Effects of Thickness and Grain Size on Harmonic Generation in Thin AlN Films

Abstract

1. Introduction

2. Experimental Procedures

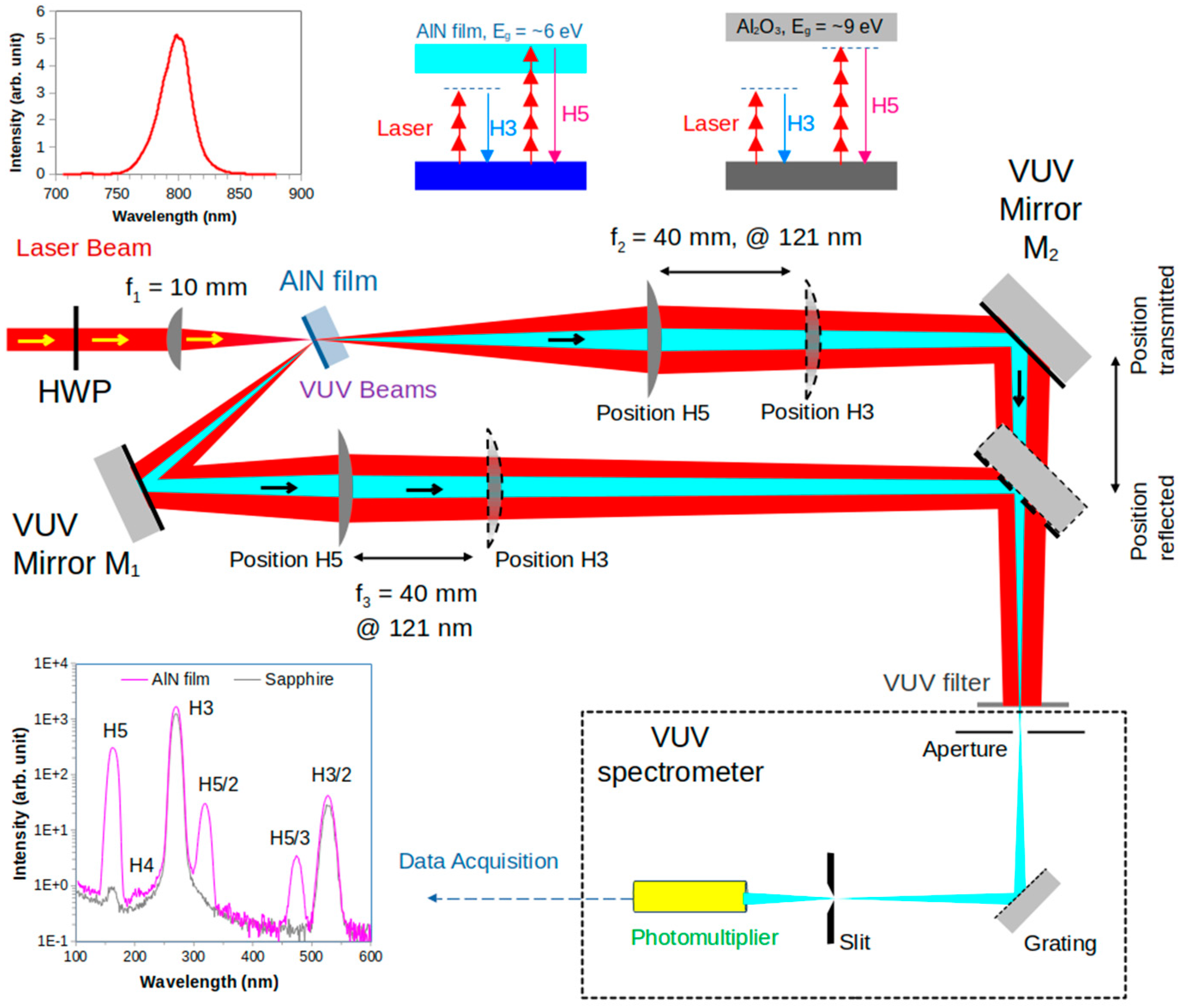

2.1. Experimental Setup for High-Harmonic Generation on Thin Films

2.2. Film Growth and Characterization

3. Measurement Results

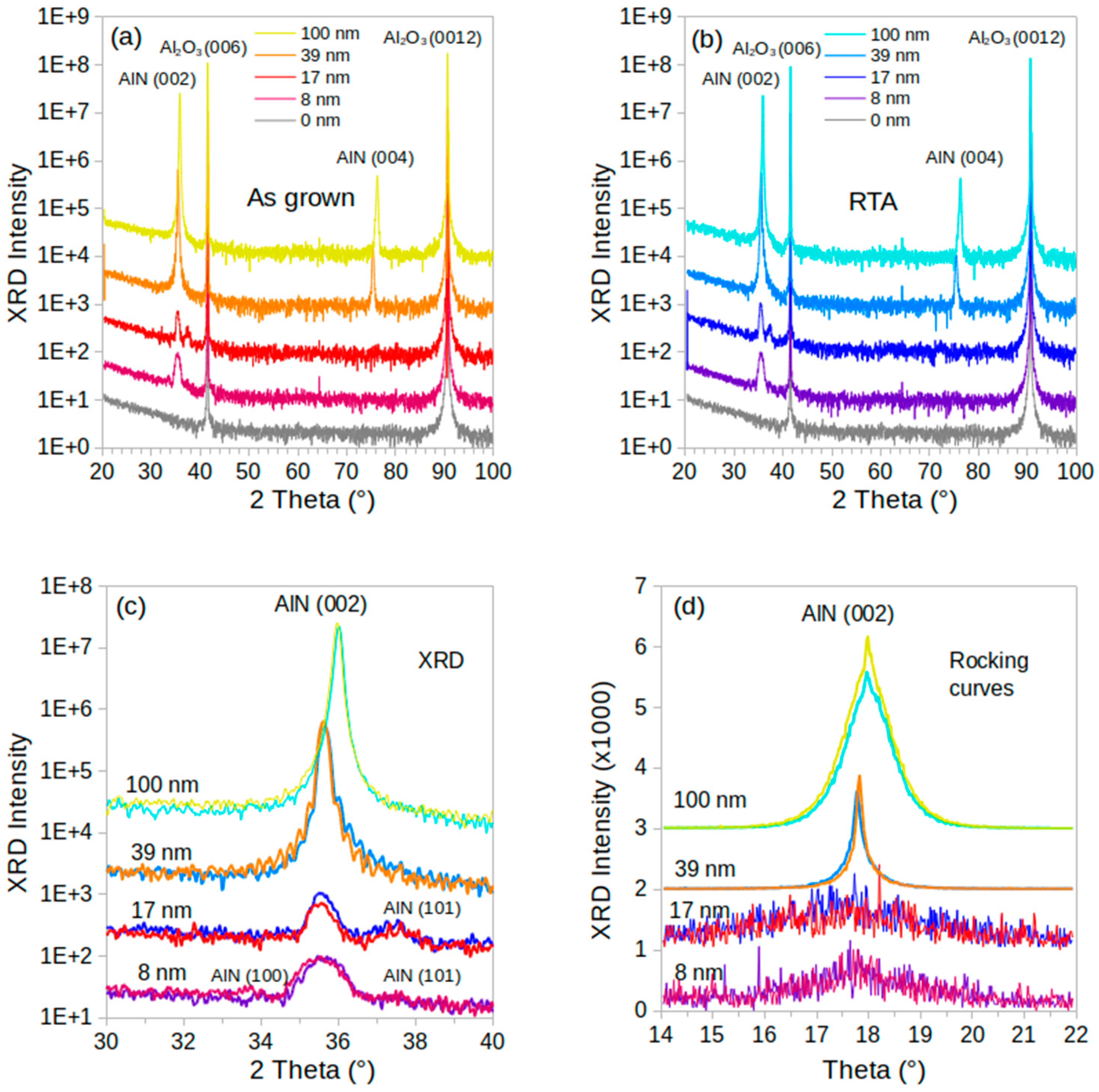

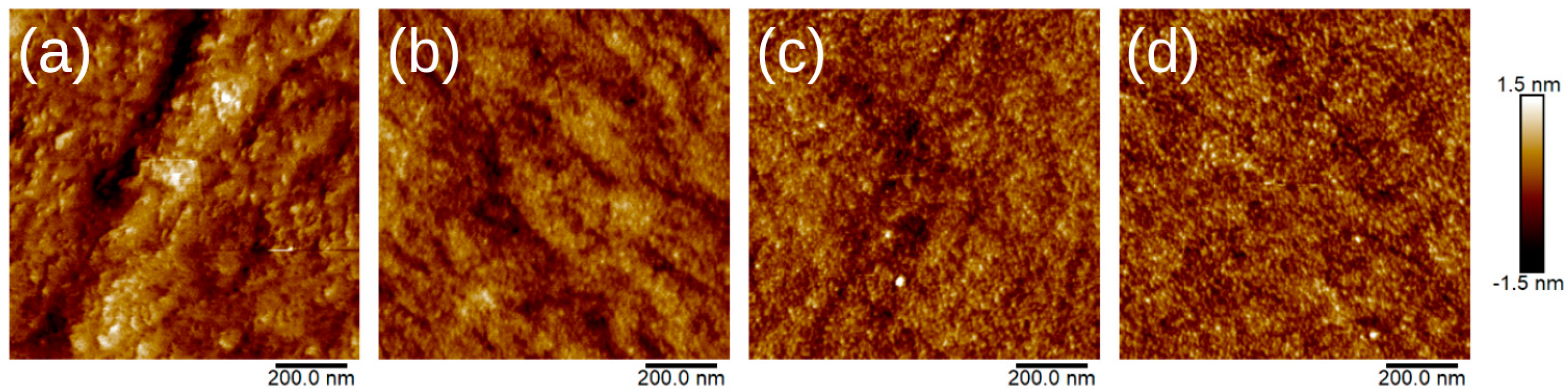

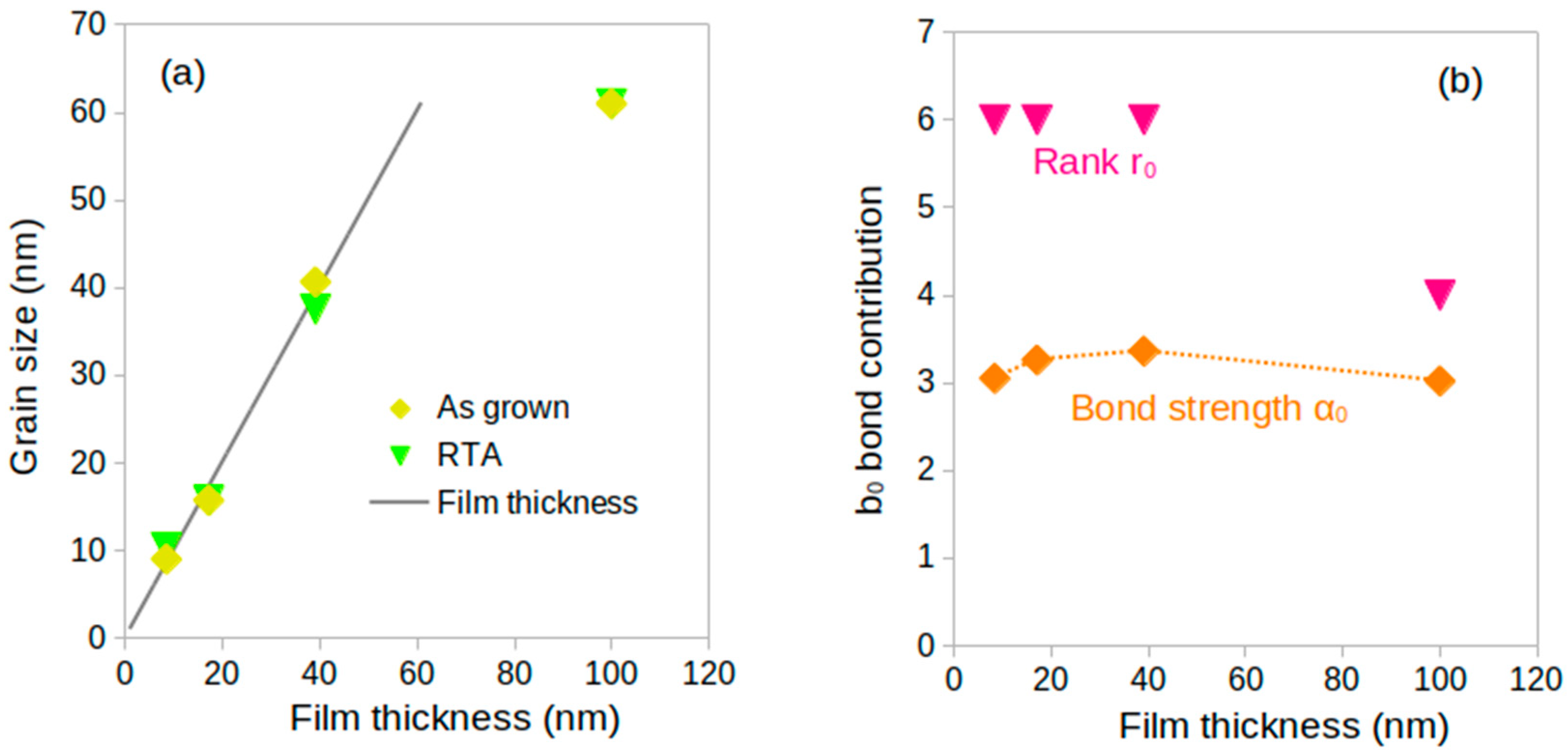

3.1. X-Ray Diffraction and AFM Measurements of the AlN Films

- AlN films “as grown” with thicknesses of 8, 17, 39 and 100 nm.

- AlN films annealed (RTA) with thicknesses of 8, 17, 39 and 100 nm.

- Al2O3 substrate without film.

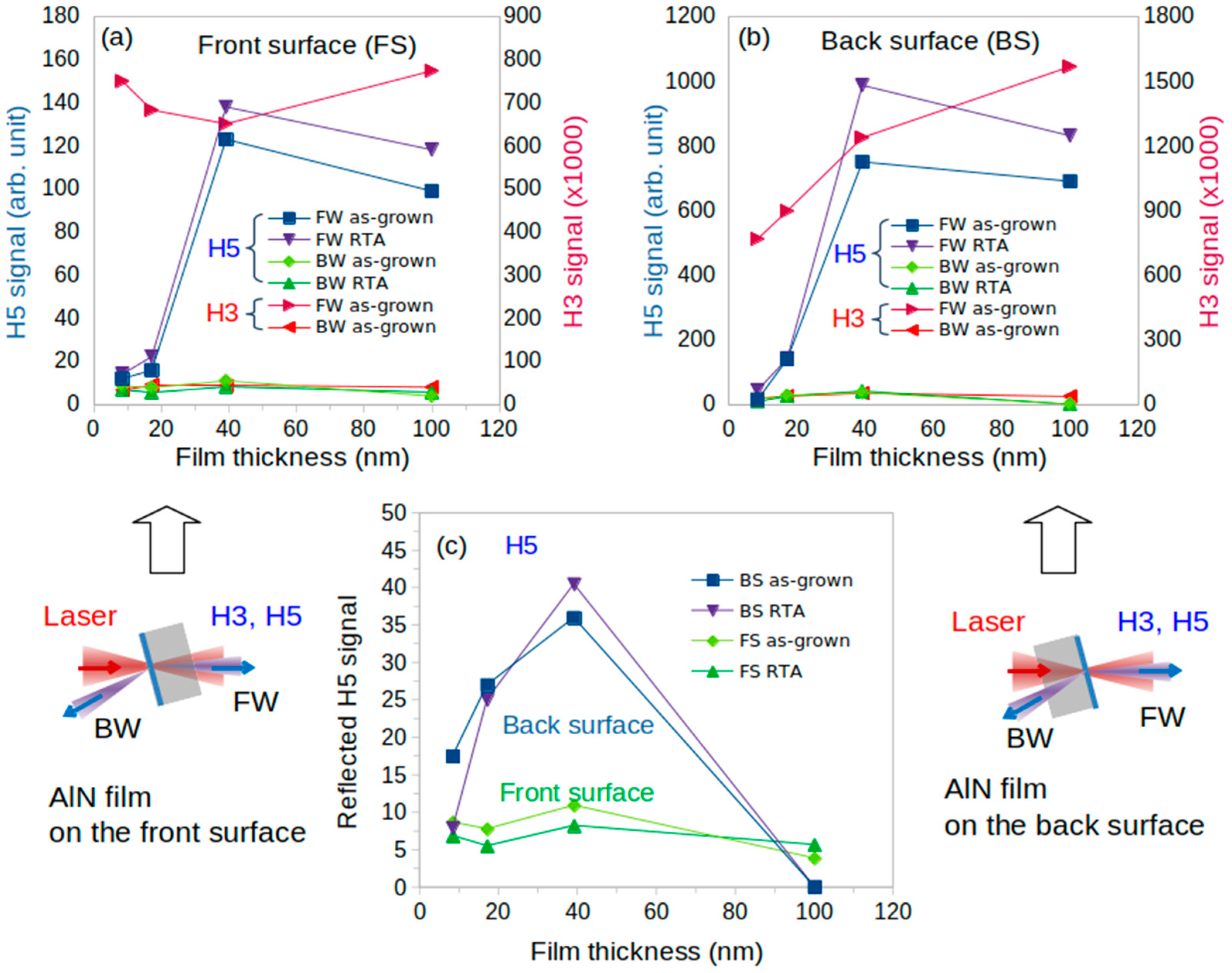

3.2. Effect of the AlN Film Thickness on the Harmonic Signal

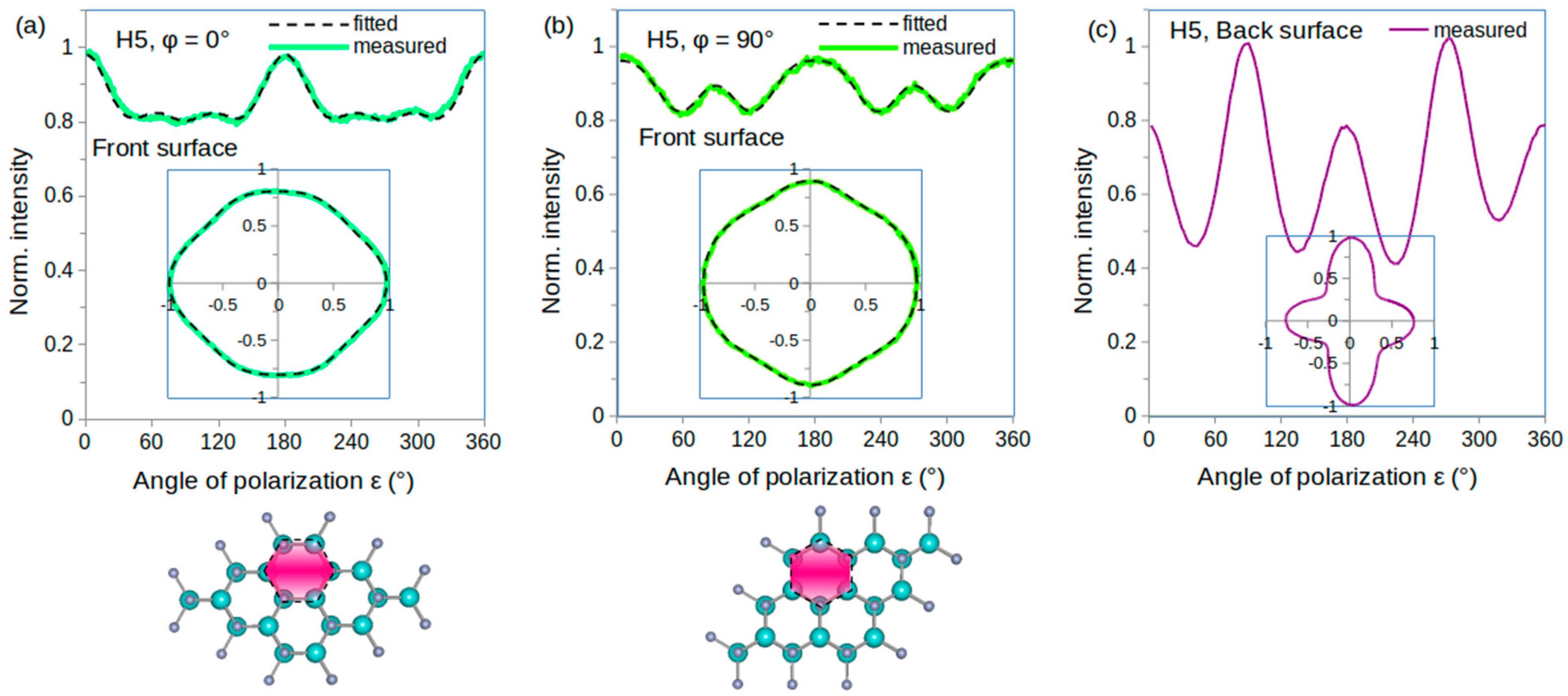

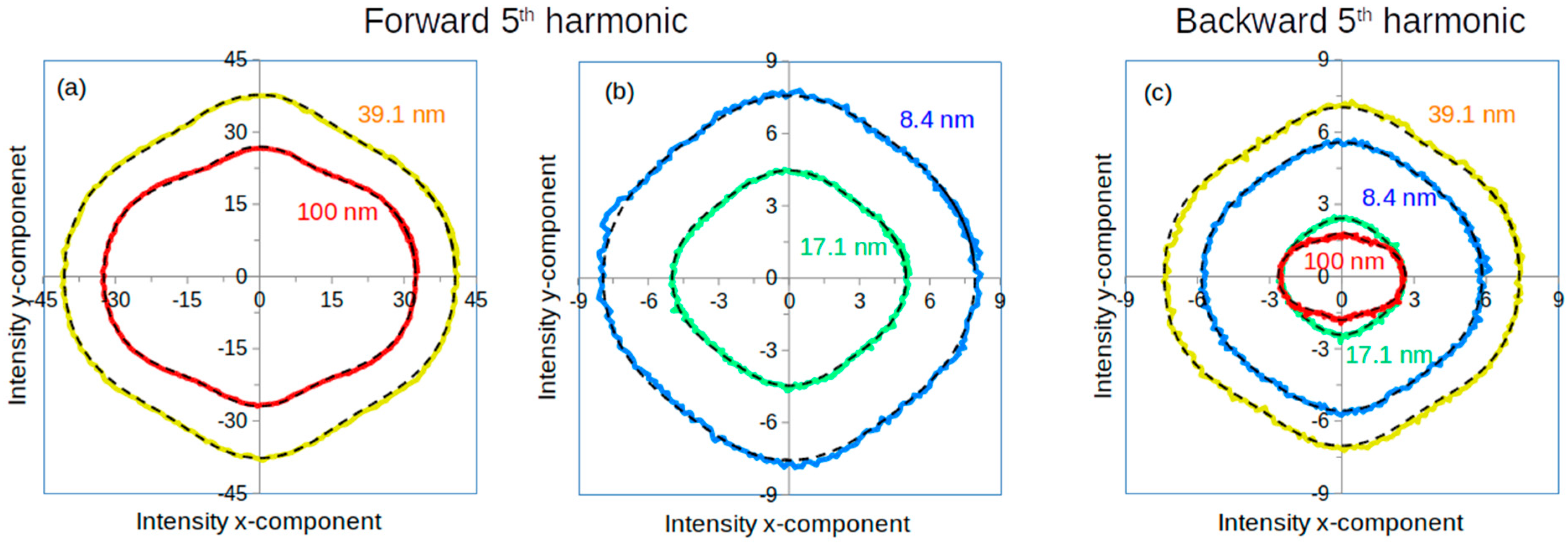

3.3. Harmonic Power Dependence on the Laser Polarization

4. Discussion

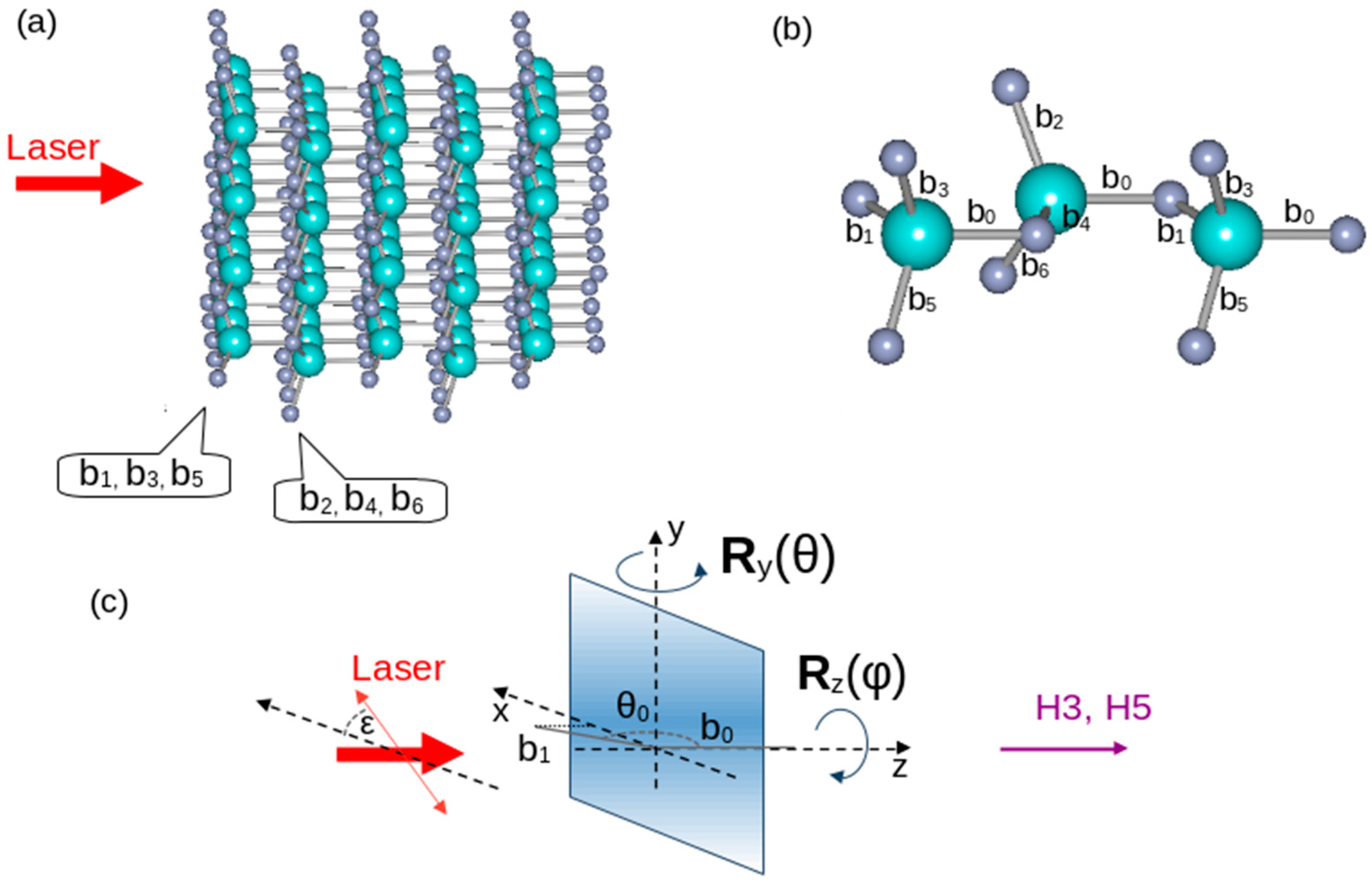

4.1. Adaptation of the Bond Model to Describe the Polarization Dependence

4.2. Obtaining the Shape of the Polarization Curves

4.3. Harmonic Power Dependence on the Film Thicknesses

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Journigan, T.; Liu, Y.; Cabello, C.; Berriel, S.N.; Rudawski, N.G.; Banerjee, P.; Chini, M. High harmonic generation in epitaxially grown zinc oxide films. J. Opt. Soc. Am. B 2024, 41, B1–B6. [Google Scholar] [CrossRef]

- Rodríguez-Suné, L.; Scalora, M.; Johnson, A.S.; Cojocaru, C.; Akozbek, N.; Coppens, Z.J.; Perez-Salinas, D.; Wall, S.; Trull, J. Study of second and third harmonic generation from an indium tin oxide nanolayer: Influence of nonlocal effects and hot electrons. APL Photonics 2020, 5, 010801. [Google Scholar] [CrossRef]

- Korolev, V.; Sinelnik, A.D.; Rybin, M.V.; Lazarenko, P.; Kushchenko, O.M.; Glukhenkaya, V.; Kozyukhin, S.; Zuerch, M.; Spielmann, C.; Pertsch, T.; et al. Tunable high-order harmonic generation in GeSbTe nano-films. Nanophotonics 2024, 13, 3411–3419. [Google Scholar] [CrossRef]

- Yi, G.; Jeon, S.; Kwon, Y.W.; Park, J.; Nguyen, D.A.; Sandeep, C.S.S.; Hwang, W.S.; Hong, S.W.; Kim, S.; Kim, Y.-J. Enhanced third harmonic generation in ultrathin free-standing β-Ga2O3 nanomembranes: Study on surface and bulk contribution. Nanoscale 2022, 14, 175–186. [Google Scholar] [CrossRef] [PubMed]

- Biswas, R.; Dandu, M.; Menon, S.; Jha, K.K.; Jyothsna, K.M.; Majumdar, K.; Raghunathan, V. Third-harmonic generation in multilayer Tin Diselenide under the influence of Fabry-Perot interference effects. Opt. Express 2019, 27, 28855–28865. [Google Scholar] [CrossRef]

- Yang, H.; Long, Z.; Tian, K.; Lin, S.; He, L.; Zhao, D.; Li, Y.; Wu, H.; Chen, Z.-Y.; Wu, L.; et al. High-harmonic generation in polycrystalline CdTe nano-films via macroscopic investigations. Opt. Express 2022, 30, 47733–47743. [Google Scholar] [CrossRef]

- Zuber, D.; Kleinert, S.; Tajalli, A.; Steinecke, M.; Jupé, M.; Babushkin, I.; Ristau, D.; Morgner, U. Third and fifth order nonlinear susceptibilities in thin HfO2 layers. Opt. Express 2023, 31, 19309–19318. [Google Scholar] [CrossRef]

- Zheng, W.; Jiang, Y.; Wang, S.; Liu, C.; Bai, Y.; Liu, P.; Li, R. Frequency shift of even-order high harmonic generation in monolayer MoS2. Opt. Express 2023, 31, 27029–27040. [Google Scholar] [CrossRef]

- Chen, M.; Zhao, Y.; Ma, H.; Guo, M.; Zhang, G.; Chai, Y.; Jiang, H.; Lian, Y.; Wang, M.; Shao, J. Wavelength dependence of nonlinear optical susceptibility of ZnSe nanocrystalline film. Opt. Mater. 2022, 134, 113114. [Google Scholar] [CrossRef]

- Seres, J.; Seres, E.; Serrat, C.; Schumm, T. High harmonic generation in AlN due to out-of-surface electron orbitals. OSA Contin. 2021, 4, 47–54. [Google Scholar] [CrossRef]

- Seres, J.; Seres, E.; Céspedes, E.; Martinez-de-Olcoz, L.; Zabala, M.; Schumm, T. Nonperturbative Generation of Harmonics by Nanometer-Scale Localized Electronic States on the Surface of Bulk Materials and Nano-Films. Optics 2023, 4, 246–257. [Google Scholar] [CrossRef]

- Sekiguchi, F.; Yumoto, G.; Hirori, H.; Kanemitsu, Y. Polarization anomaly in high harmonics in the crossover region between perturbative and extreme nonlinearity in GaAs. Phys. Rev. B 2022, 106, L241201. [Google Scholar] [CrossRef]

- Tsang, T.Y.F. Optical third-harmonic generation at interfaces. Phys. Rev. A 1995, 52, 4116–4125. [Google Scholar] [CrossRef] [PubMed]

- Tsang, T. Third- and fifth-harmonic generation at the interfaces of glass and liquids. Phys. Rev. A 1996, 54, 5454–5457. [Google Scholar] [CrossRef] [PubMed]

- Semmlinger, M.; Zhang, M.; Tseng, M.L.; Huang, T.T.; Yang, J.; Tsai, D.P.; Nordlander, P.; Halas, N.J. Generating Third Harmonic Vacuum Ultraviolet Light with a TiO2 Metasurface. Nano Lett. 2019, 19, 8972–8978. [Google Scholar] [CrossRef]

- Sato, R.; Ishii, S.; Nagao, T.; Naito, M.; Takeda, Y. Broadband Plasmon Resonance Enhanced Third-Order Optical Nonlinearity in Refractory Titanium Nitride Nanostructures. ACS Photonics 2018, 59, 3452–3458. [Google Scholar] [CrossRef]

- Ganeev, R.A.; Kim, V.V.; Shuklov, I.A.; Popov, V.S.; Lavrentyev, N.A.; Ponomarenko, V.P.; Mardini, A.A.; Dyomkin, D.V.; Milenkovič, T.; Bundulis, A.; et al. Third harmonic generation in the thin films containing quantum dots and exfoliated nanoparticles. Appl. Phys. B 2022, 128, 202. [Google Scholar] [CrossRef]

- Guo, P.; Chang, R.P.; Schaller, R.D. Transient Negative Optical Nonlinearity of Indium Oxide Nanorod Arrays in the Full-Visible Range. ACS Photonics 2017, 4, 1494–1500. [Google Scholar] [CrossRef]

- Yan, Y.; Spear, N.J.; Meng, Q.; Singh, M.R.; Macdonald, J.E.; Haglund, R.F. Harmonic Generation up to Fifth Order from Al/Au/CuS Nanoparticle Films. Nano Lett. 2024, 24, 5085–5092. [Google Scholar] [CrossRef]

- Lu, P.; Yan, T.; Huang, J.; Xing, T.; Liu, H.; Han, Z.; Xu, X.; Tao, C. ITO-Induced Nonlinear Optical Response Enhancement of Titanium Nitride Thin Films. Nanomaterials 2024, 14, 1040. [Google Scholar] [CrossRef]

- Kim, S.; Jeong, T.I.; Park, J.; Ciappina, M.F.; Kim, S. Recent advances in ultrafast plasmonics: From strong field physics to ultraprecision spectroscopy. Nanophotonics 2022, 11, 2393–2431. [Google Scholar] [CrossRef]

- Nakagawa, K.; Hirori, H.; Sato, S.A.; Tahara, H.; Sekiguchi, F.; Yumoto, G.; Saruyama, M.; Sato, R.; Teranishi, T.; Kanemitsu, Y. Size-controlled quantum dots reveal the impact of intraband transitions on high-order harmonic generation in solids. Nat. Phys. 2022, 18, 874–878. [Google Scholar] [CrossRef]

- Peterka, P.; Šobáň, Z.; Trojánek, F.; Malý, P.; Kozák, M. High harmonic generation enhanced by magnetic dipole resonance in an amorphous silicon metasurface. Opt. Express 2023, 31, 6401–6410. [Google Scholar] [CrossRef] [PubMed]

- Han, S. High-Harmonic Generation Using a Single Dielectric Nanostructure. Photonics 2022, 9, 427. [Google Scholar] [CrossRef]

- Seres, J.; Seres, E.; Céspedes, E.; Martinez-de-Olcoz, L.; Zabala, M.; Schumm, T. Probing nonperturbative third and fifth harmonic generation on silicon without and with thermal oxide layer. J. Opt. 2023, 25, 105501. [Google Scholar] [CrossRef]

- Seres, E.; Seres, J.; Martinez-de-Olcoz, L.; Schumm, T. Compact tunable 80 MHz repetition rate vacuum ultraviolet light source up to 10 eV: Intracavity high harmonic generation by nonlinear reflection on a AlN nanofilm in a mode locked Ti: Sapphire oscillator. Opt. Express 2024, 32, 17593–17605. [Google Scholar] [CrossRef]

- Xia, P.; Kim, C.; Lu, F.; Kanai, T.; Akiyama, H.; Itatani, J.; Ishii, N. Nonlinear propagation effects in high harmonic generation in reflection and transmission from gallium arsenide. Opt. Express 2018, 26, 29393–29400. [Google Scholar] [CrossRef]

- Kaassamani, S.; Auguste, T.; Tancogne-Dejean, N.; Liu, X.; Boutu, W.; Merdji, H.; Gauthier, D. Polarization spectroscopy of high-order harmonic generation in gallium arsenide. Opt. Express 2022, 30, 40531–40539. [Google Scholar] [CrossRef]

- Tilmann, B.; Huq, T.; Possmayer, T.; Dranczewski, J.; Nickel, B.; Zhang, H.; Krivitsky, L.; Kuznetsov, A.I.; de S. Menezes, L.; Vezzoli, S.; et al. Comparison of Harmonic Generation from Crystalline and Amorphous Gallium Phosphide Nanofilms. Adv. Opt. Mater. 2023, 11, 2300269. [Google Scholar] [CrossRef]

- You, Y.; Yin, Y.; Wu, Y.; Chew, A.; Ren, X.; Zhuang, F.; Gholam-Mirzaei, S.; Chini, M.; Chang, Z.; Ghimire, S. High-harmonic generation in amorphous solids. Nat. Commun. 2017, 8, 724. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Tao, J.; Tang, R.; Zheng, X. Structural, Surface, and Optical Properties of AlN Thin Films Grown on Different Substrates by PEALD. Crystals 2023, 13, 910. [Google Scholar] [CrossRef]

- Abdallah, B.; Duquenne, C.; Besland, M.P.; Gautron, E.; Jouan, P.Y.; Tessier, P.Y.; Brault, J.; Cordier, Y.; Djouadi, M.A. Thickness and substrate effects on AlN thin film growth at room temperature. Eur. Phys. J. Appl. Phys. 2008, 43, 309–313. [Google Scholar] [CrossRef]

- Galca, A.C.; Stan, G.E.; Trinca, L.M.; Negrila, C.C.; Nistor, L.C. Structural and optical properties of c-axis oriented aluminum nitride thin films prepared at low temperature by reactive radio-frequency magnetron sputtering. Thin. Solid Film. 2012, 524, 328–333. [Google Scholar] [CrossRef]

- Iqbal, A.; Mohd-Yasin, F. Reactive Sputtering of Aluminum Nitride (002) Thin Films for Piezoelectric Applications: A Review. Sensors 2018, 18, 1797. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Xu, C.H.; Hu, W.J.; Wang, W.J.; Guo, L.W.; Chen, X.L. Observation of Two-Photon Absorption and Nonlinear Refraction in AlN. Chin. Phys. Lett. 2016, 33, 104201. [Google Scholar] [CrossRef]

- Wang, Z.W.; Jiang, S.C.; Yuan, G.L.; Wu, T.; Li, C.; Qian, C.; Jin, C.; Yu, C.; Hua, W.J.; Lu, R.F. Strain effect on the orientation-dependent harmonic spectrum of monolayer aluminum nitride. Sci. China-Phys. Mech. Astron. 2020, 63, 257311. [Google Scholar] [CrossRef]

- Sun, C.J.; Kung, P.; Saxler, A.; Ohsato, H.; Haritos, K.; Razeghi, M. A crystallographic model of (00·1) aluminum nitride epitaxial thin film growth on (00·1) sapphire substrate. J. Appl. Phys. 1994, 75, 3964. [Google Scholar] [CrossRef]

- Patterson, A.L. The scherrer formula for X-ray particle size determination. Phys. Rev. 1939, 56, 978–982. [Google Scholar] [CrossRef]

- Ohtsuka, M.; Takeuchi, H.; Fukuyama, H. Effect of sputtering pressure on crystalline quality and residual stress of AlN films deposited at 823 K on nitrided sapphire substrates by pulsed dc reactive sputtering. Jpn. J. Appl. Phys. 2016, 55, 05FD08. [Google Scholar] [CrossRef]

- Aubert, T.; Assouar, M.B.; Legrani, O.; Elmazria, O.; Tiusan, C.; Robert, S. Highly textured growth of AlN films on sapphire by magnetron sputtering for high temperature surface acoustic wave applications. J. Vac. Sci. Technol. A 2011, 29, 021010. [Google Scholar] [CrossRef]

- Hardhienata, H.; Faci, S.; Alejo-Molina, A.; Priatama, M.R.; Alatas, H.; Birowosuto, M.D. Quo Vadis Nonlinear Optics? An Alternative and Simple Approach to Third Rank Tensors in Semiconductors. Symmetry 2022, 14, 127. [Google Scholar] [CrossRef]

- Powell, G.D.; Wang, J.-F.; Aspnes, D.E. Simplified bond-hyperpolarizability model of second harmonic generation. Phys. Rev. B 2002, 65, 205320. [Google Scholar] [CrossRef]

- Hardhienata, H.; Priyadi, I.; Alatas, H.; Birowosuto, M.D.; Coquet, P. Bond model of second-harmonic generation in wurtzite ZnO(0002) structures with twin boundaries. J. Opt. Soc. Am. B 2019, 36, 1127–1137. [Google Scholar] [CrossRef]

- Kecik, D.; Bacaksiz, C.; Senger, R.T.; Durgun, E. Layer- and strain-dependent optoelectronic properties of hexagonal AlN. Phys. Rev. B 2015, 92, 165408. [Google Scholar] [CrossRef]

- Bowman, S.R.; Brown, C.G.; Taczak, B. Optical dispersion and phase matching in gallium nitride and aluminum nitride. Opt. Mater. Express 2018, 8, 1091–1099. [Google Scholar] [CrossRef]

- Wethkamp, T.; Wilmers, K.; Cobet, C.; Esser, N.; Richter, W.; Ambacher, O.; Stutzmann, M.; Cardona, M. Dielectric function of hexagonal AlN films determined by spectroscopic ellipsometry in the vacuum-uv spectral range. Phys. Rev. B 1999, 59, 1845–1849. [Google Scholar] [CrossRef]

- Gao, X.D.; Jiang, E.Y.; Liu, H.H.; Li, G.K.; Mi, W.B.; Li, Z.Q.; Wu, P.; Bai, H.L. Fabrication and characterization of orientated grown AlN films sputtered at room temperature. Phys. Stat. Sol. (a) 2007, 204, 1130–1137. [Google Scholar] [CrossRef]

| α1 = … = α6 = 1 | Forward H5 | Backward H5 | Grain Size (nm) | |||||

|---|---|---|---|---|---|---|---|---|

| d (nm) | α0 | r0 | r | n | r | n | As Grown | RTA |

| 8 | 3.05 | 6 | 4.2 | 2.0 | 4.2 | 2.0 | 9 | 10 |

| 17 | 3.26 | 6 | 4.2 | 2.0 | 4.2 | 2.1 | 16 | 16 |

| 39 | 3.36 | 6 | 4.4 | 2.1 | 4.4 | 2.1 | 41 | 38 |

| 100 | 3.02 | 4 | 4.4 | 2.1 | 4.2 | 2.0 | 61 | 61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seres, J.; Seres, E.; Céspedes, E.; Martinez-de-Olcoz, L.; Zabala, M.; Schumm, T. Effects of Thickness and Grain Size on Harmonic Generation in Thin AlN Films. Photonics 2024, 11, 1078. https://doi.org/10.3390/photonics11111078

Seres J, Seres E, Céspedes E, Martinez-de-Olcoz L, Zabala M, Schumm T. Effects of Thickness and Grain Size on Harmonic Generation in Thin AlN Films. Photonics. 2024; 11(11):1078. https://doi.org/10.3390/photonics11111078

Chicago/Turabian StyleSeres, J., E. Seres, E. Céspedes, L. Martinez-de-Olcoz, M. Zabala, and T. Schumm. 2024. "Effects of Thickness and Grain Size on Harmonic Generation in Thin AlN Films" Photonics 11, no. 11: 1078. https://doi.org/10.3390/photonics11111078

APA StyleSeres, J., Seres, E., Céspedes, E., Martinez-de-Olcoz, L., Zabala, M., & Schumm, T. (2024). Effects of Thickness and Grain Size on Harmonic Generation in Thin AlN Films. Photonics, 11(11), 1078. https://doi.org/10.3390/photonics11111078