Evaluating the Applicability of High-Speed Air Flotation Technology for Water Supply: A Case Study in Tianjin Binhai New Area

Abstract

:1. Introduction

2. Materials and Methods

- (a)

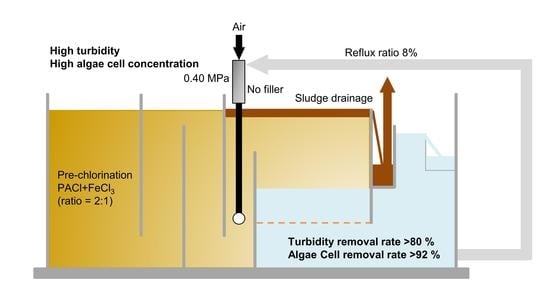

- In the coagulation zone, according to the differing quality of the raw waters, the optimal amount of coagulant is determined, based on the coagulation experiment, using polyaluminium chloride (PACL) and or ferric chloride (FeCl3) as coagulants (coagulation time: 1–2 min).

- (b)

- In the flocculation zone, hydraulic flocculation is used to facilitate the combination of flocculants with microbubbles, with flocculation times of 5–10 min.

- (c)

- The pressurized water mixing zone includes dissolved gas systems and degassing systems. The dissolved gas system is composed of a reflux booster pump, an air compressor, and a pressure dissolved gas tank. The pressured gas tank is a filler-type dissolved gas tank with an increased mass transfer area of the gas–liquid diphase to improve the dissolved gas efficiency. In the gas release system, the unique dissolved air release head efficiently generates tiny bubbles (with bubble diameters of approximately 40 μm). The arrangement of the dissolved air release head ensures the uniform distribution of microbubbles in the flotation area.

- (d)

- The area of the flotation area is 2.93 m2, with a hydraulic load of 25.6 m/h and dissolved air pressure water circulation proportion of 5–15%. The unique water trap design enables the entire flotation pool’s surface to be used to collect water. The overall flow state is uniform to reduce the influence of the turbulent flow state on separation, resulting in better anti-interference ability. The formed laminar flow upflows at rate of 20–40 m/h. Since the bubbles and flocculants in the pressured water mixing zone are fully collided, copolymerized, and greatly complexed under the action of wrapping, mesh trapping, and bridging, the upward floating speed is fast during solid–liquid separation. At the same time, the flotation selection area is induced to generate a thicker uniform bubble bed, with the purified water flowing out from the bottom.

3. Results and Discussion

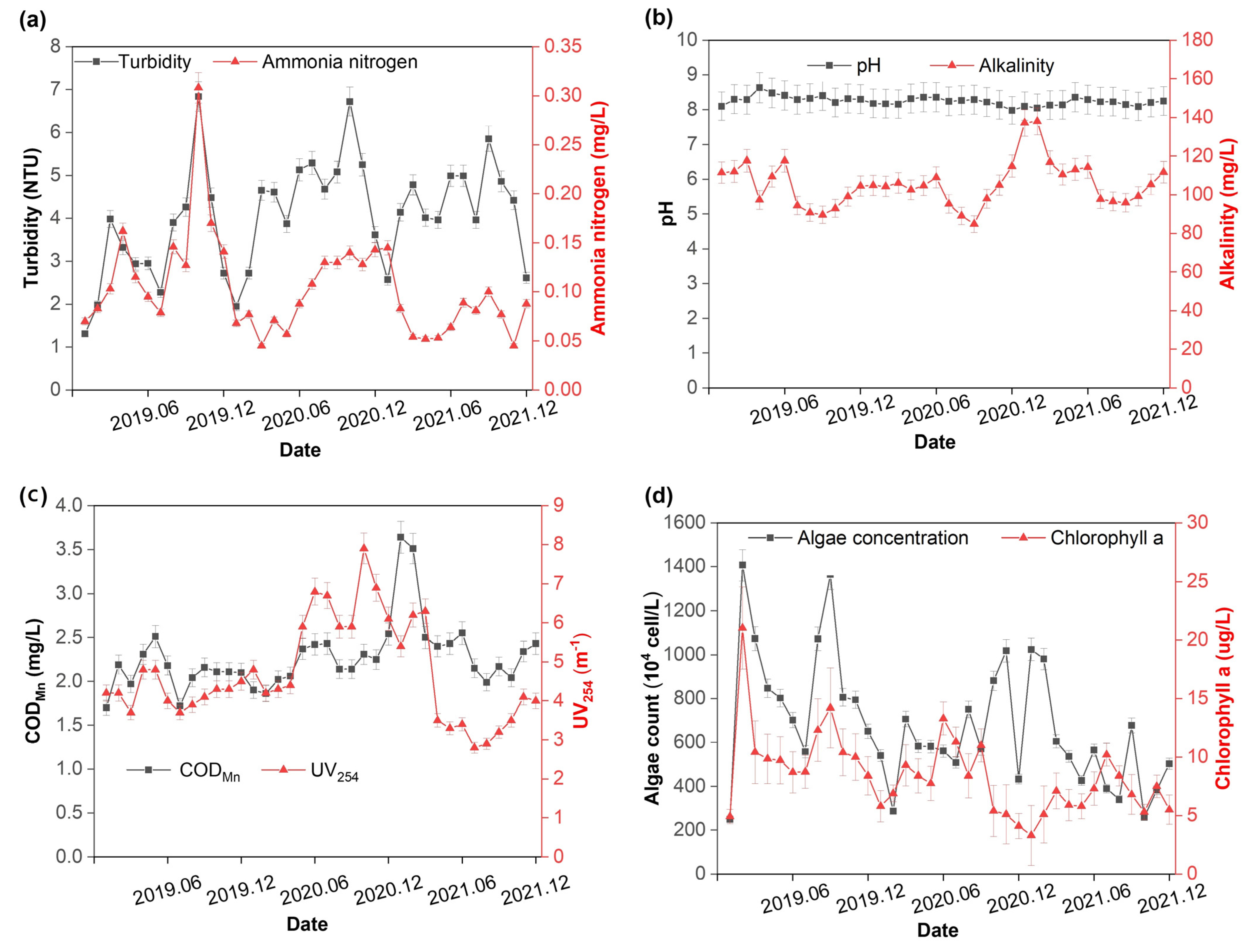

3.1. Raw Water Characteristics

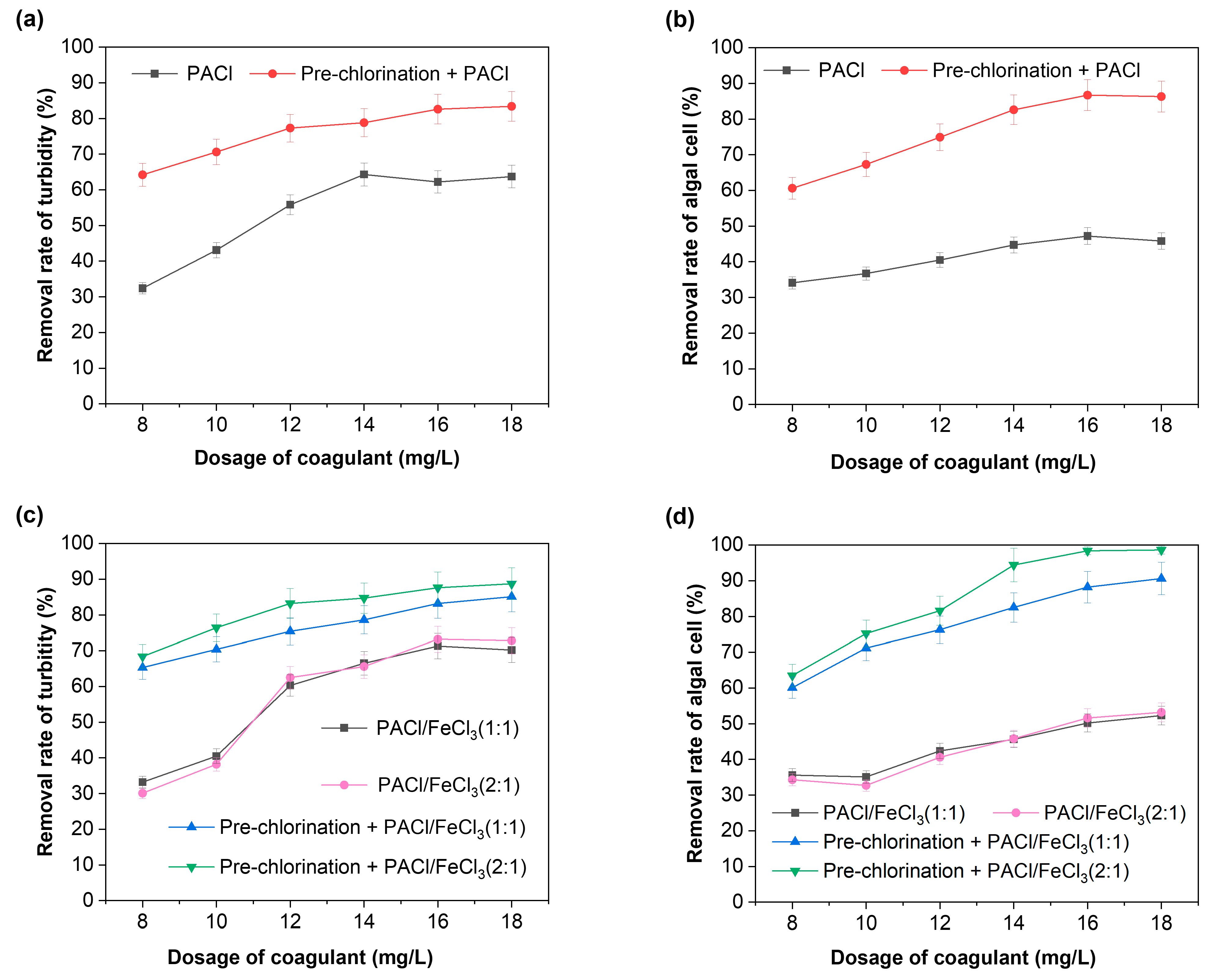

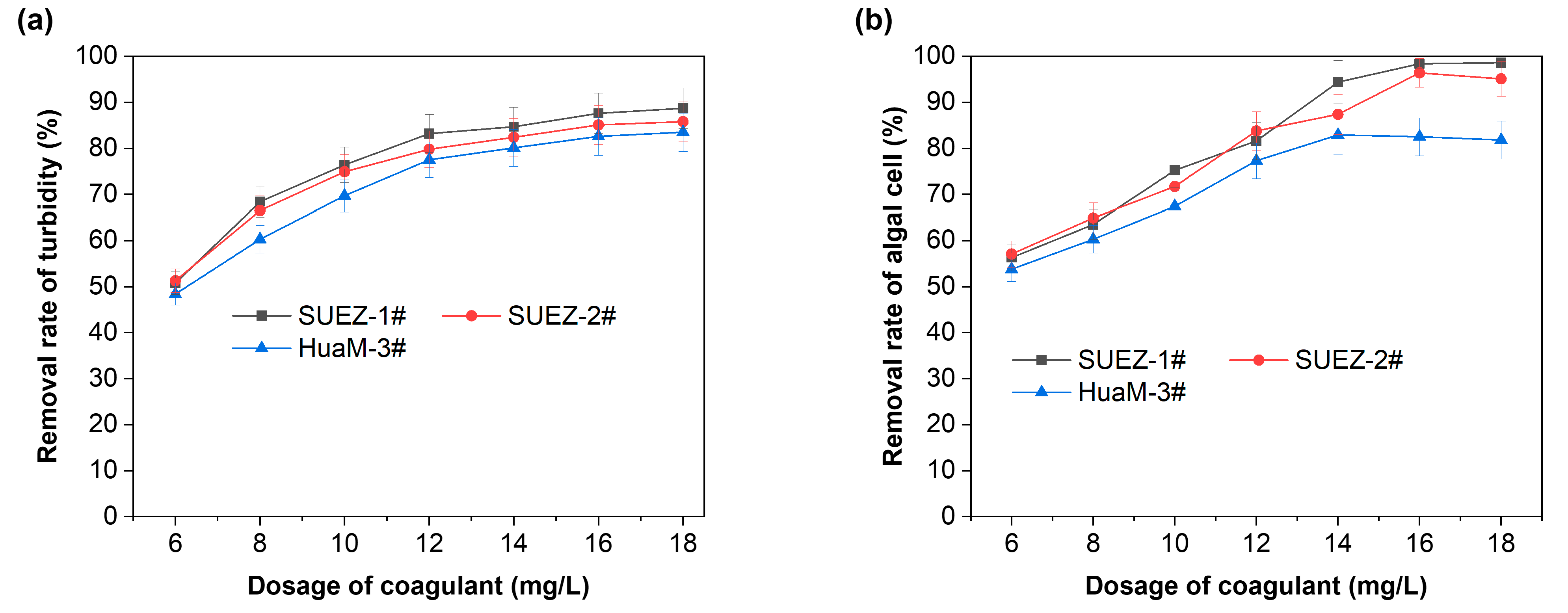

3.2. Effect of Reagents on Treatment Performance

3.3. Effect of Operating Parameters on Treatment Performance

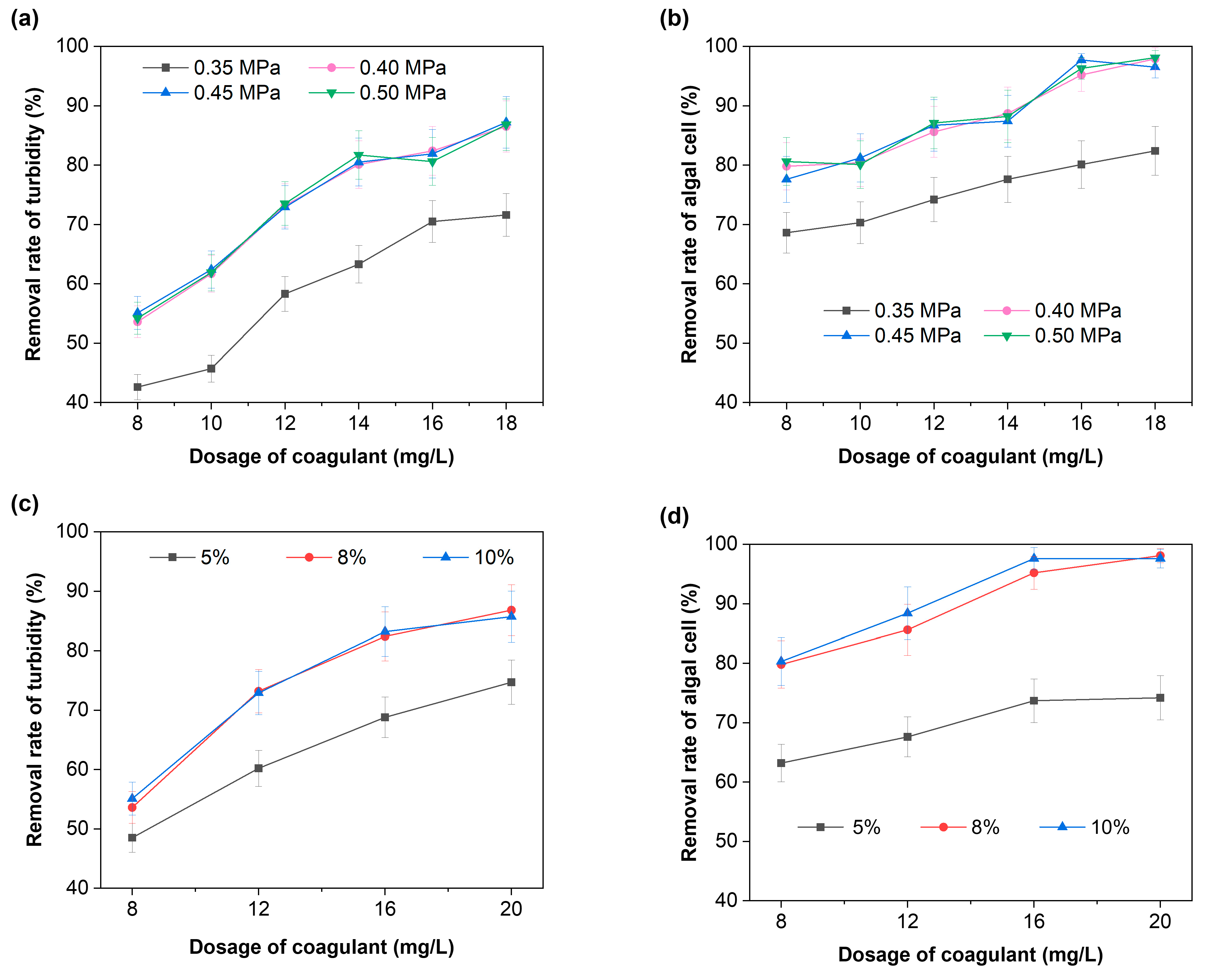

3.3.1. Pressure of Dissolved Air

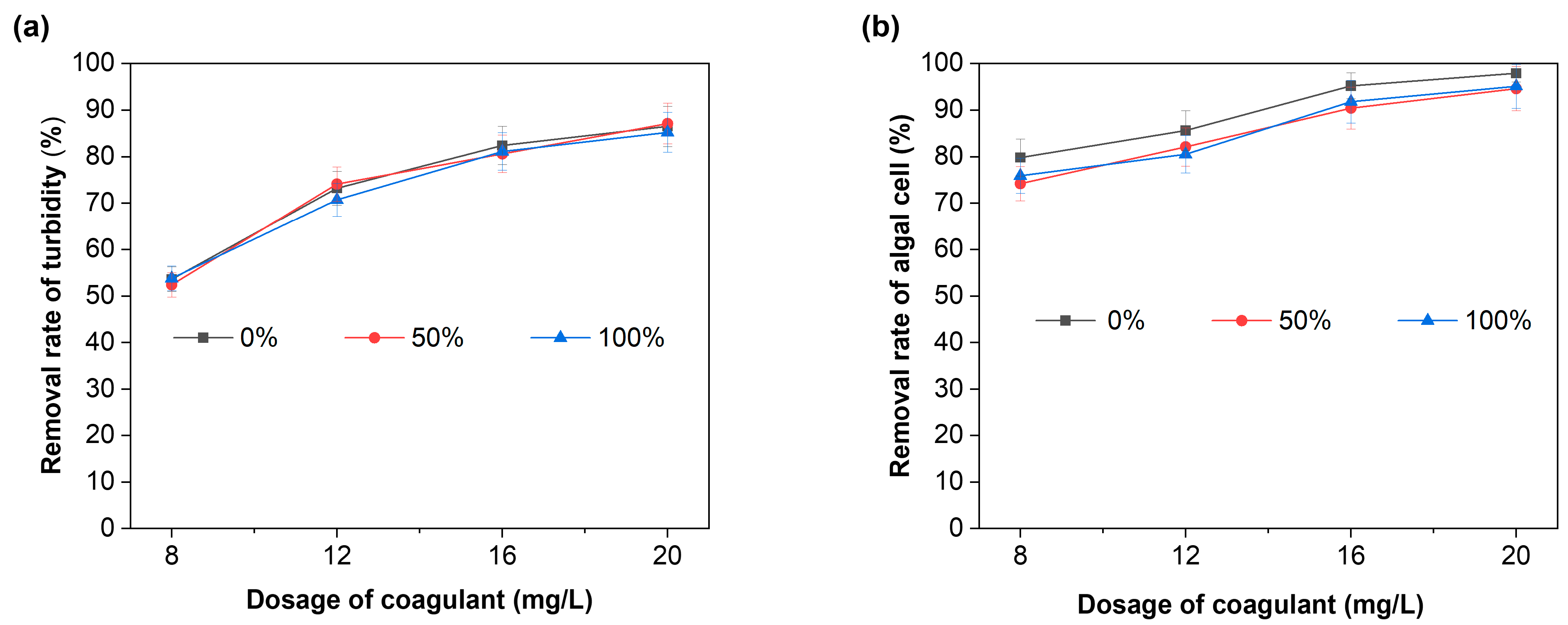

3.3.2. Reflux Ratio

3.4. Effect of the Dissolved Air Releasing System on Treatment Performance

3.4.1. Effect of Dissolved Air Release Head

3.4.2. Effect of Filler on Water Purification

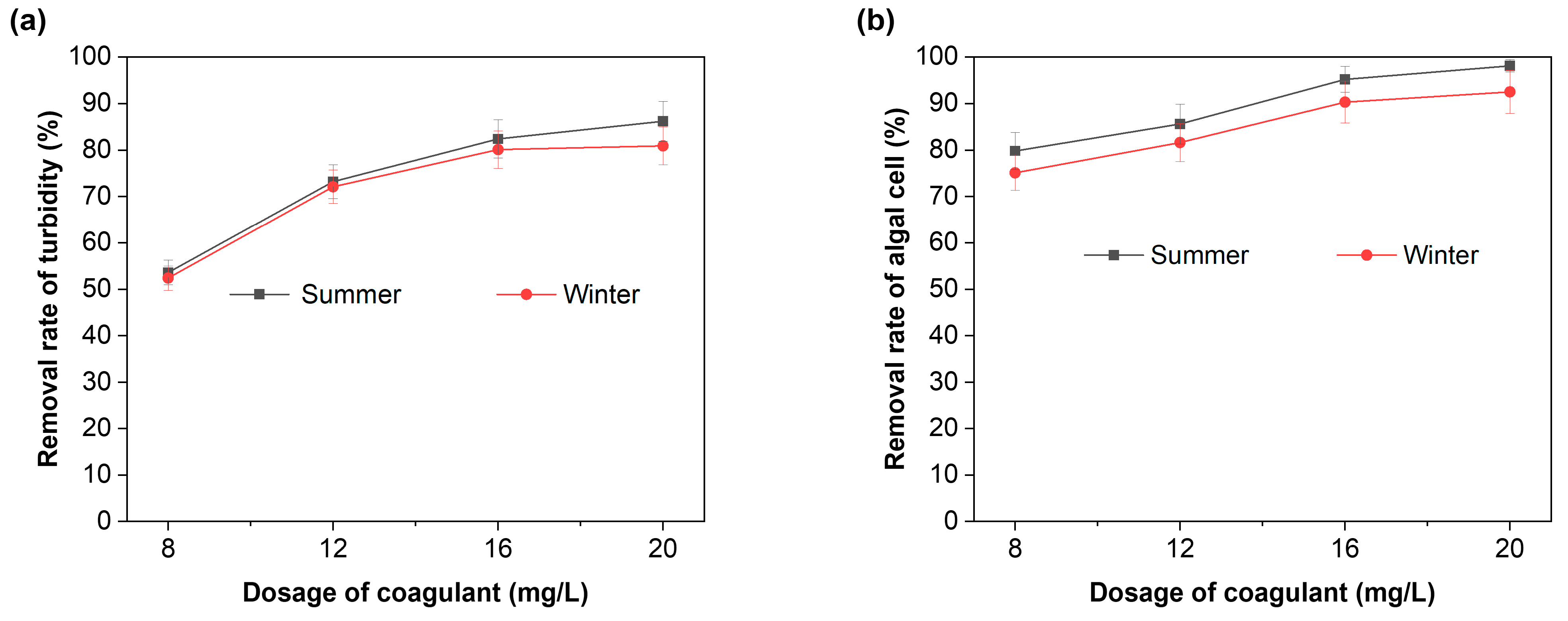

3.5. Effect of Water Resource in Different Seasons on Treatment Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Adebayo, M.A.; Areo, F.I. Removal of phenol and 4-nitrophenol from wastewater using a composite prepared from clay and Cocos nucifera shell: Kinetic, equilibrium and thermodynamic studies. Resour. Environ. Sustain. 2021, 3, 100020. [Google Scholar] [CrossRef]

- Wang, M.; Janssen, A.B.G.; Bazin, J.; Strokal, M.; Ma, L.; Kroeze, C. Accounting for interactions between Sustainable Development Goals is essential for water pollution control in China. Nat. Commun. 2022, 13, 730. [Google Scholar] [CrossRef] [PubMed]

- Ke, J.; Khanna, N.; Zhou, N. Analysis of water–energy nexus and trends in support of the sustainable development goals: A study using longitudinal water–energy use data. J. Clean. Prod. 2022, 371, 133448. [Google Scholar] [CrossRef]

- Yasmin, F.; Sakib, T.U.; Emon, S.Z.; Bari, L.; Sultana, G.N.N. The physicochemical and microbiological quality assessment of Maddhapara hard rock-mine discharged water in Dinajpur, Bangladesh. Resour. Environ. Sustain. 2022, 8, 100061. [Google Scholar] [CrossRef]

- Sinha, E.; Michalak, A.M.; Balaji, V. Eutrophication will increase during the 21st century as a result of precipitation changes. Science 2017, 357, 405–408. [Google Scholar] [CrossRef] [Green Version]

- Gu, B.; Ge, Y.; Chang, S.X.; Luo, W.; Chang, J. Nitrate in groundwater of China: Sources and driving forces. Glob. Environ. Chang. 2013, 23, 1112–1121. [Google Scholar] [CrossRef]

- Zhang, J.; Bing, J.; Li, X.; Guo, L.; Deng, Z.; Wang, D.; Liu, L. Inter-basin water transfer enhances the human health risk of heavy metals in the middle and lower Han River, China. J. Hydrol. 2022, 613, 128423. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, H.; Yue, W.; Xie, Y.; Liang, Q. An integrated approach for reducing spatially coupled water-shortage risks of Beijing-Tianjin-Hebei urban agglomeration in China. J. Hydrol. 2021, 603, 127123. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, J.; Mei, C.; Wang, H.; Shao, W. Water security evaluation based on comprehensive index in Jing-Jin-Ji district, China. Water Supply 2020, 20, 2698–2714. [Google Scholar] [CrossRef]

- Xue, J.; Zhao, Z.; Dai, Y.; Wang, B. Green Low-Carbon Development in China; Springer: Cham, Switzerland, 2013; pp. 1–252. [Google Scholar] [CrossRef]

- Hunter, T.N.; Peakall, J.; Egarr, D.; Cowell, D.M.J.; Freear, S.; Tonge, A.S.; Horton, L.; Rice, H.P.; Smith, I.; Malone, K.; et al. Concentration profiling of a horizontal sedimentation tank utilising a bespoke acoustic backscatter array and CFD simulations. Chem. Eng. Sci. 2020, 218, 115560. [Google Scholar] [CrossRef]

- Saleh, A.M.; Hamoda, M.F. Upgrading of secondary clarifiers by inclined plate settlers. Water Sci. Technol. 1999, 40, 141–149. [Google Scholar] [CrossRef]

- Goula, A.M.; Kostoglou, M.; Karapantsios, T.D.; Zouboulis, A.I. A CFD methodology for the design of sedimentation tanks in potable water treatment: Case study: The influence of a feed flow control baffle. Chem. Eng. J. 2008, 140, 110–121. [Google Scholar] [CrossRef]

- Wang, Y.; Jin, X.; Yang, S.; Wang, G.; Xu, L.; Jin, P.; Shi, X.; Shi, Y. Interactions between flocs and bubbles in the separation zone of dissolved air flotation system. Sci. Total Environ. 2021, 761, 143222. [Google Scholar] [CrossRef] [PubMed]

- Fabrizi, L.; Jefferson, B.; Parsons, S.A.; Wetherill, A.; Jarvis, P. The role of polymer in improving floc strength for filtration. Environ. Sci. Technol. 2010, 44, 6443–6449. [Google Scholar] [CrossRef]

- Schofield, T. Dissolved air flotation in drinking water production. Water Sci. Technol. 2001, 43, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Edzwald, J.K.; Tobiason, J.E.; Dunn, H.; Kaminski, G.; Galant, P. Removal and fate of Cryptosporidium in dissolved air drinking water treatment plants. Water Sci. Technol. 2001, 43, 51–57. [Google Scholar] [CrossRef]

- Villar-Navarro, E.; Baena-Nogueras, R.M.; Paniw, M.; Perales, J.A.; Lara-Martín, P.A. Removal of pharmaceuticals in urban wastewater: High rate algae pond (HRAP) based technologies as an alternative to activated sludge based processes. Water Res. 2018, 139, 19–29. [Google Scholar] [CrossRef]

- Bürger, R.; Diehl, S.; Martí, M.C.; Vásquez, Y. Simulation and control of dissolved air flotation and column froth flotation with simultaneous sedimentation. Water Sci. Technol. 2020, 81, 1723–1732. [Google Scholar] [CrossRef]

- Leite, L.S.; Dos Santos, P.R.; Daniel, L.A. Microalgae harvesting from wastewater by pH modulation and flotation: Assessing and optimizing operational parameters. J. Environ. Manag. 2020, 254, 109825. [Google Scholar] [CrossRef]

- Rathnaweera, S.S.; Rusten, B.; Manamperuma, L.D.; Gjevre, J.; Tranum, I. Evaluation of moving bed sand filter for denitrification, suspended solids removal and very low effluent total phosphorus concentrations. Water Sci. Technol. 2019, 80, 232–242. [Google Scholar] [CrossRef]

- Fettig, J.; Pick, V.; Austermann-Haun, U.; Blumberg, M.; Phuoc, N.V. Treatment of tapioca starch wastewater by a novel combination of physical and biological processes. Water Sci. Technol. 2013, 68, 1264–1270. [Google Scholar] [CrossRef] [PubMed]

- Goh, Y.T.; Harris, J.L.; Roddick, F.A. Reducing the effect of cyanobacteria in the microfiltration of secondary effluent. Water Sci. Technol. 2010, 62, 1682–1688. [Google Scholar] [CrossRef] [PubMed]

- Kwak, D.H.; Kim, M.S. Flotation of algae for water reuse and biomass production: Role of zeta potential and surfactant to separate algal particles. Water Sci. Technol. 2015, 72, 762–769. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kwak, D.H.; Lee, K.C. Enhanced phosphorus removal in the DAF process by flotation scum recycling for advanced treatment of municipal wastewater. Water Sci. Technol. 2015, 72, 600–607. [Google Scholar] [CrossRef] [PubMed]

- Ometto, F.; Pozza, C.; Whitton, R.; Smyth, B.; Gonzalez Torres, A.; Henderson, R.K.; Jarvis, P.; Jefferson, B.; Villa, R. The impacts of replacing air bubbles with microspheres for the clarification of algae from low cell-density culture. Water Res. 2014, 53, 168–179. [Google Scholar] [CrossRef] [Green Version]

- Choi, M.; Choi, D.W.; Lee, J.Y.; Kim, Y.S.; Kim, B.S.; Lee, B.H. Removal of pharmaceutical residue in municipal wastewater by DAF (dissolved air flotation)-MBR (membrane bioreactor) and ozone oxidation. Water Sci. Technol. 2012, 66, 2546–2555. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, J.; Tang, H. Pilot testing of dissolved air flotation (DAF) in a highly effective coagulation-flocculation integrated (FRD) system. J. Environ. Sci. Health A 2002, 37, 95–111. [Google Scholar] [CrossRef]

- Kurian, R.; Acharya, C.; Nakhla, G.; Bassi, A. Conventional and thermophilic aerobic treatability of high strength oily pet food wastewater using membrane-coupled bioreactors. Water Res. 2005, 39, 4299–4308. [Google Scholar] [CrossRef]

- Wei, X.; Zhu, H.; Xiong, J.; Huang, W.; Shi, J.; Wang, S.; Song, H.; Feng, Q.; Zhong, K. Anti-algal activity of a fluorine-doped titanium oxide photocatalyst against Microcystis aeruginosa and its photocatalytic degradation. New J. Chem. 2021, 45, 17483–17492. [Google Scholar] [CrossRef]

- Jokelat, P.; Immonen, J. Dissolved air flotation clarification of activated sludge and wastewaters from chemical industry. Water Sci. Technol. 2003, 47, 205–210. [Google Scholar] [CrossRef]

- Henderson, R.K.; Parsons, S.A.; Jefferson, B. Polymers as bubble surface modifiers in the flotation of algae. Environ. Technol. 2010, 31, 781–790. [Google Scholar] [CrossRef] [PubMed]

- Féris, L.A.; Gallina, C.W.; Rodrigues, R.T.; Rubio, J. Optimizing dissolved air flotation design and saturation. Water Sci. Technol. 2001, 43, 145–152. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.C.; Lien, C.S. Pretreatment of bakery wastewater by coagulation-flocculation and dissolved air flotation. Water Sci. Technol. 2001, 43, 131–137. [Google Scholar] [CrossRef] [PubMed]

- Reungoat, J.; Macova, M.; Escher, B.I.; Carswell, S.; Mueller, J.F.; Keller, J. Removal of micropollutants and reduction of biological activity in a full scale reclamation plant using ozonation and activated carbon filtration. Water Res. 2010, 44, 625–637. [Google Scholar] [CrossRef] [PubMed]

- Mels, A.R.; Rulkens, W.H.; van der Meer, A.K.; van Nieuwenhuijzen, A.F.; Klapwijk, A. Flotation with polyelectrolytes as a first step of a more sustainable wastewater treatment system. Water Sci. Technol. 2001, 43, 83–90. [Google Scholar] [CrossRef] [PubMed]

- Chuang, S.H.; Chang, W.C.; Chang, T.C.; You, S.J. Improving the removal of anions by coagulation and dissolved air flotation in wastewater reclamation. Environ. Technol. 2006, 27, 493–500. [Google Scholar] [CrossRef]

- Han, G.; Du, Y.; Huang, Y.; Wang, W.; Su, S.; Liu, B. Study on the removal of hazardous Congo red from aqueous solutions by chelation flocculation and precipitation flotation process. Chemosphere 2022, 289, 133109. [Google Scholar] [CrossRef]

- Zhu, T.; Qu, F.; Liu, B.; Liang, H. The influence of environmental factor on the coagulation enhanced ultrafiltration of algae-laden water: Role of two anionic surfactants to the separation performance. Chemosphere 2022, 291, 132745. [Google Scholar] [CrossRef]

- Han, M.; Kim, T.I.; Kim, J. Effects of floc and bubble size on the efficiency of the dissolved air flotation (DAF) process. Water Sci. Technol. 2007, 56, 109–115. [Google Scholar] [CrossRef]

- Koivunen, J.; Heinonen-Tanski, H. Dissolved air flotation (DAF) for primary and tertiary treatment of municipal wastewaters. Environ. Technol. 2008, 29, 101–109. [Google Scholar] [CrossRef]

- Qi, J.; Ma, B.; Miao, S.; Liu, R.; Hu, C.; Qu, J. Pre-oxidation enhanced cyanobacteria removal in drinking water treatment: A review. J. Environ. Sci. 2021, 110, 160–168. [Google Scholar] [CrossRef] [PubMed]

- Yap, R.K.; Whittaker, M.; Diao, M.; Stuetz, R.M.; Jefferson, B.; Bulmus, V.; Peirson, W.L.; Nguyen, A.V.; Henderson, R.K. Hydrophobically-associating cationic polymers as micro-bubble surface modifiers in dissolved air flotation for cyanobacteria cell separation. Water Res. 2014, 61, 253–262. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moreti, L.O.; Coldebella, P.F.; Camacho, F.P.; Carvalho Bongiovani, M.; Pereira de Souza, A.H.; Kirie Gohara, A.; Matsushita, M.; Fernandes Silva, M.; Nishi, L.; Bergamasco, R. Removal of Anabaena flos-aquae in water treatment process using Moringa oleifera and assessment of fatty acid profile of generated sludge. Environ. Technol. 2016, 37, 1408–1417. [Google Scholar] [CrossRef] [PubMed]

- Miranda, R.; Latour, I.; Blanco, A. Understanding the Efficiency of Aluminum Coagulants Used in Dissolved Air Flotation (DAF). Front. Chem. 2020, 8, 27. [Google Scholar] [CrossRef]

- de Oliveira, G.L.; Daniel, L.A. Removal of Giardia spp. cysts and Cryptosporididum spp. oocysts from anaerobic effluent by dissolved air flotation. Environ. Technol. 2021, 42, 141–147. [Google Scholar] [CrossRef]

- Nikfar, M.H.; Parsaeian, H.; Amani Tehrani, A.; Kouhestani, A.; Masoumi Isfahani, H.; Bazargan, A. A two-stage dissolved air flotation saturator configuration for significant microbubble improvement. Environ. Technol. 2021, 1–10. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, S.; Wang, H.; Zhang, S.; Jiang, S.; Zhao, X.; Hou, Q. Evaluating the Applicability of High-Speed Air Flotation Technology for Water Supply: A Case Study in Tianjin Binhai New Area. Separations 2022, 9, 362. https://doi.org/10.3390/separations9110362

Gong S, Wang H, Zhang S, Jiang S, Zhao X, Hou Q. Evaluating the Applicability of High-Speed Air Flotation Technology for Water Supply: A Case Study in Tianjin Binhai New Area. Separations. 2022; 9(11):362. https://doi.org/10.3390/separations9110362

Chicago/Turabian StyleGong, Shuyan, Hongpeng Wang, Shuang Zhang, Shaohong Jiang, Xinjuan Zhao, and Qidong Hou. 2022. "Evaluating the Applicability of High-Speed Air Flotation Technology for Water Supply: A Case Study in Tianjin Binhai New Area" Separations 9, no. 11: 362. https://doi.org/10.3390/separations9110362