Abstract

Photopolymers, especially acrylate-based ones with low cost and simple preparation, are promising materials for high-efficiency holographic gratings. However, it is still challenging to achieve high-performance gratings, due to the influences of many factors. In this work, we found that the dark reaction plays a critical role. The effect of the dark reaction on the optical properties of holographic gratings was investigated. Experimental results reveal that the diffraction efficiency of the gratings can be improved by a factor of three by involving the dark reaction process, and the highest diffraction efficiency for gratings can reach 97.8% after optimization. Therefore, the dark reaction can greatly enhance the optical performance of acrylate-based holographic gratings and other optical elements, thus holding great potential for many applications.

1. Introduction

Holographic gratings have attracted extensive attention in recent years, due to their high diffraction efficiency [1,2,3,4]. They are holographic optical elements (HOEs), formed through the multi-beam laser interference-induced polymerization and diffusion of monomers, which results in a modulation of the refractive index inside the grating. Currently, there are a variety of holographic recording materials, such as dichromate gelatins, silver salts, photoresists [5], photopolymers [6,7,8,9], etc. Among them, photopolymers are some of the most attractive materials, with the advantages of low scattering, high resolution, simple fabrication, and low cost. Therefore, they have been widely used in many fields, such as photolithography [10], sensors [11,12,13], additive manufacturing [14], 3D printing [15], and diffractive optical elements [6,16,17]. Generally, the photopolymer system consists of photosensitizers (dyes), photoinitiators, crosslinkers, and monomers. Upon multi-beam interference exposure, absorption by the photosensitizer results in an excited state in high-intensity regions, which then undergo electron transfer reactions, producing free radicals from the photoinitiator, and subsequently initiating the free radical polymerization of monomers [18]. The consumption of monomers leads to their diffusion from low- to high-intensity regions, resulting in localized changes in chemical composition, density, and refractive index between the low- and high-intensity regions [19]. For holography, polyvinyl alcohol-acrylamide [20,21] and phenanthrenequinone-doped polymethyl methacrylate [22] are well-known recording photopolymers. Thus far, researchers have made significant efforts to increase the sensitivity, resolution, diffraction efficiency, and material stability of these composite materials [23]. The incorporation of liquid crystals into photopolymers makes it possible to obtain composite materials for holographic recording, known as holographic polymer-dispersed liquid crystals (HPDLCs) [24,25,26,27]. Azo dye doping in photopolymers has also been explored, due to the fact that the azo dye molecules can be locally reoriented by polarized light through photoactivated isomerization, hence improving refractive index contrast and diffraction efficiency [28,29,30]. Alternative approaches include the incorporation of nanoparticles, such as silicon dioxide nanoparticles [31] and gold nanorods [32], and quantum dots [33] into photopolymer materials to enhance their diffraction performance. In addition to particle doping, new photopolymer systems have also been developed to improve upon their diffraction efficiency [34,35,36]. However, there is no straightforward and effective technique through which to improve the diffraction efficiency of holographic gratings.

The performance of photopolymer-based holographic gratings is highly dependent on the wavelength of the laser source, the exposure conditions, and the properties of the photopolymer during the recording process [37]. Under experimental conditions, long-duration continuous exposure can lead to the amplification of holographic scattering noise [38] and decreased diffraction efficiency, due to overmodulation [39]. Dark diffusion enhancement, as an effective method through which to improve the performance of holographic gratings, can alleviate this problem. In previous experiments, enhanced diffraction efficiency of holographic gratings was observed with the dark reaction after short-duration exposure in photopolymers [40,41]. This is mainly attributed to the diffusion of monomer molecules from low- to high-intensity regions, which results in enhanced modulation depth [42]. Compared with long-duration continuous exposure, a short exposure time can prevent the amplification of holographic scattering and reduce photosensitizer consumption. However, the significance of the dark reaction to the performance improvement in holographic gratings has not been well recognized, and quantitative analysis of the performance enhancement during the dark reaction has rarely been investigated.

In this work, we investigated the effect of the dark reaction on the diffraction efficiency of holographically photopolymerized acrylate-based gratings. The involvement of the dark reaction process can lead to a three-fold increase in the diffraction efficiency of the gratings. With optimized fabrication conditions, holographic transmission gratings with a high diffraction efficiency of 97.8% can be achieved. Morphological studies further revealed well-defined periodic grating structures, with much greater sagittal heights than those achieved without the dark reaction. These excellent results show that high-performance acrylate-based holographic gratings and other HOEs can be prepared by involving the dark reaction process, which could potentially be useful for various applications, such as integrated optics, data storage, and AR/VR waveguide displays.

2. Photochemical Mechanism and Diffusion Model

The photochemical process of materials can be described as a free radical polymerization reaction, which can be divided into three steps. The first step is the photoinitiation to generate free radicals. According to the generating routes of free radicals, photoinitiation can be divided into type I and type II [43,44]. In our work, type II photoinitiation was used, in which the free radicals were generated by the photoinitiator in conjunction with the co-initiator. Under the irradiation of the laser beam, the photoinitiator and the co-initiator work together to produce the initial radical R*. These initial free radicals subsequently react with monomers, resulting in the formation of monomer free radicals, denoted as M*. At the second step, monomer free radicals continuously add monomers, resulting in the formation of an active polymer chain with free radicals. This process is known as chain growth. At the third step, when the free radicals of the two active chains meet, they collide and annihilate, resulting in the termination of polymer chain growth and the end of the polymerization reaction.

The phenomenon of the dark reaction in gratings can be explained by the internal process of the materials. When a coherent light beam is incident on the material, the photosensitive molecules absorb photons and become excited from the singlet state to the triplet excited state, forming radical, R*. These excitons form a relatively weak grating, and then R* react with M or M* to form a stable photochemical product. The interference exposure causes changes in the material’s molecular structure, resulting in a spatially periodic distribution of molecular concentration. This leads to the formation of the refractive index modulation regime. At the same time, the effective gratings in the material are gradually enhanced, due to the diffusion effect. After exposure, the diffusion of free radicals from the dark region to the bright region cannot be avoided; due to the concentration gradients, the unpolymerized free excitons inside the polymer continue to polymerize for a certain amount of time. The optimal duration of the dark reaction following exposure is determined by the reaction rate. The diffusion coefficient of the R molecule plays a crucial role in determining this rate. Based on the free volume theory [45,46], the concentration of monomer molecules is directly related to the diffusion coefficient. Therefore, an approximate expression can be used to express the diffusion coefficient and the concentration of R molecules, as follows:

where D0 and C are constants, and U (x, t) represents the concentration of R molecules. Finally, when the dark reaction reaches a steady state, the diffusion of R molecules nearly ceases. At this point, the grating remains relatively stable.

3. Materials and Methods

3.1. Materials

The chemicals utilized in formulating the prepolymer solutions comprise the monomer, Dipentaerythritol penta-/hexa-acrylate (DPHPA, 99.9%, n = 1.474); the crosslinker, 1-Vinyl-2-pyrrolidone (NVP, 99.9%); the photoinitiator, Rose Bengal (RB, 99.5%); and the co-initiator, N-phenylglycine (NPG, 99.5%); all were sourced from Macklin, Shanghai, China. Experiments and optimization were carried out based on our previous report [4]. The composition of the prepolymer solution is shown in Table 1. The mixture was stirred using a magnetic stirrer for ~1 h to form a homogeneous solution. We assembled two cleaned glass substrates with a size of 2 × 2 cm2 to form a cell in which to contain the prepolymer mixture for laser beam exposure. Before assembly, special surface treatment with UV-ozone (UVO) was applied to only one of the two glass substrates to remove organic pollutants adhering to the surface and grow a layer of hydroxyl radicals [47], hence enhancing the adhesion of the polymer to the treated glass during the exposure process, and subsequently allowing the grating structure to adhere to the treated glass without damage upon cell opening. The thickness of the cell was controlled by SiO2 spacers of different sizes in diameter. To ensure the stability and uniformity of the cell gap, the SiO2 spacers were dispersed in the optical adhesive NOA65, and then applied to the four corners of the glass substrates. Afterwards, the glue was cured under UV light, resulting in a strong bond that held the glass substrates together. The prepolymer solution was infiltrated into the cells via capillary force. It is worth noting that the aforementioned mixing and infiltration operations were carried out in a dark room to avoid ambient light-induced photopolymerization.

Table 1.

Composition of the photopolymer, in wt%.

3.2. Holographic Recording and Characterization

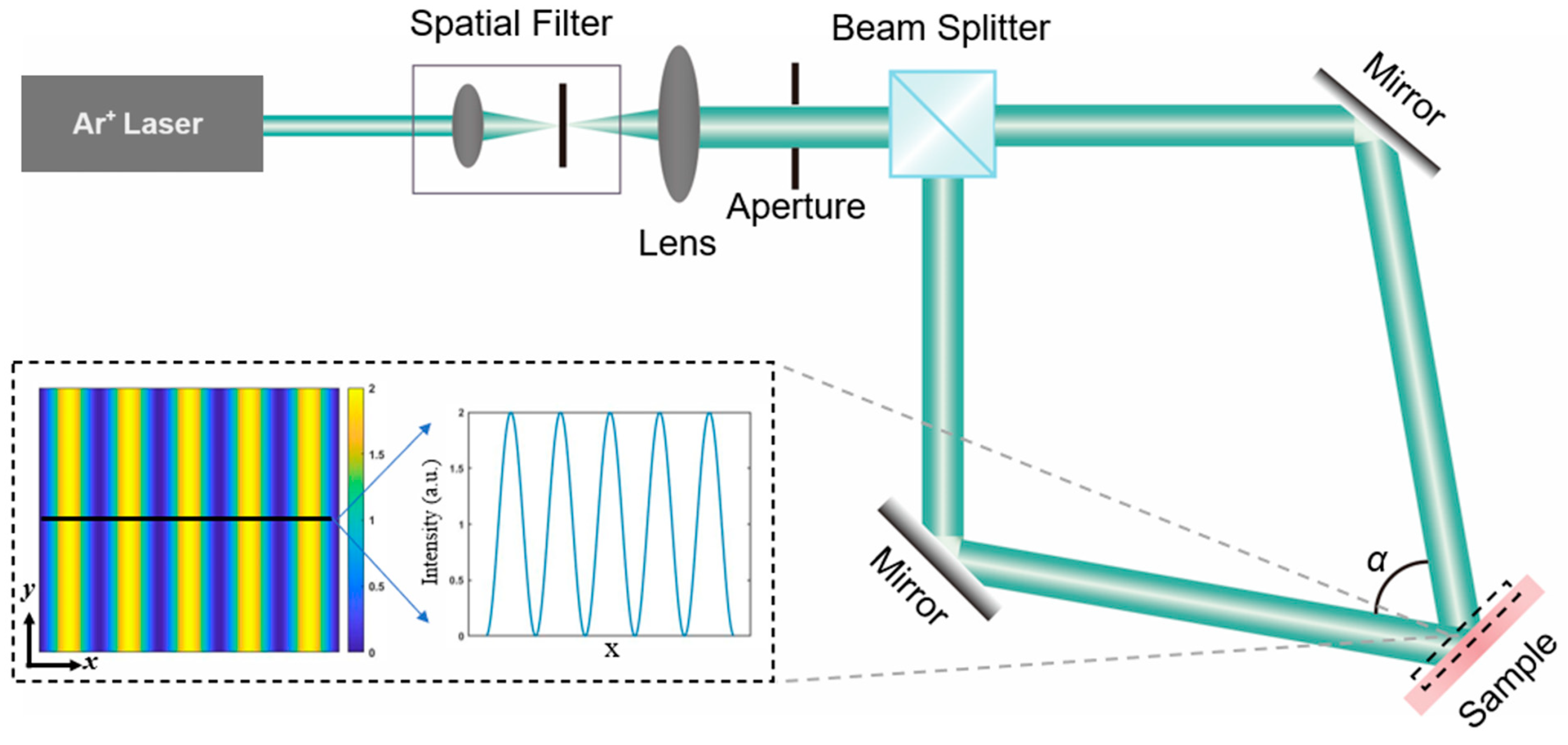

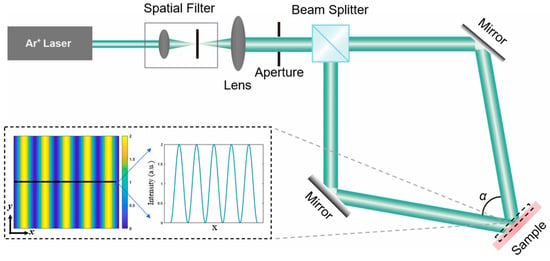

The experimental setup used to record the transmission holographic grating is shown in Figure 1. The light source was an Ar+ laser operating at 488 nm (INNOVA 300C, Coherent, Saxonburg, PA, USA). First, the laser beam was expanded, using a spatial filter, and collimated with a lens. The aperture was used to adjust the beam size. The collimated beam was then split into two beams with the same intensity. The two separated beams were then reflected by two mirrors to intersect at an angle. At the intersecting area, the two laser beams interfered to form a periodic, alternating low- and high-intensity light pattern, as shown in the inset of Figure 1. The cell infiltrated with the prepolymer solution was placed at the intersecting area to expose the light pattern. It is worth noting that one should place the cell with the surface-treated side nearest to the incoming light source to ensure that the polymer is well-adhered to the surface-treated glass substrate. After exposure, a holographic grating was recorded inside the cell. The period of the gratings depends on the angle between the two light beams, which can be calculated by the following equation:

where Λ is the period of the gratings, λ is the wavelength of the recorded light, and α is the angle between two incident light beams. After the mixture was injected into the cell by capillary force, the cell was placed on the plane where both beams overlapped. The sample was then exposed for a certain duration, and then placed in the dark area. After exposure, the cell was opened using a blade, and the polymer was only left on the surface-treated glass substrate due to enhanced hydrophilicity. The samples were then immersed in a solution of propylene glycol methyl ether acetate (PGMEA) for development. Once the development process was complete, the samples were rinsed with deionized water, and then dried with a nitrogen gun. Finally, the gratings were obtained for further characterization and measurement.

Figure 1.

Schematic diagram of the optical setup for fabricating holographic gratings.

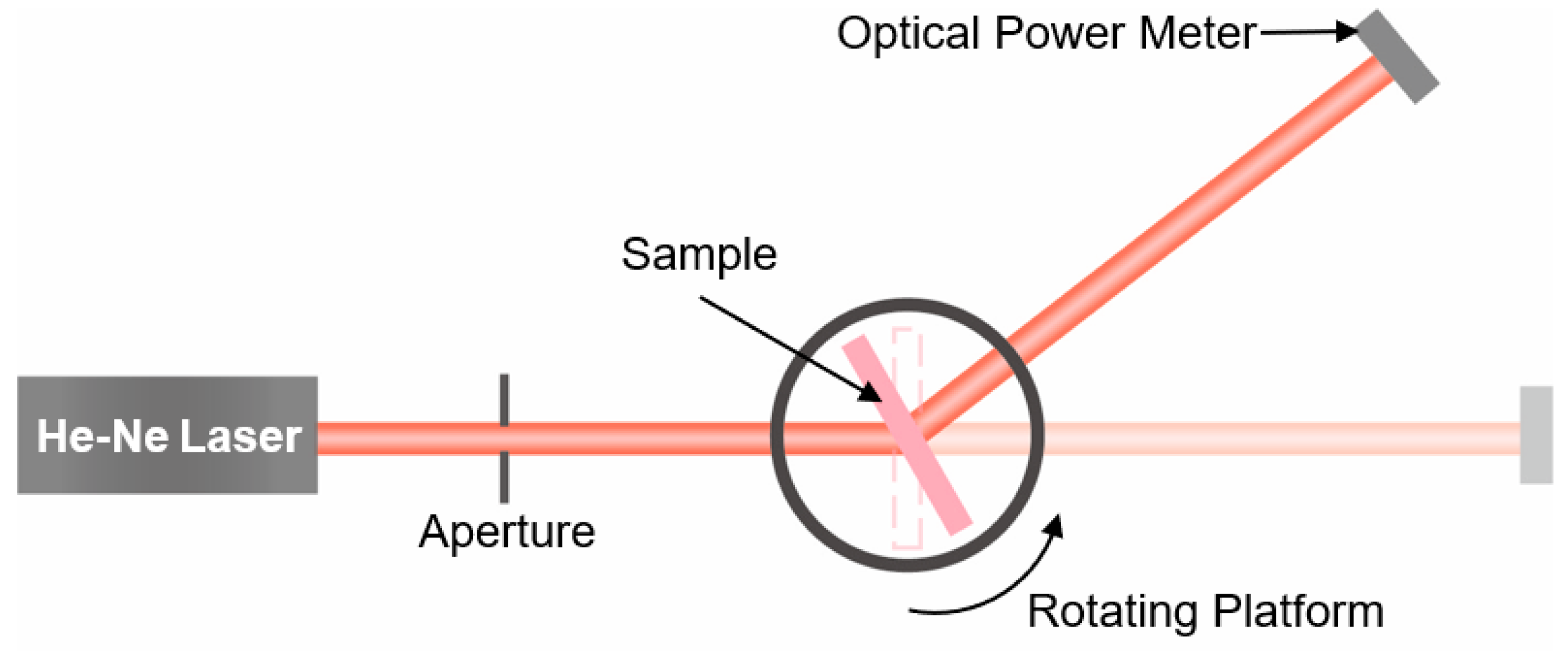

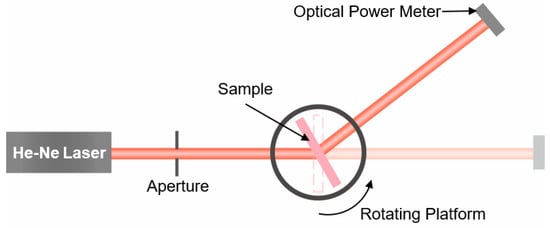

The surface morphologies of the gratings were characterized using atomic force microscopy (AFM, Dimension Edge, Bruker, Billerica, MA, USA). The diffraction efficiency was measured using a He-Ne laser (25-LHR-925, Pacific Lasertec, San Marcos, TX, USA) with a working wavelength of 633 nm. This wavelength was chosen because it is not absorbed by the material. Figure 2 shows the optical setup for measuring the diffraction efficiency of the gratings. A laser power meter (PM100A, Thorlabs, Newton, MA, USA) was used to measure the transmitted light intensity It and diffracted light intensity Id of the probe beam [48]. A rotating platform was used to rotate the sample, to ensure that the beam is incident on the gratings at the Bragg angle, for maximizing the diffraction efficiency. The diffraction efficiency was calculated by the following equation:

Figure 2.

Schematic diagram of the optical setup for diffraction efficiency measurement.

4. Results and Discussion

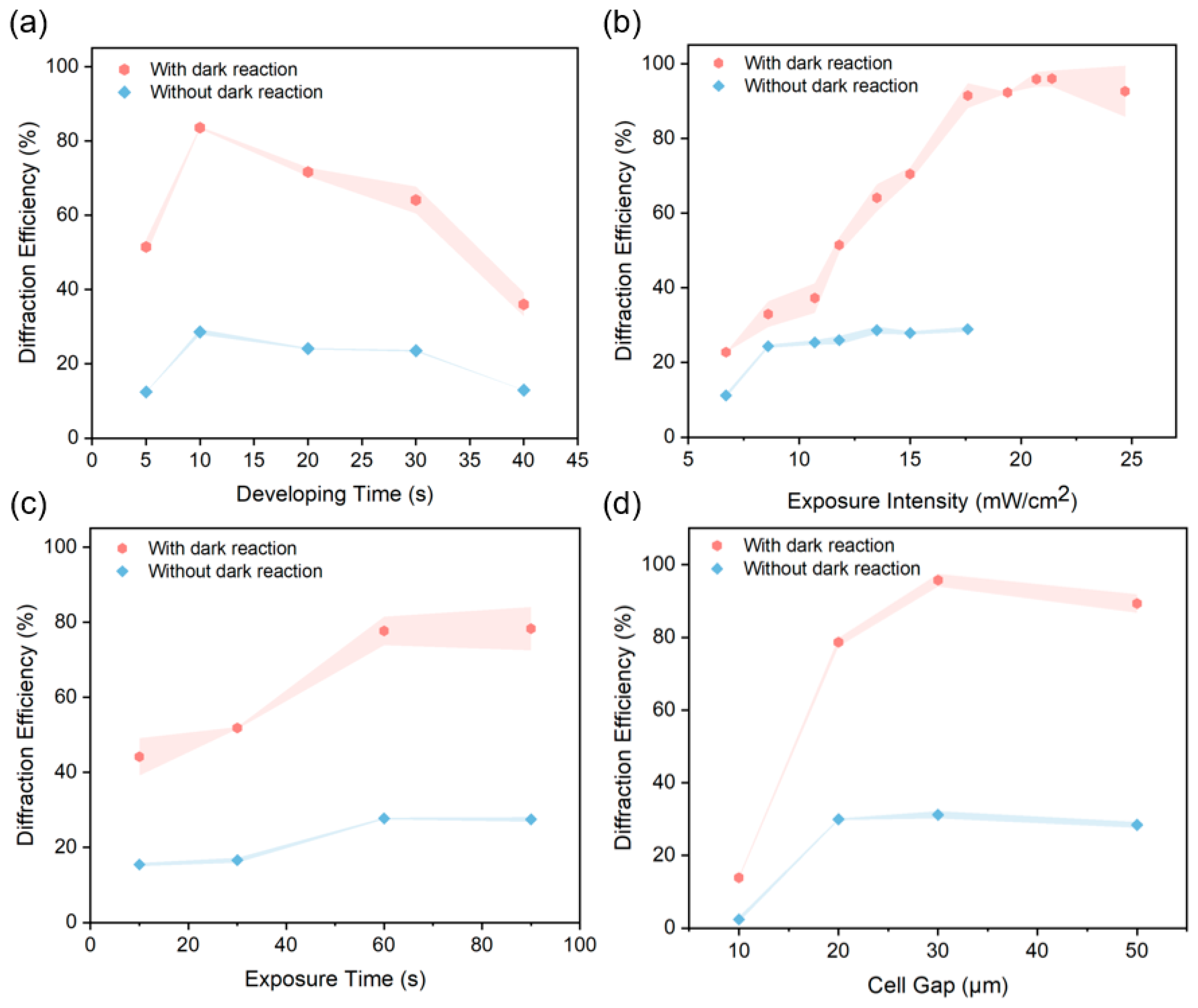

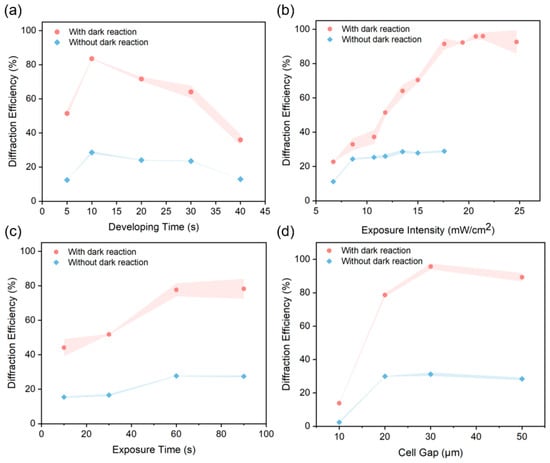

In our experiments, we holographically prepared the gratings by changing the fabrication parameters, with and without the dark reaction. By changing the fabrication parameters, such as the exposure time, intensity, and angle of incidence, we were able to control the properties of the gratings. The dark reaction, on the other hand, refers to a specific step in the holographic fabrication process. By comparing the gratings prepared with and without the dark reaction, we aimed to investigate the influence of this additional step on the performance of the gratings. This comparison allowed us to assess the impacts of the dark reaction on the diffraction efficiency, spectral response, and overall functionality of the gratings. For each set of fabrication parameters, we prepared three samples and measured their diffraction efficiency values separately. We then calculated the average value and the root mean square error (RMSE) of the diffraction efficiency values for the samples prepared under the same conditions to obtain the relationships between the diffraction efficiency and the fabrication parameters, with the error bar labeled by the filling area. Firstly, we studied the effect of the development time on the diffraction efficiency of the holographic gratings, as shown in Figure 3a. The following fabrication parameters were used: the exposure intensity was 15 mW/cm2, the exposure time was 30 s, the dark reaction time was 10 min, and the cell gap was 20 μm. It can be clearly seen from Figure 3a that, for both cases, with and without the dark reaction, the diffraction efficiency of the grating increases first, and then gradually decreases as the development time grows, demonstrating a similar trend. The highest diffraction efficiency of any grating was achieved with the development time of 10 s. During the development process, the unexposed part of the exposed film is washed away, revealing the periodic grating structure and creating the index contrast between the exposed and unexposed areas, subsequently resulting in the diffraction efficiency. At the very beginning of development, washing away the unexposed materials causes an increase in the index contrast. As a result, the diffraction efficiency of the grating gradually increases with the increase in development time. However, as the development process continues, overdevelopment occurs, meaning that the exposed materials could also be washed away. This would lead to a decrease in the index contrast for the overdeveloped gratings. Therefore, we observed a gradual decrease in the diffraction efficiency with a further increase in the development time. More importantly, comparing the prepared gratings, with and without the dark reaction, there is a significant improvement in the diffraction efficiency for the gratings involving the dark reaction.

Figure 3.

The effect of (a) the development time, (b) the exposure intensity, (c) the exposure time, and (d) the cell gap on the diffraction efficiency of holographic gratings.

Secondly, we investigated the effect of the exposure intensity on the diffraction efficiency of the fabricated gratings, with and without the dark reaction. The exposure time was set to 30 s, the development time was 10 s, the dark reaction time was 10 min, and the cell gap was 20 μm. As shown in Figure 3b, the diffraction efficiency increases until reaching saturation as the exposure intensity increases, in both cases. We found that the prepolymer mixture cannot undergo the photopolymerization reaction with the exposure intensity below 5 mW/cm2. As a result, there is no grating structure that can be formed inside the cell. This indicates that there exists a threshold regarding the exposure intensity, only above which photopolymerization could occur [49]. Moreover, the exposure light intensity affects the photopolymerization rate of the prepolymer. It is understandable that, above the photopolymerization threshold, the higher the exposure intensity is, the more the produced free radicals are. This effect would lead to an increase in the diffusion rate of the photoinduced reaction between the photosensitizer and the monomer, due to the increased free radicals, hence further accelerating the photopolymerization process. A faster photopolymerization process reduces possible light scattering, resulting in a more distinguished grating structure with higher diffraction efficiency.

Thirdly, we further investigated the effect of the exposure time on the diffraction efficiency of the gratings, as shown in Figure 3c. The exposure intensity was 18 mW/cm2, the dark reaction time was 10 min, the development time was 10 s, and the cell gap was 20 μm. The exposure time was gradually increased, from 10 to 90 s. For both cases, with and without the dark reaction, we achieved the highest diffraction efficiency for the prepared gratings with an exposure time of 60 s. We noticed that, at the fixed exposure intensity of 18 mW/cm2, there is a threshold (~10 s) for the exposure time. Below the threshold, there is no discernable grating structure formed inside the cell, and, accordingly, immeasurable diffraction efficiency. As the exposure time increases, free radicals continue to be generated, and the photopolymerization reaction proceeds, resulting in a thicker polymer layer in the high-intensity region. This leads to a larger index contrast between the exposed and unexposed regions after development, thereby enhancing the diffraction efficiency. As the exposure time continues to grow, the diffraction efficiency of the gratings will reach its saturation at a certain point. This could possibly be attributed to the completely consumed free radicals, preventing the further growth of the grating structure. As a result, the refractive index contrast between the high- and low-intensity regions does not continue to increase. Therefore, the diffraction efficiency reaches its maximum, and then saturates.

Fourthly, we investigated the effect of the cell gap on the diffraction efficiency of the fabricated gratings. Figure 3d shows the experimental results of transmission gratings recorded under identical conditions with the cell gaps of 10, 20, 30, and 50 μm, respectively. The exposure intensity was 18 mW/cm2, the exposure time was 60 s, the development time was 10 s, and the dark reaction time was 10 min. It is obvious that the diffraction efficiency of the gratings with a cell gap of 10 μm is significantly lower than that of those with a cell gap of 30 μm. When the cell gap is 50 μm, the diffraction efficiency also decreases, which might be attributed to the increased absorption and scattering of the incident beam. In general, the thick layer of the prepolymer will lower the intensity difference between the interference fringes during the holographic recording process and reduce refractive index modulation, hence leading to a decrease in diffraction efficiency [50,51].

Comparing the curves in Figure 3 with and without the dark reaction, it is obvious that the dark reaction significantly improves the diffraction efficiency under different fabrication conditions. It is straightforward that, after the exposure process, the photopolymerization and diffusion processes do not stop immediately, and some of the reactive monomers continue to transfer, polymerize, and diffuse. Therefore, placing the samples in a dark room for a period of time after exposure can ensure that the monomers have sufficient time to diffuse and fully polymerize, resulting in high-efficiency gratings.

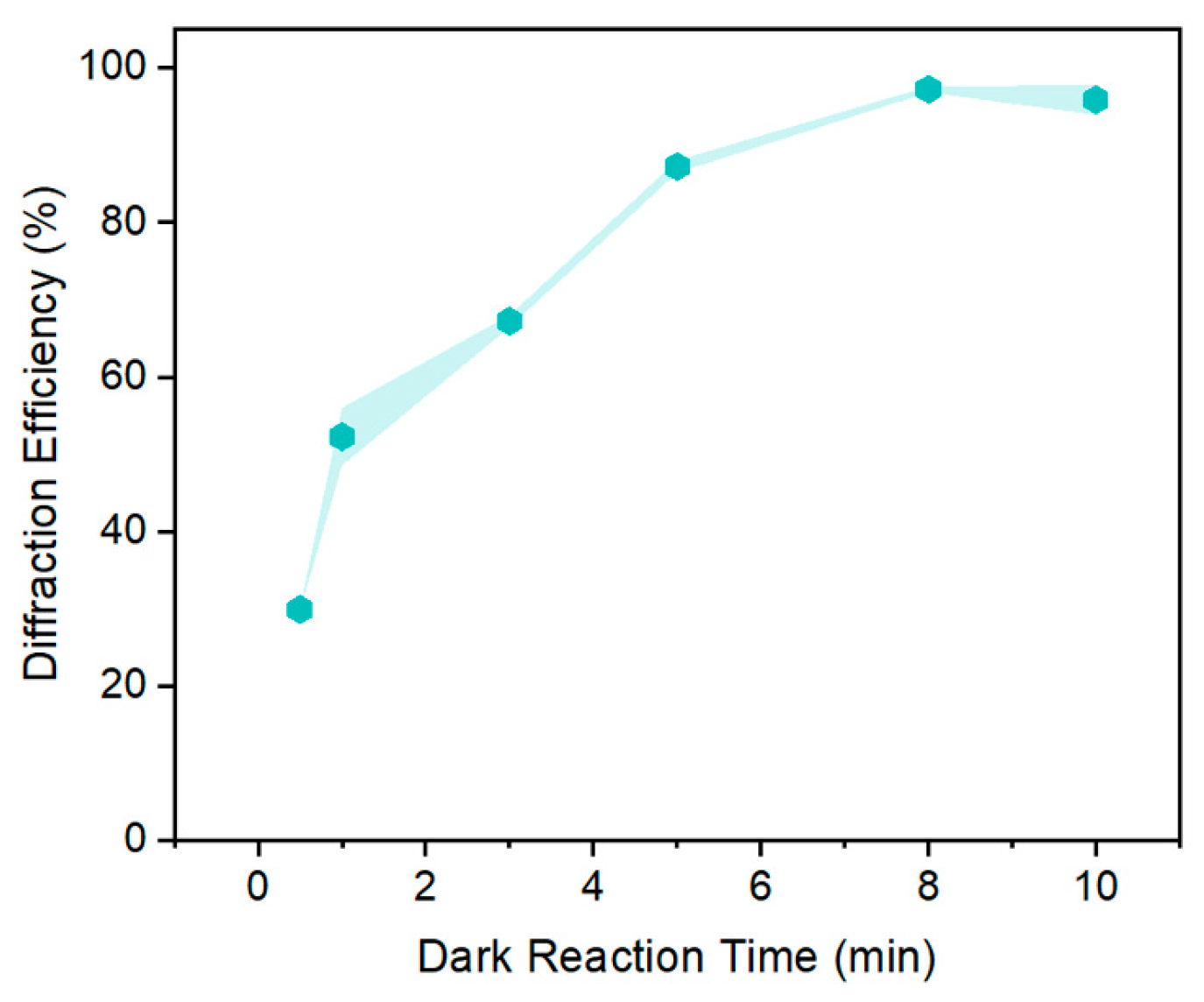

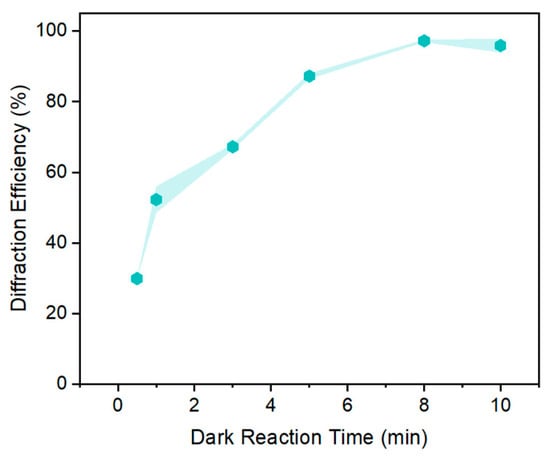

Finally, we investigated the effect of the dark reaction on the diffraction efficiency of holographic gratings. To compare the effect of the dark reaction, the prepolymer mixtures were irradiated and prepared under the same exposure and post-treatment conditions. The exposure intensity was 18 mW/cm2, the exposure time was 60 s, the development time was 10 s, and the cell gap was 30 μm. From Figure 4, it can be seen that the diffraction efficiency of the gratings increases, from 29% to 97.8%, as the dark reaction time grows. Compared to the gratings prepared without the dark reaction, the diffraction efficiency of the gratings increases significantly when the dark reaction time is greater than 5 min, but further approaches saturation beyond a dark reaction time of 8 min.

Figure 4.

The effect of the dark reaction time on the diffraction efficiency of holographic gratings.

With the above optimization process of the multi-parameter fabrication, we finally determined the optimal experimental conditions, with an exposure intensity of 18 mW/cm2, an exposure time of 60 s, a development time of 10 s, a dark reaction process time of 8 min, and a cell gap of 30 μm. The holographic gratings with the highest diffraction efficiency, 97.8%, were achieved based on this optimal condition.

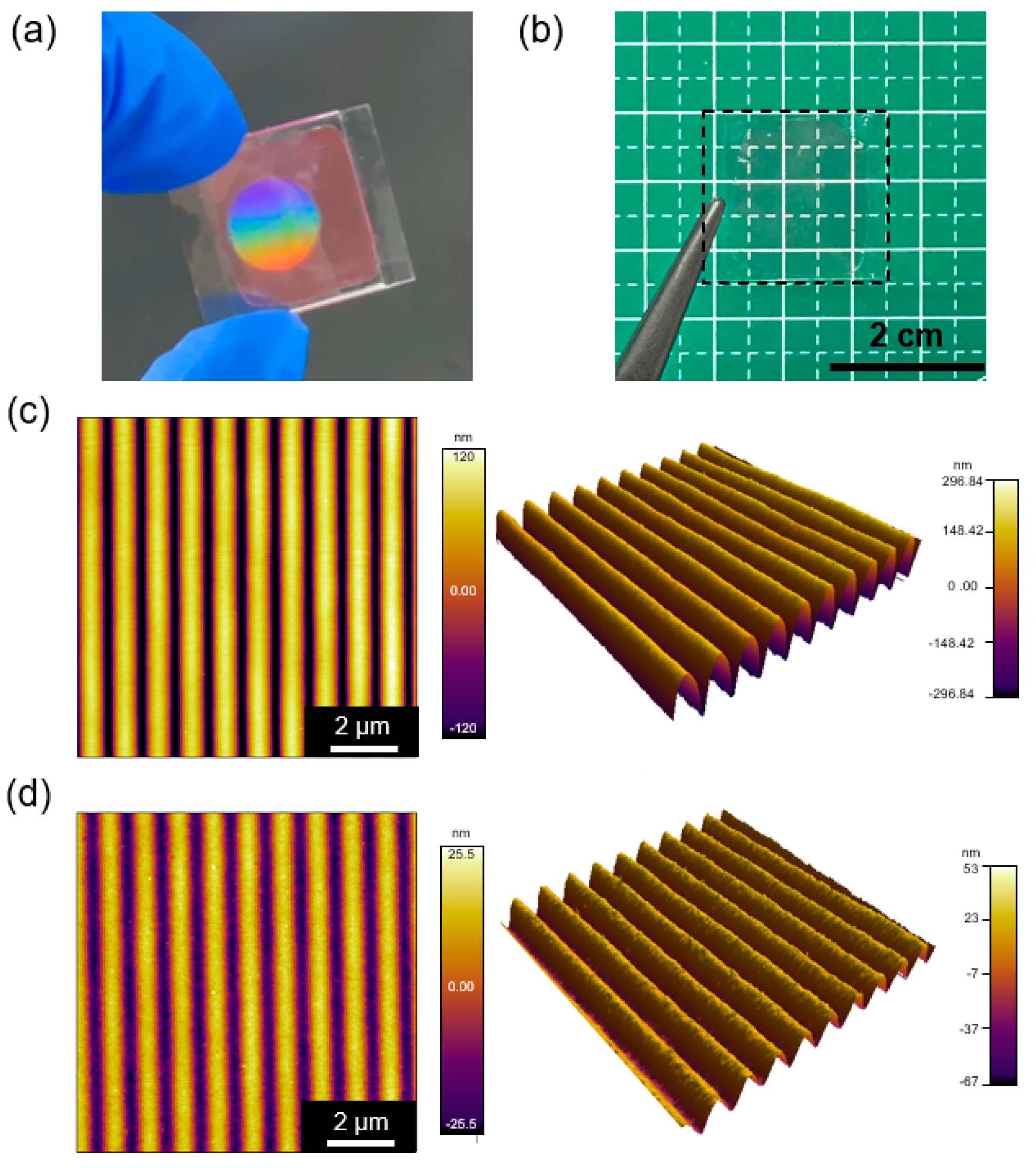

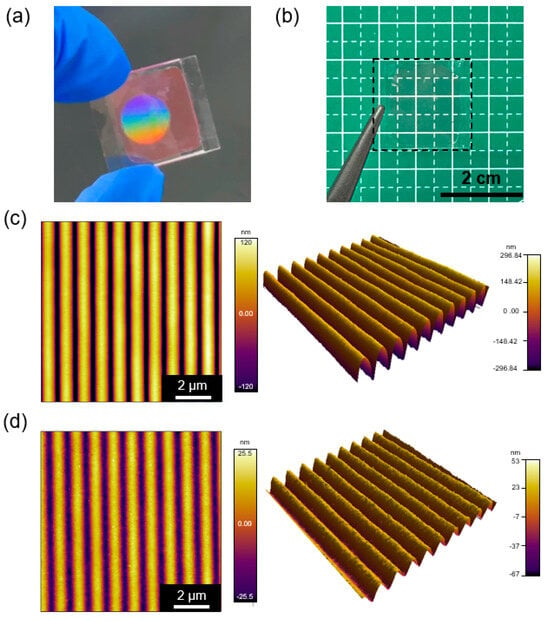

The gratings holographically prepared under the optimal fabrication conditions were further characterized. Figure 5a shows the prepared sample illuminated under white light. We can see that the diffracted light is highly dispersed with different colors, indicating that the white light can be effectively separated into different wavelengths. In addition, the prepared grating sample exhibits excellent transparency in the visible range, as shown in Figure 5b. Figure 5c,d show the AFM images of the samples with and without the dark reaction, showing their 2D and 3D surface morphologies, respectively. It is worth noting that there is a clearly visible difference in the sagittal heights of the fabricated gratings with and without the dark reaction. The measured sagittal height of the sample with the dark reaction is 256.21 nm, which is much greater than that (35.53 nm) without the dark reaction. This further confirms that a grating with a large sagittal height will have high diffraction efficiency. The AFM images also clearly illustrate the periodic fringes of the holographically fabricated gratings. In our experiment, the intersecting angle between two incident light beams was 15°, and the period was theoretically calculated to be 0.94 μm. The measured period of the gratings is ~1 μm, which is in excellent agreement with the theoretically calculated period of 0.94 μm.

Figure 5.

(a) White light diffraction from the grating illustrates strong dispersion. (b) A photo of the grating taken on a white grid with a green background, to show excellent transparency in the visible range. Black dashed lines indicate the sample size. The 2D and 3D AFM images of the gratings (c) with and (d) without the dark reaction.

5. Conclusions

In summary, we studied the effect of the dark reaction on the diffraction efficiency of acrylate-based holographic gratings under various experimental conditions, including differences in the development time, the exposure intensity, the exposure time, and the cell gap. The results indicate that the dark reaction plays a critical role in achieving high diffraction efficiency for the gratings. Our experimental results reveal that the diffraction efficiency of gratings can be significantly improved, by a factor of three, by involving the dark reaction process, and the highest diffraction efficiency of the gratings can reach 97.8% after optimization. Morphologically, the fabricated gratings also demonstrate well-defined periodic structures, with much greater sagittal heights than those achieved without the dark reaction. For acrylate-based photopolymer materials, the optical performance of holographically fabricated optical elements (i.e., gratings, lenses, prisms, computer-generated holograms [52], etc.) can be significantly enhanced by involving the dark reaction process, which hence holds great potential for many photonic applications.

Author Contributions

Conceptualization, Y.J.L. and Z.B.; methodology, Z.B., W.C. and M.C. (Ming Cheng); validation, Z.B., W.C. and M.C. (Ming Cheng); resources, S.L., J.S., D.L., Y.C. and Y.J.L.; data curation, Z.B., D.K. and M.C. (Mengjia Cen); writing—original draft preparation, Z.B.; writing—review and editing, Z.B., W.C. and Y.J.L.; supervision, Y.J.L.; funding acquisition, Y.J.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R&D Program of China (Grant No. 2022YFA1203702), the National Natural Science Foundation of China (Grant No. 62075093 and 62211530039), the Guangdong Innovative and Entrepreneurial Research Team Program (Grant No. 2017ZT07C071), the Shenzhen Development and Reform Commission (Grant No. XMHT20220114005), and the Shenzhen Science and Technology Innovation Commission (Grant No. JCYJ20220818100413030). The authors acknowledge the assistance of SUSTech Core Research Facilities.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tomita, Y.; Aoi, T.; Hasegawa, S.; Xia, F.; Wang, Y.; Oshima, J. Very high contrast volume holographic gratings recorded in photopolymerizable nanocomposite materials. Opt. Express 2020, 28, 28366–28382. [Google Scholar] [CrossRef]

- Stoilova, A.; Mateev, G.; Nazarova, D.; Nedelchev, L.; Stoykova, E.; Blagoeva, B.; Berberova, N.; Georgieva, S.; Todorov, P. Polarization holographic gratings in PAZO polymer films doped with particles of biometals. J. Photochem. Photobiol. A 2021, 411, 113196. [Google Scholar] [CrossRef]

- Liu, Y.J.; Zheng, Y.B.; Shi, J.; Huang, H.; Walker, T.R.; Huang, T.J. Optically switchable gratings based on azo-dye-doped, polymer-dispersed liquid crystals. Opt. Lett. 2009, 34, 2351–2353. [Google Scholar] [CrossRef]

- Liu, Y.J.; Dai, H.T.; Sun, X.W. Holographic fabrication of azo-dye-functionalized photonic structures. J. Mater. Chem. 2011, 21, 2982–2986. [Google Scholar] [CrossRef]

- Huang, W.; Liu, Y.H.; Li, K.; Ye, Y.; Xiao, D.; Chen, L.; Zheng, Z.G.; Liu, Y.J. Low-threshold organic lasing from a square optical microcavity fabricated by imaging holography. Opt. Express 2019, 27, 10022–10033. [Google Scholar] [CrossRef]

- Bianco, G.; Ferrara, M.A.; Borbone, F.; Roviello, A.; Striano, V.; Coppola, G. Photopolymer-based volume holographic optical elements: Design and possible applications. J. Eur. Opt. Soc. Rapid Publ. 2015, 10, 15057. [Google Scholar] [CrossRef]

- Liu, Y.J.; Sun, X.W.; Liu, J.H.; Dai, H.T.; Xu, K.S. A polarization insensitive 2 × 2 optical switch fabricated by liquid crystal–polymer composite. Appl. Phys. Lett. 2005, 86, 041115. [Google Scholar] [CrossRef]

- Liu, Y.J.; Sun, X.W.; Shum, P.; Li, H.P.; Mi, J.; Ji, W.; Zhang, X.H. Low-threshold and narrow-linewidth lasing from dye-doped holographic polymer-dispersed liquid crystal transmission gratings. Appl. Phys. Lett. 2006, 88, 061107. [Google Scholar] [CrossRef]

- Barachevsky, V.A. The current status of the development of light-sensitive media for holography (a review). Opt. Spectrosc. 2018, 124, 373–407. [Google Scholar] [CrossRef]

- Andrew, T.L.; Tsai, H.Y.; Menon, R. Confining light to deep subwavelength dimensions to enable optical nanopatterning. Science 2009, 324, 917–921. [Google Scholar] [CrossRef]

- Matusevich, V.; Wolf, F.; Tolstik, E.; Kowarschik, R. A transparent optical sensor for moisture detection integrated in a PQ-PMMA medium. IEEE Photonics Technol. Lett. 2013, 25, 969–972. [Google Scholar] [CrossRef]

- Mikulchyk, T.; Walshe, J.; Cody, D.; Martin, S.; Naydenova, I. Humidity and temperature induced changes in the diffraction efficiency and the Bragg angle of slanted photopolymer-based holographic gratings. Sens. Actuators B Chem. 2017, 239, 776–785. [Google Scholar] [CrossRef][Green Version]

- Yu, D.; Liu, H.; Mao, D.; Geng, Y.; Wang, W.; Sun, L.; Lv, J. Holographic humidity response of slanted gratings in moisture-absorbing acrylamide photopolymer. Appl. Opt. 2015, 54, 6804–6812. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Domingos, M.A.N.; Klein, T.J.; Malda, J.; Bartolo, P.J.; Hutmacher, D.W. Additive manufacturing of tissues and organs. Prog. Polym. Sci. 2012, 37, 1079–1104. [Google Scholar] [CrossRef]

- Zhao, X.; Zhao, Y.; Li, M.D.; Li, Z.; Peng, H.; Xie, T.; Xie, X. Efficient 3D Printing via Photooxidation of Ketocoumarin Based Photopolymerization. Nat. Commun. 2021, 12, 2873. [Google Scholar] [CrossRef]

- Akbari, H.; Naydenova, I.; Martin, S. Using acrylamide-based photopolymers for fabrication of holographic optical elements in solar energy applications. Appl. Opt. 2014, 53, 1343–1353. [Google Scholar] [CrossRef]

- Marín-Sáez, J.; Atencia, J.; Chemisana, D.; Collados, M.-V. Characterization of volume holographic optical elements recorded in Bayfol HX photopolymer for solar photovoltaic applications. Opt. Express 2016, 24, A720–A730. [Google Scholar] [CrossRef]

- Malallah, R.E.; Li, H.; Kelly, D.P.; Healy, J.J.; Sheridan, J.T. A review of hologram storage and self-written waveguides formation in photopolymer media. Polymers 2017, 9, 337. [Google Scholar] [CrossRef]

- Pacheco, K.; Aldea, G.; Cassagne, C.; Nunzi, J.-M. Reflection holographic gratings in acrylamide-based photopolymer. In Proceedings of the Photonics, North Quebec, QC, Canada, 5–8 June 2006. [Google Scholar]

- Fernández, R.; Gallego, S.; Márquez, A.; Francés, J.; Marínez, F.J.; Beléndez, A. Influence of index matching on AA/PVA photopolymers for low spatial frequency recording. Appl. Opt. 2015, 54, 3132–3140. [Google Scholar] [CrossRef]

- Fernández, R.; Bleda, S.; Gallego, S.; Neipp, C.; Márquez, A.; Tomita, Y.; Pascual, I.; Beléndez, A. Holographic waveguides in photopolymers. Opt. Express 2019, 27, 827–840. [Google Scholar] [CrossRef]

- Liu, P.; Chang, F.; Zhao, Y.; Li, Z.; Sun, X. Ultrafast volume holographic storage on PQ/PMMA photopolymers with nanosecond pulsed exposures. Opt. Express 2018, 26, 1072–1082. [Google Scholar] [CrossRef]

- Tomita, Y.; Hata, E.; Momose, K.; Takayama, S.; Liu, X.; Chikama, K.; Klepp, J.; Pruner, C.; Fally, M. Photopolymerizable nanocomposite photonic materials and their holographic applications in light and neutron optics. J. Mod. Opt. 2016, 63, S1–S31. [Google Scholar] [CrossRef]

- Bunning, T.J.; Natarajan, L.V.; Tondiglia, V.P.; Sutherland, R.L. Holographic polymer-dispersed liquid crystals (H-PDLCs). Annu. Rev. Mater. Sci. 2000, 30, 83–115. [Google Scholar] [CrossRef]

- Liu, Y.J.; Zhang, B.; Jia, Y.; Xu, K. Improvement of the diffraction properties in holographic polymer dispersed liquid crystal Bragg gratings. Opt. Commun. 2003, 218, 27–32. [Google Scholar] [CrossRef]

- Fernández, R.; Gallego, S.; Márquez, A.; Francés, J.; Martínez, F.J.; Pascual, I.; Beléndez, A. Analysis of holographic polymer-dispersed liquid crystals (HPDLCs) for tunable low frequency diffractive optical elements recording. Opt. Mater. 2018, 76, 295–301. [Google Scholar] [CrossRef]

- Semkin, A.; Sharangovich, S. Holographic formation of non-uniform diffraction structures by arbitrary polarized recording beams in liquid crystal-photopolymer compositions. Polymers 2019, 11, 861. [Google Scholar] [CrossRef]

- Woo, J.Y.; Kim, E.H.; Kim, B.K.; Cho, Y.H. Morphology and switching of holographic gratings containing an azo dye. Liq. Cryst. 2007, 34, 527–533. [Google Scholar] [CrossRef]

- Nedelchev, L.; Ivanov, D.; Berberova, N.; Strijkova, V.; Nazarova, D. Polarization holographic gratings with high diffraction efficiency recorded in azopolymer PAZO. Opt. Quantum Electron. 2018, 50, 1–9. [Google Scholar] [CrossRef]

- Todorov, T.; Nikolova, L.; Tomova, N. Polarization holography. 1: A new high-efficiency organic material with reversible photoinduced birefringence. Appl. Opt. 1984, 23, 4309–4312. [Google Scholar] [CrossRef]

- Tomita, Y.; Chikama, K.; Nohara, Y.; Suzuki, N.; Furushima, K.; Endoh, Y. Two-dimensional imaging of atomic distribution morphology created by holographically induced mass transfer of monomer molecules and nanoparticles in a silica-nanoparticle-dispersed photopolymer film. Opt. Lett. 2006, 31, 1402–1404. [Google Scholar] [CrossRef]

- Li, C.; Cao, L.; Wang, Z.; Jin, G. Hybrid polarization-angle multiplexing for volume holography in gold nanoparticle-doped photopolymer. Opt. Lett. 2014, 39, 6891–6894. [Google Scholar] [CrossRef]

- Liu, X.; Tomita, Y.; Oshima, J.; Chikama, K.; Matsubara, K.; Nakashima, T.; Kawai, T. Holographic assembly of semiconductor CdSe quantum dots in polymer for volume Bragg grating structures with diffraction efficiency near 100%. Appl. Phys. Lett. 2009, 95, 261109. [Google Scholar] [CrossRef]

- Fukuda, T.; Uchida, E.; Masaki, K.; Ando, T.; Shimizu, T.; Barada, D.; Yatagai, T. An investigation on polarization-sensitive materials. In Proceedings of the 2011 ICO International Conference on Information Photonics, Ottawa, ON, Canada, 18–20 May 2011. [Google Scholar]

- Liu, Y.; Fan, F.; Hong, Y.; Zang, J.; Kang, G.; Tan, X. Volume holographic recording in Irgacure 784-doped PMMA photopolymer. Opt. Express 2017, 25, 20654–20662. [Google Scholar] [CrossRef]

- Fan, F.; Liu, Y.; Hong, Y.; Zang, J.; Kang, G.; Zhao, T.; Tan, X.; Shimura, T. Volume polarization holographic recording in phenanthrenequinone doped poly (MMA-Co-BzMA) photopolymer. Chem. Lett. 2018, 47, 520–523. [Google Scholar] [CrossRef]

- Ni, M.; Peng, H.; Liao, Y.; Yang, Z.; Xue, Z.; Xie, X. 3D image storage in photopolymer/ZnS nanocomposites tailored by “photoinitibitor”. Macromolecules 2015, 48, 2958–2966. [Google Scholar] [CrossRef]

- Liu, H.; Yu, D.; Jiang, Y.; Sun, X. Characteristics of holographic scattering and its application in determining kinetic parameters in PQ-PMMA photopolymer. Appl. Phys. B 2009, 95, 513–518. [Google Scholar] [CrossRef]

- Lin, S.H.; Hsu, K.Y.; Chen, W.Z.; Whang, W.T. Phenanthrenequinone-doped poly (methyl methacrylate) photopolymer bulk for volume holographic data storage. Opt. Lett. 2000, 25, 451–453. [Google Scholar] [CrossRef]

- Wang, J.; Sun, X.; Luo, S.; Jiang, Y. The shift of Bragg angular selectivity curve in darkness in glass-like photopolymer for holographic recording. Opt. Mater. 2009, 32, 261–265. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Wang, J.; Jiang, Y.; Sun, X. Study on holographic characteristics in ZnMA doped PQ-PMMA photopolymer. Opt. Commun. 2011, 284, 2784–2788. [Google Scholar] [CrossRef]

- Veniaminov, A.; Bartsch, E. Diffusional enhancement of holograms: Phenanthrenequinone in polycarbonate. J. Opt. A Pure Appl. Opt. 2002, 4, 387–392. [Google Scholar] [CrossRef]

- Huang, T.L.; Chen, Y.C. Synthesis and free radical photopolymerization of one-component type II photoinitiator based on benzophenone segment. J. Photochem. Photobiol. A 2022, 429, 113900. [Google Scholar] [CrossRef]

- Chen, G.; Ni, M.; Peng, H.; Huang, F.; Liao, Y.; Wang, M.; Zhu, J.; Roy, V.A.L.; Xie, X. Photoinitiation and inhibition under monochromatic green light for storage of colored 3D images in holographic polymer-dispersed liquid crystals. ACS Appl. Mater. Interfaces 2017, 9, 810–1819. [Google Scholar] [CrossRef] [PubMed]

- Moreau, V.; Renotte, Y.; Lion, Y. Characterization of DuPont photopolymer: Determination of kinetic parameters in a diffusion model. Appl. Opt. 2002, 41, 3427–3435. [Google Scholar] [CrossRef] [PubMed]

- Vrentas, J.S.; Duda, J.L. Diffusion in polymer-solvent systems. I. Reexamination of the free-volume theory J. Polym. Sci. B Polym. Phys. 1977, 15, 403–416. [Google Scholar]

- Cai, W.; Xia, H.; Li, W.; Kong, D.; Ma, Z.; Cheng, M.; Wang, J.; Liu, J.; Yang, X.; Luo, D.; et al. Electrohydrodynamically printed microlens arrays with controllable curvature based on surface functionalization. Surf. Interfaces 2024, 46, 103935. [Google Scholar] [CrossRef]

- Kogelnik, H. Coupled wave theory for thick hologram gratings. Bell Syst. Tech. J. 1969, 48, 2909–2947. [Google Scholar] [CrossRef]

- Bruder, F.K.; Fäcke, T.; Rölle, T. The chemistry and physics of Bayfol®HX film holographic photopolymer. Polymers 2017, 9, 472. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, J.; Liu, H.; Yu, D.; Sun, X.; Zhang, J. Study of effective optical thickness in photopolymer for application. Opt. Lett. 2012, 37, 2241–2243. [Google Scholar] [CrossRef]

- Wang, H.; Xu, S.; Ma, J.; Wang, Z.; Hou, E. Investigation of high thickness holographic gratings in acrylamide-based photopolymer. Mod. Phys. Lett. B 2016, 30, 1650382. [Google Scholar] [CrossRef]

- Liu, Y.J.; Sun, X.W. Electrically switchable computer-generated hologram recorded in polymer-dispersed liquid crystals. Appl. Phys. Lett. 2007, 90, 191118. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).