric sulfate modified carbon/zeolite composite from coal gasification slag. J. Environ. Manag. 2022, 305, 114404. [Google Scholar] [CrossRef] [PubMed]

- Kruk, D.J.; Elektorowicz, M.; Oleszkiewicz, J.A. Struvite precipitation and phosphorus removal using magnesium sacrificial anode. Chemosphere 2014, 101, 28–33. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Wang, F. Effect of ikaite precipitation on phosphate removal in sea ice. Polar Res. 2020, 39, 3413. [Google Scholar] [CrossRef]

- Battistoni, P.; De Angelis, A.; Prisciandaro, M.; Boccadoro, R.; Bolzonella, D.P. removal from anaerobic supernatants by struvite crystallization: Long term validation and process modelling. Water Res. 2002, 36, 1927–1938. [Google Scholar] [CrossRef]

- Chen, X.; Kong, H.; Wu, D.; Wang, X.; Lin, Y. Phosphate removal and recovery through crystallization of hydroxyapatite using xonotlite as seed crystal. J. Environ. Sci. 2009, 21, 575–580. [Google Scholar] [CrossRef]

- Vasudevan, S.; Lakshmi, J.; Jayaraj, J.; Sozhan, G. Remediation of phosphate-contaminated water by electrocoagulation with aluminium, aluminium alloy and mild steel anodes. J. Hazard. Mater. 2009, 164, 1480–1486. [Google Scholar] [CrossRef]

- Rabbani, D.; Rashidipour, F.; Nasseri, S.; Abas Mousavi, S.G.; Shaterian, M. High-efficiency removal of phosphorous from filtered activated sludge effluent using electrochemical process. J. Clean. Prod. 2020, 263, 121444. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Q.; Chen, J.; Zhang, L.; Chang, N. Phosphate adsorption on hydroxyl–iron–lanthanum doped activated carbon fiber. Chem. Eng. J. 2013, 215–216, 859–867. [Google Scholar] [CrossRef]

- Takaya, C.A.; Fletcher, L.A.; Singh, S.; Okwuosa, U.C.; Ross, A.B. Recovery of phosphate with chemically modified biochars. J. Environ. Chem. Eng. 2016, 4, 1156–1165. [Google Scholar] [CrossRef]

- Heinzmann, B. Phosphorus recycling in sewage treatment plants with biological phosphorus removal. Water Sci. Technol. 2005, 52, 543–548. [Google Scholar] [CrossRef] [PubMed]

- Shen, N.; Zhou, Y. Enhanced biological phosphorus removal with different carbon sources. Appl. Microbiol. Biotechnol. 2016, 100, 4735–4745. [Google Scholar] [CrossRef] [PubMed]

- Zhao, A.D. A Pilot Study on Phosphate and Nitrate Removal from Secondary Wastewater Effluent Using a Selective Ion. Exchange Process. Environ. Technol. 2004, 25, 533–542. [Google Scholar]

- Mitrogiannis, D.; Psychoyou, M.; Baziotis, I.; Inglezakis, V.J.; Koukouzas, N.; Tsoukalas, N.; Palles, D.; Kamitsos, E.; Oikonomou, G.; Markou, G. Removal of phosphate from aqueous solutions by adsorption onto Ca(OH)2 treated natural clinoptilolite. Chem. Eng. J. 2017, 320, 510–522. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, S.; Yu, J.; Shu, Z. Novel hollow microspheres of hierarchical zinc–aluminum layered double hydroxides and their enhanced adsorption capacity for phosphate in water. J. Hazard. Mater. 2011, 192, 1114–1121. [Google Scholar] [CrossRef]

- Asaoka, S.; Kawakami, K.; Saito, H.; Ichinari, T.; Nohara, H.; Oikawa, T. Adsorption of phosphate onto lanthanum-doped coal fly ash—Blast furnace cement composite. J. Hazard. Mater. 2021, 406, 124780. [Google Scholar] [CrossRef]

- Shi, W.; Fu, Y.; Jiang, W.; Ye, Y.; Kang, J.; Liu, D.; Ren, Y.; Li, D.; Luo, C.; Xu, Z. Enhanced phosphate removal by zeolite loaded with Mg–Al–La ternary (hydr)oxides from aqueous solutions: Performance and mechanism. Chem. Eng. J. 2019, 357, 33–44. [Google Scholar] [CrossRef]

- Lin, X.; Xie, Y.; Lu, H.; Xin, Y.; Altaf, R.; Zhu, S.; Liu, D. Facile preparation of dual La-Zr modified magnetite adsorbents for efficient and selective phosphorus recovery. Chem. Eng. J. 2021, 413, 127530. [Google Scholar] [CrossRef]

- Jung, K.; Lee, S.Y.; Choi, J.; Lee, Y.J. A facile one-pot hydrothermal synthesis of hydroxyapatite/biochar nanocomposites: Adsorption behavior and mechanisms for the removal of copper(II) from aqueous media. Chem. Eng. J. 2019, 369, 529–541. [Google Scholar] [CrossRef]

- Xu, H.; Li, Q.; Shen, L.; Wang, W.; Zhai, J. Synthesis of thermostable geopolymer from circulating fluidized bed combustion (CFBC) bottom ashes. J. Hazard. Mater. 2010, 175, 198–204. [Google Scholar] [CrossRef]

- Tian, Q.; Wang, H.; Pan, Y.; Bai, Y.; Chen, C.; Yao, S.; Guo, B.; Zhang, H. Immobilization mechanism of cesium in geopolymer: Effects of alkaline activators and calcination temperature. Environ. Res. 2022, 215, 114333. [Google Scholar] [CrossRef] [PubMed]

- Aldawoodi, B.; Sabri, S.; Alchekh Wis, A. Optimum Calcination Condition of Waste Stabilized Adobe for Alkali Activated High Volume Adobe-Slag Binder Cured at Room Temperature. J. Renew. Mater. 2022, 10, 1269–1285. [Google Scholar] [CrossRef]

- Abdellaoui, Y.; Abou Oualid, H.; Hsini, A.; El Ibrahimi, B.; Laabd, M.; El Ouardi, M.; Giácoman-Vallejos, G.; Gamero-Melo, P. Synthesis of zirconium-modified Merlinoite from fly ash for enhanced removal of phosphate in aqueous medium: Experimental studies supported by Monte Carlo/SA simulations. Chem. Eng. J. 2021, 404, 126600. [Google Scholar] [CrossRef]

- Xiong, W.; Tong, J.; Yang, Z.; Zeng, G.; Zhou, Y.; Wang, D.; Song, P.; Xu, R.; Zhang, C.; Cheng, M. Adsorption of phosphate from aqueous solution using iron-zirconium modified activated carbon nanofiber: Performance and mechanism. J. Colloid Interface Sci. 2017, 493, 17–23. [Google Scholar] [CrossRef]

- Sewu, D.D.; Boakye, P.; Jung, H.; Woo, S.H. Synergistic dye adsorption by biochar from co-pyrolysis of spent mushroom substrate and Saccharina japonica. Bioresour. Technol. 2017, 244, 1142–1149. [Google Scholar] [CrossRef]

- Akram, M.; Bhatti, H.N.; Iqbal, M.; Noreen, S.; Sadaf, S. Biocomposite efficiency for Cr(VI) adsorption: Kinetic, equilibrium and thermodynamics studies. J. Environ. Chem. Eng. 2017, 5, 400–411. [Google Scholar] [CrossRef]

- Liang, Q.; Luo, H.; Geng, J.; Chen, J. Facile one-pot preparation of nitrogen-doped ultra-light graphene oxide aerogel and its prominent adsorption performance of Cr(VI). Chem. Eng. J. 2018, 338, 62–71. [Google Scholar] [CrossRef]

- Huang, W.; Chen, J.; He, F.; Tang, J.; Li, D.; Zhu, Y.; Zhang, Y. Effective phosphate adsorption by Zr/Al-pillared montmorillonite: Insight into equilibrium, kinetics and thermodynamics. Appl. Clay Sci. 2015, 104, 252–260. [Google Scholar] [CrossRef]

- Zeng, L.; Li, X.; Liu, J. Adsorptive removal of phosphate from aqueous solutions using iron oxide tailings. Water Res. 2004, 38, 1318–1326. [Google Scholar] [CrossRef] [PubMed]

- Kostura, B.; Kulveitová, H.; Leško, J. Blast furnace slags as sorbents of phosphate from water solutions. Water Res. 2005, 39, 1795–1802. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhou, Q.; Liu, J.; Chang, N.; Wan, L.; Chen, J. Phosphate adsorption on lanthanum hydroxide-doped activated carbon fiber. Chem. Eng. J. 2012, 185–186, 160–167. [Google Scholar] [CrossRef]

- Li, H.; Ru, J.; Yin, W.; Liu, X.; Wang, J.; Zhang, W. Removal of phosphate from polluted water by lanthanum doped vesuvianite. J. Hazard Mater. 2009, 168, 326–330. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Lin, H.; Dong, Y.; Wang, L. Preferable adsorption of phosphate using lanthanum-incorporated porous zeolite: Characteristics and mechanism. Appl. Surf. Sci. 2017, 426, 995–1004. [Google Scholar] [CrossRef]

- Deng, L.; Shi, Z. Synthesis and characterization of a novel Mg–Al hydrotalcite-loaded kaolin clay and its adsorption properties for phosphate in aqueous solution. J. Alloys Compd. 2015, 637, 188–196. [Google Scholar] [CrossRef]

- Ye, T.; Min, X.; Li, X.; Zhang, S.; Gao, Y. Improved holding and releasing capacities of coal gangue toward phosphate through alkali-activation. Chemosphere 2022, 287, 132382. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Yang, B.; Qian, D.; Cui, D.; Li, H.; Wang, C.; Zhu, Y.; Yu, T. Isotherm, Kinetics, and Adsorption Mechanism Studies of Coal Gasification Coarse Slag as Highly Efficient Phosphate Adsorbents. Separations 2024, 11, 182. https://doi.org/10.3390/separations11060182

Shi X, Yang B, Qian D, Cui D, Li H, Wang C, Zhu Y, Yu T. Isotherm, Kinetics, and Adsorption Mechanism Studies of Coal Gasification Coarse Slag as Highly Efficient Phosphate Adsorbents. Separations. 2024; 11(6):182. https://doi.org/10.3390/separations11060182

Chicago/Turabian StyleShi, Xuzhi, Baoguo Yang, Dayi Qian, Dong Cui, Hongbin Li, Chao Wang, Yuhao Zhu, and Tao Yu. 2024. "Isotherm, Kinetics, and Adsorption Mechanism Studies of Coal Gasification Coarse Slag as Highly Efficient Phosphate Adsorbents" Separations 11, no. 6: 182. https://doi.org/10.3390/separations11060182

APA StyleShi, X., Yang, B., Qian, D., Cui, D., Li, H., Wang, C., Zhu, Y., & Yu, T. (2024). Isotherm, Kinetics, and Adsorption Mechanism Studies of Coal Gasification Coarse Slag as Highly Efficient Phosphate Adsorbents. Separations, 11(6), 182. https://doi.org/10.3390/separations11060182