Diamond-Based Fiber-Optic Fabry–Perot Interferometer with Ultrawide Refractive-Index Measurement Range

Abstract

1. Introduction

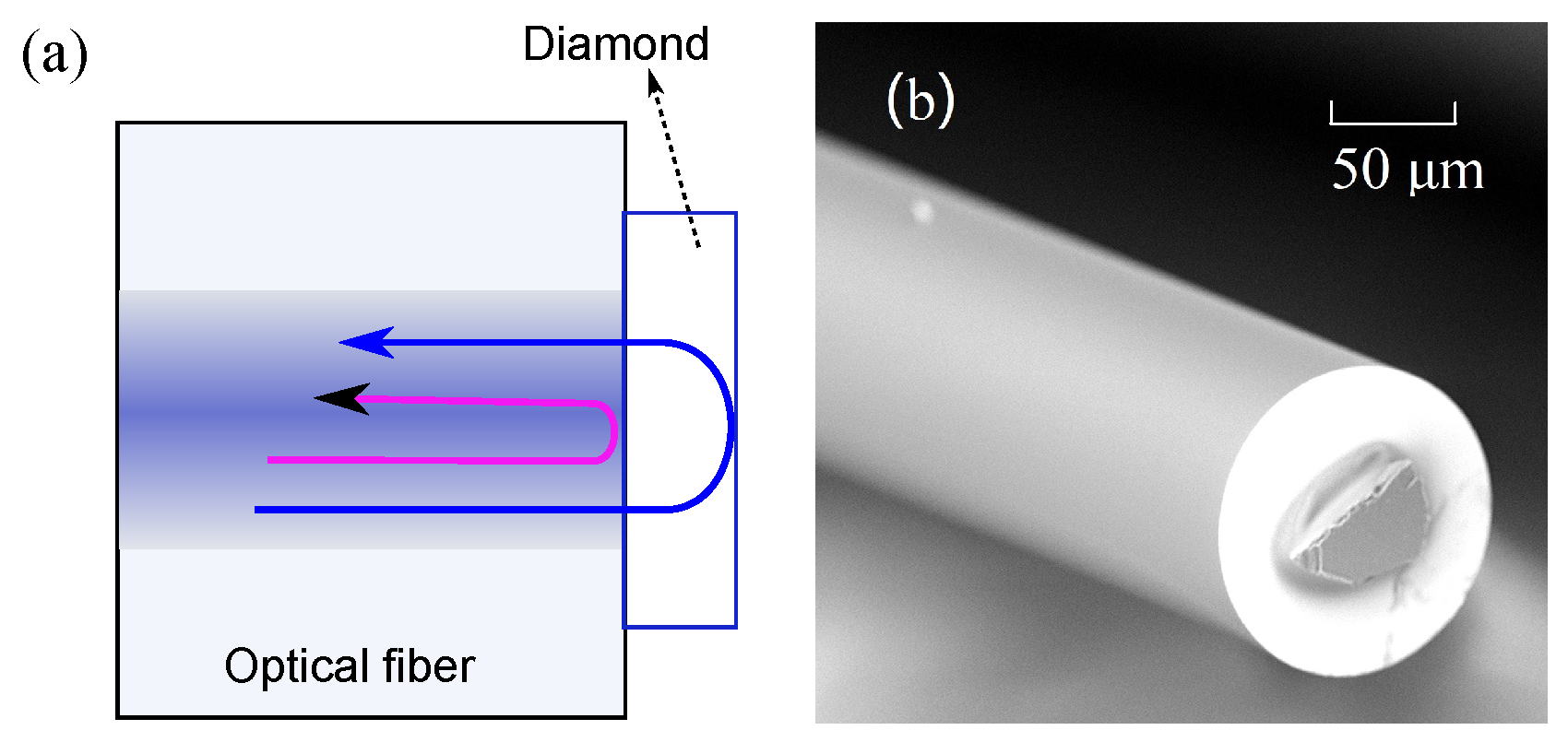

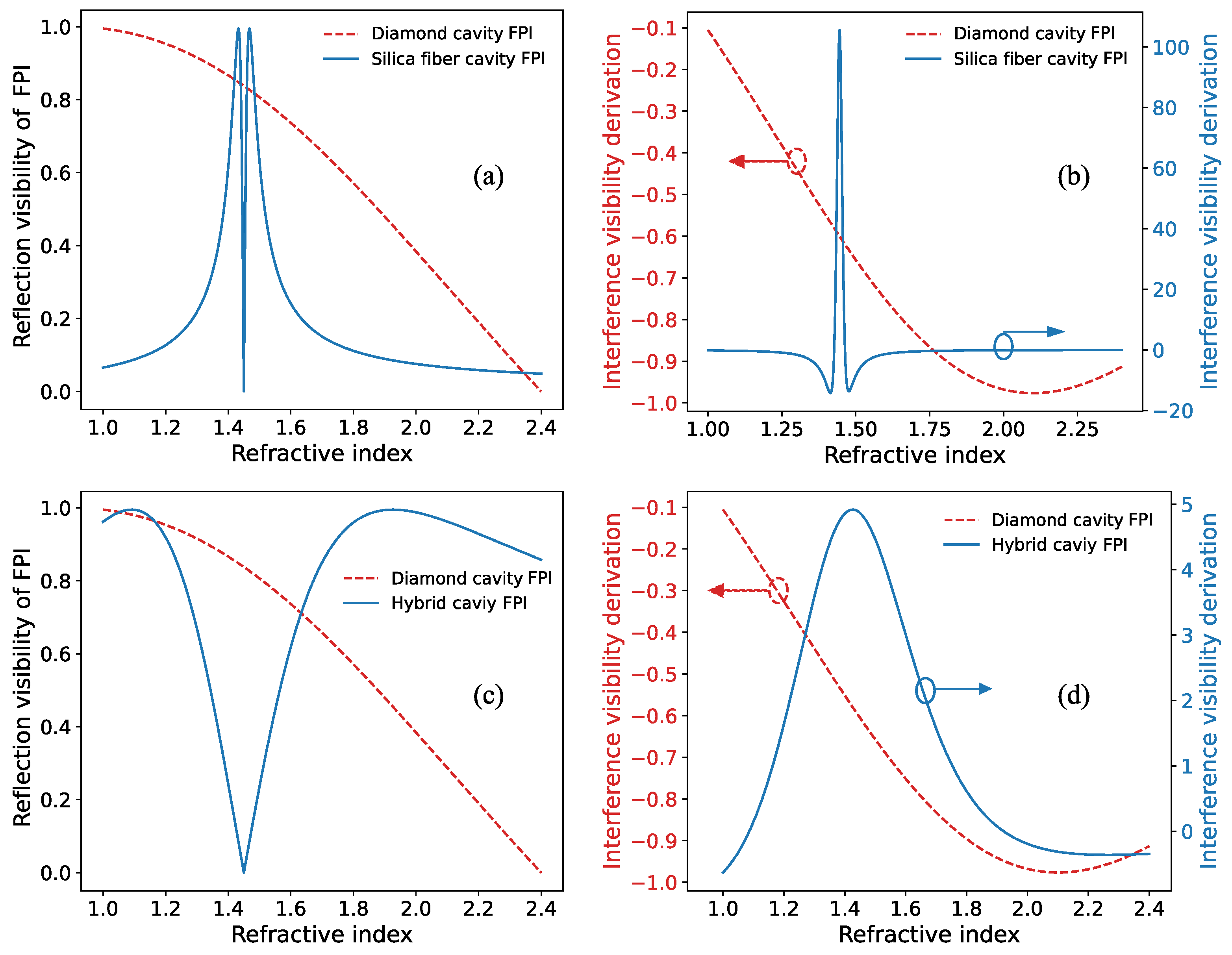

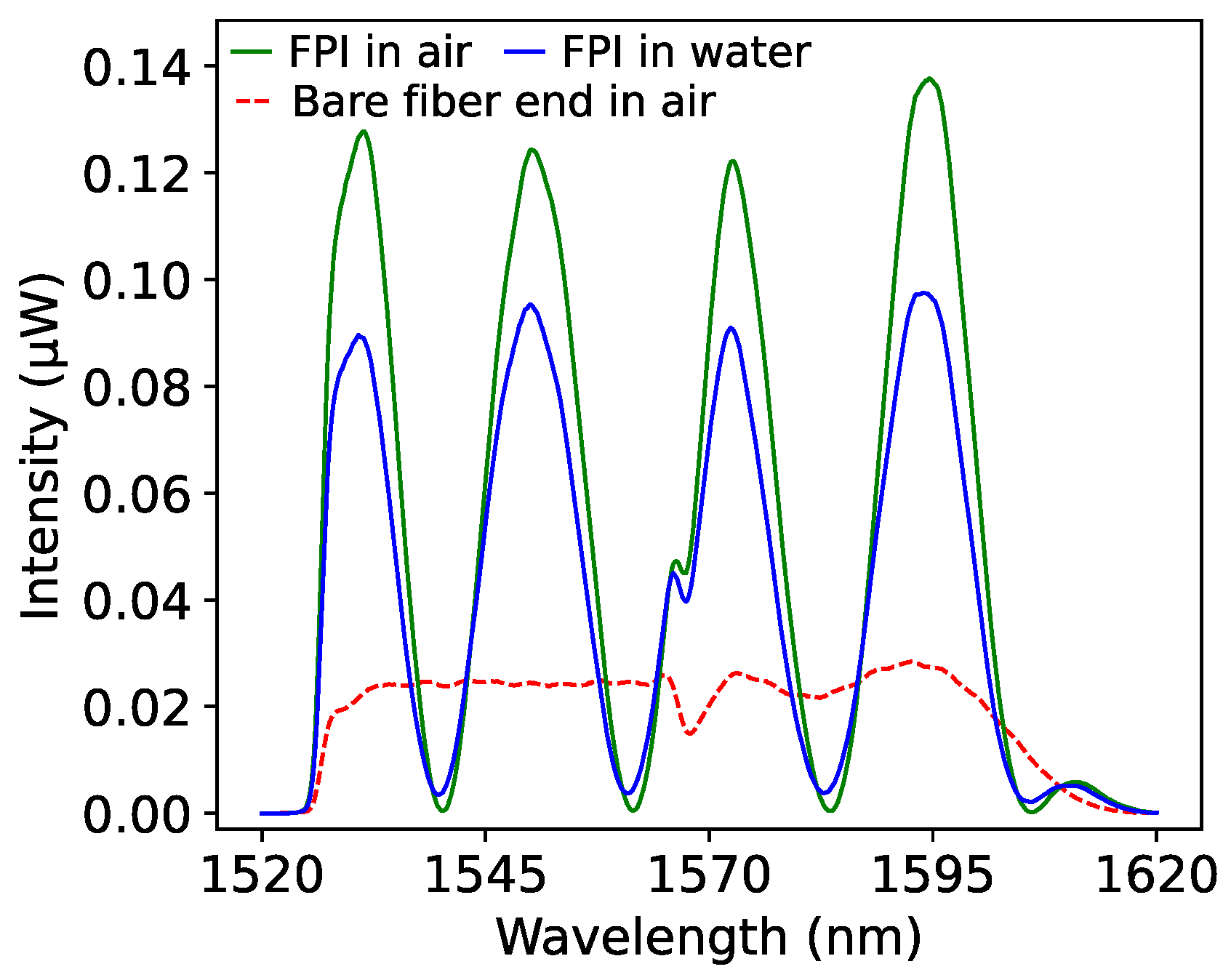

2. Sensor Fabrication and Principles

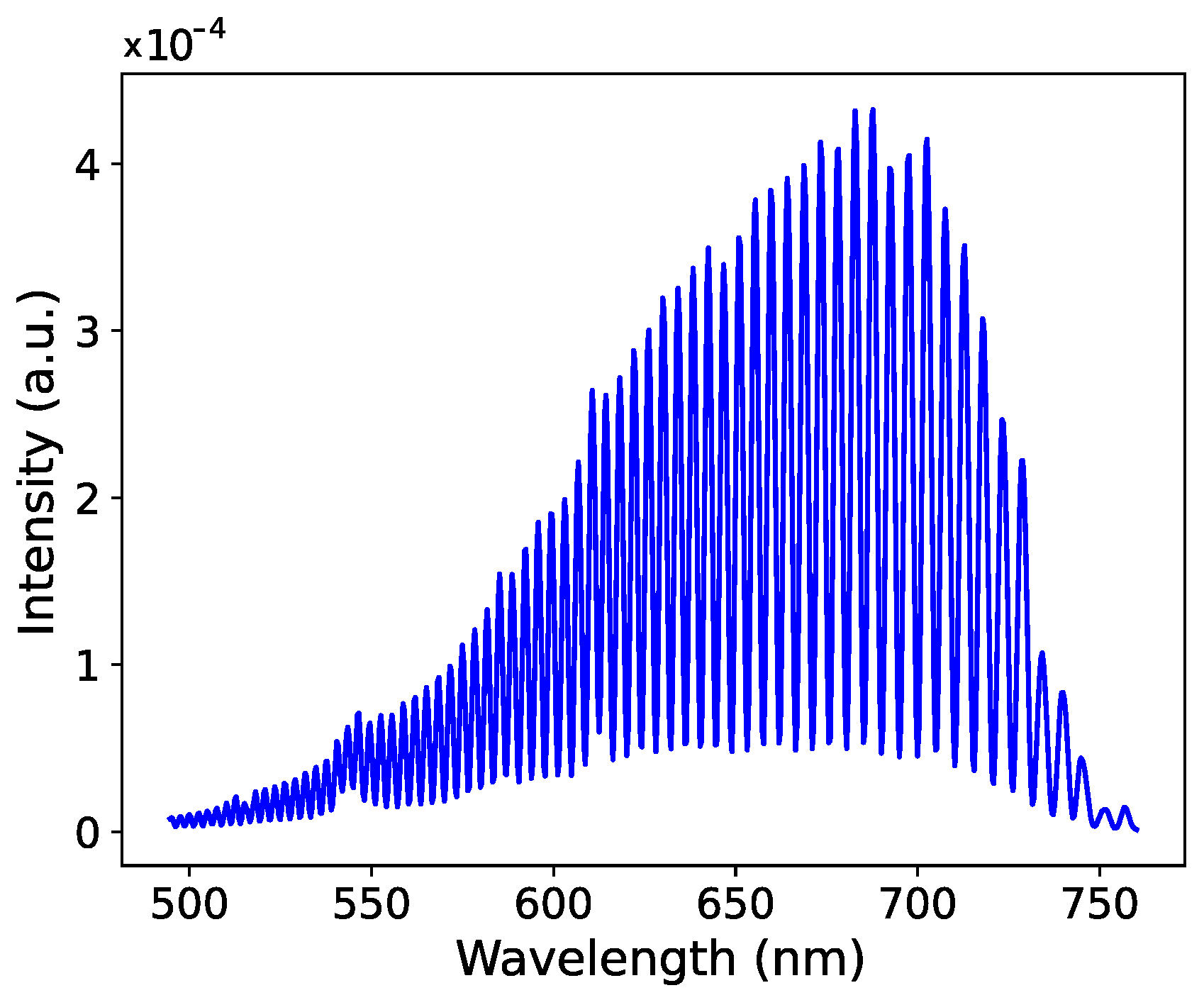

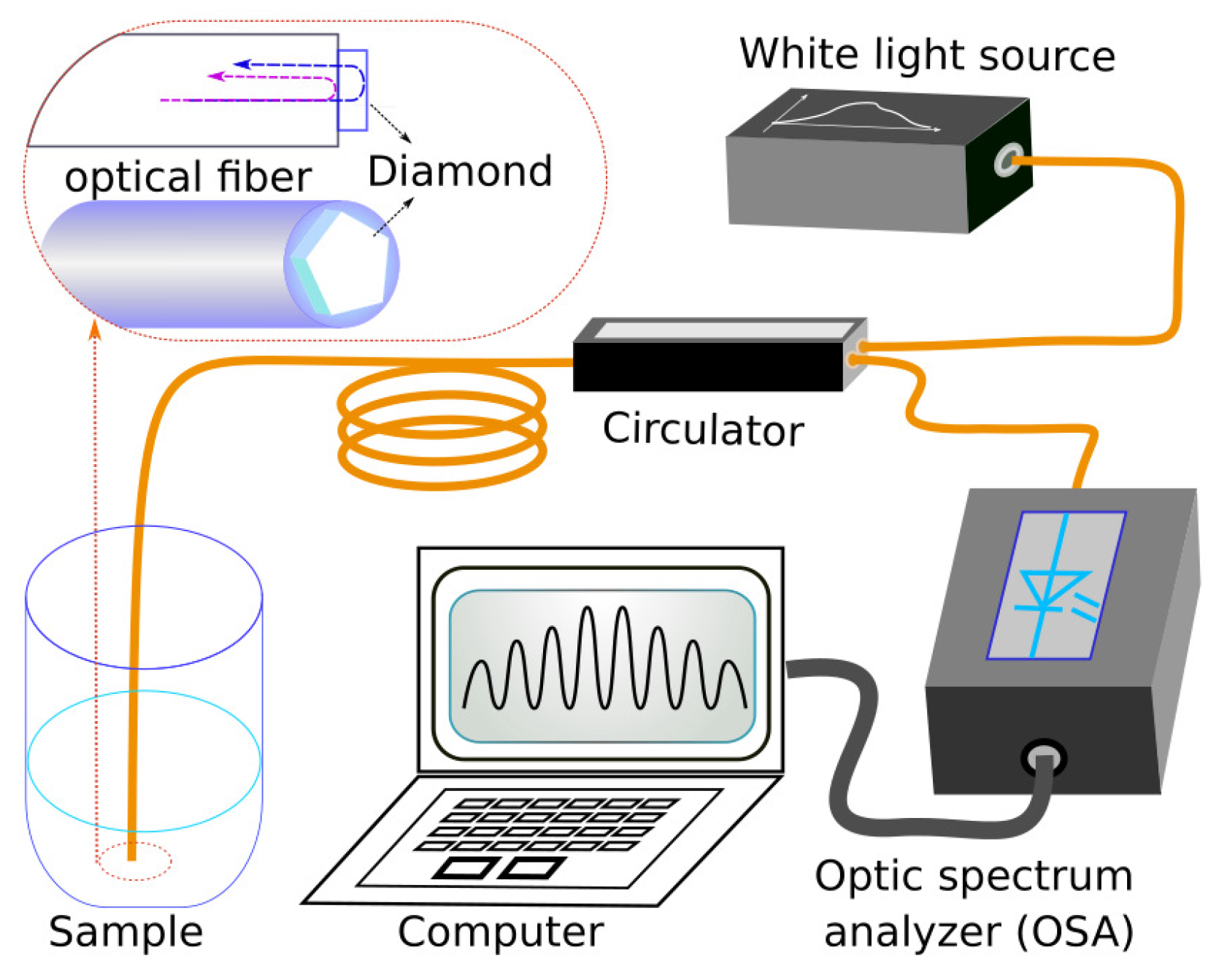

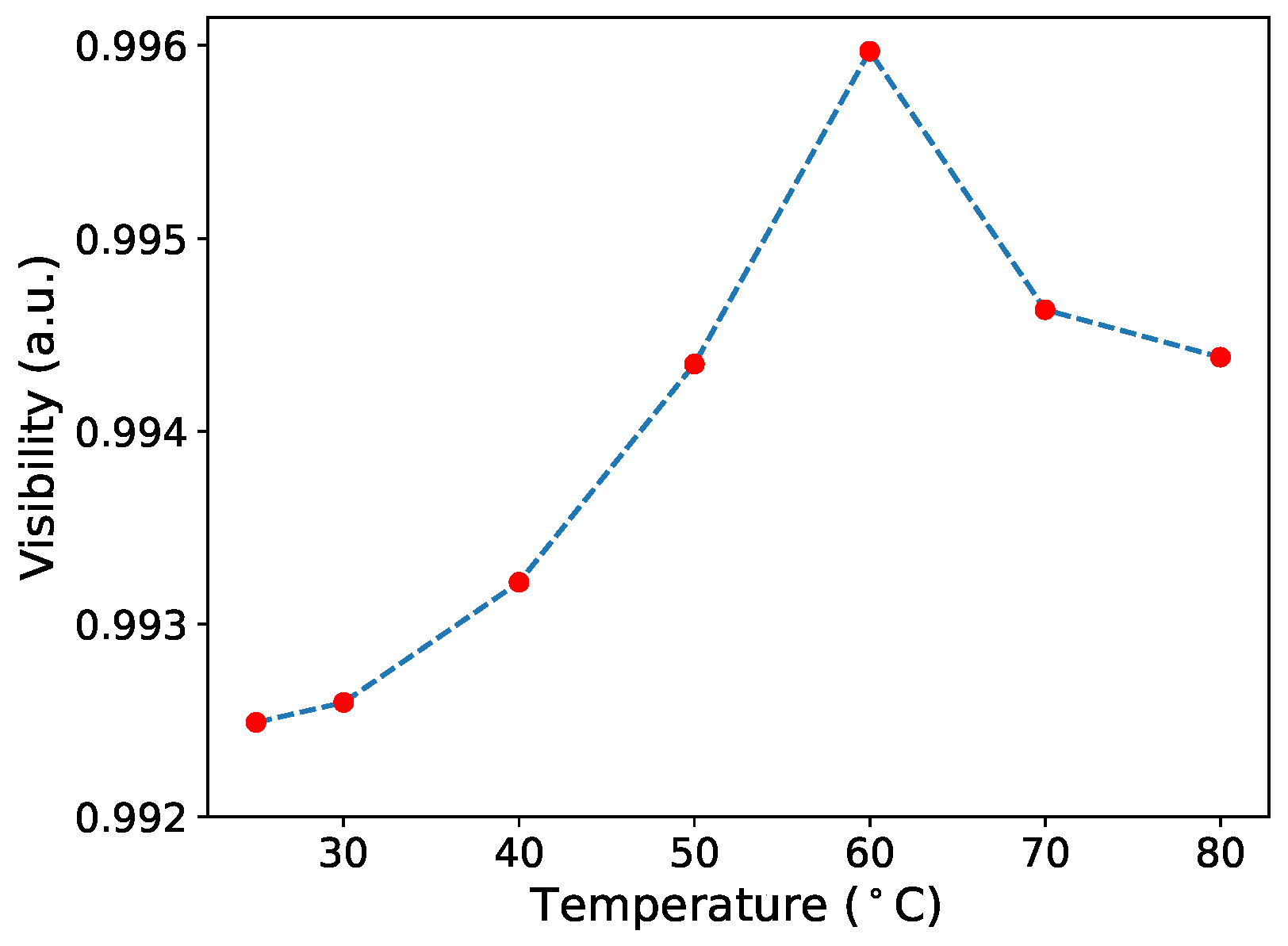

3. Experiment and Results

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aydin, D.; Barnes, J.A.; Loock, H.P. In-fiber interferometry sensors for refractive index. Appl. Phys. Rev. 2023, 10, 011307. [Google Scholar] [CrossRef]

- Xu, Y.; Bai, P.; Zhou, X.; Akimov, Y.; Png, C.E.; Ang, L.K.; Knoll, W.; Wu, L. Optical Refractive Index Sensors with Plasmonic and Photonic Structures: Promising and Inconvenient Truth. Adv. Opt. Mater. 2019, 7, 1801433. [Google Scholar] [CrossRef]

- Li, X.; Shao, Y.; Yu, Y.; Zhang, Y.; Wei, S. A Highly Sensitive Fiber-Optic Fabry–Perot Interferometer Based on Internal Reflection Mirrors for Refractive Index Measurement. Sensors 2016, 16, 794. [Google Scholar] [CrossRef]

- Lee, C.L.; Weng, Z.Y.; Lin, C.J.; Lin, Y. Leakage coupling of ultrasensitive periodical silica thin-film long-period grating coated on tapered fiber. Opt. Lett. 2010, 35, 4172–4174. [Google Scholar] [CrossRef] [PubMed]

- Gomes, A.D.; Silveira, B.; Warren-Smith, S.C.; Becker, M.; Rothhardt, M.; Frazão, O. Temperature independent refractive index measurement using a fiber Bragg grating on abrupt tapered tip. Opt. Laser Technol. 2018, 101, 227–231. [Google Scholar] [CrossRef]

- Yang, M.; Dai, J.; Li, X.; Wang, J. Side-polished fiber Bragg grating refractive index sensor with TbFeCo magnetoptic thin film. J. Appl. Phys. 2010, 108, 033102. [Google Scholar] [CrossRef]

- Guo, J.; Sun, M.; Fang, J.; Wei, G.; Shi, B.; Jiang, H. High-Sensitivity Seawater Salinity Sensing With Cladding Etched Fiber Bragg Grating Technology. IEEE Sens. J. 2023, 23, 14182–14192. [Google Scholar] [CrossRef]

- Duan, D.; Rao, Y.J.; Zhu, T. High sensitivity gas refractometer based on all-fiber open-cavity Fabry–Perot interferometer formed by large lateral offset splicing. J. Opt. Soc. Am. B 2012, 29, 912–915. [Google Scholar] [CrossRef]

- Wu, C.; Liu, Z.; Zhang, A.P.; Guan, B.O.; Tam, H.Y. In-line open-cavity Fabry–Pérot interferometer formed by C-shaped fiber for temperature-insensitive refractive index sensing. Opt. Express 2014, 22, 21757–21766. [Google Scholar] [CrossRef]

- Zhang, Q.; Hao, P.; Tian, X.; Li, Y. High-visibility in-line fiber-optic optofluidic Fabry–Pérot cavity. Appl. Phys. Lett. 2017, 111, 191102. [Google Scholar] [CrossRef]

- Duan, D.; Rao, Y.J.; Xu, L.C.; Zhu, T.; Wu, D.; Yao, J. In-fiber Mach–Zehnder interferometer formed by large lateral offset fusion splicing for gases refractive index measurement with high sensitivity. Sens. Actuators B Chem. 2011, 160, 1198–1202. [Google Scholar] [CrossRef]

- Rao, Y.J.; Deng, M.; Duan, D.W.; Zhu, T. In-line fiber Fabry-Perot refractive-index tip sensor based on endlessly photonic crystal fiber. Sens. Actuators A Phys. 2008, 148, 33–38. [Google Scholar] [CrossRef]

- Xu, B.; Yang, Y.; Jia, Z.; Wang, D.N. Hybrid Fabry-Perot interferometer for simultaneous liquid refractive index and temperature measurement. Opt. Express 2017, 25, 14483–14493. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhang, L.; Mourelatos, Z.P.; Wang, Z. Crystallization-sapphire-derived-fiber-based Fabry-Perot interferometer for refractive index and high-temperature measurement. Appl. Opt. 2018, 57, 9016–9021. [Google Scholar] [CrossRef] [PubMed]

- Field, J.E. The mechanical and strength properties of diamond. Rep. Prog. Phys. 2012, 75, 126505. [Google Scholar] [CrossRef] [PubMed]

- Schröder, T.; Mouradian, S.L.; Zheng, J.; Trusheim, M.E.; Walsh, M.; Chen, E.H.; Li, L.; Bayn, I.; Englund, D. Quantum nanophotonics in diamond [Invited]. J. Opt. Soc. Am. B 2016, 33, B65–B83. [Google Scholar] [CrossRef]

- Milewska, D.; Karpienko, K.; Jędrzejewska-Szczerska, M. Application of thin diamond films in low-coherence fiber-optic Fabry Pérot displacement sensor. Diamond Relat. Mater. 2016, 64, 169–176. [Google Scholar] [CrossRef]

- Majchrowicz, D.; Hirsch, M.; Wierzba, P.; Bechelany, M.; Viter, R.; Jędrzejewska-Szczerska, M. Application of Thin ZnO ALD Layers in Fiber-Optic Fabry-Pérot Sensing Interferometers. Sensors 2016, 16, 416. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, D.; Yang, J.; Tang, Y.; Xie, Y.-Y. Diamond-Based Fiber-Optic Fabry–Perot Interferometer with Ultrawide Refractive-Index Measurement Range. Photonics 2024, 11, 763. https://doi.org/10.3390/photonics11080763

Duan D, Yang J, Tang Y, Xie Y-Y. Diamond-Based Fiber-Optic Fabry–Perot Interferometer with Ultrawide Refractive-Index Measurement Range. Photonics. 2024; 11(8):763. https://doi.org/10.3390/photonics11080763

Chicago/Turabian StyleDuan, Dewen, Jianhao Yang, Yi Tang, and Yi-Yuan Xie. 2024. "Diamond-Based Fiber-Optic Fabry–Perot Interferometer with Ultrawide Refractive-Index Measurement Range" Photonics 11, no. 8: 763. https://doi.org/10.3390/photonics11080763

APA StyleDuan, D., Yang, J., Tang, Y., & Xie, Y.-Y. (2024). Diamond-Based Fiber-Optic Fabry–Perot Interferometer with Ultrawide Refractive-Index Measurement Range. Photonics, 11(8), 763. https://doi.org/10.3390/photonics11080763