Plastic Optical Fiber Spectral Filter Based on In-Line Holes

Abstract

1. Introduction

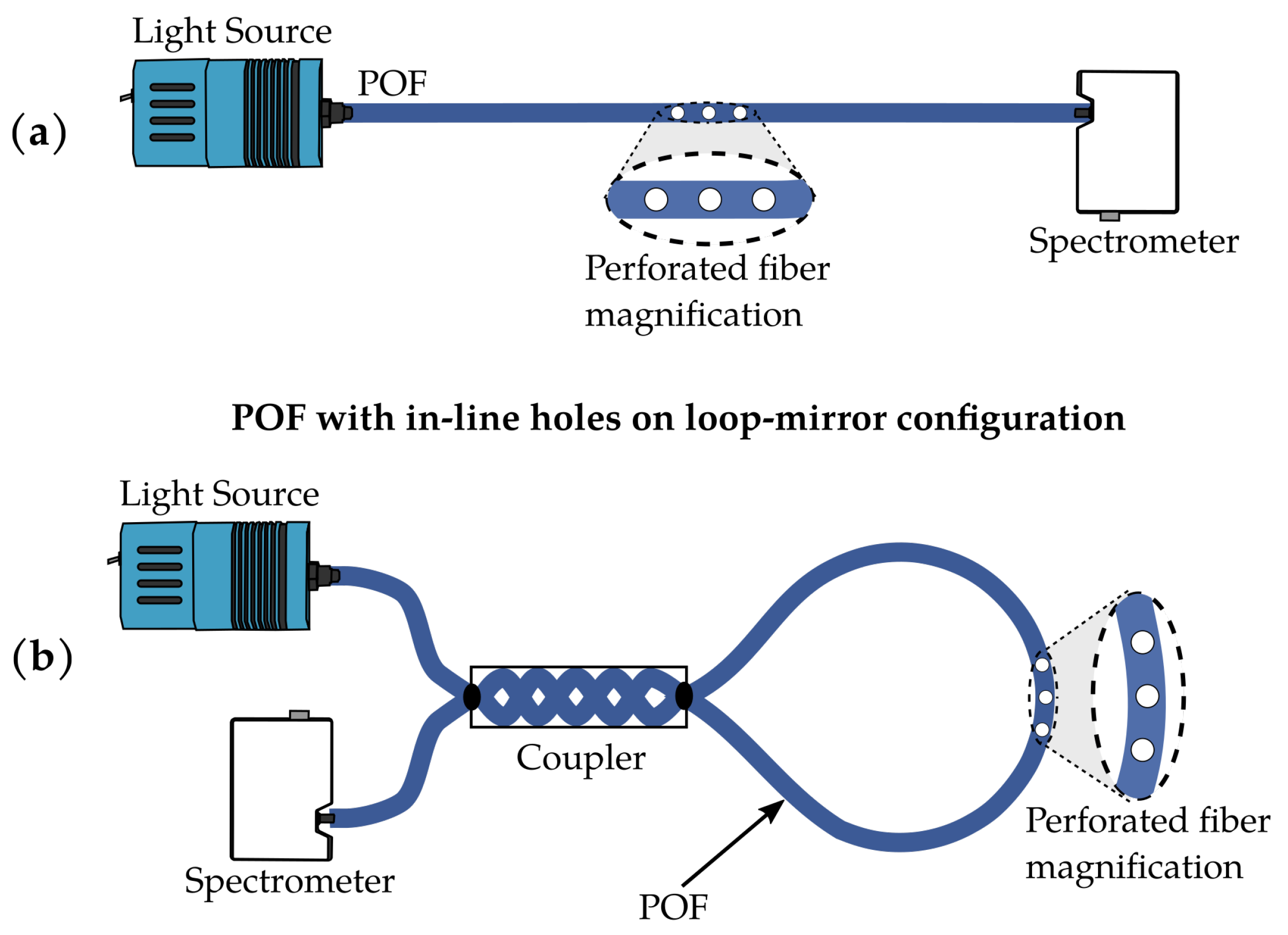

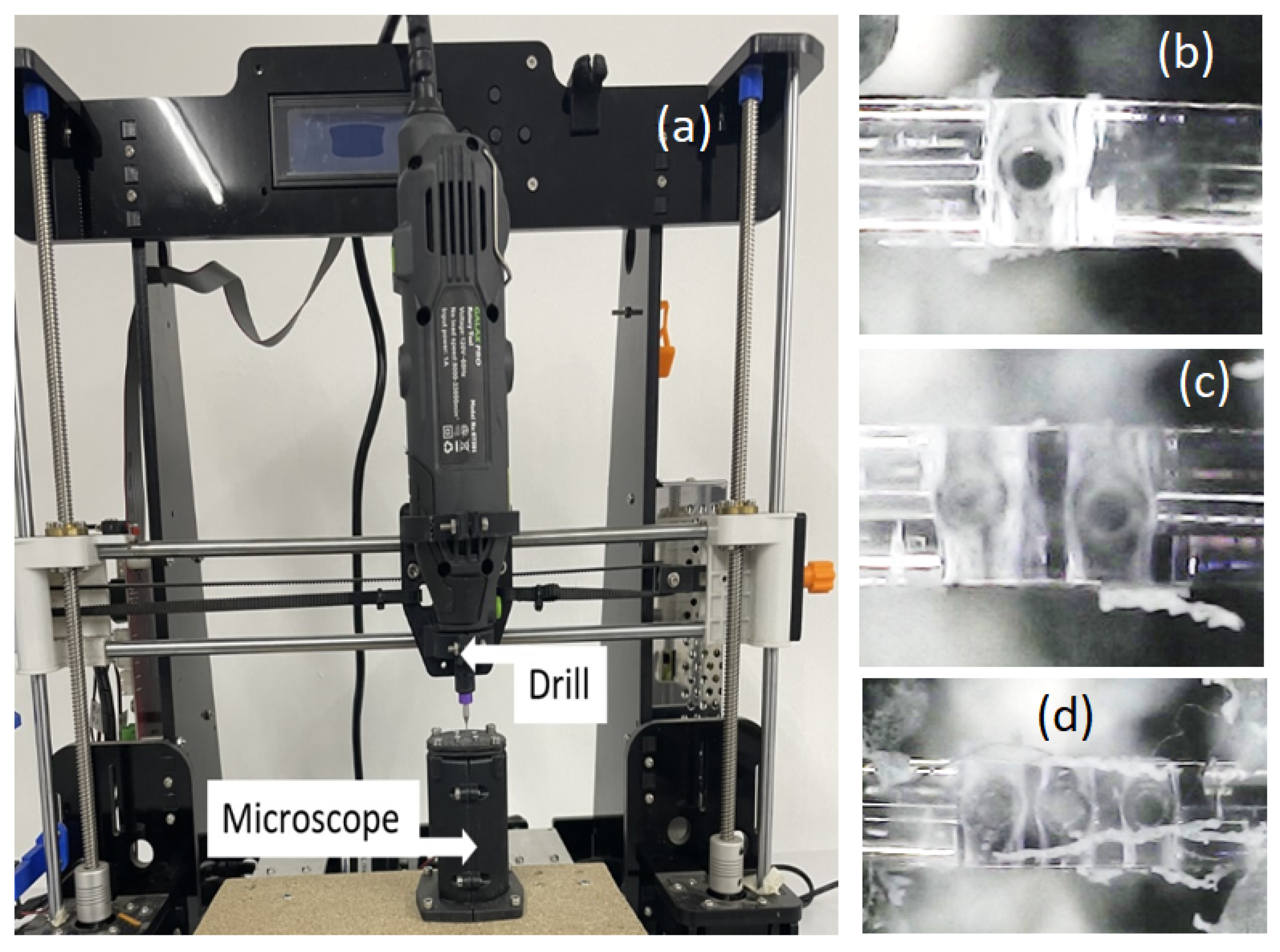

2. Experimental Setup

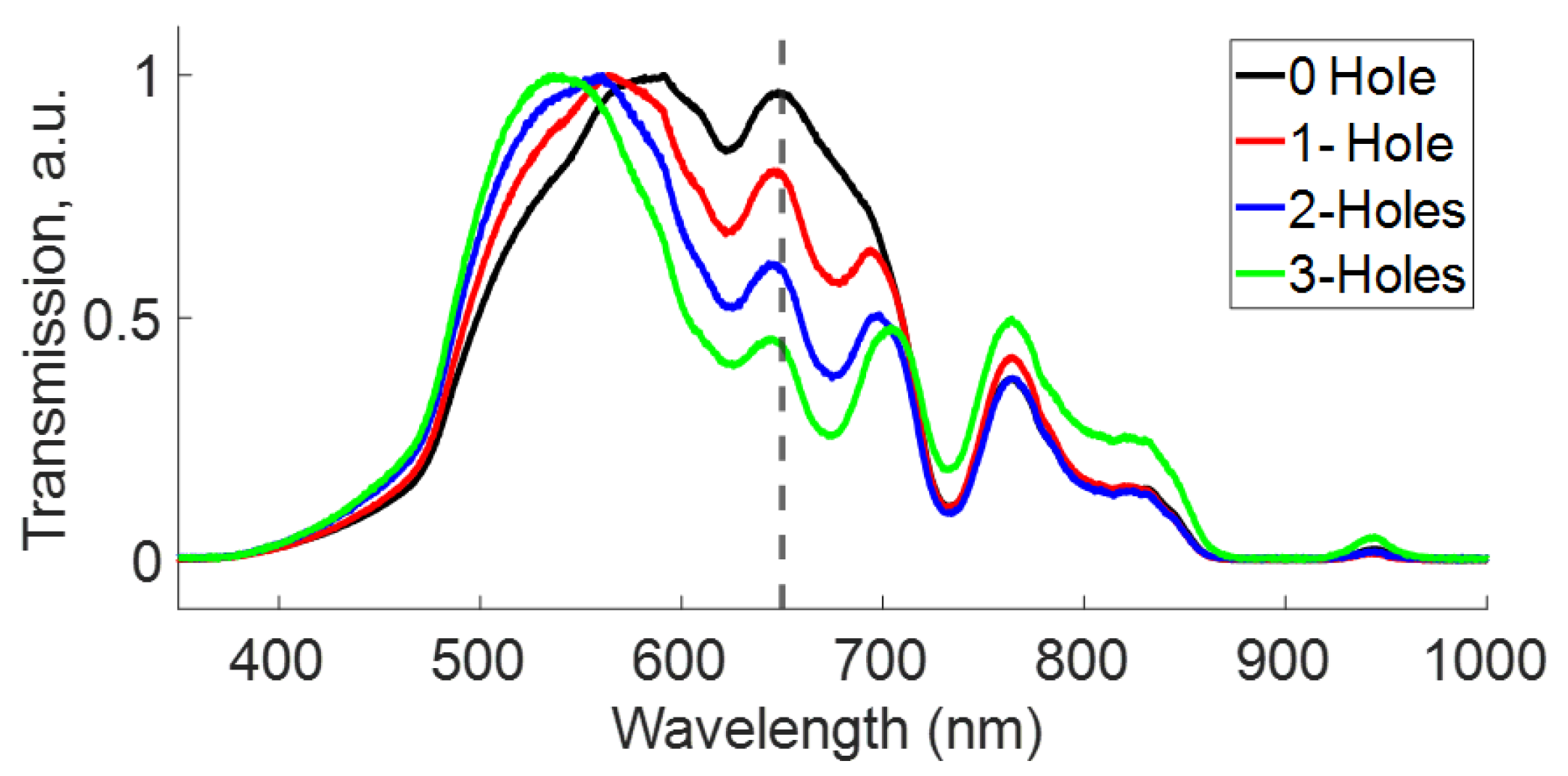

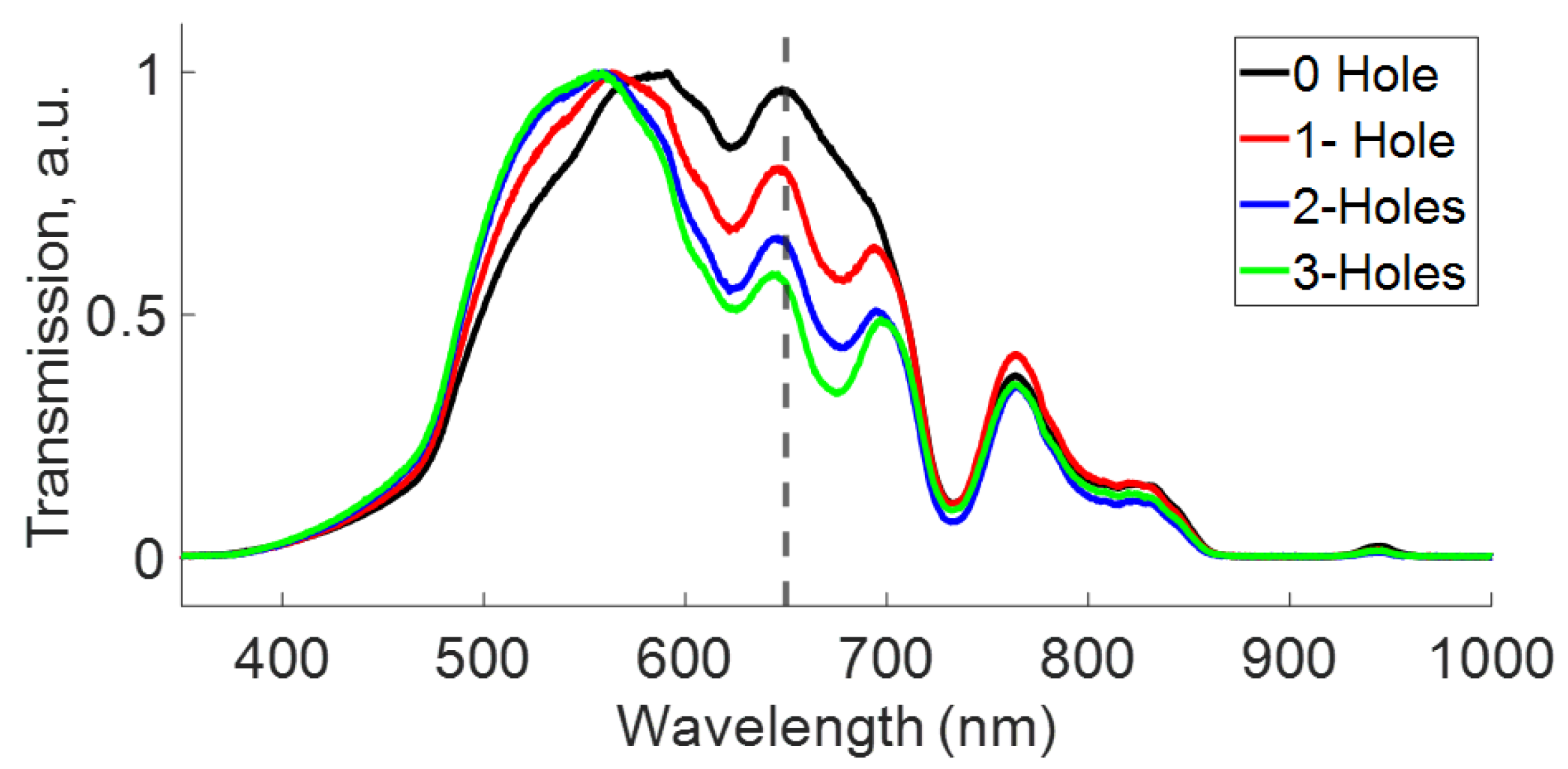

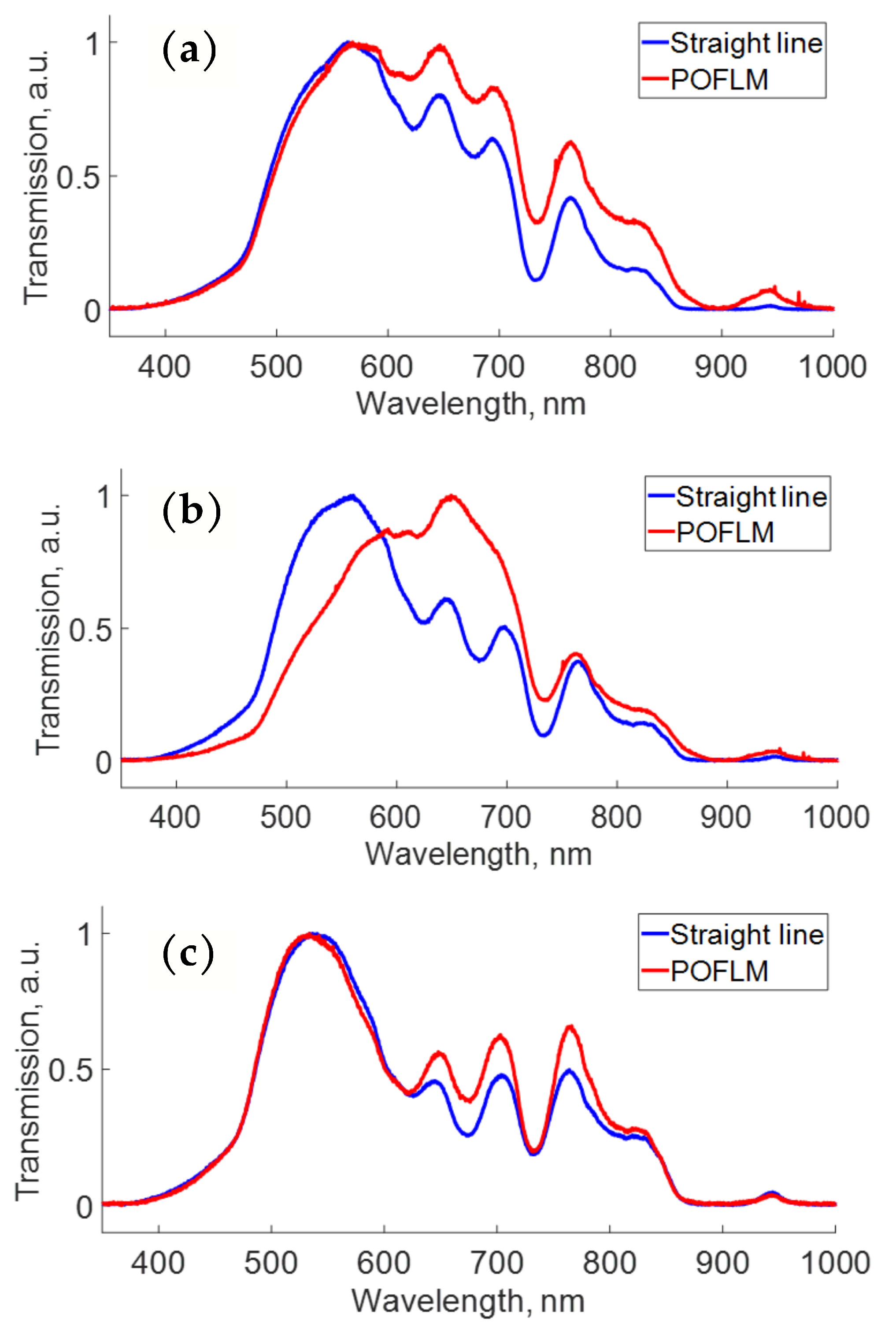

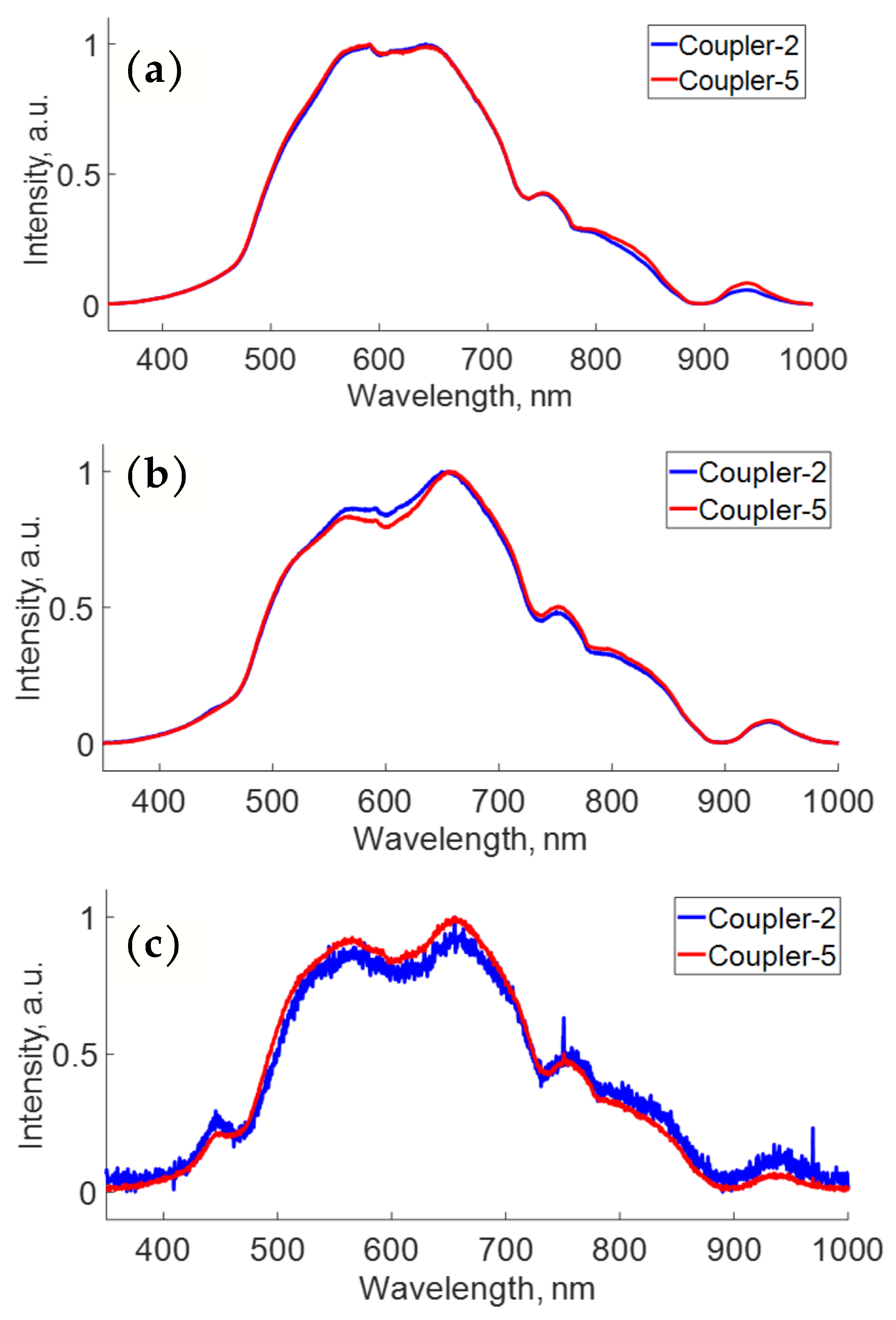

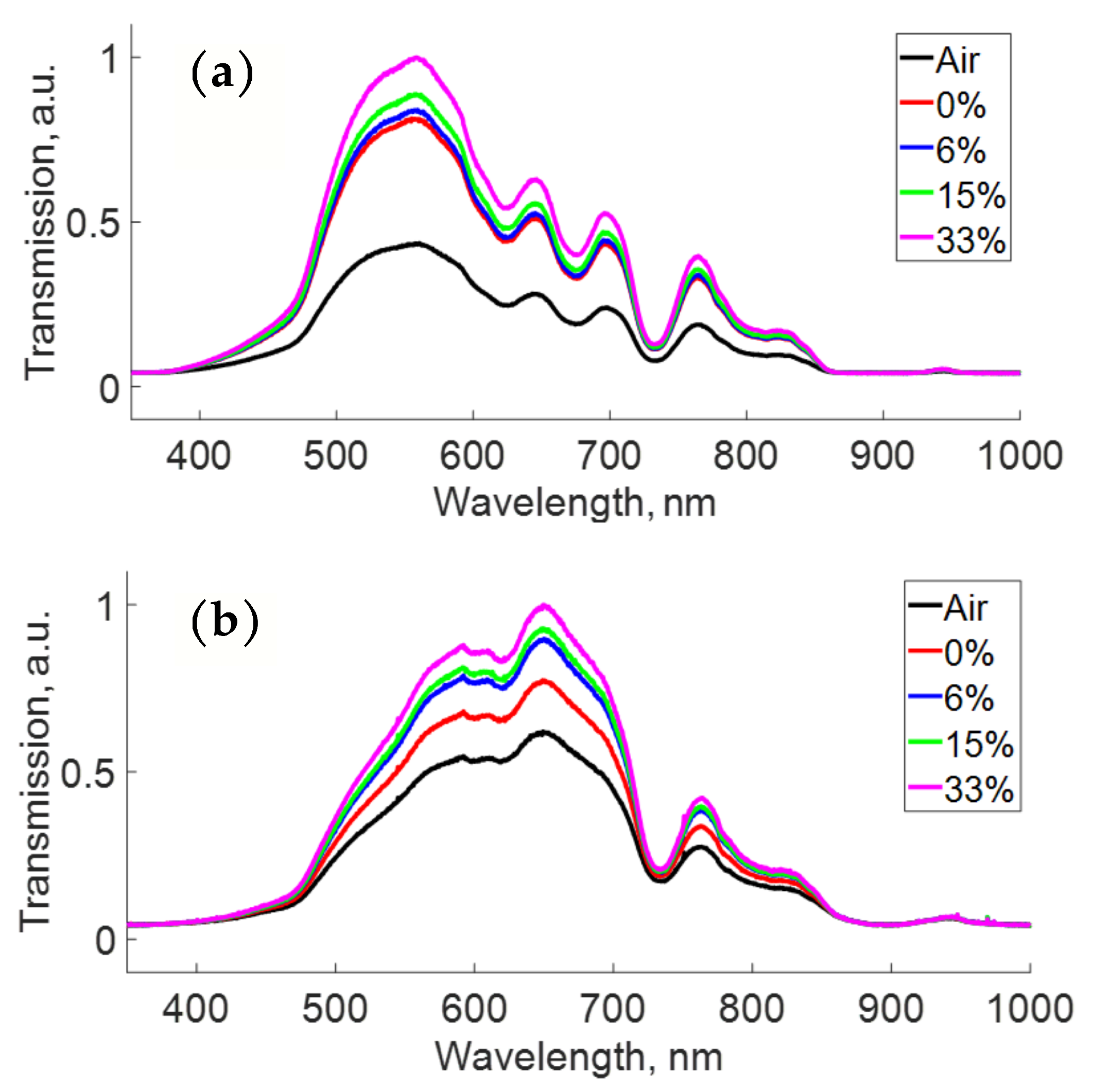

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| POF | Plastic Optical Fiber |

| PMMA | Polymethyl Methacrylate |

| WDM | Wavelength-Division Multiplexing |

| FBG | Fiber Bragg Grating |

| LPG | Long-Period Grating |

| SMF | Single-Mode Fiber |

| FOLM | Fiber Loop Mirror |

| POFLM | Plastic Optical Fiber Loop Mirror |

| CNC | Computer Numerical Control |

References

- Bartlett, R.J.; Philip-Chandy, R.; Eldridge, P.; Merchant, D.F.; Morgan, R.; Scully, P.J. Plastic optical fibre sensors and devices. Trans. Inst. Meas. Control 2000, 22, 431–457. [Google Scholar] [CrossRef]

- Prado, A.R.; Leal-Junior, A.G.; Marques, C.; Leite, S.; de Sena, G.L.; Machado, L.C.; Frizera, A.; Ribeiro, M.R.N.; Pontes, M.J. Polymethyl methacrylate (PMMA) recycling for the production of optical fiber sensor systems. Opt. Express 2017, 25, 30051–30060. [Google Scholar] [CrossRef] [PubMed]

- Joseba, Z.; Jon, A. Plastic Optical Fibers: An Introduction to Their Technological Processes and Applications. Opt. Fiber Technol. 2001, 7, 101–140. [Google Scholar]

- Teng, C.; Min, R.; Zheng, J.; Deng, S.; Li, M.; Hou, L.; Yuan, L. Intensity-modulated polymer optical fiber-based refractive index sensor: A review. Sensors 2021, 22, 81. [Google Scholar] [CrossRef] [PubMed]

- Bilro, L.; Alberto, N.; Pinto, J.L.; Nogueira, R. Optical Sensors Based on Plastic Fibers. Sensors 2012, 12, 12184–12207. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Webb, D.J.; Andre, P. Polymer optical fiber sensors in human life safety. Opt. Fiber Technol. 2017, 36, 144–154. [Google Scholar] [CrossRef]

- Gandhi, M.A.; Zhao, Y.; Huang, C.; Zhang, Y.; Fu, H.Y.; Li, Q. Highly sensitive refractive index sensor based on plastic optical fiber balloon structure. Opt. Lett. 2022, 47, 1697–1700. [Google Scholar] [CrossRef] [PubMed]

- Kibler, T.; Poferl, S.; Böck, G.; Huber, H.P.; Zeeb, E. Plastic optical fibre sensors and devices. J. Light. Technol. 2004, 22, 2184. [Google Scholar] [CrossRef]

- Irigoyen, M.; Sánchez-Martin, J.A.; Bernabeu, E. Tapered optical fiber sensor for chemical pollutants detection in seawater. Meas. Sci. Technol. 2017, 28, 045802. [Google Scholar] [CrossRef]

- Richards, D.H.; Losada, M.A.; Antoniades, N.; López, A.; Mateo, J.; Jiang, X.; Madamopoulos, N. Modeling methodology for engineering SI-POF and connectors in an avionics system. J. Light. Technol. 2013, 31, 468–475. [Google Scholar] [CrossRef]

- Jeong, Y.; Bae, S.; Oh, K. All fiber N × N fused tapered plastic optical fiber (POF) power splitters for photodynamic therapy applications. Curr. Appl. Phys. 2009, 9, e273–e275. [Google Scholar]

- Kim, K.T.; Han, B.J. High-performance plastic optical fiber coupler based on heating and pressing. IEEE Photon. Technol. Lett. 2011, 23, 1848–1850. [Google Scholar] [CrossRef]

- Min, R.; Ortega, B.; Marques, C. Latest achievements in polymer optical fiber gratings: Fabrication and applications. Photonics 2019, 6, 36. [Google Scholar] [CrossRef]

- Luo, Y.; Yan, B.; Zhang, Q.; Peng, G.-D.; Wen, J.; Zhang, J. Fabrication of polymer optical fibre (POF) gratings. Sensors 2017, 17, 511. [Google Scholar] [CrossRef] [PubMed]

- Santiago-Hernández, H.; Bravo-Medina, B.; Mora-Nuñez, A.; Flores, J.L.; García-Torales, G.; Pottiez, O. All-POF coupling ratio-imbalanced Sagnac interferometer as a refractive index sensor. Appl. Opt. 2021, 60, 7145–7151. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Wang, L.; Li, H. Phase-Inserted Fiber Gratings and Their Applications to Optical Filtering, Optical Signal Processing, and Optical Sensing. Photonics 2022, 9, 271. [Google Scholar] [CrossRef]

- Zou, X.; Li, M.; Pan, W.; Yan, L.; Azaña, J.; Yao, J. All-fiber optical filter with an ultranarrow and rectangular spectral response. Opt. Lett. 2013, 38, 3096–3098. [Google Scholar] [CrossRef]

- Fernández-Ruiz, M.R.; Carballar, A. Fiber Bragg Grating-Based Optical Signal Processing: Review and Survey. Appl. Sci. 2021, 11, 8189. [Google Scholar] [CrossRef]

- Wang, K.; Dong, X.; Köhler, M.H.; Kienle, P.; Bian, Q.; Jakobi, M.; Koch, A.W. Advances in optical fiber sensors based on multimode interference (MMI): A review. IEEE Sens. J. 2020, 21, 132–142. [Google Scholar] [CrossRef]

- Hill, K.O.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Light. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhu, T.; Shi, L.; Liu, M. All-fiber bandpass filter based on asymmetrical modes exciting and coupling. Opt. Commun. 2013, 286, 161–165. [Google Scholar] [CrossRef]

- SMohammed, W.S.; Smith, P.W.; Gu, X. All-fiber multimode interference bandpass filter. Opt. Lett. 2006, 31, 2547–2549. [Google Scholar] [CrossRef] [PubMed]

- Ishikawa, R.; Lee, H.; Lacraz, A.; Theodosiou, A.; Kalli, K.; Mizuno, Y.; Nakamura, K. Pressure dependence of fiber Bragg grating inscribed in perfluorinated polymer fiber. IEEE Photonics Technol. Lett. 2017, 29, 2167–2170. [Google Scholar] [CrossRef]

- Min, R.; Ortega, B.; Marques, C. Fabrication of tunable chirped mPOF Bragg gratings using a uniform phase mask. Opt. Express 2018, 26, 4411–4420. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Yan, B.; Li, M.; Zhang, X.; Wu, W.; Zhang, Q.; Peng, G.D. Analysis of multimode POF gratings in stress and strain sensing applications. Opt. Fiber Technol. 2011, 17, 201–209. [Google Scholar] [CrossRef]

- Webb, D.J. Fibre Bragg grating sensors in polymer optical fibres. Meas. Sci. Technol. 2015, 26, 092004. [Google Scholar] [CrossRef]

- Teng, C.; Deng, H.; Liu, H.; Yang, H.; Yuan, L.; Zheng, J.; Deng, S. Refractive index sensor based on twisted tapered plastic optical fibers. Photonics 2019, 6, 40. [Google Scholar] [CrossRef]

- Teng, C.; Yu, F.; Jing, N.; Ding, Y.; Si, Z.; Zheng, J. Investigation of refractive index sensors based on side-polished plastic optical fibers. Opt. Fiber Technol. 2017, 36, 1–5. [Google Scholar] [CrossRef]

- Xue, P.; Wu, B.; Bao, H.; Zheng, J. Screw-shaped plastic optical fibers for refractive index sensing. IEEE Sens. J. 2020, 20, 5237–5242. [Google Scholar] [CrossRef]

- Tiwari, S.; Singh, M.K.; Pandey, P.C. Refractive index sensor based on spiral-shaped plastic optical fiber. IEEE Sens. J. 2016, 17, 1692–1695. [Google Scholar] [CrossRef]

- Teng, C.; Jing, N.; Yu, F.; Ding, Y.; Zheng, J. Refractive index sensor based on a multi-notched plastic optical fiber. Appl. Opt. 2017, 56, 1833–1838. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.D.; Park, J. Plastic optical fiber refractive index sensor employing an in-line submillimeter hole. IEEE Photonics Technol. Lett. 2013, 25, 1882–1884. [Google Scholar] [CrossRef]

- Park, J.; Seo, H. Plastic optical fiber sensor based on in-fiber rectangular hole for mercury detection in water. Sens. Mater. 2020, 32, 2117–2125. [Google Scholar] [CrossRef]

- Xue, P.; Yu, F.; Cao, Y.; Zheng, J. Refractive index sensing based on a long period grating imprinted on a multimode plastic optical fiber. IEEE Sens. J. 2020, 19, 7434–7439. [Google Scholar] [CrossRef]

- Röhlig, D.; Kuhn, E.; Thränhardt, A.; Blaudeck, T. Simultaneous occurrence and compensating effects of multi-type disorder in two-dimensional photonic structures. Nano Sel. 2023, 4, 368–385. [Google Scholar] [CrossRef]

- Kuraptsev, A.S.; Sokolov, I.M. Light propagation in a random three-dimensional ensemble of point scatterers in a waveguide: Size-dependent switching between diffuse radiation transfer and Anderson localization of light. Phys. Rev. A 2022, 105, 063513. [Google Scholar] [CrossRef]

- Ziemann, O.; Krauser, J.; Zamzow, P.E.; Daum, W. POF Handbook; Springer: Berlin/Heidelberg, Germany, 2008; Chapter 8. [Google Scholar]

- Leal-Junior, A.; Avellar, L.; Frizera, A.; Marques, C. Smart textiles for multimodal wearable sensing using highly stretchable multiplexed optical fiber system. Sci. Rep. 2020, 10, 13867. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Frizera, A.; Vargas-Valencia, L.; dos Santos, W.M.; Bo, A.P.; Siqueira, A.A.; Pontes, M.J. Polymer optical fiber sensors in wearable devices: Toward novel instrumentation approaches for gait assistance devices. IEEE Sens. J. 2018, 18, 7085–7092. [Google Scholar] [CrossRef]

- Peters, K. Polymer optical fiber sensors—A review. Smart Mater. Struct. 2010, 20, 013002. [Google Scholar] [CrossRef]

- Kaino, T. Polymer optical fibers. In Polymers for Lightwave and Integrated Optics: Technology and Applications; CRC Press: Amsterdam, The Netherlands, 1992; pp. 1–38. [Google Scholar]

- Nihei, E.; Ishigure, T.; Tanio, N.; Koike, Y. Present prospect of graded-index plastic optical fiber in telecommunication. IEICE Trans. Electron. 1997, 80, 117–122. [Google Scholar]

- Soldano, L.B.; Pennings, E.C. Optical multi-mode interference devices based on self-imaging: Principles and applications. J. Light. Technol. 1995, 13, 615–627. [Google Scholar] [CrossRef]

- Guzmán-Sepúlveda, J.R.; Guzmán-Cabrera, R.; Castillo-Guzmán, A.A. Optical sensing using fiber-optic multimode interference devices: A review of nonconventional sensing schemes. Sensors 2021, 21, 1862. [Google Scholar] [CrossRef] [PubMed]

- Medjadba, H.; Lecler, S.; Simohamed, L.M.; Fontaine, J.; Meyrueis, P. Investigation of mode coupling effects on sensitivity and bias of a multimode fiber loop interferometer: Application to an optimal design of a multimode fiber gyroscope. Opt. Fiber Technol. 2011, 17, 50–58. [Google Scholar] [CrossRef]

- Mortimore, D. Fiber loop reflectors. J. Light. Technol. 1988, 6, 1217–1224. [Google Scholar] [CrossRef]

- Morishita, K.; Shimamoto, K. Wavelength-selective fiber loop mirrors and their wavelength tunability by twisting. J. Light. Technol. 1995, 13, 2276–2281. [Google Scholar] [CrossRef]

- Kumar, N.; Ramachandran, K. Mach–Zehnder interferometer concatenated fiber loop mirror based gain equalization filter for an EDFA. Opt. Commun. 2013, 289, 92–96. [Google Scholar] [CrossRef]

- Kumar, N.; Ramachandran, K.J. Dynamic spectral maneuvering by fiber Sagnac loop filter. Opt. Laser Technol. 2014, 63, 144–147. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mora-Nuñez, A.; Santiago-Hernández, H.; Bravo-Medina, B.; Beltran-Gonzalez, A.; Flores-Payán, J.; de la Cruz-González, J.L.; Pottiez, O. Plastic Optical Fiber Spectral Filter Based on In-Line Holes. Photonics 2024, 11, 306. https://doi.org/10.3390/photonics11040306

Mora-Nuñez A, Santiago-Hernández H, Bravo-Medina B, Beltran-Gonzalez A, Flores-Payán J, de la Cruz-González JL, Pottiez O. Plastic Optical Fiber Spectral Filter Based on In-Line Holes. Photonics. 2024; 11(4):306. https://doi.org/10.3390/photonics11040306

Chicago/Turabian StyleMora-Nuñez, Azael, Héctor Santiago-Hernández, Beethoven Bravo-Medina, Anuar Beltran-Gonzalez, Jesús Flores-Payán, José Luis de la Cruz-González, and Olivier Pottiez. 2024. "Plastic Optical Fiber Spectral Filter Based on In-Line Holes" Photonics 11, no. 4: 306. https://doi.org/10.3390/photonics11040306

APA StyleMora-Nuñez, A., Santiago-Hernández, H., Bravo-Medina, B., Beltran-Gonzalez, A., Flores-Payán, J., de la Cruz-González, J. L., & Pottiez, O. (2024). Plastic Optical Fiber Spectral Filter Based on In-Line Holes. Photonics, 11(4), 306. https://doi.org/10.3390/photonics11040306