Mechanically Induced Long-Period Fiber Gratings and Applications

Abstract

1. Introduction

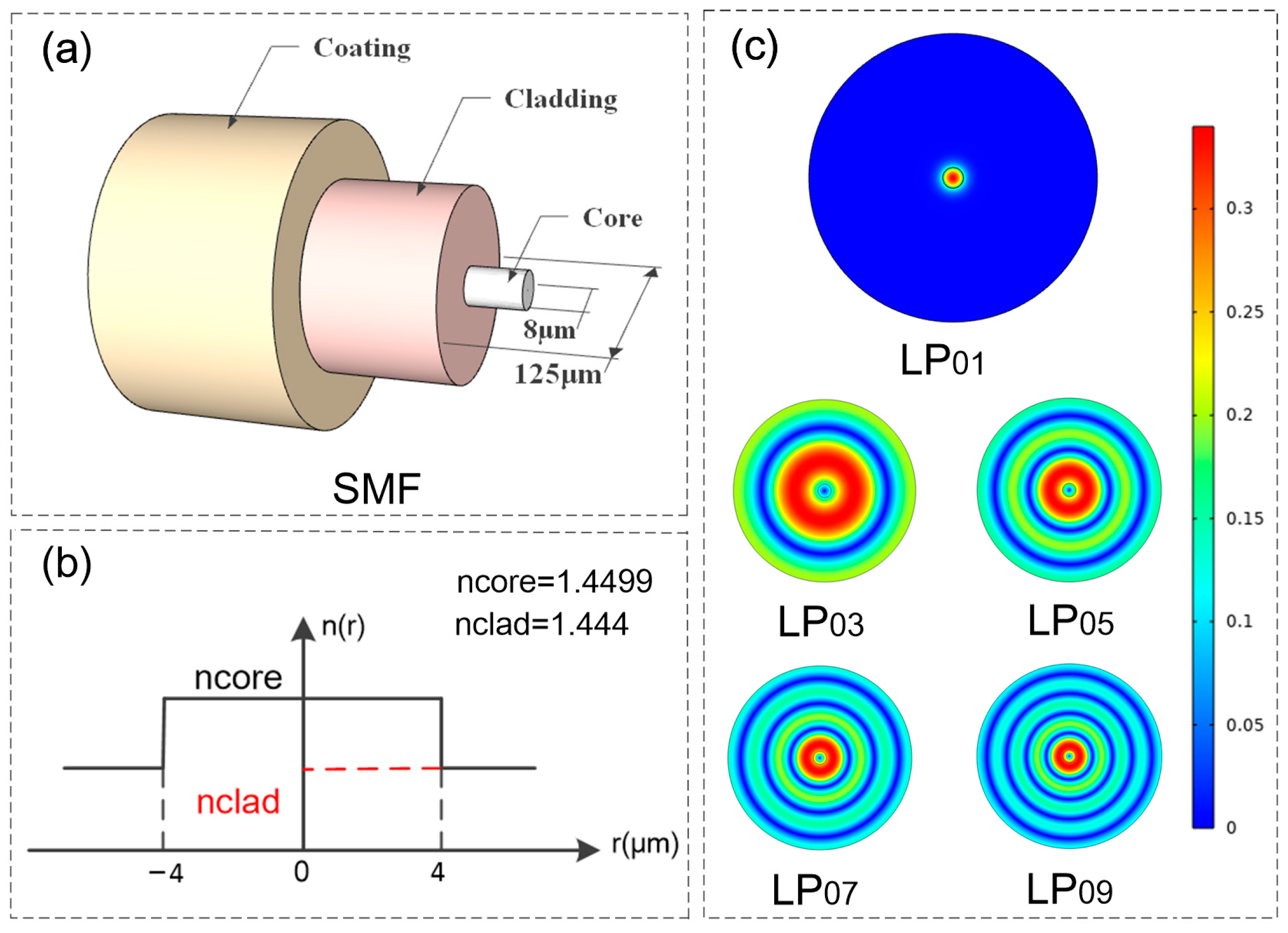

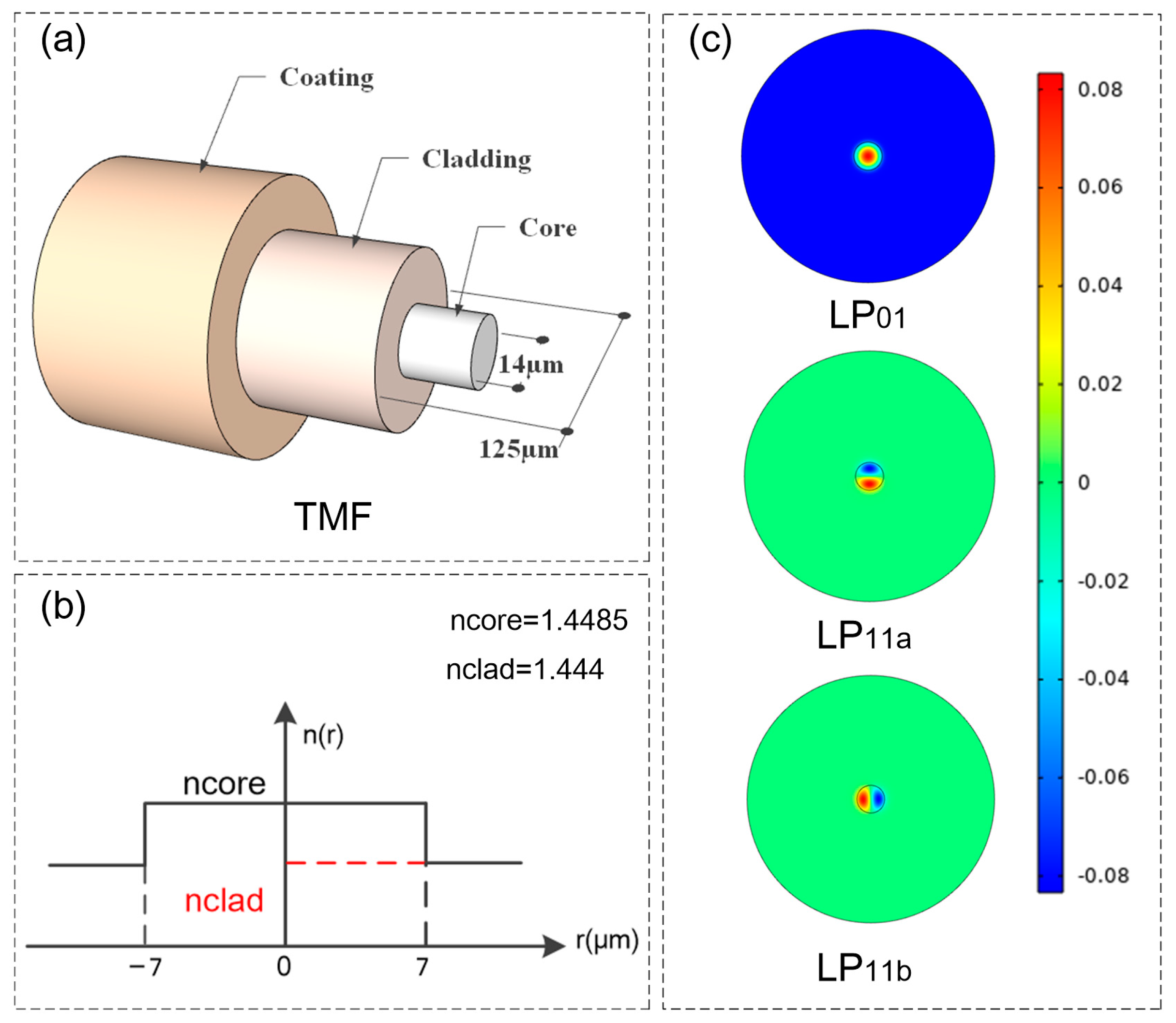

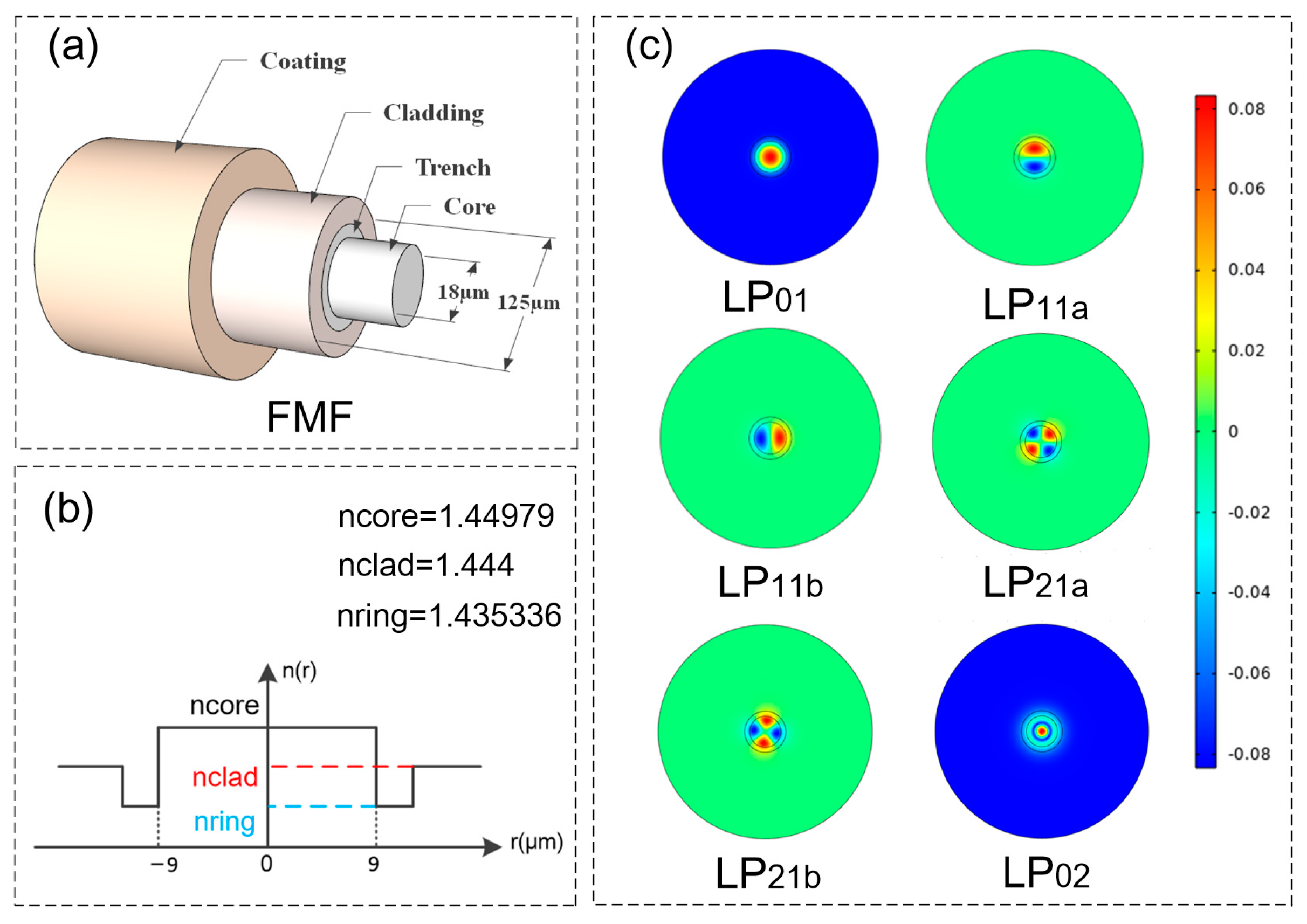

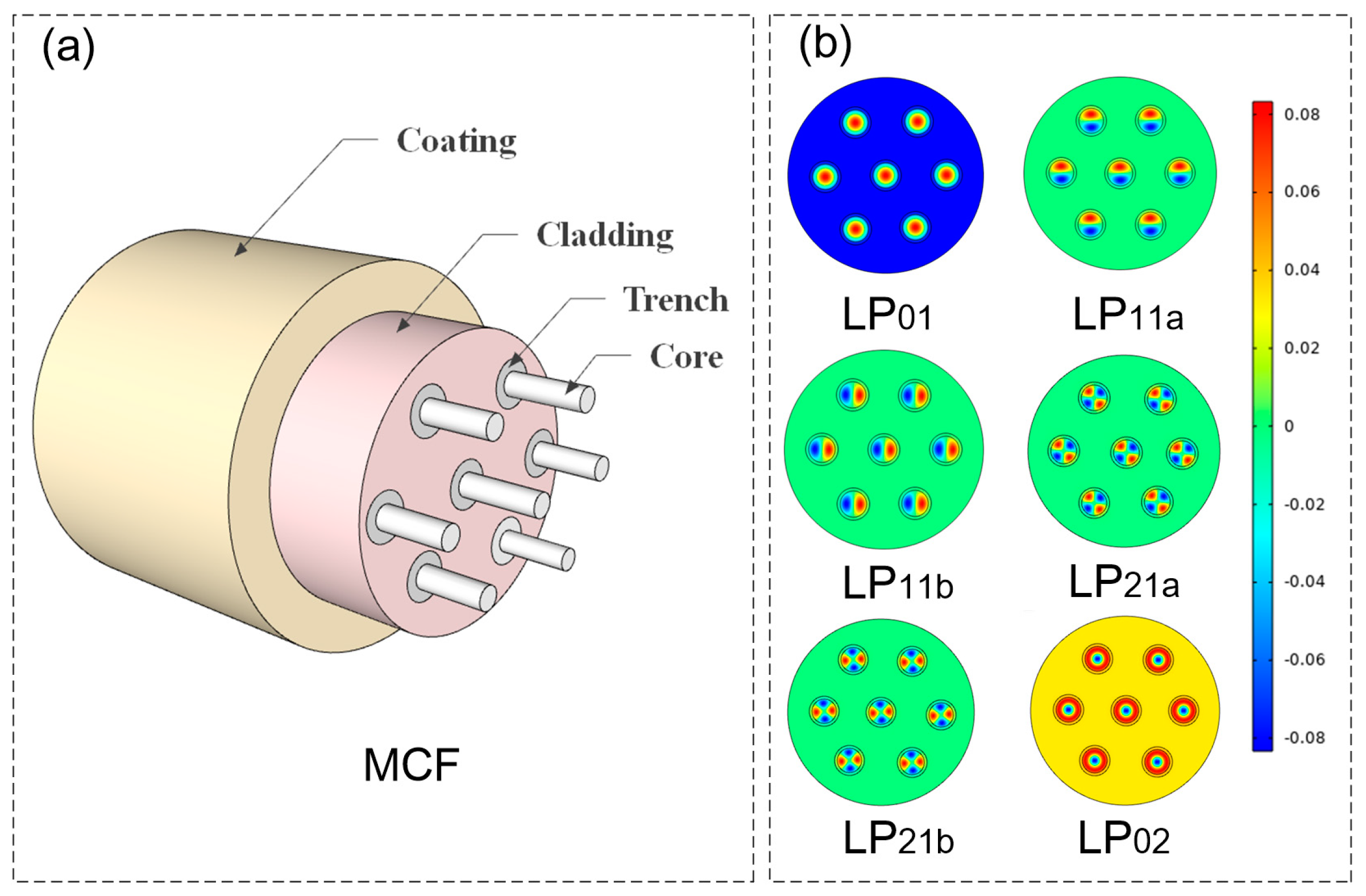

2. Fibers and Operation Principle of LPFGs

3. Applications of Mechanically Induced LPFGs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hill, K.O.; Fujii, Y.; Johnson, D.C.; Kawasaki, B.S. Photosensitivity in optical fiber waveguides: Applications to reflection filter fabrication. Appl. Phys. Lett. 1978, 32, 647–649. [Google Scholar] [CrossRef]

- Giles, C.R. Lightwave applications of fiber Bragg gratings. J. Lightw. Technol. 1997, 15, 1391–1404. [Google Scholar] [CrossRef]

- Canning, J.; Sceats, M.G. π-phase-shifted periodic distributed structures in optical fibers by UV post-processing. Electron. Lett. 1994, 30, 1344–1345. [Google Scholar] [CrossRef]

- Cusano, A.; Ladicicco, A.; Paladino, D.; Campopiano, S.; Cutolo, A. Photonic band-gap engineering in UV fiber gratings by the arc discharge technique. Opt. Exp. 2008, 16, 15332–15342. [Google Scholar] [CrossRef] [PubMed]

- Huang, A.; Shu, X. Ultra-compact strain- and temperature-insensitive torsion sensor based on a line-by-line inscribed phase-shifted FBG. Opt. Exp. 2016, 24, 17670–17679. [Google Scholar] [CrossRef] [PubMed]

- Liao, A.; Xu, L.; Wang, C.; Wang, D.N.; Wang, Y.; Wang, Q.; Yang, K.; Li, Z.; Zhong, X.; Zhou, J.; et al. Tunable phase-shifted fiber Bragg grating based on femtosecond laser fabricated in-grating bubble. Opt. Lett. 2013, 38, 4473–4476. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.; Sun, X.; Chang, Z.; Hu, Y.; Duan, J. Tunable phase-shifted fiber Bragg grating based on a microchannel fabricated by a femtosecond laser. Chin. Opt. Lett. 2021, 19, 03060. [Google Scholar] [CrossRef]

- Xian, L.; Li, H. Calibration of a phase-shift formed in a linearly chirped fiber Bragg grating and its thermal effect. J. Lightw. Technol. 2013, 31, 1185–1190. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, Z.; Zhang, M.; Hao, Y.; Wang, P.; Li, H. Broadband flat-top second-order OAM mode converter based on a phase-modulated helical long-period fiber grating. Opt. Exp. 2021, 29, 29518–29526. [Google Scholar] [CrossRef]

- Zhao, H.; Zhu, C.; Li, H. Design of an edge filter based on a phase-only modulated long-period fiber grating. IEEE Photonics J. 2018, 10, 1–9. [Google Scholar] [CrossRef]

- Zhu, C.; Zhao, Y.; Chen, M.; Tong, R.; Hu, S.; Li, H. Simultaneous measurement of directional torsion and temperature by using a DC-sampled helical long-period fiber grating. Opt. Laser Technol. 2021, 142, 107171. [Google Scholar] [CrossRef]

- Zhu, C.; Ishikami, S.; Wang, P.; Zhao, H.; Li, H. Optimal design and fabrication of multichannel helical long-period fiber gratings based on phase-only sampling method. Opt. Exp. 2019, 27, 2281–2291. [Google Scholar] [CrossRef]

- Sun, C.; Wang, R.; Jin, X.; Wang, Z.; Liu, W.; Zhang, S.; Ma, Y.; Lin, J.; Li, Y.; Geng, T.; et al. A new phase-shifted long-period fiber grating for simultaneous measurement of torsion and temperature. Chin. Opt. Lett. 2020, 18, 021203. [Google Scholar] [CrossRef]

- Jiao, K.; Shen, H.; Yang, F.; Wu, X.; Bian, Y.; Zhu, R. Optimizing output spectral linewidth of fiber laser utilizing phase-shifted long-period fiber grating. Opt. Laser Technol. 2021, 142, 107221. [Google Scholar] [CrossRef]

- Harumoto, M.; Shigehara, M.; Suganuma, H. Gain-flattening filter using long-period fiber Gratings. J. Lightw. Technol. 2002, 20, 1027. [Google Scholar] [CrossRef]

- Xian, L.; Wang, P.; Li, H. Power-interrogated and simultaneous measurement of temperature and torsion using paired helical long period fiber gratings with opposite helicities. Opt. Exp. 2014, 22, 20260–20267. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Li, H. Advances on mode-coupling theories; fabrication techniques, and applications of the helical long-period fiber gratings: A review. Photonics 2021, 8, 106. [Google Scholar] [CrossRef]

- Wang, P.; Xian, L.; Li, H. Fabrication of phase-shifted long-period fiber grating and its application to strain measurement. IEEE Photonics Technol. Lett. 2015, 27, 557–560. [Google Scholar] [CrossRef]

- Gu, Y.; Chiang, K.S.; Rao, Y.J. Writing of apodized phase-shifted long-period fiber gratings with a computer-controlled CO2 laser. IEEE Photonics Technol. Lett. 2009, 21, 657–659. [Google Scholar]

- James, S.W.; Topliss, S.M.; Tatam, R.P. Properties of length-apodized phase-shifted LPGs operating at the phase matching turning point. J. Lightw. Technol. 2012, 30, 2203–2209. [Google Scholar] [CrossRef]

- Vengsarkar, A.M.; Lemaire, P.J.; Judkins, J.B.; Bhatia, V.; Erdogan, T.; Sipe, J.E. Long-period fiber gratings as band-rejection filters. J. Lightw. Technol. 1996, 14, 58–65. [Google Scholar] [CrossRef]

- Kim, B.H.; Park, Y.; Ahn, T.J.; Kim, D.Y.; Lee, B.H.; Chung, Y.; Paek, U.C.; Han, W.T. Residual stress relaxation in the core of optical fiber by CO2 laser irradiation. Opt. Lett. 2001, 26, 1657–1659. [Google Scholar] [CrossRef] [PubMed]

- Rao, Y.J.; Wang, Y.P.; Ran, Z.L.; Zhu, T. Novel fiber-optic sensors based on long-period fiber gratings written by high-frequency CO2 laser pulses. J. Lightw. Technol. 2003, 21, 1320. [Google Scholar]

- Huang, Q.; Yu, Y.; Ruan, S.; Li, X.; Chen, X.; Zhang, Y.; Zhou, W.; Du, C. In-Fiber Grating Fabricated by Femtosecond Laser Direct Writing for Strain Sensing. IEEE Photonics Technol. Lett. 2015, 27, 1216–1219. [Google Scholar] [CrossRef]

- Esposito, F.; Ranjan, R.; Campopiano, S.; Iadicicco, A. Arc-induced long period gratings from standard to polarization maintaining and photonic crystal fibers. Sensors 2018, 18, 918. [Google Scholar] [CrossRef] [PubMed]

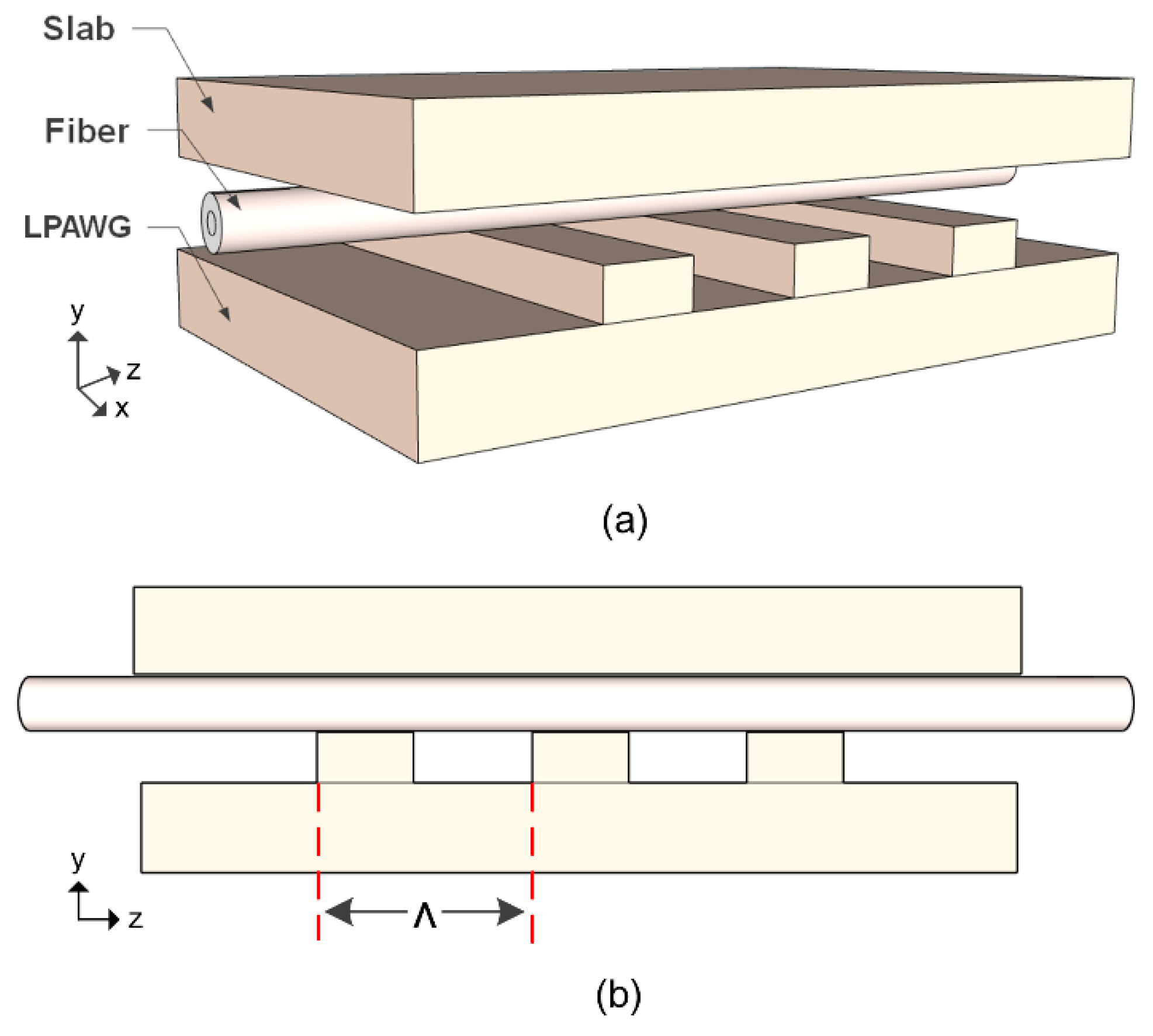

- Lim, J.H.; Lee, K.S.; Kim, J.C.; Lee, B.H. Tunable fiber gratings fabricated in photonic crystal fiber by use of mechanical pressure. Opt. Lett. 2004, 29, 331. [Google Scholar] [CrossRef]

- Wang, W.; Wu, J.; Chen, K.; Jin, W.; Chiang, K.S. Ultra-broadband mode converters based on length-apodized long-period waveguide gratings. Opt. Exp. 2017, 25, 14341–14350. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, W.; Jin, W.; Chiang, K.S. Ultra-Broadband Mode Filter Based on Phase-Shifted Long-Period Grating. IEEE Photonics Technol. Lett. 2019, 31, 1052–1055. [Google Scholar] [CrossRef]

- Davis, D.D.; Gaylord, T.K.; Glytsis, E.N.; Kosinski, S.G.; Mettler, S.C.; Vengsarkar, A.M. Long-period fibre grating fabrication with focused CO2 laser pulses. Electron. Lett. 1998, 34, 302. [Google Scholar] [CrossRef]

- Wolf, A.A.; Dostovalov, A.V.; Lobach, I.A.; Babin, S.A. Femtosecond Laser Inscription of Long-Period Fiber Gratings in a Polarization-Maintaining Fiber. J. Lightw. Technol. 2015, 33, 178–5183. [Google Scholar] [CrossRef]

- Urrutia, A.; Goicoechea, J.R.; Ricchiuti, A.L.; Barrera, D.; Sales, S.; Arregui, F.J. Simultaneous measurement of humidity and temperature based on a partially coated optical fiber long period grating. Sens. Actuators B-Chem. 2016, 227, 135–141. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, X.; Dong, J.; Zheng, Z.; Xu, O.; Fu, S.; Peng, D.; Li, J.; Qin, Y. Ultra-broadband LP11 mode converter with high purity based on long-period fiber grating and an integrated Y-junction. Opt. Exp. 2022, 30, 12751–12759. [Google Scholar] [CrossRef]

- Zhong, L.; Huang, Q.; Zhang, J.; Zheng, Z.; Li, J.; Xu, O. Reconfigurable ultra-broadband mode converter based on a two-mode fiber with pressure-loaded phase-shifted long-period alloyed waveguide grating. Opt. Exp. 2023, 31, 8286–8295. [Google Scholar] [CrossRef]

- Blake, J.N.; Kim, B.Y.; Shaw, H.J. Fiber-optic modal coupler using periodic microbending. Opt. Lett. 1986, 11, 177–179. [Google Scholar] [CrossRef]

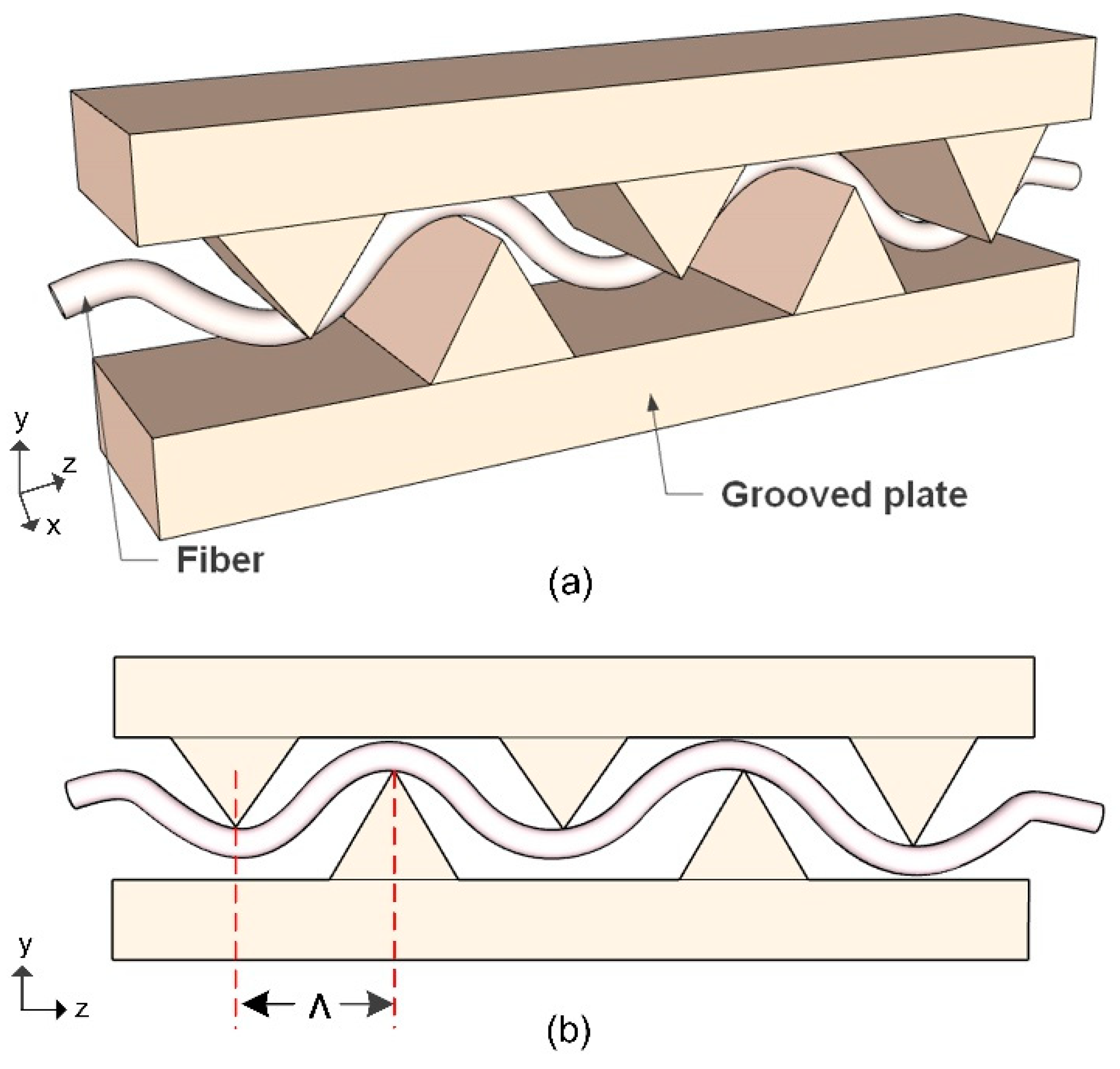

- Zahra, S.; Palma, P.D.; Vita, E.D.; Esposito, F.; Iadicicco, A.; Campopiano, S. Investigation of mechanically induced long period grating by 3-D printed periodic grooved plates. Opt. Laser Technol. 2023, 167, 109752. [Google Scholar] [CrossRef]

- Rego, G. Long-period fiber gratings mechanically induced by winding a string around a fiber/grooved tube set. Microw. Opt. Technol. Lett. 2008, 50, 2064–2068. [Google Scholar] [CrossRef]

- Torres-Gómez, I.; Ceballos-Herrera, D.E.; Salas-Alcantara, K.M. Mechanically-Induced Long-Period Fiber Gratings Using Laminated Plates. Sensors 2020, 20, 2582. [Google Scholar] [CrossRef]

- Salas-Alcántara, M.; Aparicio-Ixta, L.; Torres-Gómez, I.; Rodríguez, M.; Ramos-Ortiz, G.; Espinosa-Luna, R.; Pichardo-Molina, J.L. Modal interferometer based on a single mechanically induced long-period fiber grating and a nanoparticles-coated film section. Opt. Lett. 2017, 42, 1780–1783. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Jung, Y.; Jeong, Y.S.; Oh, K.; Kobelke, J.; Schuster, K.; Kirchhof, J. Highly polarization-dependent periodic coupling in mechanically induced long period grating over air–silica fibers. Opt. Lett. 2006, 31, 296–298. [Google Scholar] [CrossRef] [PubMed]

- Savin, S.; Digonnet, M.J.F.; Kino, G.S.; Shaw, H.J. Tunable mechanically induced long-period fiber gratings. Opt. Lett. 2000, 25, 710–712. [Google Scholar] [CrossRef] [PubMed]

- Ceballos-Herrera, D.E.; Torres-Gómez, I.; Martínez-Ríos, A.; Anzueto-Sánchez, G.; Álvarez-Chávez, J.A.; Selvas-Aguilar, R.; Sánchez-Mondragón, J.J. Ultra-widely tunable long-period holey-fiber grating by the use of mechanical pressure. Appl. Opt. 2007, 46, 307–311. [Google Scholar] [CrossRef]

- Rego, G.M.; Salgado, H.M.; Santos, J.L. Interrogation of a Fiber Bragg Grating Using a Mechanically Induced Long-Period Fiber Grating. IEEE Sens. J. 2006, 6, 1592–1595. [Google Scholar] [CrossRef]

- Matsui, T.; Nakajima, K.; Toge, K.; Kurashima, T.; Tsubokawa, M. Fiber Identification Technique Based on Mechanically-Induced Long-Period Grating for Bending-Loss Insensitive Fibers. J. Lightw. Technol. 2010, 28, 3556–3561. [Google Scholar] [CrossRef]

- Rego, G.; Fernandes, J.R.A.; Santos, J.L.; Salgado, H.M.; Marques, P.V.S. New technique to mechanically induce long-period fibre gratings. Opt. Commun. 2003, 220, 111–118. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, J.; Yang, D.; Tang, D. High-sensitivity pressure sensors based on mechanically induced long-period fiber gratings and fiber loop ring-down. Opt. Commun. 2010, 283, 3945–3948. [Google Scholar] [CrossRef]

- Das, A.K.; Lee, H.; Noda, K.; Mizuno, Y.; Leung, C.K.Y.; Nakamura, K. Potential of Mechanically Induced Cascaded Long-Period Grating Structure for Reflectometric Pressure, Strain, and Temperature Sensing. IEEE Sens. J. 2020, 20, 10539–10546. [Google Scholar] [CrossRef]

- Torres-Gómez, I.; Martínez-Rios, A.; Anzueto-Sánchez, G.; Ceballos-Herrera, D.E.; Salceda-Delgado, G. Transverse Load and Temperature Sensing Using Multiplexed Long-Period Fiber Gratings. Photonics 2021, 8, 1. [Google Scholar] [CrossRef]

- Jin, Y.; Chan, C.; Zhang, Y.; Dong, X. Mechanically induced long-period fiber grating in side-hole single-mode fiber for temperature and refractive sensing. Opt. Commun. 2010, 283, 1303–1306. [Google Scholar] [CrossRef]

- García-de-la-Rosa, A.; Torres-Gómez, I.; Martínez-Ríos, A.; Monzón-Hernández, D. Temperature impact on mechanically induced long-period fiber gratings. Opt. Lasers Eng. 2011, 49, 714–717. [Google Scholar] [CrossRef]

- Pulido-Navarro, G.; Escamilla-Ambrosio, P.J.; Marrujo-García, S.; Álvarez-Chávez, J.A.; Martínez-Piñón, F. Temperature sensing through long period fiber gratings mechanically induced on tapered optical fibers. Appl. Opt. 2017, 56, 5526–5531. [Google Scholar] [CrossRef]

- Lee, J.; Kim, Y.; Lee, J.H. A 3-D-printed, temperature sensor based on mechanically-induced long period fibre gratings. J. Mod. Opt. 2020, 67, 469–474. [Google Scholar] [CrossRef]

- Cárdenas-Sevilla, G.A.; Monzón-Hernández, D.; Torres-Gómez, I.; Martínez-Ríos, A. Tapered Mach–Zehnder interferometer based on two mechanically induced long-period fiber gratings as refractive index sensor. Opt. Laser Technol. 2012, 44, 1516–1520. [Google Scholar] [CrossRef]

- Chinggungval, T.; Khun-in, R.; Jiraraksopakun, Y.; Bhatranand, A. Feasibility study of employing mechanically induced long-period fibre grating as optical-based sensors. J. Mod. Opt. 2021, 68, 1173–1180. [Google Scholar] [CrossRef]

- Cho, Y.; Lim, J.H.; Lee, K.S. Optical Fiber Twist Sensor with Two Orthogonally Oriented Mechanically Induced Long-Period Grating Sections. IEEE Photonics Technol. Lett. 2005, 17, 453–455. [Google Scholar]

- Nair, B.U.; Kumar, V.P.S.; Pillai, V.P.M.; Nayar, V.U. Wavelength Shift of Cladding Mode Resonances in a Mechanically Induced LPFG by Twisting the Fiber. Fiber Integr. Opt. 2007, 26, 159–172. [Google Scholar] [CrossRef]

- Ceballos-Herrera, D.E.; Torres-Gómez, I.; Martínez-Ríos, A.; García, L.; Sánchez-Mondragón, J.J. Torsion Sensing Characteristics of Mechanically Induced Long-Period Holey Fiber Gratings. IEEE Sens. J. 2010, 10, 1200–1205. [Google Scholar] [CrossRef]

- Ceballos-Herrera, D.E.; Torres-Gómez, I.; Martínez-Ríos, A.; Sánchez-Mondragón, J.J. Higher-Order Core Mode Resonances in a Mechanically Induced Long-Period Holey Fiber Grating. Opt. Rev. 2010, 16, 622–626. [Google Scholar] [CrossRef]

- Nair, A.S.; Kumar, V.P.S.; Joe, H. Twist Sensitivity of Cladding-Mode Resonances and Its Cross-Sensitivity to Strain and Temperature in a Mechanically Induced Long-Period Fiber Grating. Fiber Integr. Opt. 2014, 33, 347–359. [Google Scholar] [CrossRef]

- Nair, S.; Kumar, V.P.S.; Joe, H. Widely tunable LP11 cladding-mode resonance in a twisted mechanically induced long-period fiber grating. Appl. Opt. 2015, 54, 2007–2010. [Google Scholar] [CrossRef]

- Zhang, M.; Yu, R.; Du, Y.; Zou, J.; Wang, L. Liquid-Level Sensor Based on Reflective Mechanically Induced Long-Period Grating Using Double-Cladding Fiber. IEEE Sens. J. 2018, 18, 9568–9575. [Google Scholar] [CrossRef]

- Sakata, H.; Nishio, K.; Ichikawa, M. Tunable bandpass filter based on force-induced long-period fiber grating in a double cladding fiber. Opt. Lett. 2010, 35, 1061–1063. [Google Scholar] [CrossRef]

- Sakata, H.; Yoshimi, H.; Otake, Y. Wavelength tunability of L-band fiber ring lasers using mechanically induced long-period fiber gratings. Opt. Commun. 2009, 282, 1179–1182. [Google Scholar] [CrossRef]

- Cho, J.Y.; Lee, K.S. PDL-Compensated Mechanically Induced Long Period Grating for EDFA Gain Flattening. Fiber Integr. Opt. 2004, 23, 447–451. [Google Scholar]

- Liang, Y.; Zhang, H.; Yang, M.; Lin, W.; Liu, B.; Liu, H. Generation of orbital angular momentum light based on mechanically induced long-period fiber gratings using 3D printing technique. Opt. Fiber Technol. 2022, 72, 102957. [Google Scholar] [CrossRef]

- Qiu, J.; Pang, F.; Zhang, L.; Wei, H.; Shang, Y.; Huang, S.; Wang, T. Using Mechanically-Induced Long-Period Fiber Gratings for OAM Modes Generation Based on Anti-Resonant Mechanisms in Ring-Core Fibers. IEEE Photonics J. 2022, 14, 1–6. [Google Scholar] [CrossRef]

- Wu, Z.; Li, J.; Ren, F.; Ge, D.; Zhang, Y.; Yu, J.; Li, Z.; Chen, Z.; He, Y. Reconfigurable all-fiber mode exchange enabled by mechanically induced LPFG for short-reach MDM networks. Opt. Commun. 2017, 403, 240–244. [Google Scholar] [CrossRef]

- Huang, X.; Jung, Y.; Liu, Y.; Harrington, K.; Richardson, D.J. Broadband Mode Scramblers for Few-Mode Fibers based on 3D Printed Mechanically Induced Long Period Fiber Gratings. IEEE Photonics Technol. Lett. 2022, 34, 169–172. [Google Scholar] [CrossRef]

| Advantage and Disadvantage | |

|---|---|

| UV laser-induced LPFGs [21] | High efficiency in inscription, good repeatability, high requirement for photosensitive fiber and amplitude mask. |

| CO2 laser-induced LPFGs [22,23] | Good repeatability, high efficiency in inscription, no requirement for photosensitive fiber and amplitude mask, and cost-effectiveness. |

| Femtosecond laser-induced LPFGs [24] | High efficiency in inscription, precision microfabrication, high costs of equipment and its maintenance. |

| Arc-induced LPFGs [25] | Good flexibility and stability, cost-effectiveness, limited repeatability. |

| Mechanically induced LPFGs [26] | Reconfigurability, non-invasive modification, excellent flexibility, and minimal optical loss. |

| Applications | Performance | Reference | |

|---|---|---|---|

| Type (1) | Modal interferometer | Small device size, good compatibility. | [38] |

| Band rejectors | Reconfigurable, erasable, high thermal stability. | [40,41,42,43] | |

| Transverse load/pressure sensor | Good repeatability, higher sensitivity. | [45,47] | |

| Strain and temperature sensor | Potentially enhanced degree of freedom in controlling temperature sensitivity, and a short length of sensing fiber. | [46,48,49,50,51] | |

| Refractive index sensors | Offering flexibility and real-time response. | [52,53] | |

| Tunable bandpass filter | Single-fiber configuration without insertion devices and independence between tunable range and transmission amplitude. | [61] | |

| Ring laser in the L-band | The controllable wavelength range was up to 40 nm. | [62] | |

| OAM mode generator | Obtaining a working bandwidth of 114 nm. | [64] | |

| Type (2) | EDFA’s gain equalization | Improving gain-flattening and enhancing the gain characteristics of the EDFA. | [36,63] |

| Twist sensors | High temperature stability, high sensitivity of twist sensor. | [54,55,56,57,58,59] | |

| Liquid level sensors | High sensitivity. | [60] | |

| Mode converter | Reconfigurability. | [66,67] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, J.; Chen, Y.; Wang, G.; Zhong, Z.; Zhang, J.; Xu, O.; Huang, Q.; Lei, X. Mechanically Induced Long-Period Fiber Gratings and Applications. Photonics 2024, 11, 223. https://doi.org/10.3390/photonics11030223

Ran J, Chen Y, Wang G, Zhong Z, Zhang J, Xu O, Huang Q, Lei X. Mechanically Induced Long-Period Fiber Gratings and Applications. Photonics. 2024; 11(3):223. https://doi.org/10.3390/photonics11030223

Chicago/Turabian StyleRan, Jiaqi, Yarou Chen, Guanhua Wang, Zelan Zhong, Jiali Zhang, Ou Xu, Quandong Huang, and Xueqin Lei. 2024. "Mechanically Induced Long-Period Fiber Gratings and Applications" Photonics 11, no. 3: 223. https://doi.org/10.3390/photonics11030223

APA StyleRan, J., Chen, Y., Wang, G., Zhong, Z., Zhang, J., Xu, O., Huang, Q., & Lei, X. (2024). Mechanically Induced Long-Period Fiber Gratings and Applications. Photonics, 11(3), 223. https://doi.org/10.3390/photonics11030223