Estimation of Bed Expansion and Separation Density of Gas–Solid Separation Fluidized Beds Using a Micron-Sized-Particle-Dense Medium

Abstract

:1. Introduction

2. Experimental

2.1. Apparatus

2.2. Dense Medium

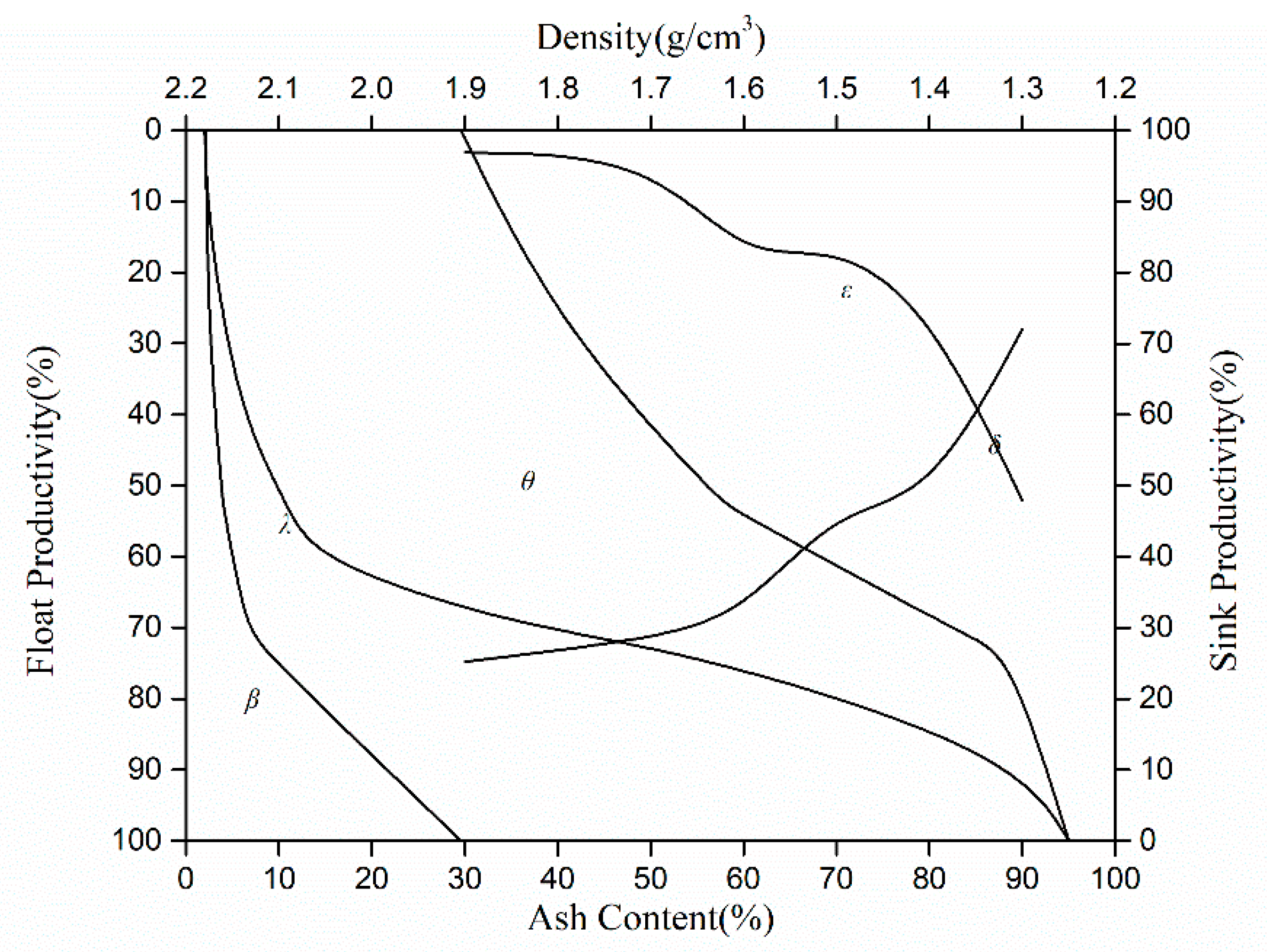

2.3. Feeding Particles’ Properties

3. Theoretic Analysis

3.1. Two-Phase Theory

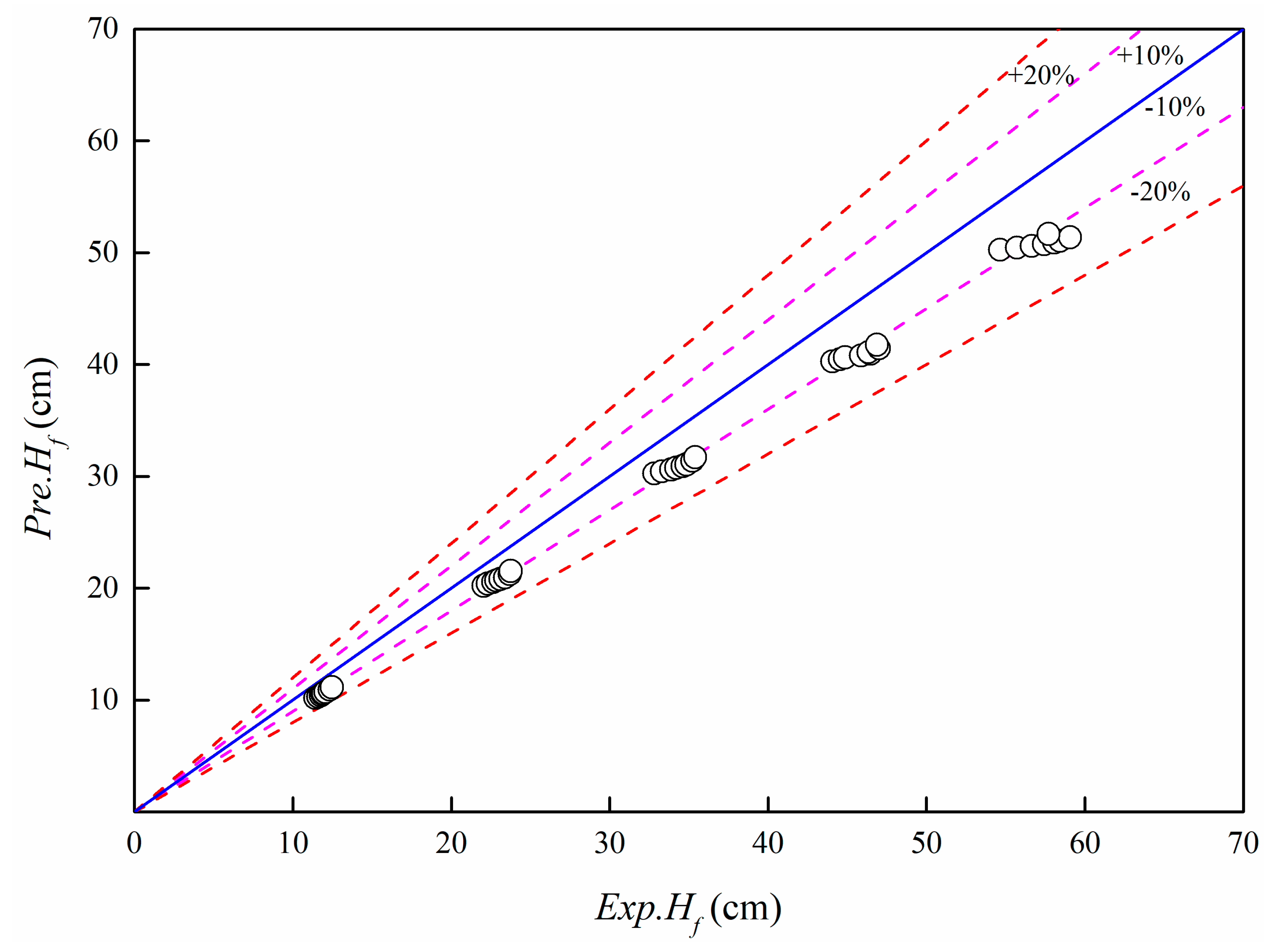

3.2. Bed Expansion Prediction

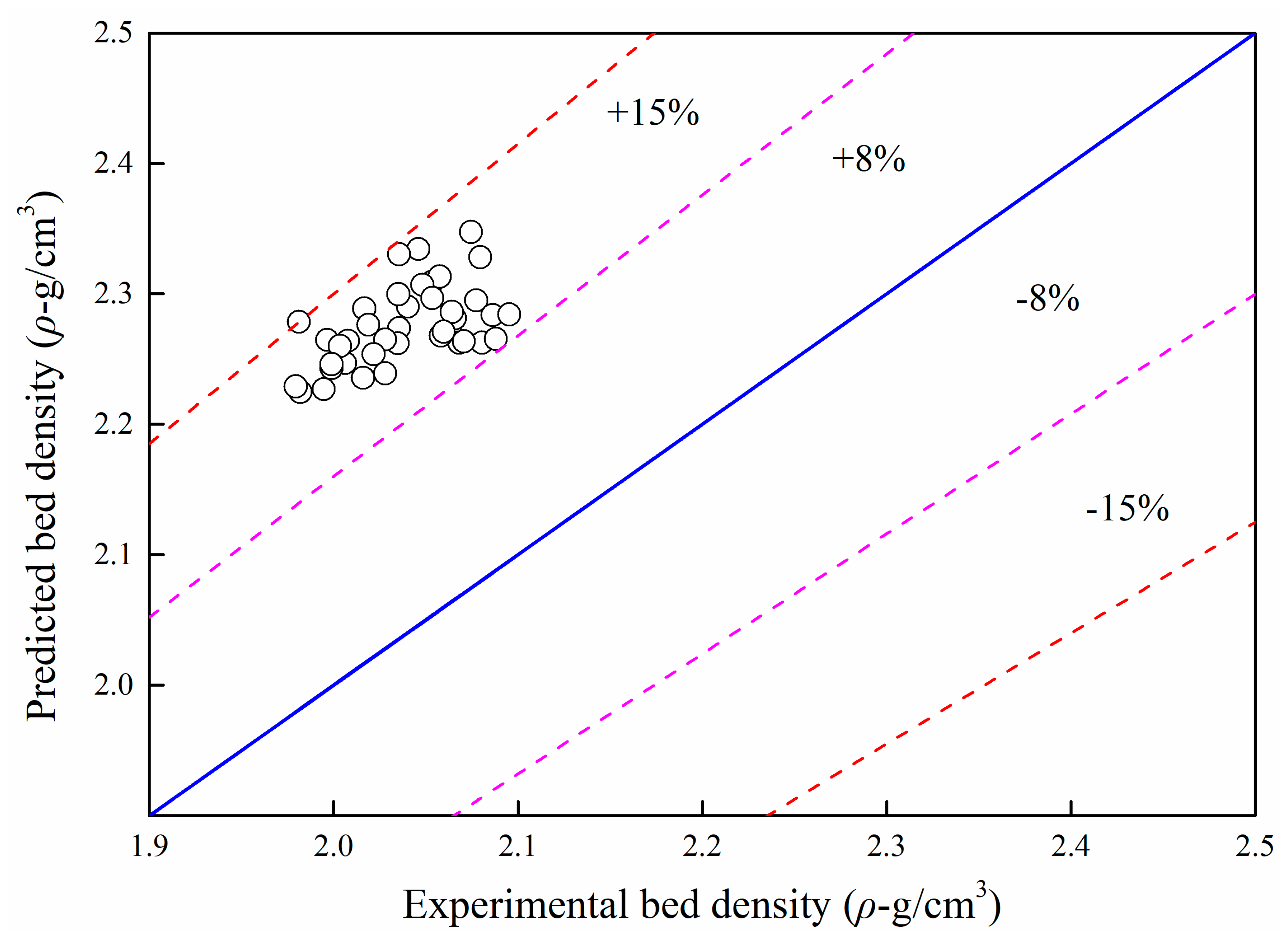

4. Results and Discussions

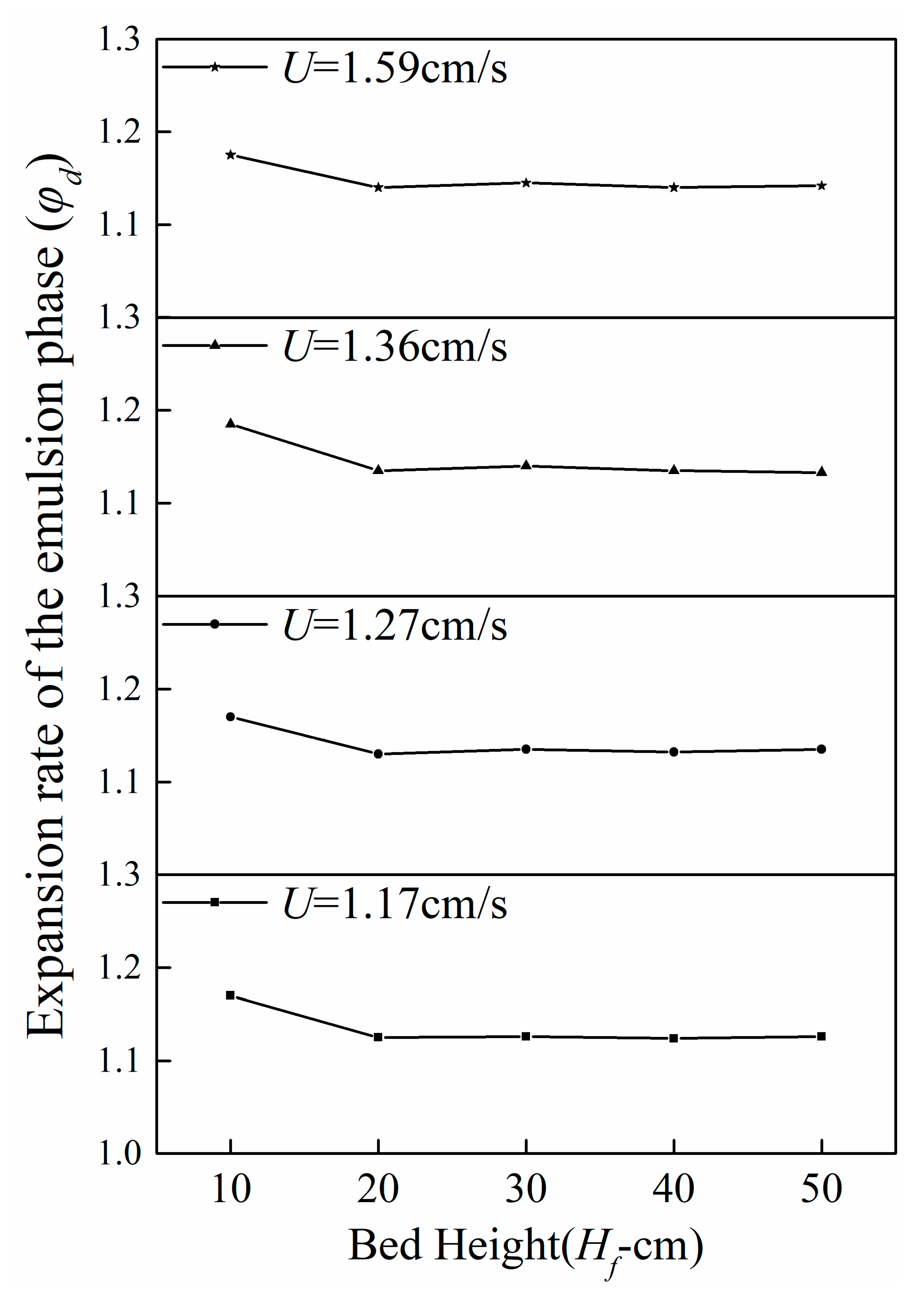

4.1. Emulsion Phase Characterization in the Fluidized Bed

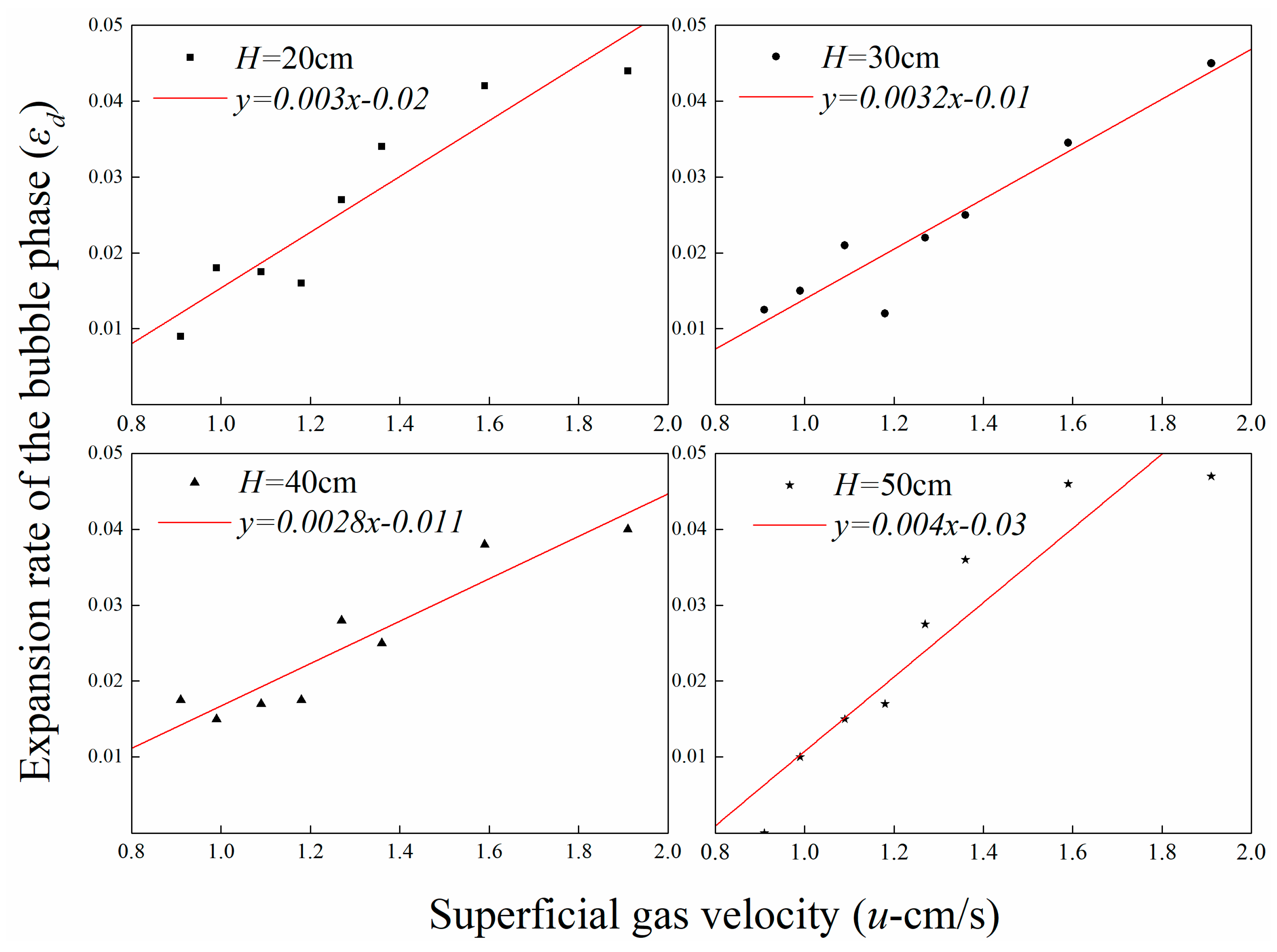

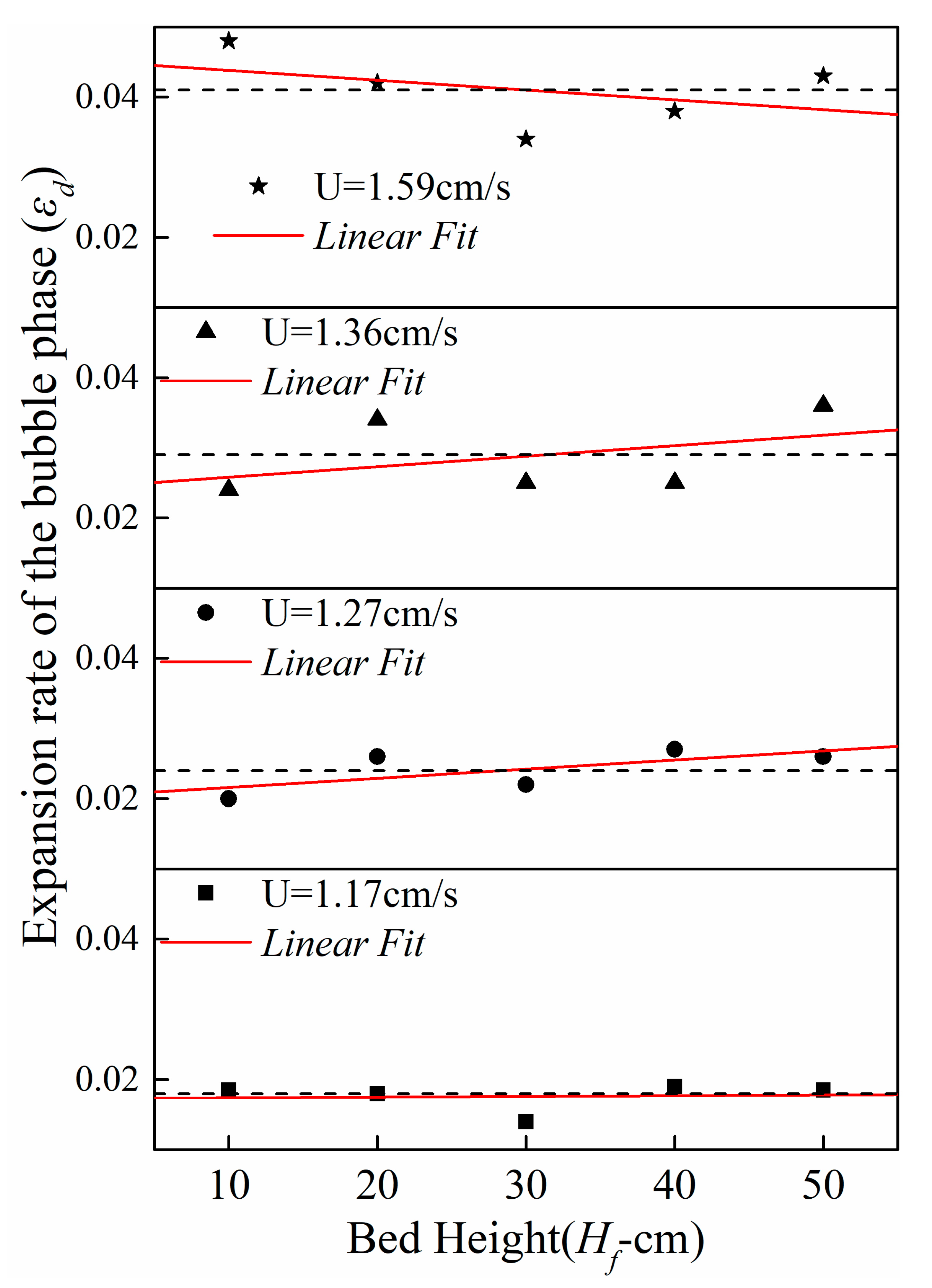

4.2. Bubble Phase Characterization in the Fluidized Bed

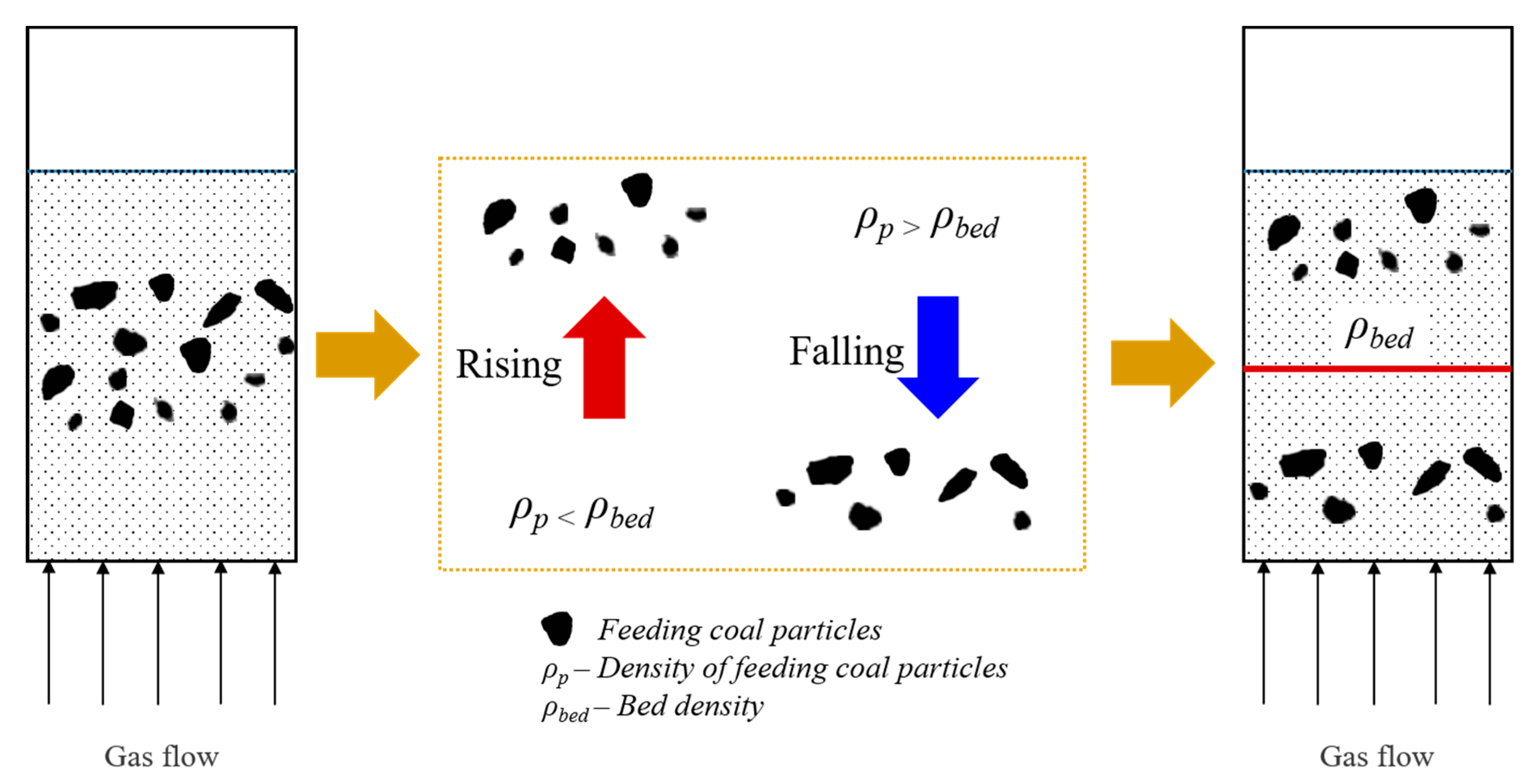

4.3. Bed Density

5. Conclusions

- (1)

- when the superficial gas velocity increased, the expansion rate of the emulsion phase first increased and then gradually stabilized and slightly decreased. With the increase of the bed height, the expansion rate of the emulsion phase decreased to a small extent and gradually stabilized;

- (2)

- With the increase of superficial gas velocity, the proportion of the bubble phase showed an increasing trend as a whole, while the initial bed height had a little influence on the bubble phase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Z.; Hou, Y.; Cao, J.; Ding, Y.; Yuan, X. What drives green development in China: Public pressure or the willingness of local government? Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- Xie, Y.; Hou, Z.; Liu, H.; Cao, C.; Qi, J. The sustainability assessment of CO2 capture, utilization and storage (CCUS) and the conversion of cropland to forestland program (CCFP) in the Water-Energy-Food (WEF) framework towards China’s carbon neutrality by 2060. Environ. Earth Sci. 2021, 80, 468. [Google Scholar] [CrossRef]

- Zhong, S.; Xin, C.; Shen, H.; Chen, X. Effects of land urbanization and internet penetration on environmental sustainability: A cross-regional study of China. Environ. Sci. Pollut. Res. 2021, 28, 66751–66771. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Zhang, G.; Zhao, Y.; Zhou, C.; Dong, L.; Duan, C. Effect of middling coal on separation efficiency in air dense gas–solid fluidized bed. Int. J. Coal Prep. Util. 2021, 41, 628–644. [Google Scholar] [CrossRef]

- Asghari, M.; Noaparast, M.; Shafaie, S.Z.; Ghassa, S.; Chelgani, S.C. Recovery of coal particles from a tailing dam for environmental protection and economical beneficiations. Int. J. Coal Sci. Technol. 2018, 5, 253–263. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, S.K.; Suresh, N.; Varma, A.K. Determining the Best Particle Size-Class for Flotation of a High Ash Coal. Int. J. Coal Prep. Util. 2017, 11, 755–765. [Google Scholar] [CrossRef]

- Saini, M.K.; Srivastava, P.K. Effect of Coal Cleaning on Ash Composition and its Fusion Characteristics for a High-Ash Non-Coking Coal of India. Coal Prep. 2017, 37, 1–11. [Google Scholar] [CrossRef]

- Zhou, E.; Zhang, Y.; Zhao, Y.; Luo, Z.; Duan, C.; Yang, X.; Dong, L.; Zhang, B. Collaborative optimization of vibration and gas flow on fluidization quality and fine coal segregation in a vibrated dense medium fluidized bed. Powder Technol. 2017, 322, 497–509. [Google Scholar] [CrossRef]

- Youqun, S.; Guilin, L.; Li, W. Research on the intelligent jigging coal separation calculation frame based on multi-agent. In Proceedings of the 2002 International Conference on Control and Automation, 2002. ICCA. Final Program and Book of Abstracts, Xiamen, China, 19 June 2002; p. 249. [Google Scholar]

- Wang, B.; Chu, K.W.; Yu, A.B.; Vince, A. Modeling the Multiphase Flow in a Dense Medium Cyclone. Ind. Eng. Chem. Res. 2009, 48, 3628–3639. [Google Scholar] [CrossRef]

- Chu, K.W.; Kuang, S.B.; Yu, A.B.; Vince, A.; Barnett, G.D.; Barnett, P.J. Prediction of wear and its effect on the multiphase flow and separation performance of dense medium cyclone. Miner. Eng. 2014, 56, 91–101. [Google Scholar] [CrossRef]

- Bu, X.; Ni, C.; Xie, G.; Peng, Y.; Ge, L.; Sha, J. Preliminary study on foreign slime for the gravity separation of coarse coal particles in a teeter bed separator. Int. J. Miner. Process. 2017, 160, 76–80. [Google Scholar] [CrossRef]

- Galvin, K.P.; Pratten, S.J.; Lambert, N.; Callen, A.M.; Lui, J. Influence of a jigging action on the gravity separation achieved in a teetered bed separator. Miner. Eng. 2002, 15, 1199–1202. [Google Scholar] [CrossRef]

- Sumer, B.M.; Fredsøe, J.; Christensen, S.; Lind, M.T. Sinking/floatation of pipelines and other objects in liquefied soil under waves. Coast. Eng. 1999, 38, 53–90. [Google Scholar] [CrossRef]

- Ren, D.; Yang, Y.; Yang, Y.; Richards, K.; Zhou, X. Land-Water-Food Nexus and indications of crop adjustment for water shortage solution. Sci. Total Environ. 2018, 626, 11–21. [Google Scholar] [CrossRef]

- Mohanta, S.; Rao, C.S.; Daram, A.B.; Chakraborty, S.; Meikap, B.C. Air Dense Medium Fluidized Bed for Dry Beneficiation of Coal: Technological Challenges for Future. Part. Sci. Technol. 2013, 31, 16–27. [Google Scholar] [CrossRef]

- Sahu, A.K.; Parida, S.K.B.; Parida, A. Development of Air Dense Medium Fluidized Bed Technology For Dry Beneficiation of Coal—A Review. Int. J. Coal Prep. Util. 2009, 29, 216–241. [Google Scholar] [CrossRef]

- Luo, Z.F.; Chen, Q.R. Dry beneficiation technology of coal with an air dense-medium fluidized bed. Int. J. Miner. Process. 2001, 63, 167–175. [Google Scholar]

- Luo, Z.; Zhao, Y.; Yu, X.; Duan, C.; Song, S.; Yang, X. Effects of characteristics of clapboard unit on separation of <6 mm fine coal in a compound dry separator. Powder Technol. 2017, 321, 232–241. [Google Scholar] [CrossRef]

- Yu, X.; Luo, Z.; Li, H.; Gan, D. Effect of vibration on the separation efficiency of oil shale in a compound dry separator. Fuel 2018, 214, 242–253. [Google Scholar] [CrossRef]

- Boylu, F.; Tali, E.; Cetinel, T.; Celik, M.S. Effect of fluidizing characteristics on upgrading of lignitic coals in gravity based air jig. Int. J. Miner. Process. 2014, 129, 27–35. [Google Scholar] [CrossRef]

- Breuer, H.; Snoby, R.J.; Mshra, S.; Biswal, D. Dry coal jigging—A suitable alternative for Indian power coals. J. Mines Met. Fuels 2009, 57, 425–428. [Google Scholar]

- Yang, X.; Fu, Z.; Zhao, J.; Zhou, E.; Zhao, Y. Process analysis of fine coal preparation using a vibrated gas-fluidized bed. Powder Technol. 2015, 279, 18–23. [Google Scholar] [CrossRef]

- Yang, X.L.; Fu, Z.J.; Zhao, Y.M. Slugging Behavior of Geldart D Particles in a Vibrated Gas-Fluidized Bed. Part. Sci. Technol. 2014, 32, 537–543. [Google Scholar] [CrossRef]

- Yang, X.L.; Zhao, Y.M.; Luo, Z.F.; Song, S.L.; Duan, C.L.; Dong, L. Fine coal dry cleaning using a vibrated gas-fluidized bed. Fuel Process. Technol. 2013, 106, 338–343. [Google Scholar] [CrossRef]

- Luo, Z.F.; Zhao, Y.M.; Chen, Q.R.; Fan, M.M.; Tao, X.X. Separation characteristics for fine coal of the magnetically fluidized bed. Fuel Process. Technol. 2002, 79, 63–69. [Google Scholar] [CrossRef]

- Hao, B.G.; Bi, H.T. Forced bed mass oscillations in gas-solid fluidized beds. Powder Technol. 2005, 149, 51–60. [Google Scholar] [CrossRef]

- Saidi, M.; Tabrizi, H.B.; Grace, J.R.; Lim, C.J.; Ahmad, G. Hydrodynamic and Mixing Characteristics of Gas-Solid Flow in a Pulsed Spouted Bed. Ind. Eng. Chem. Res. 2015, 54, 7933–7941. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, G.; Luo, Z.; Zhang, B.; Dong, L.; Liang, C.; Duan, C. Industrial Application of a Modularized Dry-Coal-Beneficiation Technique Based on a Novel Air Dense Medium Fluidized Bed. Int. J. Coal Prep. Util. 2017, 37, 44–57. [Google Scholar] [CrossRef]

- Geldart, D. Types of gas fluidization. Powder Technol. 1973, 7, 285–292. [Google Scholar] [CrossRef]

- Zhou, C.; Dong, L.; Zhao, Y.; Fan, X. Studies on Bed Density in a Gas-Vibro Fluidized Bed for Coal Cleaning. ACS Omega 2019, 4, 12817–12826. [Google Scholar] [CrossRef] [Green Version]

- Fan, X.; Zhou, C.; Zhao, Y.; Duan, C.; Liu, Q. Flow pattern transition and coal beneficiation in gas solid fluidized bed with novel secondary distributor. Adv. Powder Technol. 2018, 29, 1255–1264. [Google Scholar] [CrossRef]

- Fan, X.C.; Zhou, C.Y.; Dong, L.; Zhao, Y.M.; Duan, C.L.; Zhang, B. Novel method of air distributor design for enhancing bed stability and reducing impurities in gas-solid fluidized bed system. Part. Sci. Technol. 2019, 37, 652–664. [Google Scholar] [CrossRef]

- Geldart, D. Gas Fluidization Technology; John Wiley and Sons Inc.: New York, NY, USA, 1986. Available online: https://www.osti.gov/biblio/6808024 (accessed on 8 December 2021).

- Li, G.; Liu, X.; Duan, C.; Liu, Q.; Zhao, Y.; Gupta, R. Study on the spatial and temporal distribution of the bed density in an air dense medium fluidized bed (ADMFB) based on the electrical capacitance tomography (ECT) measurement system. Powder Technol. 2021, 393, 659–669. [Google Scholar] [CrossRef]

- Liu, X.; Fan, X.; Zhao, Y.; Duan, C.; Zhou, C. Particles movement behavior and apparent density in gas–solid fluidized bed as determined by an electronic dynamometer and electrical capacitance tomography. Chem. Eng. J. 2022, 429, 132463. [Google Scholar] [CrossRef]

- Zhou, E.; Zhang, Y.; Zhao, Y.; Tian, Q.; Chen, Z.; lv, G.; Yang, X.; Dong, L.; Duan, C. Influence of bubbles on the segregated stability of fine coal in a vibrated dense medium gas–solid fluidized bed. Particuology 2021, 58, 259–267. [Google Scholar] [CrossRef]

- Matheson, G.L.; Herbst, W.A.; Holt, P.H. Characteristics of Fluid-Solid Systems. Ind. Eng. Chem. 1949, 41, 1098–1104. [Google Scholar] [CrossRef]

- Bertil Andersson, K.E. Pressure drop in ideal fluidization. Chem. Eng. Sci. 1961, 15, 276–297. [Google Scholar] [CrossRef]

- Pyle, D.L.; Harrison, D. The rising velocity of bubbles in two-dimensional fluidised beds. Chem. Eng. Sci. 1967, 22, 531–535. [Google Scholar] [CrossRef]

- Toomey, R.D.; Johnstone, H.F. Gaseous fluidization of solid particles. Chem. Eng. Prog. 1952, 48, 220–225. [Google Scholar]

- Asthana, H.; Sarkar, S. Coal cleaning in fluidized bed. Chem. Ages India 1969, 20, 792–796. [Google Scholar]

- Peters, M.H.; Fan, L.-S.; Sweeney, T.L. Reactant dynamics in catalytic fluidized bed reactors with flow reversal of gas in the emulsion phaset. Chem. Eng. Sci. 1982, 37, 553–565. [Google Scholar] [CrossRef]

- Davidson, J.F.; Harrison, D.; Jackson, R. Fluidized particles: Cambridge University Press, 1963. 155 pp. 35s. Chem. Eng. Sci. 1964, 19, 701. [Google Scholar] [CrossRef]

- Darton, R.C.; Lanauze, R.D.; Davidson, J.F.; Harrison, D. Bubble Growth Due To Coalescence in Fluidized Beds. Trans. Inst. Chem. Eng. 1977, 55, 274–280. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, X.; Zhou, C. Estimation of Bed Expansion and Separation Density of Gas–Solid Separation Fluidized Beds Using a Micron-Sized-Particle-Dense Medium. Separations 2021, 8, 242. https://doi.org/10.3390/separations8120242

Fan X, Zhou C. Estimation of Bed Expansion and Separation Density of Gas–Solid Separation Fluidized Beds Using a Micron-Sized-Particle-Dense Medium. Separations. 2021; 8(12):242. https://doi.org/10.3390/separations8120242

Chicago/Turabian StyleFan, Xuchen, and Chenyang Zhou. 2021. "Estimation of Bed Expansion and Separation Density of Gas–Solid Separation Fluidized Beds Using a Micron-Sized-Particle-Dense Medium" Separations 8, no. 12: 242. https://doi.org/10.3390/separations8120242

APA StyleFan, X., & Zhou, C. (2021). Estimation of Bed Expansion and Separation Density of Gas–Solid Separation Fluidized Beds Using a Micron-Sized-Particle-Dense Medium. Separations, 8(12), 242. https://doi.org/10.3390/separations8120242