Influence of Vortex Finder Structure on Separation Performance of Double-Overflow Three-Product Hydrocyclones

Abstract

1. Introduction

2. Materials and Methods

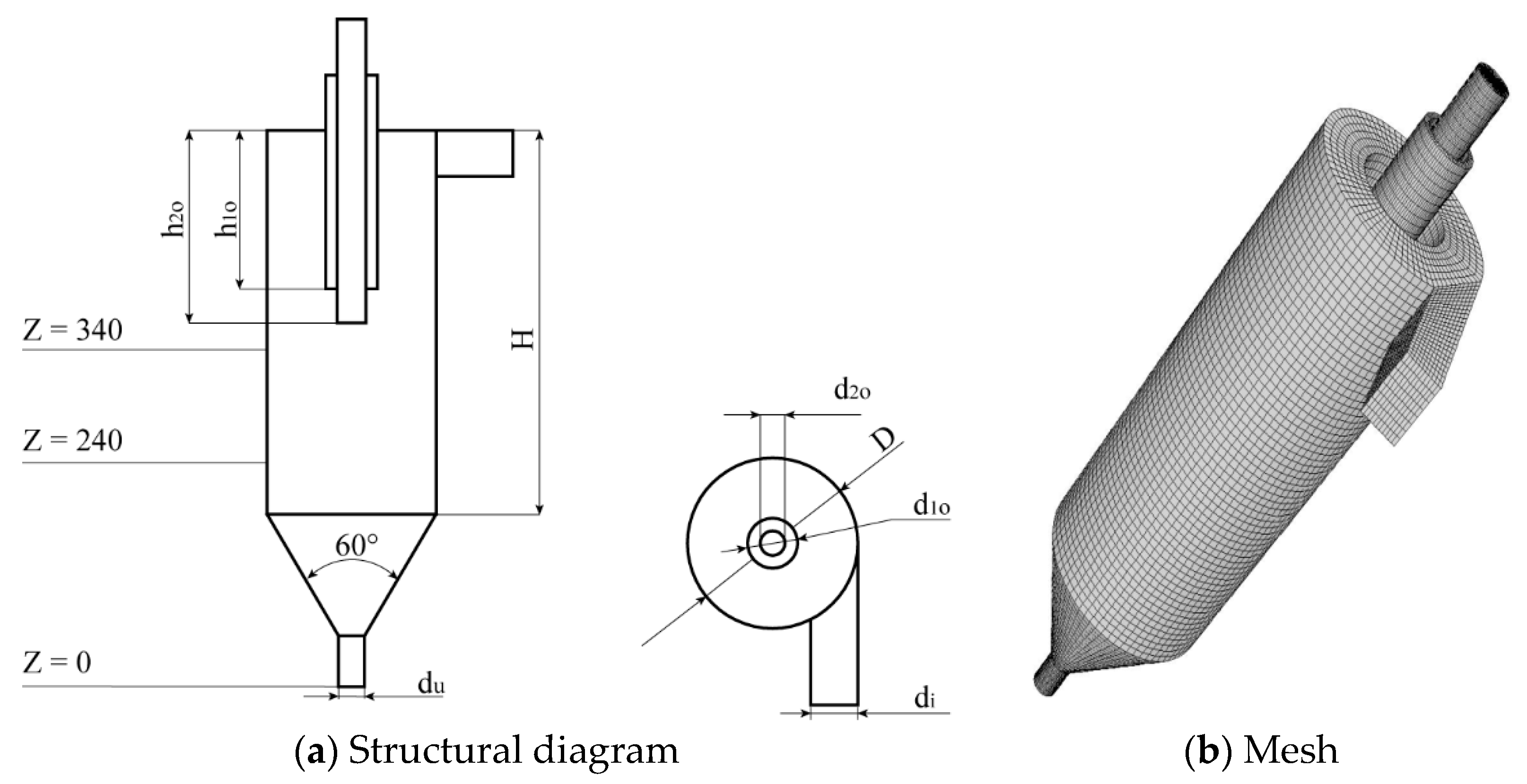

2.1. Double-Overflow Three-Product Hydrocyclone

2.2. Simulation Conditions

2.3. Simulated Solution Method

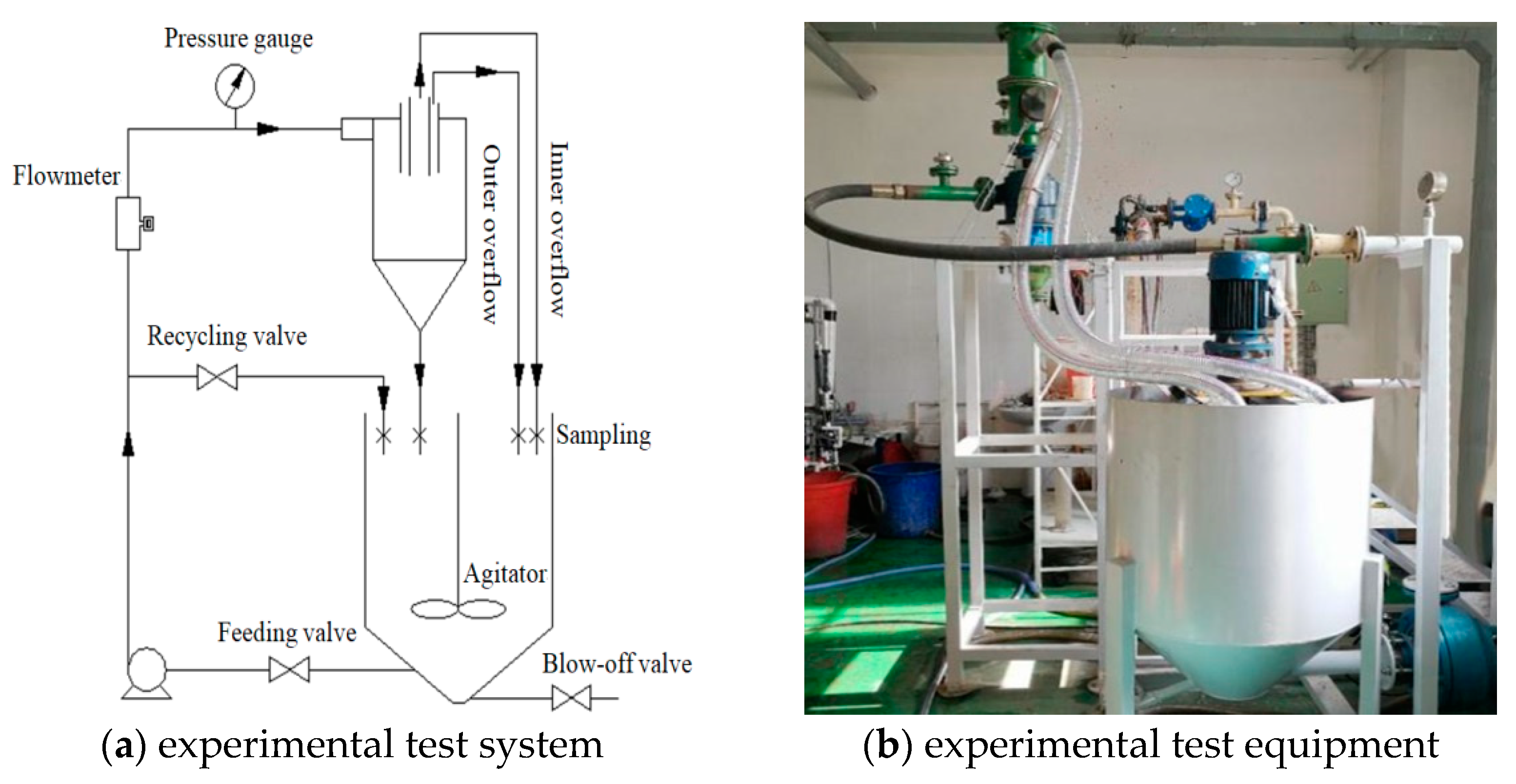

2.4. Experimental Test System

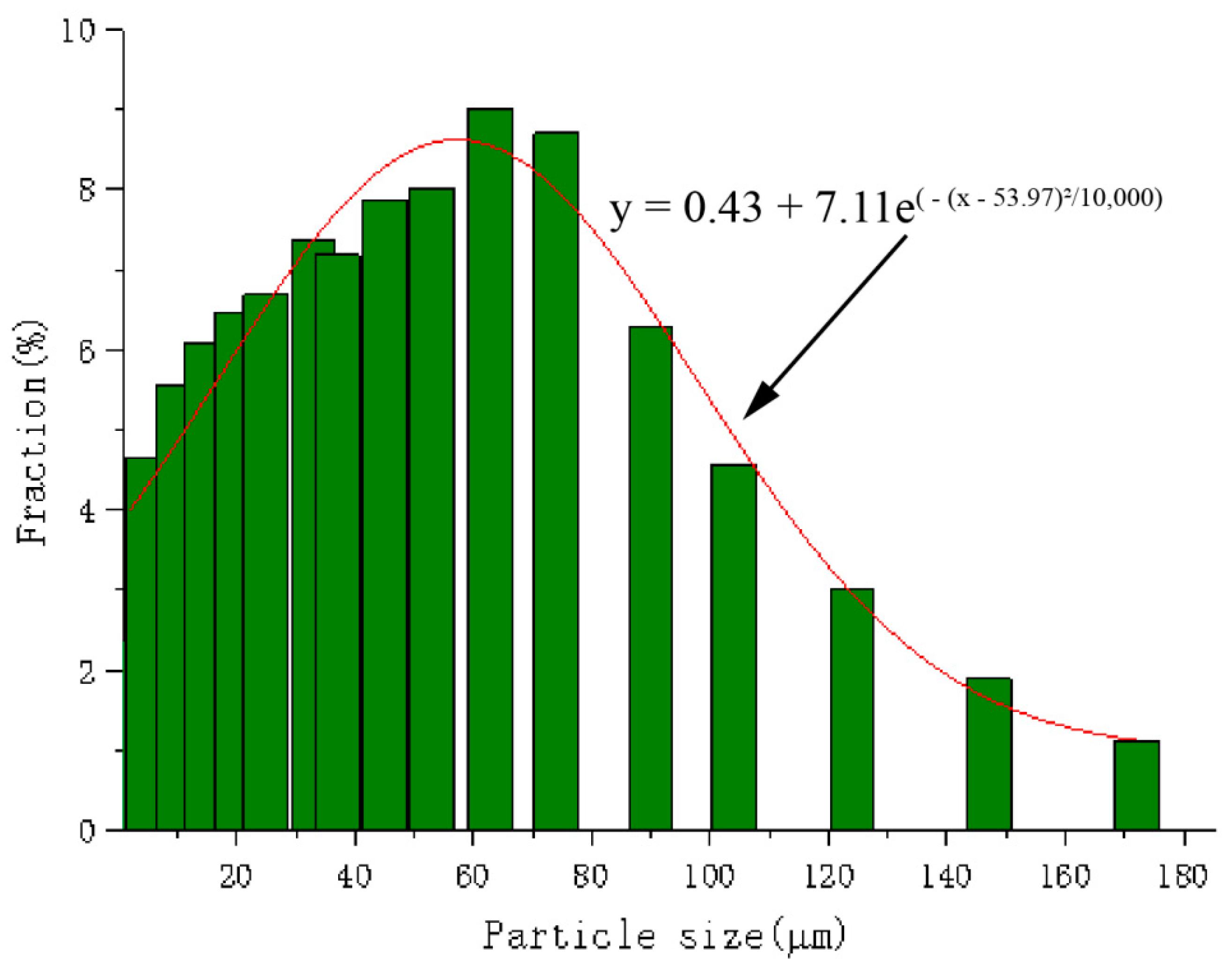

2.5. Experimental Materials

3. Results

3.1. Numerical Simulation Study

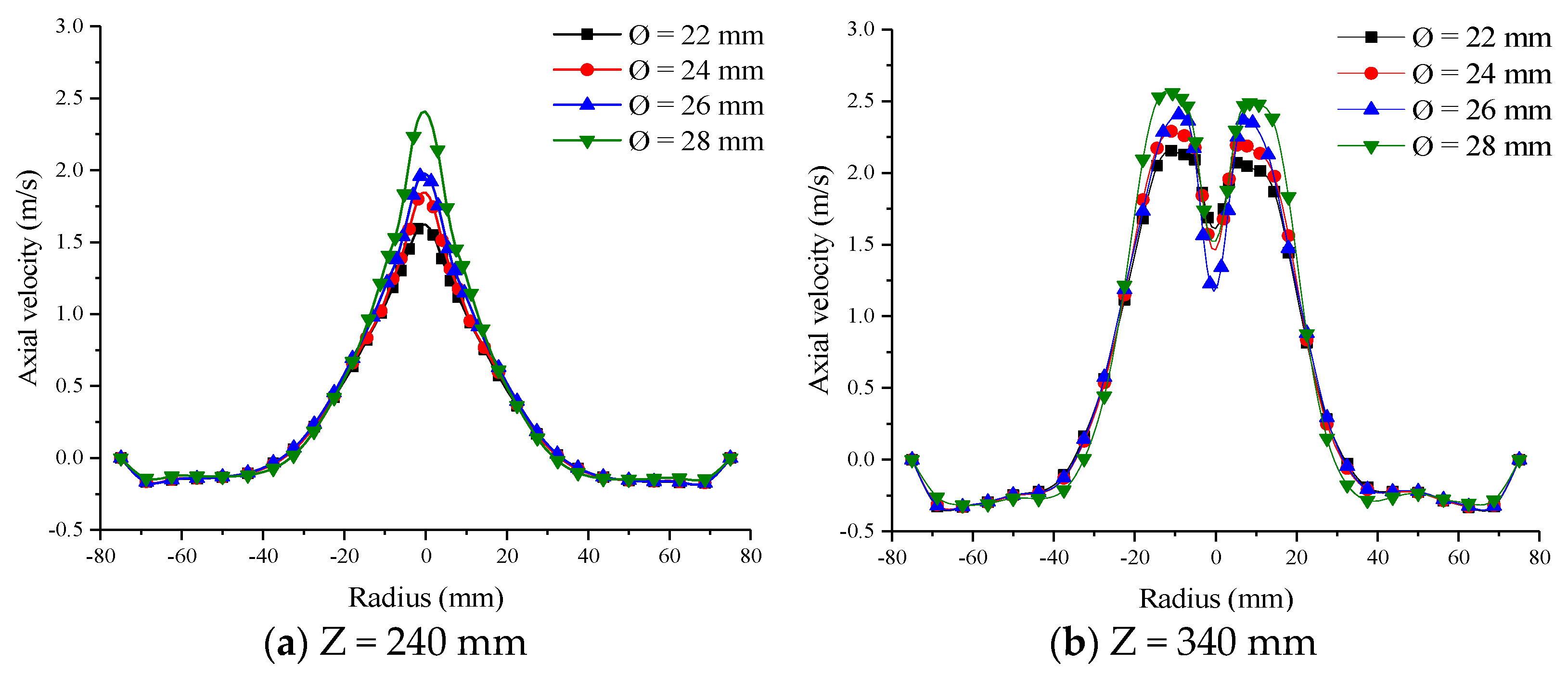

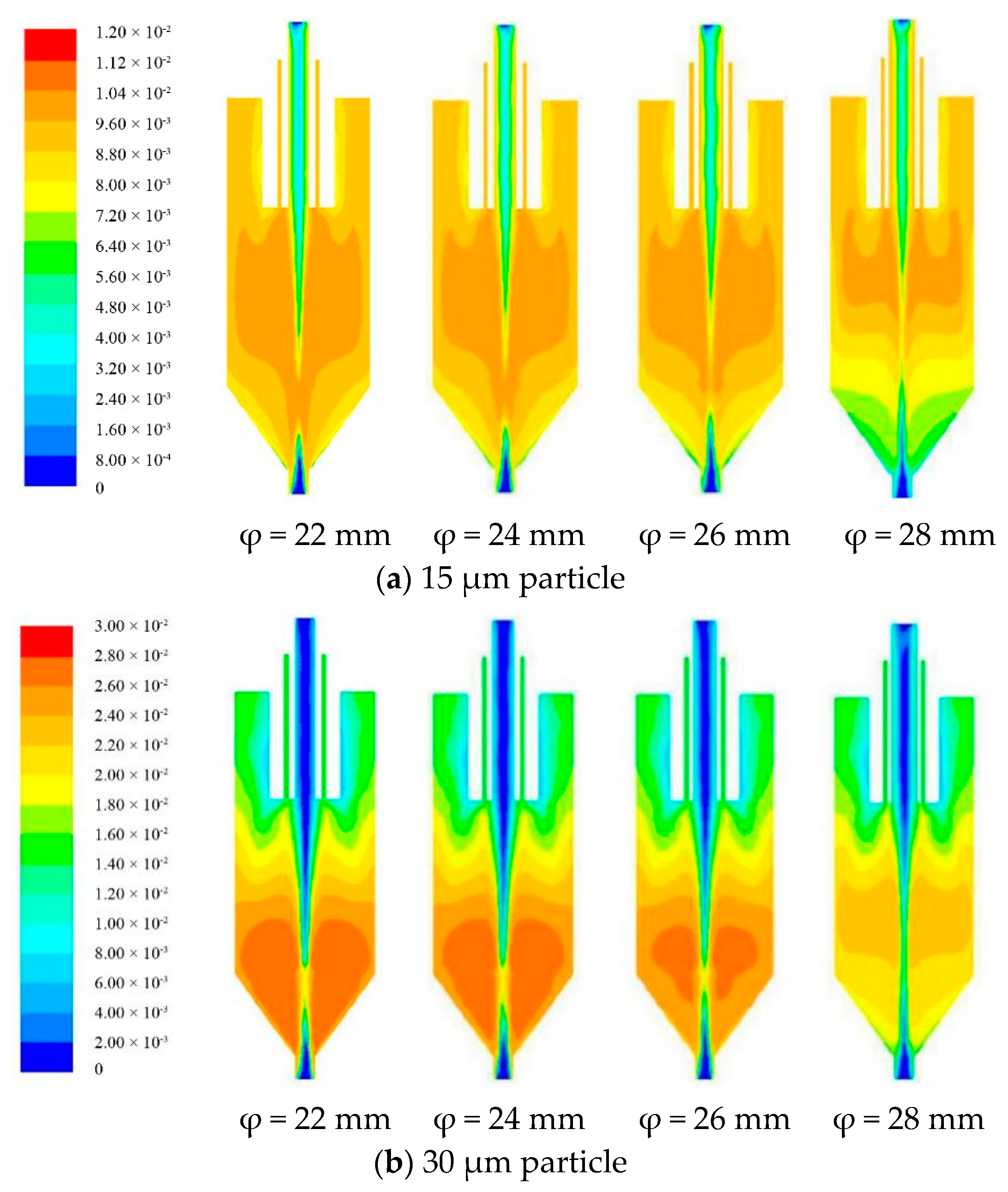

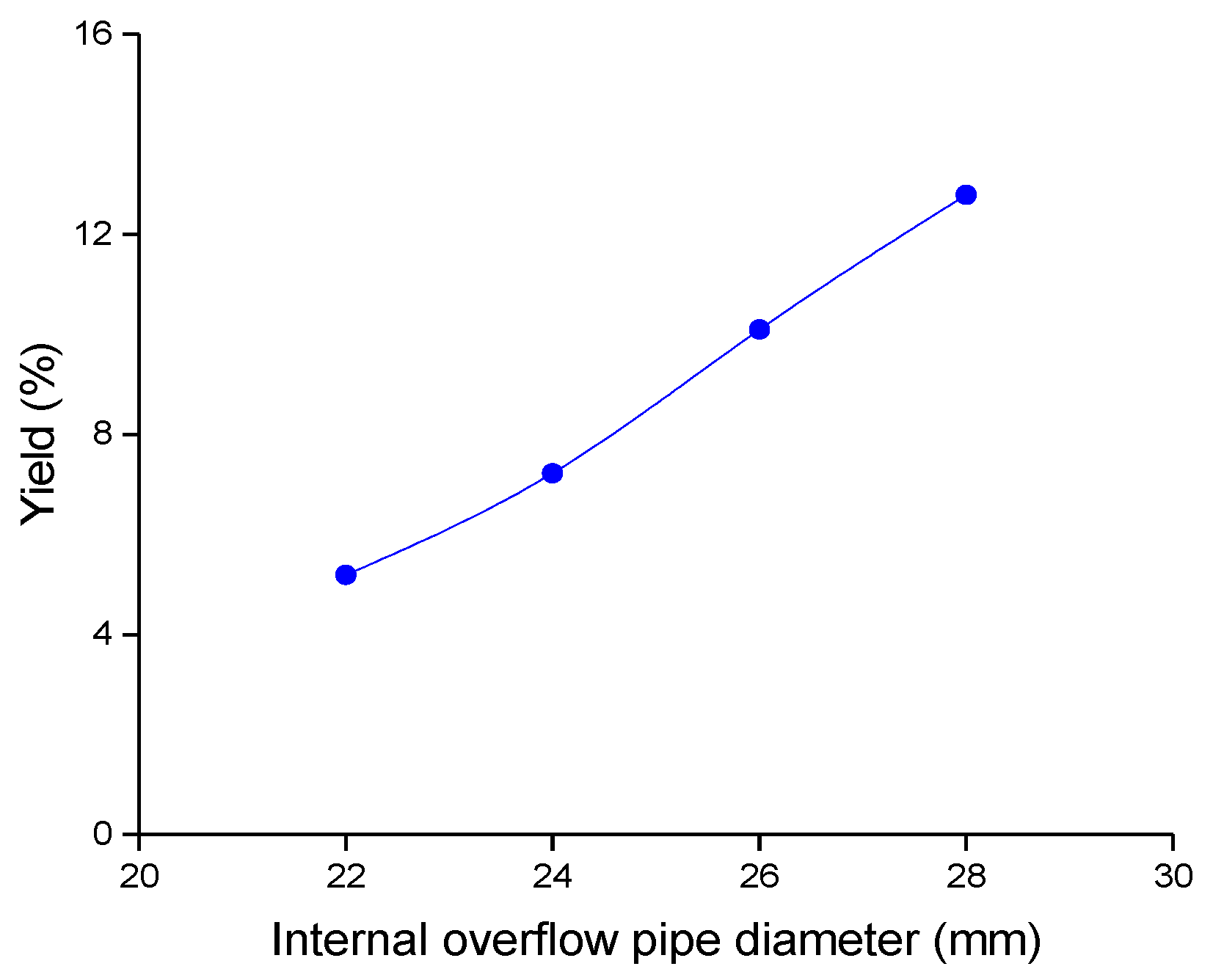

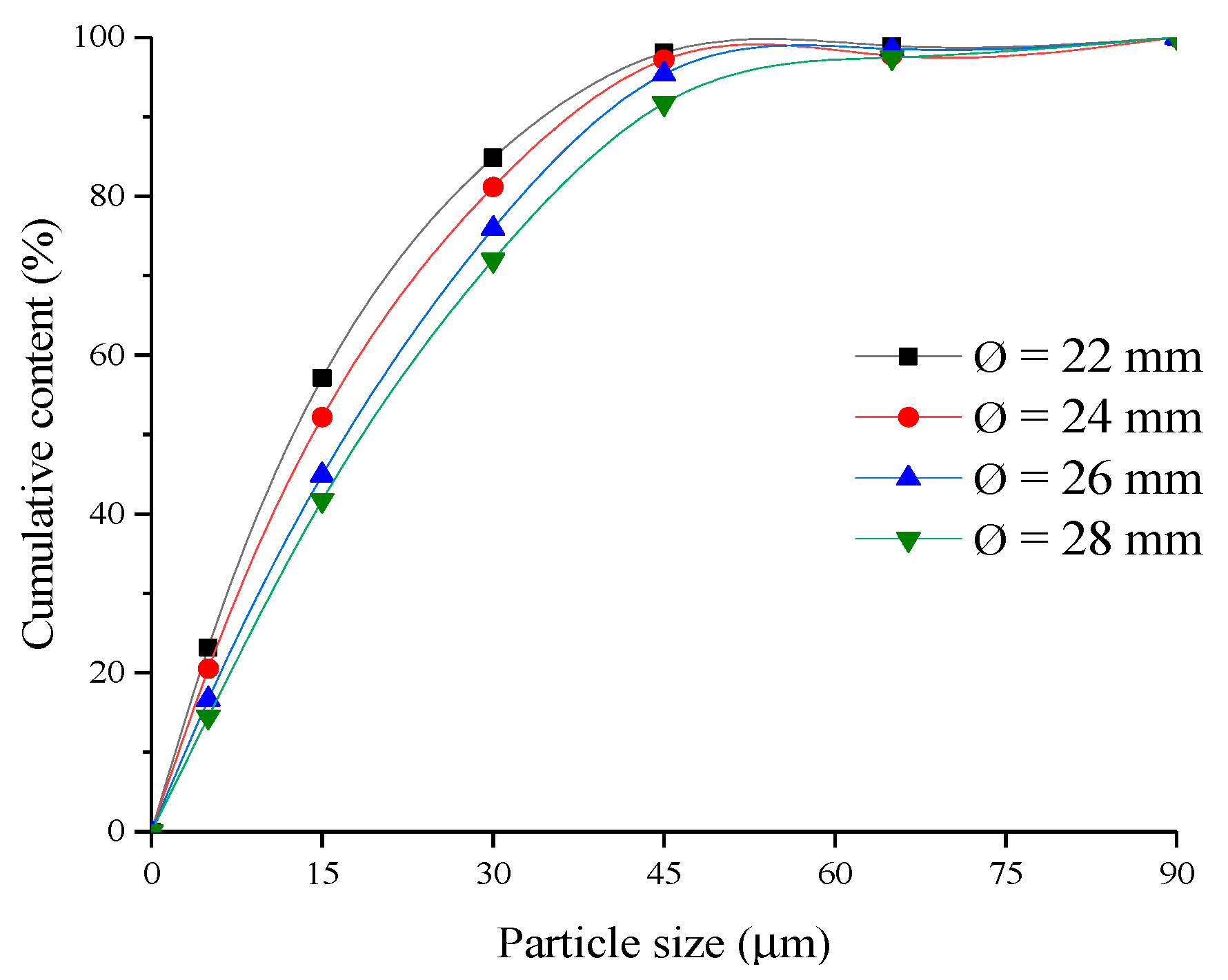

3.1.1. Influence of Vortex Finder Diameter on Separation Performance

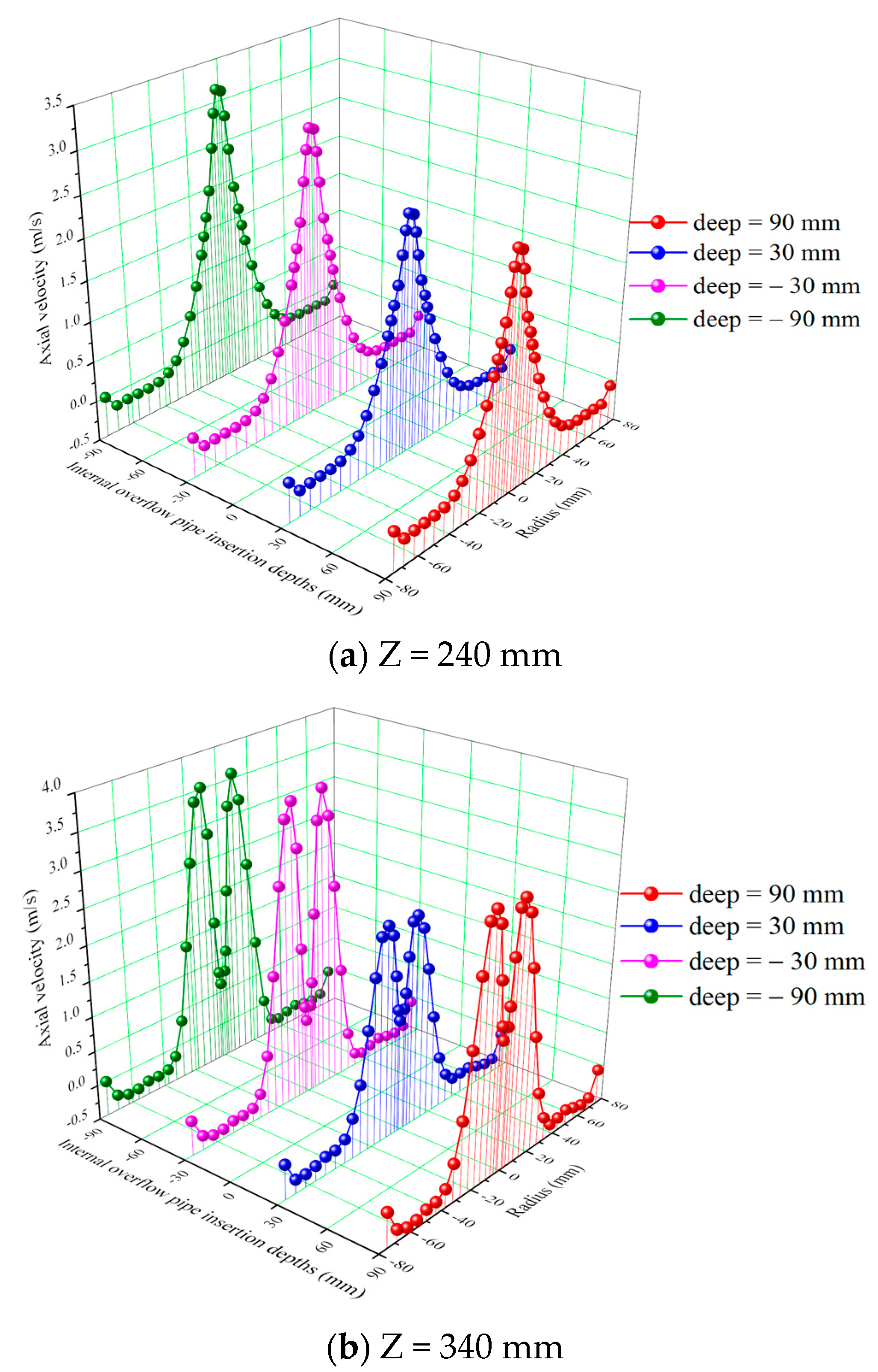

3.1.2. Influence of Vortex Finder Insertion Depth on Separation Performance

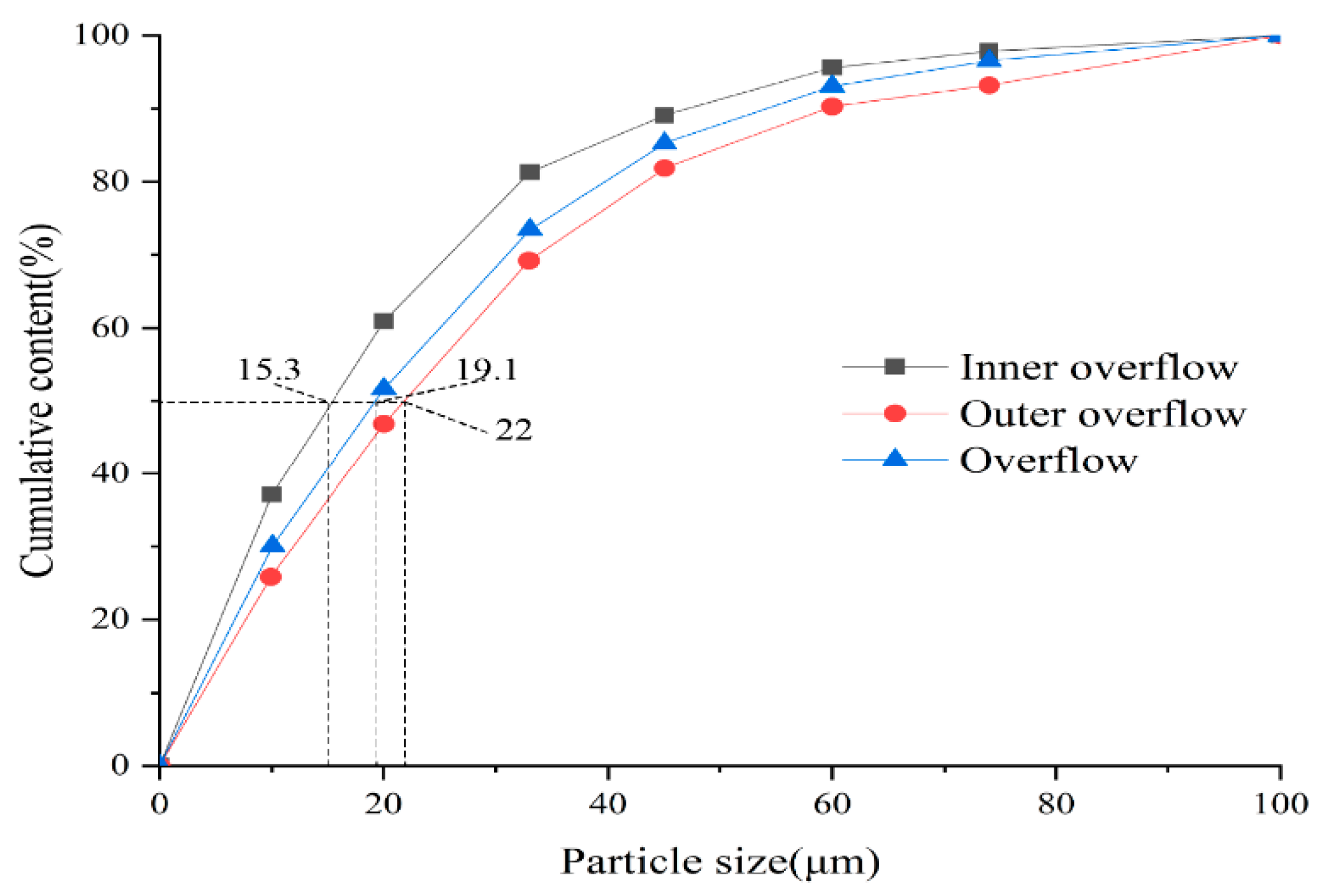

3.2. Experimental Study on Separation Performance

3.2.1. Experimental Analysis of the Influence of the Internal Vortex Finder Diameter on the Separation Performance

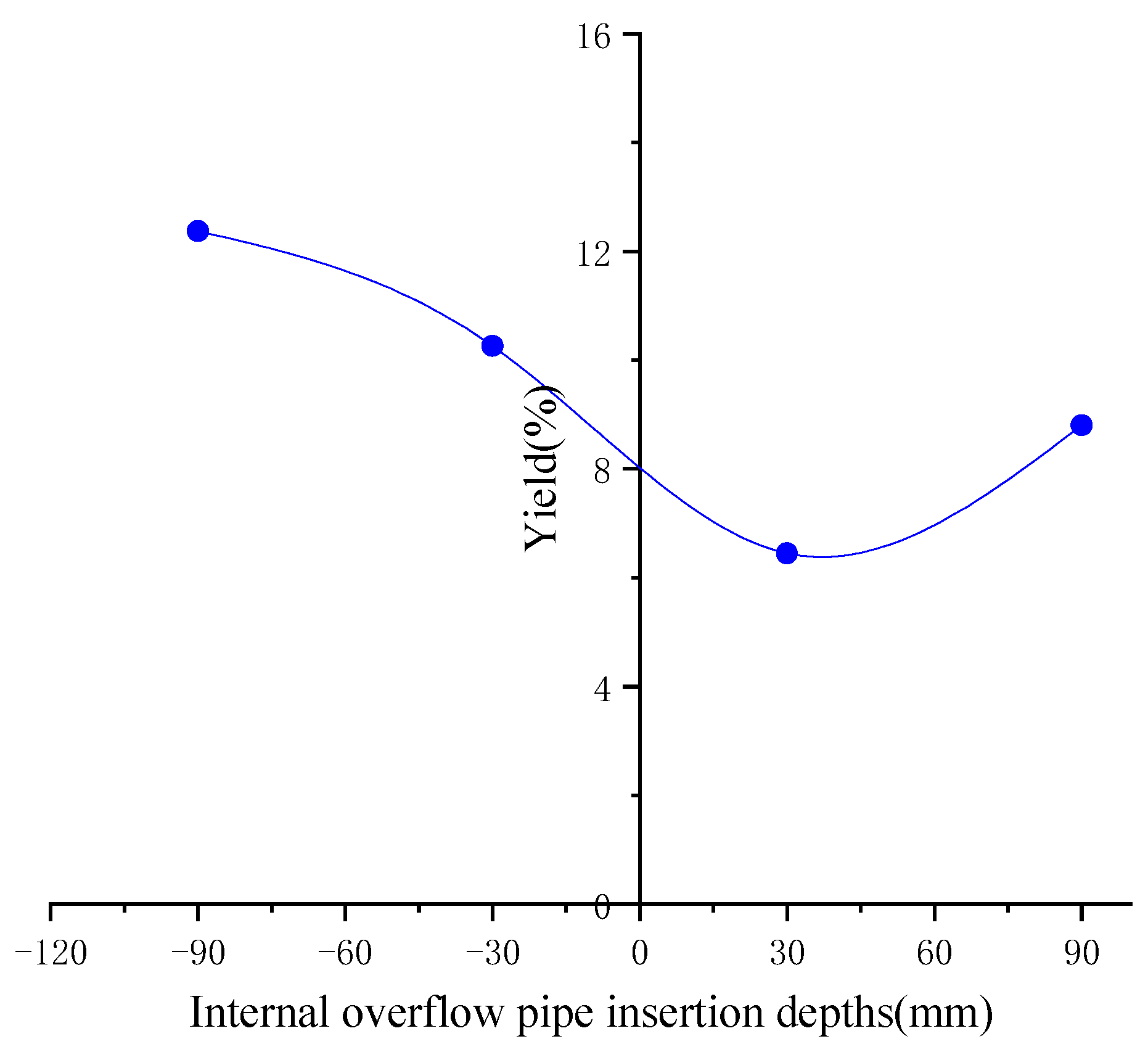

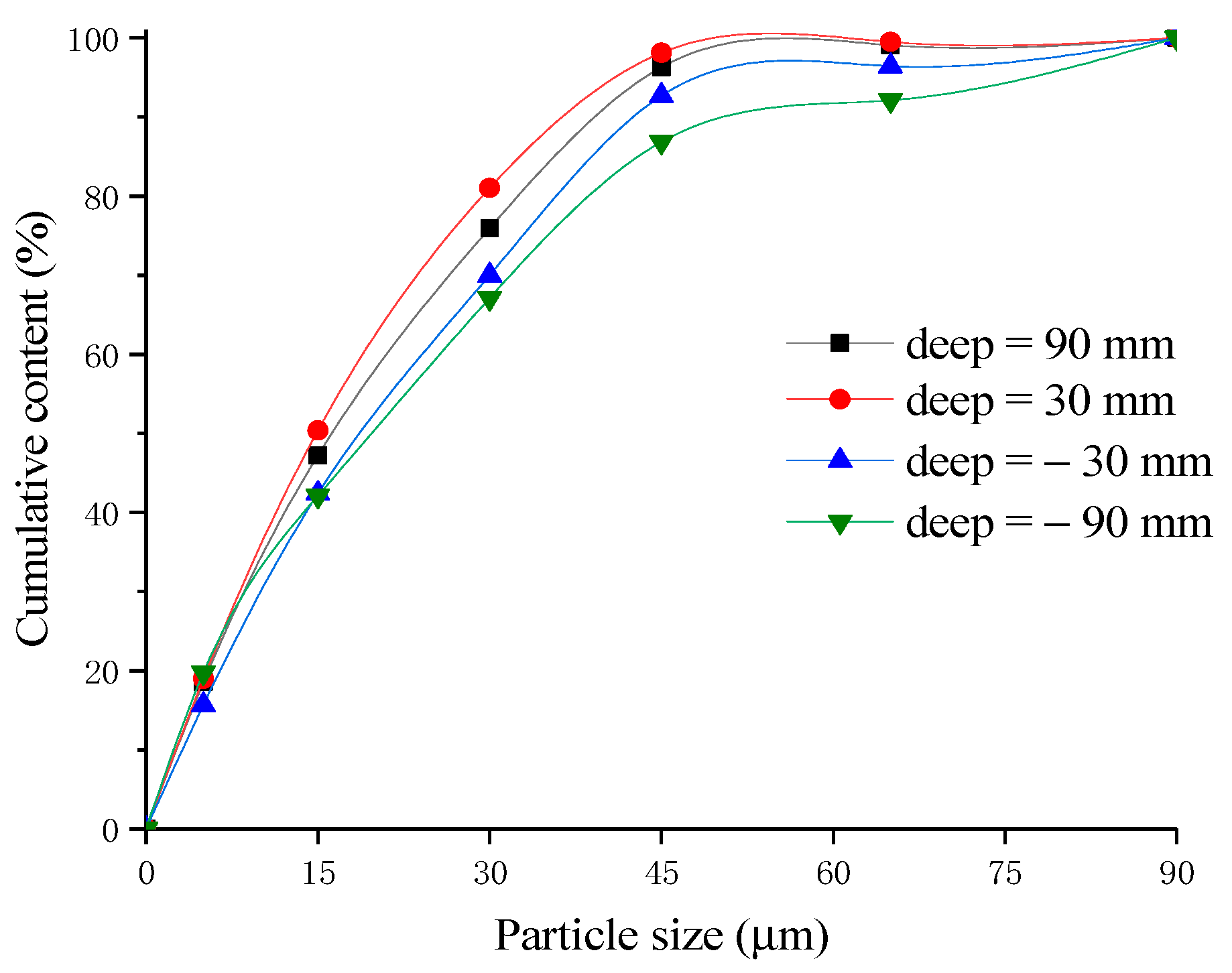

3.2.2. Influence on the Separation Performance of the Insertion Depth of the Internal Vortex Finder

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sripriya, R.; Suresh, N.; Chakraborty, S.; Meikap, B.C. Improvement of performance efficiency of a hydrocyclone with design modification by suppressing air core. Korean J. Chem. Eng. 2011, 28, 225–231. [Google Scholar] [CrossRef]

- Svarovsky, L. Solid-Liquid Separation; Butterworths: London, UK, 1981. [Google Scholar]

- Wang, B.; Chu, K.W.; Yu, A.B. Numerical Study of Particle-Fluid Flow in a Hydrocyclone. Ind. Eng. Chem. Res. 2007, 46, 4695–4705. [Google Scholar] [CrossRef]

- Wang, C.; Ji, C.; Zou, J. Simulation and experiment on transitional behaviours of multiphase flow in a hydrocyclone. Can. J. Chem. Eng. 2015, 93, 1802–1811. [Google Scholar] [CrossRef]

- Laleh, A.; Seyfi, M.M.; Nezamedin, H.S.; Alireza, F.; Ehsan, S.; Mahmoud, H.; Maryam, K. Numerical and Experimental Biomass Separation from Fermentation Process by Minihydrocyclones. Chem. Eng. Technol. 2020, 44, 23–30. [Google Scholar]

- Wang, C.; Sun, X.; Shen, L.; Wang, G. Analysis and Prediction of Influencing Parameters on the Coal Classification Performance of a Novel Three Products Hydrocyclone Screen (TPHS) Based on Grey System Theory. Processes 2020, 8, 974. [Google Scholar] [CrossRef]

- Padhi, M.; Mangadoddy, N.; Sreenivas, T.; Vakamalla, T.R.; Mainza, A.N. Study on multi-component particle behaviour in a hydrocyclone classifier using experimental and computational fluid dynamics techniques. Sep. Purif. Technol. 2019, 229, 115698. [Google Scholar] [CrossRef]

- Tan, F.; Karagoz, I.; Avci, A. The Effects of Vortex Finder Dimensions on the Natural Vortex Length in a New Cyclone Separator. Chem. Eng. Commun. 2016, 203, 1216–1221. [Google Scholar] [CrossRef]

- Sripriya, R.; Kaulaskar, M.D.; Chakraborty, S.; Meikap, B.C. Studies on the performance of a hydrocyclone and modeling for flow characterization in presence and absence of air core. Chem. Eng. Sci. 2007, 62, 6391–6402. [Google Scholar] [CrossRef]

- Habibian, M.; Pazouki, M.; Ghanaie, H.; Abbaspour-Sani, K. Application of hydrocyclone for removal of yeasts from alcohol fermentations broth. Chem. Eng. J. 2008, 138, 30–34. [Google Scholar] [CrossRef]

- Sabbagh, R.; Lipsett, M.G.; Koch, C.R.; Nobes, D.S. An experimental investigation on hydrocyclone underflow pumping. Powder Technol. 2017, 305, 99–108. [Google Scholar] [CrossRef]

- Mokni, I.; Dhaouadi, H.; Bournot, P.; Mhiri, H. Numerical investigation of the effect of the cylindrical height on separation performances of uniflow hydrocyclone. Chem. Eng. Sci. 2015, 122, 500–513. [Google Scholar] [CrossRef]

- Narasimha, M.; Brennan, M.S.; Holtham, P.N. CFD modeling of hydrocyclones: Prediction of particle size segregation. Miner. Eng. 2012, 39, 173–183. [Google Scholar] [CrossRef]

- Chu, K.; Chen, J.; Yu, A. Applicability of a coarse-grained CFD–DEM model on dense medium cyclone. Miner. Eng. 2016, 90, 43–54. [Google Scholar] [CrossRef]

- Son, J.H.; Hong, M.; Yoo, H.C.; Kim, Y.I.; Kim, H.D.; Kim, J.T. A multihydrocyclone water pretreatment system to reduce suspended solids and the chemical oxygen demand. Desalin. Water Treat 2016, 57, 2996–3001. [Google Scholar] [CrossRef]

- Santos, S.; Jones, K.; Abdul, R.; Boswell, J.; Paca, J. Treatment of wet process hardboard plant VOC emissions by a pilot scale biological system. Biochem. Eng. J. 2007, 37, 261–270. [Google Scholar] [CrossRef]

- Tian, J.; Ni, L.; Song, T.; Olson, J.; Zhao, J. An overview of operating parameters and conditions in hydrocyclones for enhanced separations. Sep. Purif. Technol. 2018, 206, 268–285. [Google Scholar] [CrossRef]

- Ji, L.; Kuang, S.; Yu, A. Numerical Investigation of Hydrocyclone Feed Inlet Configurations for Mitigating Particle Misplacement. Ind. Eng. Chem. Res. 2019, 58, 16823–16833. [Google Scholar] [CrossRef]

- Shakeel, S.M.; Fateme, M.; Christopher, M.; Taylor Robert, A.; Ebrahimi, W.M. Particle movement and fluid behavior visualization using an optically transparent 3D-printed micro-hydrocyclone. Biomicrofluidics 2020, 14, 06416. [Google Scholar]

- Lianping, D.; Jianchuan, G.; Hongli, Y.; Jiang, F. Experimental study on the separation effect based on density in hydrocyclone and the classification effect based on size in water-only cyclone. J. China Coal Soc. 2014, 39, 954–960. [Google Scholar]

- Ying, R.; Yu, J.; Wang, W.; Zhang, T.; Feng, J.; Du, S. Optimization of structural and process parameters for fine particle classifying hydrocyclone. J. Mech. Eng. 2017, 53, 124–134. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, Z.; Chen, J. Effect of Inlet Air Volumetric Flow Rate on the Performance of a Two-Stage Cyclone Separator. ACS Omega 2018, 3, 13219–13226. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, P.; Jiang, L.; Yang, X. The Study on Numerical Simulation and Experiments of Four Product Hydrocyclone with Double Vortex Finders. Minerals 2019, 9, 23. [Google Scholar] [CrossRef]

- Hwang, K.-J.; Lyu, S.-Y.; Nagase, Y. Particle separation efficiency in two 10mm hydrocyclones in series. J. Taiwan Inst. Chem. Eng. 2009, 40, 313–319. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, Q.; Zhang, B.; Feng, T. Three-phase hydrocyclone separator A review. Chem. Eng. Res. Des. 2015, 100, 554–560. [Google Scholar] [CrossRef]

- Liu, T.R.; Liu, P.K. The influence of inlet pressure control on separation performance of multiproduct cyclones. Open Mech. Eng. J. 2015, 9, 117–123. [Google Scholar] [CrossRef][Green Version]

- Zhang, X.M.; Guo, D. Determination of design parameter for three-product heavy-medium cyclone. J. Coal Sci. Eng. 2011, 17, 96–99. [Google Scholar] [CrossRef]

- Obeng, D.P. The JK three-product cyclone performance and potential applications. Int. J. Miner. Proces. 2003, 69, 129–142. [Google Scholar] [CrossRef]

- Becker, M.; Mainza, A.; Powell, M.; Bradshaw, D.; Knopjes, B. Quantifying the influence of classification with the 3 product cyclone on liberation and recovery of PGMs in UG2 ore. Miner. Eng. 2008, 21, 549–558. [Google Scholar] [CrossRef]

- Ahmed, M.; Ibrahim, G.A.; Farghaly, M.G. Performance of a three-product hydrocyclone. Int. J. Miner. Proces. 2009, 91, 34–40. [Google Scholar] [CrossRef]

- Delgadillo, J.A.; Rajamani, R.K. A comparative study of three turbulence-closure models for the hydrocyclone problem. Int. J. Miner. Process. 2005, 77, 217–230. [Google Scholar] [CrossRef]

- Vakamalla, T.R.; Mangadoddy, N. Numerical simulation of industrial hydrocyclones performance: Role of turbulence modeling. Sep. Purif. Technol. 2017, 176, 23–39. [Google Scholar] [CrossRef]

- Hsieh, K.T.; Rajamani, R.K. Phenomenological model of hydrocyclone: Model development and verification for single-phase flow. Int. J. Miner. Process. 1988, 22, 223–237. [Google Scholar] [CrossRef]

- Devulapalli, B. Hydrodynamic Modelling of Solid Liquid Flows in Large-scale Hydrocyclones; University of Utah: Salt Lake City, UT, USA, 1997. [Google Scholar]

- Crocha, A.O.; Ullmann, G.; Silva, D.O.; Vieira, L.G.M. Effect of changes in the feed duct on hydrocyclone performance. Powder Technol. 2020, 374, 283–289. [Google Scholar]

- Ye, J.; Xu, Y.; Song, X.; Yu, J. Novel conical section design for ultra-fine particlesclassification by a hydrocyclone. Chem. Eng. Res. Des. 2019, 144, 135–149. [Google Scholar] [CrossRef]

- Ghodrat, M.; Kuang, S.B.; Yu, A.B.; Andrew, V.; Barnett, G.D.; Barnett, P.J. Numerical analysis of hydrocyclones with different vortex fifinder confifigurations. Miner. Eng. 2014, 63, 125–135. [Google Scholar] [CrossRef]

- Ni, L.; Tian, J.; Song, T.; Jong, Y.; Zhao, J. Optimizing geometric parameters in hydrocyclones for enhanced separations: A review and perspective. Sep. Purif. Rev. 2018, 48, 30–51. [Google Scholar] [CrossRef]

- Murthy, Y.R.; Bhaskar, K.U. Parametric CFD studies on hydrocyclone. Powder Technol. 2012, 230, 36–47. [Google Scholar] [CrossRef]

| Structural Parameters | Dimensions |

|---|---|

| Hydrocyclone diameter, D (mm) | 150 |

| Feed inlet equivalent diameter, di (mm) | 42.8 |

| Underflow outlet diameter, du (mm) | 22 |

| External vortex finder diameter, d1o (mm) | 45 |

| External vortex finder insertion depth, h1o (mm) | 140 |

| Internal vortex finder diameter, d2o (mm) | 22, 24, 26, 28 |

| Internal vortex finder insertion depth, h2o (mm) | 50, 110, 140, 170, 230 |

| The column section height, H (mm) | 350 |

| Cone angle (°) | 60 |

| Quartz Sand Particle Size (μm) | 5 | 15 | 30 | 45 | 65 | 90 |

|---|---|---|---|---|---|---|

| Content (%) | 6.67 | 12 | 18.67 | 29.33 | 20 | 13.33 |

| Volume fraction (%) | 5 | 9 | 14 | 22 | 15 | 10 |

| Particle Size (μm) | Interval (%) | Sum (%) | Particle Size (μm) | Internal (%) | Sum (%) |

|---|---|---|---|---|---|

| 0.040–1.000 | 1.77 | 1.77 | 45.00–53.00 | 7.72 | 64.28 |

| 1.000–2.000 | 2.36 | 4.13 | 53.00–63.00 | 8.36 | 72.64 |

| 2.000–5.000 | 4.64 | 8.77 | 63.00–74.00 | 7.61 | 80.25 |

| 5.000–10.00 | 6.57 | 15.34 | 74.00–90.00 | 8.29 | 88.54 |

| 10.00–15.00 | 6.28 | 21.62 | 90.00–104.0 | 5.08 | 93.62 |

| 15.00–20.00 | 5.96 | 27.58 | 104.0–124.0 | 4.01 | 97.63 |

| 20.00–25.00 | 6.19 | 33.77 | 124.0–147.0 | 1.89 | 99.52 |

| 25.00–33.00 | 9.66 | 43.43 | 147.0–172.0 | 0.41 | 99.93 |

| 33.00–37.00 | 4.56 | 47.99 | 172.0–200.0 | 0.07 | 100 |

| 37.00–45.00 | 8.57 | 56.56 | 200.0–236.0 | 0 | 100 |

| Internal Overflow Diameter (mm) | −45 μm (%) | Overall Efficiency (%) | Cut size (μm) | ||

|---|---|---|---|---|---|

| Underflow | Internal Overflow | External Overflow | |||

| 22 | 32.69 | 89.81 | 85.55 | 50.69 | 37 |

| 24 | 30.83 | 89.52 | 85.27 | 51.27 | 42 |

| 26 | 30.98 | 87.01 | 83.92 | 53.19 | 46 |

| 28 | 28.31 | 85.98 | 80.94 | 53.66 | 48 |

| Insertion Depth of Internal Vortex Finder (mm) | −45 μm (%) | Overall Efficiency (%) | Cut Size (μm) | ||

|---|---|---|---|---|---|

| Underflow | Internal Overflow | External Overflow | |||

| −90 | 31.92 | 81.46 | 79.04 | 47.53 | 53 |

| −60 | 29.27 | 81.24 | 80.48 | 51.93 | 49 |

| −30 | 28.75 | 82.43 | 80.42 | 51.85 | 46 |

| 0 | 33.29 | 85.14 | 80.66 | 49.47 | 45 |

| 30 | 36.83 | 100 | 83.8 | 48.33 | 32 |

| 60 | 37.92 | 100 | 83.36 | 47.48 | 35 |

| 90 | 42.21 | 98.4 | 82.47 | 41.64 | 37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Ge, J.; Jiang, L.; Wang, H.; Yang, J.; Chen, B. Influence of Vortex Finder Structure on Separation Performance of Double-Overflow Three-Product Hydrocyclones. Separations 2021, 8, 79. https://doi.org/10.3390/separations8060079

Zhang Y, Ge J, Jiang L, Wang H, Yang J, Chen B. Influence of Vortex Finder Structure on Separation Performance of Double-Overflow Three-Product Hydrocyclones. Separations. 2021; 8(6):79. https://doi.org/10.3390/separations8060079

Chicago/Turabian StyleZhang, Yuekan, Jiangbo Ge, Lanyue Jiang, Hui Wang, Junru Yang, and Bo Chen. 2021. "Influence of Vortex Finder Structure on Separation Performance of Double-Overflow Three-Product Hydrocyclones" Separations 8, no. 6: 79. https://doi.org/10.3390/separations8060079

APA StyleZhang, Y., Ge, J., Jiang, L., Wang, H., Yang, J., & Chen, B. (2021). Influence of Vortex Finder Structure on Separation Performance of Double-Overflow Three-Product Hydrocyclones. Separations, 8(6), 79. https://doi.org/10.3390/separations8060079