Excimer Laser Surface Patterning for Photoluminescence Enhancement of Silicon Nanocrystals

Abstract

:1. Introduction

2. Materials and Methods

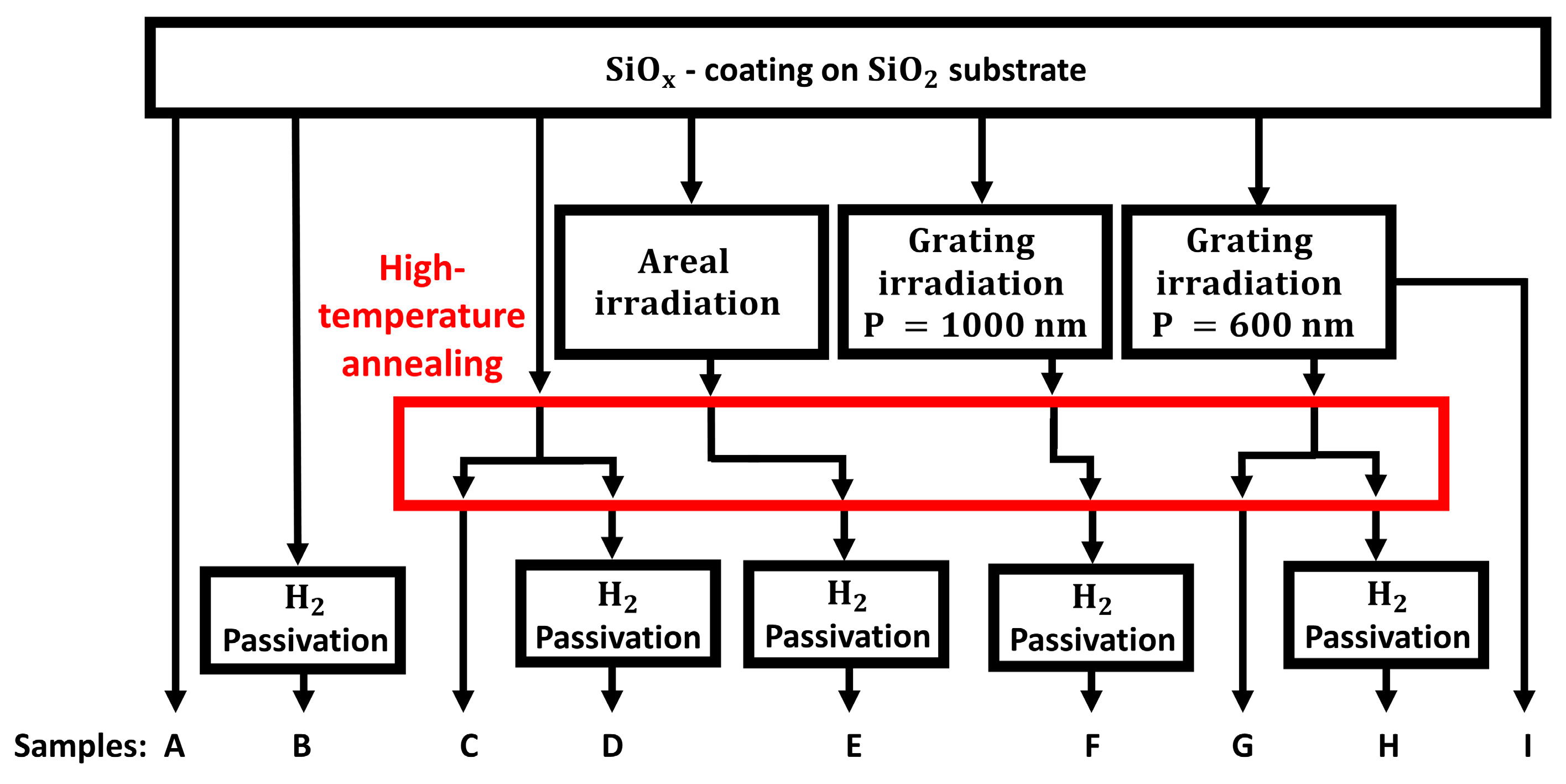

2.1. Sample Preparation

2.2. Laser Irradiation

2.3. Sample Analysis

3. Experimental Results

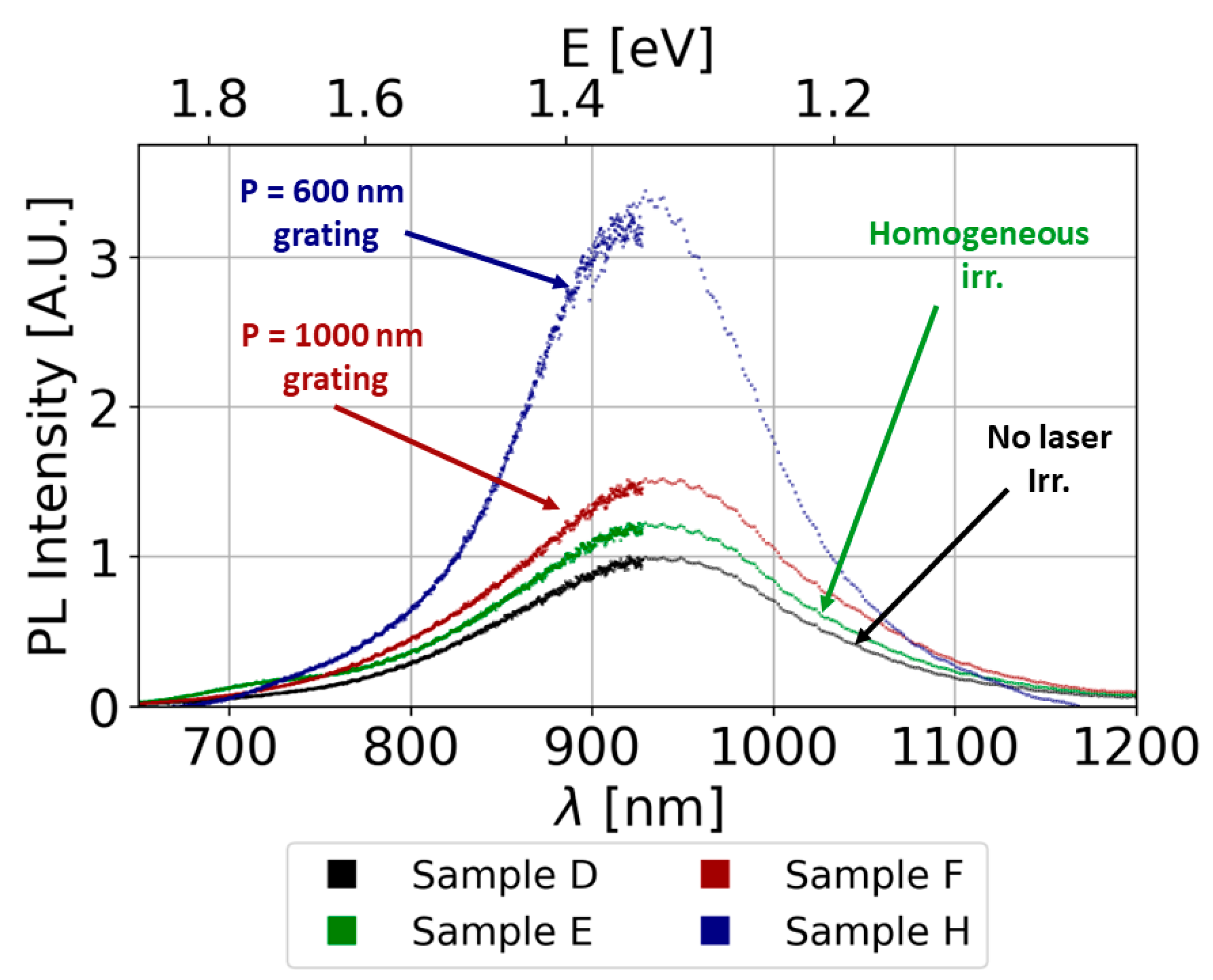

3.1. Photoluminescence Measurements

3.2. AFM and SEM Measurements of the Laser Irradiated Samples

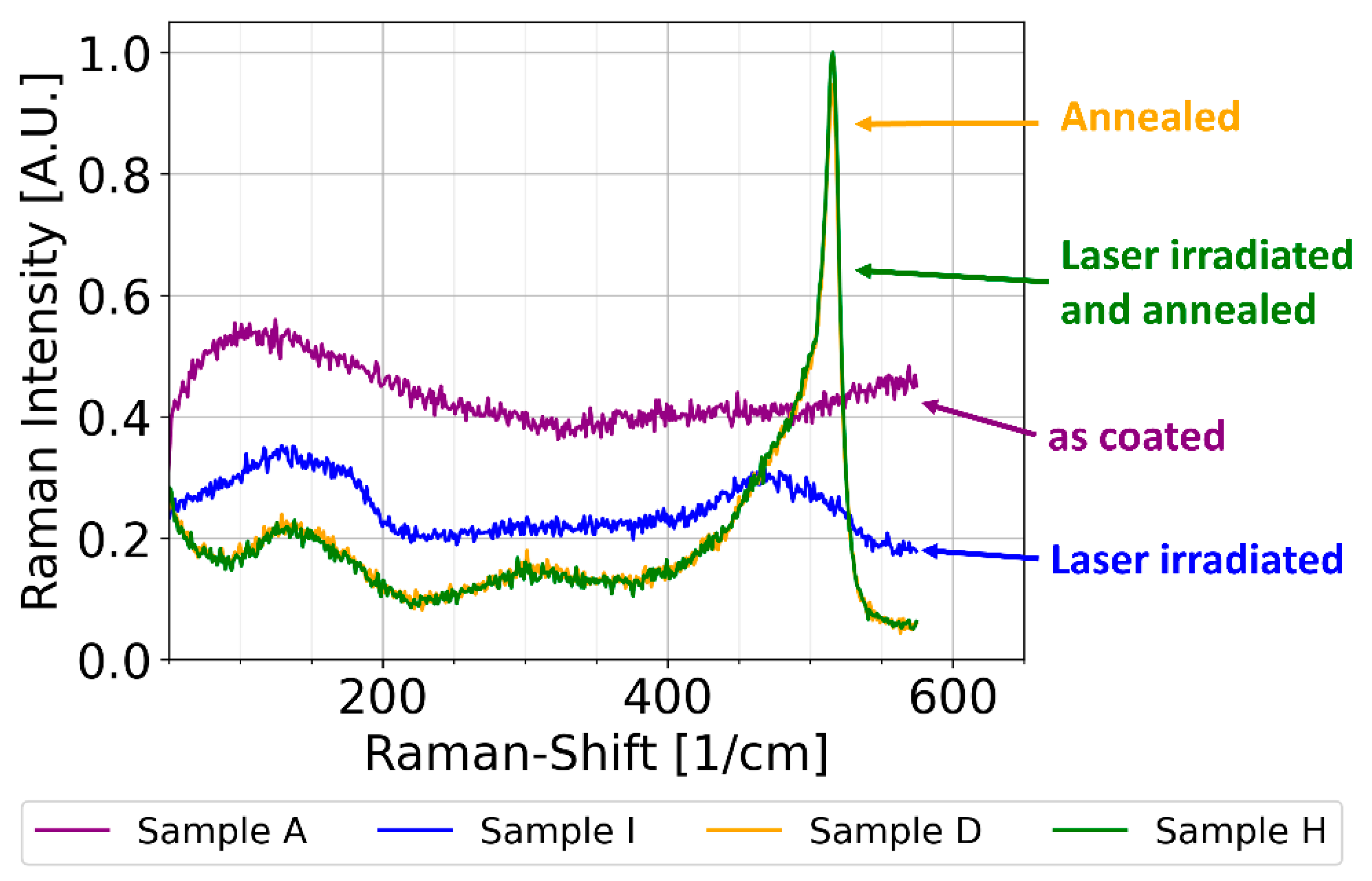

3.3. Raman Measurements

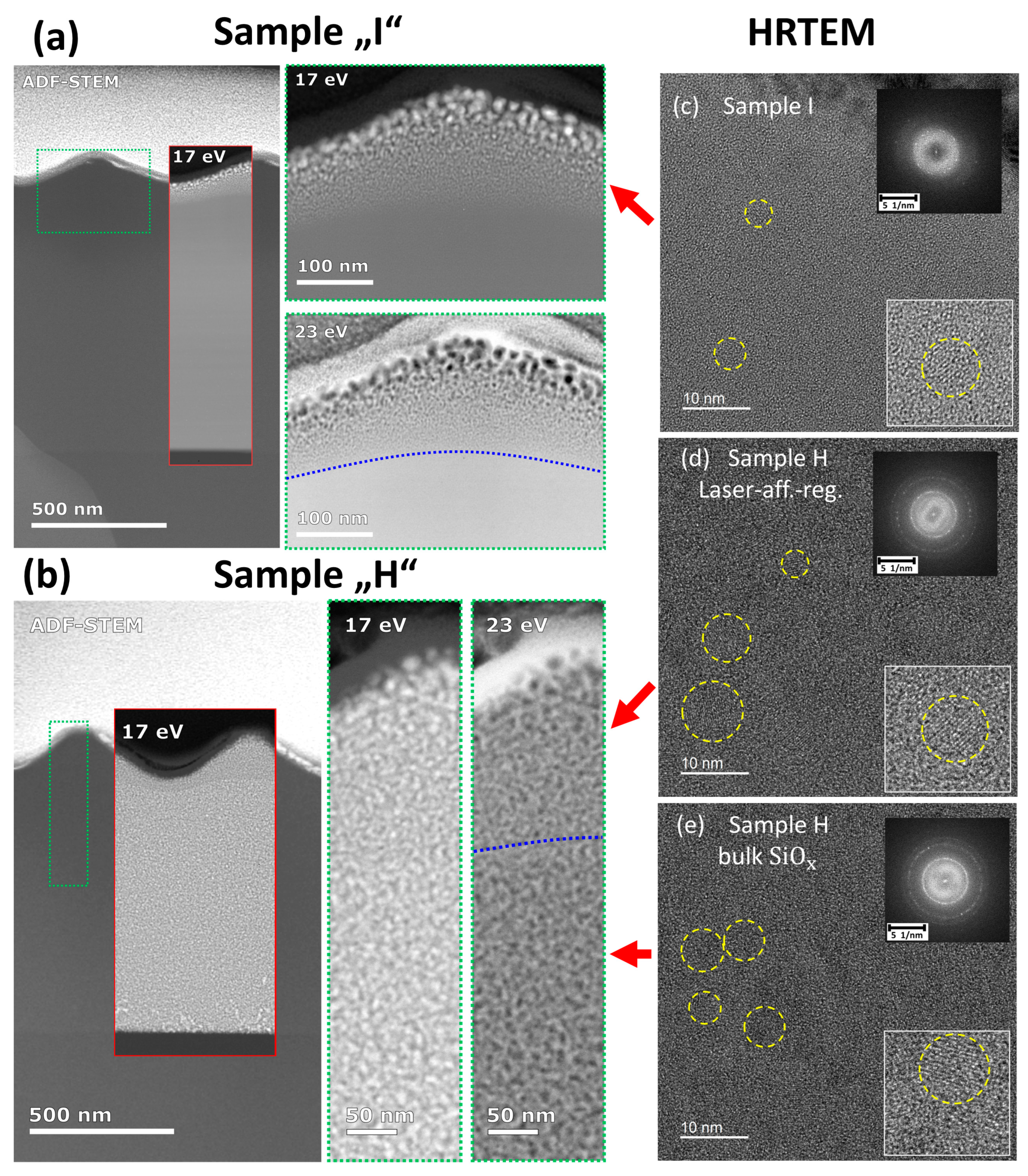

3.4. TEM Measurements

4. Discussion

4.1. Si-Nc Size, PL and Hydrogen Passivation

4.2. Influence of the Surface Grating on the PL

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pavesi, L.; Turan, L. Silicon Nanocrystals Fundamentals, Synthesis and Applications; Wiley-VCH: Hoboken, NJ, USA, 2010; ISBN 978-3-527-32160-5. [Google Scholar]

- Canham, L.T. Silicon quantum wire array fabrication by electrochemical and chemical dissolution of wafers. Appl. Phys. Lett. 1990, 57, 1046. [Google Scholar] [CrossRef]

- Cullis, A.G.; Canham, L.T. Visible light emission due to quantum size effects in highly porous crystalline silicon. Nature 1991, 353, 335–338. [Google Scholar] [CrossRef]

- Zacharias, M.; Heitmann, J.; Scholz, R.; Kahler, U.; Schmidt, M.; Bläsing, J. Size-controlled highly luminescent silicon nanocrystals: A SiO/SiO2 superlattice approach. Appl. Phys. Lett. 2002, 80, 661. [Google Scholar] [CrossRef]

- Tiwari, S.; Rana, F.; Hanafi, H.; Hartstein, A.; Crabbé, E.F.; Chan, K. A silicon nanocrystals based memory. Appl. Phys. Lett. 1996, 68, 1377. [Google Scholar] [CrossRef] [Green Version]

- Pavesi, L.; Dal Negro, L.; Mazzoleni, C.; Priolo, F. Optical gain in silicon nanocrystals. Nature 2000, 408, 440. [Google Scholar] [CrossRef] [PubMed]

- Ledoux, G.; Guillois, O.; Porterat, D.; Reynaud, C.; Huisken, F.; Kohn, B.; Paillard, V. Photoluminescence properties of silicon nanocrystals as a function of their size. Phys. Rev. B 2000, 62, 15942. [Google Scholar] [CrossRef]

- Walters, R.J.; Bourianoff, G.I.; Atwater, H.A. Field-effect electroluminescence in silicon nanocrystals. Nat. Mater. 2005, 4, 143. [Google Scholar] [CrossRef]

- Jurbergs, D.; Rogojina, E. Silicon nanocrystals with ensemble quantum yields exceeding 60%. Appl. Phys. Lett. 2006, 88, 233116. [Google Scholar] [CrossRef]

- Sinelnikov, R.; Dasog, M.; Beamish, J.; Meldrum, A.; Veinot, J.G.C. Revisiting an Ongoing Debate: What Role Do Surface Groups Play in Silicon Nanocrystal Photoluminescence? ACS Photonics 2017, 4, 1920. [Google Scholar] [CrossRef]

- Ledoux, G.; Gong, J.; Huisken, F. Effect of passivation and aging on the photoluminescence of silicon nanocrystals. Appl. Phys. Lett. 2001, 79, 4028. [Google Scholar] [CrossRef]

- Wilson, W.L.; Szajowski, P.F.; Brus, L.E. Quantum Confinement in Size-Selected, Surface-Oxidized Silicon Nanocrystals. Science 1993, 262, 1242–1244. [Google Scholar] [CrossRef] [PubMed]

- Godefroo, S.; Hayne, M.; Jivanescu, M.; Stesmans, A.; Zacharias, M.; Lebedev, O.I.; Van Tendeloo, G.; Moshchalkov, V.V. Classification and control of the origin of photoluminescence from Si nanocrystals. Nat. Nanotechnol. 2008, 3, 174. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, B.G.; Hiller, D.; Luo, J.-W.; Semonin, O.E.; Beard, M.C.; Zacharias, M.; Stradins, P. Strained Interface Defects in Silicon Nanocrystals. Adv. Funct. Mater. 2012, 22, 3223. [Google Scholar] [CrossRef]

- Hadjisavvas, G.; Jelire, P.C. Structure and Energetics of Si Nanocrystals Embedded in a−SiO2. Phys. Rev. Lett. 2004, 93, 226104. [Google Scholar] [CrossRef] [PubMed]

- Belyakov, V.A.; Burdov, V.A.; Lockwood, R.; Meldrum, A. Silicon Nanocrystals: Fundamental Theory and Implications for Stimulated Emission. Adv. Opt. Technol. 2008, 32, 279502. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, T.; Chizhik, A.I.; Chizhik, A.M.; Potrick, K.; Meixner, A.J.; Huisken, F. Radiative exciton recombination and defect luminescence observed in single silicon nanocrystals. Phys. Rev. B 2012, 86, 125302. [Google Scholar] [CrossRef]

- Wang, L.; Li, Q.; Wang, H.Y.; Huang, J.-C.; Zhang, R.; Chen, Q.-D.; Xu, H.-L.; Han, W.; Shao, Z.-Z.; Sun, H.-B. Ultrafast optical spectroscopy of surface-modified silicon quantum dots: Unraveling the underlying mechanism of the ultrabright and color-tunable photoluminescence. Light Sci. Appl. 2015, 4, 245. [Google Scholar] [CrossRef] [Green Version]

- Kahler, U.; Hofmeister, H. Size evolution and photoluminescence of silicon nanocrystallites in evaporated SiOx thin films upon thermal processing. Appl. Phys. A 2002, 74, 13–17. [Google Scholar] [CrossRef]

- Iacona, F.; Franzò, G.; Spinella, C. Correlation between luminescence and structural properties of Si nanocrystals. Appl. Phys. 1999, 87, 1295. [Google Scholar] [CrossRef]

- Kahler, U.; Hofmeister, H. Visible light emission from Si nanocrystalline composites via reactive evaporation of SiO. Opt. Mater. 2001, 17, 83. [Google Scholar] [CrossRef]

- Fricke-Begemann, T.; Wang, N.; Peretzki, P.; Seibt, M.; Ihlemann, J. Generation of silicon nanocrystals by damage free continuous wave laser annealing of substrate-bound SiOx films. J. Appl. Phys. 2015, 118, 124308. [Google Scholar] [CrossRef]

- Kenyon, A.J.; Trwoga, P.F.; Pitt, C.W.; Rehm, G. The origin of photoluminescence from thin films of silicon-rich silica. J. Appl. Phys. 1996, 79, 9291. [Google Scholar] [CrossRef]

- Wu, X.L.; Siu, G.G.; Tong, S.; Liu, X.N.; Yan, F.; Jiang, S.S.; Zhang, X.K.; Feng, D. Raman scattering of alternating nanocrystalline silicon/amorphous silicon multilayers. Appl. Phys. Lett. 1996, 69, 523. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.-W.; Cho, C.-H.; Kim, B.-H.; Park, S.-J. Quantum confinement effect in crystalline silicon quantum dots in silicon nitride grown using SiH4 and NH3. Appl. Phys. Lett. 2006, 88, 123102. [Google Scholar] [CrossRef]

- Charvet, S.; Madelon, R.; Gourbilleau, F.; Rizk, R. Spectroscopic ellipsometry analyses of sputtered Si/SiO2 nanostructures. J. Appl. Phys. 1999, 85, 4032. [Google Scholar] [CrossRef]

- Biteen, J.S.; Pacifici, D.; Lewis, N.S.; Atwater, H.A. Enhanced Radiative Emission Rate and Quantum Efficiency in Coupled Silicon Nanocrystal-Nanostructured Gold Emitters. Nano Lett. 2005, 5, 1768. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kanemitsu, Y.; Shimizu, N.; Komoda, T.; Hemment, P.L.F.; Sealy, B.J. Photoluminescent spectrum and dynamics of Si+-ion-implanted and thermally annealed SiO2 glasses. Phys. Rev. B 1996, 54, R14329. [Google Scholar] [CrossRef]

- Shimizu-Iwayama, T.; Fujita, K.; Nakao, S.; Saitoh, K.; Fujita, T.; Itoh, N. Visible photoluminescence in Si+-implanted silica glass. J. Appl. Phys. 1994, 75, 7779. [Google Scholar] [CrossRef]

- López, M.; Garrido, B.; García, C.; Pellegrino, P.; Pérez-Rodíguez, A.; Morante, J.R.; Bonagos, C.; Carrada, M.; Claverie, A. Elucidation of the surface passivation role on the photoluminescence emission yield of silicon nanocrystals embedded in SiO2. Appl. Phys. Lett. 2002, 80, 1637. [Google Scholar] [CrossRef]

- Shockley, W.; Read, W.T., Jr. Statistics of the Recombination of Holes and Electrons. Phys. Rev. 1952, 87, 835. [Google Scholar] [CrossRef]

- Hall, R.N. Electron-Hole Recombination in Germanium. Phys. Rev. 1952, 87, 387. [Google Scholar] [CrossRef]

- Mangolini, L. Synthesis, properties, and applications of silicon nanocrystals. J. Vac. Sci. Technol. B 2013, 31, 020801. [Google Scholar] [CrossRef]

- Richter, L.J.; Ihlemann, J. Photoluminescence enhancement of silicon nanocrystals by excimer laser implanted gold nanoparticles. Appl. Phys. A 2022, 128, 764. [Google Scholar] [CrossRef]

- Shimizu, K.T.; Woo, W.K.; Fisher, B.R.; Eisler, H.J.; Bawendi, M.G. Surface-Enhanced Emission from Single Semiconductor Nanocrystals. Phys. Rev. Lett. 2002, 89, 117401. [Google Scholar] [CrossRef]

- Köthemann, R.; Golla, C.; Qu, H.; Meier, C. Influence of Gold Nanoantennas on the Photoluminescence of Silicon Nanocrystals. Photonics 2022, 9, 985. [Google Scholar] [CrossRef]

- Zhuang, Z.; Guo, X.; Zhang, G.; Liu, B.; Zhang, R.; Zhi, T.; Tao, T.; Ge, H.; Ren, F.; Xie, Z.; et al. Large-scale fabrication and luminescence properties of GaN nanostructures by a soft UV-curing nanoimprint lithography. Nanotechnology 2013, 24, 405303. [Google Scholar] [CrossRef] [PubMed]

- López, J.A.L.; López, J.C.; Valerdi, D.E.; Salgado, G.G.; Díaz-Becerril, T.; Pedraza, A.P.; Gracia, F.J.F. Morphological, compositional, structural, and optical properties of Si-nc embedded in SiOx films. Nanoscale Res. Lett. 2012, 7, 604. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, W.; Wang, S.; Hu, M.; He, S.; Ge, P.; Wang, J.; Guo, Y.Y.; Zhaowei, L. Enhancement of electroluminescence from embedded Si quantum dots/SiO2multilayers film by localized-surface-plasmon and surface roughening. Sci. Rep. 2015, 5, 11881. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ondic, L.; Varga, M.; Hruska, K.; Kromka, A.; Herynkova, K.; Hönerlage, B.; Pelant, I. Two-dimensional photonic crystal slab with embedded silicon nanocrystals: Efficient photoluminescence extraction. Appl. Phys. Lett. 2013, 102, 251111. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.-B.; Ren, Y.; Xiong, R.-L.; Zhao, Y.-Y.; Lu, M. Modulation of the photoluminescence of Si quantum dots by means of CO2 laser pre-annealing. Appl. Surf. Sci. 2010, 256, 5116. [Google Scholar] [CrossRef]

- Cha, D.; Shin, J.H.; Song, I.-H.; Han, M.-K. Enhanced formation of luminescent nanocrystal Si embedded in Si/SiO2 superlattice by excimer laser irradiation. Appl. Phys. Lett. 2004, 84, 1287. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-de Marcos, L.V.; Larruquert, J.I.; Méndez, J.A.; Aznárez, J.A. Self-consistent optical constants of SiO2 and Ta2O5 films. Opt. Mater. Express 2016, 6, 3622. [Google Scholar] [CrossRef]

- Wang, N.; Fricke-Begemann, T.; Peretzki, P.; Ihlemann, J.; Seibt, M. Formation of porous silicon oxide from substrate-bound silicon rich silicon oxide layers by continuous-wave laser irradiation. J. Appl. Phys. 2018, 123, 093104. [Google Scholar] [CrossRef]

- Schamm, S.; Bonafos, C.; Coffin, H.; Cherkashin, N.; Carrada, M.; Assayag, G.B.; Claverie, A.; Tencé, M.; Colliex, C. Imaging Si nanoparticles embedded in SiO2 layers by (S)TEM-EELS. Ultramicroscopy 2008, 108, 346. [Google Scholar] [CrossRef] [PubMed]

- Jahn, M.; Richter, J.; Weichenhain-Schriever, R.; Meinertz, J.; Ihlemann, J. Ablation of silicon suboxide thin layers. Appl. Phys. A 2010, 101, 533. [Google Scholar] [CrossRef] [Green Version]

- Karstens, R.; Gödecke, A.; Prießner, A.; Ihlemann, J. Fabrication of 250-nm-hole arrays in glass and fused silica by UV laser ablation. Opt. Laser Technol. 2016, 83, 16. [Google Scholar] [CrossRef]

- Voutsas, A.T.; Hatalis, M.K.; Boyce, J.; Chiang, A. Raman spectroscopy of amorphous and microcrystalline silicon films deposited by low-pressure chemical vapor deposition. J. Appl. Phys. 1995, 78, 6999. [Google Scholar] [CrossRef]

- Parker, J.H.; Feldman, J.D.W.; Ashkin, M. Raman Scattering by Silicon and Germanium. Phys. Rev. 1967, 155, 712. [Google Scholar] [CrossRef]

- Ihlemann, J.; Meinertz, J.; Danev, G. Excimer laser ablation of thick SiOx-films: Etch rate measurements and simulation of the ablation threshold. Appl. Phys. Lett. 2012, 101, 091901. [Google Scholar] [CrossRef]

- Kachurin, G.A.; Cherkova, S.G.; Marin, D.V.; Yankov, R.A.; Deutschmann, M. Formation of light-emitting Si nanostructures in SiO2 by pulsed anneals. Nanotechnology 2008, 19, 355305. [Google Scholar] [CrossRef]

- Takeoka, S.; Fuji, M.; Hayashi, S. Size-dependent photoluminescence from surface-oxidized Si nanocrystals in a weak confinement regime. Phys. Rev. B 2000, 62, 16820. [Google Scholar] [CrossRef]

- Ledoux, G.; Gong, J.; Huisken, F.; Guillois, O.; Reynaud, C. Photoluminescence of size-separated silicon nanocrystals: Confirmation of quantum confinement. Appl. Phys. Lett. 2002, 80, 25. [Google Scholar] [CrossRef]

- Cheylan, S.; Elliman, R.G. Effect of hydrogen on the photoluminescence of Si nanocrystals embedded in a SiO2 matrix. Appl. Phys. Lett. 2001, 78, 1225. [Google Scholar] [CrossRef]

- Garcia, C.; Garrido, B.; Pellegrino, P.; Ferre, R.; Moreno, J.A.; Morante, J.R.; Pavesi, L.; Cazzanelli, M. Size dependence of lifetime and absorption cross section of Si nanocrystals embedded in SiO2. Appl. Phys. Lett. 2003, 82, 1595. [Google Scholar] [CrossRef]

- Yi, L.X.; Heitmann, J.; Scholz, R.; Zacharias, M. Si rings, Si clusters, and Si nanocrystals—Different states of ultrathin SiO𝑥 layers. Appl. Phys. Lett. 2002, 81, 22. [Google Scholar] [CrossRef]

- Sakruai, Y. Oxygen-related red photoluminescence bands in silica glasses. J. Non-Cryst. Solids 2003, 316, 389. [Google Scholar] [CrossRef]

- Lau, H.W.; Tan, O.K.; Liu, Y.; Ng, C.Y.; Chen, T.P.; Pita, K.; Lu, D. Defect-induced photoluminescence from tetraethylorthosilicate thin films containing mechanically milled silicon nanocrystals. J. Appl. Phys. 2005, 97, 104307. [Google Scholar] [CrossRef]

- Hass, G.; Salzberg, C.D. Optical Properties of Silicon Monoxide in the Wavelength Region from 0.24 to 14.0 Microns. J. Opt. Soc. Am. 1954, 44, 181. [Google Scholar] [CrossRef]

- Malitson, I.H. Interspecimen Comparison of the Refractive Index of Fused Silica. J. Opt. Soc. Am. 1965, 55, 1205. [Google Scholar] [CrossRef]

- Lin, J.H.; Liou, H.Y.; Wang, C.-D.; Tseng, C.-Y.; Lee, C.-T.; Ting, C.-C.; Kan, H.-C.; Hsu, C.C. Giant Enhancement of Upconversion Fluorescence of NaYF4:Yb3+,Tm3+ Nanocrystals with Resonant Waveguide Grating Substrate. ACS Photonics 2015, 2, 530. [Google Scholar] [CrossRef]

- Selle, A. Dielektrische Wellenleitergitter in Resonanz: Theorie, Charakterisierung und Anwendung. Ph.D. Thesis, Georg-August-Universität Göttingen, Göttingen, Germany, 2009. [Google Scholar] [CrossRef]

- Colier, R.J.; Burckhardt, C.B.; Lin, L.H. Optical Holography; Academic Press: Cambridge, MA, USA, 1971; ISBN 978-0-12-181050-4. [Google Scholar]

| Setup | Homogeneous Irradiation | Grating Irradiation P = 600 nm | Grating Irradiation P = 1000 nm |

|---|---|---|---|

| Laser system | LPX-Pro, Coherent | Novatex, Coherent | LPX-Pro, Coherent |

| Demagnification | 5.4:1 | 25:1 | 10:1 |

| Mask aperture | |||

| Phase mask period | Not used | 30 µm | 20 µm |

| Imaging lens | Spherical lensf = 100 mm | Schwarzschild-Objective; NA = 0.4 | Imaging-Objective (Thorlabs LMU-10x-193); NA = 0.27 |

| Resulting spot size | |||

| Treated samples | E | G, H, I | F |

| Sample | Area Fraction | λ1 [nm] | f1 [%] | λ2 [nm] | f2 [%] | λ3 [nm] | f3 [%] | Hydrogen Passivation | Period [nm] |

|---|---|---|---|---|---|---|---|---|---|

| C | 0.2 | 710 | 5.3 | 800 | 23.3 | 929 | 71.4 | − | No Irr. |

| D | 1 | 736 | 2.9 | 763 | 0 | 937 | 97.1 | + | No Irr. |

| E | 1.3 | 724 | 4.7 | 793 | 0.5 | 936 | 94.8 | + | ∞ |

| F | 1.5 | 732 | 2.4 | 793 | 1.2 | 939 | 96.4 | + | 1000 |

| G | 0.5 | 738 | 6.8 | 786 | 2.3 | 910 | 90.9 | − | 600 |

| H | 2.6 | 739 | 1.7 | 787 | 1.7 | 929 | 96.6 | + | 600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Richter, L.J.; Ross, U.; Seibt, M.; Ihlemann, J. Excimer Laser Surface Patterning for Photoluminescence Enhancement of Silicon Nanocrystals. Photonics 2023, 10, 358. https://doi.org/10.3390/photonics10040358

Richter LJ, Ross U, Seibt M, Ihlemann J. Excimer Laser Surface Patterning for Photoluminescence Enhancement of Silicon Nanocrystals. Photonics. 2023; 10(4):358. https://doi.org/10.3390/photonics10040358

Chicago/Turabian StyleRichter, Lukas Janos, Ulrich Ross, Michael Seibt, and Jürgen Ihlemann. 2023. "Excimer Laser Surface Patterning for Photoluminescence Enhancement of Silicon Nanocrystals" Photonics 10, no. 4: 358. https://doi.org/10.3390/photonics10040358

APA StyleRichter, L. J., Ross, U., Seibt, M., & Ihlemann, J. (2023). Excimer Laser Surface Patterning for Photoluminescence Enhancement of Silicon Nanocrystals. Photonics, 10(4), 358. https://doi.org/10.3390/photonics10040358