Numerical Simulation of the Laser Welding Process for Diamond Saw Blades

Abstract

1. Introduction

2. Calculation Method

2.1. Computation of Thermal Field

2.2. Calculation of the Stress Field

3. Results and Discussion

3.1. Parameters for Materials and Welding Processes

3.2. Refinement of the Welding Finite Element Model

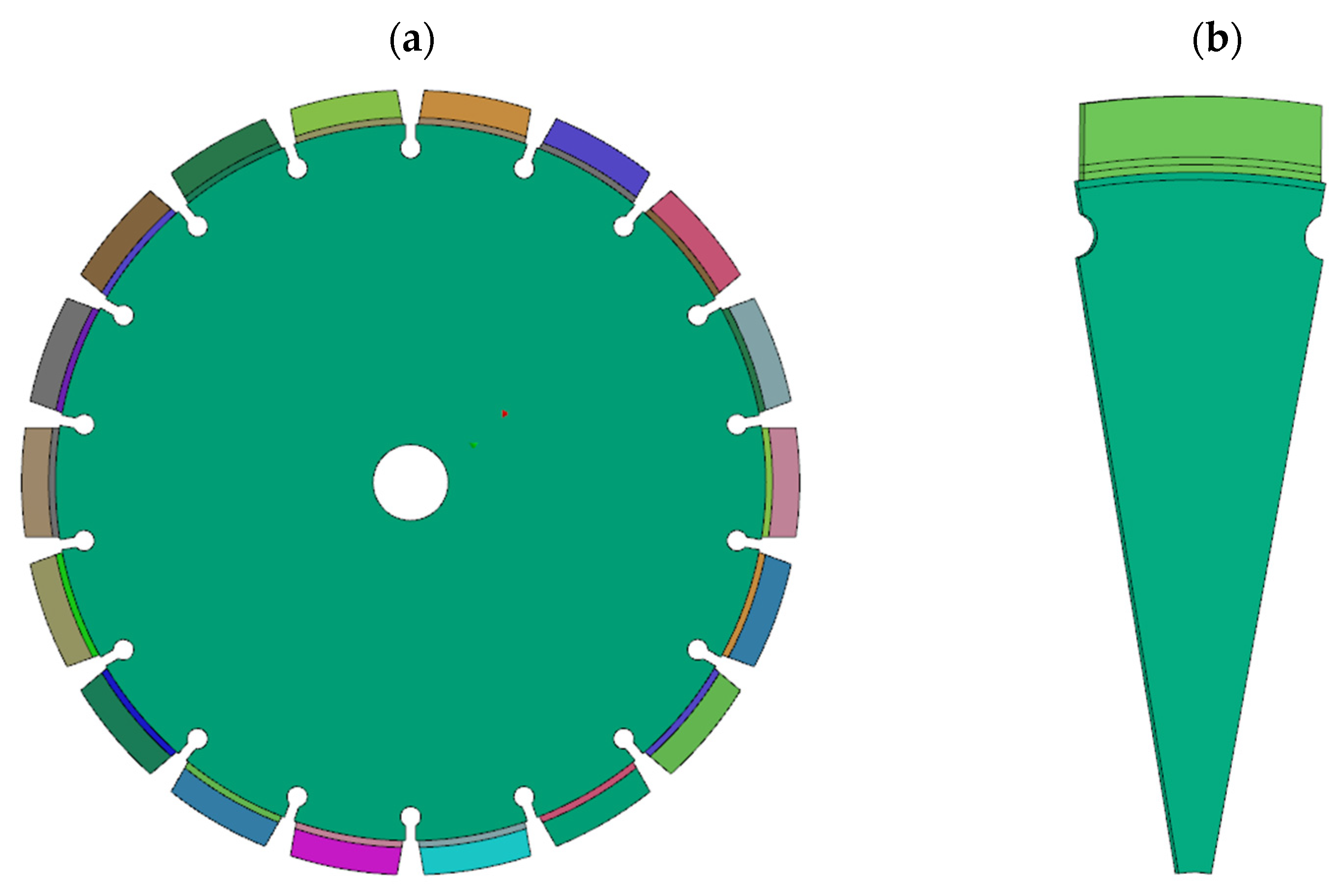

3.2.1. 3D Modeling

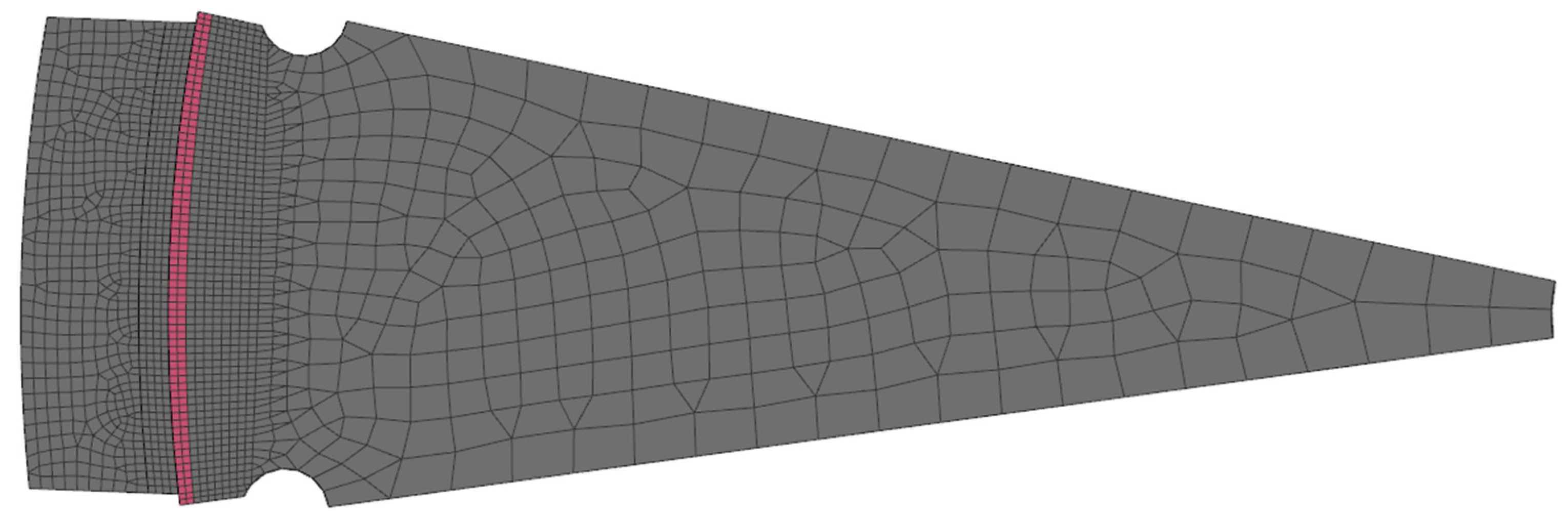

3.2.2. Grid Division

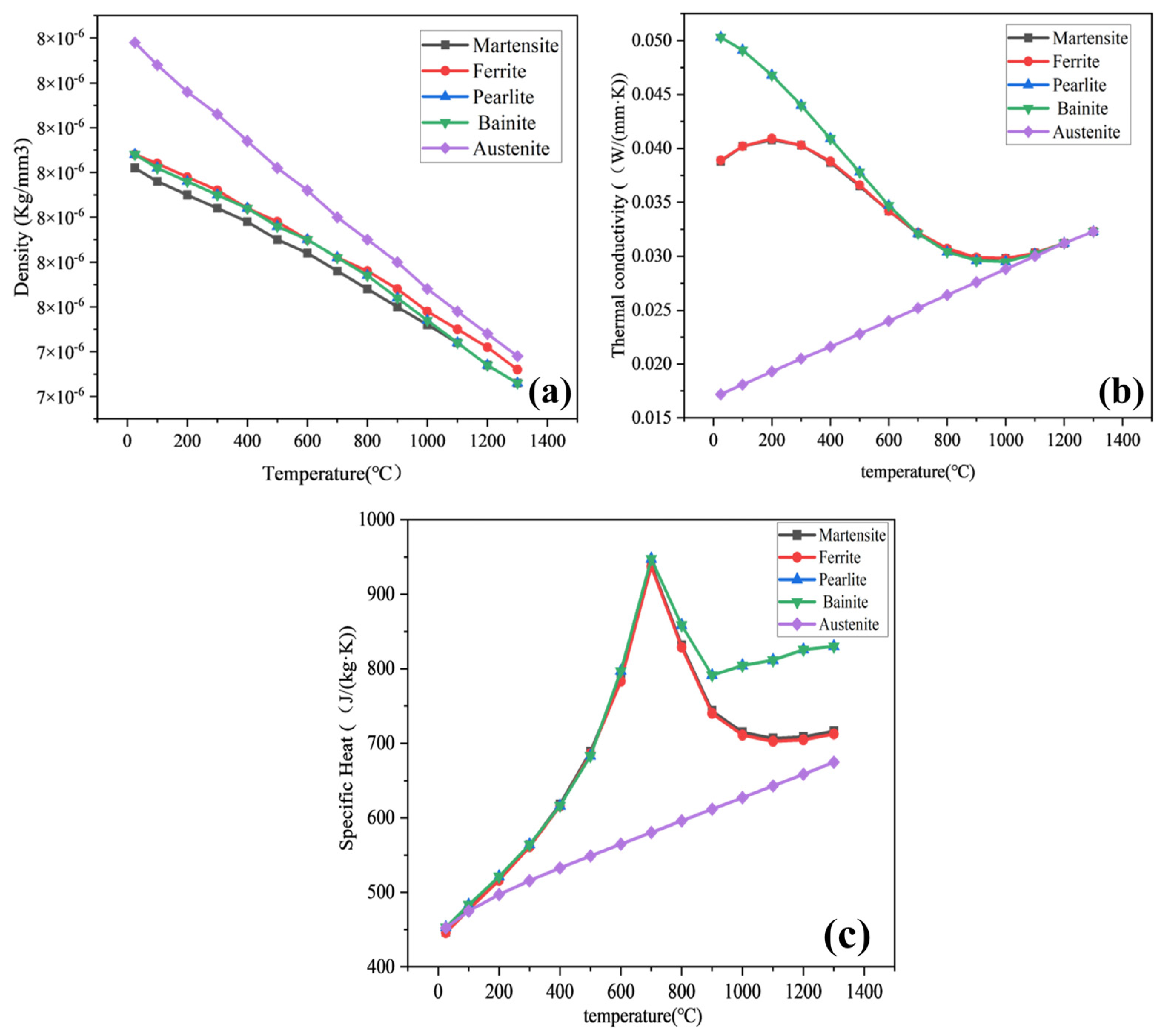

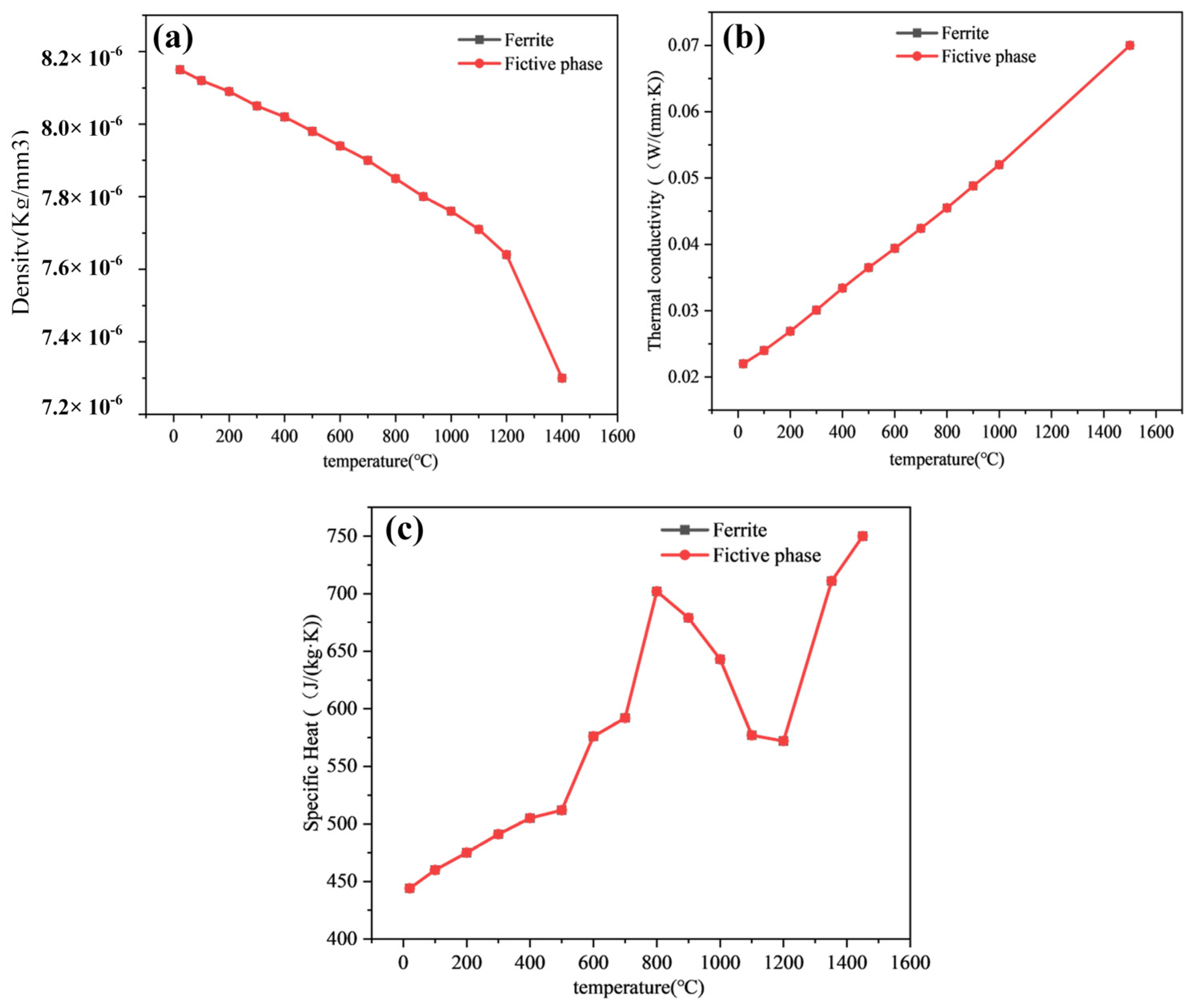

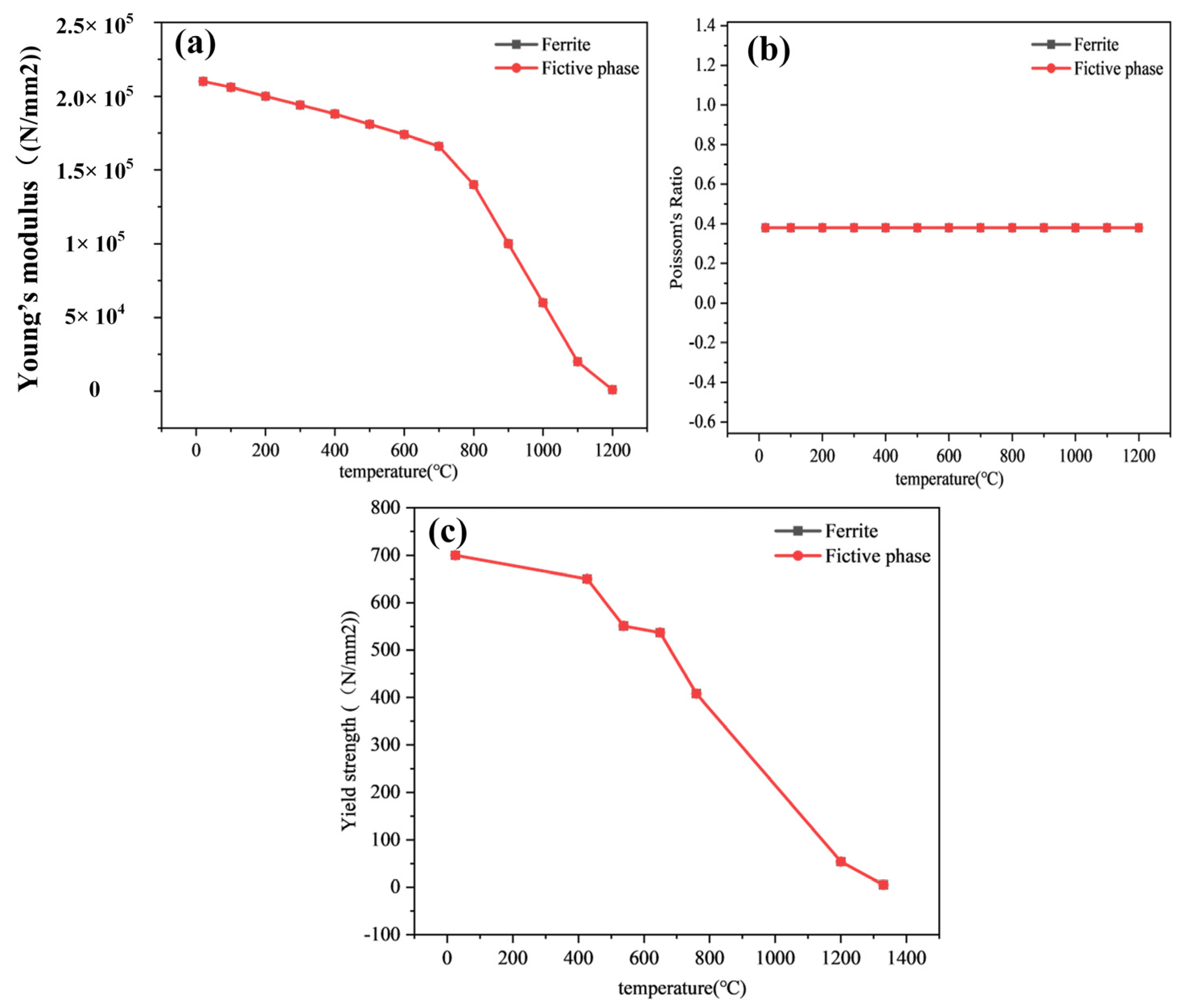

3.2.3. Definition of Material Parameters

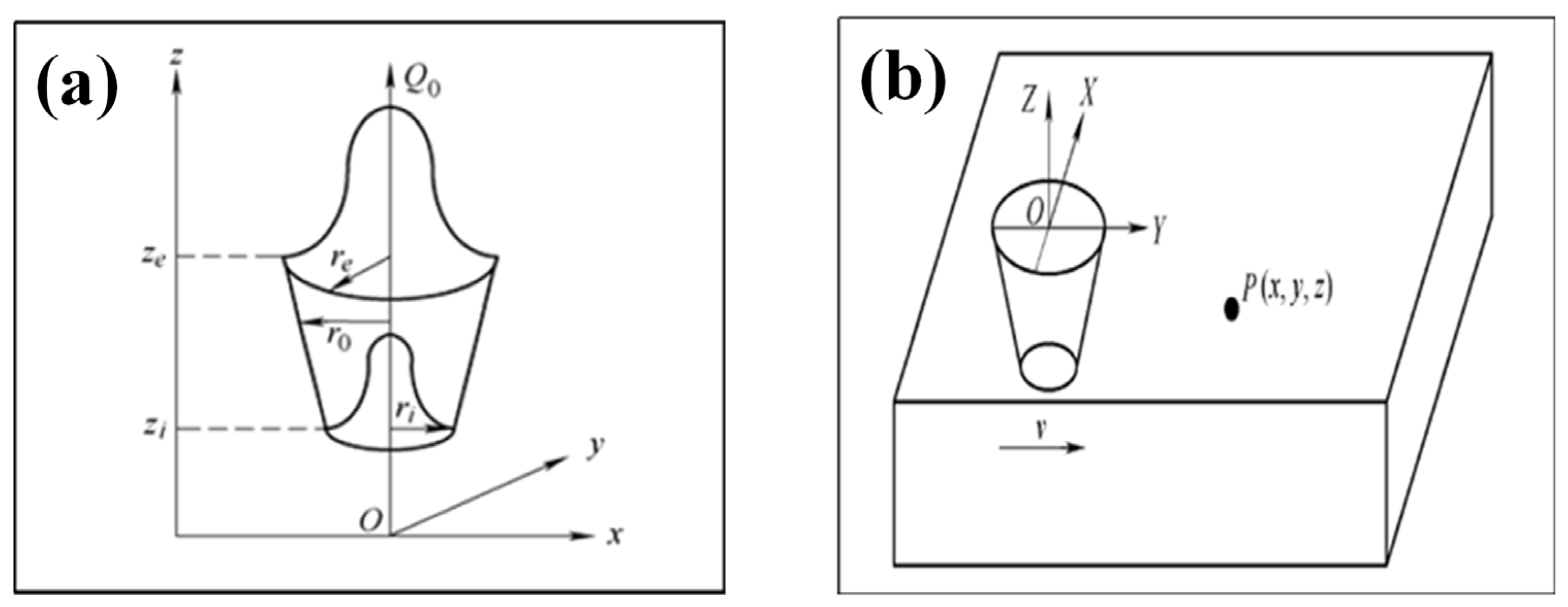

3.2.4. Definition and Characterization of Thermal Sources

3.2.5. Specification of Boundary Conditions

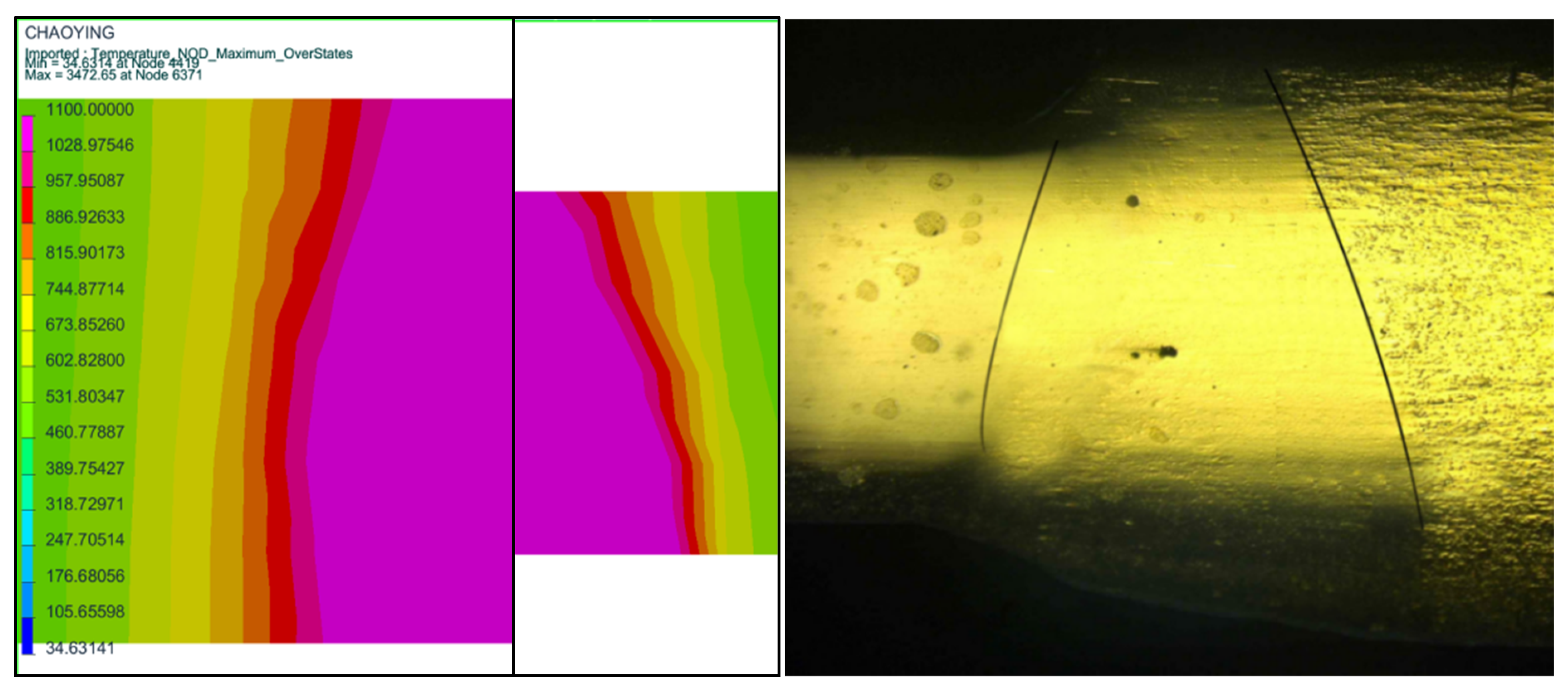

3.3. Verification of Heat Source

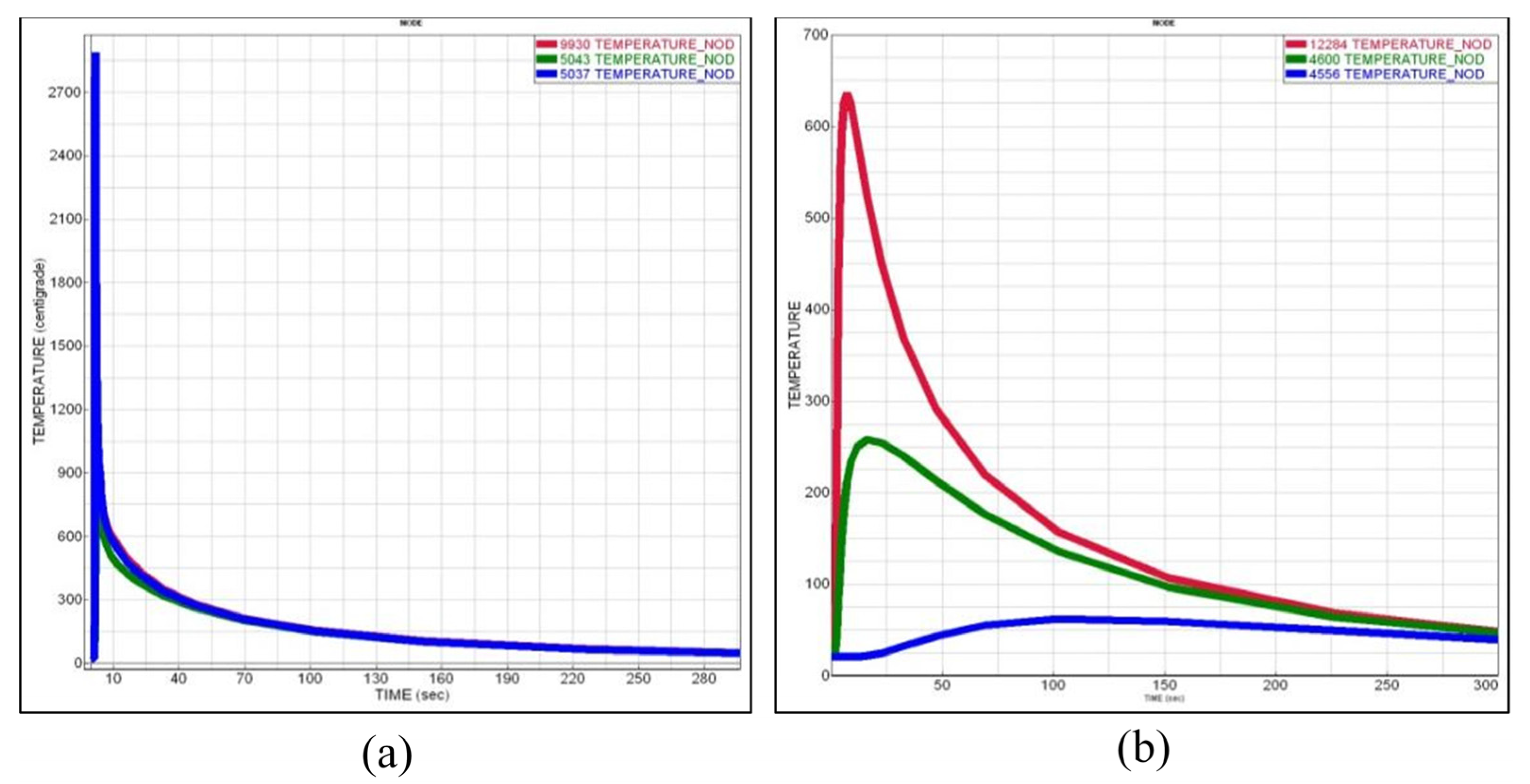

3.4. Results and Analysis of Temperature Field

3.5. Results and Analysis of Grain Calculations

3.5.1. Cross-Sectional Grain Morphology

3.5.2. Deviation in Grain Orientation

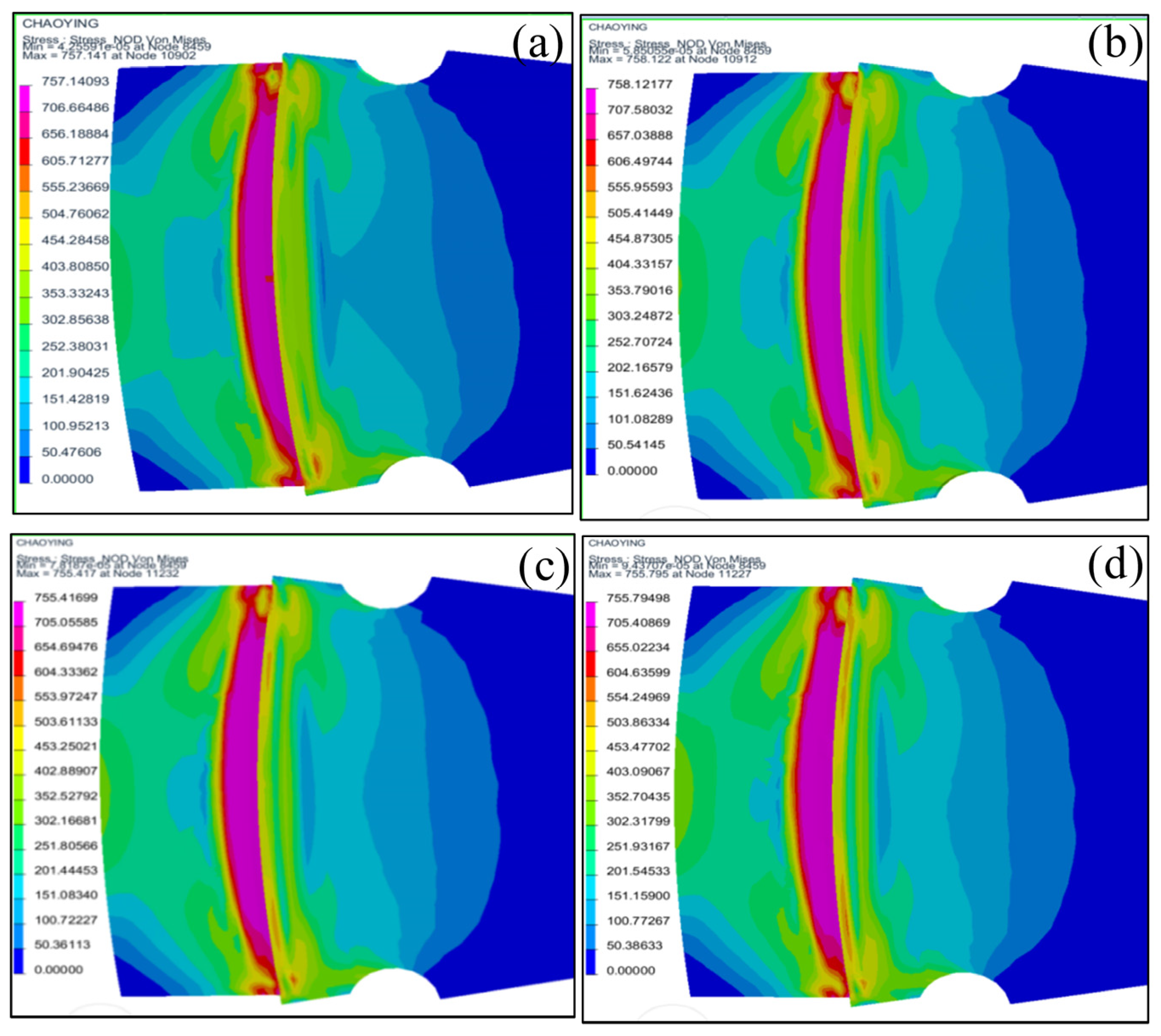

3.6. Results and Analysis of Stress Field Calculation

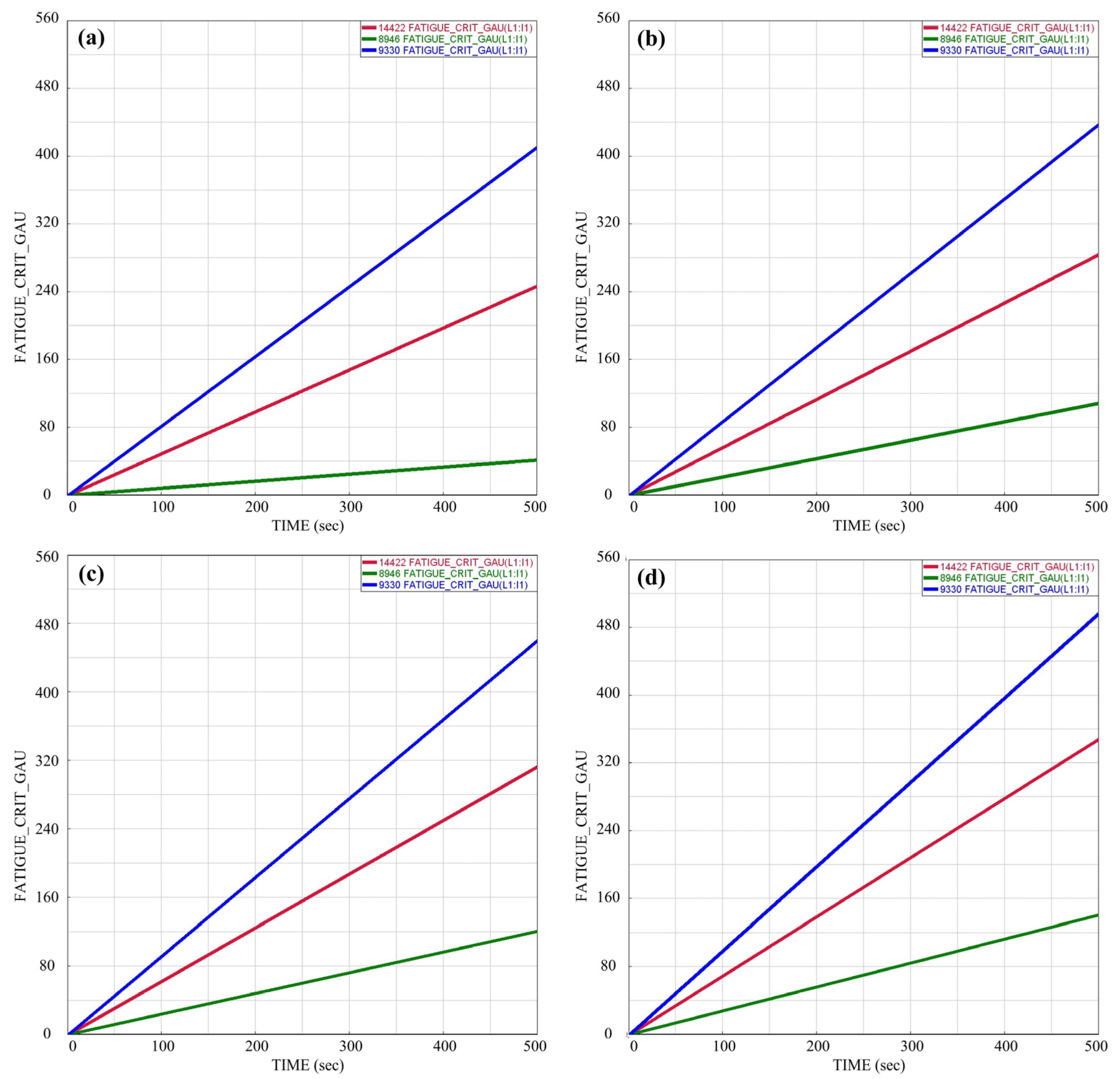

3.7. Calculation Results and Analysis of Fatigue

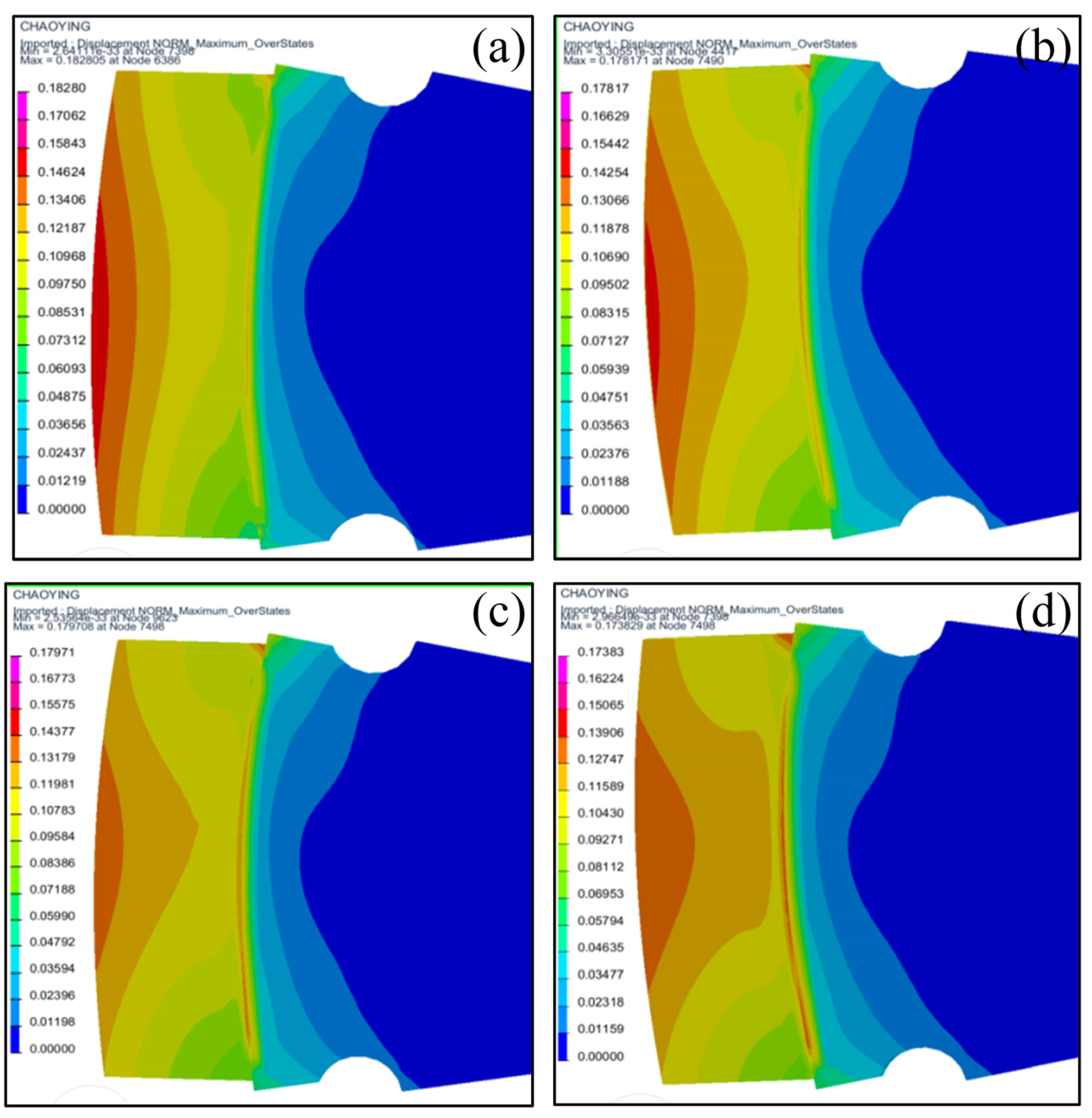

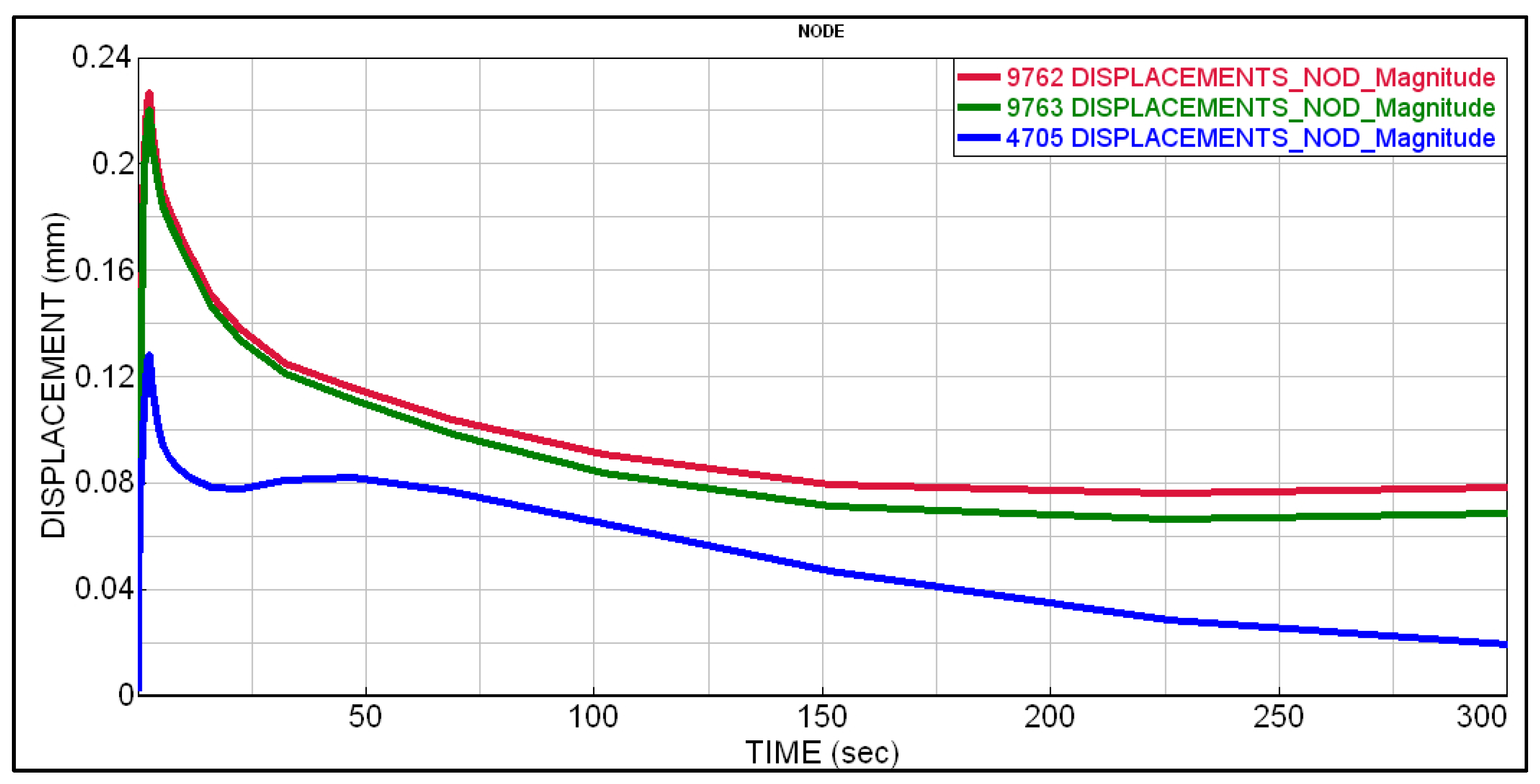

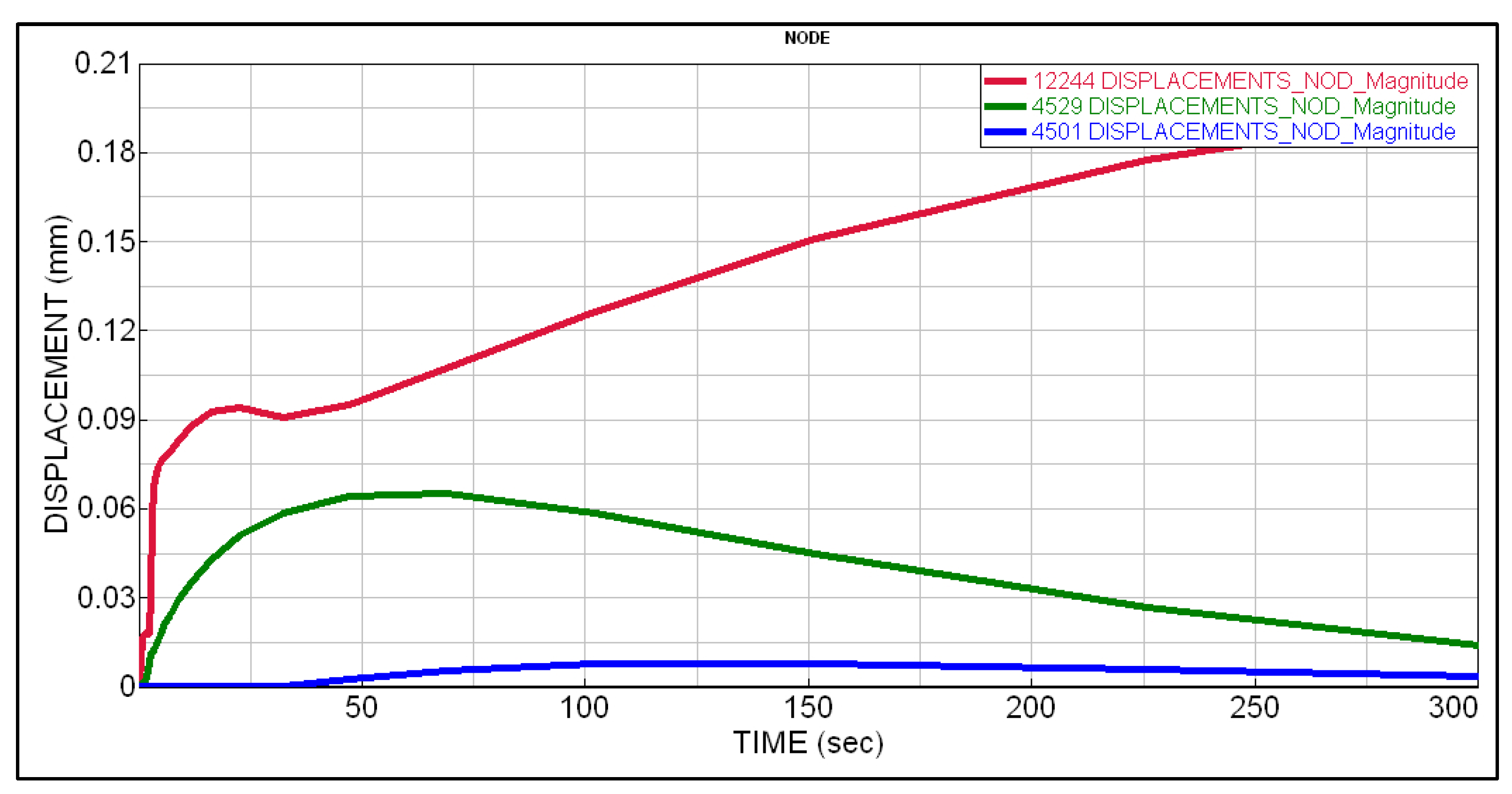

3.8. Calculation Results and Analysis of Deformation

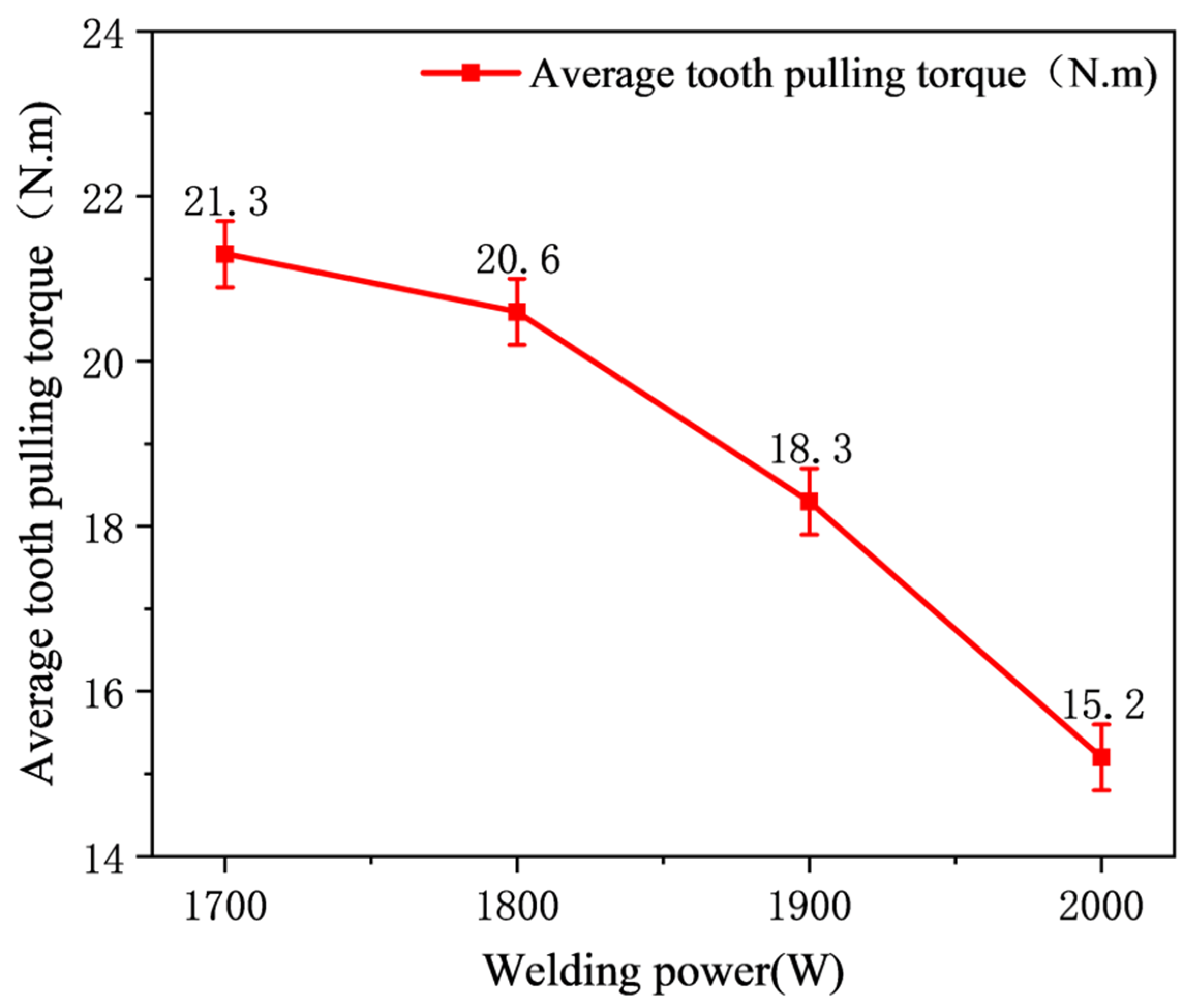

3.9. Comparison between Simulated and Measured Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tao, P.; Zhang, X.; Mi, G.; Wang, C. Research on fiber laser welding formation, microstructure, and mechanical properties of 7.5 mm 304 stainless steel. J. Mater. Res. Technol. 2023, 24, 236–249. [Google Scholar] [CrossRef]

- Liu, Z.; Jin, X.; Li, J.; Hao, Z.; Zhang, J. Numerical simulation and experimental analysis on the deformation and residual stress in trailing ultrasonic vibration assisted laser welding. Adv. Eng. Softw. 2022, 172, 103200. [Google Scholar] [CrossRef]

- Rominiyi, A.L.; Mashinini, P.M. Continuous wave laser welding of Ti6Al4V alloy joints: Microstructure and mechanical properties. Mater. Lett. 2023, 336, 133934. [Google Scholar] [CrossRef]

- Ma, X.; Wang, L.; Zhu, Z.; Su, L.; Guo, W.; Mi, G.; Xu, T. Planetary laser welding system induced equiaxed and refined grains in 2A12 aluminum alloy weldments. Opt. Laser Technol. 2023, 161, 109162. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, Z.; Wang, H.; Gui, Y.; Huang, X.; Li, Y.; Tan, Y. Influence of laser welding defocus and penetration monitoring based on advanced optical sensors. Optik 2023, 280, 170811. [Google Scholar] [CrossRef]

- Ghosh, P.S.; Sen, A.; Chattopadhyaya, S.; Sharma, S.; Singh, J.; Li, C.; Krolczyk, G.; Rajkumar, S. Progressive developments and challenges in dissimilar laser welding of steel to various other light alloys (Al/Ti/Mg): A comprehensive review. Heliyon 2022, 8, e11710. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, S.; Jiang, M.; Chen, Y.; Jiang, Y.; Wang, Z.; Jiang, N.; Chen, A.; Li, B.; Lei, Z.; et al. Microstructure and mechanical properties of laser welded hot-press-formed steel with varying thicknesses of Al–Si coatings cleaned by nanosecond pulsed laser. J. Mater. Res. Technol. 2023, 22, 2576–2588. [Google Scholar] [CrossRef]

- Kumar Goyal, D.; Yadav, R.; Kant, R. Laser transmission welding of polycarbonate sheets using electrolytic iron powder absorber. Opt. Laser Technol. 2023, 161, 109165. [Google Scholar] [CrossRef]

- Hao, K.; Gao, Z.; Huang, J.; Xu, L.; Liu, Y.; Han, Y.; Zhao, L.; Ren, W. Comparisons of laser and laser-arc hybrid welded carbon steel with beam oscillation. Opt. Laser Technol. 2023, 157, 108787. [Google Scholar] [CrossRef]

- Zubairuddin, M.; Ravi kumar, R.; Chaursaia, P.K.; Ali, B. Thermo-mechanical analysis of laser welding of Grade 91 steel plates. Optik 2021, 245, 167510. [Google Scholar] [CrossRef]

- Ramos, H.M.E.; Tavares, S.M.O.; de Castro, P.M.S.T. Numerical modelling of welded T-joint configurations using SYSWELD. Sci. Technol. Mater. 2018, 30, 6–15. [Google Scholar] [CrossRef]

- Lu, W.-L.; Sun, J.-L.; Su, H.; Chen, L.-J.; Zhou, Y.-Z. Experimental research and numerical analysis of welding residual stress of butt welded joint of thick steel plate. Case Stud. Constr. Mater. 2023, 18, e01991. [Google Scholar] [CrossRef]

- Hong, M.; Wang, S.; Sun, W.; Geng, Z.; Xin, J.; Ke, L. Effect of welding speed on microstructure and mechanical properties of selective laser melting Inconel 625 alloy laser welded joint. J. Mater. Res. Technol. 2022, 19, 2093–2103. [Google Scholar] [CrossRef]

- Heinze, C.; Schwenk, C.; Rethmeier, M. Effect of heat source configuration on the result quality of numerical calculation of welding-induced distortion. Simul. Model. Pract. Theory 2012, 20, 112–123. [Google Scholar] [CrossRef]

- Heinze, C.; Schwenk, C.; Rethmeier, M. Influences of mesh density and transformation behavior on the result quality of numerical calculation of welding induced distortion. Simul. Model. Pract. Theory 2011, 19, 1847–1859. [Google Scholar] [CrossRef]

- Chen, L.; Mi, G.; Zhang, X.; Wang, C. Numerical and experimental investigation on microstructure and residual stress of multi-pass hybrid laser-arc welded 316L steel. Mater. Des. 2019, 168, 107653. [Google Scholar] [CrossRef]

- Du, Z.; Sun, X.; Ng, F.L.; Chew, Y.; Tan, C.; Bi, G. Thermo-metallurgical simulation and performance evaluation of hybrid laser arc welding of chromium-molybdenum steel. Mater. Des. 2021, 210, 110029. [Google Scholar] [CrossRef]

- Zubairuddin, M.; Albert, S.K.; Reddy, M.S.; Ali, B.; Varaprasad, B.; Mishra, A.; Das, P.K.; Elumalai, P.V. Thermal analysis of thin P91 steel using FlexPDE and SYSWELD. Mater. Today Process. 2023, 72, 1550–1555. [Google Scholar] [CrossRef]

- Sun, J.; Dilger, K. Material hardening model effects on the calculated welding residual stresses in ultra-high strength steel S960. J. Mater. Res. Technol. 2023, 24, 557–570. [Google Scholar] [CrossRef]

- Zubairuddin, M.; Albert, S.K.; Vasudevan, M.; Mahadevan, S.; Chaudhari, V.; Suri, V.K. Numerical simulation of multi-pass GTA welding of grade 91 steel. J. Manuf. Process. 2017, 27, 87–97. [Google Scholar] [CrossRef]

- Zhang, W.; Fu, H.; Fan, J.; Li, R.; Xu, H.; Liu, F.; Qi, B. Influence of multi-beam preheating temperature and stress on the buckling distortion in electron beam welding. Mater. Des. 2018, 139, 439–446. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Han, T.; Bao, L.; Wu, Q.; Gu, S. Numerical and experimental investigation of the formation mechanism and the distribution of the welding residual stress induced by the hybrid laser arc welding of AH36 steel in a butt joint configuration. J. Manuf. Process. 2020, 51, 95–108. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, J.; Li, Y.; Deng, D. Numerical simulation of residual stress of butt-welded joint involved in complex column-beam welded structure. J. Manuf. Process. 2022, 83, 458–470. [Google Scholar] [CrossRef]

- Zhan, H.-X.; Wang, Y.; Li, C.-W.; Han, T.; Han, B.; Zhao, W.-M. Computational and experimental study of a melt-hardened zone on a roller modified by wide-band laser treatment. Opt. Laser Technol. 2009, 41, 251–257. [Google Scholar] [CrossRef]

- Zain-ul-Abdein, M.; Nelias, D.; Jullien, J.-F.; Deloison, D. Prediction of laser beam welding-induced distortions and residual stresses by numerical simulation for aeronautic application. J. Mater. Process. Technol. 2009, 209, 2907–2917. [Google Scholar] [CrossRef]

- Zain-ul-abdein, M.; Nélias, D.; Jullien, J.-F.; Boitout, F.; Dischert, L.; Noe, X. Finite element analysis of metallurgical phase transformations in AA 6056-T4 and their effects upon the residual stress and distortion states of a laser welded T-joint. Int. J. Press. Vessel. Pip. 2011, 88, 45–56. [Google Scholar] [CrossRef]

- Yuan, K.; Sumi, Y. Simulation of residual stress and fatigue strength of welded joints under the effects of ultrasonic impact treatment (UIT). Int. J. Fatigue 2016, 92, 321–332. [Google Scholar] [CrossRef]

- Yeo, H.; Son, M.; Ki, H. Investigation of microstructure and residual stress development during laser surface melting of AH36 steel using 3-D fully coupled numerical model. Int. J. Heat Mass Transf. 2022, 197, 123366. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, W.; Zhang, J.; Xu, L. Effect of fire exposure on residual stresses relief in welded high strength Q690 steel sections. J. Constr. Steel Res. 2021, 177, 106455. [Google Scholar] [CrossRef]

- Yaakoubi, M.; Kchaou, M.; Dammak, F. Simulation of the thermomechanical and metallurgical behavior of steels by using ABAQUS software. Comput. Mater. Sci. 2013, 68, 297–306. [Google Scholar] [CrossRef]

- Xu, J.J.; Gilles, P.; Duan, Y.G.; Yu, C. Temperature and residual stress simulations of the NeT single-bead-on-plate specimen using SYSWELD. Int. J. Press. Vessel. Pip. 2012, 99–100, 51–60. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, J.; Long, J. Numerical study on molten pool dynamics and solute distribution in laser deep penetration welding of steel and aluminum. Opt. Laser Technol. 2021, 140, 107085. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Di, X.; Shi, Y.; Bao, X.; Gao, X. Simulation and analysis of temperature field for in-service multi-pass welding of a sleeve fillet weld. Comput. Mater. Sci. 2013, 68, 198–205. [Google Scholar] [CrossRef]

| Saw Blade Outer Diameter /mm | Mesopore /mm | Number of Teeth /mm | Tooth Length /mm | Depth of Tooth /mm | Tooth Thickness /mm | Matrix Thickness /mm |

|---|---|---|---|---|---|---|

| 230 | 25.4 | 18 | 32 | 10 | 3.0 | 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Q.; Cao, X.; Liu, Y.; Xu, Y.; Wu, J. Numerical Simulation of the Laser Welding Process for Diamond Saw Blades. Photonics 2024, 11, 676. https://doi.org/10.3390/photonics11070676

Xu Q, Cao X, Liu Y, Xu Y, Wu J. Numerical Simulation of the Laser Welding Process for Diamond Saw Blades. Photonics. 2024; 11(7):676. https://doi.org/10.3390/photonics11070676

Chicago/Turabian StyleXu, Qiang, Xiaodie Cao, Yibo Liu, Yanjun Xu, and Jiajun Wu. 2024. "Numerical Simulation of the Laser Welding Process for Diamond Saw Blades" Photonics 11, no. 7: 676. https://doi.org/10.3390/photonics11070676

APA StyleXu, Q., Cao, X., Liu, Y., Xu, Y., & Wu, J. (2024). Numerical Simulation of the Laser Welding Process for Diamond Saw Blades. Photonics, 11(7), 676. https://doi.org/10.3390/photonics11070676