Theoretical Analysis of Thermal Distribution and Waveform Evolution in Pulsed Ytterbium-Doped Fiber Amplifier with Extra Feedback

Abstract

1. Introduction

2. Theoretical Models and Methods

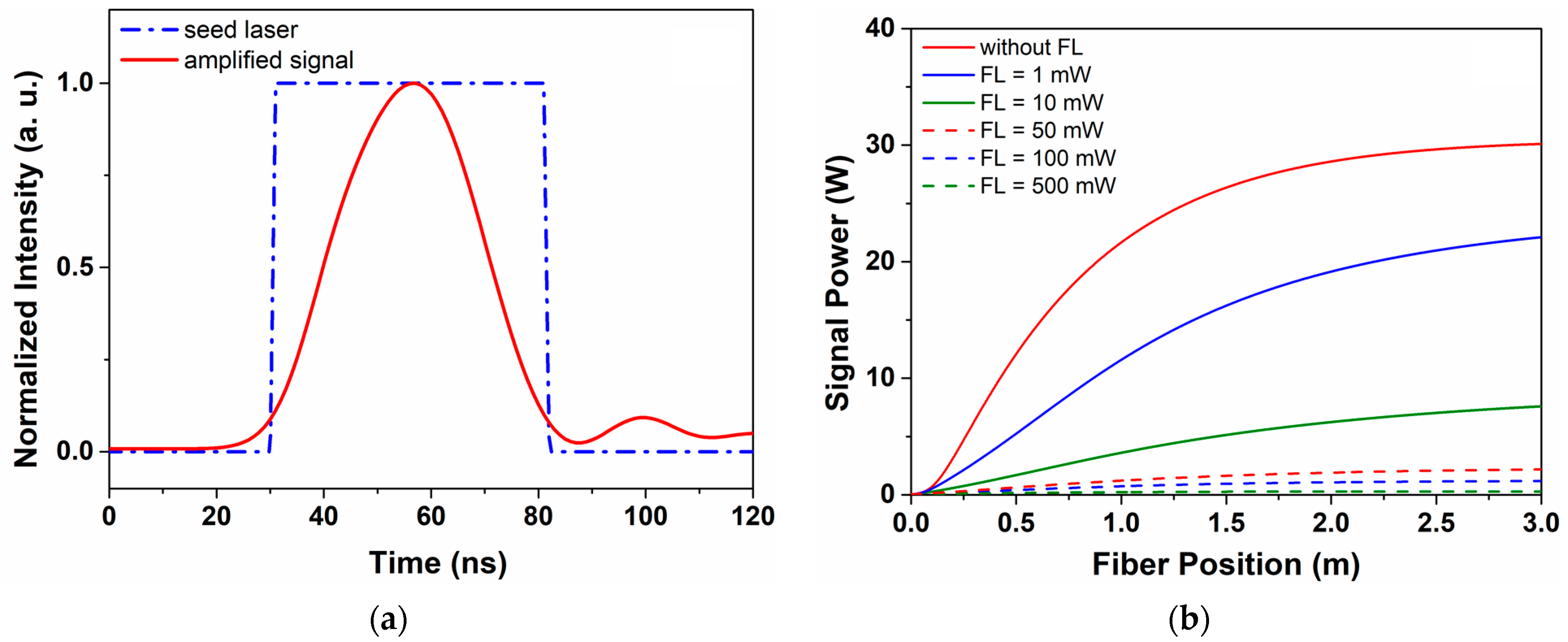

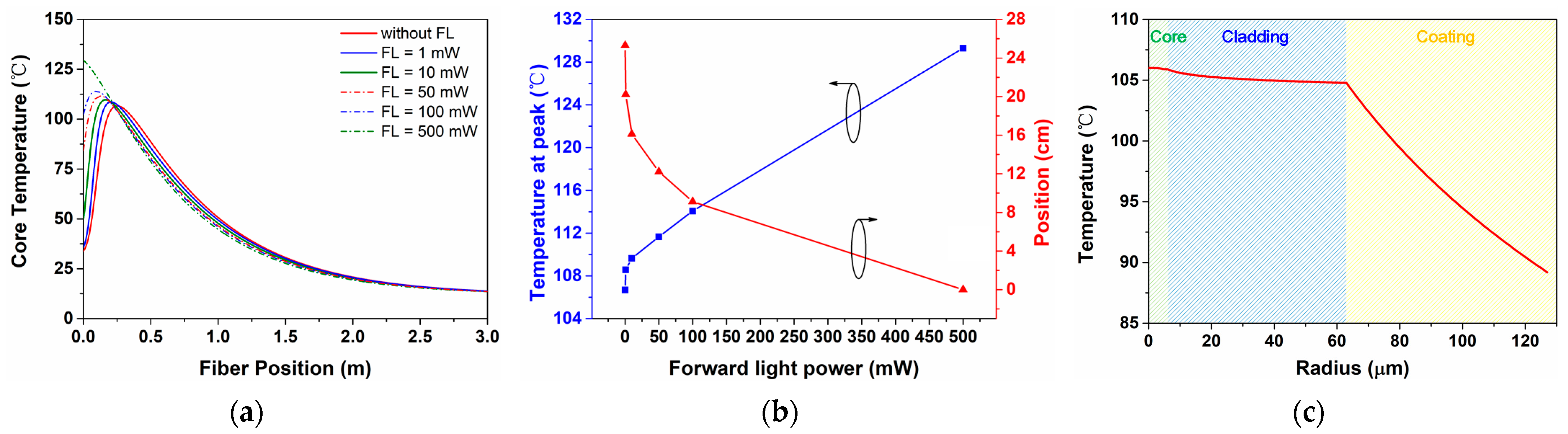

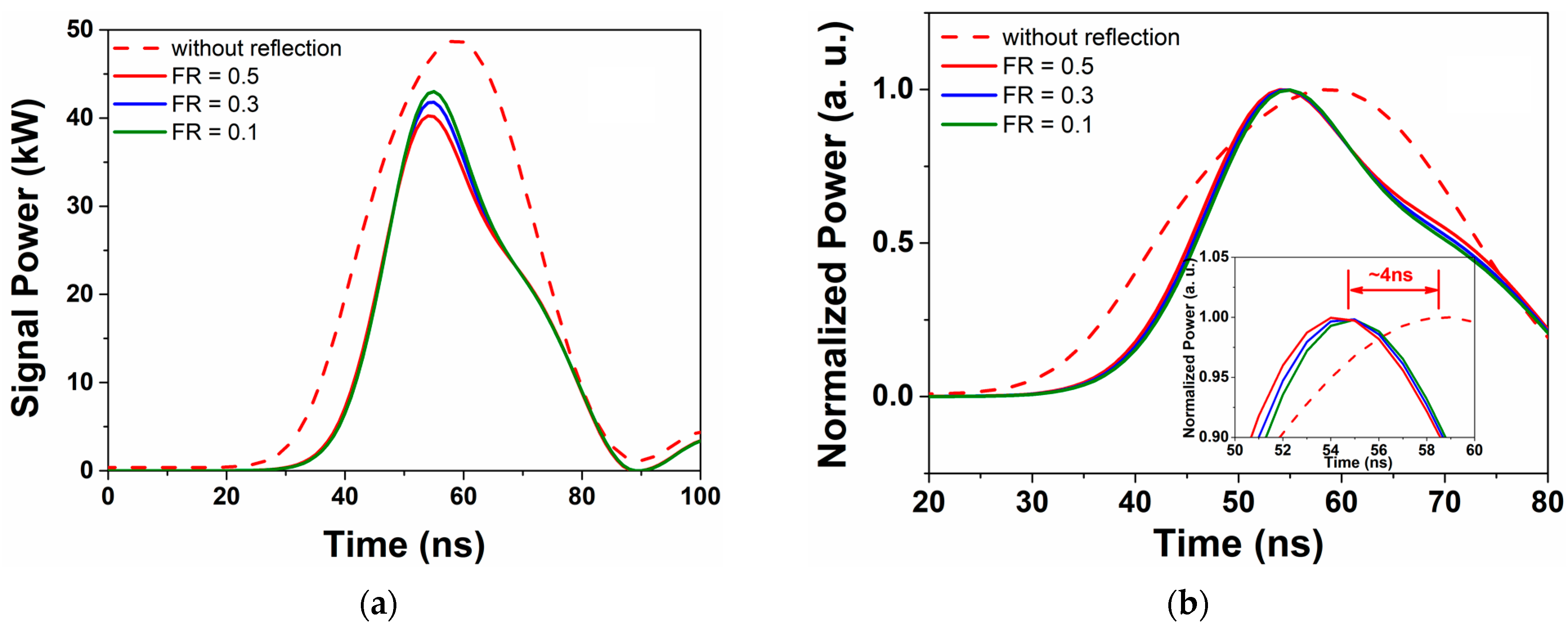

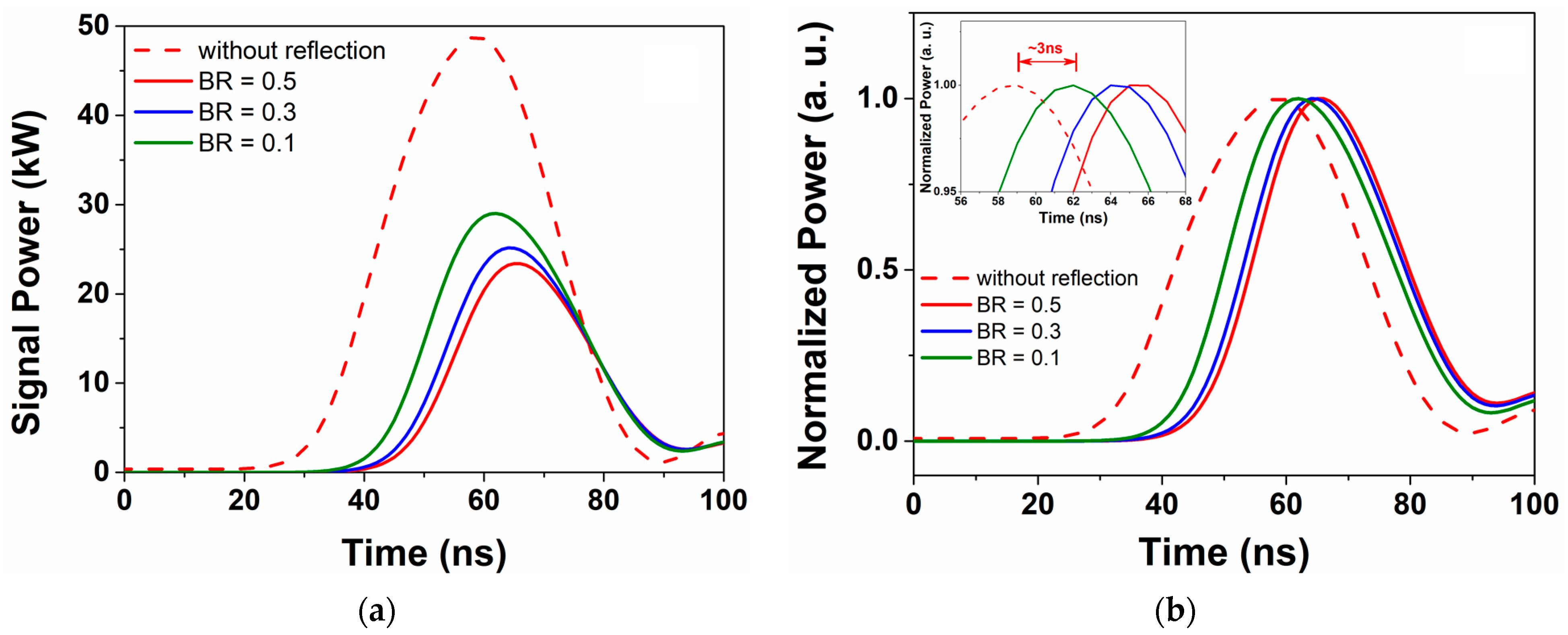

3. Results and Discussion

3.1. The Temperature Distribution with CW Signal Feedback

3.2. The Pulse Waveform Evolution with PW Signal Feedback

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shi, W.; Fang, Q.; Zhu, X.; Norwood, R.A.; Peyghambarian, N. Fiber lasers and their applications. Appl. Opt. 2014, 53, 6554–6568. [Google Scholar] [CrossRef] [PubMed]

- Zervas, M.N.; Codemard, C.A. High Power Fiber Lasers: A Review. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 219–241. [Google Scholar] [CrossRef]

- Fu, S.; Shi, W.; Feng, Y.; Zhang, L.; Yang, Z.; Xu, S.; Zhu, X.; Norwood, R.A.; Peyghambarian, N. Review of recent progress on single-frequency fiber lasers. J. Opt. Soc. Am. B 2017, 34, A49–A62. [Google Scholar] [CrossRef]

- Li, Y.; Deng, X.; Fu, S.; Sheng, Q.; Shi, C.; Zhang, J.; Zhang, L.; Shi, W.; Yao, J. High-power, high-efficiency single-frequency DBR fiber laser at 1064 nm based on Yb(3+)-doped silica fiber. Opt. Lett. 2023, 48, 598–601. [Google Scholar] [CrossRef]

- Meijer, J. Laser beam machining (LBM), state of the art and new opportunities. J. Mater. Process. Technol. 2004, 149, 2–17. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Zhou, P.; Gong, Z.; Xu, X. 6 mJ, high-average-power, all-fiberized Q-switched fiber master oscillator power amplifier with low repetition rate. Appl. Opt. 2012, 29, 6933–6936. [Google Scholar] [CrossRef]

- Fang, Q.; Qin, Y.; Wang, B.; Shi, W. 11 mJ all-fiber-based activelyQ-switched fiber master oscillator power amplifier. Laser Phys. Lett. 2013, 10, 115103. [Google Scholar] [CrossRef]

- Zhang, H.; Shen, X.; Chen, D.; Zheng, C.; Yan, P.; Gong, M. High Energy and High Peak Power Nanosecond Pulses Generated by Fiber Amplifier. IEEE Photonics Technol. Lett. 2014, 26, 2295–2298. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, H.; Gong, M. High Energy (100 mJ) and High Peak Power (8 MW) Nanosecond Pulses Delivered by Fiber Lasers and Self-Focusing Analysis Based on a Novel Mode Decomposition Method. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 1–6. [Google Scholar] [CrossRef]

- Yong, W. Heat dissipation in kilowatt fiber power amplifiers. IEEE J. Quantum Electron. 2004, 40, 731–740. [Google Scholar] [CrossRef]

- Brown, D.C.; Hoffman, H.J. Thermal, stress, and thermal-optic effects in high average power double-clad silica fiber lasers. IEEE J. Quantum Electron. 2001, 37, 207–217. [Google Scholar] [CrossRef]

- Fan, Y.; He, B.; Zhou, J.; Zheng, J.; Liu, H.; Wei, Y.; Dong, J.; Lou, Q. Thermal effects in kilowatt all-fiber MOPA. Opt. Express 2011, 19, 15162–15172. [Google Scholar] [CrossRef] [PubMed]

- Pask, H.; Carman, R.; Hanna, D.; Tropper, A.; Mackechnie, C.; Barber, P.; Dawes, J. Ytterbium-doped silica fiber lasers versatile sources for the 1–1.2 μm region. IEEE J. Quantum Electron. 1995, 1, 2–13. [Google Scholar] [CrossRef]

- Yu, W.; Yan, P.; Qi, T.; Wu, Y.; Li, D.; Xiao, Q.; Gong, M. High-power and high-brightness Er:Yb codoped fiber MOPA operating at 1535 nm. Opt. Express 2022, 30, 16837. [Google Scholar] [CrossRef]

- Shuto, Y. Evaluation of High-Temperature Absorption Coefficients of Ionized Gas Plasmas in Optical Fibers. IEEE Photonics Technol. Lett. 2010, 22, 134–136. [Google Scholar] [CrossRef]

- Facao, M.; Rocha, A.M.; de Brito Andre, P.S. Traveling Solutions of the Fuse Effect in Optical Fibers. J. Light. Technol. 2011, 29, 109–114. [Google Scholar] [CrossRef]

- Otto, H.-J.; Stutzki, F.; Jansen], F.; Eidam], T.; Jauregui, C.; Limpert, J.; Tünnermann, A. Temporal dynamics of mode instabilities in high-power fiber lasers and amplifiers. Opt. Express 2012, 20, 15710–15722. [Google Scholar] [CrossRef]

- Jauregui, C.; Otto, H.J.; Stutzki, F.; Limpert, J.; Tunnermann, A. Simplified modelling the mode instability threshold of high power fiber amplifiers in the presence of photodarkening. Opt. Express 2015, 23, 20203–20218. [Google Scholar] [CrossRef]

- Smith, A.V.; Smith, J.J. Overview of a Steady-Periodic Model of Modal Instability in Fiber Amplifiers. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 472–483. [Google Scholar] [CrossRef]

- Zhu, X.; Schülzgen, A.; Li, H.; Li, L.; Han, L.; Moloney, J.V.; Peyghambarian, N. Detailed investigation of self-imaging in largecore multimode optical fibers for application in fiber lasers and amplifiers. Opt. Express 2008, 16, 16632–16645. [Google Scholar] [CrossRef]

- Kelson, I.; Amos, A. Hardy. Strongly pumped fiber lasers. J. Light. Technol. 1998, 34, 1570–1577. [Google Scholar] [CrossRef]

- Yong, W.; Hong, P. Dynamic characteristics of double-clad fiber amplifiers for high-power pulse amplification. J. Light. Technol. 2003, 21, 2262–2270. [Google Scholar] [CrossRef]

- Liu, M.; Shum, P.P.; Xiong, Z.; Zhang, B.M.; Cheng, X. Dynamics of nanosecond pulsed pump ytterbium-doped double-clad fiber amplifier. Opt. Commun. 2017, 403, 325–329. [Google Scholar] [CrossRef]

- Mohammed, Z.; Saghafifar, H.; Soltanolkotabi, M. An approximate analytical model for temperature and power distribution in high-power Yb-doped double-clad fiber lasers. Laser Phys. 2014, 24, 115107–115118. [Google Scholar] [CrossRef]

- Han, Q.; Liu, T.; Lü, X.; Ren, K. Numerical methods for high-power Er/Yb-codoped fiber amplifiers. Opt. Quantum Electron. 2014, 47, 2199–2212. [Google Scholar] [CrossRef]

- Bi, M.; Zhang, H.; Zhao, Y.; Xue, L.; Jiang, P.; Bai, Y.; Miao, Y.; Shi, W.; Yao, J. Theoretical and Experimental Investigation of Intracavity Displacement-Sensor Based on All-Single-Mode Fiber. J. Light. Technol. 2022, 40, 2585–2593. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, X.; Chen, X.; Tian, C.; Wang, M. Theoretical Analysis of Thermal Distribution and Waveform Evolution in Pulsed Ytterbium-Doped Fiber Amplifier with Extra Feedback. Photonics 2023, 10, 437. https://doi.org/10.3390/photonics10040437

Bai X, Chen X, Tian C, Wang M. Theoretical Analysis of Thermal Distribution and Waveform Evolution in Pulsed Ytterbium-Doped Fiber Amplifier with Extra Feedback. Photonics. 2023; 10(4):437. https://doi.org/10.3390/photonics10040437

Chicago/Turabian StyleBai, Xiaolei, Xuening Chen, Chuan Tian, and Meng Wang. 2023. "Theoretical Analysis of Thermal Distribution and Waveform Evolution in Pulsed Ytterbium-Doped Fiber Amplifier with Extra Feedback" Photonics 10, no. 4: 437. https://doi.org/10.3390/photonics10040437

APA StyleBai, X., Chen, X., Tian, C., & Wang, M. (2023). Theoretical Analysis of Thermal Distribution and Waveform Evolution in Pulsed Ytterbium-Doped Fiber Amplifier with Extra Feedback. Photonics, 10(4), 437. https://doi.org/10.3390/photonics10040437