The Influence of Heat Treatment and Laser Alternative Surface Treatment Methods of Non-Alloy Steels: Review

Abstract

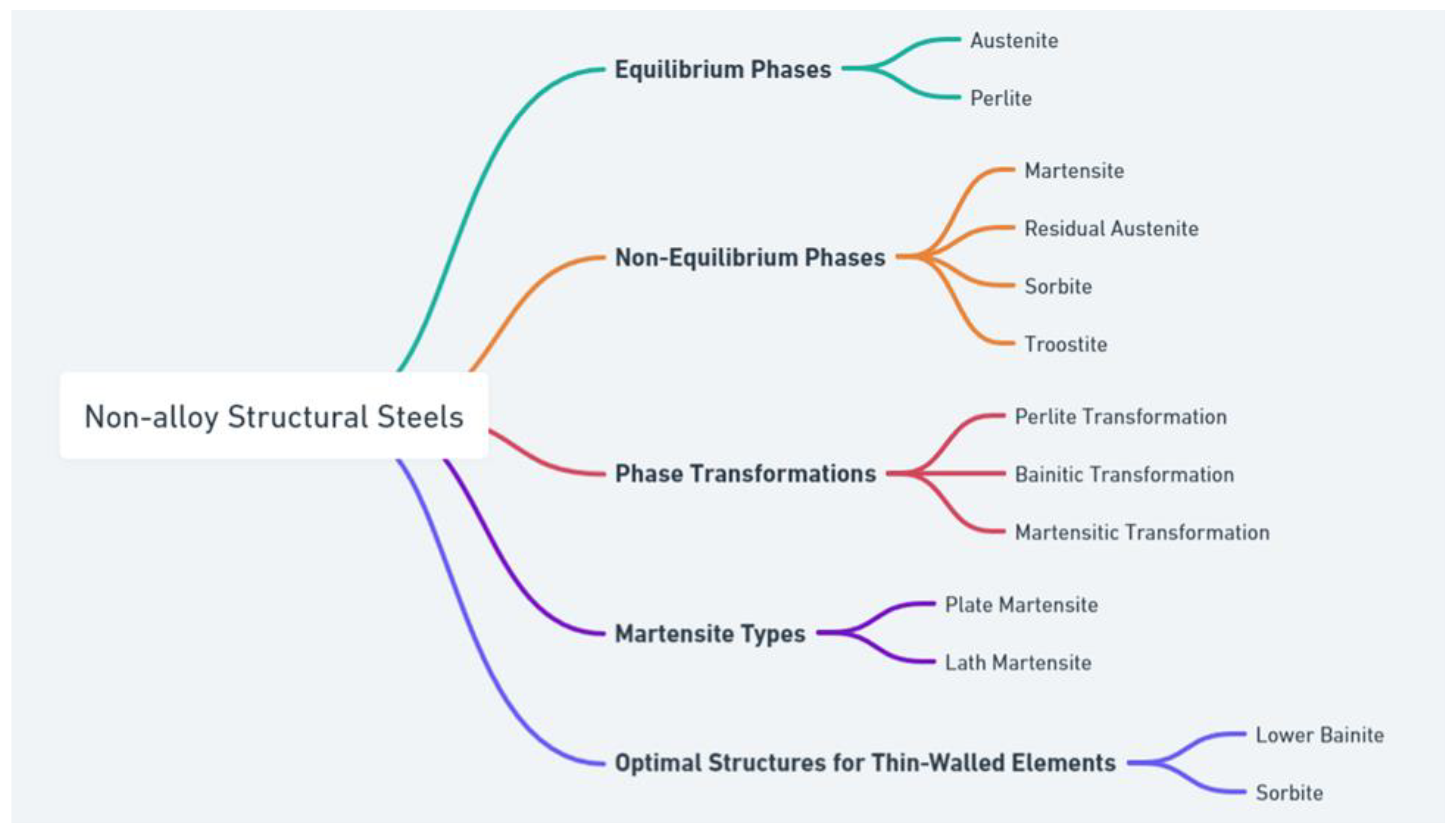

1. Introduction

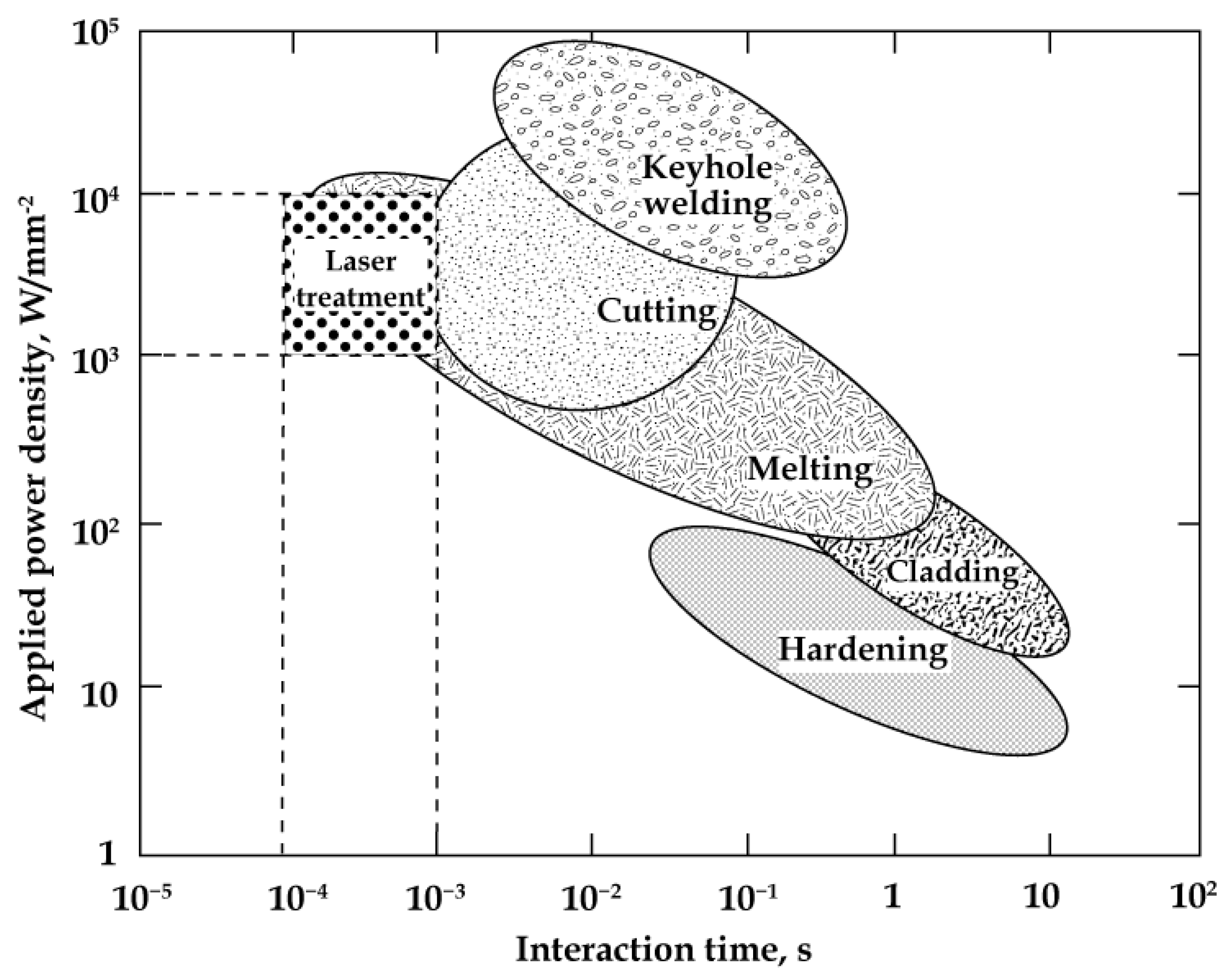

2. Overview Effect of Heat Treatment on the Properties of LCS

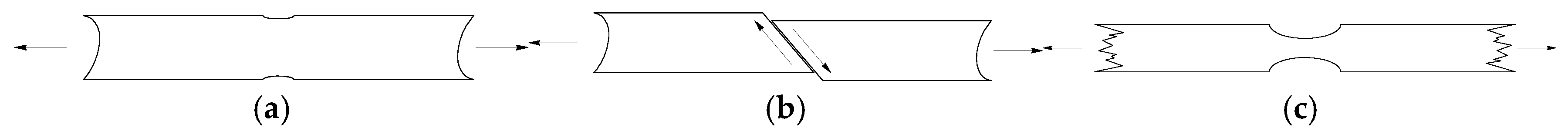

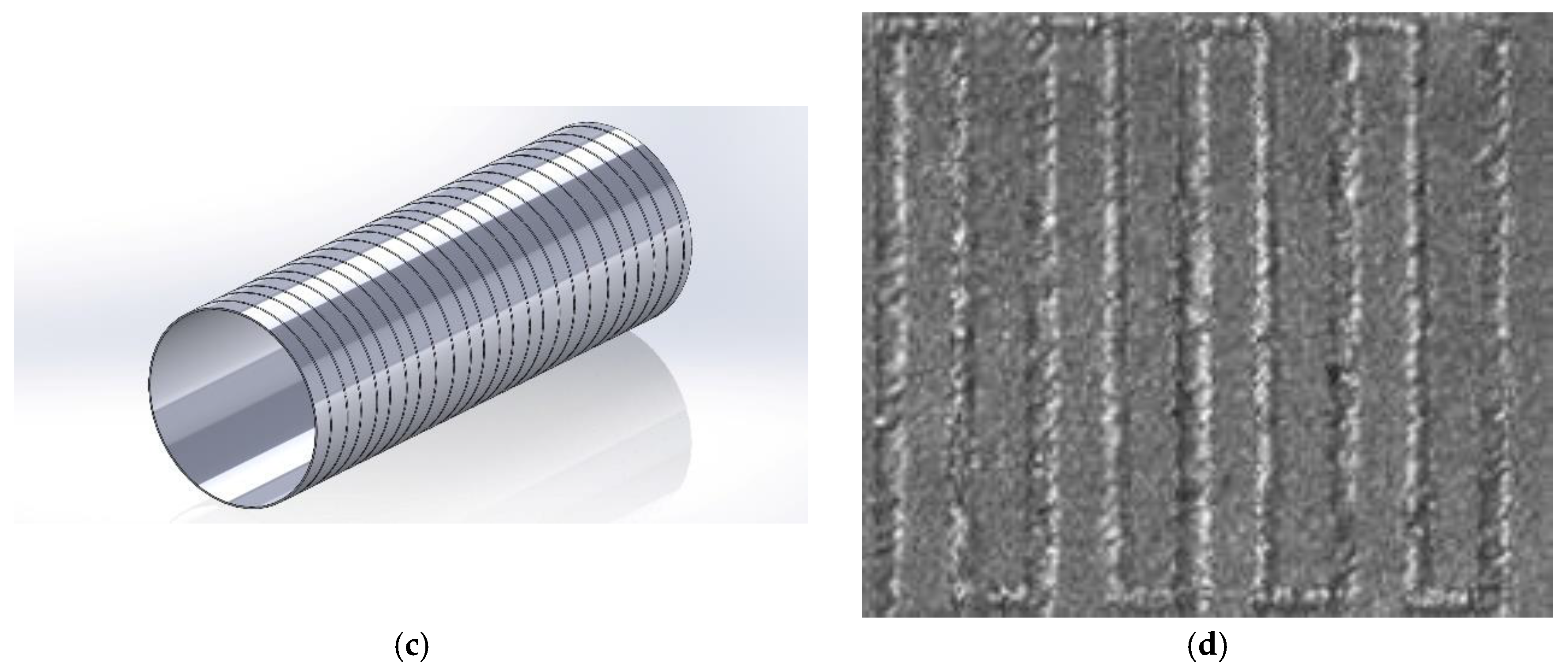

3. Basics of Lasers and Laser-Material Interaction

- Types of active medium of lasers: solid state, semiconductor, gas, liquid, and fiber lasers;

- Laser radiation wavelengths: infrared, near-infrared, visible, ultraviolet, extreme ultraviolet;

- the energy states of lasers: a ground (lower laser level) state, a metastable state, and an excited state;

- pumping mechanism: optical pumping, electric discharge pumping, beam pumping, gas dynamic, chemical reaction, thermal, injection current and others;

- time and energy parameters of laser radiation: lasers can be divided into continuous (CW), pulsed and quasi-continuous lasers;

- operating modes: free-running, Q-switched, and mode-locked;

- the safety requirements for lasers based on their potential for causing injury to humans’ eyes and skin: lasers are classified into four classes, covering eye protection, flame retardancy, reflectivity and administrative precautions.

- the photothermal process, where laser-induced thermal heating is the predominant phenomenon and structural alterations occur, including laser ablation and sintering.

- photochemical processes, where bond breaking is the dominant mechanism and there is an absence of significant thermal heating effects, such as laser reduction, doping, and graphitization.

4. Characteristics of LCS Processing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LCS | non-alloy structural steels with carbon contents below 0.3% (Low-Carbon Steel) |

| DSPD | Dynamic Surface Plastic Deformation |

| SSPD | Static Surface Plastic Deformation |

| PPD | Plasma-pulsed detonation |

| LTH | Laser Transformation Hardening |

| CW | Continuous wave |

| Pulse | Pulse oscillation |

| LD | Laser diode |

| GaAs | Gallium arsenide phosphide |

| InGaAsP | Indium gallium arsenide |

References

- Hooputra, H.; Gese, H.; Dell, H.; Werner, H. A comprehensive failure model for crashworthiness simulation of aluminium extrusions. Int. J. Crashworthiness 2004, 9, 449–464. [Google Scholar] [CrossRef]

- Estrada, Q.; Szwedowicz, D.; Tran, T.; Rodriguez-Mendez, A.; Elias-Espinosa, M.; Gómez-Vargas, O.A.; Partida-Ochoa, G. Bending crashworthiness of elliptical tubes with different aspect ratio and stiffeners. Int. J. Adv. Manuf. Technol. 2022, 120, 6661–6680. [Google Scholar] [CrossRef]

- Guo, L.; Yang, S.; Jiao, H. Behavior of thin-walled circular hollow section tubes subjected to bending. Thin-Walled Struct. 2013, 73, 281–289. [Google Scholar] [CrossRef]

- Kumar, S.; Povoden-Karadeniz, E. Plastic deformation behavior in steel during metal forming processes: A Review. In Material Flow Analysis; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Shejko, S.; Shalomeev, V.; Mishchenko, V. The effect of plastic deformation on the structure formation of low-alloy steel. In Proceedings of the MS&T 17: Materials Science & Technology, Pittsburgh, PA, USA, 8–12 October 2017. [Google Scholar] [CrossRef]

- Jones, R.M. Mechanics of Composite Materials; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2021; ISBN 156032712X. [Google Scholar]

- Nitawaki, M.; Ishii, D. The plastic deformation capacity of the structural system for thin-web steel beam reinforced with stiffener plates. ce/papers 2023, 6, 1603–1607. [Google Scholar] [CrossRef]

- Wang, Q.; Qian, C.; Wu, Z. Research on the rational design method of strength reinforcement for thin-walled structure based on limit load analysis. Appl. Sci. 2022, 12, 2208. [Google Scholar] [CrossRef]

- Choosing Between YAG and Fiber Laser Systems. Alliance Specialties and Alliance Laser Sales. Available online: https://alliancelasersales.com/yagvsfsslaser/ (accessed on 16 November 2024).

- Wang, X.; Ma, X.; Ren, Y.; Wang, J.; Cheng, W. Fiber Coupled High Power Nd:YAG Laser for Nondestructive Laser Cleaning. Photonics 2023, 10, 901. [Google Scholar] [CrossRef]

- Palomar, T.; Oujja, M.; Llorente, I.; Barat, B.R.; Canamares, M.V.; Cano, E.; Castillejo, M. Evaluation of laser cleaning for the restoration of tarnished silver artifacts. Appl. Surf. Sci. 2016, 387, 118–127. [Google Scholar] [CrossRef]

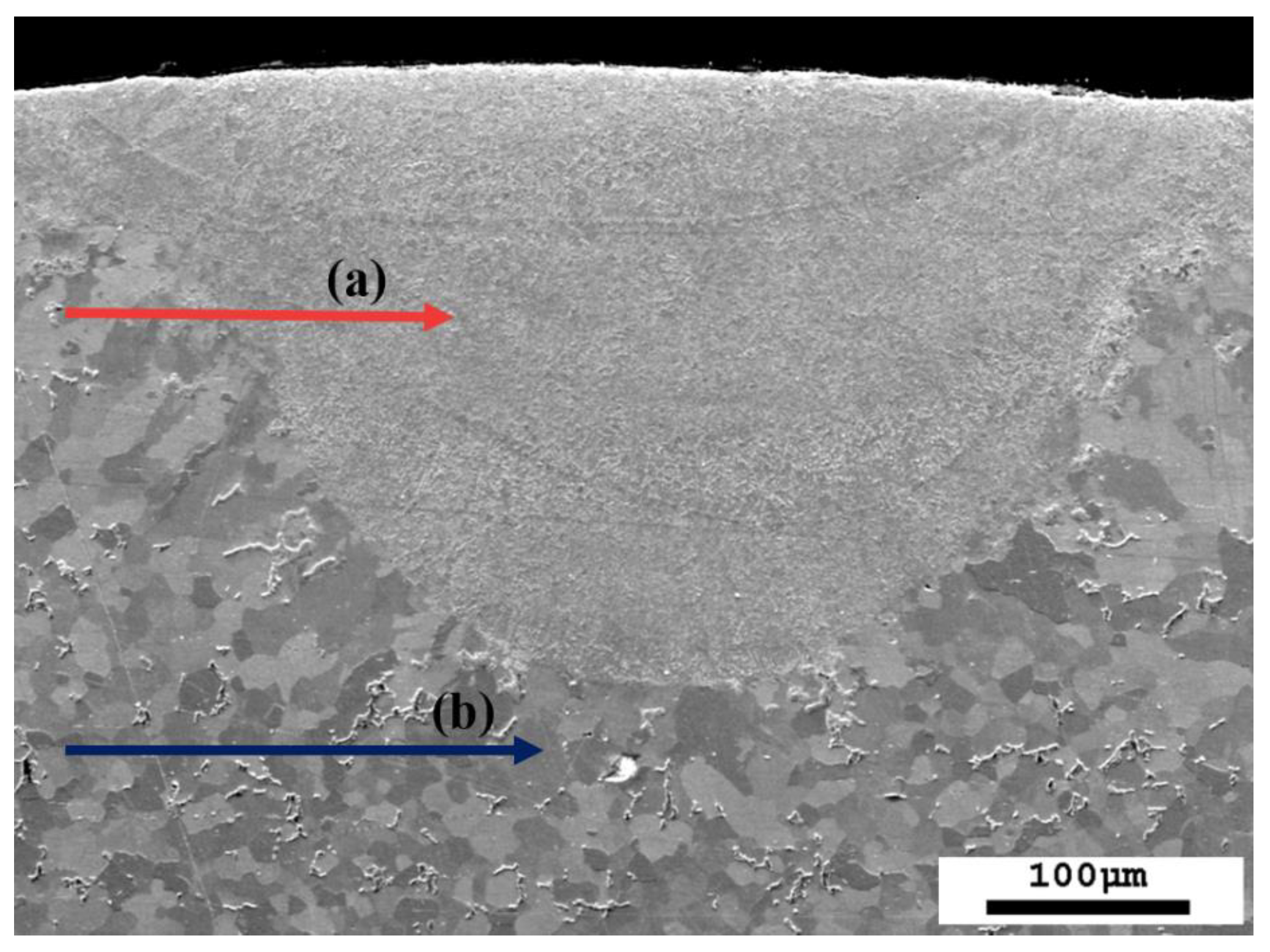

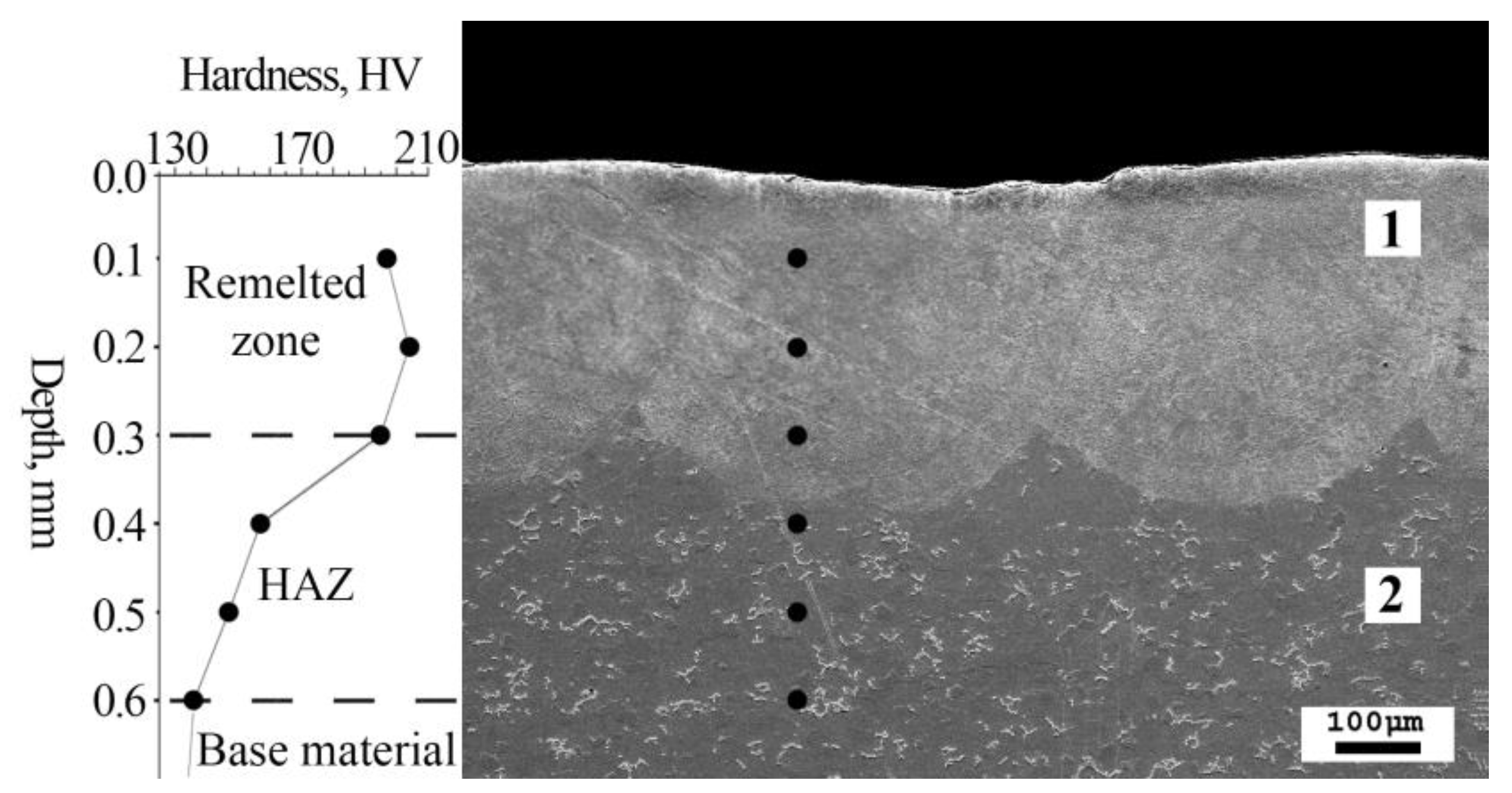

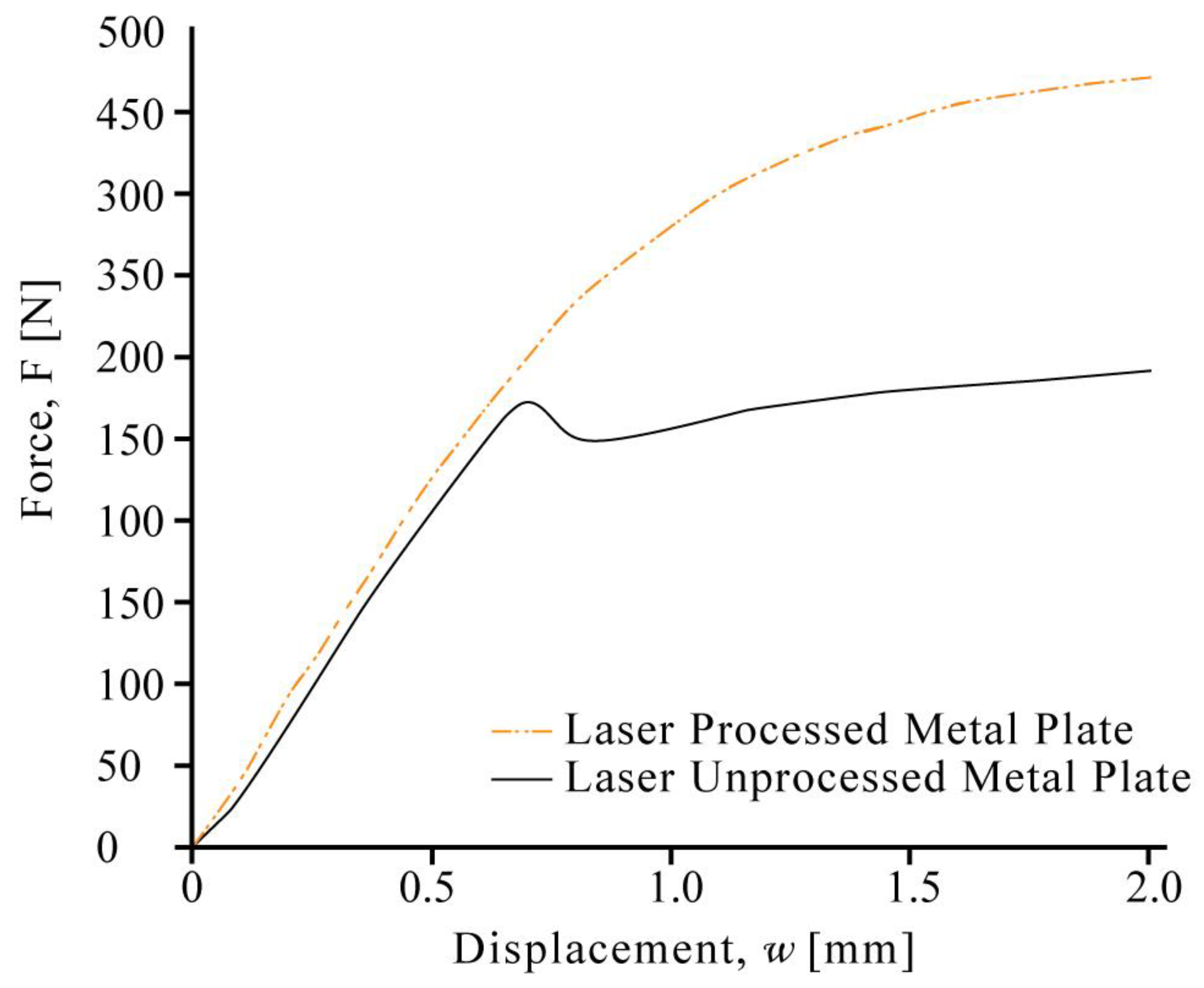

- Kapustynskyi, O.; Višniakov, N.; Černašėjus, O.; Golovko, L.; Chayeuski, V. Optimization of the parameters of local laser treatment for the creation of reinforcing ribs in thin metal sheets. In Mechanika 2019: Proceedings of the 24th International Scientific Conference; Kaunas University of Technology: Kaunas, Lithuania, 2019; ISSN 1822-2951. [Google Scholar]

- Kapustynskyi, O.; Višniakov, N. Laser treatment for strengthening of thin sheet steel. Adv. Mater. Sci. Eng. 2020, 2020, 5963012. [Google Scholar] [CrossRef]

- Majeed, J.G.; Ibrahim, Y.K.; Al-Aziz, G.A.A. Influence of Heat Treatment on Corrosion of Low Carbon Steel in Sulfuric Acid Solutions. Eur. J. Eng. Technol. Res. 2019, 4, 64–69. [Google Scholar] [CrossRef]

- Yu, Z.; Zheng, Y.; Chen, J.; Wu, C.; Xu, J.; Yu, C. Effect of laser remelting processing on the microstructure and mechanical properties of 17-4 PH stainless steel during laser direct metal deposition. J. Mater. Process. Technol. 2020, 284, 116738. [Google Scholar] [CrossRef]

- Černašėjus, O.; Škamat, J.; Markovič, V.; Višniakov, N.; Indrišiūnas, S. Effect of laser processing on surface properties of additively manufactured 18-Percent nickel maraging steel parts. Coatings 2020, 10, 600. [Google Scholar] [CrossRef]

- Miraoui, I.; Boujelbene, M.; Bayraktar, E. Effects of laser cutting main parameters on microhardness and microstructure changes of stainless steel. Adv. Mater. Res. 2013, 664, 811–816. [Google Scholar] [CrossRef]

- Peksen, M. Chapter 4—Multiphysics Modeling of Structural Components and Materials. In Multiphysics Modeling; Academic Press: Cambridge, MA, USA, 2018; pp. 105–138. [Google Scholar] [CrossRef]

- Dzwierzynska, J. Shaping of curvilinear steel bar structures for variable environmental conditions using genetic algorithms—Moving towards sustainability. Materials 2021, 14, 1167. [Google Scholar] [CrossRef]

- Kleiner, L.M.; Simonov, Y.N. Structure and properties of low-carbon martensitic steels. Met. Sci. Heat Treat. 1999, 41, 366–368. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Design of novel high strength bainitic steels: Part 1. Mater. Sci. Technol. 2001, 17, 512–516. [Google Scholar] [CrossRef]

- Krauss, G. Microstructures, processing, and properties of Steels. In Properties and Selection: Irons, Steels, and High-Performance Alloys; ASM International: Materials Park, OH, USA, 1990; pp. 126–139. [Google Scholar] [CrossRef]

- Huo, X.-D.; Li, Y.-Q.; Zhao, Y.-T.; Zhang, H.-W.; Li, Z.-H. Effect of cooling parameters on the microstructure and properties of Mo-bearing and Cr-bearing steels. Int. J. Miner. Met. Mater. 2011, 18, 551–556. [Google Scholar] [CrossRef]

- Soren, S.; Banerjee, M.K.; Gupta, R.N.; Prasad, N. Evolution of microstructure in microalloyed steel under continuous cooling. Int. J. Des. Manuf. Technol. 2013, 4, 1–7. [Google Scholar] [CrossRef]

- Müller, M.; Britz, D.; Staudt, T.; Mücklich, F. Microstructural classification of Bainitic subclasses in low-carbon multi-phase steels using Machine Learning Techniques. Metals 2021, 11, 1836. [Google Scholar] [CrossRef]

- Verhoeven, J.D. Steel Metallurgy for the Non-Metallurgist; ASM International: Materials Park, OH, USA, 2007. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P.E.J. Understanding martensite and twin formation in austenitic steels: A model describing trip and TWIP effects. Acta Mater. 2017, 128, 120–134. [Google Scholar] [CrossRef]

- Krauss, G. Deformation and fracture in martensitic carbon steels tempered at low temperatures. Metall. Mater. Trans. A 2001, 32, 861–877. [Google Scholar] [CrossRef]

- Krauss, G. Tempering of lath martensite in low and Medium Carbon Steels: Assessment and challenges. Steel Res. Int. 2017, 88, 1700038. [Google Scholar] [CrossRef]

- Zheng, Z.B.; Long, J.; Zheng, K.H.; Zhou, H.L.; Li, H.; Zhang, Q.L. Study on the microstructure and impact fracture behavior of martensitic alloy steels. Met. Mater. 2020, 57, 189–197. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, P.; Lu, Q.; Yan, H.; Shi, H.; Yu, Z.; Sun, T.; Li, R.; Wang, Q.; Wu, Y.; et al. Application and development of blue and Green Laser in Industrial Manufacturing: A Review. Opt. Laser Technol. 2024, 170, 110202. [Google Scholar] [CrossRef]

- Jelínková, H.; Šulc, J. Laser characteristics. In Lasers for Medical Applications; Woodhead Publishing: Cambridge, UK, 2013; pp. 17–46. [Google Scholar] [CrossRef]

- Asadi, S.; Saeid, T.; Valanezhad, A.; Khalil Allafi, J. Dissimilar laser welding of NiTi shape memory alloy to austenitic stainless steel archwires. J. Weld. Sci. Technol. Iran 2020, 5, 135–146. Available online: http://jwsti.iut.ac.ir/article-1-282-en.html (accessed on 11 December 2024).

- Hirsch, P.; Bastick, S.; Jaeschke, P.; van den Aker, R.; Geyer, A.; Zscheyge, M.; Michel, P. Effect of thermal properties on laser cutting of continuous glass and carbon fiber-reinforced polyamide 6 composites. Mach. Sci. Technol. 2018, 23, 1–18. [Google Scholar] [CrossRef]

- Gilboa, T.; Zvuloni, E.; Zrehen, A.; Squires, A.H.; Meller, A. Automated, ultra-fast laser-drilling of nanometer scale pores and nanopore arrays in aqueous solutions. Adv. Funct. Mater. 2019, 30, 1900642. [Google Scholar] [CrossRef]

- Brown, M.S.; Arnold, C.B. Fundamentals of Laser-Material Interaction and Application to Multiscale Surface Modification; Springer Series in Materials Science; Springer: New York, NY, USA, 2010; pp. 91–120. [Google Scholar] [CrossRef]

- Li, Y.; Hong, M. Parallel Laser Micro/Nano-processing for functional device fabrication. Laser Photonics Rev. 2020, 14, 1900062. [Google Scholar] [CrossRef]

- Son, Y.; Yeo, J.; Moon, H.; Lim, T.W.; Hong, S.; Nam, K.H.; Yoo, S.; Grigoropoulos, C.P.; Yang, D.; Ko, S.H. Nanoscale Electronics: Digital Fabrication by direct femtosecond laser processing of metal nanoparticles. Adv. Mater. 2011, 23, 3176–3181. [Google Scholar] [CrossRef] [PubMed]

- Minoshima, K.; Kowalevicz, A.M.; Hartl, I.; Ippen, E.P.; Fujimoto, J.G. Photonic device fabrication in glass by use of nonlinear materials processing with a femtosecond laser oscillator. Opt. Lett. 2001, 26, 1516. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Wang, W.; Pan, A.; Hu, L.; Mei, X. Characterization of anti-reflection structures fabricated via laser micro/nano-processing. Opt. Mater. 2022, 131, 112686. [Google Scholar] [CrossRef]

- Sygletou, M.; Petridis, C.; Kymakis, E.; Stratakis, E. Advanced photonic processes for photovoltaic and Energy Storage Systems. Adv. Mater. 2017, 29, 1700335. [Google Scholar] [CrossRef] [PubMed]

- Akman, E.; Erdoğan, Y.; Bora, M.Ö.; Çoban, O.; Oztoprak, B.G.; Demir, A. Investigation of the differences between photochemical and photothermal laser ablation on the shear strength of CFRP/CFRP adhesive joints. Int. J. Adhes. Adhes. 2020, 98, 102548. [Google Scholar] [CrossRef]

- Hong, S.; Lee, H.; Yeo, J.; Ko, S.H. Digital Selective Laser Methods for nanomaterials: From synthesis to processing. Nano Today 2016, 11, 547–564. [Google Scholar] [CrossRef]

- Koller, M.R.; Hanania, E.G.; Stevens, J.; Eisfeld, T.M.; Sasaki, G.C.; Fieck, A.; Palsson, B. High-throughput laser-mediated in situ cell purification with high purity and yield. Cytom. Part A 2004, 61A, 153–161. [Google Scholar] [CrossRef]

- Kiracofe, D.; Kobayashi, K.; Labuda, A.; Raman, A.; Yamada, H. High efficiency laser photothermal excitation of microcantilever vibrations in air and liquids. Rev. Sci. Instrum. 2011, 82, 013702. [Google Scholar] [CrossRef]

- Nguyen, D.T.; Tong, Q.C.; Ledoux-Rak, I.; Lai, N.D. One-step fabrication of submicrostructures by low one-photon absorption direct laser writing technique with local thermal effect. J. Appl. Phys. 2016, 119, 013101. [Google Scholar] [CrossRef]

- Tan, Z.; Zhang, X.; Zhou, Z.; Zhou, Z.; Yang, Y.; Guo, X.; Wang, Z.; Wu, X.; Wang, G.; He, D. Thermal effect on the microstructure of the lattice structure cu-10sn alloy fabricated through selective laser melting. J. Alloys Compd. 2019, 787, 903–908. [Google Scholar] [CrossRef]

- Geng, J.; Yan, W.; Shi, L.; Qiu, M. Surface plasmons interference nanogratings: Wafer-scale laser direct structuring in seconds. Light Sci. Appl. 2022, 11, 189. [Google Scholar] [CrossRef] [PubMed]

- Schasfoort, R.B. (Ed.) Handbook of Surface Plasmon Resonance; Royal Society of Chemistry: London, UK, 2017. [Google Scholar]

- Kreibig, U.; Vollmer, M. Optical Properties of Metal Clusters; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 25. [Google Scholar]

- Setoura, K.; Ito, S. Optical manipulation in conjunction with photochemical/photothermal responses of materials. J. Photochem. Photobiol. C Photochem. Rev. 2022, 52, 100536. [Google Scholar] [CrossRef]

- Garnett, E.C.; Cai, W.; Cha, J.J.; Mahmood, F.; Connor, S.T.; Greyson Christoforo, M.; Cui, Y.; McGehee, M.D.; Brongersma, M.L. Self-limited plasmonic welding of silver nanowire junctions. Nat. Mater. 2012, 11, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Uranga, P.; María Rodríguez-Ibabe, J. Thermomechanical Processing of Steels. Metals 2020, 10, 641. [Google Scholar] [CrossRef]

- Evdokimov, V.D.; Klimenko, L.P.; Evdokimova, A.N. Technology Hardening of Engineering Materials; NGGU: Odessa, Ukraine, 2005. [Google Scholar]

- Saber, D.; Almalki, H.M.; El-Aziz, K.A. Design and building of an automated heat-treatment system for industrial applications. Alex. Eng. J. 2020, 59, 5007–5017. [Google Scholar] [CrossRef]

- Krauss, G. Steels: Processing, Structure, and Performance; ASM International: Materials Park, OH, USA, 2006; pp. 280–288. ISBN 0871708175. [Google Scholar]

- Krauss, G. Steels: Processing, Structure, and Performance, 2nd ed.; ASM International: Materials Park, OH, USA, 2016; ISBN 162708083X. [Google Scholar]

- Pertash, L.V. Quenching Mediums; Mashgiz: Moscow, Russia, 1959. [Google Scholar]

- Hashmi, S. Comprehensive Materials Finishing; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Fuller, A.J., Jr. Introduction to carburizing and carbonitriding. In ASM Handbook, Vol 4 A Steel Heat Treating Fundamentals and Processes; Dossett, J.L., Totten, G.E., Eds.; ASM International: Materials Park, OH, USA, 2013; pp. 505–521. [Google Scholar]

- Kalinin, A.T.; Novikova, A.Y. Optimum degree of saturation with carbon and nitrogen by nitrocementation. Met. Sci. Heat Treat. 1965, 7, 622–626. [Google Scholar] [CrossRef]

- Mittemeijer, E.J. Nitriding and nitrocarburizing of steel. In Steel Heat Treating Fundamentals and Processes, Vol 4A, ASM Handbook; Dossett, J.L., Totten, G.E., Eds.; ASM International: Materials Park, OH, USA, 2013; pp. 617–701. [Google Scholar]

- Zimmerman, C. Diffusion Coating. In Steel Heat Treating Fundamentals and Processes, Vol 4A, ASM Handbook; Dossett, J.L., Totten, G.E., Eds.; ASM International: Materials Park, OH, USA, 2013; pp. 705–722. [Google Scholar]

- Stepanov, M.S.; Dombrovskii Yu, M.; Pustovoit, V.N. Diffusion saturation of carbon steel under Microarc heating. Met. Sci. Heat Treat. 2017, 59, 55–59. [Google Scholar] [CrossRef]

- Metel, A.; Grigoriev, S.; Melnik, Y.; Volosova, M.; Mustafaev, E. Surface hardening of machine parts using nitriding and tin coating deposition in glow discharge. Machines 2020, 8, 42. [Google Scholar] [CrossRef]

- Höche, D.; Kaspar, J.; Schaaf, P. Laser nitriding and carburization of materials. In Laser Surface Engineering. Processes and Applications; Woodhead Publishing Series in Electronic and Optical Materials; Waugh, D.G., Lawrence, J., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 33–58. [Google Scholar] [CrossRef]

- Furlani, M.R.; Carvalho, S.M.; Lima, M.S.F. Effect of laser surface hardening on a low carbon steel substrate wear and hardness. arXiv 2021, arXiv:2111.13183. [Google Scholar]

- Ion, J.C. Laser transformation hardening. Surf. Eng. 2002, 18, 14–31. [Google Scholar] [CrossRef]

- Babu, P.D.; Buvanashekaran, G.; Balasubramanian, K.R. Experimental studies on the microstructure and hardness of laser transformation hardening of low alloy steel. Trans. Can. Soc. Mech. Eng. 2012, 36, 241–258. [Google Scholar] [CrossRef]

- Zhang, D.; Guan, L. Laser ablation. In Comprehensive Materials Processing; Hashmi, S., Batalha, G.F., Van Tyne, C.J., Yilbas., B., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; Volume 4, pp. 125–169. [Google Scholar] [CrossRef]

- Nath, A.K.; Sarkar, S. Laser transformation hardening of steel. In Advances in Laser Materials Processing, 2nd ed.; Woodhead Publishing: Cambridge, UK, 2018; pp. 257–298. [Google Scholar] [CrossRef]

- Ion, J.C. Laser Processing of Engineering Materials; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar] [CrossRef]

- Penchal Reddy, M.; Shakoor, R.A.; Parande, G.; Manakari, V.; Ubaid, F.; Mohamed, A.M.A.; Gupta, G. Enhanced performance of nano-sized SiC reinforced Al metal matrix nanocomposites synthesized through microwave sintering and hot extrusion techniques. Prog. Nat. Sci. Mater. Int. 2017, 27, 606–614. [Google Scholar] [CrossRef]

- Schaaf, P. (Ed.) Laser Processing of Materials; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Kovalenko, V.S.; Golovko, L.F.; Merkulov, G.V.; Strizhak, A.I. Laser Beam Hardening; Tehnika: Kyiv, Ukraine, 1981. [Google Scholar]

- Rehman, Z.U.; Ullah, S.; Qayyum, H.; Irfan, M.; Tran, K.A.; Suk, H.; Qayyum, A.; Janulewicz, K.A. Phase transformations initiated by optical breakdown in bulk of fused silica. Opt. Laser Technol. 2021, 134, 106630. [Google Scholar] [CrossRef]

- Fathi, H.; Närhi, M.; Gumenyuk, R. Towards ultimate high-power scaling: Coherent beam combining of fiber lasers. Photonics 2021, 8, 566. [Google Scholar] [CrossRef]

- Leone, C.; Mingione, E.; Genna, S. Laser cutting of CFRP by Quasi-Continuous Wave (QCW) fibre laser: Effect of process parameters and analysis of the HAZ index. Compos. Part B Eng. 2021, 224, 109146. [Google Scholar] [CrossRef]

- Acherjee, B. Laser transmission welding of polymers—A review on welding parameters, quality attributes, process monitoring, and applications. J. Manuf. Process. 2021, 64, 421–443. [Google Scholar] [CrossRef]

- Velu, R.; Kumar, A.V.; Balan, A.S.S.; Mazumder, J. Laser aided metal additive manufacturing and postprocessing. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 427–456. [Google Scholar] [CrossRef]

- Xinxin, L.i.; Yingchun, G. Theoretical fundamentals of short pulse laser–metal interaction: A review. Nanotechnol. Precis. Eng. 2020, 3, 105–125. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Liu, S.; Wu, D.; Luo, Z.; Zhang, P.; Ye, X.; Yu, Z. Measurement of pulsed laser welding penetration based on keyhole dynamics and deep learning approach. Measurement 2022, 199, 111579. [Google Scholar] [CrossRef]

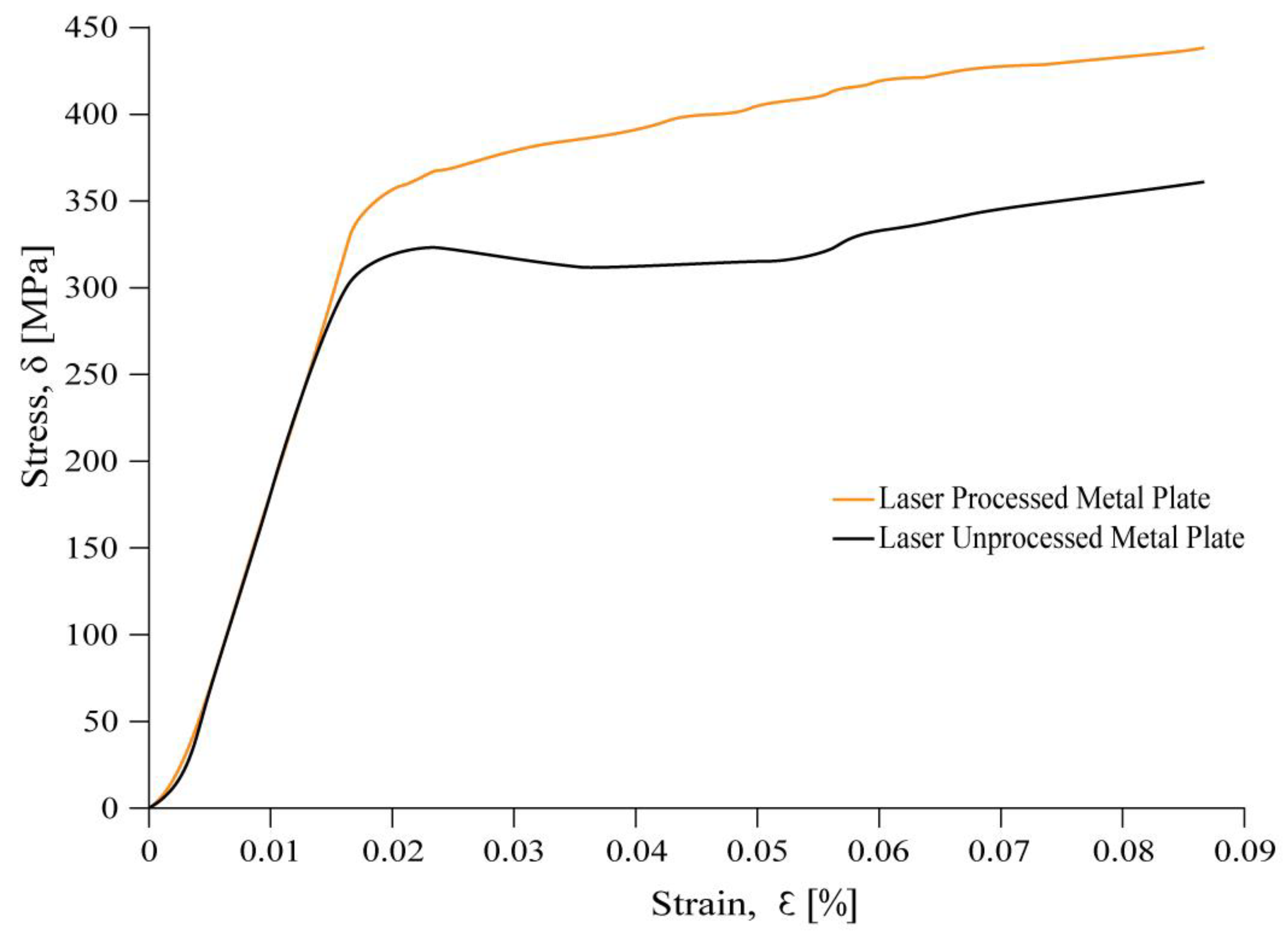

- Kapustynskyi, O.; Višniakov, N. Effect of local laser treatment on the strengthening of thin-walled structures fabricated from Non-Alloy Steel. Materials 2023, 16, 4555. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Perlite | Sorbite | Troostite | Bainite | Martensite |

|---|---|---|---|---|---|

| Sheet thickness L, µm | 0.6–2.0 | 0.2–0.3 | 0.1–0.2 | 0.08–0.12 | 0.15–0.25 |

| Hardness, HRC | 10–25 | 25–32 | 32–42 | 47–54 | 42–66 |

| Structure | Perlite | Sorbite | Troostite | Bainite | Martensite |

|---|---|---|---|---|---|

| Temperature range of transformation during cooling | 650–700 °C | 600–650 °C | 600–500 °C | 250–500 °C | Below 250 °C |

| Degree of austenite supercooling | Cooling in the oven at a rate of several degrees per minute | Air cooling at a rate of several tens of degrees per minute | Cooling in oil at a rate of several tens of degrees per second | Isothermal exposure in the range of 500–250 °C | Cooling in water at a rate of several hundred degrees per second |

| Structure | Cooling Rate, °C/s | |

|---|---|---|

| 650–550 | 300–200 | |

| Water at a temperature of 18 °C | 600 | 270 |

| Water at a temperature of 25 °C | 500 | 270 |

| Water at a temperature of 50 °C | 100 | 270 |

| Water at a temperature of 75 °C | 30 | 200 |

| Soapy water at 18 °C | 30 | 200 |

| Emulsion oil in water | 70 | 200 |

| Water saturated with carbon dioxide | 150 | 200 |

| Distilled water | 250 | 250 |

| 10% aqueous solution of caustic soda at 18 °C | 1200 | 300 |

| 10% aqueous solution of table salt at 18 °C | 1100 | 300 |

| 10% aqueous solution of sulfuric acid at 18 °C | 750 | 200 |

| 10% aqueous soda solution | 800 | 270 |

| 5% solution of potassium permanganate | 450 | 100 |

| Kerosene | 160–180 | 40–60 |

| Industrial oil | 100–150 | 20–50 |

| Transformer oil | 120 | 25 |

| Copper cooling plate | 60 | 20 |

| Iron cooling plate | 30 | 15 |

| Air | 12 | 3 |

| Compressed air | 30 | 10 |

| Laser | Wavelength | Oscillation Form | Conversion Efficiency (%) | |

|---|---|---|---|---|

| Gas | CO2 laser | 1064 nm | CW | Max. 20 |

| Pulse | ||||

| TEA-CO2 | Mainly 1064 nm (varies by gas pressure) | Pulse | ||

| Solid-state | YAG laser | 1064 nm | CW Pulse | Max. 3 |

| YVO4 | 1064 nm | Pulse | ||

| Fiber | Yb fiber | 915–1040 nm | CW Q-switch Ultra-short pulse | Max. 70 |

| Semiconductor | LD laser (GaAs InGaAsP and another) | Mainly 1064 nm (but exist variety of wavelengths) | CW | Max. 100 |

| Pulse | ||||

| Zone | Modulus of Elasticity E, GPa | Yield Strength σ0.2, MPa | Ultimate Strength σB, MPa |

|---|---|---|---|

| Base material (laser-untreated zone) | 200 | 256 | 410 |

| Laser-treated zone | 210 | 412 | 662 |

| Thermochemical Processing | Thermomechanical Processing | Mechanical Processing | Laser Treatment | |

|---|---|---|---|---|

| Advantages | - stable results in boration techniques | - cost-effective technique for annealing - normalization achieving a fine-grained structure in LCS and characterized by shorter cooling times - annealing seeks equilibrium microstructures | DSPD and SSPD effectively harden thin surface layers | - versatile surface modification technique - diverse applications in hardening, nitriding, and carburization - rapid heating and cooling rates - precise control over material microstructures |

| Disadvantages | - low productivity - high cost - prolonged procedures for boration techniques | - LCS cannot be quenched using standard methods | - substantial capital investments - limitations in applicability to thin-walled products | employing LTH without melting to strengthen LCS faces challenges due to the limited thickness of the hardened layer and the need to treat a large surface area |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapustynskyi, O.; Višniakov, N. The Influence of Heat Treatment and Laser Alternative Surface Treatment Methods of Non-Alloy Steels: Review. Photonics 2025, 12, 207. https://doi.org/10.3390/photonics12030207

Kapustynskyi O, Višniakov N. The Influence of Heat Treatment and Laser Alternative Surface Treatment Methods of Non-Alloy Steels: Review. Photonics. 2025; 12(3):207. https://doi.org/10.3390/photonics12030207

Chicago/Turabian StyleKapustynskyi, Oleksandr, and Nikolaj Višniakov. 2025. "The Influence of Heat Treatment and Laser Alternative Surface Treatment Methods of Non-Alloy Steels: Review" Photonics 12, no. 3: 207. https://doi.org/10.3390/photonics12030207

APA StyleKapustynskyi, O., & Višniakov, N. (2025). The Influence of Heat Treatment and Laser Alternative Surface Treatment Methods of Non-Alloy Steels: Review. Photonics, 12(3), 207. https://doi.org/10.3390/photonics12030207