Pump-Probe Detection of Diamond Ionization and Ablation Induced by Ultra-Fast Laser

Abstract

:1. Introduction

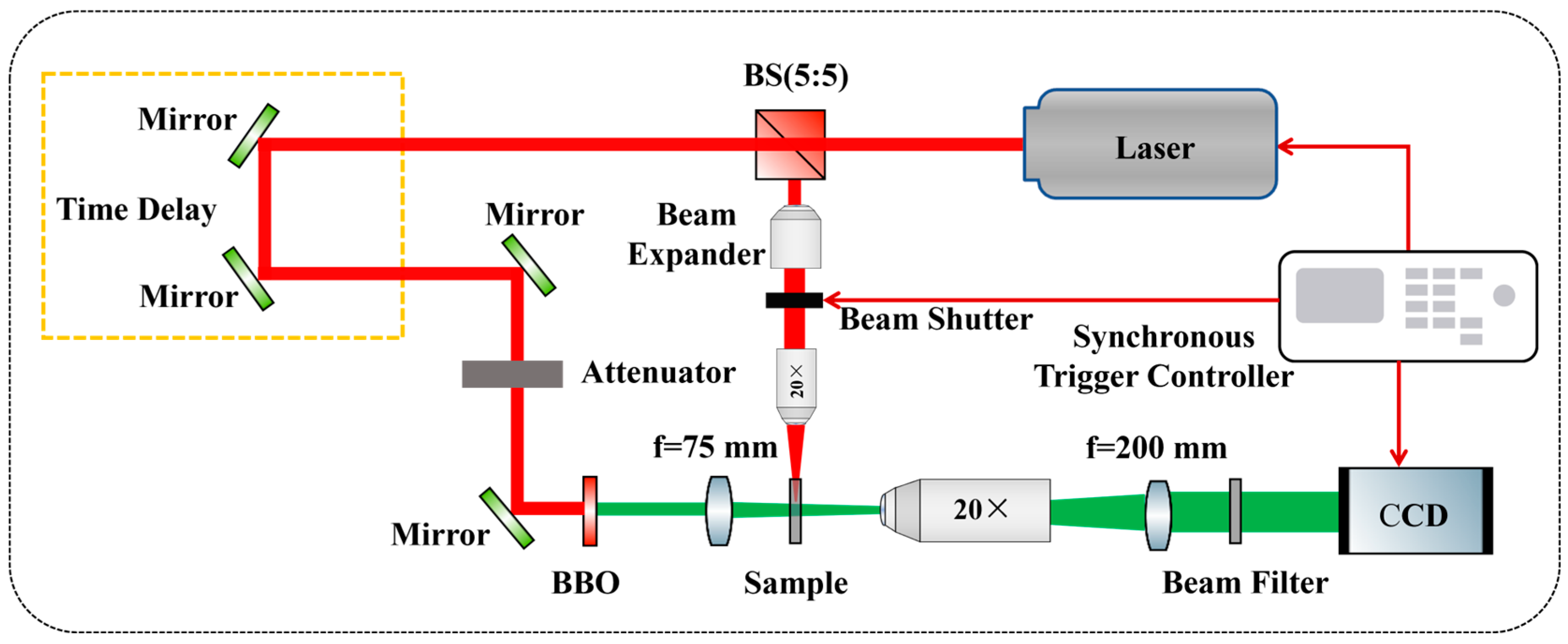

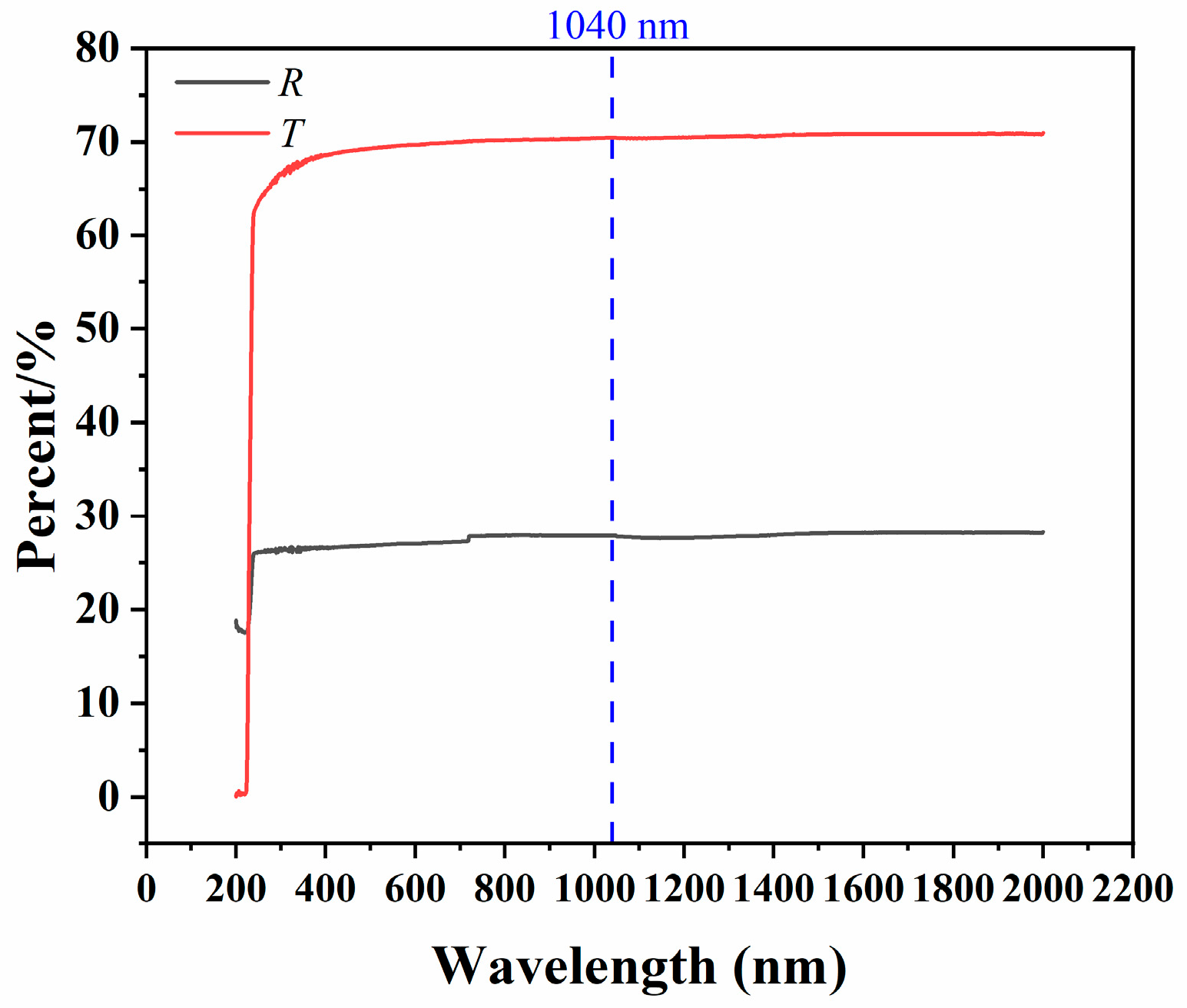

2. Materials and Methods

3. Results and Discussions

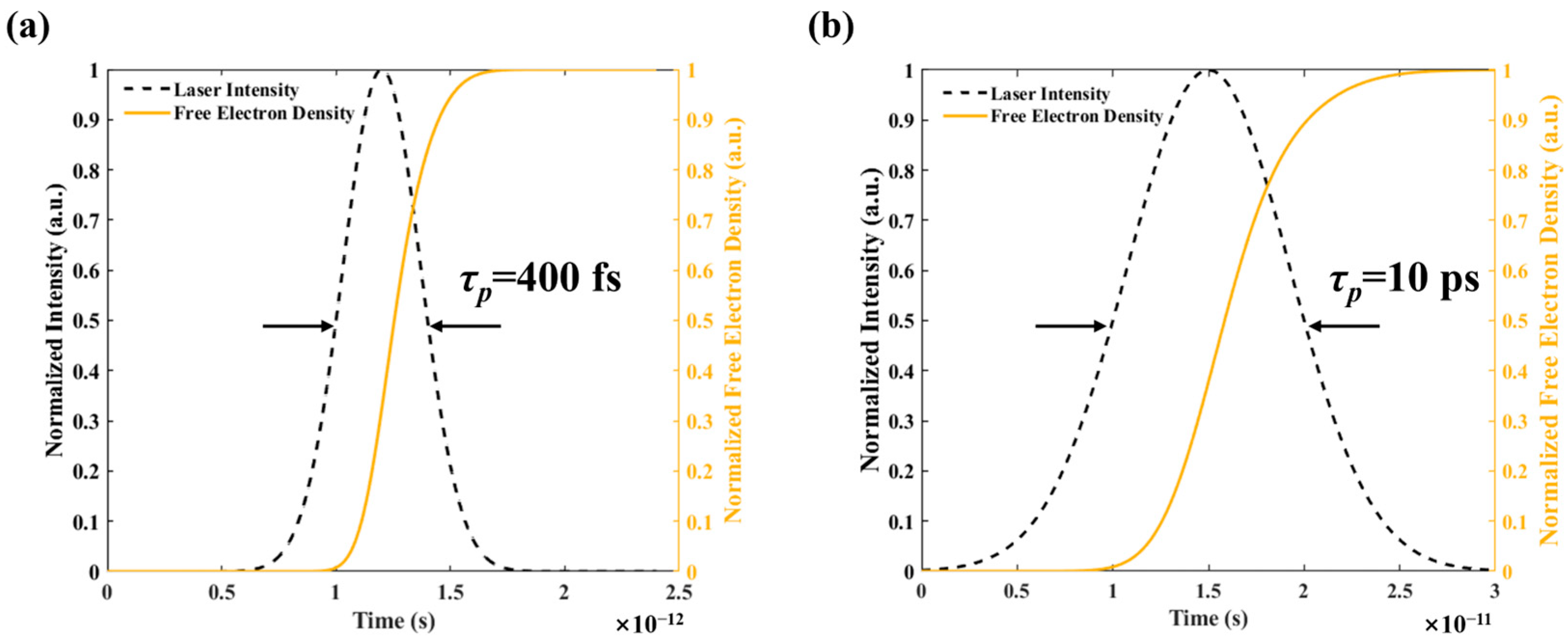

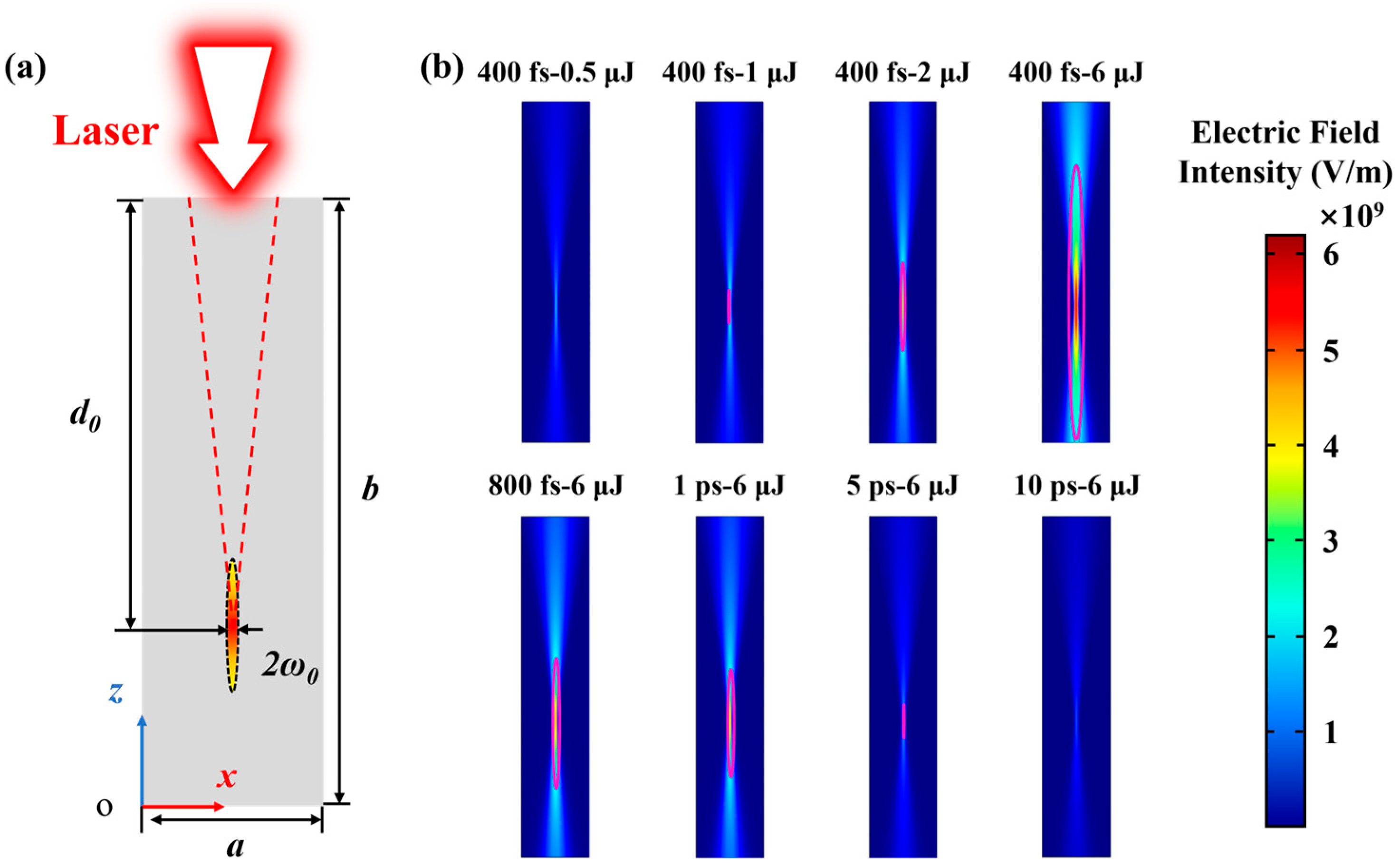

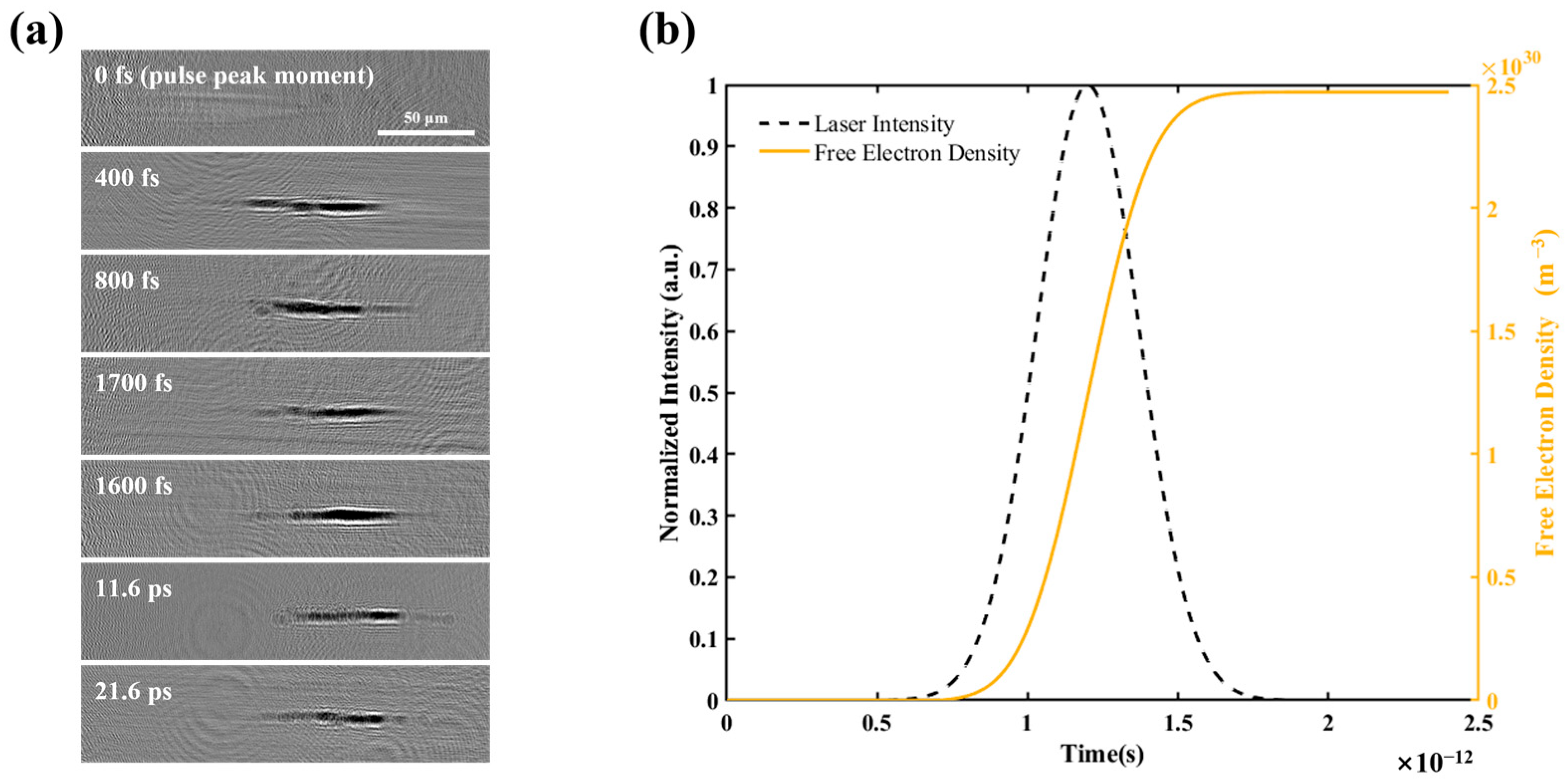

3.1. Multi-Physics Field Coupling Calculations

3.1.1. Density Functional Theory

3.1.2. Keldysh Formula

3.1.3. The Finite Element Method

- (1)

- The spatial distribution of the incident laser follows a Gaussian beam profile.

- (2)

- The optical parameters of the diamond are treated as constants independent of laser intensity.

- (3)

- The free electron density evolution under an electric field is calculated via the Keldysh formula. The plasma generation threshold is defined as the electric field intensity at which the rate of plasma density increases dramatically.

- (4)

- The diamond material is an ideal conductor.

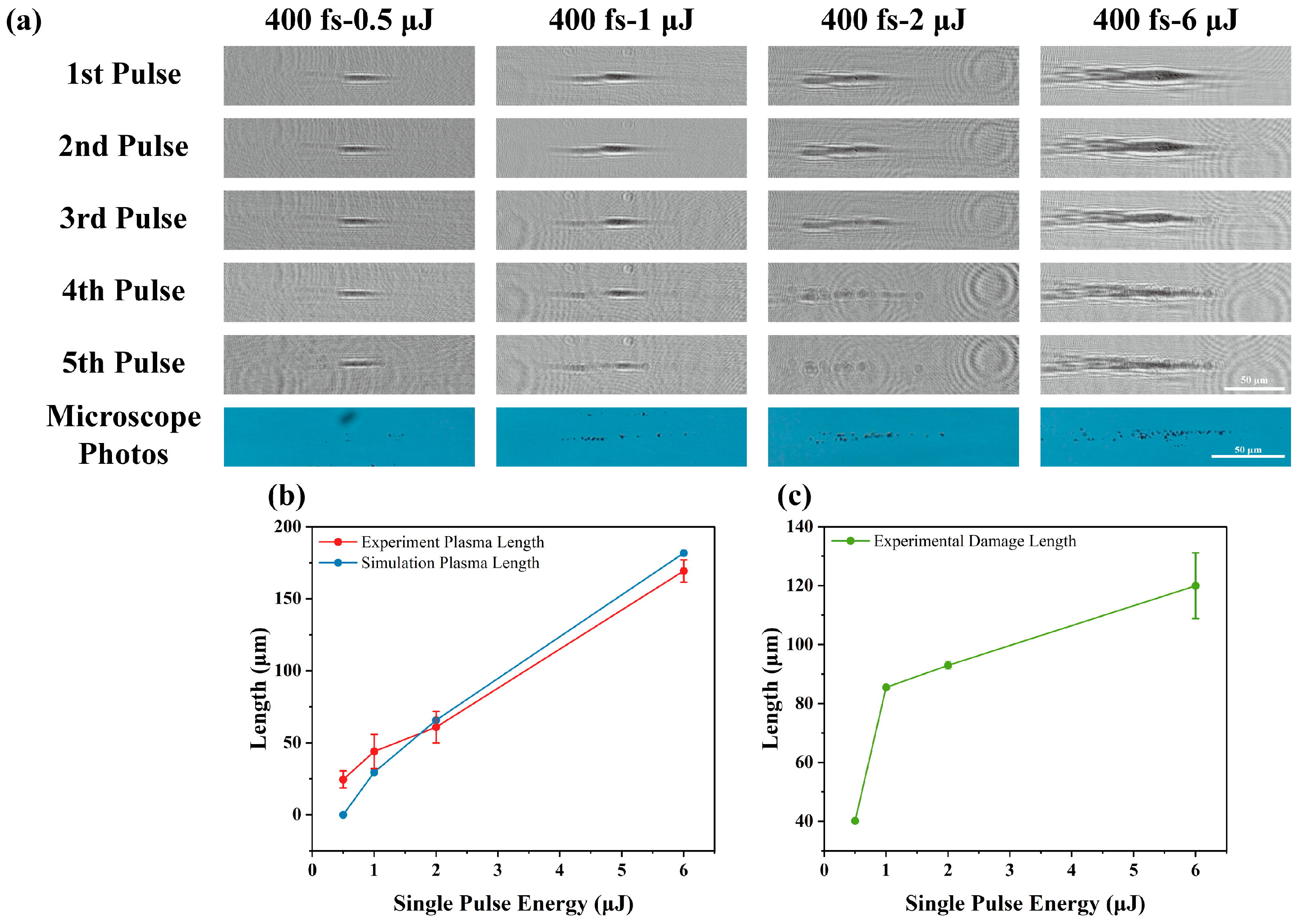

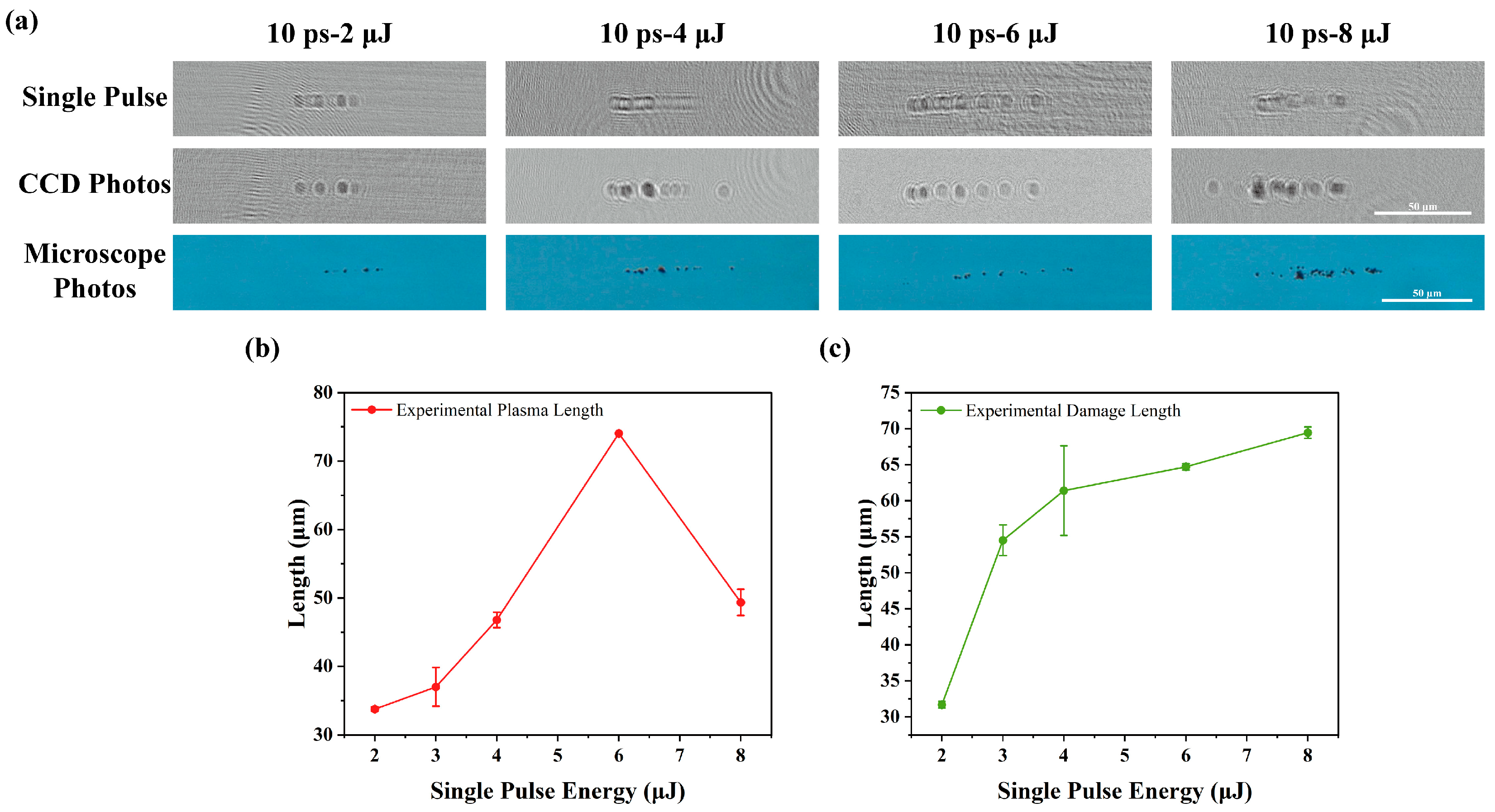

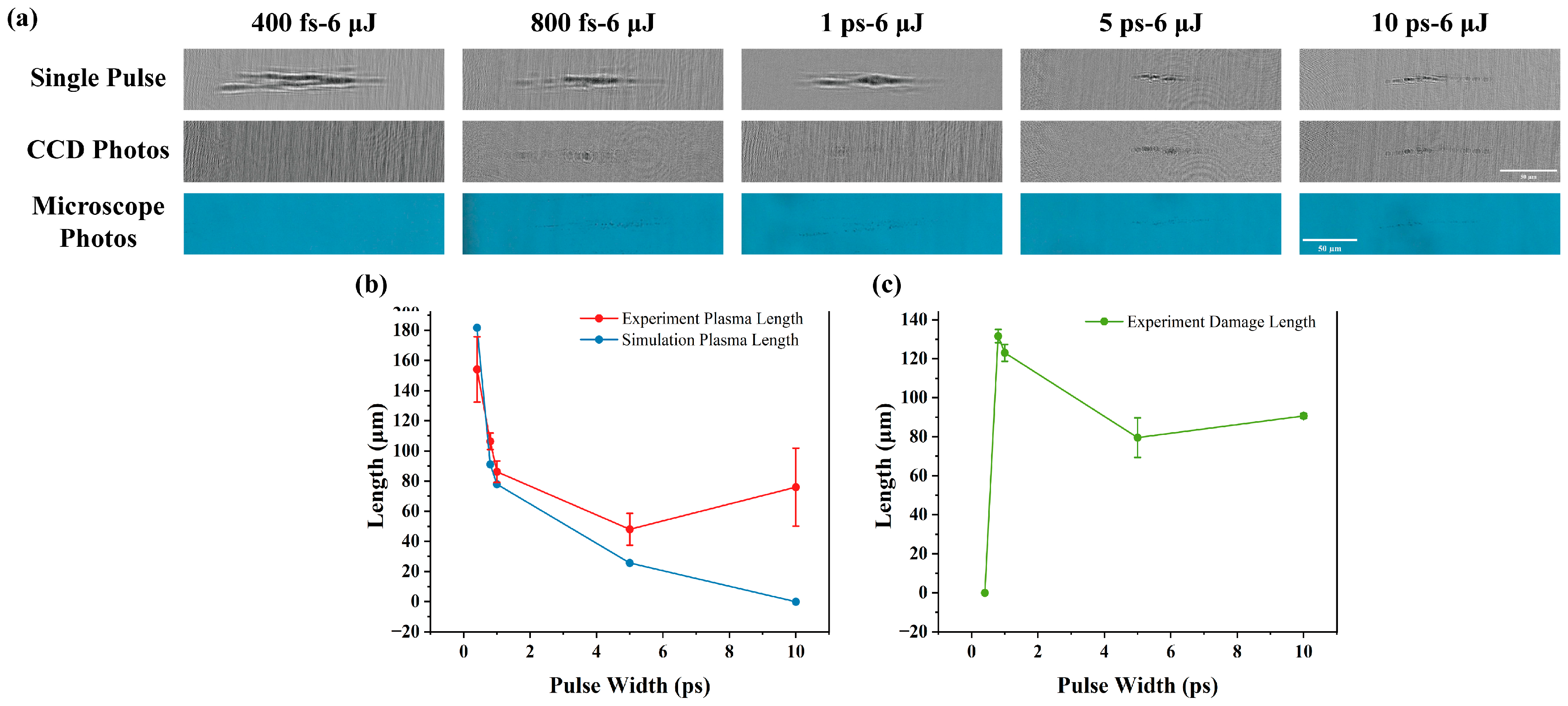

3.2. Experimental Results

4. Conclusions

- (1)

- By assigning values to multiple physical models simultaneously, the variation trends of free-electron density with laser intensity or time were simulated and calculated under the conditions of τp = 400 fs and 10 ps. Also, the electric-field distribution and the plasma length inside the diamond under different energies and pulse widths are obtained.

- (2)

- When τp = 10 ps and 400 fs, respectively, the laser energy was changed. The results showed that as the laser energy increased, the plasma length also increased. Moreover, when the laser energy exceeded a certain threshold, the temperature of the diamond increased rapidly, and the lattice structure changed, leading to graphitization.

- (3)

- When the energy was fixed and the pulse width was varied, it was found that the plasma length first decreased and then increased as the pulse width increased, while the length of graphitization damage first increased and then decreased. With the increase in pulse width, the interaction time between the laser and diamond becomes more extended, which is favorable for the lattice to absorb energy and for graphitization to occur. The graphite’s absorption of the laser is much larger than that of the diamond, which makes the morphology of the plasma nearly the same as that of the graphite damage. As the pulse width increases, the energy injection per unit time decreases, decreasing the damage length.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kononenko, V.V.; Bukin, V.V.; Komlenok, M.S.; Zavedeev, E.V.; Kononenko, T.V.; Dezhkina, M.A.; Ratnikov, P.P.; Dolmatov, T.V.; Chizhov, P.A.; Ushakov, A.A.; et al. A Diamond Terahertz Large Aperture Photoconductive Antenna Biased by a Longitudinal Field. Photonics 2023, 10, 1169. [Google Scholar] [CrossRef]

- Vyatkin, S.; Danilov, P.; Smirnov, N.; Pomazkin, D.; Kuzmin, E.; Gorevoy, A.; Muratov, A.; Matyaev, I.; Kudryashov, S. Electron Paramagnetic Resonance Sensing of «Hidden» Atomistic and Cooperative Defects in Femtosecond Laser-Inscribed Photoluminescent Encoding Patterns in Diamond. Photonics 2023, 10, 979. [Google Scholar] [CrossRef]

- Su, J.; Yang, G.; Guo, D.; Li, M.; Zhu, N.; Wang, X. Multi-Physical Analysis and Optimization in Integrated Lithium Niobate Modulator Using Micro-Structured Electrodes. Photonics 2023, 10, 795. [Google Scholar] [CrossRef]

- Komlenok, M.S.; Kononenko, V.V.; Bolshakov, A.P.; Kurochitskiy, N.D.; Pasternak, D.G.; Ushakov, A.A.; Konov, V.I. CVD Encapsulation of Laser-Graphitized Electrodes in Diamond Electro-Optical Devices. Photonics 2024, 11, 10. [Google Scholar] [CrossRef]

- Xing, Z.; Liao, J.; Xu, Z.; Cheng, X.; Zhang, J. The Design of Highly Reflective All-Dielectric Metasurfaces Based on Diamond Resonators. Photonics 2024, 11, 1015. [Google Scholar] [CrossRef]

- Yang, G.; Lu, Y.; Wang, B.; Xia, Y.; Chen, H.; Song, H.; Yi, J.; Deng, L.; Wang, Y.; Li, H. Chemical Vapor Deposition of <110> Textured Diamond Film through Pre-Seeding by Diamond Nano-Sheets. Materials 2022, 15, 7776. [Google Scholar] [CrossRef]

- Ren, Z.; Ma, Y.; Yang, S.; Yu, X.; Zhang, J.; Su, K.; Zhang, J.; Wang, H.; Hao, Y. High frequency single crystalline diamond MOSFET with high temperature (300 °C) ALD grown Al2O3 dielectric. Results Phys. 2023, 49, 106517. [Google Scholar] [CrossRef]

- Miyake, T.; Nakagawa, H.; Masuzawa, T.; Yamada, T.; Nakano, T.; Takagi, K.; Aoki, T.; Mimura, H. Diamond Radiation Detector with Built-In Boron-Doped Neutron Converter Layer. Phys. Status Solidi A 2022, 219, 2100315. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, Q.; Li, B.; Zhang, J.; Wang, R.; Bai, M.; Liang, R.; Ma, L.; Ma, T.; Zhang, J.; et al. Influence of crystal orientation and incident plane on n-type 4H-SiC wafer slicing by using picosecond laser. Opt. Laser Technol. 2025, 182 Pt B, 112174. [Google Scholar] [CrossRef]

- Sakamoto, K.; Tokunaga, D.; Itoh, S.; Hidai, H.; Matsusaka, S.; Omatsu, T.; Koyama, K.; Kim, S.; Morita, N. Laser slicing of a diamond at the {100} plane using an irradiation sequence that restricts crack propagation along the {111} plane. Diam. Relat. Mater. 2023, 136, 110045. [Google Scholar] [CrossRef]

- Wang, H.; Wen, Q.; Xu, X.; Lu, J.; Jiang, F.; Cui, C. Ablation characteristics and material removal mechanisms of a single-crystal diamond processed by nanosecond or picosecond lasers. Opt. Express 2021, 29, 22714–22731. [Google Scholar] [CrossRef] [PubMed]

- Komlenok, M.; Pashinin, V.; Sedov, V.; Konov, V. Femtosecond and nanosecond laser polishing of rough polycrystalline diamond. Laser Phys. 2022, 32, 084003. [Google Scholar] [CrossRef]

- Zhai, J.; Zhang, Q.; Zhu, Y. Picosecond laser ablation of polycrystalline CVD diamond. Opt. Laser Technol. 2022, 155, 108403. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, C.; Li, G.; Song, C.; Qin, W.; Wang, T. Mechanisms Behind Graphitization Modification in Polycrystalline Diamond by Nanosecond Pulsed Laser. Materials 2024, 17, 6200. [Google Scholar] [CrossRef]

- Wang, H.; Liu, B.; Pang, D.; Hu, M. Study of the dynamics of the graphitization in diamond induced by high repetition rate fs laser. Opt. Commun. 2024, 565, 130639. [Google Scholar] [CrossRef]

- Wen, Q.; Wang, H.; Xu, X.; Lu, J.; Huang, H.; Jiang, F. Study on nanosecond laser-induced iron plasma reactive etching of single-crystal CVD diamond. Opt. Laser Technol. 2024, 177, 111071. [Google Scholar] [CrossRef]

- Kononenko, V.V. Modification of Diamond Surface by Femtosecond Laser Pulses. Photonics 2023, 10, 1077. [Google Scholar] [CrossRef]

- Kumar, R.R.; Geethika, B.R.; Verma, N.; Chaudhari, V.; Dave, J.; Joshi, H.C.; Thomas, J. Effect of ambient on the dynamics of re-deposition in the rear laser ablation of a thin film. Opt. Laser Technol. 2025, 181 Pt C, 111954. [Google Scholar] [CrossRef]

- Pflug, T.; Olbrich, M.; Horn, A. Electron dynamics in fused silica after strong field laser excitation detected by spectroscopic imaging pump-probe ellipsometry. Phys. Rev. B 2022, 106, 014307. [Google Scholar] [CrossRef]

- Takagi, I.; Kato, T.; Kayanuma, Y.; Nakamura, G.K. Interference of optical phonons in diamond studied using femtosecond pulses of polarized near-infrared light. Solid State Commun. 2022, 350, 114747. [Google Scholar] [CrossRef]

- Arad, N.O.; Shlomi, H.D.; Manukovsky, N.; Laster, E.; Kaminker, I. Nitrogen Substitutions Aggregation and Clustering in Diamonds as Revealed by High-Field Electron Paramagnetic Resonance. J. Am. Chem. Soc. 2024, 146, 5100–5107. [Google Scholar] [CrossRef]

- Bernal, F.; Riffe, J.E.; Devlin, W.S.; Hamel, S.; Lindsey, K.R.; Reid, A.H.; Mo, M.; Luo, D.; Kramer, P.; Shen, X. Response of fs-Laser-Irradiated Diamond by Ultrafast Electron Diffraction. J. Phys. Chem. C 2024, 128, 18651–18657. [Google Scholar] [CrossRef]

- Zhang, K.; Xie, J.F.; Yang, J.; Wang, T.; Su, F.; Wu, Y.; Fang, G. Extraordinary suppression of the laser heating effect in ZrTe3 under pressure revealed by ultrafast spectroscopy. Phys. Rev. B 2024, 109, 115130. [Google Scholar] [CrossRef]

- Kachan, E.; Tsaturyan, A.; Stoian, R.; Colombier, J.P. First-principles study of ultrafast bandgap dynamics in laser-excited -quartz. Eur. Phys. J. Spec. Top. 2023, 232, 2241–2245. [Google Scholar] [CrossRef]

- Jupé, M.; Jensen, L.; Melninkaitis, A.; Sirutkaitis, V.; Ristau, D. Calculations and experimental demonstration of multi-photon absorption governing fs laser-induced damage in titania. Opt. Express 2009, 17, 12269–12278. [Google Scholar] [CrossRef]

- Martin, P.; Guizard, S.; Daguzan, P.H.; Petite, G.; D’Oliveira, P.; Meynadier, P.; Perdrix, M. Subpicosecond study of carrier trapping dynamics in wide-band-gap crystals. Phys. Rev. B 1997, 55, 5799. [Google Scholar] [CrossRef]

- Keldysh, L.V. Ionization in the field of a strong electromagnetic wave. J. Exp. Theor. Phys. 1965, 20, 1307–1314. [Google Scholar]

- Kononenko, V.V.; Konov, V.I.; Gololobov, V.M.; Zavedeev, E.V. Propagation and absorption of high-intensity femtosecond laser radiation in diamond. Quantum Electron. 2014, 44, 1099. [Google Scholar] [CrossRef]

- Halliday, D.; Resnick, R.; Walker, J. Fundamentals of Physics; Wiley: Hoboken, NJ, USA, 2002. [Google Scholar]

- Ashkroft, N.W.; Mermin, N.D. Solid State Physics; Saunders College Publishing: New York, NY, USA, 1976. [Google Scholar]

- Takabe, H. The Physics of Laser Plasmas and Applications: Physics of Laser Matter Interaction; Springer: Cham, Switzerland, 2020; Volume 1. [Google Scholar]

- Song, Y.; Zhao, S.; He, H.; Liang, H.; Dai, Z.; Lin, X.; Zhang, G. Numerical Simulation and Experimental Investigation of ps Pulsed Laser Modification inside 4H-SiC Material. Photonics 2024, 11, 189. [Google Scholar] [CrossRef]

- Kononenko, V.V.; Gololobov, V.M.; Kononenko, T.V.; Konov, V.I. Photoinduced graphitization of diamond. Laser Phys. Lett. 2015, 12, 016101. [Google Scholar] [CrossRef]

- Choi, C.K.; Kwon, Y.H.; Krasinski, J.S.; Park, G.H.; Setlur, G.; Song, J.J.; Chang, Y.C. Ultrafast carrier dynamics in a highly excited GaN epilayer. Phys. Rev. B 2001, 63, 115315. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Yin, J.; Chen, G.; Zhu, Z.; Jin, M.; Hu, B. Ablation mechanism investigation and ablation threshold prediction of single crystal diamond irradiated by femtosecond laser. Diam. Relat. Mater. 2021, 111, 108173. [Google Scholar] [CrossRef]

- Sucharita, S. Nanosecond laser ablation of graphite: A thermal model based simulation. J. Laser Appl. 2018, 30, 012008. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, J.; Song, Y.; Wu, J.; Zhao, S.; Lin, X.; Pang, Y. Pump-Probe Detection of Diamond Ionization and Ablation Induced by Ultra-Fast Laser. Photonics 2025, 12, 280. https://doi.org/10.3390/photonics12030280

Duan J, Song Y, Wu J, Zhao S, Lin X, Pang Y. Pump-Probe Detection of Diamond Ionization and Ablation Induced by Ultra-Fast Laser. Photonics. 2025; 12(3):280. https://doi.org/10.3390/photonics12030280

Chicago/Turabian StyleDuan, Jinpeng, Yiying Song, Jiawei Wu, Shusen Zhao, Xuechun Lin, and Yajun Pang. 2025. "Pump-Probe Detection of Diamond Ionization and Ablation Induced by Ultra-Fast Laser" Photonics 12, no. 3: 280. https://doi.org/10.3390/photonics12030280

APA StyleDuan, J., Song, Y., Wu, J., Zhao, S., Lin, X., & Pang, Y. (2025). Pump-Probe Detection of Diamond Ionization and Ablation Induced by Ultra-Fast Laser. Photonics, 12(3), 280. https://doi.org/10.3390/photonics12030280