High-Power Passive Fiber Components for All-Fiber Lasers and Amplifiers Application—Design and Fabrication

Abstract

:1. Introduction

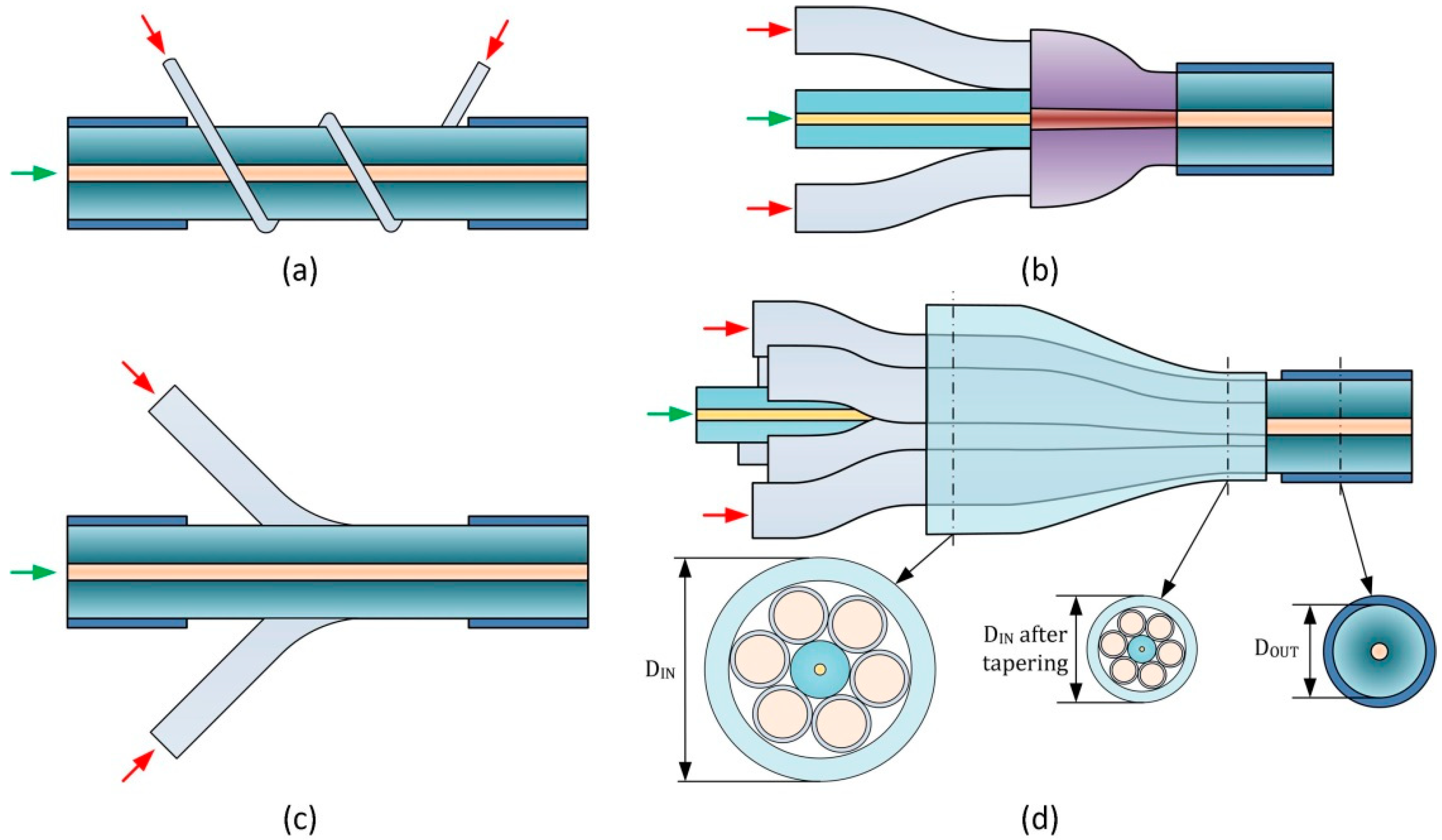

2. Passive Fiber Components—Power Combiners and Mode Field Adaptors

3. Basic Power Combiners and Mode Field Adaptors Fabrication Processes

4. Basic Criteria and Limits for Optical Fiber Tapering Process

4.1. Adiabatic Criterion for Single Mode Fiber Tapering

4.2. Brightness Ratio and Adiabatic Criterion for Multimode Fiber Tapering

5. Recent Achievements in the Field of Designing and Fabrication of High-Power Components

5.1. Pump Power Combiners

5.2. Pump and Signal Power Combiners

5.3. Signal Power Combiners

5.4. Mode Field Adaptors

6. Summary

Funding

Acknowledgments

Conflicts of Interest

References

- Philippov, V.; Codemard, C.; Jeong, Y.; Alegria, C.; Sahu, J.K.; Nilsson, J.; Pearson, G.N. High-energy in-fiber pulse amplification for coherent lidar applications. Opt. Lett. 2004, 29, 2590–2592. [Google Scholar] [CrossRef] [PubMed]

- Codemard, C.; Farrell, C.; Dupriez, P.; Philippov, V.; Sahu, J.K.; Nilsson, J. Millijoule, high-peak power, narrow-linewidth, subhundred nanosecond pulsed fibre Master-Oscillator Power- Amplifier at 1.55 µm. Comptes Rendus Phys. 2006, 7, 170–176. [Google Scholar] [CrossRef]

- Dolfi-Bouteyre, A.; Canat, G.; Valla, M.; Augere, B.; Besson, C.; Goular, D.; Lombard, L.; Cariou, J.P.; Durecu, A.; Fleury, D.; et al. Pulsed 1.5 µm LIDAR for axial aircraft wake vortex detection based on high brightness large-core fiber amplifier. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 441–450. [Google Scholar] [CrossRef]

- Braglia, A.; Califano, A.; Liu, Y.; Perrone, G. Architectures and components for high power CW fiber lasers. Int. J. Mod. Phys. B 2014, 28, 1442001. [Google Scholar] [CrossRef]

- Filippov, V.; Chamorovskii, Y.; Kerttula, J.; Golant, K.; Pessa, M.; Okhotnikov, O.G. Double clad tapered fiber for high power applications. Opt. Express 2008, 16, 1929–1944. [Google Scholar] [CrossRef] [PubMed]

- Snitzer, E.; Po, H.; Hakimi, F.; Tuminelli, R.; McCollumn, B.C. Double-clad, offset core Nd fiber laser. OSA Proc. Opt. Fiber Sens. 1988, 2. [Google Scholar] [CrossRef]

- Goldberg, L.; Cole, B.; Snitzer, E. V-groove side-pumped 1.5 µm fiber amplifier. Electron. Lett. 1997, 33, 2127–2129. [Google Scholar] [CrossRef]

- Swiderski, J.; Zajac, A.; Skorczakowski, M. Pulsed ytterbium-doped large mode area double-clad fiber amplifier in MOFPA configuration. Opto-Electron. Rev. 2007, 15, 98–101. [Google Scholar] [CrossRef] [Green Version]

- Raring, J.W.; Coldren, L.A. 40-Gb/s Widely Tunable Transceivers. IEEE J. Sel. Top. Quantum Electron. 2007, 13, 3–14. [Google Scholar] [CrossRef]

- Richardson, D.J.; Nilsson, J.; Clarkson, W.A. High power fiber lasers: Current status and future perspectives. J. Opt. Soc. Am. B 2010, 27, B63–B92. [Google Scholar] [CrossRef]

- Gapontsev, V.P.; Samartsev, L.E. High-power fiber laser. OSA Proc. Adv. Solid State Lasers 1990, 6. [Google Scholar] [CrossRef]

- Shi, W.; Fang, Q.; Zhu, X.; Norwood, R.A.; Peyghambarian, N. Fibre lasers and their applications [Invited]. Appl. Opt. 2014, 53, 6554–6568. [Google Scholar] [CrossRef] [PubMed]

- Gonthier, F.; Martineau, L.; Azami, N.; Faucher, M.; Seguin, F.; Stryckman, D.; Villeneuve, A. High-power all-fibre components: The missing link for high-power fibre lasers. Proc. SPIE 2004, 5335. [Google Scholar] [CrossRef]

- DiGiovanni, D.J.; Stentz, A.J. Tapered Fiber Bundles for Coupling Light into and Out of Cladding-Pumped Fiber Devices. U.S. Patent 5,864,644, 26 January 1999. Available online: https://patentimages.storage.googleapis.com/a9/94/bb/7cd3fbe58cd27c/US5864644.pdf (accessed on 3 September 2018).

- Kosterin, A.; Temyanko, V.; Fallahi, M.; Mansuripur, M. Tapered fiber bundles for high power applications. In Proceedings of the Technical Digest, Optical Fiber Communication Conference, Anaheim, CA, USA, 6–11 March 2005. [Google Scholar] [CrossRef]

- Braglia, A.; Olivero, M.; Neri, A.; Perrone, G. Fabrication of pump combiners for high power fibre lasers. Proc. SPIE 2011, 7914. [Google Scholar] [CrossRef]

- Holland, W.R. All Pump Combiner with Cladless Inputs. U.S. Patent 9,322,993 B1, 26 April 2016. Available online: https://patentimages.storage.googleapis.com/db/f5/e5/a72053d111d362/US9322993.pdf (accessed on 3 September 2018).

- Noordegraaf, D.; Lægsgaard, J.; Broeng, J.; Skovgaard, P.M.W. Fused Combiners for Photonic Crystal Fibers. Kgs; Technical University of Denmark (DTU): Lyngby, Denmark, 2012; 114p, Available online: http://orbit.dtu.dk/files/51271178/2012_01_02_PhD_Thesis_DNO.pdf (accessed on 3 September 2018).

- Grudinin, A.B.; Payne, D.N.; Turner, P.W.; Nilsson, L.J.A.; Zervas, M.N.; Ibsen, M.; Durkin, M.K. Multi-Fibre Arrangements for High Power Fibre Lasers and Amplifiers. U.S. Patent 6,826,335 B1, 30 November 2004. Available online: https://patentimages.storage.googleapis.com/49/ed/d2/ee2a41c11e4f73/US6826335.pdf (accessed on 3 September 2018).

- Norman, S.; Zervas, M.; Appleyard, A.; Skull, P.; Walker, D.; Turner, P.; Crowe, I. Power scaling of high power fiber lasers for micromachining and materials processing applications. Proc. SPIE 2006, 6102. [Google Scholar] [CrossRef]

- Gapontsev, V.; Samartsev, I. Coupling Arrangement between a Multi-Mode Light Source and an Optical Fiber through an Intermediate Optical Fiber Length. U.S. Patent 5,999,673, 7 December 1999. Available online: https://patentimages.storage.googleapis.com/b3/5d/29/390f769901abd7/US5999673.pdf (accessed on 3 September 2018).

- Hakimi, F.; Hakimi, H. A new side coupling method for double clad fiber amplifiers. Conf. Lasers Electron.-Opt. 2001. [Google Scholar] [CrossRef]

- Sintov, Y.; Tikva, P. Optical Apparatus. U.S. Patent 2006/0133731 A1, 22 June 2006. Available online: https://patentimages.storage.googleapis.com/16/ce/bd/20d754f19740e2/US20060133731A1.pdf (accessed on 3 September 2018).

- Nakai, M.; Shima, K.; Saito, M.; Kitabayashi, T. 30W Q-SW fiber laser. Proc. SPIE 2007, 6453. [Google Scholar] [CrossRef]

- Kosterin, A.; Temyanko, V.; Fallahi, M.; Mansuripur, M. Tapered fiber bundles for combining high-power diode lasers. Appl. Opt. 2004, 43, 3893–3900. [Google Scholar] [CrossRef] [PubMed]

- Séguin, F.; Wetter, A.; Martineau, L.; Faucher, M.; Delisle, C.; Caplette, S. Tapered fused bundle coupler package for reliable high optical power dissipation. Proc. SPIE 2006, 6102. [Google Scholar] [CrossRef]

- Gooch & Housego, Multimode Power Combiner. Available online: https://goochandhousego.com/wp-content/uploads/2018/02/GH-DS-FO-TFB-Multimode-Power-Combiner.pdf (accessed on 3 September 2018).

- ITF Technologies, 3 × 1, 4 × 1, 7 × 1 and 19 × 1 High Power Pump Combiners. Available online: http://www.itftechnologies.com/files/13/JR_ITF_DataSheet_D_3x1_4x1_7x1_19x1_v6_2018-06-06-09-59.pdf (accessed on 3 September 2018).

- Gooch & Housego, Multimode Power Combiner with Signal Feedthrough. Available online: https://goochandhousego.com/wp-content/pdfs/PEC_0131i3_Multimode_Power_Combiner_with_Signal_Feedthrough.pdf (accessed on 3 September 2018).

- Laser Components, LIGHTEL, Pump Combiners and Other Optical Components for High Power Fiber Lasers. Available online: https://www.lasercomponents.com/de/?embedded=1&file=fileadmin/user_upload/home/Datasheets/lightel/pump-combiners.pdf&no_cache=1 (accessed on 3 September 2018).

- ITF Technologies, (6 + 1) × 1 and (18 + 1) × 1 High Power Pump and Signal Combiners. Available online: http://www.itftechnologies.com/files/13/11_DataSheet_PRODUCT_MM_COMBINER_EP1_2017-06-20-14-42.pdf (accessed on 3 September 2018).

- ITF Technologies, 3 × 1 Fiber Laser Combiner. Available online: http://www.itftechnologies.com/files/13/ITFT%20-%203x1%20FLC%20Rev.02_2018-01-26-16-56.pdf (accessed on 3 September 2018).

- Martínez-Rios, A.; Torres-Gómez, I.; Monzon-Hernandez, D.; Barbosa-Garcia, O.; Duran-Ramirez, V.M. Reduction of Splice Loss between Dissimilar Fibers by Tapering and Fattening. Rev. Mex. Física 2010, 56. Available online: http://www.redalyc.org/articulo.oa?id=57016003012 (accessed on 3 September 2018).

- Gattass, R.R.; Thapa, R.; Kung, F.H.; Busse, L.E.; Shaw, L.B.; Sanghera, J.S. Review of infrared fiber-based components. Appl. Opt. 2015, 54, F25–F34. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Sun, Y.; Wang, Y.; Li, T.; Feng, Y.; Ma, Y. The study of the thermally expanded core technique in end-pumped (N + 1) × 1 type combiner. Proc. SPIE 2015, 9255. [Google Scholar] [CrossRef]

- Hanafusa, H.; Horiguchi, M.; Noda, J. Thermally-diffused expanded core fibres for low-loss and inexpensive photonic components. Electron. Lett. 1991, 27, 1968–1969. [Google Scholar] [CrossRef]

- Kihara, M.; Matsumoto, M.; Haibara, T.; Tomita, S. Characteristics of thermally expanded core fiber. J. Light. Technol. 1996, 14, 2209–2214. [Google Scholar] [CrossRef]

- Shiraishi, K.; Aizawa, Y.; Kawakami, S. Beam expanding fiber using thermal diffusion of the dopant. J. Light. Technol. 1990, 8, 1151–1161. [Google Scholar] [CrossRef]

- Harper, J.S.; Botham, C.P.; Hornung, S. Tapers in single-mode optical fibre by controlled core diffusion. Electron. Lett. 1988, 24, 245–246. [Google Scholar] [CrossRef]

- Wang, B.; Mies, E. Review of fabrication techniques for fused fiber components for fiber lasers. Proc. SPIE 2009, 7195. [Google Scholar] [CrossRef]

- Snyder, A.W.; Love, J.D. Optical Waveguide Theory; Chapman and Hall: London, UK, 1983. [Google Scholar]

- Marcuse, D. Loss analysis of single-mode fiber splices. Bell Syst. Tech. J. 1997, 56, 703. [Google Scholar] [CrossRef]

- Fielding, A.J.; Edinger, K.; Davis, C.C. Experimental observation of mode evolution in single-mode tapered optical fibers. J. Light. Technol. 1999, 17, 1649. [Google Scholar] [CrossRef]

- Love, J.D.; Henry, W.M. Quantifying loss minimisation in single-mode fibre tapers. Electron. Lett. 1986, 22, 912–914. [Google Scholar] [CrossRef]

- Birks, T.A.; Li, Y.W. The shape of fiber tapers. J. Light. Technol. 1992, 10, 432–438. [Google Scholar] [CrossRef]

- Saleh, B.E.A.; Teich, M.C. Fundamentals of Photonics, 2nd ed.; Wiley: Hoboken, NJ, USA, 1991. [Google Scholar]

- Sévigny, B.; Poirier, P.; Faucher, M. Pump combiner loss as a function of input numerical aperture power distribution. Proc. SPIE 2009, 7195. [Google Scholar] [CrossRef]

- Xiao, Q.; Ren, H.; Chen, X.; Yan, P.; Gong, M. Tapered Fiber Bundle 7 × 1 End-Pumping Coupler Capable of High Power CW Operation. IEEE Photon. Technol. Lett. 2013, 25, 2442–2445. [Google Scholar] [CrossRef]

- Kim, J.K.; Hagemann, C.; Schreiber, T.; Peschel, T.; Böhme, S.; Eberhardt, R.; Tünnermann, A. Monolithic all-glass pump combiner scheme for high-power fiber laser systems. Opt. Express 2010, 18, 13194–13203. [Google Scholar] [CrossRef] [PubMed]

- Wetter, A.; Faucher, M.; Lovelady, M.; Séguin, F. Tapered fused-bundle splitter capable of 1kW CW operation. Proc. SPIE 2007, 6453. [Google Scholar] [CrossRef]

- Cao, Y.; Shi, W.; Sheng, Q.; Fu, S.; Zhang, H.; Bai, X.; Qi, L.; Yao, J. Investigation on high transmission efficiency 7 × 1 pump combiner. Opt. Eng. 2016, 55, 126102. [Google Scholar] [CrossRef]

- Jauregui, C.; Böhme, S.; Wenetiadis, G.; Limpert, J.; Tünnermann, A. Side-pump combiner for all-fiber monolithic fiber lasers and amplifiers. J. Opt. Soc. Am. B 2010, 27, 1011–1015. [Google Scholar] [CrossRef]

- Stachowiak, D.; Kaczmarek, P.; Abramski, K.M. High-power pump combiners for Tm-doped fibre lasers. Opto-Electron. Rev. 2015, 23, 259–264. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Chen, Z.; Zhou, X.; Hou, J.; Chen, J. All-fiber 7 × 1 pump combiner for high power fiber laser. Opt. Commun. 2015, 347, 137–140. [Google Scholar] [CrossRef]

- Xiao, Q.; Huang, Y.; Sun, J.; Wang, X.; Li, D.; Gong, M.; Yan, P. Research on multi-kilowatts level tapered fiber bundle N × 1 pumping combiner for high power fiber laser. Front. Optoelectron. 2016, 9, 301–305. [Google Scholar] [CrossRef]

- Kim, B.H.; Kim, S.-J.; Yoon, Y.; Hann, S. Fabrication of the reliable (14 − 18) × 1 fiber laser power combiner by the novel double bundling method. Proc. SPIE 2013, 8621. [Google Scholar] [CrossRef]

- Faucher, M.; Sevigny, B.; Perreault, R.; Wetter, A.; Holehouse, N. All-fiber 32 × 1 pump combiner with high isolation for high power fiber laser. In Proceedings of the 2008 Conference on Lasers and Electro-Optics and 2008 Conference on Quantum Electronics and Laser Science, San Jose, CA, USA, 4–9 May 2008; pp. 1–2. [Google Scholar] [CrossRef]

- Neugroschl, D.; Park, J.; Wlodawski, M.; Singer, J.; Kopp, V.I. High-efficiency (6 + 1) × 1 combiner for high power fiber lasers and amplifiers. Proc. SPIE 2013, 8601. [Google Scholar] [CrossRef]

- Theeg, T.; Sayinc, H.; Overmeyer, L.; Neumann, J.; Kracht, D. Manufacturing and optical characterization of side-pumped high power fiber combiner for LMA-fibers. In Proceedings of the 2015 European Conference on Lasers and Electro-Optics—European Quantum Electronics Conference, Munich, Germany, 21–25 June 2015; Optical Society of America: Washington, DC, USA Paper CE_2_4. [Google Scholar]

- Koška, P.; Baravets, Y.; Peterka, P.; Bohata, J.; Písařík, M. Mode-field adapter for tapered-fiber-bundle signal and pump combiners. Appl. Opt. 2015, 54, 751–756. [Google Scholar] [CrossRef] [PubMed]

- Koška, P.; Baravets, Y.; Peterka, P.; Písařík, M.; Bohata, J. Optimized mode-field adapter for low-loss fused fiber bundle signal and pump combiners. Proc. SPIE 2015, 9344. [Google Scholar] [CrossRef]

- Theeg, T.; Sayinc, H.; Neumann, J.; Overmeyer, L.; Kracht, D. Pump and signal combiner for bi-directional pumping of all-fiber lasers and amplifiers. Opt. Express 2012, 20, 28125–28141. [Google Scholar] [CrossRef] [PubMed]

- Sliwinska, D.; Kaczmarek, P.; Abramski, K.M. Tapered fiber bundle couplers for high-power fiber amplifiers. Proc. SPIE 2014, 9441. [Google Scholar] [CrossRef]

- Theeg, T.; Sayinc, H.; Neumann, J.; Overmeyer, L.; Kracht, D. Side pumping scheme for all-fiber counter-pumping of high power single-frequency fiber amplifiers. In Proceedings of the 2013 Conference on Lasers & Electro-Optics Europe & International Quantum Electronics Conference CLEO EUROPE/IQEC, Munich, Germany, 12–16 May 2013. [Google Scholar] [CrossRef]

- Stachowiak, D.; Kaczmarek, P.; Abramski, K.M. (5 + 1) × 1 pump and signal power combiner with 9/80μm feed-through signal fiber. Opt. Laser Technol. 2017, 93, 33–40. [Google Scholar] [CrossRef]

- Zhao, K.; Chang, X.; Chen, Z.; Wang, Z.; Jiang, H. Fabrication of high-efficiency pump and signal combiner based on a thermally expanded core technique. Opt. Laser Technol. 2015, 75, 1–5. [Google Scholar] [CrossRef]

- Kopp, V.I.; Park, J.; Wlodawski, M.; Singer, J.; Neugroschl, D. Polarization maintaining, high-power and high-efficiency (6 + 1) × 1 pump/signal combiner. Proc. SPIE 2014, 8961. [Google Scholar] [CrossRef]

- Zou, S.; Chen, H.; Yu, H.; Sun, J.; Zhao, P.; Lin, X. High-efficiency (6 + 1) × 1 pump-signal combiner based on low-deformation and high-precision alignment fabrication. Appl. Phys. B 2017, 123, 288. [Google Scholar] [CrossRef]

- Zheng, J.; Zhao, W.; Zhao, B.; Li, Z.; Chang, C.; Li, G.; Gao, Q.; Ju, P.; Gao, W.; She, S.; et al. High pumping-power fiber combiner for double-cladding fiber lasers and amplifiers. Opt. Eng. 2018, 57, 036105. [Google Scholar] [CrossRef]

- Liu, K.; Zhao, C.; Yang, Y.; Chen, X.; Wang, J.; He, B.; Zhou, J. Low beam quality degradation, high-efficiency pump and signal combiner by built-in mode field adapter. Appl. Opt. 2017, 56, 2804–2809. [Google Scholar] [CrossRef] [PubMed]

- Noordegraaf, D.; Maack, M.D.; Skovgaard, P.M.W.; Agger, S.; Alkeskjold, T.T.; Lægsgaard, J. 7 + 1 to 1 pump/signal combiner for air-clad fiber with 15 µm MFD PM single-mode signal feed-through. Proc. SPIE 2010, 7580. [Google Scholar] [CrossRef]

- Xiao, Q.; Yan, P.; Ren, H.; Chen, X.; Gong, M. Pump-signal combiner with large-core signal fiber feed-through for fiber lasers and amplifiers. Appl. Opt. 2013, 52, 409–414. [Google Scholar] [CrossRef] [PubMed]

- Braglia, A.; Califano, A.; Olivero, M.; Penna, A.; Perrone, G. All-fiber kilowatt signal combiners for high power fiber lasers. In Proceedings of the 2013 Conference on Lasers & Electro-Optics Europe & International Quantum Electronics Conference CLEO EUROPE/IQEC, Munich, Germany, 12–16 May 2013. [Google Scholar] [CrossRef]

- Wickham, M.; Cheung, E.C.; Ho, J.G.; Goodno, G.D.; Rice, R.R.; Rothenberg, J.; Thielen, P.; Weber, M. Coherent Combination of Fiber Lasers with a Diffractive Optical Element. OSA Proc. Adv. Solid-State Photonics 2008, WA5. [Google Scholar] [CrossRef]

- Shamir, Y.; Sintov, Y.; Shtaif, M. Incoherent beam combining of multiple single-mode fiber lasers utilizing fused tapered bundling. Proc. SPIE 2010, 7580. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, Z.; Zhou, X.; Hou, J.; Chen, J. All-fiber 7 × 1 signal combiner with high beam quality for high-power fiber lasers. Chin. Opt. Lett. 2015, 13, 061406. [Google Scholar] [CrossRef]

- Loftus, T.H.; Liu, A.; Hoffman, P.R.; Thomas, A.M.; Norsen, M.; Royse, R.; Honea, E. 522 W average power, spectrally beam-combined fiber laser with near-diffraction-limited beam quality. Opt. Lett. 2007, 32, 349–351. [Google Scholar] [CrossRef] [PubMed]

- Shamir, Y.; Sintov, Y.; Shtaif, M. Large-mode-area fused-fiber combiners, with nearly lowest-mode brightness conservation. Opt. Lett. 2011, 36, 2874–2876. [Google Scholar] [CrossRef] [PubMed]

- Shamir, Y.; Zuitlin, R.; Sintov, Y.; Shtaif, M. 3kW-level incoherent and coherent mode combining via all-fiber fused Y-couplers. In Frontiers in Optics 2012/Laser Science XXVIII; Optical Society of America: Washington, DC, USA, 2012. [Google Scholar]

- Noordegraaf, D.; Maack, M.D.; Skovgaard, P.M.W.; Johansen, J.; Becker, F.; Belke, S.; Blomqvist, M.; Laegsgaard, J. All-fiber 7 × 1 signal combiner for incoherent laser beam combining. Proc. SPIE 2011, 7914. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Jin, A.; Chen, Z.; Zhang, B.; Zhou, X.; Chen, S.; Hou, J.; Chen, J. Combined supercontinuum source with >200 W power using a 3 × 1 broadband fiber power combiner. Opt. Lett. 2015, 40, 3810–3813. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Chen, Z.; Wang, Z.; Hou, J.; Xu, X. Beam Quality Analysis of Incoherent Beam Combining by a 7 × 1 All-Fiber Signal Combiner. IEEE Photon. Technol. Lett. 2016, 28, 2265–2268. [Google Scholar] [CrossRef]

- Lei, C.; Gu, Y.; Chen, Z.; Wang, Z.; Zhou, P.; Ma, Y.; Xiao, H.; Leng, J.; Wang, X.; Hou, J.; et al. Incoherent beam combining of fiber lasers by an all-fiber 7 × 1 signal combiner at a power level of 14 kW. Opt. Express 2018, 26, 10421–10427. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Chen, Z.; Zhou, X.; Hou, J.; Chen, J. All-fiber 7 × 1 signal combiner for high power fiber lasers. Appl. Opt. 2015, 54, 3090–3094. [Google Scholar] [CrossRef] [PubMed]

- Malka, D.; Cohen, E.; Zalevsky, Z. Design of 4 × 1 Power Beam Combiner Based on MultiCore Photonic Crystal Fiber. Appl. Sci. 2017, 7, 695. [Google Scholar] [CrossRef]

- Nielsen, M.D.; Srensen, M.H.; Liem, A.; Kozak, M.; Skovgaard, P.M. High power PCF-based pump combiners. Proc. SPIE 2007, 6453. [Google Scholar] [CrossRef]

- Hansen, K.P.; Olausson, C.B.; Broeng, J.; Noordegraaf, D.; Maack, M.D.; Alkeskjold, T.T.; Laurila, M.; Nikolajsen, T.; Skovgaard, P.M.W.; Srensen, M.H.; et al. Airclad fiber laser technology. Opt. Eng. 2011, 50, 111609. [Google Scholar] [CrossRef] [Green Version]

- Ishikura, A.; Kato, Y.; Miyauchi, M. Taper splice method for single-mode fibers. Appl. Opt. 1986, 25, 3460–3465. [Google Scholar] [CrossRef] [PubMed]

- Kihara, M.; Tomita, S.; Matsumoto, M. Loss characteristics of thermally diffused expanded core fiber. IEEE Photon. Technol. Lett. 1992, 4, 1390–1391. [Google Scholar] [CrossRef]

- Shigihara, K.; Shiraishi, K.; Kawakami, S. Modal field transforming fiber between dissimilar waveguides. J. Appl. Phys. 1986, 60, 4293–4296. [Google Scholar] [CrossRef]

- Faucher, M.; Lize, Y.K. Mode field adaptation for high power fiber lasers. In Proceedings of the Conference Lasers and Electro-Optics, San Jose, CA, USA, 6–11 May 2007. [Google Scholar] [CrossRef]

- Mafi, A.; Hofmann, P.; Jollivet Salvin, C.; Schülzgen, A. Low-loss coupling between two single-mode optical fibers with different mode-field diameters using a graded-index multimode optical fiber. Opt. Lett. 2011, 36, 3596–3598. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, P.; Mafi, A.; Jollivet, C.; Tiess, T.; Peyghambarian, N.; Schulzgen, A. Detailed Investigation of Mode-Field Adapters Utilizing Multimode-Interference in Graded Index Fibers. J. Light. Technol. 2012, 30, 2289–2298. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, Z.; Chen, H.; Li, J.; Hou, J. Mode field adaptation between single-mode fiber and large mode area fiber by thermally expanded core technique. Opt. Laser Technol. 2013, 47, 72–75. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, Z.; Zhou, H.; Hou, J. Mode-field adaptor between large-mode-area fiber and single-mode fiber based on fiber tapering and thermally expanded core technique. Appl. Opt. 2014, 53, 5053–5057. [Google Scholar] [CrossRef] [PubMed]

- Kaczmarek, P.; Stachowiak, D.; Abramski, K.M. 40 W All-Fiber Er/Yb MOPA System Using Self-Fabricated High-Power Passive Fiber Components. Appl. Sci. 2018, 8, 869. [Google Scholar] [CrossRef]

| Config. | Input Pump Fiber, Core NA | Output DC Fiber, Clad NA | Pump Transmission Efficiency | Year/Ref. |

|---|---|---|---|---|

| 7 × 1 | 105/125 µm, NA = 0.22 | 30/250 µm, NA = 0.46 | 98.9% | 2016/[51] |

| 7 × 1 | Core φ = 110 µm, NA = 0.22 | 20/400 µm, NA = 0.46 | ~80% | 2010/[52] |

| 7 × 1 | 105/125 µm, NA = 0.22 | 9/125 µm, NA = 0.46 | ~80% | 2015/[53] |

| 7 × 1 | 220/242 µm, NA = 0.22 | 20/400 µm, NA = 0.46 | 98.4% | 2015/[54] |

| 7 × 1 | 200/220 µm, NA = 0.22 | 400/550 µm, NA = 0.46 | 99.4% | 2016/[55] |

| 3 × 1 | 200/220 µm, NA = 0.22 | 400/440 µm, NA = 0.22 | 95.1% | |

| 16 × 1 | 105/125 µm, NA = 0.15 | 200/220 µm, NA = 0.46 | 93% | 2013/[56] |

| 32 × 1 | 105/125 µm, NA = 0.15 | 20/400 µm, NA = 0.46 | 92.8% | 2008/[57] |

| Config. | Input Signal Fiber, Core/Clad NA | Input Pump Fiber, Core NA | Output DC Fiber, Core/Clad NA | Signal/Pump Transmission Efficiency | Year/Ref. |

|---|---|---|---|---|---|

| (4 + 1) × 1 | 25/250 µm, NA = 0.06/0.46 | Core φ = 105 µm, NA = 0.22 | 25/250 µm, NA = 0.06/0.46 | 97/90% | 2013/[64] |

| (5 + 1) × 1 | 9/80 µm, NA = 0.13 | 105/125 µm, NA = 0.22 | 9/125 µm, NA = 0.122/0.46 | 94.5/91% | 2017/[65] |

| (6 + 1) × 1 | 8.2/125 µm, NA = 0.14 | 105/125 µm, NA = 0.15 | 25/250 μm, NA = 0.6/0.46 | 94/96–99% | 2015/[66] |

| (6 + 1) × 1 | 6–10/125 µm, NA = 0.14 | 105/125 µm, NA = 0.15–0.22 | 25/250 µm, NA = 0.06/0.46 | 94/94% | 2011/[16] |

| (6 + 1) × 1 | DC PM 20/400 µm, NA = 0.065/- | 200/240 µm, NA = 0.22 | DC PM 20/400 µm, NA = 0.065/- | 91/~99.8% | 2014/[67] |

| (6 + 1) × 1 | DC 20/400 μm, NA = 0.06/0.46 | 200/220 µm, NA = 0.22 | 20/400 μm, NA = 0.06/0.46 | 97.7/98% | 2017/[68] |

| (6 + 1) × 1 | DC 30/220 μm, NA = 0.06/- | 200/220 µm, NA = 0.22 | 30/600 μm, NA = 0.06/- | ~99.8/94.8% | 2018/[69] |

| (6 + 1) × 1 | 10/125 μm, NA = 0.08/0.46 | 105/125 µm, NA = 0.22 | 20/400 μm, NA = 0.06/0.46 | 87.52/98.6% | 2017/[70] |

| (7 + 1) × 1 | SM PM MFD = 15 µm, clad φ = 160 µm, NA = 0.06/- | 105/125 µm, NA = - | SM PM MFD = 15 µm, clad φ = 133 µm, NA = 0.06/- | ~85/~94.5% | 2010/[71] |

| (8 + 1) × 1 | 100/200 µm, NA = 0.054/0.46 | 105/125 µm, NA = 0.15 | 100/400 µm, NA = 0.054/0.46 | 98/96.8% | 2013/[72] |

| Config. | Input Fibers, Core/Clad NA | Output Fiber, Core NA | Signal Transmission Efficiency, M2, Power Handling | Year/Ref. |

|---|---|---|---|---|

| 7 × 1 | SM 17/125 µm, NA = - | MM 100/660 µm, NA = 0.22 | 94.7%, M2 = 6.5, 2.5 kW | 2011/[80] |

| 3 × 1 | 30/125 µm, NA = 0.08/0.46 | 100/360 µm, NA = 0.2 | >96%, M2 = 1.2/1.3, >200 W | 2015/[81] |

| 7 × 1 | 20/130 µm, NA = 0.08/0.46 | 50/70/360 µm, NA = 0.22 | 98%, M2 = 4.3, 6.26 kW | 2016/[82] |

| 7 × 1 | 20/400 µm, NA = 0.06 | 50/70/360 µm, NA = 0.22 | >98.5%, M2 = 5.37, >10 kW | 2018/[83] |

| Input Fiber, Core NA | Output Fiber, Core NA | Signal Transmission Efficiency | Year/Ref. |

|---|---|---|---|

| 5.3/125 µm, NA = 0.14, (Corning Hi1060) | 20/400 µm, NA = 0.06 | ~95% | 2007/[91] |

| 4/125 µm, NA = 0.2, (HI1060FLEX) | 15/130 µm, NA = 0.08 | ~93% | 2013/[94] |

| 5/125 µm, NA = 0.14, (HI1060) | 15/130 µm, NA = 0.08 | ~91% | |

| 4/125 µm, NA = 0.2, (HI1060FLEX) | 25/250 µm, NA = 0.06 | >90% | 2014/[95] |

| 5/125 µm, NA = 0.14, (HI1060) | 25/250 µm, NA = 0.06 | ~90% | |

| 20/200 µm, NA = 0.08 | 25/300 µm, NA = 0.09 | 92% | 2018/[96] |

| 8.2/125 µm, NA = 0.14 | 20/130 µm, NA = 0.08 | 90% |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stachowiak, D. High-Power Passive Fiber Components for All-Fiber Lasers and Amplifiers Application—Design and Fabrication. Photonics 2018, 5, 38. https://doi.org/10.3390/photonics5040038

Stachowiak D. High-Power Passive Fiber Components for All-Fiber Lasers and Amplifiers Application—Design and Fabrication. Photonics. 2018; 5(4):38. https://doi.org/10.3390/photonics5040038

Chicago/Turabian StyleStachowiak, Dorota. 2018. "High-Power Passive Fiber Components for All-Fiber Lasers and Amplifiers Application—Design and Fabrication" Photonics 5, no. 4: 38. https://doi.org/10.3390/photonics5040038

APA StyleStachowiak, D. (2018). High-Power Passive Fiber Components for All-Fiber Lasers and Amplifiers Application—Design and Fabrication. Photonics, 5(4), 38. https://doi.org/10.3390/photonics5040038