Study on the Technology and Mechanism of Cleaning Architectural Aluminum Formwork for Concrete Pouring by High Energy and High Repetition Frequency Pulsed Laser

Abstract

:1. Introduction

2. Characteristic Analysis of Residual Concrete on the Surface of Aluminum Alloy Formwork

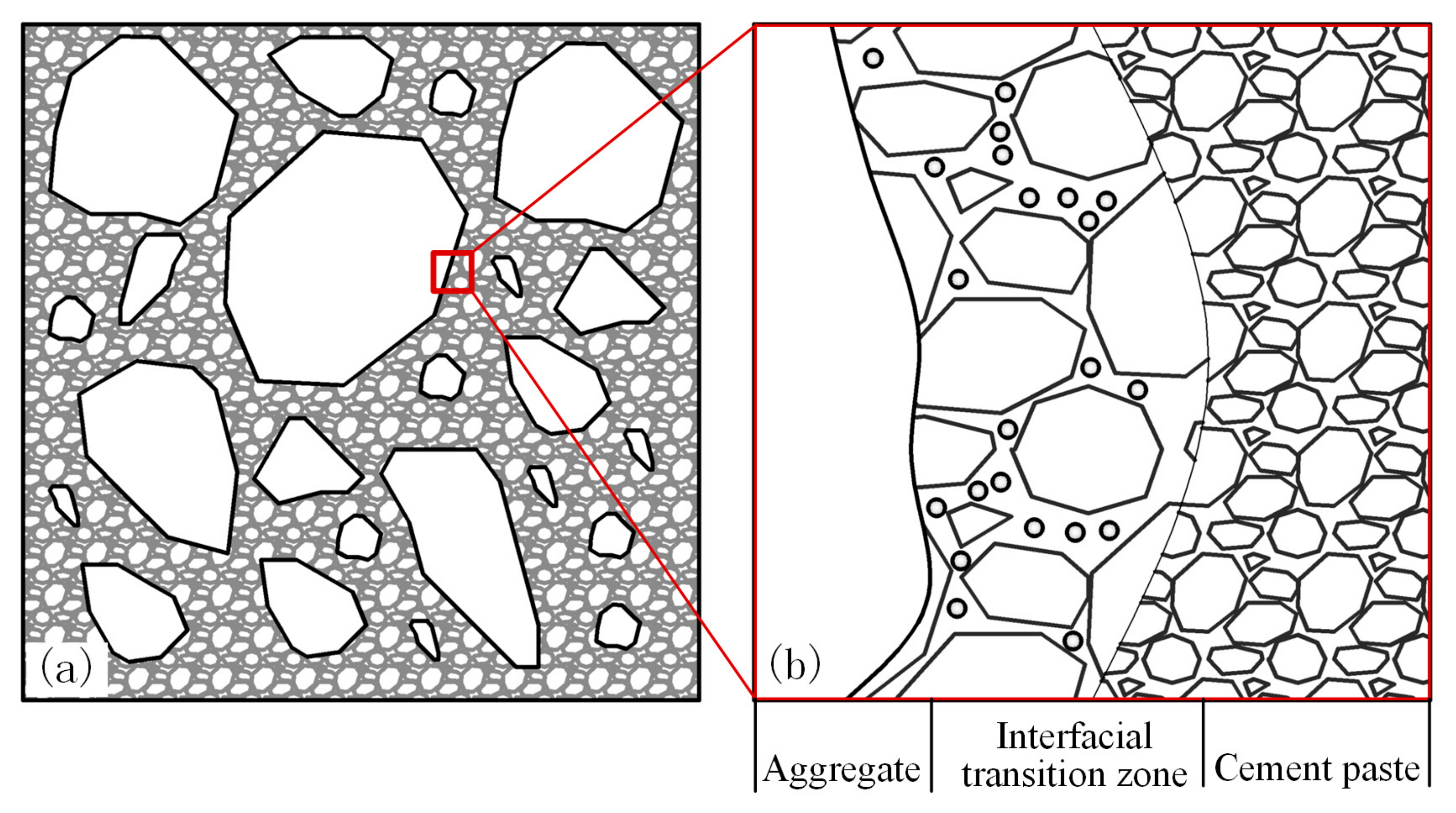

2.1. Concrete Composition

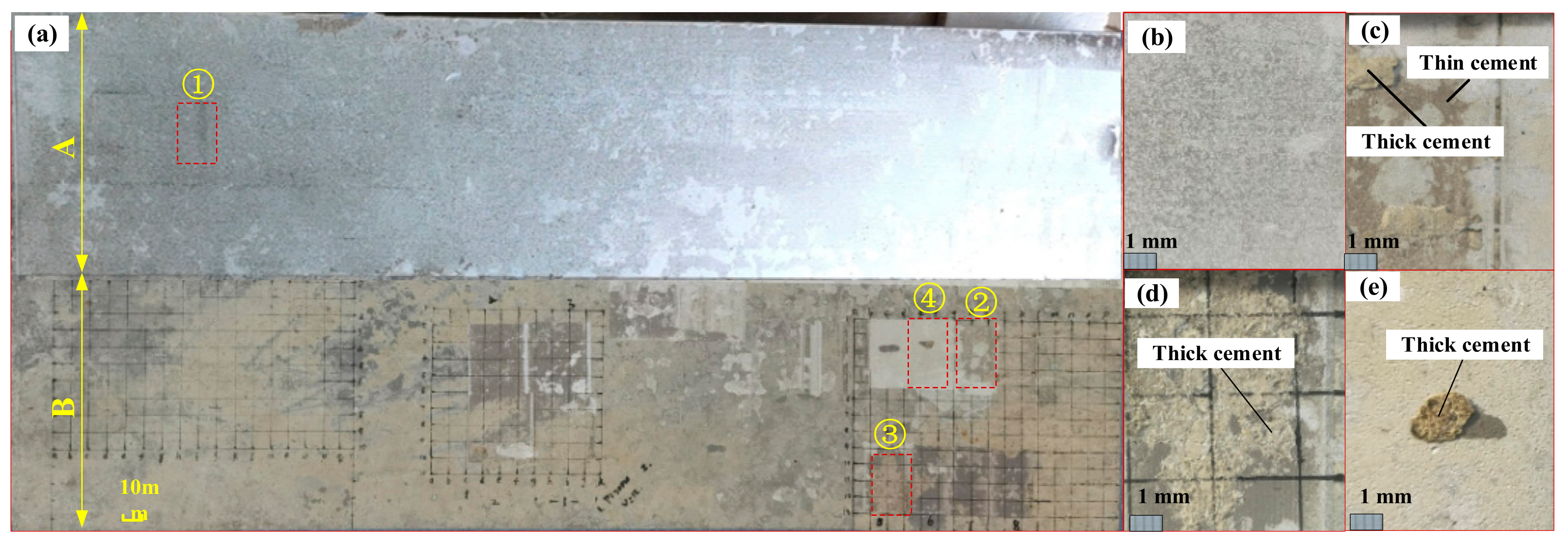

2.2. Characteristics of Residual Concrete on the Surface of Aluminum Alloy Formwork

3. Laser Cleaning Experiment of Residual Concrete on Aluminum Alloy Formwork Surface

3.1. Laser Cleaning Experiment and Testing System

3.2. Experimental Sample

3.3. Experimental Method

4. Experimental Result

4.1. Effect of Residual Time of Concrete on Cleaning Efficiency

4.1.1. Comparison of the Macroscopic Morphology

4.1.2. Comparison of the Thickness of the Residual Layer on the Cleaning Surface

4.2. Comparison of Micro-Morphology

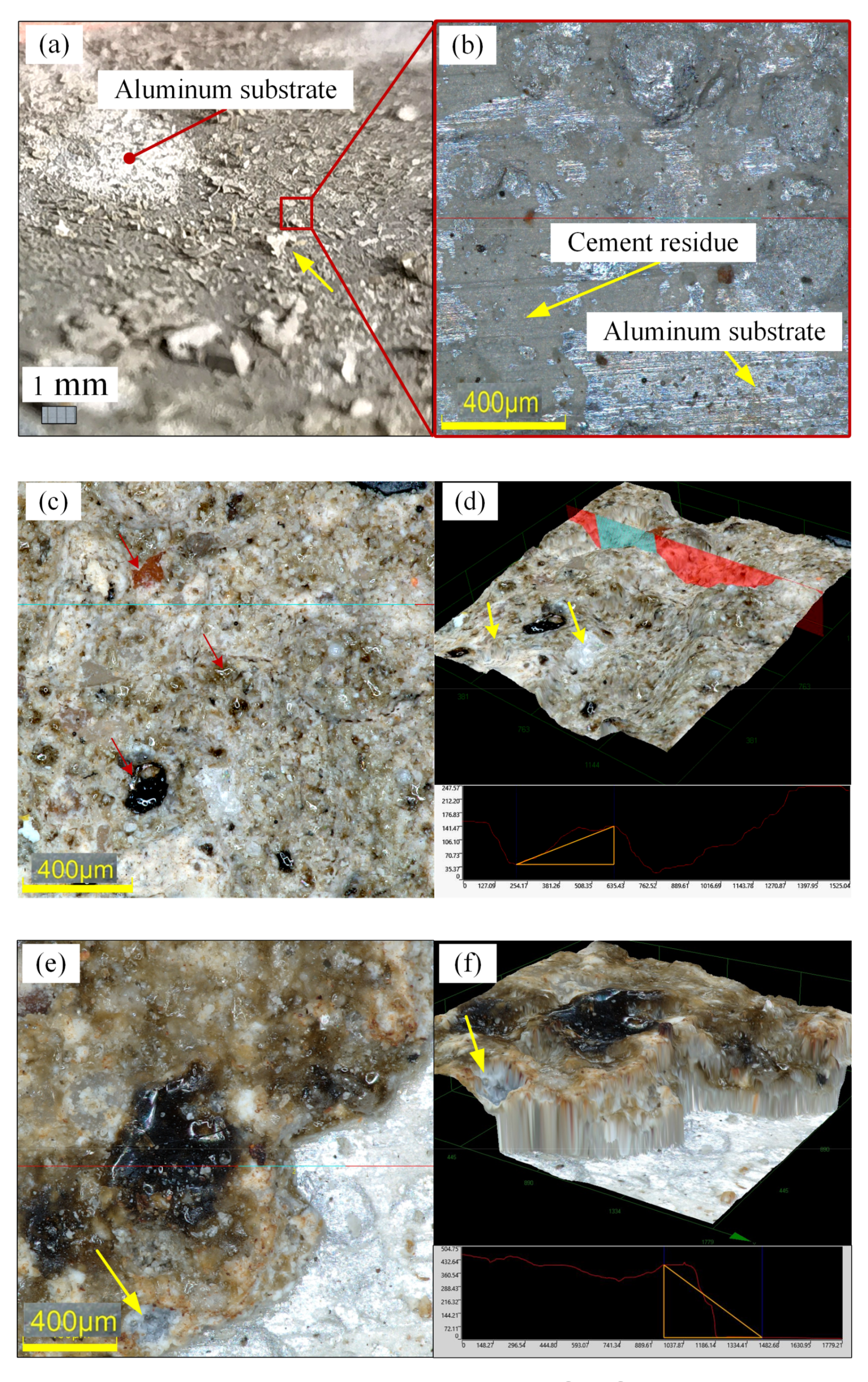

4.2.1. The Surface Morphology of Area A after Being Completely Cleaned

4.2.2. The Surface Topography of Area B That Cannot Be Cleaned

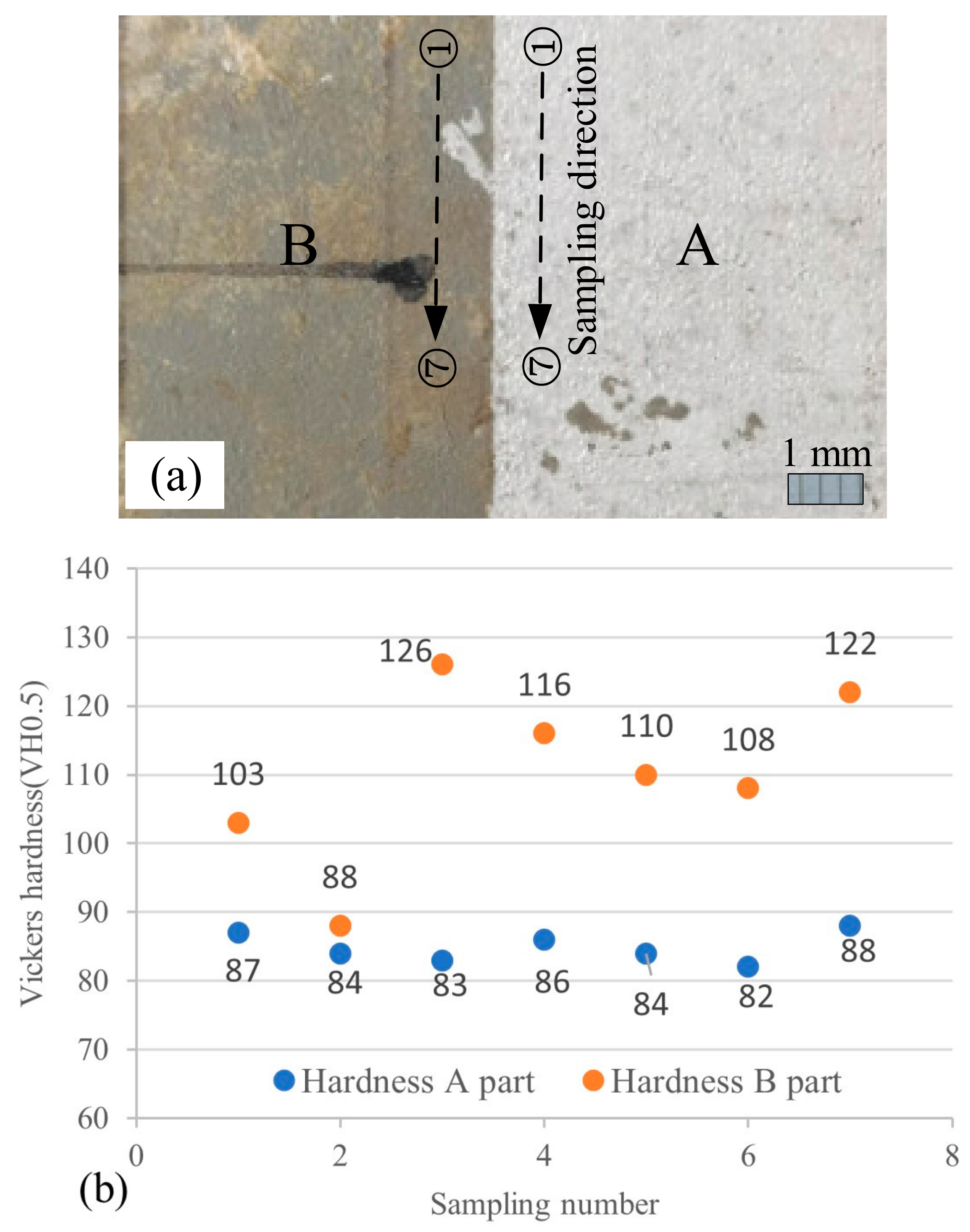

4.3. Surface Hardness Test of Aluminum Alloy Formwork after Laser Cleaning

5. Mechanism Discussion

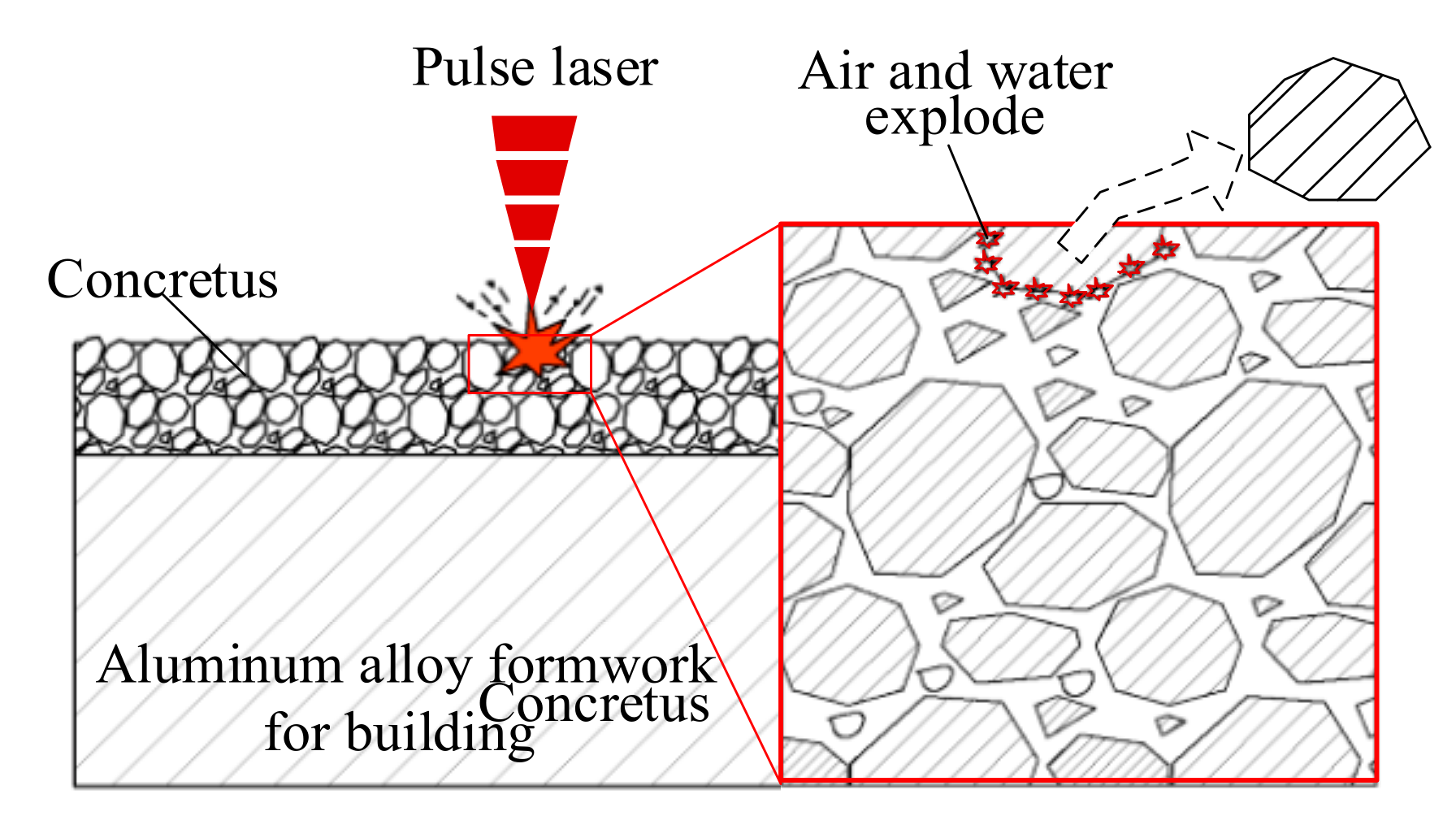

5.1. Laser Cleaning Mechanism of Thick Concrete Slurry Layer

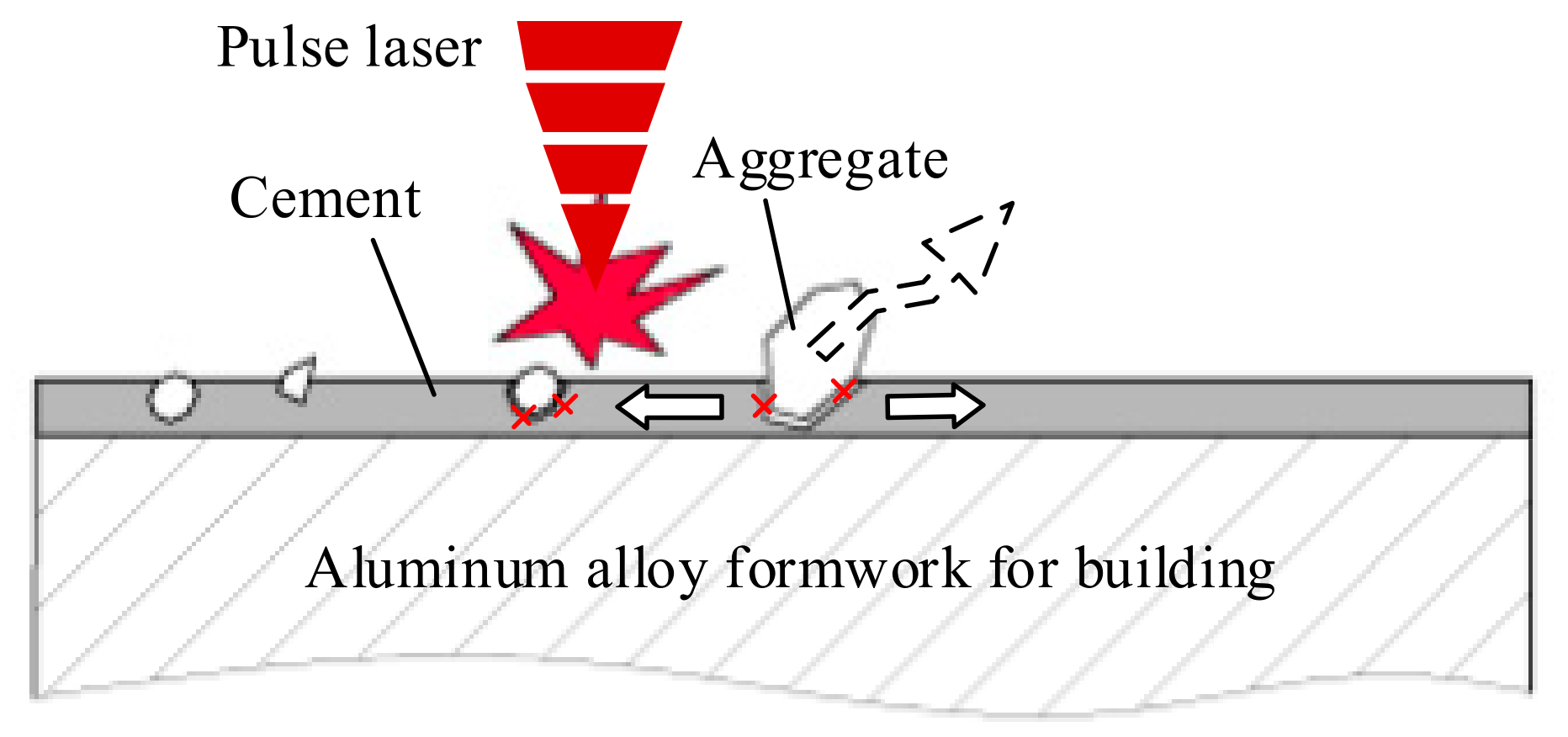

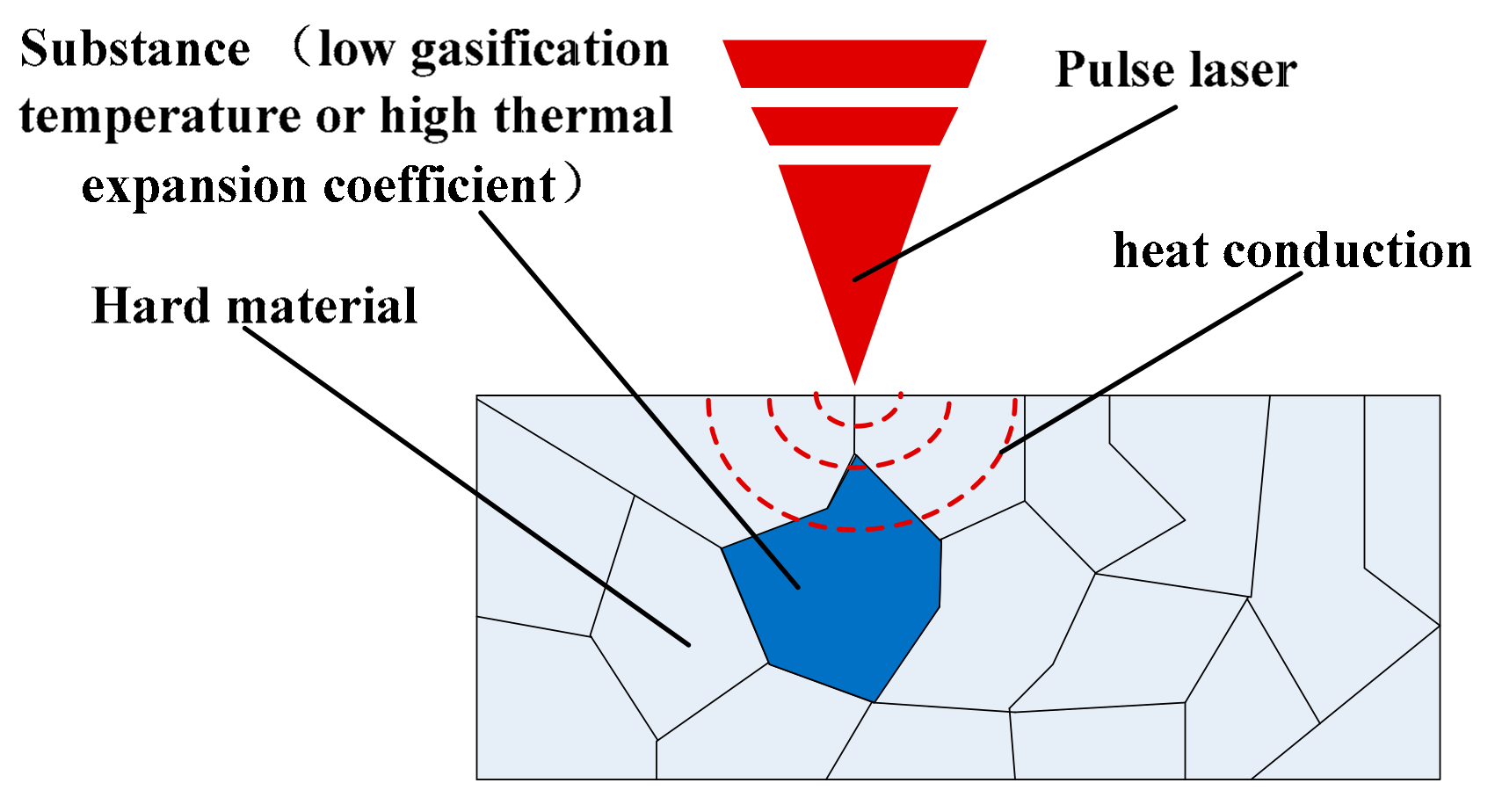

5.2. Laser Cleaning Mechanism of Thin Concrete Slurry Layer

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.H.; Li, Q.Z. Application of Architectural aluminum formwork in Some Super Tall Building. Constr. Technol. 2011, 40, 35–37+75. [Google Scholar]

- Zhang, A.Q. Research and Application of Aluminum Formwork Technology in Super Tall Building. Master’s Thesis, Changchun Institute of Technology, Changchun, China, 2016. [Google Scholar]

- Li, Y. A pass-through cleaning system of aluminum alloy template. Clean. World 2019, 35, 10–11. [Google Scholar]

- Song, F.; Liu, S.J. Principle and application research on laser cleaning. Clean. World 2005, 21, 1–6. [Google Scholar]

- Pleasants, S.; Kane, D.M. Laser cleaning of aluminum particles on glass and silica substrates: Experiment and quasistatic model. Appl. Phys. 2003, 93, 8862–8866. [Google Scholar] [CrossRef]

- Cooper, M.; Larson, J. The use of laser cleaning to preserve patina on marble sculpture. Conservator 1996, 20, 28–35. [Google Scholar] [CrossRef]

- Qiu, T.W.; Yi, J.L. Characteristics of Nanosecond Pulse Laser Cleaning Paint Coatings on 2024 Aluminum Alloy Surface. Laser Optoelectron. Prog. 2021, 58, 0514001. [Google Scholar]

- Guo, L.; Li, Y. Numerical and experimental analysis for morphology evolution of 6061 aluminum alloy during nanosecond pulsed laser cleaning. Surf. Coat. Technol. 2022, 432, 128056. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, J. Removal mechanism of blue paint on aluminum alloy substrate during surface cleaning using nanosecond pulsed laser. Opt. Laser Technol. 2022, 149, 107882. [Google Scholar] [CrossRef]

- Qi, X.S.; Ren, Z.G. Study on effect of laser derusting technology on properties of high speed train collector ring. Laser Technol. 2019, 43, 168–173. [Google Scholar]

- Shi, S.D. Researches on Theoretical Model, Numerical Simulation and Application of Painting Removal by Laser Cleaning. Doctor’s Thesis, Nankai University, Tianjin, China, 2012. [Google Scholar]

- Zhang, Z.Y.; Wang, Y.B. Removal of Low Thermal Conductivity Paint with High Repetition Rate Pulse Laser. Chin. J. Lasers 2019, 46, 148–156. [Google Scholar]

- Lei, Z.; Tian, Z. Laser Cleaning Technology in Industrial Fields. Laser Optoelectron. Prog. 2018, 55, 60–72. [Google Scholar]

- Zhang, G.; Hua, X. Investigation on mechanism of oxide removal and plasma behavior during laser cleaning on aluminum alloy. Appl. Surf. Sci. 2020, 506, 144666. [Google Scholar] [CrossRef]

- Zhu, G.D.; Wang, S.R. Corrosion and wear performance of aircraft skin after laser cleaning. Opt. Laser Technol. 2020, 132, 106475. [Google Scholar] [CrossRef]

- Ünaldi, S.; Papadopoulos, K. Towards selective laser paint stripping using shock waves produced by laser-plasma interaction for aeronautical applications on AA 2024 based substrates. Opt. Laser Technol. 2021, 141, 107095. [Google Scholar] [CrossRef]

- Gao, K.; Zeng, Q.S. Adhesion of Residual Primer Paint After Laser Cleaning Aircraft Aluminum Alloy Skin. Laser Optoelectron. Prog. 2021, 58, 296–302. [Google Scholar]

- Zheng, G. Study on Laser Paint Stripping of Aircraft Surface. Master’s Thesis, Institute of Electrics, CAS, Beijing, China, 2005. [Google Scholar]

- Li, J.M. Development, Trend and Application of High Average Power Diode Pumped Lasers. Laser Optoelectron. Prog. 2008, 45, 16–29. [Google Scholar]

- Zhang, F.Q. Concrete Material; Chemical Industry Press: Beijing, China, 2015. [Google Scholar]

| Materials | Elastic Modulus (MPa) | Coefficient of Linear Expansion (K−1) | Poisson’s Ratio (υa) | Thermal Diffusivity (m2/s) | Thermal Conductivity (W/(m·K)) | Melting Point (°C) |

|---|---|---|---|---|---|---|

| Aluminum formwork 6061-T6 | 7 × 104 | 23 × 10−6 | 0.3 | 2.3 × 10−5 | 155 | 580~650 |

| Concrete C15~C80 | 2.20~3.80 × 106 | 4.76~12.1 × 10−6 | 0.2 | 1.34 × 10−3 | 1.28 | 1800~2500 |

| Laser Power P (W) | Frequency f (kHz) | X-Axis Scanning Width D (mm) | X-Axis Scanning Speed Vx (mm/s) | Y-Axis Speed Vy (mm/s) | Spot Diameter (mm) |

|---|---|---|---|---|---|

| 600 | 20 | 50 | 2000 | 10 | 0.8 |

| Area | Measuring Time | a | b | c | d | e |

|---|---|---|---|---|---|---|

| ① | before | 38.7 | 27.8 | 57.1 | 243 | 47.9 |

| after | 1.3 | 2.3 | 2.1 | 4.8 | 1 | |

| ② | before | 46.9 | 57 | 47.4 | 13.9 | 54.5 |

| after | 13.4 | 6.4 | 21.5 | 2.3 | 8.7 | |

| ③ | before | 780 | 923 | 849 | 408 | 582 |

| after | 724 | 892 | 792 | 384 | 342 | |

| ④ | before | 54.3 | 241 | 470 | 68.2 | 34.6 |

| after | 10.2 | 211 | 453 | 15.6 | 8.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, K.; Xu, J.; Zhu, Y.; Zhang, Z.; Zeng, Q. Study on the Technology and Mechanism of Cleaning Architectural Aluminum Formwork for Concrete Pouring by High Energy and High Repetition Frequency Pulsed Laser. Photonics 2023, 10, 242. https://doi.org/10.3390/photonics10030242

Gao K, Xu J, Zhu Y, Zhang Z, Zeng Q. Study on the Technology and Mechanism of Cleaning Architectural Aluminum Formwork for Concrete Pouring by High Energy and High Repetition Frequency Pulsed Laser. Photonics. 2023; 10(3):242. https://doi.org/10.3390/photonics10030242

Chicago/Turabian StyleGao, Kun, Jinjun Xu, Yue Zhu, Zhiyan Zhang, and Quansheng Zeng. 2023. "Study on the Technology and Mechanism of Cleaning Architectural Aluminum Formwork for Concrete Pouring by High Energy and High Repetition Frequency Pulsed Laser" Photonics 10, no. 3: 242. https://doi.org/10.3390/photonics10030242

APA StyleGao, K., Xu, J., Zhu, Y., Zhang, Z., & Zeng, Q. (2023). Study on the Technology and Mechanism of Cleaning Architectural Aluminum Formwork for Concrete Pouring by High Energy and High Repetition Frequency Pulsed Laser. Photonics, 10(3), 242. https://doi.org/10.3390/photonics10030242