Abstract

The separation and purification process of alkaloids faces great challenges of pollution, high energy consumption and low continuity. In this study, the effects of ceramic microfiltration (MF) membrane (membrane pore size of 0.50 μm, 0.20 μm, 0.05 μm) and organic ultrafiltration (UF) membrane (membrane molecular weight cut-off of 10 KDa and 1 KDa) on the separation and purification of Caulis sinomenii extract solution in pilot scale were studied. The cleaning effects of different cleaning methods (pure water, 1% HCl-NaOH, 1% sodium hypochlorite) were investigated. The experimental results indicated that 0.05 μm ceramic membrane and 1 kDa UF membrane have higher sinomenine hydrochloride (SH) permeabilities and total solids (TS) removal rates. The ceramic membrane was circulating cleaned by 1% sodium hypochlorite solution for 1 h; the membrane flux can be restored to more than 90% of the original, the membrane flux of 1 kDa UF membrane can be restored to 99.2% of the original by pure water washing. From the above study, the optimal technic parameters was determined in which 0.05 μm ceramic MF membrane and 1 kDa UF membrane were used to separate and purify the Caulis sinomenii extract solution to remove the invalid ingredients, and the two kinds of membranes were cleaned with 1% sodium hypochlorite solution and pure water, respectively, to keep satisfactory membrane fluxes. The study provided an environment-friendly alternative for the separation and purification of alkaloids in natural products, which has a good prospect for the industrial application.

1. Introduction

There are many problems in The Traditional Chinese Medicine (TCM) industry which need urgent solutions, such as complicated process, time consuming, high energy consumption, consumption of toxic reagents and so on. Because there is a large number of soluble macromolecular impurities in the TCM materials, such as starchs, pectins [1], proteins [2], tannins [3], etc., These macromolecules are easily form suspended hydrosol in solvent, which is typical thermodynamic unstable system. In the subsequent drying, impurity removal and crystallization processes, caking and adhesion can easily occur and ultimately affect the stability and security of the TCM products [4]; this requires removal with a large number of organic reagents in the industrial production. In the industrial production of sinomenine hydrochloride (SH), a series of unit operations, such as percolation, pH adjustment, suspension centrifugation, extraction twice with chloroform, alcohol precipitation and crystallization are needed, to obtain a high-quality active pharmaceutical ingredient (API).

At present, membrane separation technology is widely used in food [5,6,7], wastewater treatment [8,9], seawater desalination, agricultural waste treatment [10,11], and other areas. Membrane separation technology can retain effective components and remove ineffective components by selecting membrane pore size and molecular weight cut-off (MWCO). It has the advantages of high efficiency, no phase changes, low energy consumption and convenient operation [4]. According to the different separation demands, membrane separation technology can be divided into microfiltration (MF), ultrafiltration (UF), nanofiltration (NF) and reverse osmosis (RO). The MF membrane has a pore size range of 0.01–10 μm is often used as the first step in the membrane separation process to remove microparticles such as bacteria, colloids and insoluble substances in the fluid [12]. UF membrane can generally retain more than 90% of the substances with relative molecular weight of 1000–300,000 Da, and can separate macromolecular organics (such as proteins, bacteria), colloids, suspended solids, etc. [4]. NF is between UF and RO. The MWCO of NF is 80–1000 Da, and the pore size is nanometer. It can intercept more than 90% of organic solutes with a MWCO greater than 300 Da and the organic matter with relatively small molecular weight that passing through the UF membrane and can be used for dialysis of inorganic salts trapped by RO membrane [13,14]. In the single TCM ingredients, such as sophora flavescens [15], ephedra [16], and compound Qingluotongbitang [17], the membrane separation method has a significant effect on the removal of impurities and the enrichment of effective components in the above water extract, and also in the separation and purification of volatile TCM components, such as volatile oil in patchouli [18], asarum [19], forsythia [20]. In addition, the TCM pharmaceutical industry has begun to use UF-MD hybrid system for resource utilization of TCM wastewater [21]. The National Development and Reform Commission (NDRC) of China has proposed in The guidance catalogue of industrial structure adjustment (2019 edition) to encourage the development and application of membrane separation technology in the process of drug production, the development and application of energy saving and emissions reduction technology in the production of API, new technology for quality control of TCM and process technology of modern dosage forms of TCM to solve the above problems. There is a need to produce high efficiency extraction equipment and continuous production technology and equipment.

Chinese Pharmacopoeia regulated that Caulis sinomenii (Qingfengteng) derived from the dry cane stem of Menispermaceae plants of Sinomenium acutum (Thunb.) Rehd. et Wils. and Sinomenium acutum (Thunb.) Rehd. et Wils. Var. cinereum Rehd. et Wils, which are distributed in the Yangtze River Basin and the south provinces of China. As a TCM, Caulis sinomenii has a long history in the treatment of rheumatism [22]. Caulis sinomenii was firstly recorded in the Illustrations of Materia Medica of the Song Dynasty, and later recorded in the Compendium of Materia Medica of the Ming Dynasty in ancient China. It is described in the Compendium of Materia Medica as being added to wine for the treatment of rheumatism, gout, tuberculous arthritis, pruritus, trauma and ulcers. Caulis sinomenii is rich in alkaloids. 91 kinds of alkaloids have been screened out in Caulis sinomenii, in which sinomenine (SIN) is a monomer alkaloid. It accounts for about 2% in Caulis sinomenii, and its hydrochloride form, i.e., SH, is commonly used in clinic [23]; which has good analgesic and immunosuppressive effects [24], and its different dosage forms, such as enteric coated capsules, sustained release tablets, and injections, were widely used in clinical for the treatment of rheumatoid arthritis, chronic nephritis, gout, ankylosing spondylitis and other diseases [25]. The traditional extraction process of SH, liquid-liquid extraction, in which a large amount of benzene, ethyl acetate or chloroform used, is a commonly used purification method, which could seriously damage the health of operators and cause serious environmental pollution [26]. Therefore, it is urgent to develop a green and efficient separation techniques to address this issue [27].

In this paper, the separation and purification of the extract solution of Caulis sinomenii by ceramic MF membrane, an organic UF membrane and under given operating conditions were studied, the aim is to achieve enrichment of the active ingredient, SH, and the removal of impurities, such as biological macromolecules and other alkaloids with similar structures. The technology developed in this paper can provide reference for the development of separation and purification methods of alkaloids in natural products.

2. Materials and Methods

2.1. Materials and Chemicals

Caulis sinomenii (No. 20200601) is purchased from Anhui Yuankang Herbal Pieces Co., Ltd., (Bozhou, Anhui, China) and its origin area is Shangluo City, Shaanxi Province. SH reference substance (No. S27281, ≥98%) is provided by Shanghai Yuanye Biotechnology Co., Ltd., (Shanghai, China). Hydrochloric acid is purchased by Tianjin Damao chemical reagent factory, (Tianjin, China). Calcium hydroxide is obtained by Shanghai Meryer Chemical Technology Co., Ltd., (Shanghai, China). Sodium dihydrogen phosphate is obtained by Tianjin Kermel Chemical Reagent Co., Ltd., (Tianjin, China). Acetonitrile is purchased by Fisher chemical. Sodium hypochlorite is purchased by Tianjin Bohua Chemical Reagent Co., Ltd., (Tianjin, China). Hydrochloric acid, calcium hydroxide, sodium dihydrogen phosphate and sodium hypochlorite are analytical pure and acetonitrile is chromatographic pure.

2.2. Preparation of Caulis sinomenii Extract Solution

1000 g of Caulis sinomenii was put into the percolation tube and soaked in 20 L of 0.1 mol·L−1 hydrochloric acid solution for 24 h. Medicinal materials were percolated at a flow rate of 15–20 mL·min−1, the pH of the extract solution was adjusted to 11–12 with calcium hydroxide after percolated, then adjusted to pH 8–9 with 6 mol·L−1 hydrochloric acid solution after filtrated.

2.3. Filtrating and Cleaning Procedures

Ceramic MF membrane equipment is purchased by Jiangsu JiuWu Hi-Tech Co., Ltd. (Nanjing, China) and UF membrane equipment is purchased by Jinan Bona Biotechnology Co., Ltd. (Jinan, China) The equipments information is listed in Table 1.

Table 1.

Equipment parameters of ceramic membrane and organic membrane.

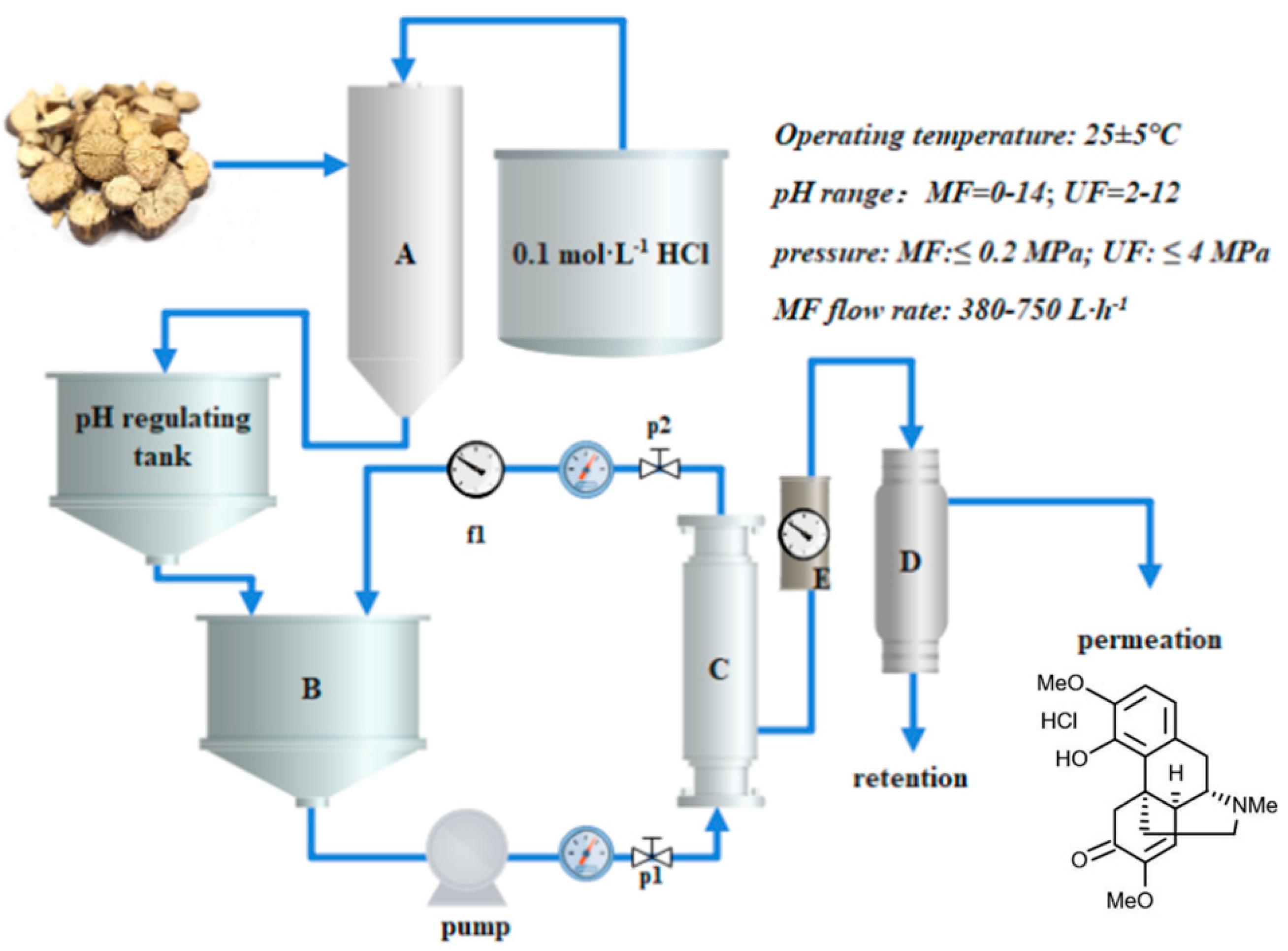

The ceramic membrane material is Al2O3, and the UF membrane material is polyethersulfone (PES). The pore sizes and MWCOs of the membranes were 0.5 μm, 0.2 μm, 0.05 μm and 10 kDa 1 kDa respectively. Ceramic membrane equipment operating transmembrane press (TMP): 0.05–0.2 MPa, temperature: 25 ± 5 °C, flow rate: 380–750 L·h−1. UF membrane equipment parameters: operating pressure ≤ 0.1 MPa. The operation flow of the experiment is shown in Figure 1. The extract solution of Caulis sinomenii described in Section 2.2 was added into the feed tank, driven by centrifugal pump and circulated in the membrane separation equipment. TMP was controlled through adjusting valves P1 and P2, and the flow rate was recorded with current meter f1. The extracted solution passes through the ceramic membrane, the retention part is introduced into the feed tank for circulating operation, and the permeating solution enters the feed tank of UF module for filtrating, the flux data of ceramic MF membranes were obtained by metal tube rotameter. The flux data of UF membranes were calculated according to the volume of permeate discharged per minute.

Figure 1.

Separation and purification flow chart of Caulis sinomenii extract solution. (A) percolation tank; (B) feed tank; (C) ceramic MF membrane module; (D) UF membrane module; (E) metal tube rotameter.

The ceramic membranes were cleaned with clean water, 1% HCl-NaOH (It refers to cleaning with 1% hydrochloric acid solution for 1 h, followed by 1% sodium hydroxide solution for 1 h) and 1% sodium hypochlorite solution for 1 h at the end of the experiment respectively, and the cleaning volume was 20 L. After cleaning, the ceramic membrane was washed with clean water twice, 30 min each time. After the UF testing, clean membrane with clean water until the membrane flux is restored.

2.4. Analytical Methods

The HPLC method of SH content refers to the first part of Chinese Pharmacopoeia 2020 edition [28]. An HPLC (ACQuity Arc, Waters, MI, USA) system equipped with a UV detector was used. Analyses were conducted on a Waters Symmetry-C18 column (4.6 mm × 250 mm, 5 μm) with the column temperature controlled at 25 ± 5 °C. The flow rate of solvent was maintained at 1.0 mL·min−1, while the injection volume of sample was 5 μL. Isocratic elution of the mobile phase containing acetonitrile and 0.78% sodium dihydrogen phosphate (12:88, v/v) was used. The detection wavelength was set at 262 nm. Finally, the regression equation (y = 3.837 × 103x − 4.666 × 103, R2 = 1) was obtained, and the precision RSD of the method was 0.3%; the repeatability RSD was 2.2%; the stability RSD was 1.8%; the average recovery was 99% (RSD = 0.2%). The test samples are the extract solution and membrane separating permeates in Section 2.2 and Section 2.3.

Total solids (TS) contents: 100 mL permeating solution was placed in an evaporating dish, evaporated in water bath, dried at 105 °C for 3 h, cooled in a dryer and weighed [29]. Calculation formula of the TS removal rates and SH permeabilities as follow:

where Cs is the TS in the permeating solution; Cs0 is the TS in the extract solution of Caulis sinomenii.

where C refers to the SH content of permeating solution; C0 refers to the SH content of the extract solution.

TS removal rate = (Cs0 − Cs)/Cs0 × 100%,

SH permeability = C/C0 × 100%,

Evaluation of degree membrane pollution: if the membrane pollution degree reaches more than 30%, it means that the membrane is seriously polluted and the membrane performance is seriously degraded, so it needs to be cleaned. The cleaning effect is expressed by the recovery degree of membrane flux. The formulas of membrane fouling degree and membrane flux recovery rate are (3) and (4) respectively:

where Jd refers to the membrane pollution degree, Jw is the water flux before fouling and Jp is the water flux after fouling, and Ji is the pure water flux after cleaning. When the membrane flux restored over 80%, it can be considered that the membrane has been cleaned.

Jd = (1 − Jp)/Jw × 100%,

Jr = (Ji − Jp)/(Jw − Jp) × 100%,

2.5. Statistical Analysis

Each assay was performed in triplicate, and results were expressed as mean ± SD. Pearson’s coefficient (r) was used for the correlational analyses. The SPSS 25.0 (SPSS Inc., Chicago, IL, USA) was used to perform the one-way analysis of variance (ANOVA) with Scheffe as post hoc test. Statistical significance level, except for the ones specially marked, was set at p < 0.05.

3. Results

3.1. Effect of Microfiltration

The content of SH in the extract solution was 0.80 mg·mL−1 and TS content was 2.28 g·100 mL−1 determined with the analysis methods described in Section 2.4. In the extraction process of Caulis sinomenii, due to the large amount of medicinal materials used in one test, even for the same batch of medicinal materials, the quality of medicinal materials in each package also has difference, resulting in higher RSD value. The results of SH permeabilities and TS removal rates of Caulis sinomenii extract solution separated and purified by three different pore size ceramic membranes are listed in Table 2. It can be seen from the results that the SH permeability and TS removal rate of 0.05 μm ceramic membrane are the highest. The ANOVA results are listed in Table 3, the SH permeabilities were not significantly different among the three different pore size ceramic membranes, but there was a significant difference in the TS removal rate, the clarity of Caulis sinomenii extract solutions were significantly improved. There was no significant difference in the SH permeability between the 0.5 μm and 0.2 μm ceramic membranes, 0.05 μm ceramic membrane can enrich SH to some extent, and the TS removal rate is the highest. The 0.05 μm ceramic membrane was selected to study the effect of different TMP and flow rate on the filtration of Caulis sinomenii extract solution.

Table 2.

SH permeabilities and TS removal rates (n = 3).

Table 3.

ANOVA results of SH permeabilities and TS removal rates.

The results of SH permeabilities and TS removal rates of 0.05 μm ceramic membrane under different TMP and flow rates are listed in Table 4. Under the TMP of 0.05 MPa and 0.1 MPa, the SH permeabilities are higher, the TS removal rates are higher under the TMP of 0.15 MPa and 0.2 MPa. The flow rates are 380 L·h−1, 550 L·h−1 and 640 L·h−1, the SH permeabilities are higher, but the TS removal rates has no significant difference. The flow rates has little effects on the SH permeabilities and has limited effects on the TS removal rates. High flow velocity can produce wall shear force and reduce the formation of deposition layer on the membrane surface [30], however, excessive flow rate will not only reduce membrane flux [31], but also cause a lot of difficult to remove foam, which will affect subsequent cleaning steps. The results of ANOVA are listed in Table 5, there was no significant difference between the SH permeabilities and the TS removal rates in 0.05 μm ceramic membrane by controlling different TMP and flow rates. Higher TMP causes the concentration polarization of the surface of the membrane [32], which results of the increase in the pollution grade of the ceramic membrane. The large flow rates also causes a large number of difficult to eliminate bubbles in the circulation process, it results in volume loss of the extract solution, which makes it difficult for subsequent cleaning steps. Under different TMP and flow rates, when there is no significant difference in the indexes, the most appropriate operating parameters, 0.1 MPa, 550 L·h−1 should be selected.

Table 4.

SH permeabilities and TS removal rates under TMP and flow rates (n = 3).

Table 5.

ANOVA results of SH permeabilities and TS removal rates.

3.2. Effect of Ultrafiltration

After 0.05 μm ceramic membrane separation and purification, Caulis sinomenii extract solution would be treated by UF membrane. After 10 kDa UF separation and purification, the SH permeability was 56.95 ± 2.1% and the TS removal rate was 63.46 ± 0.3%. After 1 kDa UF treatment, the SH permeability was 60.77 ± 2.7%, and the TS removal rate was 64.24 ± 0.2%. Only from the results, the treatment effect of 1 kDa UF is better, the SH permeabilities and the TS removal rates are higher than that of 10 kDa UF. According to the ANOVA results listed in Table 6, the removal efficiency of 1 kDa UF membrane is better than that of 10 kDa in terms of TS remove; there was no significant difference in the SH permeabilities. Therefore, 1 kDa UF membrane can be used as the second treatment step of Caulis sinomenii extract solution.

Table 6.

ANOVA results of SH permeabilities and TS removal rates.

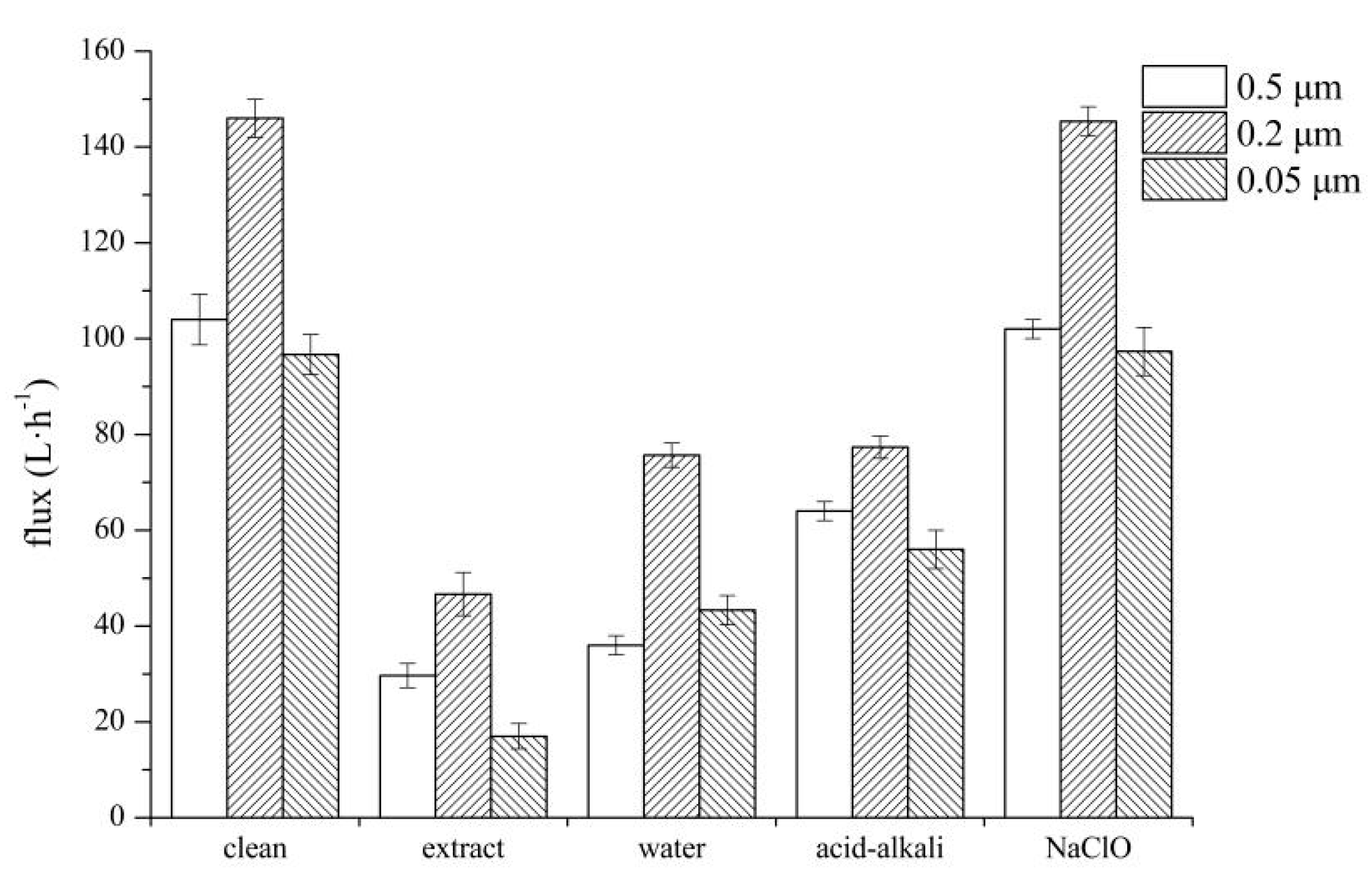

3.3. Effect of Membrane Cleaning

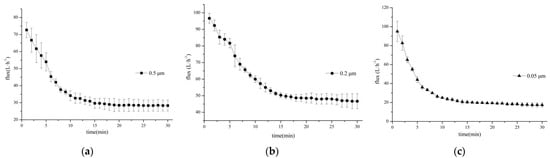

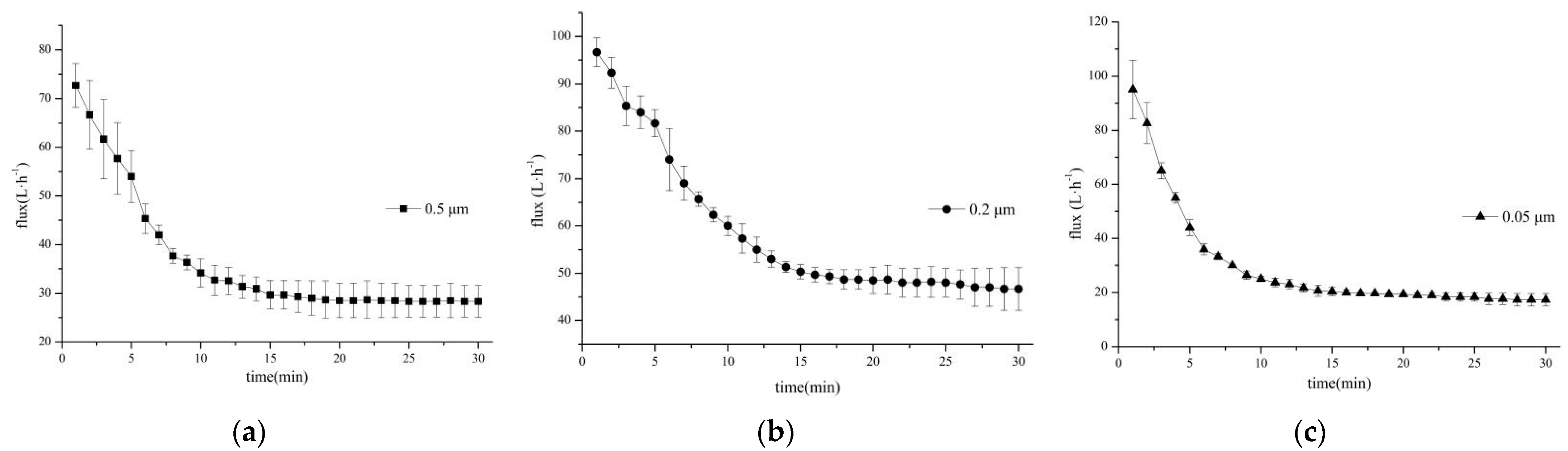

TCM extract solution contain a lot of carbohydrate, protein and other nutrients that can be used for the growth and reproduction of bacteria. If the membrane modules are not cleaned in time, or the cleaning effect is poor, there will be scaling phenomenon on the membrane surface and in the pipeline: bacterial adhesion, biofilm formation [33]. As shown in Figure A1 of Appendix A, 0.5 μm, 0.2 μm, 0.05 μm with TMP = 0.1 MPa and the flow rate was 550 L·h−1, the flux attenuation curves of Caulis sinomenii extract solution were obtained. During MF processes, the flux of 0.5 μm ceramic membrane decreased significantly in 6 min, and stabilized at 32 L·h−1 after 15 min. The flux of 0.2 μm ceramic membrane decreased rapidly in 5 min and slowly in 14 min, was stable at 51 L·h−1 after 15 min. The flux of 0.05 μm ceramic membrane decreased to 44 L·h−1 in 5 min, reaching half of the membrane performance, and the flux stabilized to 20 L·h−1 after 14 min. After the percolation process, the pH of extract solution was adjusted by calcium hydroxide, a large amount of calcium chloride was produced, and precipitated in the extract to form suspension. Therefore, calcium chloride is the most direct cause of ceramic membrane pollution, followed by the soluble non effective components. The pollution degree of these three kinds of ceramic membranes is more than 60%, as listed in Table 7.

Table 7.

Flux and pollution degrees of ceramic membranes (n = 3), (0.1 MPa, 550 L·h−1).

In this experiment, pure water, 1% HCl-NaOH and 1% sodium hypochlorite were used to clean the membranes to compare the recovery rates of membrane flux by the above methods. The fouling degrees of these membranes were more than 30%, and their performances were seriously reduced. The fouling degrees of 0.5 μm, 0.2 μm and 0.05 μm ceramic membranes were 71%, 66% and 85%, respectively. The flux recovery effects of ceramic membranes are shown in Figure 2. The Flux of 0.5 μm ceramic membrane was restored to 34.5%, 58.2% and 92.7% after cleaning with pure water, 1% HCl-NaOH and 1% sodium hypochlorite solution, respectively; the flux of 0.02 μm ceramic membrane was restored to 50.6%, 53.3% and 97.3% after cleaning with pure water, 1% HCl–NaOH and 1% sodium hypochlorite solution, respectively. The flux of the 0.05 μm ceramic membrane was restored to 44.0%, 56.0% and 92.0% after initial cleaning with pure water, 1% HCl-NaOH and 1% sodium hypochlorite solution, respectively, and 1% sodium hypochlorite is the most effective of the three cleaning methods.

Figure 2.

Flux changes of ceramic membranes under different treatment conditions, (0.1 MPa, 550 L·h−1).

PES, polyvinylidene difluoride (PVDF), polyethylene (PE) and other organic materials are the main materials to produce UF membranes, which can not withstand the scouring of strong acid, alkali and oxidation reagents for a long time [34]. On the other hand, sodium hypochlorite is an important reason for the aging of organic membranes. Sodium hypochlorite is a common membrane cleaning agent and swelling agent in drink water and wastewater treatment [35]. Long term exposure to sodium hypochlorite may change the polymer membranes properties, resulting in the decrease of tensile strength and retention capacity, the permeability increase and finally shortening the membrane life [36]. As the extract solution was pretreated by ceramic membrane, the UF membrane was not polluted by large particles, and only macromolecular substances attached to the membrane surface, the flux of 10 kDa and 1 kDa UF membranes could be restored to 96.4% and 99.2% of the original, respectively, after washing with pure water, the cleaning results are listed in Table 8. In this section, the best cleaning method of ceramic membrane is 1% sodium hypochlorite solution circulating cleaning for 1 h, the organic membrane is pure water continuous circulating cleaning.

Table 8.

Recovery effects of membrane flux (L·h−1).

4. Discussion

This paper is based on the exploration of pilot scale production experiment. In three parallel experiments, the SH content of the extract solution casused by each batch of Caulis sinomenii were different; the control of the volume of percolate, pH adjustment and the judgment of the separation end point may also cause fluctuations in the results. Therefore, it is very important to narrow the differences between groups. A researcher have investigated 73 TCM pharmaceutical enterprises [37]; the demand rate of membrane separation technology was more than 80%, but only half of the companies had undertaken process exploration and practical application, which shows that a large amount of researches on the membrane separation of TCM products were carried out on the laboratory scale, but have not taken proceeded to the pilot and industrial production scale-up and verification [38]. The later further maintenance of membrane separation equipment requires comes at a large cost, and a large amount of hypochlorous acid solution is also required for membrane cleaning. In the laboratory environment, researchers can try to ignore the loss of time, electricity and water resources to achieve more ideal results. However, in industrialized production, TCM pharmaceutical companies need to take full consideration of the production cost, organic solvent residues and compliance with the regulations on drug production supervision to avoid the problems caused by process changes and environmental issues. At present, the application of membrane separation technology in TCM pharmaceutical industry is still in the exploratory stage and cannot be compared. This research is committed to developing membrane separation technology of SH to replace the traditional chloroform extraction process, which can provide reference for the solution of similar problems in the industrialized production of TCM.

5. Conclusions

In this study, a combination of MF and UF method was established for the separation and purification of Caulis sinomenii extract solution. On the premise purpose of protecting the subsequent organic membrane from being polluted by large particles, the most suitable pore size of ceramic membrane was selected. The optimal pore size of ceramic membrane is 0.05 μm, whose SH permeability and TS removal rate are the highest. Under optimized process conditions, the TMP is 0.1 MPa and the flow rate is 550 L·h−1, the TS removal rate was 59.74 ± 0.8%, and the SH permeability reached 80.85 ± 6.4%. The SH permeability and TS removal rate of 1 kDa UF membrane are higher than 10 kDa membrane. The SH permeability of 1 kDa UF membrane was 60.77 ± 2.7%, and the removal rate of TS was 64.24 ± 0.2%. In the process of membrane cleaning, a washing method of ceramic membrane with 1% sodium hypochlorite solution for 1 h was accepted. The ceramic membrane flux can be restored to more than 90%, and the UF membrane can be restored more than 99% after pure water washing. In the context of increasingly stringent regulations, membrane separation technology can be used as a technical reservation for the green production of TCM.

Author Contributions

Conceptualization, W.L., Z.L., Z.P. and P.Q.; methodology, Z.P., P.Q., X.W., H.M. and H.F.; software, X.W. and H.M.; validation, X.W., H.F. and W.L.; formal analysis, X.W. and W.L.; investigation, X.W., H.F. and H.M.; resources, Z.P., P.Q., W.L. and Z.L.; data curation, X.W., H.F. and H.M.; writing—original draft preparation, X.W.; writing—review and editing, X.W., Z.P., P.Q. and W.L.; visualization, X.W., H.F. and H.M.; supervision, W.L. and Z.L.; project administration, Z.L. and W.L.; funding acquisition, Z.L. and W.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Tianjin Science and technology project (No. 20ZYJDJC00090) and the National Nature Science Foundation of China (No. 82074276).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| MF | microfiltration |

| UF | ultrafiltration |

| NF | nanofiltration |

| RO | reverse osmosis |

| SH | sinomenine hydrochloride |

| TS | total solids |

| TCM | tradition Chinese medicine |

| SIN | sinomenine |

| API | active pharmaceutical ingredient |

| MWCO | molecular weight cut-off |

| NDRC | national development and Reform Commission |

| PES | polyethersulfone |

| TMP | transmembrane press |

| ANOVA | analysis of variance |

| PVDF | polyvinylidene difluoride |

| PE | polyethylene |

Appendix A

Figure A1.

(a) 0.5 μm flux decay curve; (b) 0.2 μm flux decay curve and (c) 0.05 μm flux decay curve.

Figure A1.

(a) 0.5 μm flux decay curve; (b) 0.2 μm flux decay curve and (c) 0.05 μm flux decay curve.

References

- Shao, F.L.; Xu, J.T.; Zhang, J.Y.; Wei, L.Y.; Zhao, C.C.; Lu, C.X.; Fu, Y.Z. Study on the Influencing Factors of Natural Pectin’s Flocculation: Their Sources, Modification and Optimization. Water Environ. Res. 2021. online ahead of print. [Google Scholar] [CrossRef]

- Xu, D.H.; Yu, C.L.; Wang, J.J.; Fan, Q.R.; Wang, Z.Z.; Xiao, W.; Duan, J.A.; Zhou, J.; Ma, H.Y. Ultrafiltration strategy combined with nanoLC-MS/MS based proteomics for monitoring potential residual proteins in TCMIs. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2021, 1178, 122818. [Google Scholar] [CrossRef] [PubMed]

- Das, I.; Sasmal, S.; Arora, A. Effect of thermal and non-thermal processing on astringency reduction and nutrient retention in cashew apple fruit and its juice. J. Food Sci. Technol. 2021, 58, 2337–2348. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.W.; Zhu, H.X.; Tang, Z.S.; Li, B.; Pan, Y.L. Chinese Medicine Pharmaceutical Separation Technology Based on Membrane Process: Foundamentals and Applications, 1st ed.; Science Press: Beijing, China, 2019; pp. 49–137. [Google Scholar]

- Pelin, O. Production of high quality clarified pomegranate juice concentrate by membrane processes. J. Membr. Sci. 2013, 442, 264–271. [Google Scholar]

- Echavarría, A.P.; Torras, C.; Pagán, J.; Ibarz, A. Fruit Juice Processing and Membrane Technology Application. Food. Eng. Rev. 2011, 3, 136–158. [Google Scholar] [CrossRef]

- Sjölin, M.; Thuvander, J.; Wallberg, O.; Lipnizki, F. Purification of Sucrose in Sugar Beet Molasses by Utilizing Ceramic Nanofiltration and Ultrafiltration Membranes. Membranes 2019, 10, 5–22. [Google Scholar] [CrossRef] [Green Version]

- Pramanik, B.K.; Pramanik, S.K.; Monira, S. Understanding the fragmentation of microplastics into nano-plastics and removal of nano/microplastics from wastewater using membrane, air flotation and nano-ferrofluid processes. Chemosphere 2021, 282, 131053. [Google Scholar] [CrossRef]

- Vemuri, B.; Xia, L.C.; Chilkoor, G.; Jawaharraj, K.; Sani, R.K.; Amarnath, A.; Kilduff, J.; Gadhamshetty, V. Anaerobic wastewater treatment and reuse enabled by thermophilic bioprocessing integrated with a bioelectrochemical/ultrafiltration module. Biosour. Technol. 2021, 321, 124406. [Google Scholar] [CrossRef]

- Didaskalou, C.; Buyuktiryaki, S.; Kecili, R.; Fonte, C.P.; Gyorgy, S. Valorisation of agricultural waste with an adsorption/nanofiltration hybrid process: From materials to sustainable process design. Green Chem. 2017, 19, 13–30. [Google Scholar] [CrossRef] [Green Version]

- Voros, V.; Drioli, E.; Fonte, C.; Szekely, G. Process Intensification via Continuous and Simultaneous Isolation of Antioxidants: An Upcycling Approach for Olive Leaf Waste. ACS Sustain. Chem. Eng. 2019. [Google Scholar] [CrossRef]

- Adam, M.R.; Othman, M.H.D.; Kadir, S.H.S.A.; Sokri, M.N.M.; Tai, Z.S.; Iwamoto, Y.; Tanemura, M.; Honda, S.; Puteh, M.H.; Rahman, M.A.; et al. Influence of the Natural Zeolite Particle Size Toward the Ammonia Adsorption Activity in Ceramic Hollow Fiber Membrane. Membranes 2020, 10, 63–81. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Qiu, P.; Peng, X.S.; Li, Z.; Li, W.L. Applications of Integrated Membrane Technology in Pharmaceutical Industry of Traditional Chinese Medicine. Chin. J. Pharm. 2020, 55, 1836–1841. [Google Scholar]

- Hailemariam, R.H.; Woo, Y.C.; Damtie, M.M.; Kim, B.C.; Park, K.D.; Choi, J.S. Reverse osmosis membrane fabrication and modification technologies and future trends: A review. Adv. Colloid interface Sci. 2020, 276, 102100. [Google Scholar] [CrossRef] [PubMed]

- Echavarria, A.P.; Torras, C.; Pagan, J.; Ibarz, A.; Gao, H.N.; Jin, W.Q.; Guo, L.W. Research on refining of radix sophorae flavescentis decoction by microfiltration-ultrafiltration technology. Tradit. Chin. Drug Res. Clin. Pharm. 2009, 20, 571–573. [Google Scholar]

- Shen, R.M.; Hu, B.; Zhang, Y.; Xia, Y.; Chen, Y.; Wan, D.J. Application of membrane separation technology in ephedrine production. Chem. Bioeng. 2008, 7, 58–60. [Google Scholar]

- Cao, Y.T.; Pan, L.M.; Zhu, H.X.; Guo, L.W.; Shi, D.L. The research of different molecular membrane gradient purificate Qingluotongbi decoction. World Sci-Tech RD 2009, 31, 1000–1002. [Google Scholar]

- Wang, H.; Liu, H.B.; Li, B.; Pan, L.M.; Fu, T.M.; Zhang, Y.; Song, Z.X.; Tang, Z.S.; Zhu, H.X. Separation of volatile oil from Pogostemon cablin based on ultrafiltration and vapor permeation membrane methods. Chin. Tradit. Herb. Drugs 2021, 52, 1582–1590. [Google Scholar]

- Zhang, Q.; Zhu, H.X.; Tang, Z.S.; Li, B.; Pan, Y.L.; Yao, W.W.; Liu, H.B.; Fu, T.M.; Guo, L.W. Feasibility of vapor permeation technology for separating of Asari Radix et Rhizoma essential oil-bearing water. Chin. Tradit. Herb. Drugs 2019, 50, 1795–1803. [Google Scholar]

- Zhang, Q.; Zhu, H.X.; Tang, Z.S.; Pan, Y.L.; Li, B.; Fu, T.M.; Yao, W.W.; Liu, H.B.; Pan, L.M. Study on essential oil separation from Forsythia suspensa oil-bearing water body based on vapor permeation membrane separation technology. Chin. J. Chin. Mater. Med. 2018, 43, 1642–1648. [Google Scholar]

- Zhong, W.W.; Zhao, Y.N.; Chen, S.Q.; Zhong, J.L.; Guo, L.W.; Zheng, D.Y.; Xie, C.; Ji, C.; Guo, Y.; Dong, G.X.; et al. Resources recycle of traditional Chinese medicine (TCM) wastewater 1: Effectiveness of the UF-MD hybrid system and MD process optimization. Desalination 2021, 504, 114953. [Google Scholar] [CrossRef]

- Chen, L.G.; Wang, H.J.; Ji, T.F.; Zhang, C.J. Chemoproteomics-based target profiling of sinomenine reveals multiple protein regulators of inflammation. Chem. Commun. 2021, 57, 5981–5984. [Google Scholar] [CrossRef]

- Jiang, Z.M.; Wang, L.J.; Pang, H.Q.; Guo, Y.; Xiao, P.T.; Chu, C.; Guo, L.; Liu, E.H. Rapid profiling of alkaloid analogues in Sinomenii Caulis by an integrated characterization strategy and quantitative analysis. J. Pharm. Biomed. Anal. 2019, 174, 376–385. [Google Scholar] [CrossRef]

- Zhao, Z.Z.; Liang, Z.T.; Zhou, H.; Jiang, Z.H.; Liu, Z.Q.; Wong, Y.F.; Xu, H.X.; Liu, L. Quantification of sinomenine in caulis sinomenii collected from different growing regions and wholesale herbal markets by a modified HPLC method. Biol. Pharm. Bull. 2005, 28, 105–109. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zhang, Z.Y.; Qiu, P.; Peng, X.S.; Li, Z.; Li, Y.X.; Li, W.L. Research progress on Caulis Sinomenii, Sinomenine and related preparations. Chin. J. Pharm. 2021, 56, 85–93. [Google Scholar]

- Milić, M.; Antović, A.; Trandafilović, M.; Zdravković, M. Fatal consequences caused by prolonged chloroform inhalation in a child. Srp. Arh. za Celok. Lek. 2019, 147, 230–234. [Google Scholar] [CrossRef]

- Cheng, Y.Y.; Qu, H.B.; Zhang, B.L. Innovation guidelines and strategies for pharmaceutical engineering of Chinese medicine and their industrial translation. China. J. Chin. Mater. Med. 2013, 38, 3–5. [Google Scholar]

- Chinese Pharmacopoeia; The Medicine Science and Technology Press of China: Beijing, China, 2015; Volume 1, p. 195.

- Pan, J.J.; Shao, J.Y.; Qu, H.B.; Gong, X.C. Ethanol precipitation of Codonopsis Radix concentrate with a membrane dispersion micromixer. J. Clean. Prod. 2020, 251, 119633. [Google Scholar] [CrossRef]

- Qu, P.; Gésan-Guiziou, G.; Bouchoux, A. Dead-end fifiltration of sponge-like colloids: The case of casein micelle. J. Membr. Sci. 2012, 11, 10–19. [Google Scholar] [CrossRef] [Green Version]

- Roland, S.; Florian, S.; Johanna, L.; Ulrich, K. Comparative Assessment of Tubular Ceramic, Spiral Wound, and Hollow Fiber Membrane Microfiltration Module Systems for Milk Protein Fractionation. Foods 2021, 10, 692–706. [Google Scholar]

- Daisuke, S.; Karkhanechi, H.; Matsuura, H.; Matsuyama, H. Effect of operating conditions on biofouling in reverse osmosis membrane processes: Bacterial adhesion, biofilm formation, and permeate flux decrease. Desalination 2016, 378, 74–79. [Google Scholar]

- Vries, H.J.D.; Kleibusch, E.; Hermes, G.D.A.; Brink, P.V.D.; Plugge, C.M. Biofouling control: The impact of biofilm dispersal and membrane flushing. Water Res. 2021, 198, 117163. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Su, Q.; Li, S.; Wen, G.; Huang, T. Aging of PVDF and PES ultrafiltration membranes by sodium hypochlorite: Effect of solution pH. J. Environ. Sci. 2021, 104, 444–455. [Google Scholar] [CrossRef] [PubMed]

- Woo, Y.C.; Lee, J.J.; Oh, J.S.; Kim, H.S. Effect of chemical cleaning conditions on the flux recovery of MF membrane as pretreatment of seawater desalination. Desalin. Water Treat. 2013, 51, 6329–6337. [Google Scholar] [CrossRef]

- Conidi, C.; Cassano, A.; Drioli, E. A membrane-based study for the recovery of polyphenols from bergamot juice. J. Membr. Sci. 2011, 375, 182–190. [Google Scholar] [CrossRef]

- Zhu, H.X.; Tang, Z.S.; Pan, L.M.; Li, B.; Guo, L.W.; Fu, T.M.; Zhang, Q.C.; Pan, Y.L.; Duan, J.A.; Liu, H.B.; et al. Design, integration, and application of special membrane materials and equipment for new separation process in Chinese materia medica industry. Chin. Tradit. Herb. Drugs 2019, 50, 1776–1784. [Google Scholar]

- Guo, L.W. Thoughts on the systematic research of “separation principle and technology of traditional Chinese medicine”-modern separation science and separation of traditional Chinese medicine. World Sci. Tech Mod. Tradit. Chin. Med. 2005, 4, 61–88. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).